Top 5 Nylon Tubes Suppliers (And How to Choose)

Introduction: Navigating the Global Market for nylon tubes

In today’s rapidly evolving industrial landscape, sourcing high-quality nylon tubes can present significant challenges for international B2B buyers. Whether you’re in Africa, South America, the Middle East, or Europe, understanding the diverse types, applications, and suppliers of nylon tubing is crucial for making informed purchasing decisions. This guide serves as a comprehensive resource, addressing key factors such as the various grades of nylon tubes, their specific uses in industries ranging from automotive to healthcare, and essential criteria for vetting suppliers.

As you navigate the global market, this guide empowers you with actionable insights on pricing strategies, performance metrics, and regulatory compliance. It breaks down the complexities of sourcing nylon tubes, highlighting critical considerations such as temperature resistance, chemical compatibility, and flexibility, which can significantly affect your operations. With a focus on ensuring durability and performance, the guide also offers practical advice on negotiating contracts and establishing reliable supplier relationships.

By leveraging the information within this guide, B2B buyers will be well-equipped to make strategic decisions that enhance operational efficiency and drive long-term success in their respective markets.

Understanding nylon tubes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Nylon Tubing | Lightweight, flexible, resistant to chemicals and UV radiation | Pneumatics, automotive, and general industrial applications | Pros: Cost-effective, versatile. Cons: Limited temperature range compared to specialized types. |

| High-Pressure Nylon Tubing | Designed for high-pressure applications; thicker walls for strength | Hydraulic systems, pneumatic tools | Pros: Durable, high tensile strength. Cons: Heavier, may require specific fittings. |

| Nylon 11 Tubing | Excellent chemical resistance, lower moisture absorption | Chemical processing, food and beverage industries | Pros: Superior chemical resistance. Cons: Higher cost than standard nylon. |

| Nylon 12 Tubing | Enhanced flexibility and impact resistance, lower friction | Robotics, automotive, and aerospace | Pros: Lightweight, flexible. Cons: May not be suitable for high-temperature applications. |

| FDA-Compliant Nylon Tubing | Meets FDA regulations for food contact; non-toxic | Medical devices, food and beverage handling | Pros: Safe for food and medical applications. Cons: More expensive due to compliance costs. |

What Are the Key Characteristics of Standard Nylon Tubing?

Standard nylon tubing, or polyamide tubing, is recognized for its lightweight and flexible nature, making it suitable for various applications, particularly in pneumatic systems and automotive industries. It boasts good resistance to chemicals and UV radiation, allowing it to perform well in diverse environments. When purchasing, buyers should consider the specific temperature and pressure requirements of their applications, as standard nylon may not withstand extreme conditions.

How Does High-Pressure Nylon Tubing Differ from Other Types?

High-pressure nylon tubing is engineered to handle significant pressure loads, featuring thicker walls that enhance its strength and durability. This type is widely used in hydraulic systems and pneumatic tools, where reliability under pressure is crucial. Buyers should assess compatibility with existing fittings and the potential need for reinforcement, as this tubing can be heavier and may require specific handling procedures.

Why Choose Nylon 11 Tubing for Chemical Resistance?

Nylon 11 tubing is particularly valued for its excellent chemical resistance and lower moisture absorption, making it ideal for applications in chemical processing and the food and beverage industry. Its ability to withstand a wide range of chemicals ensures longevity and reliability in demanding environments. B2B buyers should weigh the higher costs against the benefits of reduced maintenance and longer service life.

What Advantages Does Nylon 12 Tubing Offer?

Nylon 12 tubing is known for its enhanced flexibility and impact resistance, which makes it suitable for robotics and automotive applications where movement and shock absorption are essential. It also has a lower coefficient of friction, which can improve the efficiency of systems using this tubing. Buyers should consider the specific flexibility and temperature requirements of their applications, as nylon 12 may not be suitable for extreme heat.

How Is FDA-Compliant Nylon Tubing Essential for Safety?

FDA-compliant nylon tubing is designed to meet strict regulations for food and medical applications, ensuring that it is safe for contact with consumables. This type of tubing is crucial in medical devices and food processing, where contamination can have serious consequences. Buyers must be prepared for higher costs associated with compliance but should view this as an investment in safety and reliability.

Key Industrial Applications of nylon tubes

| Industry/Sector | Specific Application of nylon tubes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Fuel and brake line systems | Enhanced durability and resistance to chemicals | Ensure compliance with automotive standards and temperature ratings. |

| Manufacturing | Pneumatic systems for automation | Lightweight, flexible, and resistant to wear | Focus on pressure ratings and compatibility with existing systems. |

| Medical Devices | Surgical tubing and catheter systems | Biocompatibility and chemical resistance | Verify FDA compliance and specific material certifications. |

| Food and Beverage | Beverage dispensing systems | Resistance to moisture and easy cleaning | Check for food safety regulations and certifications. |

| Construction | Water supply and drainage systems | Corrosion resistance and longevity | Assess UV stability and adaptability to various environmental conditions. |

How Are Nylon Tubes Used in the Automotive Industry?

In the automotive sector, nylon tubes are crucial for fuel and brake line systems. Their inherent strength and chemical resistance help ensure safety and reliability under high-pressure conditions. By utilizing nylon tubes, manufacturers can enhance the durability of these systems, reducing the likelihood of leaks or failures. International buyers must consider compliance with automotive industry standards and temperature ratings to ensure optimal performance in their specific regions, especially in climates that may fluctuate significantly.

What Role Do Nylon Tubes Play in Manufacturing Automation?

Nylon tubes are extensively used in pneumatic systems within manufacturing automation. Their lightweight and flexible nature allows for efficient movement of air and fluids, which is essential for operating machinery and tools. The resistance to wear and abrasion extends the lifespan of these tubes, ultimately reducing maintenance costs. Buyers should focus on sourcing options that meet specific pressure ratings and compatibility with existing pneumatic systems to ensure seamless integration.

Why Are Nylon Tubes Important for Medical Devices?

In the medical field, nylon tubes are employed in surgical tubing and catheter systems due to their biocompatibility and chemical resistance. These properties are vital for ensuring patient safety and the effectiveness of medical devices. When sourcing nylon tubes for medical applications, buyers must verify compliance with FDA regulations and obtain specific material certifications to guarantee that the products meet stringent health and safety standards.

How Do Nylon Tubes Benefit the Food and Beverage Sector?

Nylon tubes are increasingly utilized in beverage dispensing systems, where their resistance to moisture and ease of cleaning are significant advantages. These properties help maintain the integrity of the beverage while ensuring sanitary conditions. For international buyers in the food and beverage industry, it is essential to check for food safety regulations and certifications that confirm the suitability of nylon tubes for contact with consumable products.

What Are the Advantages of Using Nylon Tubes in Construction?

In construction, nylon tubes serve as effective solutions for water supply and drainage systems. Their corrosion resistance and longevity make them ideal for various environmental conditions, ensuring that they can withstand exposure to moisture and UV light. Buyers should assess the UV stability of nylon tubes and their adaptability to different climates when sourcing materials for construction projects, particularly in regions with extreme weather conditions.

3 Common User Pain Points for ‘nylon tubes’ & Their Solutions

Scenario 1: Sourcing Quality Nylon Tubes Amid Global Supply Chain Issues

The Problem: In the current global market, B2B buyers often face significant challenges in sourcing high-quality nylon tubes due to supply chain disruptions. This issue is especially pronounced for companies operating in regions like Africa and South America, where availability can be limited and lead times extended. Buyers may receive subpar products that do not meet their specifications, leading to production delays and increased costs. Additionally, fluctuating prices can complicate budgeting and financial planning.

The Solution: To mitigate these challenges, B2B buyers should establish relationships with multiple suppliers across different regions to diversify their sourcing options. This can help ensure a steady supply of quality nylon tubes. When evaluating suppliers, it is crucial to request detailed product specifications and certifications to ensure that the nylon tubes meet industry standards. Additionally, leveraging technology, such as supply chain management software, can help track inventory levels and forecast needs, allowing businesses to place orders proactively before stock runs low. Regularly assessing supplier performance and maintaining open lines of communication can also enhance reliability and responsiveness.

Scenario 2: Ensuring Compatibility of Nylon Tubes with Existing Systems

The Problem: A common pain point for B2B buyers is ensuring that newly purchased nylon tubes are compatible with existing systems and components. Many buyers may not have comprehensive technical knowledge about the specifications required, which can lead to mismatches in size, pressure ratings, or chemical resistance. This oversight can result in system failures, costly downtime, and potential safety hazards.

The Solution: To address this compatibility issue, buyers should conduct a thorough assessment of their current systems before making a purchase. This includes measuring existing tubing dimensions, understanding the operating conditions (such as temperature and pressure), and identifying any specific chemical exposures that the tubes must withstand. Buyers should consult with engineering or technical teams to gather detailed requirements and specifications. When sourcing nylon tubes, it is advisable to select suppliers that offer technical support and consultation services. This ensures that the chosen products align perfectly with operational needs, thereby minimizing the risk of compatibility issues.

Scenario 3: Managing Cost and Quality Trade-offs in Nylon Tube Selection

The Problem: B2B buyers often grapple with the dilemma of balancing cost and quality when selecting nylon tubes. While lower-priced options may seem attractive, they can compromise performance, leading to increased maintenance costs and shorter lifespans. Conversely, high-quality nylon tubes can strain budgets, especially for businesses operating in competitive markets where margins are tight.

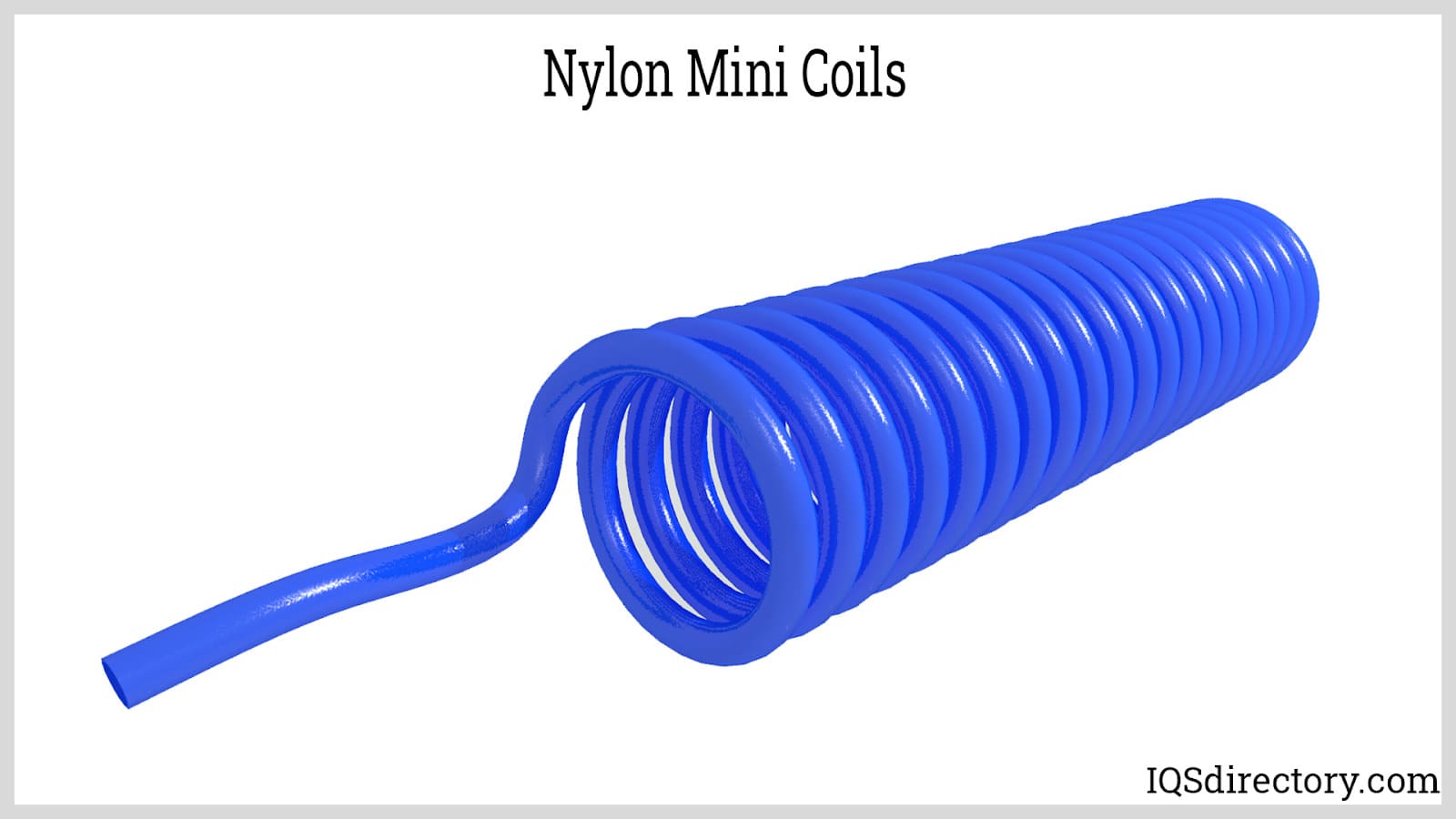

Illustrative image related to nylon tubes

The Solution: To navigate this cost-quality trade-off effectively, buyers should adopt a value-based purchasing strategy. This involves looking beyond the initial purchase price and evaluating the total cost of ownership, which includes factors like durability, maintenance needs, and potential downtime costs. Buyers can request samples and conduct performance tests to assess the quality of different nylon tubes before committing to larger orders. Additionally, consider bulk purchasing agreements or long-term contracts with suppliers to negotiate better pricing without sacrificing quality. Engaging in supplier partnerships can also lead to shared innovation, which may uncover cost-effective solutions that maintain high performance. By focusing on long-term value rather than upfront costs, buyers can make informed decisions that enhance operational efficiency and profitability.

Strategic Material Selection Guide for nylon tubes

What Are the Key Properties of Common Nylon Tube Materials?

When selecting nylon tubes for various applications, understanding the properties of different nylon materials is essential for B2B buyers. The most common materials for nylon tubes include Nylon 6, Nylon 11, Nylon 12, and Polyamide blends. Each material has distinct characteristics that influence its performance in specific environments.

How Does Nylon 6 Compare in Terms of Performance and Application?

Nylon 6 is one of the most widely used nylon materials due to its excellent mechanical properties and versatility. It has a high melting point of around 220°C and offers good tensile strength and impact resistance. However, it is susceptible to moisture absorption, which can affect its dimensional stability over time.

Pros: Nylon 6 is relatively cost-effective, making it suitable for large-scale applications. Its availability in various grades allows for customization based on specific needs.

Cons: Its moisture absorption can lead to swelling, which may not be ideal for precision applications. Additionally, it may require additional treatments for UV stability.

Impact on Application: Nylon 6 is suitable for applications involving pneumatic systems and industrial automation, but care should be taken in humid environments.

What Are the Advantages of Using Nylon 11?

Nylon 11 is derived from renewable resources, making it an eco-friendlier option compared to other nylons. It has a lower moisture absorption rate, which enhances its dimensional stability. With a temperature resistance of up to 180°C, it is ideal for applications requiring flexibility and durability.

Pros: Its low moisture absorption makes it suitable for high-precision applications. Additionally, it exhibits excellent chemical resistance.

Cons: Nylon 11 is generally more expensive than Nylon 6, which may impact budget-sensitive projects. Its availability may also be limited in certain regions.

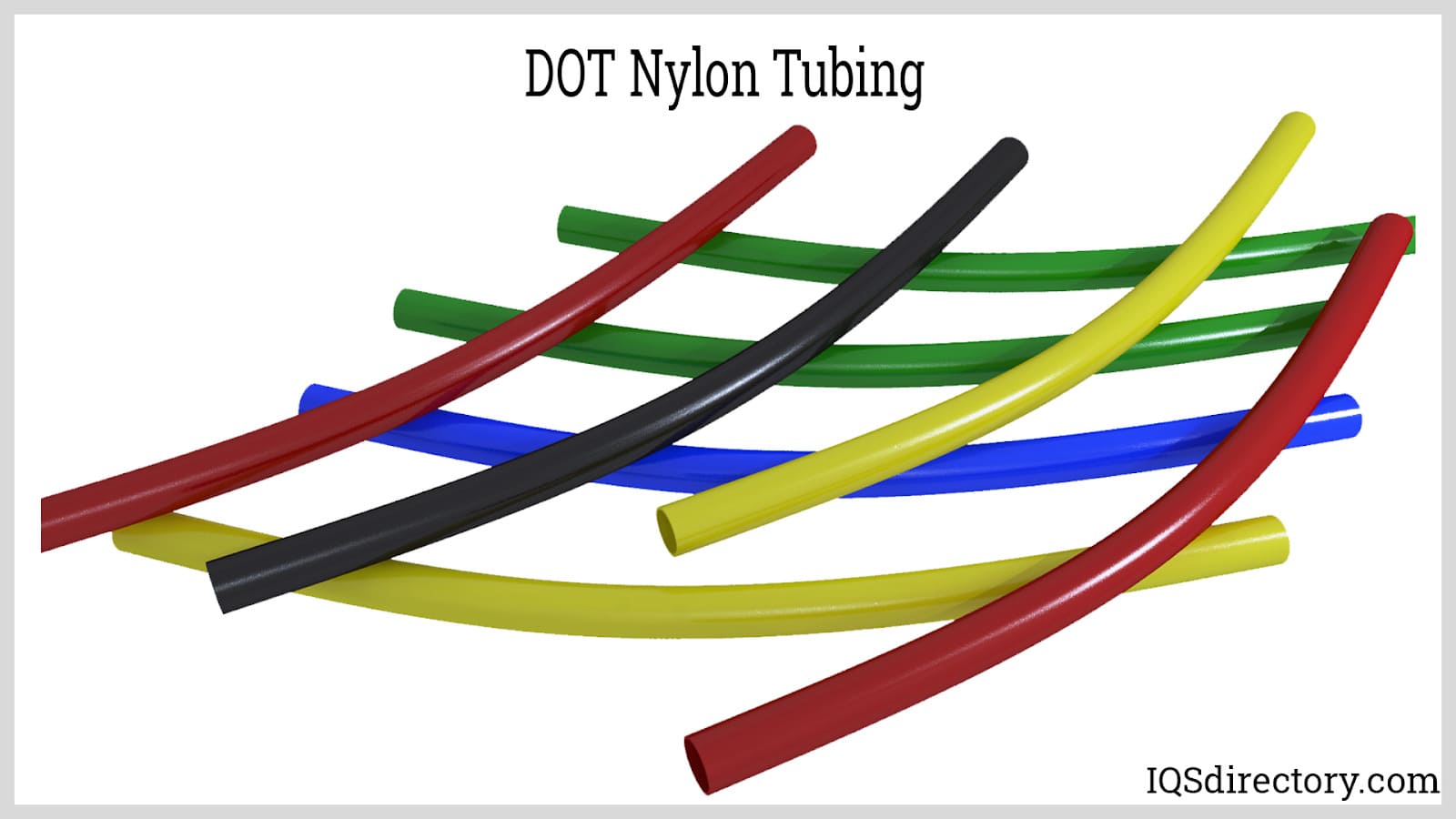

Illustrative image related to nylon tubes

Impact on Application: This material is particularly beneficial in the automotive and aerospace industries, where lightweight and durable components are essential.

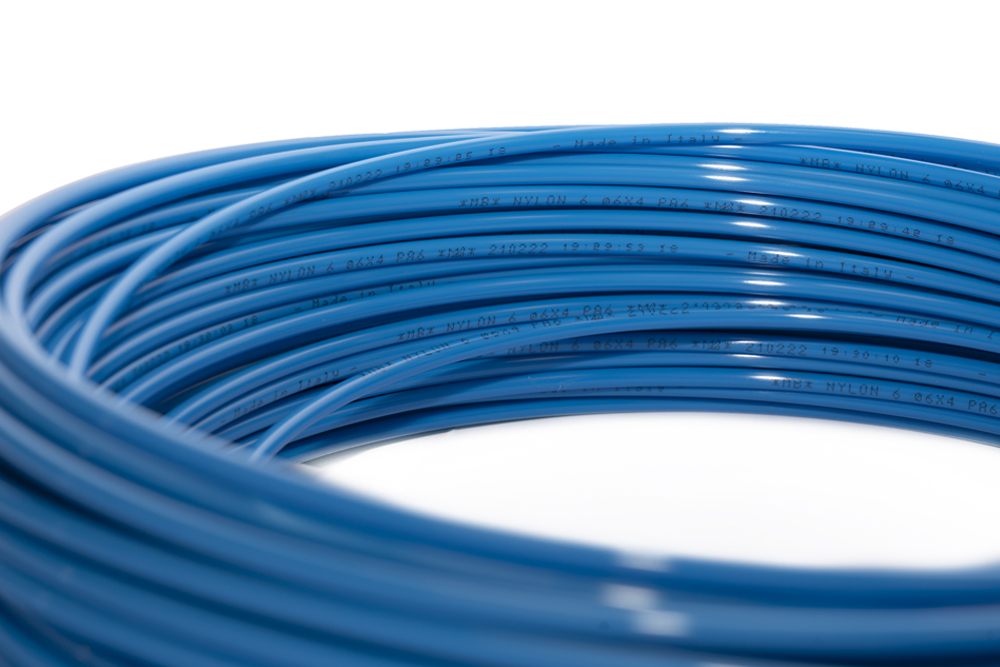

Why Choose Nylon 12 for High-Pressure Applications?

Nylon 12 is known for its superior flexibility and low density, making it a preferred choice for high-pressure applications. It maintains its integrity under extreme conditions, with a temperature resistance of up to 180°C.

Pros: Nylon 12 offers excellent chemical resistance and is less prone to hydrolysis compared to other nylons, extending its lifespan in harsh environments.

Illustrative image related to nylon tubes

Cons: The higher cost of Nylon 12 can be a drawback for large-scale applications. Its manufacturing complexity may also lead to longer lead times.

Impact on Application: Ideal for hydraulic systems and applications involving aggressive chemicals, Nylon 12 ensures reliable performance in demanding conditions.

What Are the Benefits of Polyamide Blends?

Polyamide blends combine the strengths of various nylon types to enhance performance characteristics. These materials can be engineered for specific properties such as increased strength, flexibility, or chemical resistance.

Pros: The customization potential allows for tailored solutions that meet specific application requirements. They often exhibit improved durability and resistance to environmental factors.

Cons: The complexity of manufacturing polyamide blends can lead to higher costs and longer production times.

Impact on Application: These blends are suitable for specialized applications in industries such as pharmaceuticals, where compliance with strict regulations is necessary.

Summary of Material Selection for Nylon Tubes

| Material | Typical Use Case for nylon tubes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon 6 | Pneumatic systems, industrial automation | Cost-effective and widely available | Moisture absorption affects stability | Medium |

| Nylon 11 | Automotive, aerospace applications | Low moisture absorption, eco-friendly | Higher cost and limited availability | High |

| Nylon 12 | Hydraulic systems, aggressive chemical environments | Excellent chemical resistance and flexibility | Higher cost and manufacturing complexity | High |

| Polyamide blends | Specialized applications in pharmaceuticals | Customizable for specific needs | Higher costs and longer lead times | High |

This strategic material selection guide provides B2B buyers with crucial insights into nylon tube materials, helping them make informed decisions based on application requirements, cost considerations, and material properties.

In-depth Look: Manufacturing Processes and Quality Assurance for nylon tubes

What Are the Main Stages in the Manufacturing Process of Nylon Tubes?

Manufacturing nylon tubes involves several key stages, each crucial to ensuring the product meets the necessary specifications and quality standards. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing process involves selecting the appropriate nylon resin, often polyamide, based on the intended application. This material is then dried to remove moisture, which can affect the mechanical properties of the final product. In some cases, additives such as colorants or UV stabilizers are mixed with the resin to enhance specific properties, such as chemical resistance or color.

Forming Techniques

Once the materials are ready, the forming process begins. Common techniques include extrusion and injection molding. In extrusion, the nylon is melted and forced through a die to create continuous lengths of tubing. This method is efficient for producing large volumes. Injection molding, on the other hand, involves injecting molten nylon into a mold to create complex shapes or specific dimensions. This technique is often used for custom parts and can provide a higher degree of precision.

Assembly

For applications requiring fittings or connections, the assembly stage is critical. This may involve adding end fittings, connectors, or valves to the nylon tubes. Each component must be securely attached to ensure the integrity of the system in which the tubing will be used.

Finishing

The final stage of manufacturing involves finishing processes, such as cutting to length, surface treatment, or additional machining to achieve the required tolerances. Quality checks are often integrated into this stage to verify that the tubing meets all specifications before being packaged for shipment.

How Is Quality Assurance Implemented in Nylon Tube Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final products meet both international standards and specific customer requirements. Key elements of QA include adherence to relevant standards, quality control checkpoints, and testing methods.

Relevant International Standards

Manufacturers often adhere to internationally recognized standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with CE marking indicates conformity with health, safety, and environmental protection standards within the European Economic Area. For certain applications, certifications from organizations like the American Petroleum Institute (API) may also be relevant, particularly in industries such as oil and gas.

Quality Control Checkpoints

Quality control (QC) involves multiple checkpoints throughout the manufacturing process. Incoming Quality Control (IQC) ensures that raw materials meet specified criteria before production begins. In-Process Quality Control (IPQC) monitors the manufacturing process, checking for consistency and adherence to specifications during production. Finally, Final Quality Control (FQC) assesses the completed products before they are shipped. This multi-tiered approach minimizes defects and ensures that only high-quality products reach the customer.

What Common Testing Methods Are Used for Nylon Tubes?

Testing is essential to validate the properties and performance of nylon tubes. Common methods include:

-

Tensile Strength Testing: This measures the maximum amount of tensile stress that a material can withstand before failure. It helps determine the durability of the nylon tube under various conditions.

-

Chemical Resistance Testing: This assesses how well the nylon tube can withstand exposure to different chemicals, which is vital for applications in industries such as pharmaceuticals and food processing.

-

Thermal Stability Testing: Given that nylon tubes may be exposed to varying temperatures, this test evaluates how the material performs under heat and cold conditions.

-

Dimensional Inspection: Using precision measuring tools, manufacturers check that the dimensions of the tubing meet specified tolerances. This step is crucial for ensuring compatibility with fittings and other components.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is paramount. Here are some actionable steps to ensure due diligence:

-

Conduct Supplier Audits: Regular audits can provide insights into the supplier’s manufacturing processes and quality management systems. Buyers should look for compliance with international standards such as ISO 9001.

-

Request Quality Assurance Reports: Suppliers should provide documentation outlining their quality control measures, including testing results and certifications. This transparency is vital for building trust.

-

Engage Third-Party Inspectors: Consider hiring independent third-party inspectors to evaluate the manufacturing process and the final products. This can offer an unbiased assessment of quality.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of several nuances when it comes to quality control and certification:

-

Regional Standards Variability: Different regions may have varying standards and certifications. For example, while CE marking is critical in Europe, other regions may prioritize different certifications. Buyers should familiarize themselves with the regulations pertinent to their market.

-

Language and Documentation: Ensure that all quality documentation is available in a language that the buyer can understand. This can include test reports, material safety data sheets, and compliance certificates.

-

Cultural Differences in Communication: Understanding cultural nuances in communication can help in negotiating and establishing a strong relationship with suppliers. This is particularly important when addressing quality issues or changes in specifications.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for nylon tubes is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing, alongside rigorous quality control measures, buyers can ensure they partner with reliable suppliers that meet their standards for quality and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nylon tubes’

When sourcing nylon tubes, it’s essential to approach the process methodically to ensure you select the right product for your application. This guide provides a step-by-step checklist to help B2B buyers navigate their procurement journey effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial as it directly impacts the performance of nylon tubes in your applications. Consider factors such as diameter, wall thickness, and length. Additionally, evaluate the environmental conditions the tubes will be exposed to, including temperature, pressure, and chemical exposure, to ensure compatibility.

Illustrative image related to nylon tubes

- Key Attributes: Look for high tensile strength, flexibility, and chemical resistance as these are fundamental for durability in various applications.

Step 2: Research Different Nylon Types

There are various types of nylon tubing available, including Nylon 6, Nylon 11, and Nylon 12, each offering unique properties. Understanding these differences will help you select the most suitable type for your needs, especially regarding temperature tolerance and chemical resistance.

- Considerations: For instance, Nylon 11 and 12 are often more flexible and resistant to moisture compared to Nylon 6, making them ideal for specific applications.

Step 3: Evaluate Potential Suppliers

Thoroughly vetting suppliers is vital to ensure reliability and product quality. Request comprehensive company profiles, product catalogs, and references from other businesses in your industry.

- Assessment Criteria: Look for suppliers with a proven track record in your region, positive customer feedback, and certifications that meet international standards.

Step 4: Request Samples and Test

Before making a bulk purchase, it’s advisable to request samples of the nylon tubes. Testing the samples in real-world conditions will provide insights into their performance and suitability for your specific applications.

- Testing Focus: Pay attention to aspects such as flexibility, resistance to chemicals, and overall durability during the trial phase.

Step 5: Verify Supplier Certifications

Confirm that your chosen supplier holds the necessary certifications, such as ISO 9001 or specific industry compliance standards. These certifications are indicators of quality assurance and adherence to safety protocols.

- Importance of Compliance: Certifications ensure that the products meet both local and international regulations, reducing risks associated with non-compliance.

Step 6: Negotiate Terms and Pricing

Once you have selected a supplier, engage in discussions regarding pricing, payment terms, and delivery schedules. A clear understanding of these terms can prevent misunderstandings and foster a smoother transaction process.

- Negotiation Tips: Consider factors such as bulk order discounts, shipping costs, and return policies. Ensure that all terms are documented to avoid future disputes.

Step 7: Establish a Long-term Relationship

Building a long-term relationship with your supplier can lead to better pricing, priority service, and enhanced collaboration on product development. Regularly communicate your needs and feedback to foster trust and mutual benefit.

- Partnership Benefits: A reliable supplier can become a valuable partner in your business, helping you to innovate and respond to market demands effectively.

By following this checklist, you will be well-equipped to source nylon tubes that meet your technical requirements and align with your business objectives.

Illustrative image related to nylon tubes

Comprehensive Cost and Pricing Analysis for nylon tubes Sourcing

What Are the Key Cost Components in Sourcing Nylon Tubes?

Understanding the cost structure of nylon tubes is vital for international B2B buyers looking to optimize their procurement strategy. The primary cost components in sourcing nylon tubes include:

-

Materials: The type of nylon resin used significantly impacts costs. Nylon 6 and Nylon 11 are commonly used, with Nylon 11 typically being more expensive due to its superior chemical resistance and flexibility. The choice of material will depend on the application and performance requirements.

-

Labor: Labor costs can vary greatly depending on the region and the complexity of the manufacturing process. Countries with lower labor costs may offer more competitive pricing, but it’s essential to balance this with the quality of workmanship.

-

Manufacturing Overhead: This includes costs associated with the facilities, equipment, and utilities required for production. Efficient production processes can help minimize overhead costs, impacting the overall price of nylon tubes.

-

Tooling: Custom tooling for specific designs or dimensions can add significant costs. Buyers should consider whether they need standard sizes or custom specifications, as the latter will require additional investment in tooling.

-

Quality Control (QC): Ensuring product quality often involves additional inspections and testing, which can increase costs. Buyers should inquire about the QC processes of suppliers to ensure that they meet required standards.

-

Logistics: Transportation costs can be significant, especially for international shipments. Factors such as distance, shipping method, and customs duties must be considered when calculating total costs.

-

Margin: Suppliers typically add a margin to cover their costs and generate profit. Understanding the market dynamics and competition can provide leverage in negotiations.

How Do Price Influencers Affect Nylon Tubes Pricing?

Several factors can influence the pricing of nylon tubes:

-

Volume/MOQ: Larger orders often lead to reduced per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their needs to optimize pricing.

-

Specifications and Customization: Custom specifications can lead to higher prices. Buyers should assess whether custom features are essential or if standard options will suffice.

-

Quality and Certifications: Suppliers offering higher quality materials or certifications (e.g., FDA compliance) may charge a premium. However, investing in quality can lead to lower Total Cost of Ownership (TCO) in the long run.

-

Supplier Factors: Supplier reputation, reliability, and location can impact pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) can significantly affect total costs, including shipping and insurance. Buyers should negotiate terms that best fit their logistics strategy.

What Are Effective Buyer Tips for Sourcing Nylon Tubes?

To navigate the complexities of sourcing nylon tubes, consider these actionable tips:

-

Negotiate Wisely: Leverage volume commitments and long-term relationships to negotiate better prices. Building rapport with suppliers can lead to favorable terms and discounts.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial costs, consider factors such as durability, maintenance, and potential downtime. A lower upfront cost may not always translate to savings if the product has a shorter lifespan.

-

Understand Regional Pricing Nuances: Pricing can vary significantly by region due to local demand, supply chain dynamics, and economic conditions. For example, buyers in Africa or South America may encounter different pricing structures than those in Europe.

-

Stay Informed About Market Trends: Regularly review market conditions, material costs, and supplier capabilities. This knowledge can empower buyers during negotiations and help them identify the best sourcing opportunities.

-

Request Samples: Before placing large orders, request samples to evaluate quality and performance. This step can prevent costly mistakes down the line.

Disclaimer on Pricing

Prices for nylon tubes can fluctuate based on market conditions, supplier pricing strategies, and material availability. Buyers should always request updated quotes and confirm pricing details before finalizing their orders to ensure they receive the best value.

Alternatives Analysis: Comparing nylon tubes With Other Solutions

Exploring Alternatives to Nylon Tubes: A Comparative Analysis

In the world of industrial applications, selecting the right tubing solution is crucial for operational efficiency and cost-effectiveness. While nylon tubes are widely recognized for their versatility and performance, various alternative solutions can also meet specific needs depending on the application. This analysis compares nylon tubes with two viable alternatives: polyurethane tubes and polyethylene tubes.

| Comparison Aspect | Nylon Tubes | Polyurethane Tubes | Polyethylene Tubes |

|---|---|---|---|

| Performance | High strength, chemical resistance, and flexibility; suitable for high-pressure applications. | Excellent flexibility, abrasion resistance, and low-temperature performance; ideal for dynamic applications. | Good chemical resistance and UV stability; less flexible than nylon or polyurethane. |

| Cost | Moderate cost, generally higher than polyethylene but competitive with polyurethane. | Higher cost due to advanced properties and manufacturing processes. | Generally the lowest cost option; budget-friendly for large applications. |

| Ease of Implementation | Easy to install with standard fittings; requires careful cutting for custom sizes. | Requires specific fittings and may need expertise for installation; generally user-friendly. | Simple installation process; widely available fittings make it easy to implement. |

| Maintenance | Low maintenance; resistant to wear and tear. | Low maintenance but can degrade with prolonged exposure to UV light. | Very low maintenance; durable and long-lasting under most conditions. |

| Best Use Case | Ideal for high-pressure pneumatic systems, automotive applications, and chemical processing. | Best suited for applications requiring high flexibility, such as robotics and conveyor systems. | Suitable for general-purpose applications, including irrigation and low-pressure fluid transfer. |

What Are the Pros and Cons of Polyurethane Tubes?

Polyurethane tubes are known for their remarkable flexibility and resistance to abrasion, making them ideal for dynamic applications that require bending and movement. They can perform well in environments with low temperatures, maintaining their integrity without cracking. However, they tend to be more expensive than nylon tubes and may not withstand high temperatures or direct UV exposure as effectively. This could limit their use in outdoor or high-temperature settings.

What Advantages Do Polyethylene Tubes Offer?

Polyethylene tubes provide a cost-effective solution for a wide array of applications, including irrigation and low-pressure fluid transfer. They exhibit good chemical resistance and UV stability, making them suitable for outdoor use. The major downside is their relatively lower flexibility and strength compared to nylon and polyurethane, which may limit their application in high-pressure systems. Additionally, while they are easy to install, they may not perform well in high-stress environments.

Illustrative image related to nylon tubes

How Can B2B Buyers Choose the Right Tubing Solution?

When choosing between nylon tubes and their alternatives, B2B buyers should consider specific operational requirements such as pressure ratings, environmental conditions, and budget constraints. Nylon tubes excel in high-pressure and chemical environments, while polyurethane offers superior flexibility for dynamic applications. Conversely, polyethylene serves as an economical choice for general-purpose needs. Assessing these factors against application demands will guide buyers in selecting the most appropriate tubing solution for their unique operational challenges.

Essential Technical Properties and Trade Terminology for nylon tubes

Understanding the key technical properties and trade terminology associated with nylon tubes is essential for B2B buyers seeking to make informed purchasing decisions. This section outlines critical specifications and common industry jargon that will enhance your procurement strategy.

What Are the Essential Technical Properties of Nylon Tubes?

1. Material Grade

Nylon tubes are typically manufactured from polyamide, with common grades including Nylon 6 and Nylon 11. The choice of material grade affects properties such as strength, flexibility, and chemical resistance. For instance, Nylon 6 offers good tensile strength and impact resistance, making it suitable for high-stress applications. Understanding material grades is crucial for buyers to ensure that the selected tube meets specific performance requirements in their applications.

2. Tolerance

Tolerance refers to the allowable deviation from specified dimensions in the manufacturing process. For nylon tubes, tolerances are critical, especially in applications requiring precise fit and function, such as in pneumatic systems or hydraulic applications. Accurate tolerances ensure seamless integration with other components, minimizing the risk of leaks or failures. Buyers should request detailed tolerance specifications to align with their engineering needs.

3. Chemical Resistance

Nylon’s inherent chemical resistance makes it suitable for various industrial applications, including those involving exposure to oils, fuels, and solvents. This property is vital for buyers in sectors like automotive or chemical processing, where materials face harsh environments. Buyers should inquire about the chemical resistance ratings of nylon tubes to ensure compatibility with the substances they will encounter.

4. Operating Temperature Range

Nylon tubes can withstand varying temperature ranges, often up to 120°C (248°F) or higher, depending on the grade. This feature is significant for applications in extreme conditions, such as automotive or aerospace industries. When selecting nylon tubes, buyers should verify the operating temperature to avoid material degradation or failure during use.

5. Bend Radius

The bend radius indicates the minimum curvature a nylon tube can withstand without compromising its integrity. A smaller bend radius is often preferred in applications where space is limited. Buyers must understand the bend radius to ensure that the tubing can be routed appropriately in their systems without kinking or breaking.

6. UV Stability

For applications exposed to sunlight, UV stability is an essential property. Nylon tubes with UV stabilization resist degradation caused by ultraviolet light, making them suitable for outdoor use. Buyers in regions with high sunlight exposure, such as Africa or the Middle East, should prioritize UV-stabilized nylon tubes for longevity.

Illustrative image related to nylon tubes

What Are Common Trade Terms in the Nylon Tube Industry?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the nylon tube industry, understanding OEM relationships helps buyers identify reliable suppliers who can provide high-quality products that meet specific standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it impacts inventory management and cash flow. Knowing the MOQ allows buyers to plan their purchases effectively and negotiate better terms with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers requesting pricing and terms for specific products. This process is essential for comparing offers and ensuring that buyers receive competitive pricing and favorable conditions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is critical for B2B buyers engaging in cross-border trade, as they clarify aspects such as shipping costs, risk transfer, and delivery obligations.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. Understanding lead times helps buyers plan their inventory and production schedules. Longer lead times may necessitate more strategic planning to avoid disruptions in operations.

6. Customization

Customization refers to the ability to tailor products to meet specific requirements, such as dimensions, colors, or materials. Buyers often seek customization options to ensure that the nylon tubes fit their unique applications perfectly. Understanding available customization options can enhance product performance and satisfaction.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing nylon tubes, ultimately leading to better procurement outcomes and enhanced operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the nylon tubes Sector

What Are the Current Market Trends in the Nylon Tubes Sector?

The nylon tubes market is experiencing significant growth, driven by various global factors. Increased demand in industries such as automotive, aerospace, and manufacturing is propelling market dynamics. Particularly in regions like Africa, South America, the Middle East, and Europe, the need for lightweight and durable materials is fostering innovation in nylon tubing applications. Emerging technologies, such as 3D printing and advanced manufacturing processes, are streamlining production, allowing for custom solutions that meet specific client needs. Additionally, the rise of automation in manufacturing is enhancing efficiency, reducing costs, and improving the quality of nylon tubes.

Another trend is the growing emphasis on high-performance materials. Nylon tubing’s inherent properties, such as flexibility, chemical resistance, and high tensile strength, make it an attractive option for various applications. For instance, industries requiring high-pressure systems are increasingly adopting nylon tubes due to their ability to withstand stress and maintain structural integrity. Furthermore, the market is witnessing a shift towards sourcing from local suppliers to mitigate logistics costs and lead times, particularly as companies aim for just-in-time inventory practices.

How Is Sustainability Influencing the Sourcing of Nylon Tubes?

Sustainability is becoming a crucial factor in the sourcing of nylon tubes, as businesses recognize the environmental impact of their supply chains. The production of nylon can be energy-intensive and often involves petrochemical derivatives, raising concerns about its carbon footprint. As a response, manufacturers are increasingly investing in more sustainable practices, including the use of recycled materials and energy-efficient production processes.

Moreover, ethical sourcing is gaining traction among international B2B buyers. Companies are prioritizing suppliers who adhere to sustainability certifications, such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances). These certifications not only ensure compliance with environmental regulations but also enhance brand reputation and customer loyalty. Buyers are advised to engage with suppliers who demonstrate a commitment to sustainability, as this can significantly impact their own market positioning and consumer perception.

What Is the Historical Evolution of Nylon Tubing?

Nylon was first synthesized in the 1930s, and its applications quickly expanded due to its unique properties. Initially used in textiles, nylon’s versatility soon led to its adoption in industrial applications, including tubing. The development of nylon tubes was a game-changer for various sectors, offering a lightweight, durable, and chemically resistant alternative to traditional materials like metal and rubber.

Over the decades, advancements in polymer science have improved the performance characteristics of nylon tubing, resulting in better flexibility, higher temperature resistance, and enhanced durability. Today, nylon tubes are integral to numerous applications, from automotive fuel lines to pneumatic systems, reflecting the material’s evolution from a textile to a critical engineering solution. As the market continues to grow, the focus on innovation and sustainability will likely shape the future of nylon tubing in B2B contexts.

Frequently Asked Questions (FAQs) for B2B Buyers of nylon tubes

-

How do I choose the right nylon tube for my application?

Selecting the appropriate nylon tube depends on several factors including temperature, pressure, chemical exposure, and flexibility requirements. Consider the operational environment; for instance, high-temperature applications may require heat-resistant nylon. Evaluate the necessary diameter and wall thickness based on your system’s specifications. Additionally, assess chemical compatibility with the materials the tubing will encounter. Consulting with suppliers for sample testing can also help ensure the selected nylon tube meets your operational needs effectively. -

What is the best nylon tubing for high-pressure applications?

For high-pressure applications, nylon tubing with reinforced construction, such as Nylon 11 or Nylon 12, is recommended due to their superior strength and durability. These materials are engineered to withstand significant pressure without compromising structural integrity. It is also essential to confirm the tube’s pressure rating and ensure it aligns with your operational requirements. Always consult product specifications and engage with suppliers to understand the optimal choices for your specific application. -

What customization options are available for nylon tubes?

Many suppliers offer customization options including specific diameters, wall thicknesses, lengths, and colors to suit various applications. Some manufacturers can also provide tubing with specific chemical resistance properties or UV stabilization for outdoor use. When requesting customization, be clear about your requirements and application to ensure the product meets your needs. Additionally, ask about the lead times for custom orders to plan your procurement effectively. -

What are the minimum order quantities (MOQs) for nylon tubes?

Minimum order quantities can vary widely among suppliers, often ranging from a few meters to several hundred meters. It’s crucial to inquire about MOQs when sourcing nylon tubes, as this can affect your overall purchasing strategy and budget. Some suppliers may offer flexibility in MOQs for first-time buyers or larger orders, so it’s worth discussing your specific needs and potential for future orders to negotiate better terms. -

What payment terms should I expect when sourcing nylon tubes internationally?

Payment terms for international transactions can vary based on the supplier and the buyer’s location. Common terms include advance payment, letters of credit, or payment upon delivery. It’s advisable to clarify payment terms upfront to avoid misunderstandings. Additionally, consider the implications of currency exchange rates and transaction fees, especially when dealing with international suppliers from regions like Africa, South America, or Europe. -

How do I ensure quality assurance when purchasing nylon tubes?

To ensure quality, request certifications and compliance documents from your supplier, such as ISO or ASTM standards. It’s also beneficial to ask for samples before placing a bulk order to evaluate the product’s performance and suitability for your application. Consider conducting third-party quality inspections, especially for larger orders, to ensure that the products meet the specified requirements and are free from defects. -

What logistics considerations should I keep in mind when importing nylon tubes?

Logistics play a critical role in the timely delivery of nylon tubes. Consider shipping methods, potential customs regulations, and import duties that may apply in your country. Additionally, verify the supplier’s shipping capabilities and their experience with international deliveries. Establish clear timelines for shipping and delivery to align with your project schedules, and ensure you have adequate insurance coverage for the shipment. -

What are the common uses of nylon tubes in various industries?

Nylon tubes are widely used across multiple industries due to their versatility. Common applications include pneumatic systems, automotive fuel lines, medical devices, and food processing equipment. Their resistance to chemicals, moisture, and extreme temperatures makes them ideal for manufacturing, construction, and agricultural purposes. Understanding the specific requirements of your industry can help you select the most appropriate nylon tube for your applications.

Top 5 Nylon Tubes Manufacturers & Suppliers List

1. Curbell Plastics – Nylon Tube Natural Cast

Domain: curbellplastics.com

Registered: 2000 (25 years)

Introduction: {“Product Name”: “Nylon, Tube, Natural, Cast”, “Item Number”: “W03-00690”, “Reference Number”: “13073”, “Price”: “$374.85 /each”, “Dimensions”: {“Length”: “26 in”, “Outside Diameter”: “8 in”, “Inside Diameter”: “6.5 in”}, “Color Group”: “Natural / White”, “Shape”: “Tube”, “Color”: “Natural”, “Grade”: “Unfilled”, “Manufacturing Method”: “Cast”, “Material Type”: “Nylon / Cast Nylon Type 6”}

2. Polyconn – Nylon Tubing

Domain: polyconn.com

Registered: 1995 (30 years)

Introduction: Nylon tubing, also known as polyamide tubing, can withstand higher temperatures, making it ideal for a wide variety of applications. Compared to other Nylon resins, this nylon plastic tubing allows for a lighter weight wall, greater flexibility, and smaller bend radius. It is more corrosion resistant due to its resistance to moisture absorption. Its heat and UV stabilization makes it resistant to …

3. Professional Plastics – Natural Nylon Tube 0.250 ID x 0.375 OD

Domain: professionalplastics.com

Registered: 1997 (28 years)

Introduction: {“Product Code”: “TNYLNA.250X.375-50”, “Material”: “Nylon”, “Type”: “Natural Nylon Tube – Extruded”, “Inner Diameter (ID)”: “0.250 in”, “Outer Diameter (OD)”: “0.375 in”, “Length”: “50 ft”, “Category”: “Nylon 6/6 Fractional Tubing (up to 1″ ID)”}

4. Interstate Plastics – Nylon Tubes

Domain: interstateplastics.com

Registered: 1997 (28 years)

Introduction: Nylon Tubes | Natural Cast Tubular Bar Plastic Sheet

– Material: Nylon (Polyamide)

– Compliance: FDA Compliant

– Warning: OD will be significantly oversized, ID will be significantly undersized to allow for machining to listed dimension.

– Review Rating: 5 stars based on 4 reviews

– Available Sizes: Various options with outer diameter (OD) and inner diameter (ID) combinations, all 26″ long, includ…

5. McMaster-Carr – Nylon Tubing

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster-Carr – Nylon Tubing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for nylon tubes

Nylon tubes present a versatile solution for a wide array of industrial applications, offering benefits such as high strength, flexibility, and resistance to chemicals and moisture. For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding the unique properties of nylon tubing is crucial for optimizing supply chains and enhancing operational efficiency. Strategic sourcing not only allows for the procurement of high-quality materials but also supports the establishment of reliable supplier relationships that can lead to cost savings and improved supply chain resilience.

As industries evolve and demand for durable, lightweight materials increases, the outlook for nylon tubes remains promising. Buyers should focus on suppliers who can provide customized solutions that meet specific application needs, ensuring compliance with local regulations and standards.

In conclusion, now is the time to leverage strategic sourcing for nylon tubes. Engaging with trusted suppliers can empower your business to stay ahead of market trends and capitalize on emerging opportunities. Take the next step—explore your options today and position your company for success in an increasingly competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to nylon tubes