The Definitive Guide to Types Of Spring Clips: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for types of spring clips

Navigating the global market for types of spring clips can be daunting, especially for B2B buyers seeking reliable, high-quality components for diverse applications. As industries across Africa, South America, the Middle East, and Europe continue to innovate, the demand for versatile spring clips—used in everything from automotive assemblies to medical devices—grows exponentially. However, sourcing the right type of spring clip that meets specific performance requirements while ensuring cost-effectiveness presents a significant challenge.

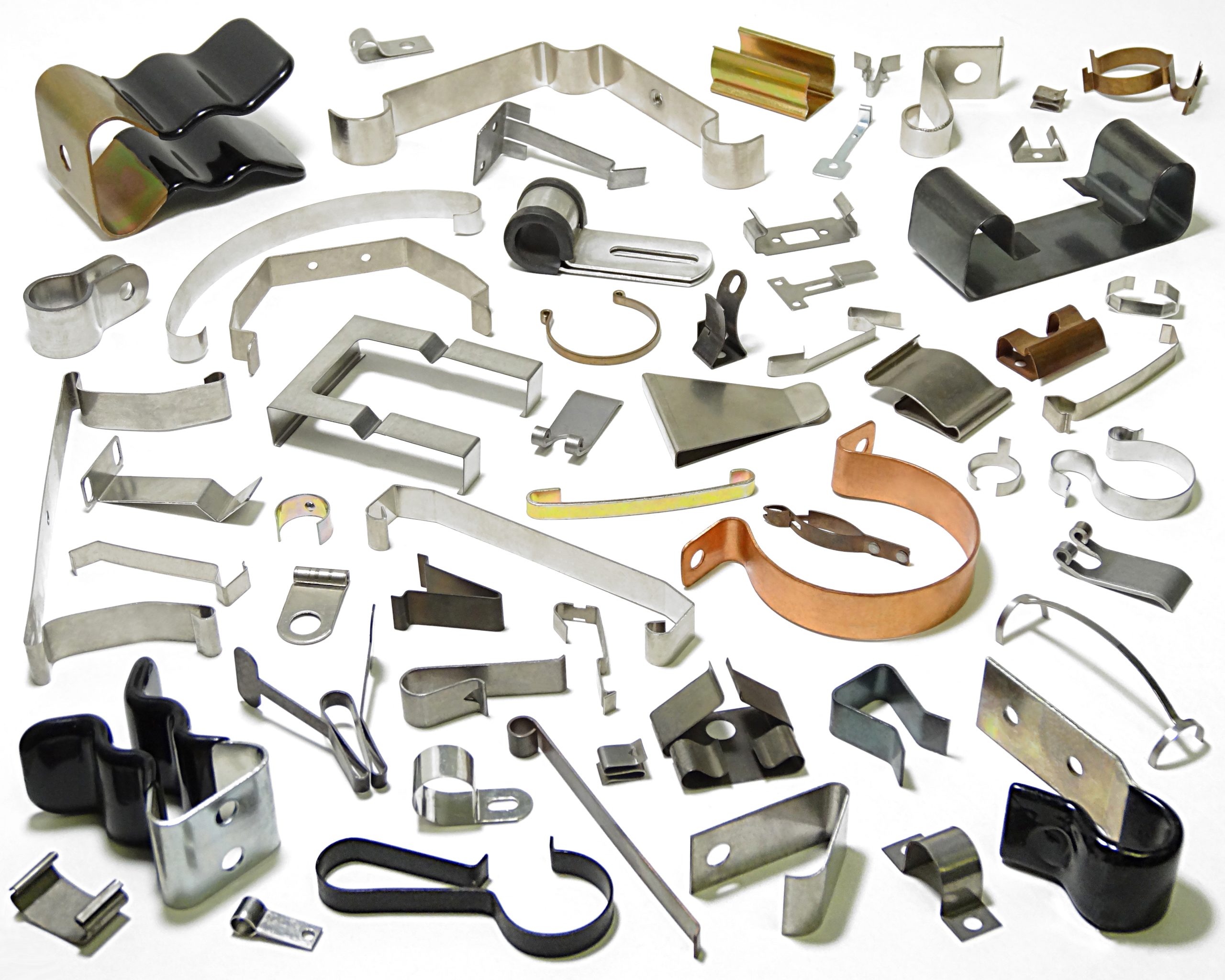

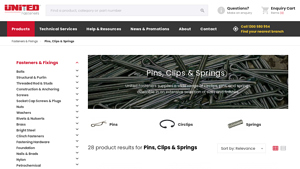

This comprehensive guide delves into the various types of spring clips available in the market, including sheet metal clips, wire clips, and heavy-duty options. It outlines their applications, from securing electronic components to fastening automotive parts, and highlights the importance of material selection for optimal performance. Additionally, the guide provides critical insights on supplier vetting processes, helping buyers identify reputable manufacturers who can deliver quality products.

By equipping international B2B buyers with actionable knowledge on types, applications, and sourcing strategies, this guide empowers them to make informed purchasing decisions. Whether you are a buyer in Nigeria looking for durable spring clips for construction or a procurement manager in Germany aiming to streamline your supply chain, the insights provided will help navigate the complexities of the global spring clip market.

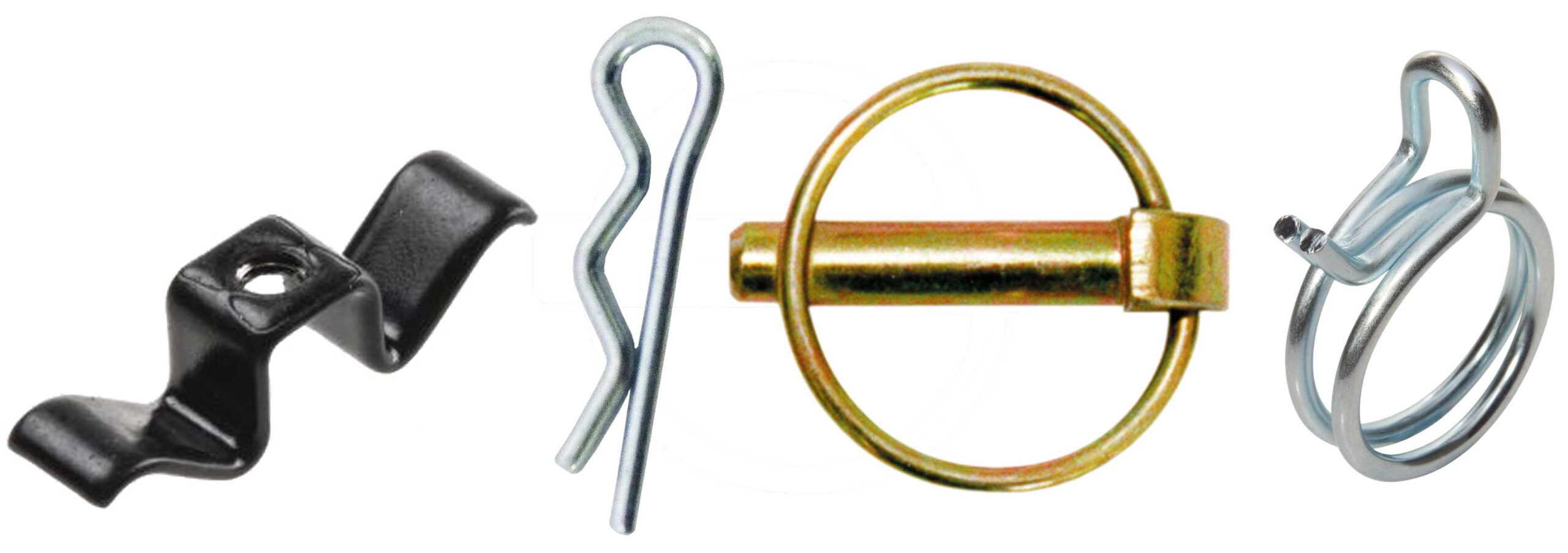

Understanding types of spring clips Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Sheet Metal Clips | Stamped or laser cut from sheet metal; durable | Electronics, automotive, aerospace, medical devices | Pros: High strength, customizable; Cons: May require specific tooling for production. |

| Flat Spring Clips | U-shaped design; simple and lightweight | Paper holding, light component fastening | Pros: Cost-effective, easy to use; Cons: Limited load-bearing capacity. |

| R-Clips | Curved prong design; self-retaining | Automotive, machinery, construction | Pros: Secure fit, resistant to vibration; Cons: Can be challenging to remove. |

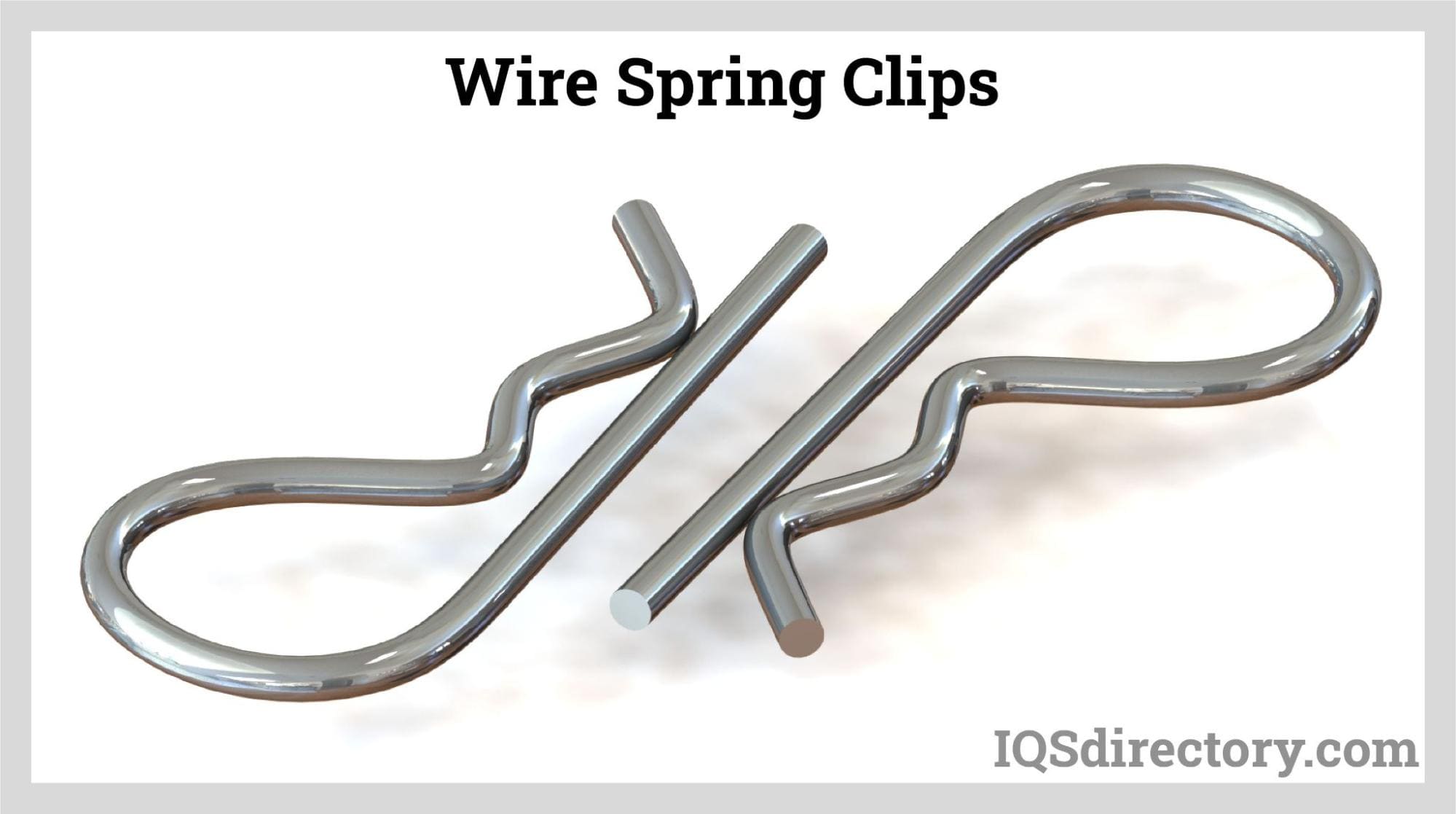

| Wire Spring Clips | Flexible wire construction; versatile | Greenhouses, cable management, lightweight fastening | Pros: Lightweight, adaptable; Cons: May not be suitable for heavy-duty applications. |

| Heavy-Duty Terry Clips | Robust design for demanding applications | Industrial equipment, construction, heavy machinery | Pros: High load capacity, durable; Cons: Bulkier, may require more storage space. |

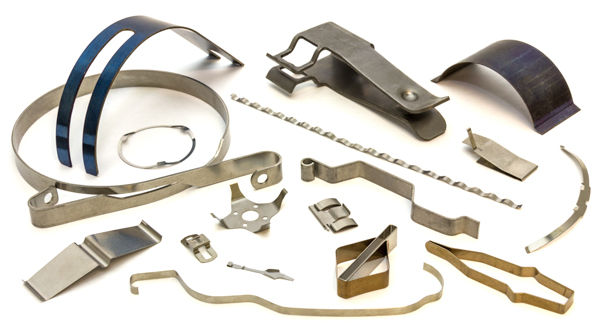

What Are Sheet Metal Clips and Their Key Characteristics?

Sheet metal clips are crafted through processes like stamping or laser cutting, making them highly durable and customizable. They are extensively used in sectors such as electronics, automotive, and aerospace due to their strength and ability to withstand varying environmental conditions. When purchasing, consider the material thickness and type, as these factors influence the clip’s performance and longevity. Customization options are also crucial for ensuring compatibility with specific applications.

How Do Flat Spring Clips Stand Out in the Market?

Flat spring clips, characterized by their simple U-shape, are primarily used for holding lightweight materials like paper or thin components. Their cost-effectiveness and ease of use make them attractive for businesses looking for efficient fastening solutions. However, they are limited in terms of load-bearing capacity, making them less suitable for heavy-duty applications. Buyers should assess the required strength and application type before opting for flat spring clips.

Illustrative image related to types of spring clips

What Are the Advantages of R-Clips for Industrial Use?

R-clips feature a unique design that allows them to securely fit onto shafts or pins, making them ideal for automotive and machinery applications. Their self-retaining nature helps prevent loosening due to vibrations, a critical factor in demanding environments. While they provide a secure fastening solution, the challenge lies in their removal, which may require specific tools. Businesses should weigh the benefits of secure fastening against the potential complexities of installation and removal.

How Versatile Are Wire Spring Clips for Various Applications?

Wire spring clips offer flexibility and versatility, making them suitable for a range of applications, from managing cables to securing greenhouse glass panes. Their lightweight design allows for easy installation and adaptability in various settings. However, they may not perform well in heavy-duty scenarios, so buyers should evaluate the intended use and load requirements before choosing wire spring clips.

Why Choose Heavy-Duty Terry Clips for Industrial Applications?

Heavy-duty Terry clips are designed to handle significant loads, making them ideal for industrial equipment and construction applications. Their robust construction ensures durability and reliability in demanding environments. However, their bulkier design may require more storage space and could be less convenient for lighter applications. Buyers should consider the balance between load capacity and space constraints when selecting heavy-duty Terry clips for their projects.

Key Industrial Applications of types of spring clips

| Industry/Sector | Specific Application of types of spring clips | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Securing components in car engines and body assemblies | Enhances safety and reliability by preventing component failure | Material durability and resistance to vibrations |

| Electronics | Mounting circuit boards and securing heat sinks | Improves thermal management and device longevity | Precision in dimensions and material compatibility |

| Aerospace | Fastening parts in aircraft assemblies | Ensures lightweight solutions that meet stringent safety standards | Compliance with aerospace regulations and certifications |

| Construction | Holding pipes, brackets, and fixtures in place | Streamlines assembly processes and reduces installation time | Load-bearing capacity and weather resistance |

| Medical Devices | Securing components in diagnostic and therapeutic equipment | Enhances device reliability and patient safety | Biocompatibility and sterilization capabilities |

How are Spring Clips Used in the Automotive Industry?

In the automotive sector, spring clips play a critical role in securing various components within engines and body assemblies. Their ability to provide consistent clamping force helps prevent vibrations and potential failures, ensuring vehicle safety. Buyers should consider sourcing clips made from high-strength materials that can withstand extreme temperatures and vibrations common in automotive applications. Additionally, compliance with automotive industry standards is essential for international buyers to ensure quality and reliability.

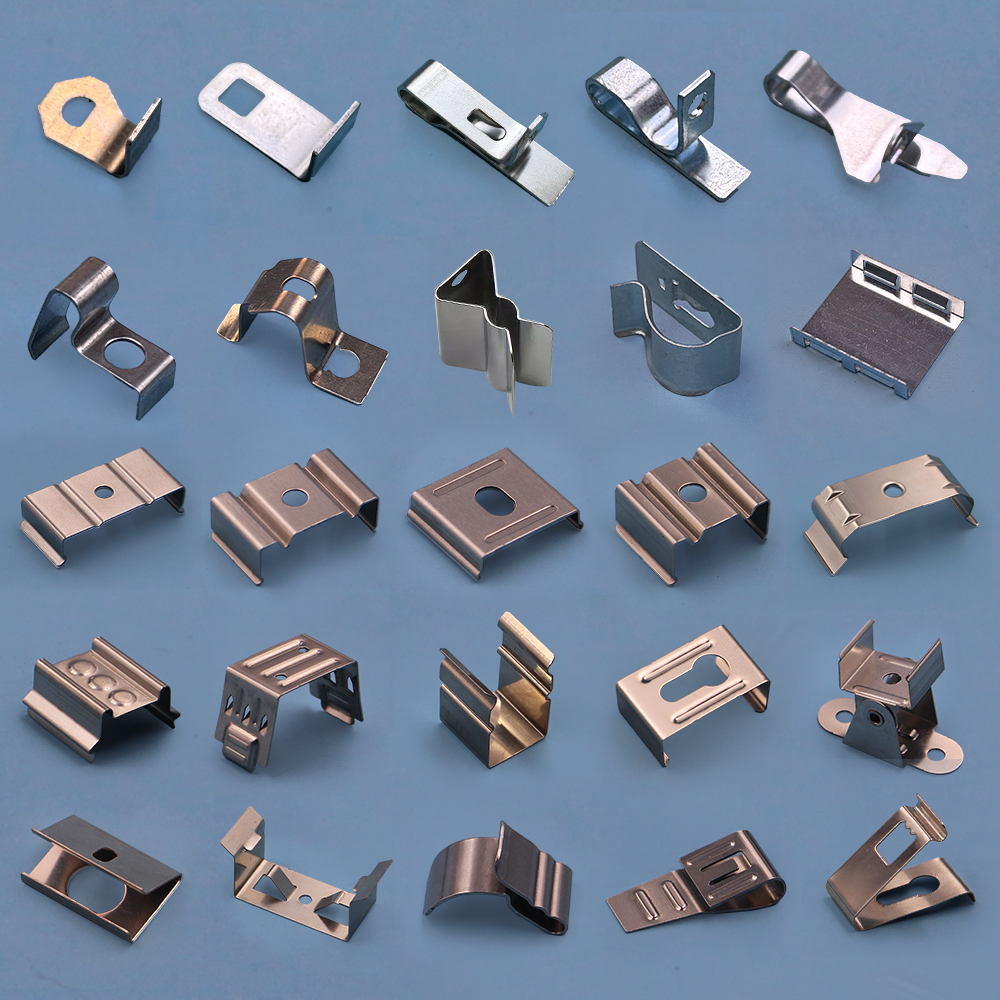

Illustrative image related to types of spring clips

What is the Role of Spring Clips in Electronics?

In electronics, spring clips are utilized for mounting circuit boards and securing heat sinks to manage thermal output effectively. This application is vital for maintaining optimal performance and longevity of electronic devices. Buyers in this sector must prioritize precision in dimensions and material compatibility to ensure proper fit and function. Sourcing clips that meet industry standards for electrical conductivity and thermal resistance is crucial, especially for international buyers from regions with varying manufacturing regulations.

Why are Spring Clips Important in Aerospace Applications?

Aerospace applications demand lightweight and durable fastening solutions, making spring clips indispensable for securing parts in aircraft assemblies. These clips help maintain structural integrity while adhering to strict safety standards. International buyers should focus on sourcing materials that are not only lightweight but also resistant to corrosion and fatigue. Compliance with aerospace certifications and regulations is vital to ensure the reliability of components in critical flight systems.

How are Spring Clips Used in Construction Projects?

In construction, spring clips are employed to hold pipes, brackets, and fixtures securely in place, facilitating streamlined assembly processes. Their ease of use can significantly reduce installation time and labor costs. Buyers should consider the load-bearing capacity and weather resistance of the clips to ensure they can withstand various environmental conditions. International buyers should also be aware of local building codes and standards to ensure compliance and safety in their projects.

What is the Application of Spring Clips in Medical Devices?

In the medical device industry, spring clips secure components in diagnostic and therapeutic equipment, enhancing device reliability and patient safety. The choice of materials is particularly critical in this sector, as clips must often be biocompatible and capable of withstanding sterilization processes. Buyers should prioritize sourcing from manufacturers that meet medical device regulations and certifications, ensuring that the clips can safely function in sensitive environments.

3 Common User Pain Points for ‘types of spring clips’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Spring Clip for Specific Applications

The Problem: B2B buyers often struggle with selecting the appropriate type of spring clip for their specific application. Given the wide variety of spring clips available—each designed for different functions and materials—this can lead to confusion. For example, a buyer in the automotive industry might need clips that can withstand high temperatures and vibrations, while another in the electronics sector may require clips that provide strong electrical insulation. Misjudging the specifications can result in product failure, operational inefficiencies, or costly recalls.

The Solution: To mitigate this challenge, B2B buyers should engage in a thorough material and design assessment before making a purchase. Start by clearly defining the operational parameters such as temperature ranges, load capacities, and environmental conditions. Collaborating with suppliers who offer custom spring clips can provide tailored solutions that meet specific requirements. Additionally, consider requesting samples for testing in real-world conditions to ensure compatibility before committing to larger orders. This proactive approach minimizes risks and optimizes performance.

Scenario 2: Inconsistent Quality and Performance of Spring Clips

The Problem: Another significant pain point for B2B buyers is the inconsistency in quality and performance of spring clips sourced from different manufacturers. In industries such as aerospace or medical, where precision and reliability are critical, using subpar clips can lead to catastrophic failures. Buyers may find that clips from various suppliers do not perform uniformly, leading to issues like fatigue failure or inadequate retention, which can compromise the entire assembly.

The Solution: To ensure consistent quality, buyers should prioritize sourcing from reputable manufacturers with established quality control measures. Look for suppliers who are ISO certified and have a track record of serving similar industries. Establishing long-term relationships with a select number of trusted suppliers can lead to better understanding and alignment on quality standards. Furthermore, conducting periodic quality audits and requesting detailed material certifications can help maintain high standards in the production of spring clips.

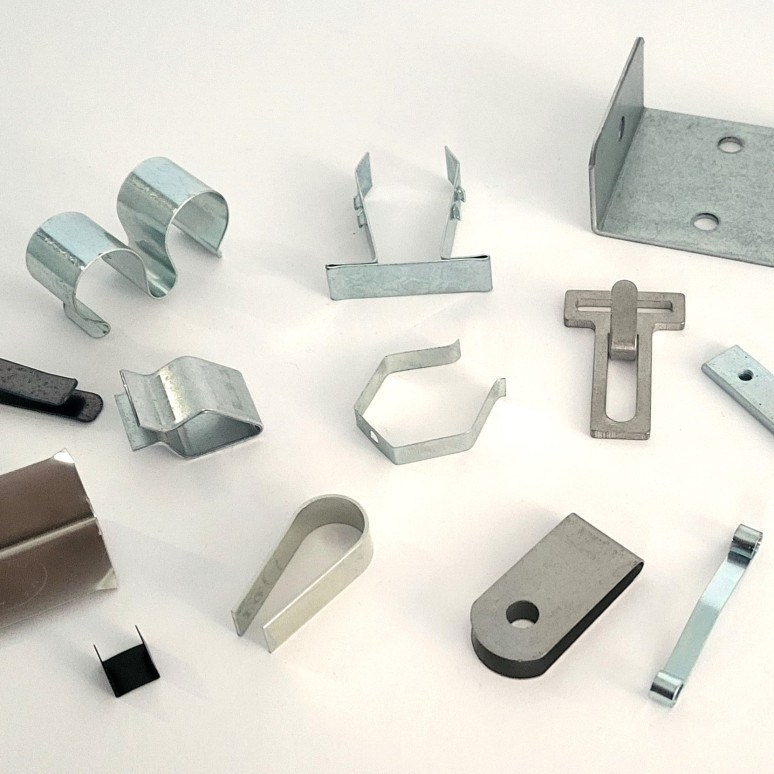

Illustrative image related to types of spring clips

Scenario 3: Challenges in Cost Management and Budgeting for Spring Clips

The Problem: Cost management is a common concern, especially for buyers operating in competitive markets. The price of spring clips can vary widely based on material, design complexity, and supplier pricing strategies. Buyers often face the dilemma of balancing quality with cost, which can lead to purchasing lower-quality clips that ultimately incur higher replacement costs or production delays.

The Solution: To navigate this financial challenge, buyers should implement a strategic sourcing approach that includes bulk purchasing and long-term contracts with suppliers. This can often lead to reduced unit costs and better financial predictability. Additionally, conducting a total cost of ownership analysis can provide insights into the long-term implications of clip choices, factoring in durability and replacement rates. Engaging in negotiations with suppliers for better pricing based on projected volumes can also yield cost savings. Finally, exploring alternative materials or designs that meet performance needs without compromising budget can provide an effective balance between quality and cost.

Strategic Material Selection Guide for types of spring clips

What Are the Key Properties of Common Materials for Spring Clips?

When selecting materials for spring clips, several factors must be considered, including mechanical properties, environmental resistance, and manufacturing capabilities. Below, we analyze four common materials used in spring clip production, focusing on their performance characteristics and suitability for various applications.

How Does High Carbon Steel Perform in Spring Clip Applications?

High carbon steel, such as grades 1074, 1075, and 1095, is frequently used in spring clips due to its excellent strength and hardness. These steels can withstand high stress and are capable of maintaining their shape under pressure, making them ideal for applications requiring significant force. However, they are susceptible to corrosion if not properly treated or coated.

Pros: High carbon steel offers superior durability and fatigue resistance, making it suitable for high-load applications. It is also cost-effective compared to other materials.

Cons: The primary limitation is its susceptibility to rust and corrosion, which can be a critical factor in humid or corrosive environments. Additionally, manufacturing processes may require heat treatment to achieve the desired properties, adding complexity.

Impact on Application: High carbon steel clips are well-suited for mechanical applications, such as automotive and industrial machinery, where strength is paramount. However, they may not be suitable for environments exposed to moisture unless properly coated.

What Are the Advantages of Stainless Steel for Spring Clips?

Stainless steel, particularly the 300 series and 17-4PH and 17-7PH grades, is another popular choice for spring clips due to its excellent corrosion resistance and mechanical properties. Stainless steel clips can withstand harsh environments, including exposure to chemicals and moisture, making them ideal for applications in the medical and food processing industries.

Pros: The key advantage of stainless steel is its resistance to rust and corrosion, which prolongs the lifespan of the clips. It also maintains strength at elevated temperatures, making it suitable for high-temperature applications.

Cons: The main drawback is the higher cost compared to carbon steel. Additionally, the manufacturing processes for stainless steel can be more complex, requiring specialized equipment.

Impact on Application: Stainless steel clips are often used in applications where hygiene is critical, such as in medical devices and food processing equipment. Compliance with international standards for food safety and medical use is essential, particularly for buyers in Europe and the Middle East.

Why Choose Beryllium Copper for Specialized Spring Clips?

Beryllium copper is known for its excellent electrical conductivity and high strength, making it a preferred material for spring clips used in electrical applications. It is particularly effective in environments where electrical properties are critical, such as in connectors and circuit boards.

Pros: Beryllium copper offers outstanding fatigue resistance and can operate effectively in high-stress environments. Its electrical conductivity is a significant advantage for electronic applications.

Illustrative image related to types of spring clips

Cons: The primary disadvantage is its cost, which is typically higher than that of steel. Additionally, beryllium is a toxic material, requiring careful handling and compliance with safety regulations.

Impact on Application: Beryllium copper clips are ideal for applications in the electronics sector, particularly in regions where high-performance electrical components are required. Buyers must ensure compliance with safety standards regarding beryllium handling.

How Do Exotic Alloys Enhance Spring Clip Performance?

Exotic alloys, such as Inconel and Elgiloy, are used in specialized applications where extreme conditions are present, such as high temperatures and corrosive environments. These materials provide exceptional strength and resistance to oxidation.

Pros: The significant advantage of using exotic alloys is their ability to perform in extreme conditions, ensuring reliability and longevity in critical applications.

Cons: The cost of these materials is considerably higher, and the manufacturing processes can be complex, requiring specialized techniques.

Impact on Application: Exotic alloys are often used in aerospace and defense applications, where performance and reliability are non-negotiable. Buyers from regions with stringent industry standards, such as Europe, must ensure compliance with relevant regulations.

Summary of Material Selection for Spring Clips

| Material | Typical Use Case for types of spring clips | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High Carbon Steel | Automotive and industrial machinery | Superior strength and fatigue resistance | Susceptible to corrosion | Low |

| Stainless Steel | Medical devices and food processing | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Beryllium Copper | Electrical connectors and circuit boards | Outstanding electrical conductivity | Toxicity and higher cost | High |

| Exotic Alloys | Aerospace and defense applications | Exceptional performance in extreme conditions | High cost and complex manufacturing | High |

This guide provides a comprehensive overview of material selection for spring clips, tailored to the needs of international B2B buyers across diverse regions. Understanding these materials’ properties and applications can help buyers make informed decisions that align with their specific requirements and industry standards.

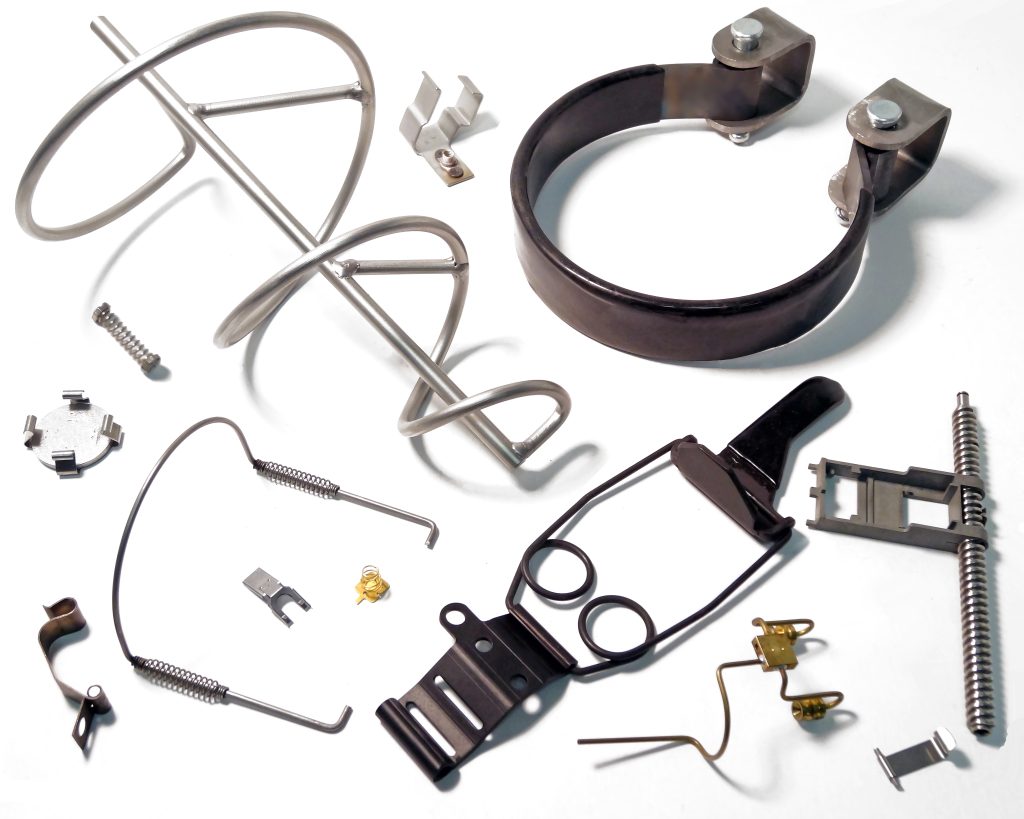

In-depth Look: Manufacturing Processes and Quality Assurance for types of spring clips

What Are the Main Stages of Manufacturing Spring Clips?

The manufacturing of spring clips involves a series of well-defined stages, each critical to ensuring the final product meets quality standards and performance specifications. Here’s an overview of the typical processes involved:

Illustrative image related to types of spring clips

Material Preparation: How Is Raw Material Selected and Processed?

The first step in the manufacturing process is the selection and preparation of raw materials. Common materials for spring clips include high carbon steels, stainless steels, and specialized alloys such as Inconel and Elgiloy. The choice of material is crucial, as it determines the clip’s strength, flexibility, and fatigue life.

Once the appropriate material is selected, it undergoes processes such as cutting and shearing to create blanks of the desired size and shape. The thickness of the material is also adjusted to meet specific application requirements. Quality assurance begins at this stage, where the material is inspected for any defects or inconsistencies that could affect performance.

How Are Spring Clips Formed and Shaped?

The next stage involves the forming and shaping of the clips. Techniques such as stamping, laser cutting, and photo-chemical etching are commonly used. Stamping, for example, allows for high-volume production with precise tolerances. After the initial shaping, the clips may undergo heat treatment to enhance their mechanical properties, ensuring they can withstand the required loads without failure.

Advanced forming techniques, including bending and coiling, can also be employed to create more complex designs. The versatility of these processes enables manufacturers to produce a wide range of spring clips tailored to specific applications, from automotive to aerospace.

Illustrative image related to types of spring clips

What Assembly Techniques Are Used in Spring Clip Production?

In some cases, spring clips may require assembly, especially if they are part of a larger assembly or system. This can include the integration of additional components such as fasteners or adhesives. Automated assembly processes can enhance efficiency and consistency, while manual assembly may be used for more intricate products. Regardless of the method, careful attention is paid to ensure that all components fit together correctly and function as intended.

How Is the Finishing Process Conducted for Quality Assurance?

The final manufacturing stage involves finishing processes that enhance the appearance and durability of the spring clips. This can include surface treatments such as plating, anodizing, or powder coating to improve corrosion resistance and aesthetic appeal. The finishing process is also an opportunity for final quality checks, ensuring that the clips meet both visual and functional standards.

What Quality Control Measures Are Essential for Spring Clip Manufacturing?

Quality control (QC) is a critical aspect of the manufacturing process, ensuring that each spring clip produced meets the required specifications and standards. Here are the key QC measures employed in the industry:

Illustrative image related to types of spring clips

Which International Standards Govern Spring Clip Quality?

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO standards helps ensure consistent product quality and operational efficiency. Additionally, industry-specific standards such as CE marking for European markets or API specifications for oil and gas applications may apply, depending on the intended use of the spring clips.

What Are the Key Quality Checkpoints in the Manufacturing Process?

Quality control in spring clip manufacturing typically includes several checkpoints:

-

Incoming Quality Control (IQC): This is the initial inspection of raw materials before they enter the production process. It ensures that all materials meet specified standards and are free from defects.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the production process. This includes checking tolerances, dimensions, and material properties to identify any deviations from specifications.

-

Final Quality Control (FQC): After production, the finished spring clips undergo a comprehensive inspection to verify that they meet all design and performance criteria. This may involve mechanical testing, dimensional checks, and visual inspections.

What Common Testing Methods Are Used in Spring Clip Quality Assurance?

Common testing methods include tensile testing, fatigue testing, and dimensional verification. Tensile tests assess the strength of the material, while fatigue tests evaluate how the clips perform under repeated stress. Dimensional verification ensures that the clips conform to the specified measurements and tolerances.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are several methods to ensure that suppliers meet high-quality standards:

What Steps Can Be Taken for Supplier Audits and Inspections?

Conducting supplier audits is an effective way to evaluate a manufacturer’s quality management system. This can involve on-site inspections to review processes, equipment, and documentation. Buyers should look for certifications such as ISO 9001 and any relevant industry-specific standards during these audits.

How Can Buyers Request Quality Reports and Testing Documentation?

Buyers should request comprehensive quality reports and testing documentation from their suppliers. This documentation should detail the results of IQC, IPQC, and FQC processes, as well as any third-party testing conducted. Transparency in these reports is a good indicator of a supplier’s commitment to quality.

What Role Do Third-Party Inspections Play in Ensuring Quality?

Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control processes. These agencies can perform random inspections and testing, ensuring that the products meet the specified standards before shipment. This is especially important for international buyers who may not have the resources to conduct on-site inspections.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must be aware of the nuances in quality control practices that may vary by region. For instance, different countries may have varying regulatory requirements and industry standards. Buyers should familiarize themselves with the specific standards applicable in their market and ensure that their suppliers comply accordingly.

Understanding the local context, including language and cultural differences, can also play a role in effective communication regarding quality expectations. Establishing clear quality agreements and expectations upfront can help mitigate potential issues down the line.

Illustrative image related to types of spring clips

In summary, a thorough understanding of the manufacturing processes and quality assurance practices for spring clips is essential for B2B buyers. By focusing on material selection, manufacturing techniques, and stringent quality control measures, buyers can ensure they source high-quality spring clips that meet their specific needs and applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of spring clips’

To assist B2B buyers in effectively procuring spring clips, this practical sourcing guide outlines essential steps to ensure a successful purchase. Spring clips are versatile components used across various industries, making it crucial to choose the right type and supplier. Follow this checklist to navigate the sourcing process efficiently.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is fundamental to sourcing the appropriate spring clips. Consider factors such as dimensions, material types, load requirements, and environmental conditions. This clarity will help in communicating your needs to suppliers and ensuring that the clips will perform as expected in your application.

- Material Requirements: Identify if you need standard materials like stainless steel or more specialized options like Inconel or beryllium copper.

- Dimensions and Load: Specify the size and weight capacity required for your specific use case.

Step 2: Research Various Types of Spring Clips

Understanding the different types of spring clips available is crucial for making an informed decision. From U-shaped clips to heavy-duty Terry clips, each type serves a unique purpose. This knowledge will help you choose the most suitable clip for your application.

Illustrative image related to types of spring clips

- Common Variants: Familiarize yourself with types like wire spring clips, circular spring clips, and command spring clips.

- Application Suitability: Consider the specific tasks each type is designed for, such as securing cables or fastening components.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers before making a commitment. A reliable supplier can significantly impact the quality and performance of your spring clips. Request detailed company profiles, case studies, and references from clients within your industry.

- Supplier Certifications: Check for relevant industry certifications like ISO 9001 to ensure quality management practices.

- Experience and Expertise: Look for suppliers with a proven track record in your specific market segment.

Step 4: Request Samples for Testing

Before finalizing your order, it’s advisable to request samples of the spring clips. This step allows you to evaluate the quality, fit, and performance under your specific conditions. Testing samples can prevent costly mistakes later in the procurement process.

- Quality Assurance: Assess the clips for durability, fatigue resistance, and overall quality.

- Functional Testing: Ensure that the samples meet the load and operational requirements specified in your technical documentation.

Step 5: Negotiate Pricing and Terms

Once you’ve identified suitable suppliers and tested samples, it’s time to negotiate pricing and terms. Effective negotiation can lead to better pricing, favorable payment terms, and improved delivery schedules, which are essential for maintaining your supply chain.

Illustrative image related to types of spring clips

- Bulk Order Discounts: Inquire about discounts for larger orders, as this can significantly reduce your overall costs.

- Lead Times and Shipping: Confirm lead times and shipping options to ensure timely delivery of your clips.

Step 6: Confirm After-Sales Support and Warranty

After selecting a supplier, confirm their after-sales support and warranty policies. Reliable support can be invaluable in case you encounter issues with the clips post-purchase. Understanding warranty terms can also protect your investment.

- Technical Assistance: Ensure the supplier offers technical support for any installation or application issues.

- Warranty Coverage: Review the warranty details to understand what is covered and for how long.

Step 7: Establish a Long-Term Relationship

Building a strong relationship with your chosen supplier can lead to better service, quicker responses, and potential cost savings in future transactions. Regular communication and feedback can help both parties understand needs and improve collaboration.

- Feedback Loop: Provide feedback on the products and services received to foster a collaborative relationship.

- Future Procurement Plans: Discuss future needs and potential for bulk ordering to secure better terms.

By following this structured checklist, B2B buyers can streamline their sourcing process for spring clips, ensuring that they acquire the right products for their applications.

Illustrative image related to types of spring clips

Comprehensive Cost and Pricing Analysis for types of spring clips Sourcing

What Are the Key Cost Components for Sourcing Spring Clips?

When sourcing spring clips, understanding the cost structure is essential for effective budgeting and procurement. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of raw materials significantly impacts pricing. Common materials include high-carbon steels, stainless steels, and exotic alloys like Inconel and Elgiloy. Prices can vary dramatically based on the material’s availability and market demand.

-

Labor: Labor costs depend on the manufacturing location. Regions with higher labor costs, such as Europe, may see increased prices compared to emerging markets in Africa or South America.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as facility maintenance and utilities. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Initial tooling costs can be substantial, particularly for custom designs. However, these costs are often amortized over large production runs, making them less impactful per unit in high-volume orders.

-

Quality Control: Ensuring that spring clips meet specific quality standards incurs additional costs. Certifications, testing, and inspections contribute to the overall price but are crucial for maintaining product integrity.

-

Logistics: Transporting spring clips to their final destination can add significant costs, particularly for international shipments. Factors such as shipping method, distance, and Incoterms influence these expenses.

-

Margin: Suppliers will typically add a profit margin on top of their costs, which can vary widely based on market conditions and the supplier’s business model.

How Do Price Influencers Affect Spring Clip Costs?

Several factors influence the pricing of spring clips in the B2B marketplace:

-

Volume/MOQ: Minimum order quantities (MOQs) play a crucial role in determining unit prices. Higher volumes often lead to lower per-unit costs due to economies of scale.

-

Specifications/Customization: Custom designs or specific material requirements can increase costs. Suppliers may charge a premium for tailored solutions, so it’s essential to define specifications clearly.

-

Materials: The grade and type of materials used directly impact pricing. Higher-quality materials, while more expensive, may provide better performance and longevity, influencing Total Cost of Ownership (TCO).

-

Quality/Certifications: Products that meet industry standards or have specific certifications (like ISO) may command higher prices. Buyers should consider whether these certifications are necessary for their applications.

-

Supplier Factors: The supplier’s reputation, location, and operational efficiency can affect pricing. Established suppliers with robust processes may offer better reliability and quality, justifying a higher price.

-

Incoterms: Understanding Incoterms is vital for international transactions. They dictate who bears the costs and risks during shipping, influencing the final price.

What Buyer Tips Can Help Optimize Costs?

B2B buyers can employ several strategies to optimize costs when sourcing spring clips:

-

Negotiation: Building strong relationships with suppliers can facilitate better pricing and terms. Open communication about needs and expectations can lead to mutually beneficial agreements.

-

Cost-Efficiency: Assessing the total cost of ownership rather than just the purchase price is crucial. Consider factors like durability, maintenance, and potential replacements when evaluating options.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa or South America should be aware of additional costs related to tariffs, import duties, and currency fluctuations. Understanding these nuances can prevent unexpected expenses.

-

Long-Term Partnerships: Establishing long-term partnerships with suppliers can lead to improved pricing structures and reliability in supply chains, particularly for repeat orders.

Disclaimer on Indicative Prices

Prices for spring clips can vary widely based on the aforementioned factors. It is advisable to request quotes from multiple suppliers to ensure competitive pricing and to factor in all associated costs when making procurement decisions.

Alternatives Analysis: Comparing types of spring clips With Other Solutions

Exploring Alternatives to Spring Clips: What Are the Best Options?

When evaluating the best fastening solutions for various applications, it’s essential to consider alternatives to spring clips. While spring clips offer unique benefits such as ease of use and versatility, other fastening methods may better suit specific needs or applications. Below, we compare spring clips with two viable alternatives: screws and adhesive bonding.

Comparison Table

| Comparison Aspect | Types Of Spring Clips | Screws | Adhesive Bonding |

|---|---|---|---|

| Performance | Excellent for vibration dampening and self-retaining. | Strong holding power but may loosen over time. | Provides a permanent bond with no mechanical looseness. |

| Cost | Generally low-cost, especially in bulk. | Moderate cost, varies with type and size. | Can be higher due to material and application costs. |

| Ease of Implementation | Quick installation without tools; requires minimal training. | Requires tools and skill for installation. | Needs surface preparation and curing time. |

| Maintenance | Low maintenance; easy to replace. | Moderate; screws may need periodic tightening. | Low once set, but difficult to replace if needed. |

| Best Use Case | Ideal for applications needing frequent assembly/disassembly. | Suitable for heavy-duty applications with high load. | Best for applications requiring a permanent bond with no visible hardware. |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Using Screws?

Screws are a traditional fastening solution known for their strength and reliability. They are versatile and can be used in a variety of materials, including wood, metal, and plastic. The main advantage of screws is their holding power, making them suitable for heavy-duty applications like construction or machinery assembly. However, they require tools for installation, which can slow down the assembly process. Additionally, screws can loosen over time due to vibrations, necessitating periodic maintenance to ensure secure fastening.

How Does Adhesive Bonding Compare to Spring Clips?

Adhesive bonding involves using a chemical adhesive to join two surfaces together, providing a strong, permanent bond. This method is advantageous for applications that require a clean look without visible hardware, making it popular in automotive and electronics industries. Adhesives can also distribute stress evenly across surfaces, which can enhance durability. However, the initial cost can be higher due to the price of quality adhesives and the need for surface preparation. Moreover, once set, adhesives can be challenging to remove, making repairs more complicated than with spring clips.

Conclusion: How Should B2B Buyers Choose the Right Fastening Solution?

Choosing the right fastening solution depends on specific application requirements, such as load-bearing capacity, ease of assembly, and maintenance needs. Spring clips are ideal for applications requiring frequent adjustments and quick assembly, while screws offer robust holding power for permanent installations. On the other hand, adhesive bonding provides a clean aesthetic and is suitable for permanent applications. B2B buyers should carefully assess their operational needs, considering factors like cost, performance, and the potential need for future disassembly, to select the most effective fastening solution for their projects.

Essential Technical Properties and Trade Terminology for types of spring clips

What Are the Key Technical Properties of Spring Clips for B2B Buyers?

When selecting spring clips for industrial applications, several technical properties are crucial to ensure optimal performance and longevity. Here are some essential specifications to consider:

-

Material Grade

The material of spring clips significantly influences their strength, flexibility, and corrosion resistance. Common materials include high-carbon steels (like 1074 and 1095) for their hardness and tensile strength, and stainless steels (300 series) for their excellent corrosion resistance. Understanding the material grade helps buyers select clips that will withstand environmental conditions and mechanical stresses specific to their applications. -

Tensile Strength

This property indicates the maximum amount of tensile (pulling) stress that a material can withstand before failing. For spring clips, high tensile strength is vital to ensure they can maintain their holding force without deformation. Buyers should specify tensile strength requirements based on the application to prevent premature failure in service. -

Deflection Capacity

Deflection capacity refers to how much a spring clip can bend or stretch under load without losing its spring characteristics. It is crucial for applications where clips need to accommodate movement or vibration. Understanding the deflection capabilities can help buyers choose the right clip for dynamic environments, ensuring reliability and performance. -

Fatigue Life

Fatigue life measures how many cycles of loading and unloading a spring clip can endure before failure. This is particularly important in applications subjected to repeated stresses, such as automotive or aerospace components. Buyers should consider fatigue life ratings to ensure the clips will perform reliably over their expected operational lifespan. -

Tolerance Levels

Tolerance levels define the permissible limits of variation in dimensions and are critical for ensuring proper fit and functionality. Tight tolerances are essential in precision applications, where even minor deviations can lead to malfunction. Buyers should work with manufacturers to specify tolerance levels that align with their product requirements. -

Surface Finish

The surface finish of spring clips can affect their performance and durability. Common finishes include plating, anodizing, or passivation, which enhance corrosion resistance and reduce friction. Buyers should consider the operating environment when selecting surface finishes to ensure longevity and performance.

What Trade Terms Are Essential for Understanding Spring Clip Procurement?

To navigate the procurement process effectively, familiarity with key industry terminology is essential. Here are some common terms:

Illustrative image related to types of spring clips

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships helps buyers identify suppliers that can provide components that meet specific quality and performance standards for their applications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is critical for budget planning and inventory management. Buyers should negotiate MOQs with suppliers to align with their production needs and avoid excess stock. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products. It is essential for establishing pricing and terms before placing an order. Buyers should prepare detailed RFQs to ensure they receive accurate and competitive quotes from manufacturers. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, insurance responsibilities, and liability, facilitating smoother international trade. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is crucial for effective inventory management and production scheduling. Buyers should communicate their timelines clearly to suppliers to ensure timely delivery. -

Certification Standards

Certification standards indicate that a product meets specific safety, quality, and performance criteria. Common standards include ISO certifications or industry-specific requirements. Buyers should inquire about certifications to ensure that the spring clips comply with relevant regulations and quality benchmarks.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing spring clips, ensuring they meet their specific operational needs and maintain product quality.

Navigating Market Dynamics and Sourcing Trends in the types of spring clips Sector

What Are the Key Drivers and Trends Shaping the Spring Clips Market?

The global market for spring clips is currently experiencing dynamic growth driven by several key factors. The increasing demand for lightweight and durable fastening solutions across diverse industries such as automotive, electronics, and healthcare is a significant driver. As manufacturers strive to enhance product performance, there is a growing focus on advanced materials that offer better fatigue resistance and environmental compatibility. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

Emerging B2B technology trends, such as automation in manufacturing and the use of advanced CAD software for custom designs, are transforming the way spring clips are produced. This shift not only reduces lead times but also allows for the rapid prototyping of specialized components. Additionally, the increasing adoption of e-commerce platforms for procurement is making it easier for buyers to access a wider range of suppliers and products, enhancing competition and driving down costs.

The market is also witnessing a trend toward customization, where buyers seek tailored solutions that meet specific application requirements. This customization can range from material selection to design specifications, which is essential for applications in sectors like aerospace and medical devices. Furthermore, the rise of smart manufacturing practices is influencing the sourcing of spring clips, with an emphasis on quality control and supply chain transparency to ensure reliable performance.

Illustrative image related to types of spring clips

How Are Sustainability and Ethical Sourcing Influencing the Spring Clips Sector?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the spring clips market. The environmental impact of manufacturing processes and materials used in production is under increasing scrutiny. As global awareness of climate change and resource depletion grows, companies are compelled to adopt more sustainable practices. This includes sourcing materials that are recyclable or made from recycled content, which can significantly reduce the carbon footprint associated with spring clip production.

Buyers are increasingly looking for suppliers who prioritize ethical supply chains, ensuring fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 for environmental management and other green certifications can serve as indicators of a supplier’s commitment to sustainable practices. Additionally, the use of advanced materials like bioplastics or low-impact metals is gaining traction, offering buyers environmentally friendly alternatives without compromising on performance.

Incorporating sustainability into procurement strategies not only aligns with corporate social responsibility (CSR) goals but can also enhance brand reputation in competitive markets. For international buyers, particularly those in regions with stringent regulations on environmental impact, partnering with suppliers that emphasize sustainability can provide a competitive edge and facilitate compliance with local laws.

How Have Spring Clips Evolved Over Time to Meet Market Demands?

The evolution of spring clips can be traced back to their origins as simple fastening devices in various mechanical applications. Initially, these components were made from basic materials, primarily steel, and were designed for straightforward functionality. Over the years, advancements in material science and manufacturing technology have significantly enhanced the design and capabilities of spring clips.

Illustrative image related to types of spring clips

Today, spring clips are available in a variety of materials, including high carbon steels, stainless steels, and exotic alloys, each selected based on specific performance requirements. The introduction of computer-aided design (CAD) has allowed for intricate designs that enhance performance while reducing weight. Innovations such as the development of specialized clips for heat sinks in electronic devices and custom solutions for automotive applications underscore the ongoing adaptation of spring clips to meet the needs of modern industries.

As the market continues to evolve, the focus on customization and sustainability will likely shape the future of spring clip manufacturing, ensuring that these essential components remain relevant in an ever-changing industrial landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of types of spring clips

-

How do I choose the right spring clip for my application?

Choosing the right spring clip involves understanding your specific requirements, such as the force needed, the environment in which it will operate, and the materials involved. Consider factors like the clip’s material, thickness, and design, as these will affect its performance, fatigue life, and deflection capabilities. Engage with suppliers who can provide technical expertise and recommend suitable options based on your application, whether it’s for automotive, medical, or industrial use. -

What is the best material for spring clips in harsh environments?

For harsh environments, stainless steel or specialized alloys like Inconel or Elgiloy are often the best choices due to their corrosion resistance and strength. Stainless steel, especially the 300 series, offers excellent durability and resistance to rust, making it ideal for applications in humid or saline conditions. Discuss your application with manufacturers to identify the most suitable material that meets your performance criteria and environmental challenges. -

Can I customize spring clips according to my specifications?

Yes, many manufacturers offer customization services for spring clips. You can specify dimensions, materials, and design features to meet your unique requirements. Providing detailed drawings or specifications will help suppliers understand your needs better. Custom solutions can enhance performance and ensure that the clips fit perfectly in your applications, whether in electronics, automotive, or other industries. -

What are the typical minimum order quantities (MOQs) for spring clips?

Minimum order quantities for spring clips can vary significantly among manufacturers. Generally, MOQs may range from a few hundred to several thousand pieces, depending on the complexity of the design and materials used. It’s advisable to inquire directly with suppliers about their MOQs, as some may offer flexibility for smaller businesses or specific projects. -

How can I vet potential suppliers for spring clips?

Vetting suppliers involves several steps. Start by checking their certifications, such as ISO standards, to ensure quality compliance. Review their experience in your industry and request references or case studies. Evaluate their manufacturing capabilities, including material sourcing and production processes. Additionally, consider their customer service responsiveness and ability to meet delivery timelines, as these factors are crucial for a successful partnership. -

What payment terms should I expect when sourcing spring clips internationally?

Payment terms can vary widely among suppliers, but common practices include upfront deposits (often 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer net 30 or net 60 terms depending on your relationship and order size. Be sure to clarify payment methods accepted, such as wire transfers or letters of credit, and ensure that terms are documented in your contract to avoid misunderstandings. -

What quality assurance measures should I look for in spring clip production?

Quality assurance measures can include thorough inspections at various stages of production, such as incoming material checks, in-process inspections, and final product evaluations. Look for suppliers who utilize statistical process control (SPC) and have a dedicated quality management system in place. Request to see their quality certifications and any testing protocols they follow to ensure that the spring clips meet your standards. -

What logistics considerations should I keep in mind when ordering spring clips internationally?

When sourcing spring clips internationally, consider shipping times, customs clearance, and potential tariffs or import duties. Ensure that the supplier can provide detailed shipping documents and is familiar with international shipping regulations. It’s also wise to discuss packaging methods to prevent damage during transit. Establish a clear communication plan with your supplier regarding logistics to avoid delays and ensure timely delivery of your products.

Top 5 Types Of Spring Clips Manufacturers & Suppliers List

1. Peninsula Spring – Sheet Metal Spring Clips

Domain: peninsulaspring.com

Registered: 1996 (29 years)

Introduction: Sheet Metal Spring Clips are used to hold components by applying consistent force. Their force, deflection capabilities, and fatigue life depend on material type, thickness, and design. They are in high demand across various industries, including machinery, medical devices, and aerospace. Types of spring clips manufactured include Heat Sink Clips, Clamps, Clasps, and Closures. These clips are stam…

2. Seastrom Manufacturing – Spring Clips

Domain: seastrom-mfg.com

Registered: 1997 (28 years)

Introduction: Seastrom Manufacturing offers a variety of spring clips, including standard and slotted styles. Standard style spring clips are designed for general applications, providing uniform pressure to hold components in place, with variations for external tabs, nylon insulation, and different hole sizes. They are available in materials such as Beryllium Copper and Spring Steel, with various finishes inclu…

3. Components Direct – Tool Clips

Domain: components-direct.com

Registered: 1999 (26 years)

Introduction: Tool Clips, also known as Metal Spring Clips or Terry Clips, are designed for secure and flexible management of pipes, cables, and equipment. Made from high-quality carbon spring steel, these clips rotate 360°, allowing pipes or cables to follow their natural contour, reducing vibration and chafing. The central mounting hole allows easy installation with rivets or screws, while the stand-off base …

4. Essentra Components – Spring Clips

Domain: essentracomponents.com

Registered: 2012 (13 years)

Introduction: Spring Clips, Screw Mount, Steel, Vinyl Coating

5. United Fasteners – Pins, Clips, and Springs

Domain: unitedfasteners.com.au

Introduction: United Fasteners supplies a wide range of pins, clips, and springs, available in an extensive selection of sizes and finishes. Key products include: 1. Internal Circlip – 760 variants (Metric: Dia M8 – M950, Imperial: Dia 0.25″ – 10″, Material/Finish: Plain, Stainless Steel) 2. External Circlip – 761 variants (Metric: Dia M3 – M950, Imperial: Dia 0.125″ – 10″, Material/Finish: Plain, Stainless Ste…

Strategic Sourcing Conclusion and Outlook for types of spring clips

In navigating the diverse landscape of spring clips, international B2B buyers must prioritize strategic sourcing to ensure optimal performance and cost-efficiency. Understanding the various types of spring clips—such as sheet metal, wire, and flat spring clips—enables companies to select the right components tailored to their specific applications, whether in electronics, automotive, or construction. The choice of material and design significantly impacts the functionality, durability, and overall value of these critical fasteners.

Illustrative image related to types of spring clips

Strategic sourcing not only enhances product quality but also fosters long-term partnerships with reliable suppliers who can meet evolving market demands. Buyers should leverage their regional networks to connect with manufacturers that align with their operational needs while considering factors like lead times, customization capabilities, and compliance with international standards.

As global markets continue to expand, now is the time for businesses in Africa, South America, the Middle East, and Europe to engage in proactive sourcing strategies. By investing in high-quality spring clips and forging strong supplier relationships, companies can secure a competitive edge and drive innovation in their respective industries. Embrace the opportunity to refine your supply chain and elevate your product offerings today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.