Membrane Switch Panel Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for membrane switch panel

In today’s competitive landscape, sourcing high-quality membrane switch panels can pose significant challenges for international B2B buyers. As these panels serve as crucial interfaces between users and machinery across various industries, understanding the nuances of their design, functionality, and application is essential. This guide is designed to equip buyers from regions such as Africa, South America, the Middle East, and Europe, including Brazil and Vietnam, with the insights needed to navigate the global market effectively.

We will explore the diverse types of membrane switch panels available, their applications in various sectors, and the critical factors to consider when vetting suppliers. Additionally, we will provide a comprehensive analysis of cost structures, ensuring that buyers can make informed decisions that align with their budgetary constraints and operational needs.

By delving into the intricacies of membrane switch panels, this guide empowers B2B buyers to enhance their procurement strategies. From understanding the technical specifications to evaluating the reliability of manufacturers, readers will gain the knowledge required to secure the best solutions for their unique applications. Whether you are looking to improve user interfaces in medical devices, industrial equipment, or consumer electronics, this resource will help streamline your purchasing process and ensure you partner with the right suppliers for success in the global market.

Understanding membrane switch panel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Membrane Switch | Printed polyester or polycarbonate overlay, momentary action | Consumer electronics, appliances | Pros: Cost-effective, customizable. Cons: Limited tactile feedback. |

| Tactile Membrane Switch | Embossed keys for tactile feedback, durable materials | Medical devices, industrial equipment | Pros: Enhanced user experience. Cons: Higher production costs. |

| Backlit Membrane Switch | Integrated LED or electroluminescent backlighting | Control panels, automotive applications | Pros: Improved visibility in low light. Cons: More complex design. |

| FPC (Flexible Printed Circuit) | Ultra-thin design, lightweight, flexible | Wearable technology, portable devices | Pros: Space-saving, lightweight. Cons: Fragile compared to rigid options. |

| Metal Dome Switch Array | Metal dome for tactile feedback, robust construction | High-use environments, heavy machinery | Pros: Long lifespan, reliable performance. Cons: Higher initial cost. |

What are the characteristics and suitability of Standard Membrane Switches?

Standard membrane switches are characterized by their printed overlays made from polyester or polycarbonate, featuring momentary action functionality. These switches are ideal for applications in consumer electronics and household appliances due to their cost-effectiveness and customizable designs. B2B buyers should consider the balance between affordability and functionality, especially in projects with tight budgets. However, the lack of tactile feedback may be a drawback in applications requiring precise user interaction.

How do Tactile Membrane Switches enhance user experience?

Tactile membrane switches incorporate embossed keys that provide physical feedback to users, making them suitable for medical devices and industrial equipment where user interaction is critical. Their durability and ability to withstand harsh environments make them a preferred choice for demanding applications. B2B buyers should evaluate the enhanced user experience against the higher production costs, ensuring that the benefits justify the investment in environments where reliability and user satisfaction are paramount.

What advantages do Backlit Membrane Switches offer for visibility?

Backlit membrane switches are designed with integrated LED or electroluminescent backlighting, making them particularly useful in control panels and automotive applications where visibility in low-light conditions is essential. These switches enhance user interaction by illuminating keys and symbols, thereby improving operational efficiency. Buyers should weigh the benefits of improved visibility against the complexity and potential costs of more intricate designs, particularly in industries with stringent lighting requirements.

Why are FPC Membrane Switches favored in portable devices?

Flexible Printed Circuit (FPC) membrane switches are ultra-thin and lightweight, making them ideal for wearable technology and portable devices. Their flexibility allows for creative designs that can fit into compact spaces, appealing to B2B buyers focused on innovation and user comfort. However, the fragility of FPC switches compared to their rigid counterparts may necessitate careful consideration regarding the application environment and expected durability.

What makes Metal Dome Switch Arrays a reliable choice?

Metal dome switch arrays are known for their robust construction and tactile feedback, making them suitable for high-use environments such as heavy machinery and industrial applications. Their long lifespan and reliable performance are significant advantages for B2B buyers seeking durability in demanding operational settings. While the initial investment may be higher, the longevity and reliability of these switches can result in lower total cost of ownership over time, making them a smart choice for businesses focused on sustainability and efficiency.

Key Industrial Applications of membrane switch panel

| Industry/Sector | Specific Application of Membrane Switch Panel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Equipment | Control panels for diagnostic devices | Enhanced user interface for precision control | Compliance with medical regulations and standards |

| Industrial Automation | Machine control interfaces | Improved operational efficiency and safety | Durability and resistance to environmental factors |

| Consumer Electronics | User interfaces for appliances | Increased user satisfaction through design | Aesthetic customization and backlighting options |

| Automotive | Dashboard controls | Streamlined functionality and reliability | Temperature and moisture resistance requirements |

| Military & Defense | Tactical equipment interfaces | Robustness and reliability in harsh conditions | Compliance with military specifications and standards |

How Are Membrane Switch Panels Used in Medical Equipment?

In the medical sector, membrane switch panels serve as critical control interfaces for diagnostic devices, such as MRI machines and patient monitoring systems. They allow healthcare professionals to operate complex machinery with precision and ease. The panels are designed to be user-friendly, reducing the risk of operational errors. For international buyers, compliance with medical regulations, such as ISO 13485, is essential, ensuring the switches can withstand rigorous cleaning protocols and maintain functionality in sterile environments.

What Role Do Membrane Switch Panels Play in Industrial Automation?

In industrial automation, membrane switch panels are utilized for machine control interfaces, allowing operators to manage equipment efficiently. These panels enhance operational safety by providing clear visual indicators and tactile feedback. They can be designed to withstand harsh environments, such as extreme temperatures and exposure to chemicals. Buyers should prioritize sourcing panels that meet industry standards for durability and can be customized to fit specific machinery requirements, ensuring seamless integration and long-term reliability.

How Are Membrane Switch Panels Beneficial in Consumer Electronics?

In the consumer electronics industry, membrane switch panels are commonly found in user interfaces for appliances like microwaves and washing machines. Their sleek design enhances the aesthetic appeal of products while providing intuitive navigation for users. The ability to customize graphics and incorporate backlighting can significantly improve user satisfaction. For B2B buyers, sourcing switches that offer high-quality printing and durability is vital, particularly in regions where environmental factors may affect product longevity.

Why Are Membrane Switch Panels Important for Automotive Applications?

Membrane switch panels play a pivotal role in automotive dashboard controls, providing drivers with a streamlined interface for managing various vehicle functions. They are essential for ensuring both functionality and reliability, as they must operate effectively in diverse temperature and humidity conditions. Buyers in the automotive sector should focus on sourcing panels that comply with automotive industry standards, ensuring they can withstand vibrations and provide longevity in demanding environments.

How Do Membrane Switch Panels Serve Military and Defense Applications?

In military and defense applications, membrane switch panels are integral to tactical equipment interfaces, where reliability and robustness are paramount. These panels are designed to function in extreme conditions, ensuring that soldiers can operate equipment without failure. Buyers must consider sourcing panels that meet stringent military specifications, which often include resistance to shock, vibration, and environmental factors. Additionally, customization options for backlighting and tactile feedback can enhance usability in low-light conditions, making them crucial for operational effectiveness.

3 Common User Pain Points for ‘membrane switch panel’ & Their Solutions

Scenario 1: Ensuring Durability in Harsh Environments

The Problem: B2B buyers often face challenges when sourcing membrane switch panels that can withstand extreme conditions. Industries such as oil and gas, manufacturing, or outdoor equipment require switches that can endure temperature fluctuations, humidity, dust, and even chemical exposure. Buyers may find that many standard membrane switches fail prematurely under these circumstances, leading to costly replacements and operational downtime.

The Solution: To address this durability concern, buyers should prioritize sourcing membrane switch panels that meet specific environmental standards. Look for manufacturers that offer IP-rated products, indicating their panels are designed for water and dust resistance. Additionally, opt for materials such as polycarbonate or polyester that are treated for chemical resistance. Request samples to test in actual operational conditions before making bulk purchases. Establishing a close relationship with the manufacturer can also facilitate customization of the switch design, ensuring it meets all environmental challenges.

Scenario 2: Achieving the Desired Aesthetic and Functionality

The Problem: In competitive markets, the visual appeal and user experience of machinery interfaces can significantly impact customer satisfaction and brand reputation. B2B buyers often struggle to find membrane switch panels that not only function correctly but also align with their branding and product design requirements. Limited options can lead to compromises in aesthetics or functionality, diminishing the overall quality of the final product.

The Solution: Buyers should work with manufacturers that offer extensive customization options for membrane switch panels. This includes a variety of graphic overlays, color choices, and tactile feedback features. Request a design consultation with the manufacturer to explore advanced printing techniques like digital printing or screen printing that can produce high-quality graphics. Also, consider integrating backlighting options to enhance visibility and user interaction. By collaborating closely with the manufacturer during the design phase, buyers can ensure that the final product meets both aesthetic and functional needs.

Scenario 3: Overcoming Sourcing and Supply Chain Challenges

The Problem: International B2B buyers often encounter difficulties in the sourcing process due to varying quality standards, lead times, and shipping logistics. This is especially true when dealing with suppliers from different regions, such as Africa or South America, where supply chain disruptions can lead to delays in production and delivery. Such issues can significantly impact project timelines and client satisfaction.

The Solution: To mitigate sourcing challenges, buyers should conduct thorough research on potential suppliers, focusing on their production capabilities, quality control measures, and delivery reliability. Establishing partnerships with manufacturers that have a proven track record in international shipping can streamline the procurement process. It is also beneficial to utilize digital platforms that facilitate instant quoting and order tracking, ensuring transparency throughout the process. Maintaining regular communication with suppliers can help anticipate potential delays and adjust project timelines accordingly. Additionally, consider diversifying the supplier base to include local manufacturers who can provide quicker turnaround times and reduce shipping complications.

Strategic Material Selection Guide for membrane switch panel

What Are the Key Properties of Polyester in Membrane Switch Panels?

Polyester is one of the most commonly used materials for membrane switch panels due to its versatility and favorable properties. It exhibits excellent dimensional stability and is resistant to moisture, making it suitable for various environments. Polyester can withstand temperatures up to 125°C (257°F) and has good resistance to many chemicals, including acids and alkalis.

Pros include its cost-effectiveness and ease of printing, which allows for high-quality graphics and branding. However, cons involve its relatively lower durability compared to some other materials, particularly in harsh environments. Polyester is suitable for applications where flexibility and a lightweight design are crucial, but it may not hold up well in extreme conditions.

International buyers should consider compliance with standards such as ASTM D882 for tensile strength and ASTM D1004 for tear resistance. In regions like Africa and South America, where environmental conditions can vary significantly, ensuring the right specifications is essential.

How Does Polycarbonate Compare for Membrane Switch Panels?

Polycarbonate is another popular choice for membrane switch panels, known for its high impact resistance and clarity. It can endure temperatures ranging from -40°C to 120°C (-40°F to 248°F) and offers excellent resistance to UV light, making it ideal for outdoor applications.

The advantages of polycarbonate include its durability and ability to withstand significant physical stress, making it suitable for demanding environments. However, it tends to be more expensive than polyester and can be prone to scratching without proper coatings.

For international buyers, especially in Europe where stringent safety standards are prevalent, polycarbonate’s compliance with EN 71 (safety of toys) and other relevant directives is crucial. This material is often preferred in industries such as automotive and medical devices, where safety and durability are paramount.

What Role Does Acrylic Play in Membrane Switch Panel Construction?

Acrylic, or PMMA (polymethyl methacrylate), is favored for its optical clarity and aesthetic appeal. It can withstand temperatures up to 80°C (176°F) and has good weather resistance, making it suitable for both indoor and outdoor applications.

The key benefits of acrylic include its lightweight nature and superior light transmission, which is particularly advantageous for illuminated panels. However, it is less impact-resistant than polycarbonate and can be more susceptible to scratching and chemical damage.

Buyers from the Middle East and Africa should be aware of the specific environmental conditions that could affect acrylic’s performance. Compliance with ISO 4892 for weathering testing can help ensure that the material will perform well in diverse climates.

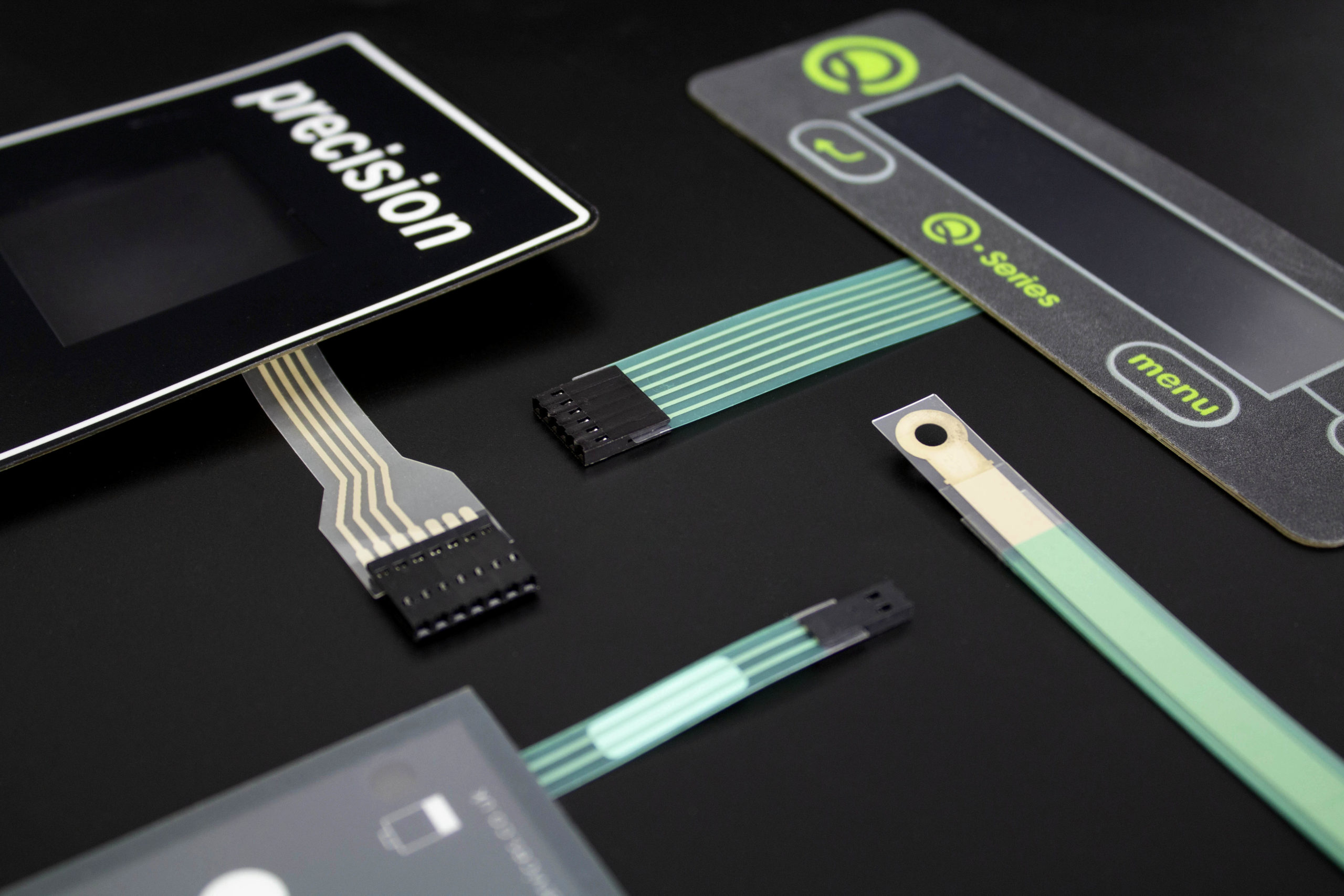

What Are the Advantages of Using Metal Domes in Membrane Switch Panels?

Metal domes are often incorporated into membrane switch panels to provide tactile feedback. These components are typically made from stainless steel or nickel-plated materials, offering excellent durability and a long lifespan. They can withstand high temperatures and are resistant to corrosion, making them suitable for various applications.

Illustrative image related to membrane switch panel

The primary advantage of metal domes is their tactile response, which enhances user experience. However, they can increase manufacturing complexity and costs due to the need for precise placement and assembly.

For B2B buyers in regions like South America and Europe, understanding the compliance with standards like ISO 9001 for quality management can be critical. Metal domes are often preferred in industrial applications where reliability and user interaction are vital.

Summary Table of Material Selection for Membrane Switch Panels

| Material | Typical Use Case for membrane switch panel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | General consumer electronics | Cost-effective and easy to print | Lower durability in harsh conditions | Low |

| Polycarbonate | Automotive and medical devices | High impact resistance | More expensive and prone to scratches | High |

| Acrylic | Outdoor signage and displays | Excellent optical clarity | Less impact-resistant and more prone to scratches | Med |

| Metal Domes | Industrial machinery and control panels | Provides tactile feedback | Increases manufacturing complexity | Med |

This strategic material selection guide provides essential insights for B2B buyers across diverse regions, enabling informed decisions based on specific application needs and environmental considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for membrane switch panel

What Are the Main Stages of Manufacturing Membrane Switch Panels?

The manufacturing of membrane switch panels involves several critical stages that ensure quality and functionality. Understanding these stages will help B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, make informed decisions when sourcing these components.

Material Preparation: What Materials Are Used in Membrane Switch Manufacturing?

The first step in manufacturing membrane switch panels is the selection and preparation of materials. Common materials include polyester and polycarbonate for overlays, which provide durability and resistance to wear. Conductive inks, typically made from silver or carbon, are used for the circuitry. These materials must meet specific standards to ensure they can withstand environmental factors such as humidity and temperature variations, which are crucial for applications in diverse climates.

Before production, materials undergo rigorous checks to verify their quality. This initial quality control (IQC) step is vital, as it prevents inferior materials from entering the manufacturing process, thus safeguarding the final product’s integrity.

Forming: How Are Membrane Switch Panels Shaped?

Once materials are prepared, the forming stage begins. This involves several key techniques, including printing and cutting. Screen printing is commonly used to apply the graphic overlays and conductive traces onto the chosen substrate. The printing must be precise, as any misalignment can affect the functionality of the switches.

After printing, the overlay is cut to the desired shape using laser or die-cutting methods. These cutting techniques ensure clean edges and accurate dimensions, which are essential for the assembly phase. Additionally, embossing techniques may be employed to create tactile feedback on certain keys, enhancing user experience.

Assembly: What Does the Assembly Process Entail?

The assembly stage is where all components come together. The printed overlay is aligned and adhered to the circuit layer, often using a pressure-sensitive adhesive. This step requires precision to ensure that the switches align perfectly with the underlying circuitry.

Metal dome switches may be integrated during this phase to provide tactile feedback. The assembly process is typically automated, which helps maintain consistency and reduces the risk of human error. However, it still requires skilled operators to monitor the process and address any issues that arise.

Finishing: What Final Touches Are Applied to Membrane Switch Panels?

In the finishing stage, additional features such as backlighting and protective coatings may be applied. Backlighting options include LEDs and electroluminescent (EL) panels, which enhance visibility in low-light conditions. Protective coatings, such as UV-resistant finishes, are also applied to extend the product’s lifespan and improve its aesthetic appeal.

Final inspections are conducted at this stage to ensure that all elements meet the specified design and functional requirements. This thorough approach to finishing is essential for creating a high-quality membrane switch panel.

What Quality Assurance Processes Are Essential for Membrane Switch Panels?

Quality assurance (QA) is a critical aspect of the membrane switch manufacturing process. It ensures that the final product meets both international and industry-specific standards, which is particularly important for B2B buyers looking for reliable suppliers.

What International Standards Should B2B Buyers Look for in Membrane Switch Suppliers?

One of the most recognized international standards in manufacturing is ISO 9001, which focuses on quality management systems. Suppliers that adhere to ISO 9001 demonstrate their commitment to maintaining quality throughout their processes. Additionally, industry-specific certifications such as CE for European markets and API for certain industrial applications can indicate compliance with safety and performance standards.

For buyers from regions like Africa and South America, understanding these standards can help in evaluating potential suppliers and ensuring that products meet necessary regulatory requirements.

What Are the Key Quality Control Checkpoints in Membrane Switch Manufacturing?

Quality control in membrane switch manufacturing typically involves several checkpoints:

- Incoming Quality Control (IQC): This initial step verifies the quality of raw materials before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, operators conduct regular checks to ensure that the production process is consistent and that any defects are identified early.

- Final Quality Control (FQC): This final inspection ensures that the completed products meet all specifications and standards before shipment.

By understanding these checkpoints, B2B buyers can inquire about a supplier’s QA processes and ensure that they are receiving products that meet their standards.

How Can B2B Buyers Verify a Supplier’s Quality Control Practices?

B2B buyers should take proactive steps to verify a supplier’s quality control practices. This can include:

- Audits: Conducting on-site audits to evaluate the manufacturing processes and quality control measures in place.

- Quality Reports: Requesting detailed reports on quality control activities, including statistics on defect rates and corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection services to conduct independent assessments of the supplier’s products and processes.

Such due diligence can help mitigate risks associated with sourcing and ensure that the buyer receives high-quality membrane switch panels.

What Are the Common Testing Methods for Membrane Switch Panels?

Testing methods for membrane switch panels are essential to ensure that they function correctly and meet the required standards. Common testing methods include:

- Electrical Testing: Ensures that the switches operate correctly and that the conductive paths are intact.

- Environmental Testing: Simulates conditions such as humidity and temperature to test the durability and performance of the switches in various environments.

- Mechanical Testing: Assesses the physical robustness of the switches, including their resistance to wear and tear.

By utilizing these testing methods, manufacturers can provide confidence to B2B buyers that their products will perform reliably in the intended applications.

Conclusion: How Can International B2B Buyers Navigate Quality Assurance for Membrane Switch Panels?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, navigating the complexities of quality assurance in membrane switch panels is crucial. By understanding the manufacturing processes, recognizing the importance of international standards, and employing diligent verification methods, buyers can ensure that they partner with reliable suppliers who deliver high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘membrane switch panel’

This practical sourcing guide is designed to assist international B2B buyers in effectively procuring membrane switch panels. By following these steps, you can ensure that your sourcing process is thorough, efficient, and aligns with your business requirements.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital to ensure that the membrane switch panels meet your operational needs. Consider factors such as dimensions, materials, and functionality.

– Material Type: Decide between polyester or polycarbonate overlays based on durability and aesthetic requirements.

– Functionality: Determine whether you need tactile feedback, backlighting options, or additional features like embossing.

Step 2: Research Potential Suppliers

A comprehensive supplier search can reveal manufacturers who specialize in membrane switch panels that fit your criteria. Look for companies with a strong reputation in your region and industry.

– Industry Experience: Assess how long the supplier has been in business and their experience with similar products.

– Customer Reviews: Explore testimonials and case studies to gauge customer satisfaction and product reliability.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, ensure they hold relevant certifications that guarantee product quality and safety. Certifications can indicate compliance with international standards.

– ISO Certification: Look for suppliers with ISO 9001 certification, which reflects their commitment to quality management.

– Industry-Specific Standards: Depending on your sector (e.g., medical, military), verify if the supplier complies with specific industry regulations.

Step 4: Request Prototypes and Samples

Asking for prototypes or samples is essential to evaluate the quality of the membrane switch panels before bulk ordering. This allows you to assess the material quality and functionality firsthand.

– Testing Functionality: Ensure the prototype meets your performance expectations, including tactile response and durability.

– Design Accuracy: Check if the graphic overlays match your design specifications and branding needs.

Step 5: Negotiate Pricing and Terms

Once you’ve narrowed down your options, initiate negotiations to get the best pricing and terms. Understanding market rates can empower you during this process.

– Volume Discounts: Inquire about bulk order discounts and pricing tiers based on quantity.

– Payment Terms: Clarify payment options and terms to ensure they align with your cash flow requirements.

Step 6: Verify Production Capabilities

Assess the supplier’s production capabilities to ensure they can meet your order volume and deadlines. This step is crucial to avoid delays in your supply chain.

– Lead Times: Understand the typical lead times for production and delivery to align with your project timelines.

– Production Technology: Investigate the technologies used in manufacturing to gauge their capacity for customization and quality control.

Step 7: Establish Communication Protocols

Effective communication with your supplier is critical throughout the sourcing process. Establish clear protocols to ensure smooth collaboration.

– Point of Contact: Designate a specific contact person from the supplier for consistent communication.

– Regular Updates: Agree on a schedule for updates regarding production status, shipping timelines, and any potential issues.

By following this checklist, you can streamline your procurement process for membrane switch panels, ensuring that you choose the right supplier to meet your business needs effectively.

Comprehensive Cost and Pricing Analysis for membrane switch panel Sourcing

Understanding the cost structure and pricing dynamics of membrane switch panels is crucial for international B2B buyers aiming to optimize their procurement strategies. This section delves into the various cost components, pricing influencers, and practical tips for buyers from diverse regions including Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Membrane Switch Panel Manufacturing?

-

Materials: The primary materials used in membrane switches include polyester or polycarbonate for overlays, conductive inks (often silver or carbon-based), and adhesive materials. The choice of materials greatly affects the durability and functionality of the switches, thus impacting overall costs.

-

Labor: Labor costs can vary significantly depending on the manufacturing location. Regions with lower labor costs can offer competitive pricing, but this must be balanced against potential quality trade-offs. Skilled labor is essential for tasks such as circuit printing and assembly.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help reduce overhead, thereby lowering the overall cost of the membrane switches.

-

Tooling: The initial tooling costs for molds and specialized equipment can be substantial, especially for custom designs. However, these costs can be amortized over larger production runs, making volume purchases more cost-effective.

-

Quality Control (QC): Implementing stringent QC processes is vital to ensure product reliability and compliance with industry standards. While this adds to the cost, it can prevent costly recalls and replacements, ultimately benefiting the buyer.

-

Logistics: Shipping and handling costs can vary based on the supplier’s location and the buyer’s destination. Buyers should consider both the direct shipping costs and potential tariffs or duties when calculating total expenses.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the supplier’s pricing strategy can assist buyers in negotiations.

What Influences Pricing for Membrane Switch Panels?

-

Volume/MOQ: Minimum order quantities (MOQs) play a significant role in pricing. Larger orders often attract discounts, as they allow manufacturers to spread fixed costs over more units.

-

Specifications and Customization: Custom features such as backlighting, embossing, or specialized circuitry can increase costs. Buyers should evaluate the necessity of these features against their budget and application needs.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., IP ratings for water resistance) typically come at a premium. Buyers should assess whether these certifications are essential for their application.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their quality assurance and service guarantees.

-

Incoterms: Understanding shipping terms is crucial for total cost calculation. Different Incoterms can shift responsibilities and costs between the buyer and supplier, impacting the overall pricing strategy.

What Tips Can Help Buyers Negotiate Better Prices?

-

Leverage Volume Discounts: If your purchasing strategy allows, consolidate orders to meet or exceed MOQs. This can lead to significant savings.

-

Understand Total Cost of Ownership (TCO): Consider not only the initial purchase price but also the long-term costs associated with maintenance, replacements, and potential downtime due to product failures.

-

Negotiate Customization Options: Be clear about your requirements. Sometimes, opting for standard designs can significantly reduce costs compared to fully customized solutions.

-

Research Supplier Alternatives: Conduct thorough market research to identify multiple suppliers. This can provide leverage during negotiations and help you find the best value.

-

Factor in Regional Pricing Nuances: Be aware of regional economic conditions that may affect pricing. For instance, suppliers in emerging markets may offer competitive prices, but ensure that quality and reliability are not compromised.

Conclusion

In conclusion, a thorough understanding of the cost structure and pricing influencers associated with membrane switch panels enables international B2B buyers to make informed purchasing decisions. By strategically evaluating these factors and implementing effective negotiation tactics, buyers can achieve cost efficiency while ensuring high-quality products that meet their operational needs.

Alternatives Analysis: Comparing membrane switch panel With Other Solutions

In today’s competitive market, businesses are continuously seeking efficient solutions for user interfaces. Membrane switch panels are a popular choice due to their versatility and functionality, but there are several alternative technologies that can also serve similar purposes. This section explores viable alternatives, comparing them across various aspects to help B2B buyers make informed decisions.

| Comparison Aspect | Membrane Switch Panel | Capacitive Touch Panels | Mechanical Switches |

|---|---|---|---|

| Performance | Reliable, momentary action | High sensitivity, multi-touch | Robust, tactile feedback |

| Cost | Moderate initial investment | Higher upfront costs | Lower initial cost |

| Ease of Implementation | Straightforward installation | Requires calibration | Simple setup |

| Maintenance | Low maintenance needs | Minimal maintenance required | May require frequent servicing |

| Best Use Case | Medical devices, consumer electronics | Smart appliances, industrial equipment | Heavy machinery, automotive |

What Are the Advantages and Disadvantages of Capacitive Touch Panels?

Capacitive touch panels utilize the electrical properties of the human body to detect touch. These panels offer a sleek, modern interface and are capable of multi-touch functionality, making them ideal for applications requiring complex gestures. However, they can be more expensive than membrane switch panels and may necessitate calibration during installation. Their sensitivity can also lead to unintended activations in environments with high electromagnetic interference.

How Do Mechanical Switches Compare to Membrane Switch Panels?

Mechanical switches provide tactile feedback, which is crucial in applications where users need to feel a distinct click when activating a function. They are often more durable and suitable for heavy-duty use in industrial settings. However, mechanical switches typically require more space and can be more expensive in terms of long-term maintenance due to wear and tear. They may also not be as aesthetically pleasing as membrane switch panels, which offer a more integrated design option.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting a user interface technology, B2B buyers should consider their specific application needs, budget constraints, and environmental factors. Membrane switch panels excel in environments where low maintenance and aesthetic appeal are priorities, while capacitive touch panels are better suited for modern, interactive applications. Mechanical switches are ideal for rugged environments requiring reliable tactile feedback. By evaluating these alternatives against the specific demands of their projects, buyers can ensure they select the most effective solution for their operations.

Essential Technical Properties and Trade Terminology for membrane switch panel

What Are the Essential Technical Properties of Membrane Switch Panels?

When considering membrane switch panels for your product, understanding their technical properties is crucial. Here are some of the key specifications that B2B buyers should be aware of:

Material Grade and Type

Membrane switches are typically made from materials like polyester or polycarbonate. Polyester is often chosen for its durability and cost-effectiveness, while polycarbonate offers superior clarity and resistance to impact. Selecting the right material is vital as it affects the switch’s longevity, performance, and overall aesthetic appeal. For B2B buyers, choosing the right material can lead to reduced costs and enhanced product reliability.

Tolerance and Dimensional Accuracy

Tolerance refers to the allowable variation in the dimensions of the membrane switch. High precision is critical, especially in applications where switches must align perfectly with other components. A typical tolerance for membrane switches might range from ±0.1 mm to ±0.5 mm. Understanding tolerances helps buyers ensure compatibility with existing designs, thus minimizing the risk of costly rework or returns.

Circuitry Types

Membrane switches utilize different types of circuitry, including printed silver circuits and etched copper on flexible substrates like Kapton. Printed silver circuits provide flexibility and a lower profile, while etched copper offers durability and conductivity. For B2B buyers, knowing the differences in circuitry can guide decisions based on performance requirements, environmental conditions, and budget constraints.

Environmental Sealing and Protection Ratings

Sealing is critical for membrane switches used in challenging environments. Ratings such as IP67 indicate resistance to dust and water ingress. Buyers should consider the operating environment of their product; for instance, medical or industrial applications may require higher protection levels. Understanding these ratings ensures that the selected membrane switch will perform reliably in its intended application.

Backlighting Options

Backlighting can enhance usability and aesthetics. Options include LEDs, electroluminescent (EL) layers, and light guide films. Each technology has its benefits, such as energy efficiency or uniform illumination. For B2B buyers, evaluating backlighting options can add significant value to the end product, improving user experience and functionality.

What Are Common Trade Terms Related to Membrane Switch Panels?

Navigating the world of membrane switch panels involves familiarizing oneself with specific industry jargon. Here are some key terms that B2B buyers should understand:

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify the best suppliers for their membrane switches, ensuring quality and compatibility with their products.

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is particularly important for B2B buyers as it can affect inventory management and cash flow. Knowing the MOQ can help businesses plan their purchasing strategy effectively.

RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests a quote from suppliers for specific products or services. Including detailed specifications in an RFQ can streamline the procurement process, leading to better pricing and quicker responses from manufacturers.

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for B2B buyers to understand shipping costs, risk, and responsibilities during transportation.

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for B2B buyers to manage their production schedules and inventory levels effectively. Short lead times can provide a competitive advantage in fast-paced markets.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing membrane switch panels, ensuring they meet their specific needs and requirements.

Navigating Market Dynamics and Sourcing Trends in the membrane switch panel Sector

What Are the Current Market Dynamics and Key Trends Influencing Membrane Switch Panels?

The membrane switch panel sector is witnessing dynamic changes driven by technological advancements and evolving consumer preferences. One of the primary global drivers is the increasing demand for user-friendly interfaces across various industries, including automotive, medical, and consumer electronics. As businesses strive for enhanced user experience, membrane switches are being favored for their lightweight design, aesthetic flexibility, and adaptability to different environments. The growing trend toward automation and smart devices is also propelling the need for sophisticated membrane switch panels, which offer features such as backlighting and tactile feedback.

Moreover, international B2B buyers are increasingly gravitating towards customization options. Manufacturers are now providing extensive design capabilities, enabling companies to tailor products to specific market needs. This customization trend is particularly significant in regions like Africa and South America, where local preferences vary widely. Additionally, the rise of e-commerce platforms has streamlined the procurement process, allowing buyers to access competitive pricing and quick delivery options, which is crucial for fast-paced market conditions.

Emerging technologies such as IoT and smart manufacturing are further influencing sourcing strategies. Companies are incorporating smart technologies into membrane switches, enhancing functionality and connectivity. Buyers are advised to stay abreast of these technological trends to ensure they are sourcing the most innovative products that align with their operational requirements.

How Are Sustainability and Ethical Sourcing Impacting Membrane Switch Panel Procurement?

Sustainability has become a cornerstone of procurement strategies in the membrane switch panel sector. Environmental impact is increasingly scrutinized, leading businesses to prioritize suppliers who demonstrate commitment to sustainable practices. B2B buyers are now looking for manufacturers that utilize eco-friendly materials and processes, such as recyclable polycarbonate overlays and low-impact manufacturing techniques.

Moreover, ethical sourcing is gaining traction, with buyers demanding transparency in supply chains. This trend is particularly prominent in regions such as Europe and the Middle East, where consumers are increasingly conscious of the environmental and social implications of their purchases. Certifications such as ISO 14001 for environmental management and RoHS compliance for hazardous materials are becoming essential criteria for supplier selection.

Incorporating ‘green’ certifications and materials not only enhances a company’s brand reputation but also opens up access to markets that prioritize sustainability. By aligning procurement strategies with these ethical standards, international buyers can not only meet regulatory requirements but also appeal to a growing demographic of environmentally conscious consumers.

What Is the Brief Evolution and Historical Context of Membrane Switch Panels?

The membrane switch panel has evolved significantly since its inception in the 1960s. Initially used in simple electronic devices, membrane switches have transformed into sophisticated user interfaces that cater to a wide array of applications. The integration of graphic overlays and tactile feedback mechanisms has enhanced their usability, making them suitable for complex machinery and consumer electronics.

As technology progressed, the materials used in membrane switches improved, leading to greater durability and functionality. The advent of digital printing and advanced circuit design techniques allowed for more intricate designs and greater customization options. Today, membrane switches are not only functional but also serve as integral design elements in product interfaces, reflecting the brand identity of the manufacturers. This evolution underscores the importance of innovation in the sector, as companies continue to seek competitive advantages through enhanced product offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of membrane switch panel

-

How do I choose the right membrane switch panel for my application?

Selecting the right membrane switch panel begins with understanding your application’s specific requirements. Consider factors such as the environment (temperature, moisture, dust), the required durability, and whether tactile feedback is necessary. Evaluate the materials used, such as polyester or polycarbonate, and their resistance to chemicals or UV exposure. Additionally, think about customization options like backlighting and graphic overlays to enhance user interaction. Collaborate closely with manufacturers to ensure your design meets both functional and aesthetic needs. -

What are the typical lead times for membrane switch panel orders?

Lead times for membrane switch panels can vary based on complexity, customization, and order volume. Generally, standard orders may take anywhere from 2 to 4 weeks for production, while customized designs could require longer—up to 6 weeks or more. It’s crucial to discuss timelines upfront with your supplier to align expectations, especially if you have specific deadlines. Inquire about expedited options if your project requires a quicker turnaround. -

What is the minimum order quantity (MOQ) for membrane switch panels?

Minimum order quantities (MOQ) for membrane switch panels can vary significantly between manufacturers. Some suppliers may have an MOQ as low as 10 units for standard designs, while custom configurations might require a minimum of 100 or more. Understanding the MOQ is essential for budgeting and inventory planning. Always clarify these details with your supplier before placing an order, as they can impact your overall costs and production timelines. -

What payment terms should I expect when ordering membrane switch panels?

Payment terms for membrane switch panels typically vary by supplier and may include options such as full payment upfront, a deposit with the balance upon delivery, or net 30/60 terms. International buyers should also consider potential additional costs, such as customs duties and taxes. It’s essential to establish clear payment agreements and confirm acceptable methods (e.g., wire transfer, credit card) before proceeding with an order to avoid any financial misunderstandings. -

How can I ensure quality assurance for my membrane switch panels?

To ensure quality assurance, work with manufacturers who have established quality control processes in place. Request information about their testing protocols, including material inspections, functionality tests, and environmental resistance evaluations. Consider asking for samples before placing a larger order to assess their product quality firsthand. Additionally, inquire about any certifications the manufacturer holds, such as ISO standards, which can further guarantee product reliability. -

What factors should I consider when vetting a supplier for membrane switch panels?

When vetting a supplier, assess their experience in the industry, production capabilities, and customer reviews. Look for suppliers who specialize in membrane switches and have a proven track record of delivering quality products on time. Evaluate their communication responsiveness and willingness to collaborate on design and customization. It’s also beneficial to check their compliance with international standards, especially if you’re importing to regions with strict regulations. -

What customization options are available for membrane switch panels?

Customization options for membrane switch panels can be extensive. You can choose different materials, colors, and finishes for overlays, as well as features like tactile feedback, backlighting, and embossing. Manufacturers may also offer various circuit layouts and connector types to suit your specific device requirements. Discuss your needs with potential suppliers to explore the full range of available options and how they can enhance your product’s usability and aesthetics. -

How do logistics and shipping work for international orders of membrane switch panels?

Logistics for international orders typically involve several steps: production, quality checks, packaging, and shipping. It’s essential to discuss shipping options with your supplier, including carriers and estimated delivery times. Understand the implications of customs regulations in your country, including potential duties and taxes. Many suppliers offer door-to-door delivery services, which can simplify the process. Ensure you have all necessary documentation ready to prevent delays at customs.

Top 6 Membrane Switch Panel Manufacturers & Suppliers List

1. JRPanel – Membrane Switch Panels

Domain: jrpanel.com

Registered: 2018 (7 years)

Introduction: JRPanel specializes in manufacturing Membrane Switch Panels, Graphic Overlays, Acrylic Panels, and Metal Dome Switch Arrays. Key product details include: 1. **Graphic Overlay**: Size options up to 80x80mm, made from PC with a glossy finish, thickness of 0.175mm, using 3M55236 adhesive. Pricing: 10pcs for $111, 100pcs for $235, 500pcs for $326, 1000pcs for $439. 2. **Membrane Switch**: Size options…

2. CSI Keyboards – Custom Membrane Switches and Keypads

Domain: csikeyboards.com

Registered: 1997 (28 years)

Introduction: Custom membrane switches and keypads manufactured by CSI Keyboards. Features include tactile feel, backlighting options (LED, Light Guide Film, Fiber Optic, EL), sealing and shielding (EMI/ESD/RFI), embossing options (pillow, perimeter, Braille), integrated displays and touch screens, epoxy and UV coated keys, chemical and UV resistance, and rigid support backers. Circuitry options include etched …

3. Membrane USA – Membrane Switches & Overlays

Domain: membraneusa.com

Registered: 2009 (16 years)

Introduction: Membrane Switch & Panel manufactures membrane switches, graphic overlays, and nameplates. They support OEM customers through product development from prototype to production, offering state-of-the-art tools such as 3-D printing, 3-D scanning, digital print proof, laser cutting, and a variety of sample configurations. Manufacturing capabilities include high-volume semi-automatic screen printing, di…

4. General Label – Membrane Switches

Domain: general-label.com

Registered: 1999 (26 years)

Introduction: Membrane switches are thin electronic circuits that allow users to interface with devices using pressure. They are used in various industries including commercial foodservice, HVAC, medical electronics, portable electronics, and more. Types of membrane switches include tactile, non-tactile, backlit, capacitive touch, and those with metal dome arrays. Features include the ability to print graphics …

5. Rice Lake – 720i Panel Mount Membrane Switch Panel

Domain: scalesplus.com

Introduction: {“Product Name”: “Rice Lake 720i Panel Mount Membrane Switch Panel for Remote Display”, “Manufacturer”: “Rice Lake Weighing Systems”, “Part Number”: “101256”, “MSRP”: “$145.00”, “Current Price”: “$138.18”, “Savings”: “$6.82”, “UPC”: “”, “Availability”: “Typically ships in 1-2 days”, “Compatible Indicators”: “Rice Lake 720i Panel Mount”, “Compliance”: “ROHS”}

6. Dyna-Graphics – Custom Membrane Switches

Domain: dyna-graphics.com

Registered: 1996 (29 years)

Introduction: Membrane switches are custom-designed components used in various products, including household appliances and medical equipment. Dyna-Graphics Corporation offers a range of customization options, including specialty graphics, custom panels, LED lights, backlighting, waterproofing, and LCD screens. Key features include:

1. **Backlighting Options**: Light Guide Film, LEDs, EL lighting, and Fiber Op…

Strategic Sourcing Conclusion and Outlook for membrane switch panel

In the dynamic landscape of membrane switch panel sourcing, strategic partnerships and informed decision-making are essential for international B2B buyers. Emphasizing quality, customization, and technological advancements can significantly enhance product performance and user experience. With the increasing demand for membrane switches across diverse sectors—from medical to consumer electronics—leveraging suppliers that offer rapid prototyping, robust design support, and efficient logistics can yield a competitive edge.

Moreover, understanding regional manufacturing capabilities and supply chain dynamics is crucial. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers who demonstrate flexibility in meeting specific regional needs while ensuring compliance with international standards. Engaging with manufacturers that provide transparent pricing, quality guarantees, and after-sale support can further streamline the sourcing process.

As we look to the future, the membrane switch panel market is poised for growth, driven by innovations in design and functionality. Now is the time for international buyers to act—evaluate potential suppliers, explore customization options, and harness the benefits of strategic sourcing to elevate their product offerings. By making informed choices today, you can position your business for success in this evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.