Unlocking Value: A Strategic Analysis of the Takoyaki Maker Market

Introduction: Navigating the Global Market for takoyaki maker

In the dynamic world of culinary equipment, sourcing the right takoyaki maker can be a pivotal decision for businesses aiming to tap into the growing demand for unique and authentic dining experiences. The challenge lies not only in finding a reliable supplier but also in ensuring that the equipment meets specific operational needs, particularly in diverse markets across Africa, South America, the Middle East, and Europe. This comprehensive guide delves into the various types of takoyaki makers available, their applications in different culinary contexts, and essential considerations for vetting suppliers.

By exploring factors such as cost, capacity, and functionality, this guide equips international B2B buyers with the insights necessary to make informed purchasing decisions. Whether you are a restaurant owner looking to diversify your menu or a distributor seeking to expand your product offerings, understanding the nuances of takoyaki makers will empower you to choose the right equipment that aligns with your business goals. From assessing the benefits of electric versus traditional models to evaluating customer reviews and warranty policies, this guide provides a roadmap to navigate the complexities of the global market for takoyaki makers. By leveraging this information, you can enhance your operational efficiency and meet the evolving tastes of your clientele, ultimately driving growth in your business.

Understanding takoyaki maker Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Takoyaki Maker | Electric heating, temperature control, compact size | Small restaurants, food trucks, catering | Pros: Easy to use, consistent heating. Cons: Limited capacity for high-volume needs. |

| Commercial Takoyaki Grill | Large cooking surface, multi-plate design, high output | Restaurants, large events, buffets | Pros: High capacity, quick cooking. Cons: Higher upfront cost, requires more space. |

| Nonstick Takoyaki Pan | Nonstick surface, lightweight, portable | Home kitchens, small food businesses | Pros: Easy to clean, affordable. Cons: Less durable for heavy use. |

| Gas Takoyaki Maker | Uses gas for heating, often larger and more powerful | Outdoor catering, festivals, street vendors | Pros: High heat output, versatile. Cons: Requires gas supply, less portable. |

| Multi-functional Takoyaki Maker | Versatile designs for various snacks, adjustable heat settings | Cafés, bars, snack shops | Pros: Multi-purpose, innovative cooking options. Cons: May be more complex to operate. |

What are the Characteristics of Electric Takoyaki Makers?

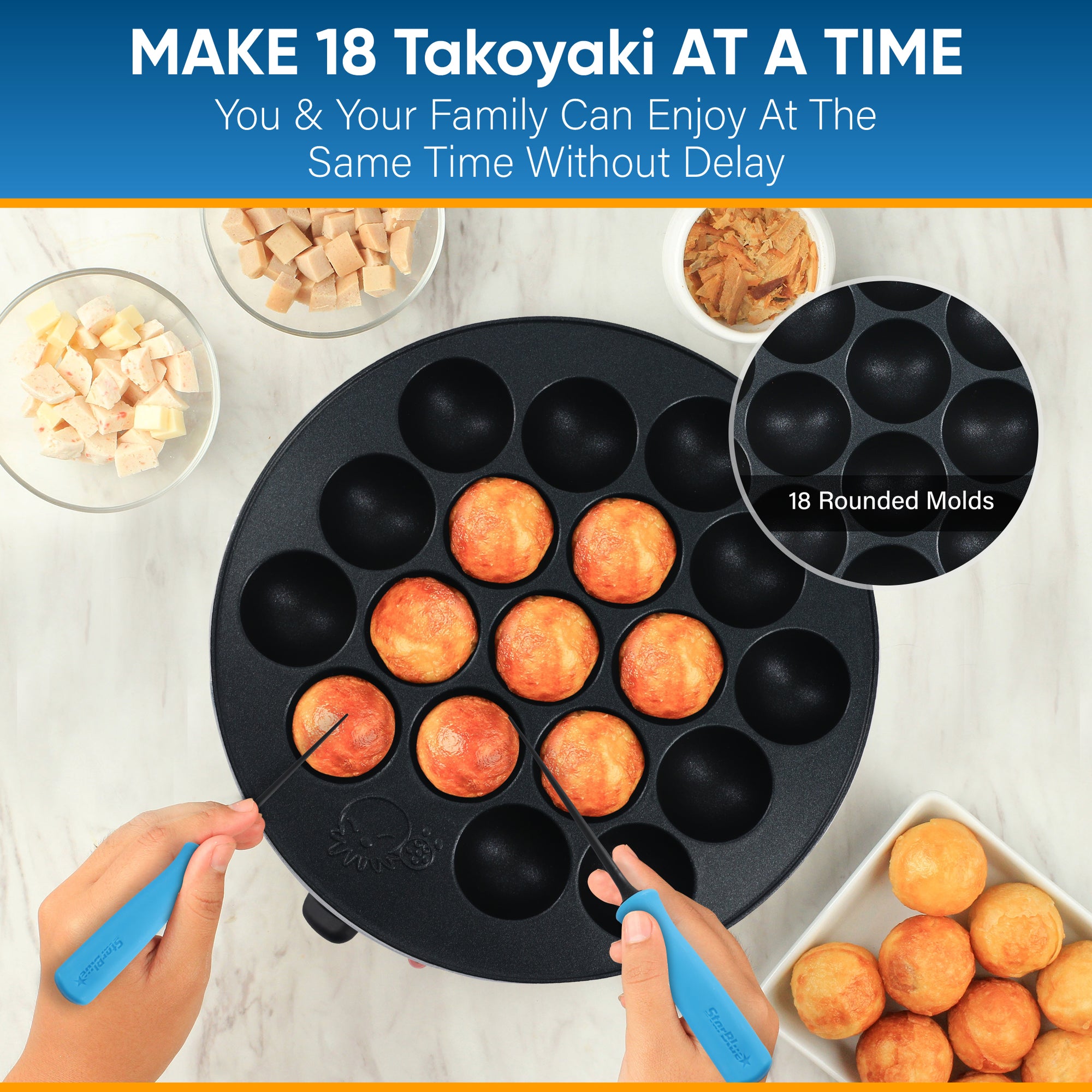

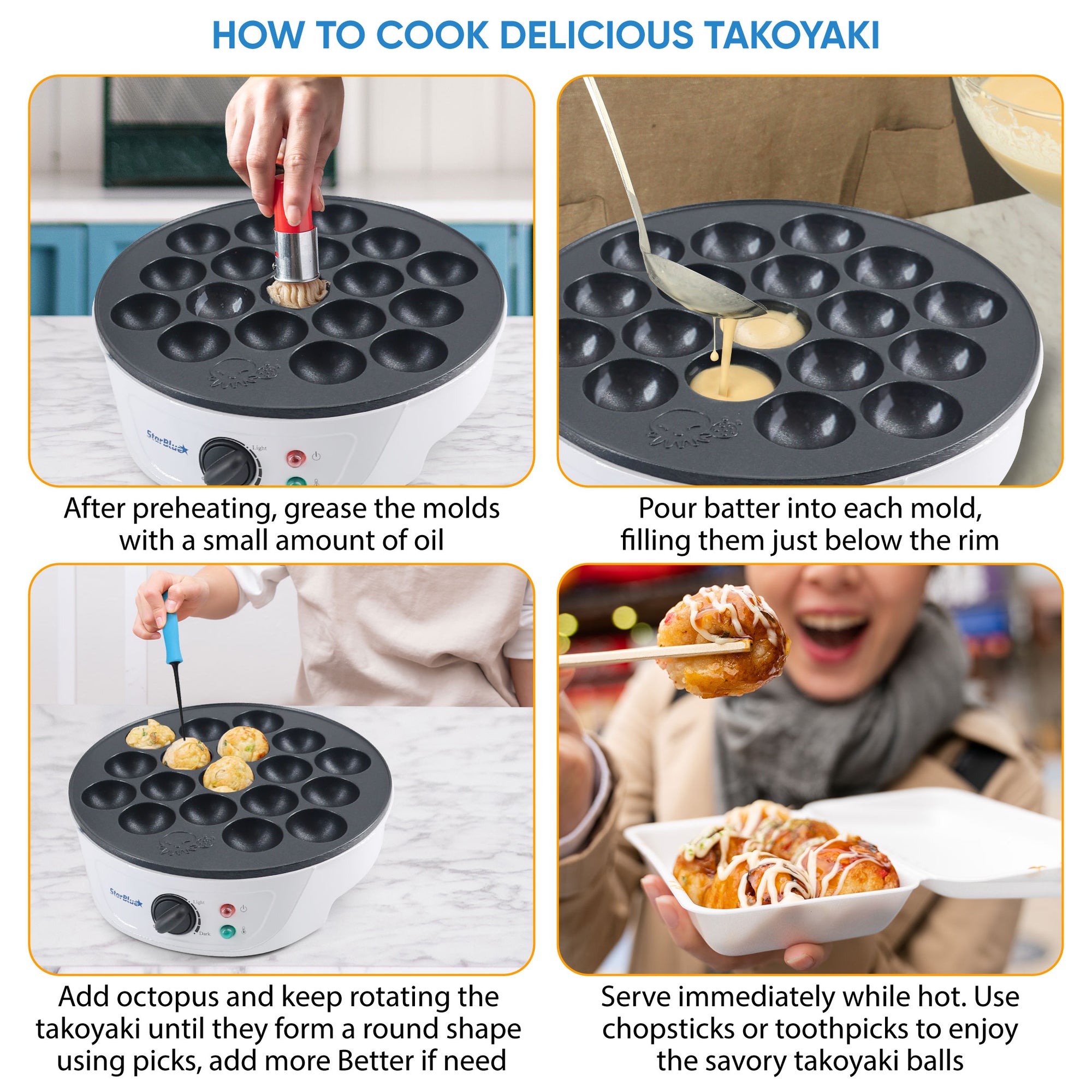

Electric takoyaki makers are designed for ease of use, featuring temperature control and a compact design that makes them suitable for small kitchens and food trucks. They typically come with nonstick surfaces, ensuring that the takoyaki balls can be easily removed without sticking. For B2B buyers, these machines are ideal for businesses looking to serve takoyaki as a quick snack option, but they may struggle with high-volume demands due to their limited cooking capacity.

How Do Commercial Takoyaki Grills Enhance Business Operations?

Commercial takoyaki grills are built for high output, with multiple cooking plates that allow for the preparation of dozens of takoyaki balls simultaneously. This type of grill is perfect for restaurants, catering services, or large events where speed and efficiency are essential. The ability to cook in bulk can significantly enhance turnover rates, making these grills a worthwhile investment despite their higher initial cost and space requirements.

Why Choose Nonstick Takoyaki Pans for Small Operations?

Nonstick takoyaki pans are lightweight and portable, making them an excellent choice for home kitchens or small food businesses. Their easy-to-clean surfaces and affordable price point make them appealing for budding entrepreneurs. However, their durability may be a concern for businesses that require heavy usage over time, as they might not withstand the rigors of a commercial kitchen environment.

Illustrative image related to takoyaki maker

What Are the Advantages of Gas Takoyaki Makers?

Gas takoyaki makers provide a powerful heating option that allows for quick cooking, making them suitable for outdoor events and street vendors. These machines can achieve higher temperatures than electric counterparts, providing a unique cooking experience. However, they require a consistent gas supply and may not be as portable as electric models, which could limit their use in certain scenarios.

How Can Multi-functional Takoyaki Makers Benefit Diverse Food Businesses?

Multi-functional takoyaki makers are designed to prepare various snacks beyond traditional takoyaki, such as pancakes and meatballs. These versatile machines often come with adjustable heat settings, appealing to cafés, bars, and snack shops looking to diversify their menu offerings. While they provide innovative cooking options, their complexity may require additional training for staff, making them a consideration for businesses aiming for operational efficiency.

Key Industrial Applications of takoyaki maker

| Industry/Sector | Specific Application of Takoyaki Maker | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Street Food Vendors | High turnover with quick cooking of popular snacks | Durability, ease of cleaning, and energy efficiency are essential. |

| Hospitality | Restaurants and Catering Services | Diversification of menu offerings and unique dining experiences | Capacity and temperature control for consistent cooking results. |

| Retail and Food Retailing | Grocery Stores and Supermarkets | Attracting customers with fresh, ready-to-eat snacks | Compliance with local health regulations and food safety standards. |

| Event Management | Food Stalls at Festivals and Events | Catering to large crowds with high-demand food items | Portability and ease of setup for temporary installations. |

| Culinary Education | Cooking Schools and Training Programs | Teaching diverse cooking techniques and cuisines | Versatility in cooking various snacks beyond takoyaki. |

How is the Takoyaki Maker Used in the Food Service Industry?

In the food service sector, particularly street food vendors, the takoyaki maker is pivotal for producing quick, delicious snacks that appeal to a wide audience. Vendors can prepare takoyaki, which is a popular Japanese street food, efficiently, allowing them to serve a high volume of customers during peak hours. This equipment helps solve the challenge of high demand by enabling rapid cooking and serving, which is crucial for maintaining customer satisfaction and maximizing profits. When sourcing, vendors should prioritize durability and ease of cleaning to ensure long-term operational efficiency.

What Role Does the Takoyaki Maker Play in Hospitality?

Restaurants and catering services leverage the takoyaki maker to diversify their menu and enhance the dining experience. By offering unique items like takoyaki, establishments can attract new customers and create memorable dining experiences. The ability to control cooking temperatures is essential for achieving consistent quality, which is vital in maintaining a restaurant’s reputation. Buyers in this sector should consider the machine’s capacity and reliability to ensure it meets the demands of busy service environments.

How Can Grocery Stores Benefit from a Takoyaki Maker?

In grocery stores and supermarkets, the takoyaki maker can be used to prepare fresh, ready-to-eat snacks that appeal to health-conscious consumers looking for quick meal options. This application can help retailers stand out in a competitive market by offering unique products that draw in foot traffic. Compliance with local food safety regulations is crucial when sourcing this equipment, as it ensures that the products served meet health standards and build consumer trust.

Illustrative image related to takoyaki maker

Why is the Takoyaki Maker Ideal for Event Management?

For event management companies, having a takoyaki maker at food stalls during festivals and events allows them to cater to large crowds with popular and high-demand food items. The compact nature of the takoyaki maker makes it easy to transport and set up at various locations, addressing the logistical challenges often faced in event catering. Portability and setup ease are key factors for sourcing, as these features contribute to a smooth operation during busy events.

How Does the Takoyaki Maker Enhance Culinary Education?

Culinary schools utilize the takoyaki maker to teach students about diverse cooking techniques and the preparation of international cuisines. This machine not only introduces students to Japanese cooking but also allows for creativity in crafting various ball-shaped snacks. Versatility is a significant requirement for buyers in this sector, as they may want to use the equipment for multiple culinary applications beyond just takoyaki, enhancing the educational experience for aspiring chefs.

3 Common User Pain Points for ‘takoyaki maker’ & Their Solutions

Scenario 1: Uneven Cooking Results in High-Volume Environments

The Problem: In a bustling restaurant or food stall setting, achieving consistent cooking results with a takoyaki maker can be a significant challenge. Many B2B buyers report that uneven heating leads to some takoyaki balls being perfectly cooked while others remain undercooked or burnt. This inconsistency not only affects customer satisfaction but also increases food waste, impacting the bottom line.

The Solution: To mitigate this issue, B2B buyers should invest in a high-quality takoyaki maker that features independent temperature controls for each cooking plate. This allows users to adjust the heat based on the specific needs of different recipes or cooking times. Additionally, thorough training for staff on how to manage the cooking process, including rotating the balls at the right time, can enhance cooking consistency. Regular maintenance and cleaning of the heating elements will also ensure optimal performance. Buyers should consider machines with built-in temperature indicators or digital displays to monitor cooking progress effectively.

Scenario 2: Difficulty in Cleaning and Maintenance

The Problem: After a busy service, the last thing kitchen staff want to deal with is a takoyaki maker that is hard to clean. B2B buyers often encounter machines that have intricate designs or non-nonstick surfaces, making post-service cleanup a tedious task. This can lead to increased labor costs and a longer turnaround time between service periods, ultimately affecting profitability.

Illustrative image related to takoyaki maker

The Solution: When selecting a takoyaki maker, buyers should prioritize models with nonstick surfaces and removable plates. Nonstick coatings make it easier to wipe down the surface without the need for harsh chemicals, while removable plates can be soaked and cleaned separately. Regularly scheduled maintenance, including deep cleaning at the end of each week, can prevent the buildup of grease and batter, ensuring longevity and optimal performance of the equipment. Additionally, investing in cleaning tools specifically designed for nonstick surfaces can help maintain the equipment without causing damage.

Scenario 3: Limited Versatility in Cooking Options

The Problem: Many businesses purchasing a takoyaki maker find that it limits them to just one type of dish, which can be a drawback in a competitive market. For B2B buyers, the challenge lies in maximizing the return on investment by offering a diverse menu that attracts various customer preferences. If a takoyaki maker can only produce traditional octopus balls, it may not appeal to all clientele.

The Solution: To expand the versatility of the takoyaki maker, buyers should look for models that come with interchangeable molds or multi-functional capabilities. For instance, some machines allow for the creation of not only takoyaki but also other snacks like quail eggs, pancake balls, and even mini meatballs. This adaptability can enable businesses to introduce innovative menu items, catering to different tastes and dietary restrictions. Moreover, investing in recipe development can help chefs experiment with various ingredients, allowing for unique offerings that can set the business apart from competitors. By diversifying the menu, businesses can attract a broader customer base, thereby increasing sales and enhancing brand reputation.

Strategic Material Selection Guide for takoyaki maker

What Materials Are Commonly Used in Takoyaki Makers?

When selecting materials for a takoyaki maker, it’s essential to consider their properties, advantages, and limitations. The following analysis covers four common materials: aluminum, stainless steel, cast iron, and non-stick coatings. Each material has unique characteristics that can significantly impact the performance and suitability of the equipment for different markets.

How Does Aluminum Perform in Takoyaki Makers?

Aluminum is a popular choice for takoyaki makers due to its excellent thermal conductivity, allowing for quick heating and even cooking. It typically has a temperature rating of around 200°C (392°F), making it suitable for the high temperatures required in cooking takoyaki.

Illustrative image related to takoyaki maker

Pros: Aluminum is lightweight, cost-effective, and easy to manufacture, which can lower production costs. It also provides good corrosion resistance when anodized.

Cons: However, aluminum can warp under extreme heat and is prone to scratching, which can affect its longevity. Additionally, it may react with acidic ingredients, leading to potential flavor changes.

Impact on Application: Aluminum is compatible with most cooking media, but care must be taken to avoid using highly acidic ingredients.

Illustrative image related to takoyaki maker

Considerations for International Buyers: Buyers should ensure compliance with food safety standards in their regions, such as FDA regulations in the U.S. or EFSA guidelines in Europe. Anodized aluminum options may be preferred for better durability.

What Are the Advantages of Stainless Steel in Takoyaki Makers?

Stainless steel is favored for its durability and resistance to corrosion, making it an excellent choice for commercial applications. It can withstand high temperatures, typically rated above 300°C (572°F), ensuring consistent performance.

Pros: Its non-reactive nature makes it ideal for various food types, and it is easy to clean and maintain. Stainless steel also offers a professional aesthetic that appeals to B2B buyers.

Illustrative image related to takoyaki maker

Cons: The primary drawback is its higher cost compared to aluminum and its heavier weight, which can affect transport and installation.

Impact on Application: Stainless steel is compatible with all cooking media and is particularly suitable for environments requiring rigorous hygiene standards.

Considerations for International Buyers: Buyers should verify that the stainless steel used meets international standards, such as ASTM A240, to ensure quality and compliance.

How Does Cast Iron Compare for Takoyaki Makers?

Cast iron is known for its excellent heat retention and even cooking capabilities, making it a traditional choice for many cooking appliances, including takoyaki makers.

Pros: It provides superior heat distribution and can create a crispy exterior on the takoyaki. Cast iron is also very durable and can last a lifetime with proper care.

Illustrative image related to takoyaki maker

Cons: The main disadvantages are its weight and the need for regular seasoning to maintain its non-stick properties. It is also more expensive to manufacture.

Impact on Application: Cast iron is suitable for high-heat cooking but may not be ideal for all users due to its maintenance requirements.

Considerations for International Buyers: Buyers should consider the availability of maintenance resources and whether they can meet the specific needs of cast iron cookware in their regions.

What Role Do Non-Stick Coatings Play in Takoyaki Makers?

Non-stick coatings, often applied to aluminum or stainless steel, enhance the cooking experience by preventing food from sticking.

Pros: They simplify the cooking and cleaning process, making them appealing for both home and commercial use. Non-stick surfaces can also reduce the need for oil, promoting healthier cooking.

Cons: The coatings can wear off over time, especially under high heat, and may require special care to avoid scratching. There are also concerns about the safety of some non-stick materials at high temperatures.

Impact on Application: Non-stick coatings are compatible with a variety of cooking media but may limit the cooking temperature depending on the type of coating used.

Illustrative image related to takoyaki maker

Considerations for International Buyers: Buyers should ensure that non-stick coatings comply with safety standards, such as FDA regulations, and consider the longevity of the coatings in their specific cooking environments.

Summary Table of Material Selection for Takoyaki Makers

| Material | Typical Use Case for takoyaki maker | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Home and light commercial use | Lightweight and cost-effective | Prone to warping and scratching | Low |

| Stainless Steel | Commercial and high-end appliances | Durable and corrosion-resistant | Heavier and more expensive | High |

| Cast Iron | Traditional cooking applications | Excellent heat retention | Heavy and requires maintenance | Med |

| Non-Stick Coating | Home use and convenience-focused | Easy to clean and maintain | Coating wear and potential safety issues | Med |

This guide provides a comprehensive overview of material selection for takoyaki makers, helping international B2B buyers make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for takoyaki maker

What Are the Key Stages in the Manufacturing Process of Takoyaki Makers?

The manufacturing process of takoyaki makers involves several critical stages that ensure quality, durability, and functionality. Each stage is designed to optimize production efficiency while adhering to international standards.

Illustrative image related to takoyaki maker

1. Material Preparation

The first step in manufacturing a takoyaki maker is sourcing and preparing high-quality materials. Commonly used materials include stainless steel for the body and aluminum for the cooking plates. Stainless steel is favored for its durability, resistance to rust, and ease of cleaning, while aluminum is chosen for its excellent heat conduction properties.

Before manufacturing begins, raw materials undergo inspections to ensure they meet specified criteria. This includes checking for consistency in thickness, surface quality, and alloy composition. Any substandard materials are rejected at this stage, preventing defects in the final product.

2. Forming Techniques Used in Takoyaki Maker Production

Once materials are prepared, the forming stage begins. This typically involves several key techniques:

Illustrative image related to takoyaki maker

-

Stamping and Cutting: Sheets of stainless steel and aluminum are stamped and cut into required shapes for the outer body and cooking plates. Precision cutting ensures that each part fits perfectly during assembly.

-

Die-Casting: For certain components, die-casting techniques may be employed to create complex shapes that are lightweight yet robust. This is particularly useful for parts that require intricate designs, such as handles and knobs.

-

Welding: The body components are welded together to form a sturdy structure. Automated welding machines ensure consistent quality and reduce the likelihood of human error.

3. Assembly of Takoyaki Makers

The assembly process is where the components come together to form the final product. Key steps in this process include:

-

Electrical Assembly: Electrical components, such as heating elements and temperature control circuits, are integrated. This stage requires skilled technicians to ensure that electrical safety standards are met.

-

Integration of Non-Stick Coatings: Non-stick coatings are applied to cooking plates to facilitate easy release of takoyaki balls and to simplify cleaning. The application process must be carefully controlled to maintain consistency and effectiveness.

-

Final Assembly: After all components are in place, the takoyaki maker undergoes a final assembly check to ensure that all parts are securely attached and that the unit is ready for operation.

4. Finishing Processes for a Polished Product

The finishing stage involves several processes aimed at enhancing the aesthetic appeal and functionality of the takoyaki maker:

-

Surface Treatment: This may include polishing, painting, or applying additional coatings for enhanced appearance and corrosion resistance.

-

Quality Control Checks: Before the product is packaged, it undergoes rigorous quality control checks to ensure that it meets predefined specifications and standards.

What Quality Assurance Standards Are Relevant for Takoyaki Makers?

Quality assurance is critical in the manufacturing of takoyaki makers, ensuring that products meet safety, performance, and durability standards. Key international and industry-specific standards include:

-

ISO 9001: This standard is focused on quality management systems and is essential for manufacturers aiming to consistently provide products that meet customer and regulatory requirements.

-

CE Marking: For European markets, CE marking indicates that the product conforms to health, safety, and environmental protection standards. It is crucial for B2B buyers in Europe to ensure that their suppliers have CE certification.

-

Electrical Safety Standards (e.g., UL, IEC): Compliance with electrical safety standards is vital, especially for electrically operated appliances. B2B buyers should verify that the takoyaki makers meet the relevant electrical safety certifications for their target markets.

How Are Quality Control Checkpoints Structured in Takoyaki Maker Production?

Quality control (QC) is integrated throughout the manufacturing process, with several checkpoints established to catch defects early:

-

Incoming Quality Control (IQC): At this initial stage, raw materials are inspected for quality. Any materials that do not meet specifications are rejected.

-

In-Process Quality Control (IPQC): During the manufacturing process, various inspections are conducted at critical stages, such as after forming and before assembly. This proactive approach helps identify issues before they escalate.

-

Final Quality Control (FQC): Before shipping, the finished products undergo a comprehensive inspection. This includes testing for functionality, safety, and compliance with specifications.

What Testing Methods Are Commonly Used for Takoyaki Makers?

Several testing methods are employed to ensure that takoyaki makers meet quality and safety standards:

-

Functional Testing: Each unit is tested for its cooking performance, including heating efficiency and temperature control accuracy. This ensures that the product operates as intended.

-

Durability Testing: Takoyaki makers undergo stress testing to assess their durability under typical usage conditions. This includes evaluating the non-stick coating’s performance over time.

-

Safety Testing: Electrical safety tests are conducted to ensure that there are no risks of short circuits or overheating. These tests are crucial for compliance with international safety standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying the quality control practices of suppliers is essential to ensure product reliability. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits can help assess the supplier’s manufacturing processes and QC practices. These audits should focus on material sourcing, production methods, and adherence to quality standards.

-

Request Quality Reports: Suppliers should provide documentation of their quality control processes, including IQC, IPQC, and FQC reports. These documents should detail testing methods and outcomes.

-

Engage Third-Party Inspectors: For added assurance, buyers can employ third-party inspection services to evaluate the manufacturing process and product quality before shipment. This independent verification can help mitigate risks associated with international sourcing.

What Nuances Should International B2B Buyers Be Aware of in Quality Control?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of several nuances in quality control:

-

Regulatory Compliance: Different regions have varying regulations governing electrical appliances. Buyers must ensure that their suppliers comply with local standards to avoid import issues.

-

Cultural Differences in Quality Expectations: Quality perceptions may vary across cultures. Buyers should communicate their specific quality expectations clearly to avoid misunderstandings.

-

Post-Purchase Support and Warranty: Inquire about the warranty and post-purchase support offered by suppliers. Understanding the terms of support can provide peace of mind regarding product reliability and maintenance.

In conclusion, understanding the manufacturing processes and quality assurance practices for takoyaki makers is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions and ensure they are sourcing high-quality, reliable products that meet their business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘takoyaki maker’

When sourcing a takoyaki maker, it is essential to follow a structured approach to ensure you select the right equipment that meets your business needs. This guide provides a practical checklist to streamline your procurement process, focusing on key considerations for international B2B buyers.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for selecting the right takoyaki maker. Consider the capacity you require, which will depend on your anticipated volume of sales. For example, a machine that can produce 84 pieces per batch may be ideal for busy food service operations. Additionally, consider the power requirements (110V or 220V) based on your location and operational setup.

Step 2: Research Market Trends and Customer Preferences

Understanding market trends and customer preferences will guide your purchasing decision. Takoyaki’s popularity can vary by region, so assess local demand and potential menu integration. Conduct market research to identify preferred flavors and variations, which can influence the type of machine you choose, such as those capable of cooking different types of snacks beyond takoyaki.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is essential. Request comprehensive company profiles, including years in business, client testimonials, and case studies relevant to your industry. Ensure they have experience supplying to businesses in your region, as this can indicate their understanding of local regulations and customer expectations.

- Check for certifications: Verify that suppliers comply with international quality standards (e.g., ISO, CE) to ensure product safety and reliability.

- Assess after-sales support: Strong customer service and technical support can be invaluable for maintenance and troubleshooting.

Step 4: Compare Product Features and Pricing

Once you have shortlisted potential suppliers, compare the features and pricing of their takoyaki makers. Look for machines that offer adjustable temperature controls, non-stick surfaces, and ease of cleaning. These features can significantly enhance operational efficiency and product quality.

- Consider warranty terms: A longer warranty can provide peace of mind regarding the machine’s durability and the supplier’s confidence in their product.

Step 5: Request Samples or Demonstrations

Before making a bulk purchase, request samples or demonstrations of the takoyaki makers. This step allows you to evaluate the machine’s performance firsthand. Check for consistency in cooking results and ease of use, especially if your staff will be operating the equipment.

- Test various recipes: Use different batters and fillings to assess the machine’s versatility and ability to meet your menu requirements.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate favorable terms and conditions. Discuss payment terms, delivery timelines, and return policies to ensure they align with your business needs. Clarity on these aspects can help avoid potential disputes later on.

- Understand shipping costs: Factor in shipping and customs duties, particularly for international purchases, as these can impact your overall budget.

Step 7: Finalize Your Order and Monitor Delivery

After agreeing on the terms, finalize your order and monitor the delivery process. Ensure that the supplier provides tracking information and maintain communication regarding any potential delays. Once the equipment arrives, inspect it thoroughly to confirm that it meets your specifications.

By following this checklist, B2B buyers can make informed decisions when sourcing takoyaki makers, ultimately enhancing their operational capabilities and customer satisfaction.

Comprehensive Cost and Pricing Analysis for takoyaki maker Sourcing

What Are the Key Cost Components in Takoyaki Maker Manufacturing?

When analyzing the cost structure of takoyaki makers, several key components come into play. Understanding these can help international B2B buyers make informed sourcing decisions.

-

Materials: The primary materials for takoyaki makers typically include aluminum for the cooking plates and stainless steel for the body. High-quality nonstick coatings also add to the cost but are essential for ease of use and cleaning. The choice of materials directly impacts both durability and performance.

-

Labor: Labor costs can vary significantly depending on the manufacturing location. In countries with lower labor costs, such as some Southeast Asian nations, the overall production cost can be more favorable. However, it is essential to consider the skill level of the workforce, which affects the quality of the final product.

-

Manufacturing Overhead: This encompasses factory costs, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead costs, but buyers should be wary of overly low prices that may indicate compromised quality.

-

Tooling: For customized designs or larger production runs, tooling costs can be substantial. Buyers should consider whether they require standard models or specialized designs, as this will significantly affect the initial investment.

-

Quality Control (QC): Investing in stringent QC processes ensures that each unit meets international safety and quality standards. This may involve additional costs, but it ultimately leads to fewer returns and higher customer satisfaction.

-

Logistics: Shipping and handling costs can vary based on the destination and chosen Incoterms. For buyers in regions like Africa or South America, these costs may be higher due to distance and potential customs delays.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary widely based on competition, market demand, and the brand’s reputation.

How Do Pricing Influencers Impact Takoyaki Maker Costs?

Several factors can influence the pricing of takoyaki makers, particularly for B2B buyers looking to source these products internationally.

Illustrative image related to takoyaki maker

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit costs. Suppliers are generally more willing to negotiate prices for bulk orders, making it advantageous for businesses planning to resell or use multiple units.

-

Specifications and Customization: Customized takoyaki makers with specific features may come at a premium. Buyers should weigh the benefits of customization against potential cost increases.

-

Quality and Certifications: Higher-quality products often come with certifications that assure compliance with international safety standards. While these may increase upfront costs, they can reduce the Total Cost of Ownership (TCO) by minimizing returns and enhancing brand reputation.

-

Supplier Factors: The reliability and reputation of the supplier can significantly impact pricing. Established suppliers with a track record of quality may charge higher prices but offer better service and support.

-

Incoterms: The terms of shipping and delivery can greatly affect the final price. Buyers should carefully consider who bears the responsibility for shipping costs, insurance, and customs duties.

What Are the Best Practices for Negotiating Takoyaki Maker Prices?

For international B2B buyers, especially from diverse markets like Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant savings.

-

Research and Benchmarking: Understanding the market price range for takoyaki makers can provide leverage during negotiations. Buyers should gather quotes from multiple suppliers to establish a baseline.

-

Highlight Long-Term Relationships: Suppliers may be more willing to offer discounts or favorable terms to buyers who express intentions for ongoing business. Building a partnership can lead to better pricing over time.

-

Focus on Total Cost of Ownership: Emphasizing long-term value rather than just initial costs can help negotiate better terms. Discussing aspects like warranty, maintenance, and reliability can lead to a more favorable deal.

-

Be Open to Alternative Options: If a specific model is too costly, buyers should be prepared to consider alternative designs or features that may lower the price without sacrificing quality.

-

Understand Cultural Negotiation Styles: Different regions have unique negotiation styles. Adapting to the supplier’s culture can facilitate smoother discussions and more successful outcomes.

Conclusion

While indicative prices for takoyaki makers can vary widely, understanding the underlying cost components, pricing influencers, and negotiation strategies can empower international B2B buyers to make informed purchasing decisions. By focusing on quality, supplier reliability, and long-term value, businesses can secure favorable deals that enhance their operational efficiency and market competitiveness.

Alternatives Analysis: Comparing takoyaki maker With Other Solutions

When evaluating the best equipment for producing takoyaki, it’s essential to consider alternatives that could meet similar culinary needs. Each option presents unique benefits and drawbacks, influencing a buyer’s decision based on their operational requirements, budget constraints, and target market. Below, we compare the traditional takoyaki maker with two viable alternatives: an electric pancake maker and a commercial electric grill.

| Comparison Aspect | Takoyaki Maker | Electric Pancake Maker | Commercial Electric Grill |

|---|---|---|---|

| Performance | Specialized for takoyaki; heats quickly and evenly | Versatile; can make various shapes but less effective for takoyaki | High capacity; suitable for diverse cooking styles |

| Cost | $29.99 to $200 depending on features | $30 to $150 based on brand and features | $300 to $1,500 depending on size and capacity |

| Ease of Implementation | Simple setup; plug-and-play design | Easy to use; minimal training required | More complex installation; may require professional setup |

| Maintenance | Low maintenance; easy to clean | Moderate; cleaning plates can be tedious | Higher maintenance; requires regular cleaning and upkeep |

| Best Use Case | Ideal for dedicated takoyaki production | Suitable for diverse applications, including pancakes and more | Best for high-volume food service with varied menu items |

What are the Advantages and Disadvantages of Electric Pancake Makers?

Electric pancake makers offer versatility, allowing users to create various types of food, including pancakes and other batter-based snacks. This equipment is generally easy to operate and can appeal to a broader customer base. However, while they can produce spherical shapes, they may not achieve the authentic texture and flavor of traditional takoyaki. Additionally, the cooking process may take longer, as the temperature control is less precise compared to specialized takoyaki machines.

How Do Commercial Electric Grills Compare in Cooking Capacity?

Commercial electric grills stand out for their high capacity, making them ideal for businesses with high turnover rates. These grills can accommodate a range of foods, from meats to vegetables, providing flexibility in menu options. The downside is that they often require more maintenance and can involve a higher initial investment. Furthermore, they may not replicate the authentic cooking style of takoyaki, which could be a significant factor for businesses focused on Japanese cuisine.

How Can B2B Buyers Choose the Right Solution?

When deciding between a takoyaki maker and its alternatives, B2B buyers should assess their specific operational needs. Factors such as menu diversity, cooking volume, and budget will significantly influence the decision. For businesses primarily focused on Japanese street food, a dedicated takoyaki maker would be the most suitable choice, ensuring quality and authenticity. On the other hand, businesses that want to offer a varied menu might consider an electric pancake maker or a commercial grill for their versatility. Ultimately, understanding the target market and operational workflow will guide buyers to the right investment for their culinary aspirations.

Essential Technical Properties and Trade Terminology for takoyaki maker

What Are the Key Technical Properties of a Takoyaki Maker?

Understanding the technical specifications of a takoyaki maker is crucial for B2B buyers aiming to invest in kitchen equipment. Here are some essential properties to consider:

-

Material Grade

The material used in a takoyaki maker can significantly affect its durability and performance. High-grade stainless steel is commonly utilized for the body due to its resistance to rust and corrosion. Nonstick aluminum or Teflon-coated plates are favored for cooking surfaces, ensuring easy release of takoyaki and simplifying cleaning. For buyers, choosing machines made from quality materials means longer lifespan and lower maintenance costs. -

Heating Capacity and Temperature Control

A reliable takoyaki maker should have adjustable temperature settings to accommodate various cooking needs. Machines with multiple heating zones allow users to cook different foods simultaneously at optimal temperatures. This feature is vital for businesses, as it enables faster service and better quality control, enhancing customer satisfaction. -

Production Capacity

The number of takoyaki balls a machine can produce per cycle is a critical specification. High-capacity models can create dozens of pieces in a matter of minutes, which is especially beneficial for restaurants and food vendors. Understanding production capacity helps businesses estimate turnover rates and plan service accordingly, ensuring they meet customer demand during peak times. -

Power Supply Options

Takoyaki makers are available in various voltage specifications, such as 110V or 220V. It is essential for international buyers to confirm the appropriate voltage for their location to ensure compatibility with local power supplies. This aspect is vital for avoiding operational disruptions and ensuring compliance with local electrical standards. -

Nonstick Properties

The nonstick feature of cooking plates is essential for both ease of use and cleaning. It minimizes the need for excessive oil, promoting healthier cooking. Buyers should look for models that emphasize this property as it significantly impacts user experience and food quality.

What Are Common Trade Terms Related to Takoyaki Makers?

Familiarity with industry jargon can empower B2B buyers to navigate negotiations and purchasing processes more effectively. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of takoyaki makers, buyers may engage with OEMs to create custom machines tailored to specific needs, which can be beneficial for branding and differentiation in competitive markets. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for businesses, particularly startups or small enterprises, as it helps in assessing budget requirements and inventory management strategies. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to provide pricing and terms for a specific order. Crafting a detailed RFQ can facilitate better negotiations and ensure that all necessary specifications are communicated, leading to more accurate quotations. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with these terms can help businesses understand shipping costs, risks, and responsibilities, which is particularly important for international buyers importing takoyaki machines from overseas manufacturers. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead time is essential for inventory planning and ensuring that businesses can meet customer demand without delay.

By grasping these technical properties and trade terminology, international B2B buyers can make informed decisions, enhancing their purchasing strategies and optimizing operations in their respective markets.

Navigating Market Dynamics and Sourcing Trends in the takoyaki maker Sector

What Are the Key Drivers and Trends Influencing the Takoyaki Maker Market?

The global takoyaki maker market is experiencing robust growth, driven by the increasing popularity of Japanese cuisine worldwide. As international consumers become more adventurous with their food choices, the demand for authentic cooking appliances, such as takoyaki makers, is rising. This trend is particularly evident in regions like Africa, South America, the Middle East, and Europe, where culinary diversification is becoming a norm. B2B buyers in these regions can capitalize on this trend by sourcing high-quality takoyaki machines that cater to local tastes and preferences.

Technological advancements are also reshaping the market. Modern takoyaki makers now feature enhanced functionalities, such as temperature control, non-stick surfaces, and energy-efficient designs. These innovations not only improve cooking efficiency but also enhance the user experience. For international B2B buyers, sourcing machines equipped with advanced technology can provide a competitive edge in the marketplace. Additionally, the emergence of e-commerce platforms has streamlined the procurement process, allowing buyers to access a wider range of products and suppliers globally.

Moreover, the trend towards customization is gaining momentum. Buyers are increasingly seeking equipment that can accommodate diverse cooking styles and recipes, enabling them to offer unique culinary experiences. This trend is especially relevant for businesses looking to cater to niche markets or those focused on fusion cuisine. Understanding these dynamics can empower B2B buyers to make informed decisions that align with market demands.

How Is Sustainability and Ethical Sourcing Shaping the Takoyaki Maker Industry?

Sustainability and ethical sourcing are becoming pivotal considerations in the takoyaki maker sector. As environmental concerns grow, manufacturers are increasingly under pressure to adopt sustainable practices. This includes the use of eco-friendly materials in production, such as recyclable metals and non-toxic coatings. For B2B buyers, sourcing takoyaki makers made from sustainable materials not only aligns with consumer demand for responsible products but also enhances brand reputation.

Incorporating sustainability into the supply chain is essential for long-term viability. Buyers should prioritize suppliers who demonstrate a commitment to ethical sourcing practices, such as fair labor conditions and transparent supply chains. Certifications, such as ISO 14001 for environmental management, can help buyers identify responsible manufacturers. Additionally, the use of energy-efficient appliances can significantly reduce the carbon footprint, appealing to environmentally conscious consumers.

Investing in sustainable products can also lead to cost savings in the long run. Energy-efficient takoyaki makers can lower operational costs, while durable materials reduce the need for frequent replacements. By prioritizing sustainability, B2B buyers can differentiate themselves in a crowded market, attract new customers, and contribute to global efforts towards environmental preservation.

What Is the Historical Context of the Takoyaki Maker’s Evolution?

The takoyaki maker, originating from Japan in the early 20th century, has evolved significantly over the decades. Initially designed for street vendors, these machines were simple, cast-iron plates that relied on manual flipping techniques. Over time, with advancements in technology and the globalization of culinary practices, the takoyaki maker has transformed into a sophisticated kitchen appliance.

In the 1980s and 1990s, the rise of Japanese cuisine in global markets spurred innovations in design and functionality. Modern takoyaki makers now incorporate features such as electric heating, non-stick surfaces, and temperature control, making them accessible and user-friendly for home cooks and commercial establishments alike. This evolution reflects broader trends in consumer preferences, where convenience and quality are paramount.

As international B2B buyers explore opportunities in the takoyaki maker sector, understanding this historical context can provide valuable insights into current market dynamics and future trends. Recognizing the heritage of this culinary tool can also inform branding and marketing strategies that resonate with consumers seeking authenticity in their culinary experiences.

Frequently Asked Questions (FAQs) for B2B Buyers of takoyaki maker

-

How do I choose the right takoyaki maker for my business?

When selecting a takoyaki maker, consider factors like capacity, heating efficiency, and ease of cleaning. For larger operations, opt for machines with multiple plates to increase production, such as those that can cook 84 pieces at once. Ensure the machine has adjustable temperature controls to accommodate different recipes and cooking styles. Additionally, evaluate the materials used in construction—stainless steel bodies and non-stick plates often provide durability and better performance. -

What are the key features to look for in a commercial takoyaki maker?

Look for features that enhance usability and efficiency, such as adjustable temperature settings for precise cooking, non-stick surfaces for easy food release, and robust construction for long-term use. A model with multiple cooking plates can significantly boost output, which is vital for busy establishments. Also, consider safety features, such as heat-resistant handles and automatic shut-off functions, to protect staff during operation. -

What is the typical minimum order quantity (MOQ) for takoyaki makers?

Minimum order quantities vary by supplier but typically range from 10 to 50 units for commercial-grade takoyaki makers. Some suppliers may offer lower MOQs for smaller businesses or initial trial orders. It’s essential to communicate your needs clearly to suppliers, as they may provide flexibility based on your purchasing capabilities and the potential for future orders. -

How can I verify the reliability of a takoyaki maker supplier?

To verify a supplier’s reliability, check for reviews and testimonials from previous buyers. Request references and look for certifications that indicate compliance with international safety and quality standards. Additionally, consider visiting the supplier’s manufacturing facility if feasible, or request product samples to assess quality firsthand. Engaging in direct communication can also help gauge their responsiveness and willingness to meet your business needs. -

What are common payment terms when sourcing takoyaki makers internationally?

Payment terms can vary but typically include options like 30% upfront deposit and 70% upon shipment. Some suppliers may offer net terms for established businesses, allowing payment after delivery. It’s crucial to clarify payment methods accepted (e.g., bank transfer, credit card) and any potential fees for international transactions. Always ensure you have a written agreement outlining the terms to avoid misunderstandings. -

What logistics considerations should I keep in mind when importing takoyaki makers?

When importing takoyaki makers, consider shipping methods, customs duties, and delivery timelines. Work with reliable logistics partners who specialize in international shipping to ensure smooth transport. Familiarize yourself with import regulations and potential tariffs in your country, as these can impact overall costs. Additionally, have a plan for handling any delays or issues that may arise during customs clearance. -

How do I ensure quality assurance for my takoyaki makers?

Implement a quality assurance process by requesting product specifications and certifications from your supplier. Conduct thorough inspections of products upon arrival, checking for defects and performance issues. Establish a clear return policy with your supplier to address any quality concerns promptly. Consider using third-party inspection services for larger orders to ensure compliance with your quality standards. -

Can I customize my takoyaki maker orders?

Many suppliers offer customization options, such as branding or specific design features tailored to your business needs. Discuss your requirements with potential suppliers to understand their capabilities and any associated costs. Customization might involve minimum order quantities, so it’s essential to factor this into your planning. Additionally, ensure that any customized features do not compromise the machine’s performance and safety.

Top 5 Takoyaki Maker Manufacturers & Suppliers List

1. Reddit – Electric Takoyaki Maker

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Electric takoyaki maker, used successfully 10 times, ideal for making simplified takoyaki with imitation crab meat, convenient for breakfast, allows cooking at the dining table, easier than cast iron versions.

2. Facebook – Takoyaki Maker Test

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Takoyaki Maker Test, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

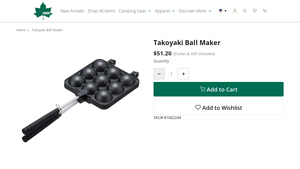

3. Logos Global – Takoyaki Ball Maker

Domain: logos-global.com

Registered: 2023 (2 years)

Introduction: Product Name: Takoyaki Ball Maker

Price: $51.20 (Duties & VAT included)

SKU: 81062244

Key Features:

– Great for outdoor use, adds variety to camp cooking.

– Can cook not only takoyaki but also baby sponge cakes, grilled rice balls, and more.

– Easy to clean with silicon resin coating to prevent food sticking.

– Top and bottom can be separated for easy washing.

– Detachable handle for compact stora…

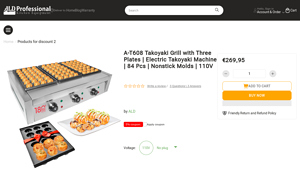

4. ALDKitchen – Electric Takoyaki Grill

Domain: ald.kitchen

Introduction: ALDKitchen Takoyaki Grill with Three Plates | Electric Takoyaki Machine | 84 Pcs | Nonstick | Stainless Steel

5. Iwatani – Non-Stick Takoyaki Grill Pan

Domain: foodtoursjapan.com

Registered: 2015 (10 years)

Introduction: 1. Iwatani Non-Stick Takoyaki Grill Pan CB-P-TAF:

– Makes 16 regular-sized 1.6″/40mm takoyaki balls

– Non-stick coating

– Designed for stove-top cooking

– Dimensions: W 10.2″/260mm x D 8.2″/210mm x H 1.5″/39mm

– Weight: 1.6lb/730g

2. Iwatani Takoyaki Pan and Gas Stove Super Entako CB-ETK1:

– Makes 20 regular-sized 1.6″/40mm takoyaki balls

– Gas-powered

– Dimension…

Strategic Sourcing Conclusion and Outlook for takoyaki maker

In today’s competitive food service landscape, strategic sourcing of takoyaki makers offers significant advantages for international B2B buyers. By investing in high-quality, versatile machines—such as those with adjustable temperature controls and multiple cooking plates—businesses can enhance their menu offerings and boost customer satisfaction. The ability to produce a variety of popular snacks, like takoyaki and other ball-shaped delicacies, allows vendors to cater to diverse culinary preferences, thereby driving sales and increasing foot traffic.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for innovative and efficient cooking equipment is on the rise. Sourcing takoyaki makers that combine durability with user-friendly features can lead to improved operational efficiency and reduced labor costs. Additionally, considering suppliers with robust return policies and support services ensures peace of mind when making investment decisions.

Illustrative image related to takoyaki maker

Looking ahead, the potential for growth in the street food and casual dining sectors presents an exciting opportunity for B2B buyers. By strategically sourcing the right equipment now, businesses can position themselves as leaders in culinary innovation. Take the next step to explore reliable suppliers and elevate your food offerings with top-tier takoyaki makers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to takoyaki maker