How to Source Die Cut Signs Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for die cut signs

In today’s competitive landscape, international businesses face the pressing challenge of sourcing effective marketing tools that resonate with diverse audiences. Die cut signs offer a unique solution, providing custom shapes and vibrant designs that capture attention across various sectors. However, navigating the global market for these signs can be daunting, especially for B2B buyers from regions like Africa, South America, the Middle East, and Europe, including countries such as Brazil and Nigeria. This guide is designed to demystify the complexities of sourcing die cut signs, outlining essential factors such as types, applications, supplier vetting, and cost considerations.

By leveraging insights from industry experts and case studies, this comprehensive resource empowers buyers to make informed purchasing decisions. We explore the versatility of die cut signs, from promotional yard signs for local events to intricate designs for corporate branding. Additionally, we address the importance of selecting reliable suppliers who can deliver quality products on time, ensuring that your marketing efforts are not only visually appealing but also effective.

Whether you are a small business owner or a large corporation, this guide equips you with the knowledge and tools necessary to navigate the global market confidently, maximizing your investment in die cut signs for impactful marketing campaigns.

Understanding die cut signs Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Die-Cut Yard Signs | Custom shapes, weather-resistant materials, vibrant printing | Real estate, political campaigns, event promotions | Pros: High visibility, customizable sizes; Cons: May require stakes for installation. |

| Custom Shaped Signs | Various materials (PVC, aluminum), creative designs | Retail signage, branding displays, events | Pros: Unique shapes enhance brand recognition; Cons: Higher costs for complex designs. |

| Floor Decals | Non-slip surface, custom graphics | Retail stores, exhibitions, event venues | Pros: Engaging way to direct foot traffic; Cons: Surface preparation is essential for adherence. |

| Acrylic Signs | High durability, modern aesthetic, versatile applications | Office branding, awards, directional signage | Pros: Professional look, long-lasting; Cons: Can be heavier and more expensive than alternatives. |

| Lawn Signs | Lightweight, easy to reposition, often double-sided | Local business advertising, community events | Pros: Cost-effective for mass distribution; Cons: May not withstand extreme weather conditions. |

What are Die-Cut Yard Signs and Their B2B Benefits?

Die-cut yard signs are custom-shaped signs made from durable materials like corflute or plastic, designed to withstand outdoor conditions. They are particularly effective for real estate promotions, political campaigns, and event announcements. The ability to customize size and shape enhances visibility and engagement, making them a valuable tool for businesses looking to attract attention. Buyers should consider the installation requirements, such as the need for stakes, and the potential for bulk discounts when ordering multiple units.

How Do Custom Shaped Signs Stand Out in the Market?

Custom shaped signs are versatile and can be crafted from various materials including PVC, aluminum, and acrylic. Their unique shapes can significantly enhance brand recognition, making them ideal for retail signage and event displays. When purchasing, businesses should assess the design complexity and associated costs, as intricate shapes may lead to higher production expenses. However, the impact on customer engagement can justify the investment.

What Makes Floor Decals an Effective Choice for Retail Environments?

Floor decals are designed with a non-slip surface and can feature custom graphics tailored to direct foot traffic in retail stores or event venues. They offer a creative way to engage customers and guide them through a space. Buyers should be aware that proper surface preparation is crucial for the adhesion of these decals. While they are effective in increasing visibility, the investment in high-quality materials is essential to ensure durability and longevity.

Why Choose Acrylic Signs for Professional Branding?

Acrylic signs are known for their modern aesthetic and high durability, making them suitable for office branding, awards, and directional signage. They provide a polished look that can elevate a business’s image. However, businesses should consider the weight and cost, as acrylic can be pricier than other materials. The long-lasting nature of acrylic signs often makes them a worthwhile investment for organizations aiming for a professional appearance.

How Do Lawn Signs Serve Local Businesses?

Lawn signs are lightweight, easy to reposition, and often feature double-sided printing for maximum exposure. They are particularly effective for local business advertising and community events. Their cost-effectiveness makes them an appealing option for businesses looking to spread their message widely without significant investment. However, buyers should be cautious about the material’s ability to withstand extreme weather conditions, which can affect the longevity of these signs.

Key Industrial Applications of die cut signs

| Industry/Sector | Specific Application of die cut signs | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Real Estate | Open House and Property Promotion Signs | Attract potential buyers with eye-catching visuals. | Ensure weather resistance and durability for outdoor use. |

| Event Management | Custom Event Signage for Conferences and Festivals | Enhance brand visibility and guide attendees effectively. | Look for customization options and fast turnaround times. |

| Retail | Promotional Displays and Directional Signage | Increase foot traffic and improve customer navigation. | Consider size flexibility and material options for indoor/outdoor use. |

| Political Campaigns | Candidate and Issue Advocacy Signs | Create impactful messaging to engage voters. | Evaluate options for bulk orders and localized design features. |

| Hospitality | Wayfinding Signs for Hotels and Resorts | Improve guest experience through clear navigation. | Focus on aesthetic appeal and durability under varying conditions. |

How Are Die Cut Signs Used in Real Estate Promotions?

In the real estate sector, die cut signs are pivotal for open house events and property promotions. These signs can be customized to reflect the branding of real estate agents, showcasing properties in a visually appealing manner that captures attention. By utilizing weather-resistant materials, these signs maintain their integrity outdoors, solving the problem of visibility in various weather conditions. For international buyers, sourcing from local suppliers may reduce shipping costs and delivery times, while ensuring compliance with regional regulations.

What Role Do Die Cut Signs Play in Event Management?

Die cut signs serve as essential tools in event management, particularly for conferences and festivals. These signs can be tailored to provide crucial information, such as schedules and directions, while also enhancing brand visibility through unique shapes and designs. The ability to create custom sizes and shapes allows event organizers to think creatively, ensuring that signage stands out in crowded environments. Buyers should prioritize suppliers who offer quick production times, especially for last-minute events, to avoid logistical challenges.

How Do Retail Businesses Benefit from Die Cut Signs?

Retail businesses leverage die cut signs for promotional displays and directional signage to boost foot traffic and enhance customer navigation. These signs can be designed in various shapes to align with marketing campaigns, making them visually striking and effective. The choice of durable materials ensures that these signs can withstand high foot traffic and varying indoor conditions. When sourcing, retailers should consider the potential for bulk discounts and the versatility of materials for both temporary and permanent installations.

Why Are Die Cut Signs Important for Political Campaigns?

In political campaigns, die cut signs are crucial for conveying messages about candidates and issues. Their custom shapes allow for unique branding that can differentiate candidates in a crowded field. The visibility and impact of these signs can significantly influence voter engagement, making them a vital component of campaign strategy. Campaign managers should look for suppliers that can accommodate bulk orders and offer localized design options to resonate with target demographics.

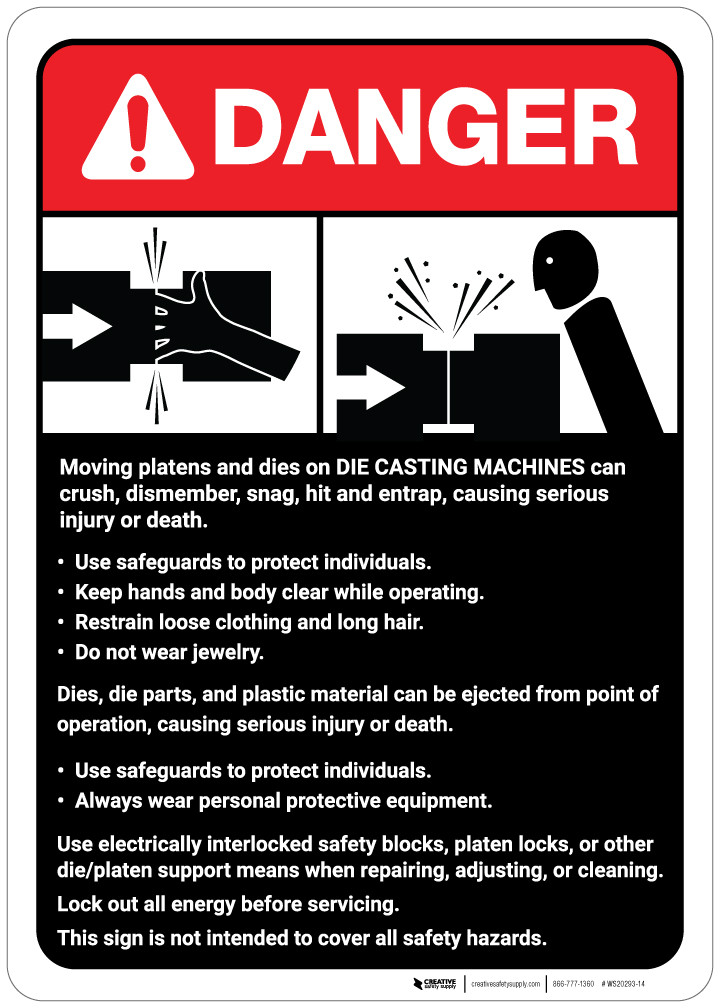

Illustrative image related to die cut signs

How Can Die Cut Signs Enhance Guest Experience in Hospitality?

In the hospitality sector, die cut signs are instrumental for wayfinding in hotels and resorts. They guide guests to amenities, rooms, and event spaces, thereby enhancing the overall guest experience. These signs can be designed to complement the aesthetic of the property, reinforcing brand identity while ensuring clarity. Buyers in this sector should focus on sourcing signs that are not only visually appealing but also durable enough to endure high traffic and environmental factors.

3 Common User Pain Points for ‘die cut signs’ & Their Solutions

Scenario 1: Difficulty in Achieving Desired Customization for Brand Messaging

The Problem: B2B buyers often encounter challenges when trying to create die cut signs that accurately reflect their brand identity and messaging. The frustration can stem from limited design options or inadequate assistance from suppliers, leading to a product that doesn’t meet their expectations. This issue is particularly pronounced for businesses in regions with diverse cultural nuances, where a misalignment in design can lead to misunderstandings or lack of engagement with the target audience.

The Solution: To ensure that die cut signs effectively communicate brand messaging, businesses should work closely with suppliers who offer comprehensive customization options. When sourcing die cut signs, look for vendors that provide a user-friendly online design platform that allows for easy manipulation of templates or complete custom designs. Opt for suppliers that have a robust proofing process, where buyers can review and amend designs before finalizing the order. Engaging with professional designers offered by suppliers can also enhance the outcome, ensuring that the final product resonates well with the intended audience. Additionally, investing in high-resolution graphics and materials that maintain clarity, such as UV printing on weather-resistant substrates, will further elevate the quality of the signs.

Scenario 2: Concerns About Durability and Weather Resistance

The Problem: B2B buyers, especially those in regions with extreme weather conditions, often worry about the durability of die cut signs. Signs that are not weather-resistant can fade, warp, or become damaged, leading to additional costs for replacements or repairs. This is a significant concern for businesses that rely on outdoor advertising, such as real estate agencies or event organizers, where visibility and professionalism are crucial.

The Solution: To address durability concerns, it is essential to select die cut signs made from premium materials that are specifically designed to withstand various weather conditions. When evaluating options, buyers should prioritize signs made from robust substrates like corflute or aluminum, which offer superior weather resistance and longevity. Furthermore, inquire about the printing technology used—high-quality UV printing ensures that colors remain vibrant and resistant to fading. For added protection, consider applying a lamination finish, which can further enhance the durability of the signs. Buyers should also plan for proper installation, ensuring that the signs are securely placed to withstand wind and adverse weather.

Scenario 3: Challenges with Order Turnaround Times

The Problem: Timely delivery of die cut signs can pose a significant challenge for B2B buyers, particularly when they are under tight deadlines for events or promotional campaigns. Delays can result from various factors, including production bottlenecks or miscommunication with suppliers, which can jeopardize marketing efforts and lead to lost opportunities. This is especially critical for businesses operating in fast-paced industries or those with specific seasonal promotions.

The Solution: To mitigate issues with turnaround times, businesses should establish clear communication channels with their suppliers from the outset. When placing an order, provide detailed specifications and deadlines to ensure that the supplier understands the urgency. It is advisable to partner with manufacturers known for their reliability and swift production processes. In addition, consider ordering die cut signs in bulk to take advantage of faster processing times, or utilize suppliers that offer expedited production services for urgent requests. Lastly, tracking orders proactively and maintaining regular check-ins with the supplier can help identify potential delays before they become critical issues, allowing for timely adjustments.

Strategic Material Selection Guide for die cut signs

What Are the Key Properties of Common Materials Used for Die Cut Signs?

When selecting materials for die cut signs, understanding the properties and performance characteristics of each option is crucial for B2B buyers. Here, we analyze four common materials: Corflute, PVC, Aluminum, and Acrylic, focusing on their key properties, advantages, disadvantages, and specific considerations for international buyers.

How Does Corflute Perform as a Material for Die Cut Signs?

Corflute, a lightweight and durable corrugated plastic, is often utilized for outdoor signage. Its key properties include excellent weather resistance and a temperature tolerance that allows it to perform well in various climates. Corflute is also resistant to corrosion, making it suitable for prolonged outdoor exposure.

Pros and Cons: The primary advantage of Corflute is its cost-effectiveness, making it an ideal choice for bulk orders. However, it may not be as durable as other materials, particularly in high-wind areas, where it can bend or break under pressure.

Illustrative image related to die cut signs

Impact on Application: Corflute is compatible with various printing methods, including digital and screen printing. However, its lightweight nature may limit its use in high-traffic areas where signs are subject to physical contact.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local environmental regulations, as some areas have restrictions on plastic use. Standards such as ASTM D1593 may apply.

What Advantages Does PVC Offer for Die Cut Signs?

PVC (Polyvinyl Chloride) is a versatile plastic material known for its robustness and flexibility. It has a high-temperature rating, making it suitable for both indoor and outdoor applications. PVC is also resistant to chemicals and moisture, enhancing its longevity.

Pros and Cons: The key advantage of PVC is its durability, which allows it to withstand harsh weather conditions. However, the manufacturing process can be more complex and costly compared to Corflute, potentially increasing the overall price of the signs.

Impact on Application: PVC is compatible with various printing techniques and can be die-cut into intricate designs, making it suitable for custom-shaped signage. Its solid structure provides excellent visibility and professionalism.

Considerations for International Buyers: Buyers should be aware of the different grades of PVC available and their compliance with international standards such as DIN EN 71 for safety. Markets in the Middle East may have specific requirements for PVC signage.

How Does Aluminum Compare as a Material for Die Cut Signs?

Aluminum is a premium material known for its strength and lightweight properties. It offers excellent corrosion resistance, making it ideal for outdoor signage that needs to endure various environmental conditions.

Pros and Cons: The main advantage of aluminum is its longevity and professional appearance, which can enhance brand image. However, it comes at a higher cost compared to plastic materials, which may deter budget-conscious buyers.

Impact on Application: Aluminum is compatible with digital printing and vinyl graphics, allowing for high-quality designs. Its rigidity makes it suitable for high-traffic areas where signs are likely to face wear and tear.

Considerations for International Buyers: Buyers should check for compliance with international standards like ASTM B209 for aluminum sheets. In regions like Europe, environmental regulations may also dictate the use of recyclable materials.

Illustrative image related to die cut signs

What Makes Acrylic a Preferred Choice for Die Cut Signs?

Acrylic is a clear plastic that provides a sleek, modern look and is often used for high-end signage. It offers excellent UV resistance and can withstand temperature fluctuations without warping.

Pros and Cons: The primary advantage of acrylic is its aesthetic appeal and clarity, which can enhance visibility. However, it is more susceptible to scratches and impacts compared to other materials, which may require additional protective measures.

Impact on Application: Acrylic is suitable for both indoor and outdoor applications and can be die-cut into intricate shapes. Its compatibility with various printing methods allows for vibrant graphics.

Considerations for International Buyers: Buyers should be aware of the different grades of acrylic and their compliance with international standards such as JIS K 6922 for plastics. In regions like South America, the availability of high-quality acrylic may vary.

Summary of Material Selection for Die Cut Signs

| Material | Typical Use Case for die cut signs | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Corflute | Temporary outdoor signage | Cost-effective for bulk orders | Less durable in high-wind areas | Low |

| PVC | Indoor/outdoor custom signs | Durable and moisture-resistant | Higher manufacturing complexity | Medium |

| Aluminum | High-end outdoor signage | Long-lasting and professional look | Higher cost compared to plastics | High |

| Acrylic | Premium indoor/outdoor displays | Aesthetic appeal and clarity | Susceptible to scratches | Medium |

This guide provides actionable insights for B2B buyers looking to select the right materials for die cut signs, ensuring that they make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for die cut signs

What Are the Key Stages in the Manufacturing Process of Die Cut Signs?

The manufacturing process for die cut signs involves several critical stages, ensuring both quality and efficiency. Understanding these stages is essential for B2B buyers looking for reliable suppliers.

Material Preparation: What Materials Are Used and How Are They Prepared?

The first step in the manufacturing of die cut signs is material selection. Common materials include corflute, PVC, acrylic, aluminum, and foam board. Each material offers unique benefits, such as durability, weight, and cost-effectiveness.

Once the material is selected, it undergoes preparation, which typically involves cutting sheets to size and ensuring they are clean and free from defects. This stage is crucial, as any imperfections can affect the final product’s appearance and longevity.

Illustrative image related to die cut signs

How Are Die Cut Signs Formed Using Advanced Techniques?

The forming stage is where the die cutting magic happens. Manufacturers use precision die-cutting machines that can create intricate shapes and designs. This process allows for custom shapes that stand out in the marketplace.

Techniques such as flatbed die cutting and laser cutting are commonly employed. Flatbed die cutting is efficient for bulk orders, while laser cutting allows for more intricate designs. These techniques ensure that the signs not only meet design specifications but also maintain structural integrity.

What Assembly Processes Are Common in Die Cut Sign Production?

After forming, the assembly phase may involve adding additional components, such as stakes for yard signs or mounting hardware for wall displays. This step is essential for ensuring that the signs are ready for installation and use.

In cases where multiple materials are used, like combining acrylic with a metal frame, the assembly process requires careful attention to detail. This is where quality control starts to become crucial, as any misalignment or improper attachment can lead to product failures.

What Finishing Techniques Are Applied to Enhance Die Cut Signs?

Finishing processes include printing, lamination, and edge finishing. High-resolution UV printing is often employed to apply vibrant graphics that are resistant to fading. For added protection, especially in outdoor settings, a lamination process may be utilized to enhance durability and resistance to environmental factors.

Edge finishing is also important; it can prevent fraying or damage to the sign edges, ensuring a polished and professional appearance. These finishing touches significantly contribute to the overall quality and appeal of the final product.

How Does Quality Assurance Ensure the Reliability of Die Cut Signs?

Quality assurance (QA) is a critical component in the manufacturing of die cut signs. It encompasses a series of checkpoints and testing methods to ensure that each product meets established standards.

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 provide a framework for quality management systems. This certification indicates that a supplier adheres to best practices in manufacturing and quality control. For specific markets, additional certifications such as CE for European products or API for the oil and gas industry may apply.

Buyers should look for suppliers who are certified by recognized international bodies to ensure compliance with these standards, particularly when sourcing from regions like Africa, South America, the Middle East, and Europe.

What Quality Control Checkpoints Are In Place During Production?

Quality control involves several key checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint examines raw materials for defects before they enter production.

- In-Process Quality Control (IPQC): During manufacturing, random samples are taken to ensure that production processes are being followed correctly.

- Final Quality Control (FQC): Once production is complete, each batch undergoes thorough inspection to verify that it meets all specifications.

These checkpoints help identify potential issues early, reducing waste and ensuring that only high-quality products reach the customer.

What Testing Methods Are Used to Verify Product Quality?

Common testing methods for die cut signs include:

- Visual Inspections: Checking for defects in printing, cutting, and assembly.

- Durability Testing: Assessing how well the signs withstand environmental factors like UV exposure, moisture, and temperature changes.

- Adhesion Tests: For signs that are printed with adhesives or coatings, ensuring that these elements adhere correctly is critical.

These tests help guarantee that the signs will perform well in their intended environments, providing value to the end-user.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Buyers looking to ensure the quality of their suppliers should consider several verification methods:

What Audits and Reports Should Buyers Request?

Requesting audits and quality control reports from potential suppliers is a good starting point. These documents provide insight into the supplier’s quality management practices and adherence to international standards.

Buyers should also inquire about the frequency of internal audits and any third-party inspections that have been conducted. This transparency can help build trust between buyers and suppliers.

What Role Do Third-Party Inspections Play in Ensuring Quality?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing processes. These services typically conduct comprehensive evaluations, including material quality checks, process audits, and final product inspections.

Illustrative image related to die cut signs

For international buyers, particularly those from diverse regions like Africa or South America, utilizing third-party inspections can mitigate risks associated with overseas sourcing. This added layer of scrutiny can ensure that products meet the expected standards before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing die cut signs internationally, buyers must be aware of additional quality control nuances:

- Cultural Differences: Different regions may have varying quality standards and practices. Understanding local norms can aid in communication and expectation setting.

- Regulatory Compliance: Ensure that products meet the regulatory requirements of the target market. This may involve additional certifications or testing, depending on the region.

- Logistics Challenges: International shipping can introduce risks such as damage during transit. Buyers should discuss packaging and handling practices with suppliers to minimize these risks.

By comprehensively understanding the manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing die cut signs, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘die cut signs’

In today’s competitive marketplace, die cut signs are an effective way to enhance visibility and communicate messages clearly. This guide serves as a practical checklist for international B2B buyers seeking to procure high-quality die cut signs tailored to their business needs. Follow these steps to ensure a successful sourcing experience.

Step 1: Identify Your Specific Requirements

Before reaching out to suppliers, clearly define the specifications of your die cut signs. Consider factors such as size, shape, material, and intended use.

– Material Options: Evaluate whether you need lightweight options like corflute for temporary signage or more durable materials like aluminum for long-term installations.

– Design Complexity: Determine if your design requires intricate cuts or simpler shapes, as this can affect both production time and cost.

Step 2: Research Potential Suppliers

Conduct thorough research to compile a list of potential suppliers specializing in die cut signs. Look for companies with a solid reputation and experience in your region.

– Supplier Reviews: Check online reviews and testimonials to gauge customer satisfaction and product quality.

– Industry Experience: Prioritize suppliers who have experience working with businesses in your sector, as they will better understand your specific needs.

Step 3: Request Samples

Once you have shortlisted suppliers, request samples of their die cut signs. This step is crucial for assessing the quality of materials and printing techniques used.

– Material Quality: Examine the durability and finish of the sample materials to ensure they meet your standards.

– Print Clarity: Evaluate the print quality for color vibrancy and clarity, which is essential for effective communication.

Step 4: Verify Supplier Certifications

It is important to ensure that your chosen supplier adheres to industry standards and best practices. Verify any relevant certifications they may hold.

– Quality Assurance: Look for ISO certifications or other relevant accreditations that demonstrate a commitment to quality.

– Sustainability Practices: If environmentally friendly practices are important to your brand, inquire about their sustainability certifications.

Step 5: Discuss Customization Options

Customization can significantly impact the effectiveness of your die cut signs. Discuss the available options with your supplier to ensure they can meet your vision.

– Design Tools: Inquire whether they offer online design tools or professional design services to assist you in creating your sign.

– Printing Techniques: Ask about the printing methods available (e.g., UV printing) to ensure high-quality output that is resistant to fading and weather conditions.

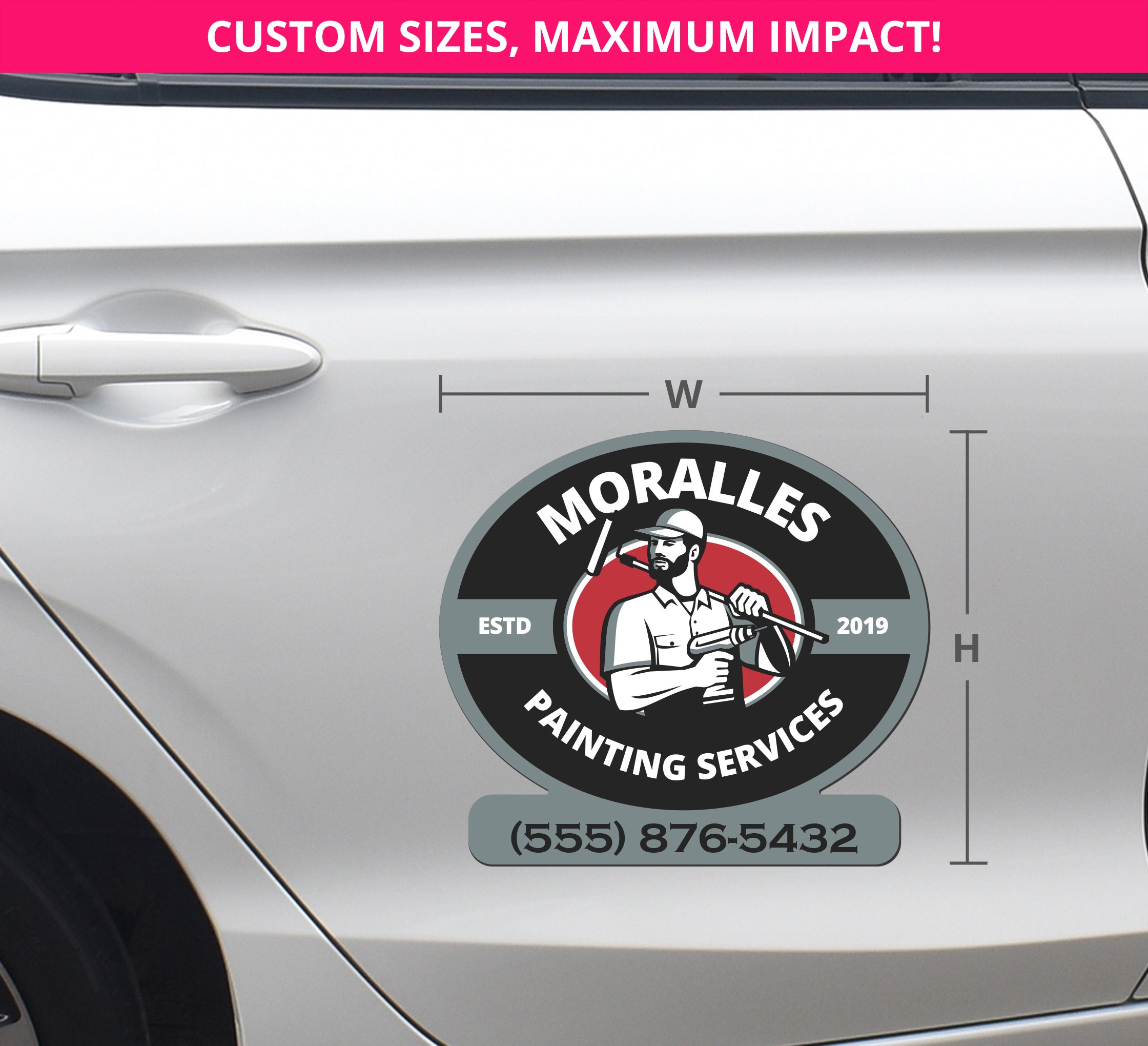

Illustrative image related to die cut signs

Step 6: Evaluate Pricing and Payment Terms

After finalizing your design and specifications, review the pricing and payment terms from potential suppliers. This step is essential for budgeting effectively.

– Bulk Discounts: Inquire about pricing structures for larger orders, as many suppliers offer discounts for bulk purchases.

– Payment Flexibility: Understand the payment terms, including deposits, payment methods, and any financing options available.

Step 7: Confirm Production and Delivery Timelines

Lastly, clarify the expected production and delivery timelines to avoid any scheduling conflicts. Knowing when to expect your signs will aid in planning your marketing efforts.

– Lead Times: Ask about standard lead times for production and any factors that could cause delays.

– Shipping Options: Discuss shipping methods and costs, particularly if you are ordering internationally, to ensure timely delivery.

By following these steps, B2B buyers can confidently navigate the process of sourcing die cut signs, ensuring they select the right supplier to meet their marketing needs effectively.

Illustrative image related to die cut signs

Comprehensive Cost and Pricing Analysis for die cut signs Sourcing

What Are the Key Cost Components of Die Cut Signs?

When sourcing die cut signs, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of substrate significantly impacts the cost. Options such as corflute, PVC, aluminum, and acrylic vary in price based on durability and application. For instance, corflute is often favored for its cost-effectiveness, while aluminum may be selected for high-end applications due to its longevity.

-

Labor: Labor costs encompass design, production, and installation. Custom designs require skilled labor for vectorization and proofing, which can increase costs. Automated processes may reduce labor costs but might not offer the same level of customization.

-

Manufacturing Overhead: This includes expenses related to equipment maintenance, utilities, and facility costs. Efficient production facilities can mitigate these overheads, impacting the final pricing.

-

Tooling: Die-cutting requires specific tools and machinery, which can lead to initial capital expenses. These costs are typically amortized over production runs, influencing pricing based on order volume.

-

Quality Control (QC): Ensuring the quality of die cut signs involves inspection processes that contribute to overall costs. A robust QC system can prevent costly errors and reprints.

-

Logistics: Shipping costs can vary greatly, especially for international orders. Factors such as shipping method, distance, and weight play a significant role in the final cost.

-

Margin: Suppliers typically add a profit margin to cover their risks and business expenses. Understanding the market rates can help buyers negotiate better.

What Influences Pricing for Die Cut Signs?

Several factors influence the pricing of die cut signs, which international buyers should consider:

-

Volume/MOQ: Bulk orders often lead to cost savings. Suppliers may offer discounts for minimum order quantities (MOQs), making it essential for buyers to assess their needs accurately.

-

Specifications and Customization: Custom shapes, sizes, and finishes will generally increase costs. Detailed specifications can lead to higher initial pricing but may result in better alignment with marketing goals.

-

Material Choices: Higher-quality materials will naturally increase costs but may offer better durability and performance, leading to a lower Total Cost of Ownership (TCO) over time.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can influence costs. Established suppliers may charge more due to perceived value but often provide better service and quality assurance.

-

Incoterms: Understanding shipping terms is vital for international buyers. Incoterms dictate who is responsible for shipping, insurance, and tariffs, which can significantly affect the final landed cost.

How Can Buyers Optimize Costs When Sourcing Die Cut Signs?

To maximize cost-efficiency when sourcing die cut signs, consider the following tips:

-

Negotiate: Don’t hesitate to negotiate prices, especially for bulk orders. Suppliers may be willing to offer discounts or flexible payment terms to secure larger contracts.

-

Assess Total Cost of Ownership (TCO): Evaluate not just the initial price but also the long-term value. Consider factors like durability, maintenance, and potential reprints, which can impact overall costs.

-

Understand Pricing Nuances: Be aware of the variations in pricing based on region. For buyers from Africa, South America, the Middle East, and Europe, factors like currency exchange rates and local market conditions can affect costs.

-

Leverage Technology: Utilize online design tools and templates to reduce design costs. Many suppliers offer free design proofs, which can help in avoiding costly mistakes.

-

Plan for Logistics: Factor in shipping costs and timelines when placing orders. Opting for consolidated shipments can help reduce logistics costs.

Conclusion: What Should International Buyers Consider?

While sourcing die cut signs, international B2B buyers must remain vigilant about the various cost components and pricing influencers. Understanding these elements not only aids in negotiating better prices but also ensures that the selected solutions align with business objectives. Always approach suppliers with a clear understanding of your requirements, and don’t overlook the importance of quality and service when making your decision.

Alternatives Analysis: Comparing die cut signs With Other Solutions

When evaluating marketing materials, it’s essential to consider various options that can effectively convey your message. Die cut signs are a popular choice, but other alternatives may better suit specific needs. This analysis compares die cut signs with two viable alternatives: vinyl banners and acrylic signs, assessing their performance, cost, ease of implementation, maintenance, and best use cases.

Illustrative image related to die cut signs

| Comparison Aspect | Die Cut Signs | Vinyl Banners | Acrylic Signs |

|---|---|---|---|

| Performance | High visibility with custom shapes and designs; weather-resistant | Excellent for indoor/outdoor use; vibrant colors | Premium look with clarity; suitable for long-term displays |

| Cost | Moderate, with bulk discounts available | Generally lower cost; can be economical for large formats | Higher initial cost; durable investment |

| Ease of Implementation | Easy to customize and install, often with metal stakes | Lightweight and easy to hang; can be rolled for transport | Requires professional installation for larger sizes |

| Maintenance | Minimal; clean with a damp cloth | Low maintenance; wipe clean as needed | Durable but can scratch; requires careful handling |

| Best Use Case | Ideal for outdoor events, real estate, and political campaigns | Great for promotions, trade shows, and temporary advertising | Suitable for permanent installations, awards, and upscale displays |

What Are the Pros and Cons of Vinyl Banners Compared to Die Cut Signs?

Vinyl banners are a cost-effective alternative, especially for businesses needing large-format advertising. They are lightweight, making them easy to transport and install in various settings. However, they may not offer the same level of customization in shape and size as die cut signs. Additionally, while vinyl is durable, it may not withstand harsh weather as effectively as die cut signs made from robust materials like corflute.

How Do Acrylic Signs Compare to Die Cut Signs in Terms of Quality and Appearance?

Acrylic signs provide a high-end appearance that is often preferred for professional environments, such as offices and retail spaces. They are known for their clarity and vibrant colors, creating an impressive visual impact. However, the initial investment for acrylic signs can be significantly higher than die cut signs. Installation can also be more complex, requiring professional assistance, which could extend project timelines and increase costs.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right signage solution, B2B buyers should consider factors such as budget, intended use, and installation preferences. Die cut signs are excellent for outdoor and customizable needs, while vinyl banners offer an economical and versatile solution for temporary promotions. Acrylic signs, though more expensive, provide a polished look suitable for long-term displays. Evaluating these aspects will ensure that your signage effectively meets your marketing goals and resonates with your target audience.

Essential Technical Properties and Trade Terminology for die cut signs

What Are the Key Technical Properties of Die Cut Signs for B2B Buyers?

When considering die cut signs, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications that highlight the quality and functionality of these signs:

Illustrative image related to die cut signs

1. Material Grade

The material used in die cut signs significantly impacts durability and appearance. Common materials include corflute, PVC, acrylic, and aluminum. For instance, corflute is lightweight yet sturdy, making it ideal for outdoor use. Choosing the right material ensures that the sign can withstand environmental factors while maintaining its visual appeal.

2. Weight and Thickness

Weight and thickness are critical metrics that influence the sign’s stability and durability. For example, a 5mm thick corflute sign weighs approximately 26.25 oz, providing a balance of portability and resistance to wind and weather conditions. A heavier sign typically offers better stability, especially in outdoor settings, which is essential for maintaining visibility and effectiveness.

3. Printing Resolution

High-resolution printing is vital for clear and vibrant graphics. A resolution of 600 DPI (dots per inch) is standard for quality die cut signs, ensuring that images and text are sharp and easily readable from a distance. This quality is particularly important for businesses aiming to attract attention and convey messages quickly, enhancing brand visibility.

4. Weather Resistance

Weather-resistant properties are essential for outdoor signage. Signs that feature UV-resistant coatings or non-reflective surfaces maintain clarity and color vibrancy despite exposure to sunlight and rain. This quality ensures longevity, reducing the need for frequent replacements and providing a better return on investment.

5. Customization Options

Customization is a crucial aspect of die cut signs. Options such as single or double-sided printing and various shapes and sizes allow businesses to tailor their signage to specific needs. This flexibility is beneficial for creating distinctive marketing materials that stand out in competitive environments.

Illustrative image related to die cut signs

What Are Common Trade Terms in the Die Cut Sign Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B space. Here are some common terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

In the context of die cut signs, OEM refers to companies that produce components or products that are then marketed by another company under its brand name. Understanding OEM relationships can help buyers identify reputable manufacturers and negotiate better pricing.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is significant for B2B buyers, as it affects budgeting and inventory management. Knowing the MOQ helps businesses plan their orders effectively, especially when considering bulk purchases for marketing campaigns.

3. RFQ (Request for Quotation)

An RFQ is a formal process used by buyers to request pricing and terms from suppliers. This document outlines the specifics of what is needed, allowing suppliers to provide accurate quotes. For B2B buyers, issuing an RFQ can lead to better pricing and terms through competitive bidding.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding these terms is crucial for B2B buyers involved in cross-border transactions, ensuring clarity on who is responsible for costs and risks during transportation.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to delivery. This metric is crucial for businesses with tight timelines, as it impacts project planning and execution. Knowing the lead time helps buyers align their marketing efforts with production schedules.

By grasping these technical specifications and trade terms, B2B buyers can enhance their understanding of die cut signs, leading to more strategic purchasing decisions that align with their marketing goals.

Navigating Market Dynamics and Sourcing Trends in the die cut signs Sector

What Are the Current Market Dynamics and Key Trends Influencing Die Cut Signs?

The die cut signs market is experiencing robust growth driven by various global factors. Increasing demand for customized signage solutions across industries such as real estate, retail, and events is propelling market expansion. In regions like Africa, South America, the Middle East, and Europe, businesses are increasingly recognizing the value of effective visual communication, driving the need for high-quality, tailored signage. Additionally, advancements in printing technologies, such as high-resolution UV printing, allow for vibrant and durable signage options, enhancing market appeal.

Emerging trends also highlight the importance of digitalization in the sourcing process. B2B buyers are now leveraging online platforms for instant quotes and design tools, facilitating a smoother purchasing experience. The rise of e-commerce has made it easier for international buyers to access a wider range of suppliers, contributing to a more competitive market landscape. Furthermore, customization capabilities, including various materials and shapes, are becoming essential as brands strive to differentiate themselves and create unique marketing messages.

As the market continues to evolve, factors such as pricing strategies, bulk discounts, and customer service quality are critical for B2B buyers. Suppliers who offer quick turnaround times and reliable support are likely to gain a competitive edge, especially in regions where timely delivery can significantly impact marketing campaigns.

How Is Sustainability and Ethical Sourcing Affecting the Die Cut Signs Industry?

Sustainability and ethical sourcing are becoming paramount considerations for B2B buyers in the die cut signs sector. As environmental concerns rise globally, businesses are increasingly scrutinizing their supply chains and material choices. The production of signage materials often involves plastics and other non-biodegradable components, which contribute to environmental degradation. Thus, suppliers are under pressure to adopt eco-friendly practices.

B2B buyers are now prioritizing suppliers who utilize sustainable materials, such as recycled plastics or biodegradable substrates, which are gaining traction in the market. Certifications such as FSC (Forest Stewardship Council) and ISO 14001 are becoming essential for demonstrating commitment to sustainability. These certifications not only enhance a company’s reputation but also appeal to environmentally conscious consumers.

Moreover, the demand for transparency in supply chains is growing. Buyers are seeking assurance that their suppliers adhere to ethical labor practices and environmental regulations. By fostering ethical sourcing, companies can improve brand loyalty and customer trust, further establishing their market presence.

How Has the Die Cut Signs Industry Evolved Over Time?

The evolution of the die cut signs industry has been marked by significant technological advancements and changing consumer preferences. Initially, signage was limited to standard shapes and sizes, often made from wood or metal. However, the introduction of die-cutting technology revolutionized the sector, allowing for intricate designs and customization options that cater to specific business needs.

As digital printing technology advanced, the quality and vibrancy of signage improved dramatically, enabling businesses to create eye-catching visuals that enhance brand identity. The rise of digital platforms has also transformed the way businesses order signage, making the process more accessible and efficient.

Today, the die cut signs market is characterized by a blend of creativity and technology, with suppliers offering a wide array of materials and customization options. This evolution reflects a broader trend in marketing, where visual communication plays a crucial role in capturing consumer attention and driving engagement. As the industry continues to develop, B2B buyers are positioned to benefit from innovative solutions that enhance their marketing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of die cut signs

1. How do I choose the right die cut sign for my business needs?

Choosing the right die cut sign involves understanding your specific marketing goals, target audience, and the environment where the sign will be displayed. Consider factors such as size, shape, material, and printing options that align with your branding. For outdoor use, opt for durable, weather-resistant materials like corflute or PVC. If customization is key, look for suppliers that offer flexible design options and assistance. Lastly, evaluate the supplier’s portfolio to ensure they can meet your quality and aesthetic standards.

2. What are the benefits of using die cut signs over traditional signs?

Die cut signs offer several advantages, including unique shapes that can attract more attention than standard rectangular signs. They can be tailored to fit specific branding needs, providing a distinctive visual identity. The advanced printing techniques used in die-cut signage ensure vibrant, fade-resistant graphics, enhancing visibility. Additionally, die cut signs are often lightweight and easy to install, making them versatile for various applications, from events to real estate promotions.

3. What customization options should I consider for die cut signs?

When customizing die cut signs, consider the following options: shape, size, material, and printing style. Choose from various shapes that represent your brand or message creatively. Select materials based on the intended use—outdoor signs may require weather-resistant options like corrugated plastic, while indoor signs might use foamcore or acrylic. Additionally, decide between single or double-sided printing to maximize visibility. Many suppliers offer design templates or professional assistance to help refine your vision.

4. What are the minimum order quantities (MOQs) for die cut signs?

Minimum order quantities can vary significantly depending on the supplier and the specific products. Some suppliers may offer MOQs as low as 5 to 10 signs for custom orders, while others may require larger quantities to maintain cost-effectiveness. Always inquire about bulk discounts and pricing structures, as ordering in larger quantities can lead to significant savings. Ensure that the MOQ aligns with your marketing strategy and budget considerations.

5. How can I vet suppliers for die cut signs in international markets?

To effectively vet suppliers for die cut signs, start by researching their online presence, including reviews and testimonials from previous clients. Request samples of their work to assess quality and craftsmanship firsthand. Verify their production capabilities, lead times, and certifications to ensure they comply with international standards. Engaging in direct communication can also provide insights into their customer service and responsiveness. Finally, consider their experience with international shipping and customs regulations to avoid potential delays.

6. What payment terms are typically offered for die cut sign orders?

Payment terms for die cut sign orders can vary widely among suppliers. Common practices include upfront payment, partial payment upon order confirmation with the balance due prior to shipping, or net payment terms (e.g., net 30 or net 60 days) for established businesses. Always clarify the payment options available and negotiate terms that fit your cash flow needs. Additionally, inquire about acceptable payment methods, including credit cards, bank transfers, or platforms like PayPal.

7. How do I ensure quality assurance for my die cut sign orders?

To ensure quality assurance for die cut sign orders, establish clear specifications regarding materials, dimensions, and printing quality before production begins. Request proofs or samples for approval to verify that the design aligns with your expectations. Some suppliers may offer quality checks during production, so inquire about their processes. Additionally, consider including quality assurance clauses in your contract to outline expectations and remedies for any discrepancies.

8. What logistics considerations should I keep in mind when ordering die cut signs internationally?

When ordering die cut signs internationally, consider shipping costs, delivery times, and customs regulations that may affect your order. Confirm whether the supplier offers international shipping and their experience with customs clearance in your country. It’s also wise to discuss packaging methods to prevent damage during transit. Finally, be aware of any import duties or taxes that may apply, as these can impact your overall budget and timeline for receiving the signs.

Top 8 Die Cut Signs Manufacturers & Suppliers List

1. BannerBuzz – Die-Cut Yard Signs

Domain: bannerbuzz.com

Registered: 2009 (16 years)

Introduction: {“Product Name”: “Die-Cut Yard Signs”, “SKU”: “BBDCYSG01”, “Price”: “$9.43 (originally $15.72)”, “Discount”: “Save 40%”, “Material”: “5mm corflute, 26.25 oz weight”, “Printing”: “High-resolution 600 DPI UV printing”, “Features”: [“Custom Sizes”, “Free design templates”, “Artwork proofing”, “Expert designer assistance”, “Weather Resistant”, “Non-reflective surface”, “Optional metal stakes”], “Appli…

2. Deadline Signs – Custom Shaped Signs

Domain: deadlinesigns.com

Registered: 2019 (6 years)

Introduction: Custom Shaped Signs – Die-cutting available for various materials including lawn signs, acrylic, PVC, aluminum, and more. Cut-Contour technique allows for creative shapes and sizes. Products include adhesive decals, polystyrene, corrugated plastic, non-skid floor decals, handheld paddle signs, aluminum composite, PVC, foamcore, reusable door hangers, acrylic, oversized head cutouts, and custom yar…

3. Best of Signs – Die-Cut Yard Signs

Domain: bestofsigns.com

Registered: 2013 (12 years)

Introduction: Die-Cut Yard Signs: Key Features – Material Strength: Heavy-duty corflute material for outdoor performance – Print Technology: Advanced UV printing for vibrant colors – Custom Dimensions: Flexible sizing options available – Design Expertise: Professional templates and design consultation – Weather Resistant: Specialized coating for visibility in harsh conditions – Quick Setup: Lightweight with stu…

4. Print Window Cleaner – Custom Die Cut Yard Signs

Domain: print.windowcleaner.com

Registered: 1998 (27 years)

Introduction: Custom Die Cut Yard Signs, also known as Lawn Signs or Bandit Signs, are customizable to almost any shape. They are made from 4 mm corrugated plastic, designed to withstand weather and fading, and come with H-Stakes (upgraded stakes available). Ideal for service businesses, these signs help brands stand out and capture audience attention.

5. MegaPrint – Die Cut Signs

Domain: megaprint.com

Registered: 1996 (29 years)

Introduction: Die Cut Signs are produced using CNC routing and UV printing on materials such as Ultraboard, Sintra, styrene, and Gatorboard. The CNC router allows for custom cut shapes that are consistent, smooth, and attractive. This method is cost-effective for shorter runs and is preferred for materials that are too brittle for die cutting. Typical applications include retail store signage, trade show graphi…

6. Yard Sign Plus – Custom Die-Cut Yard Signs

Domain: yardsignplus.com

Registered: 2022 (3 years)

Introduction: Custom Die-Cut Yard Signs

– Discount: 10% OFF with code SAVE10

– Free Shipping on Orders $50+

– Overnight Delivery available

– Ships Same Day

– Fully Customizable: Upload your own design or use templates

– Sizes Available: 6×18, 6×24, 9×12, 9×24, 12×12, 12×18, 18×12, 18×24, 24×18, 24×24 inches

– Material: 4mm thick corrugated plastic (coroplast), weather-resistant

– Printing Method: Digital full C…

7. Sticker Mule – Custom Die Cut Acrylic Signs

Domain: stickermule.com

Registered: 2009 (16 years)

Introduction: Custom die cut acrylic signs, uniquely shaped, premium quality, custom-cut to design, optional drill holes and mounting hardware included. Available sizes: 5″ × 5″, 10″ × 10″, 20″ × 20″, 30″ × 30″, 40″ × 40″, custom sizes. Pricing: 1 sign for $36, 5 signs for $82 (54% savings), 10 signs for $137 (62% savings), 20 signs for $243 (66% savings), 50 signs for $548 (70% savings). Free shipping in 4 day…

8. Teelaunch – Metal Home Decor Sign

Domain: teelaunch.com

Registered: 2012 (13 years)

Introduction: This company, Teelaunch – Metal Home Decor Sign, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for die cut signs

The strategic sourcing of die-cut signs presents an invaluable opportunity for businesses seeking to enhance their visibility and branding in competitive markets. As outlined, the versatility of die-cut signage—including its customizable shapes, durable materials, and high-quality printing—positions it as a preferred choice for effective marketing across various sectors. By leveraging these attributes, businesses can effectively communicate their messages, whether for promotional campaigns, events, or directional signage.

Engaging with reliable suppliers who prioritize quality and cost-effectiveness is crucial. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate the procurement process, establishing partnerships with manufacturers that offer robust customization options and rapid turnaround times can significantly streamline operations. Moreover, bulk ordering opportunities can yield substantial savings, enabling companies to maximize their marketing budgets.

Looking ahead, the demand for innovative and eye-catching signage will only continue to rise. By embracing strategic sourcing practices, businesses can ensure they remain at the forefront of their industries. Now is the time to invest in die-cut signs that not only elevate brand presence but also resonate with target audiences. Explore your options today and transform your marketing approach with impactful visual solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.