Is Your Three Way Solenoid Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for three way solenoid

In today’s dynamic industrial landscape, sourcing the right three-way solenoid valves can be a daunting task for B2B buyers, particularly those operating across diverse markets in Africa, South America, the Middle East, and Europe. As automation becomes increasingly critical in various sectors, the challenge lies not only in selecting the appropriate valve types but also in ensuring compatibility with specific applications—be it fluid control, gas management, or other specialized functions. This comprehensive guide addresses these challenges head-on, offering insights into the different types of three-way solenoid valves, their applications, and essential criteria for supplier vetting.

Throughout this guide, we delve into the intricacies of three-way solenoid valves, including their operational mechanisms, variations in design, and the importance of material compatibility for various media. We also explore cost considerations, helping buyers navigate budget constraints while ensuring quality. Additionally, the guide emphasizes best practices for evaluating suppliers, which is crucial for maintaining reliability and performance in critical operations.

By empowering international B2B buyers with actionable insights and detailed information, this guide serves as a vital resource for making informed purchasing decisions. Whether you’re in Germany, Nigeria, or any other global market, understanding the nuances of three-way solenoid valves can enhance operational efficiency and lead to successful project outcomes.

Understanding three way solenoid Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Normally Closed 3-Way Solenoid | Exhaust port is closed when de-energized; commonly used. | Fluid control in automation systems | Pros: Reliable, prevents backflow. Cons: Limited flow direction options. |

| Normally Open 3-Way Solenoid | Inlet port is open when de-energized; used for specific applications. | Air and gas control in HVAC systems | Pros: Immediate flow when power is off. Cons: Not suitable for all applications. |

| Universal 3-Way Solenoid | Can be configured as normally open or closed; versatile. | Diverse applications in manufacturing | Pros: Flexible, adaptable to various systems. Cons: Complexity in selection and configuration. |

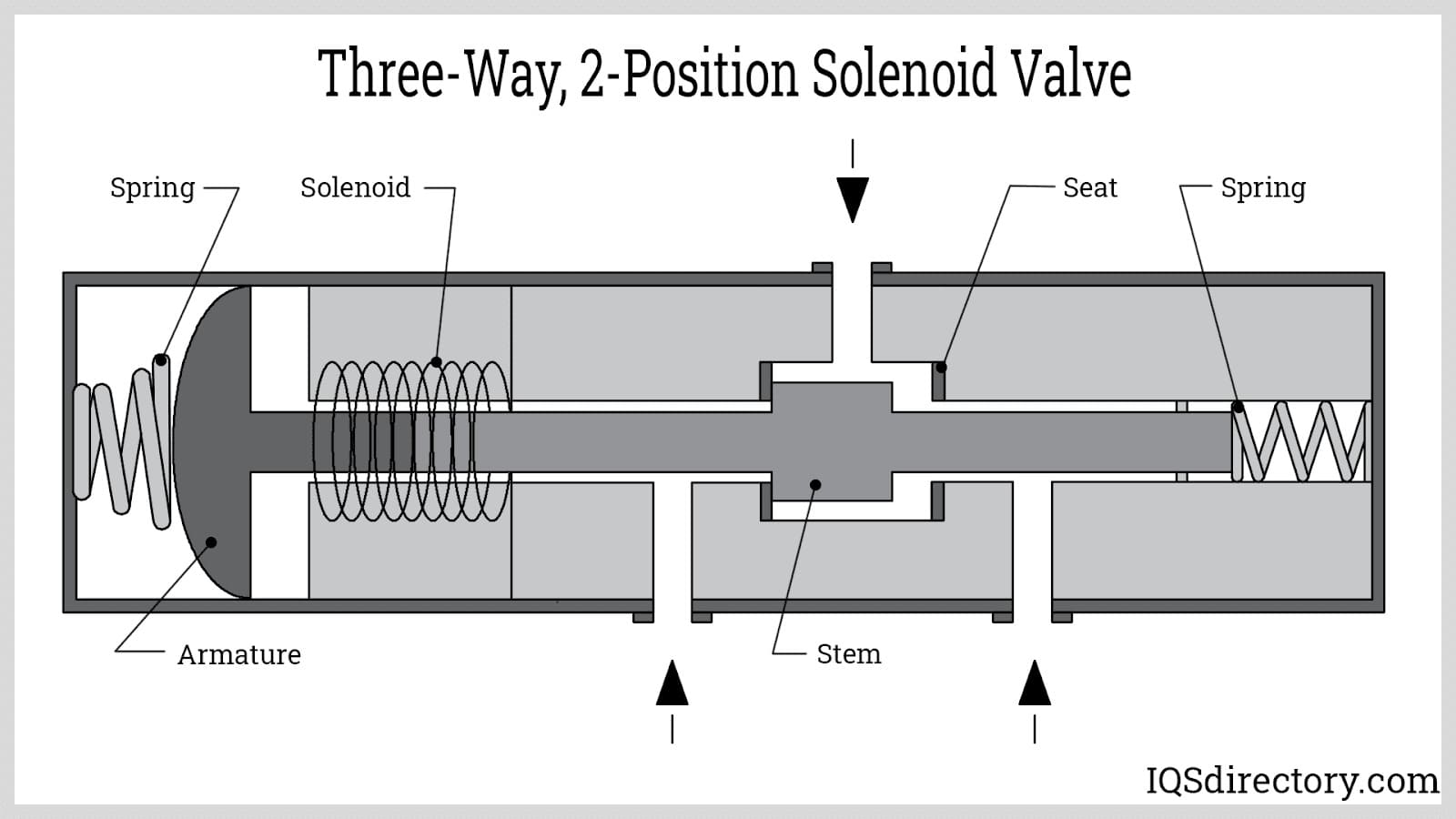

| Direct-Acting 3-Way Solenoid | Operates directly with minimal delay; suitable for quick response needs. | Automotive and industrial applications | Pros: Quick actuation, compact design. Cons: May not handle high flow rates efficiently. |

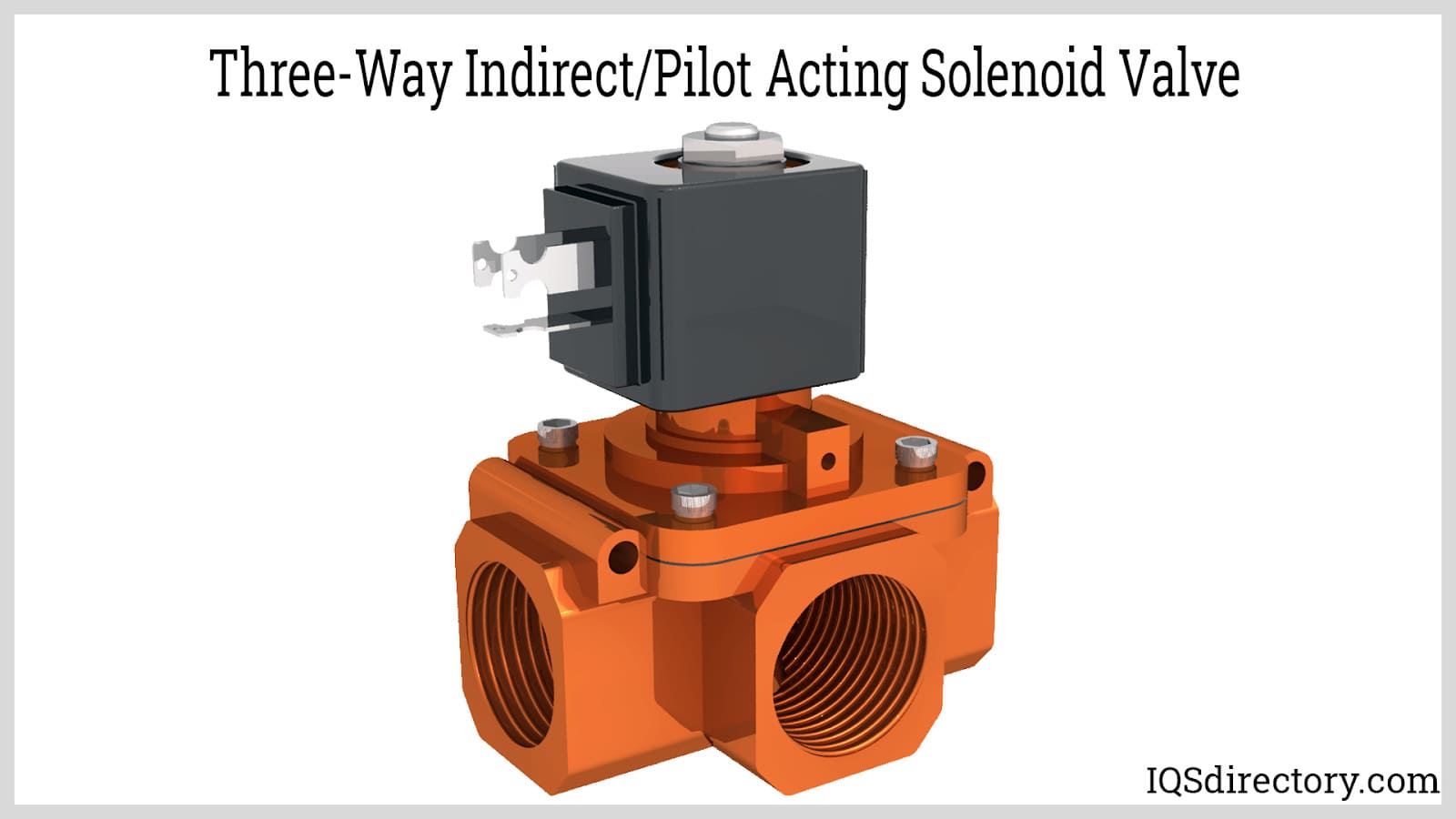

| Pilot-Operated 3-Way Solenoid | Requires a pilot signal for operation; ideal for larger flows. | Heavy machinery and large-scale systems | Pros: Handles larger volumes, energy-efficient. Cons: More complex installation and maintenance. |

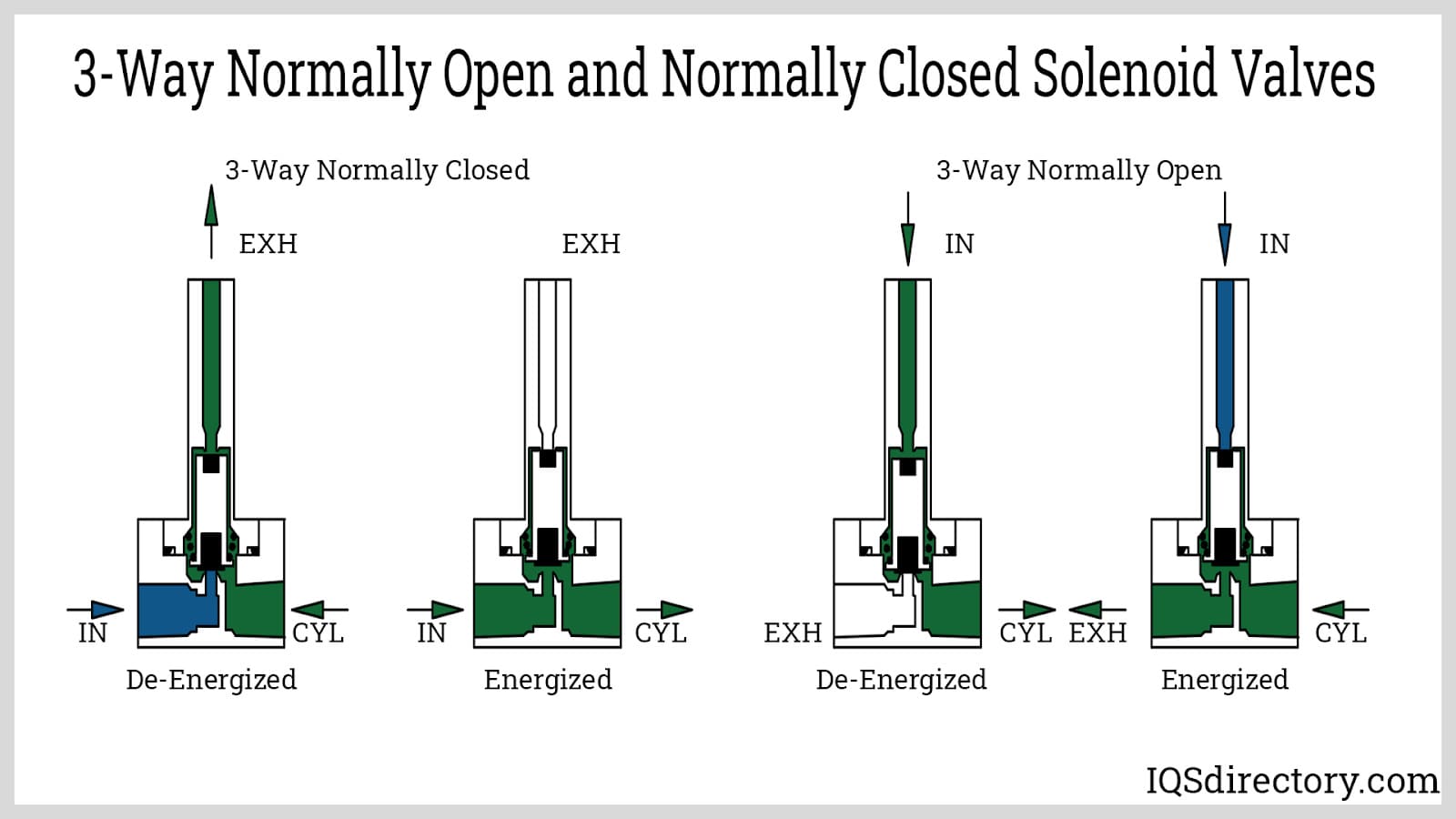

What Are the Key Characteristics of Normally Closed 3-Way Solenoids?

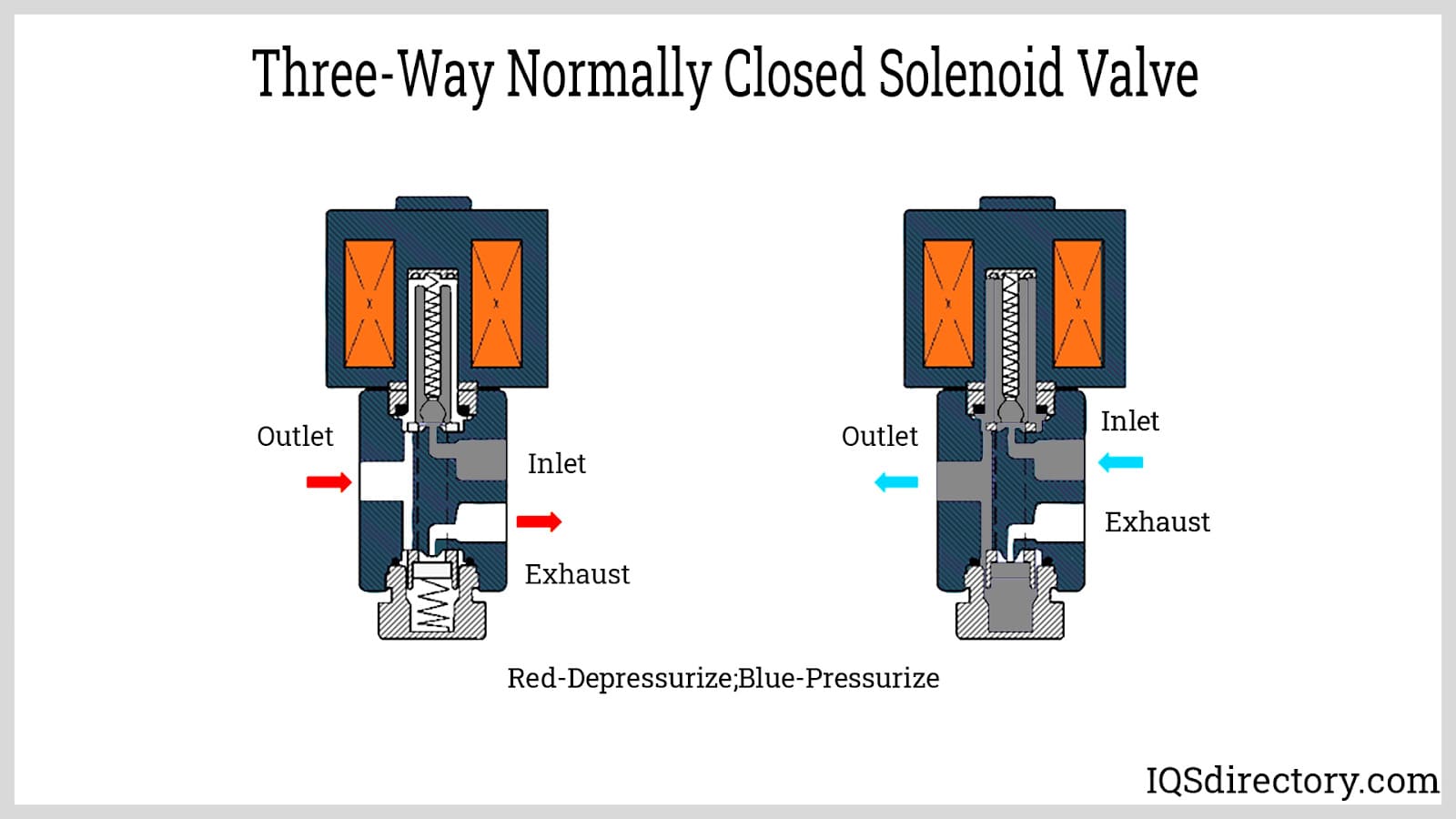

Normally closed 3-way solenoids are designed to keep the exhaust port closed when de-energized, making them ideal for applications requiring reliable fluid control. These valves are commonly used in automation systems to prevent backflow and ensure safety. Buyers should consider the specific media compatibility and the valve’s pressure ratings when selecting this type, as these factors can influence overall system performance.

How Do Normally Open 3-Way Solenoids Function?

In contrast to normally closed variants, normally open 3-way solenoids maintain an open inlet port when de-energized. This design is particularly useful for applications in HVAC systems where air or gas needs to flow freely when the system is inactive. Buyers should assess the operational environment and potential media corrosiveness to ensure the valve materials are suitable for their specific needs.

What Makes Universal 3-Way Solenoids a Versatile Choice?

Universal 3-way solenoids can be configured as either normally open or normally closed, providing significant flexibility for diverse applications. This adaptability makes them a favorite among manufacturers who require a single solution for varying operational needs. However, buyers should be aware of the complexity involved in selecting the right configuration, as improper setup can lead to inefficiencies.

What Are the Advantages of Direct-Acting 3-Way Solenoids?

Direct-acting 3-way solenoids are known for their quick response times, making them suitable for applications that require immediate actuation, such as in automotive or industrial environments. Their compact design allows for easy integration into tight spaces. Buyers should consider the valve’s flow rate capabilities, as they may not perform well under high-volume conditions.

Why Choose Pilot-Operated 3-Way Solenoids for Heavy Machinery?

Pilot-operated 3-way solenoids are engineered to handle larger flow volumes, making them ideal for heavy machinery and large-scale systems. They operate using a pilot signal, which can enhance energy efficiency and reduce wear. Buyers should factor in the complexity of installation and maintenance, as these systems may require more extensive setup and oversight compared to simpler solenoid types.

Key Industrial Applications of three way solenoid

| Industry/Sector | Specific Application of three way solenoid | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Fluid control in automated assembly lines | Enhances efficiency and precision in production | Ensure compatibility with various media and pressure ratings. |

| Agriculture | Irrigation systems for precise water distribution | Optimizes water usage and crop yield | Evaluate environmental conditions and material resilience. |

| Oil & Gas | Control of gas and oil flow in pipelines | Improves safety and operational reliability | Focus on durability and resistance to corrosive environments. |

| Food & Beverage | Automation in bottling and packaging processes | Increases speed and reduces waste | Compliance with food safety standards and material certifications. |

| Pharmaceuticals | Fluid transfer in production processes | Ensures accuracy and minimizes contamination risks | Verify compatibility with specific chemicals and sterilization processes. |

How is a Three Way Solenoid Used in Manufacturing?

In the manufacturing sector, three-way solenoids are integral for controlling fluid flow in automated assembly lines. These valves can efficiently manage the distribution of lubricants, coolants, or other fluids necessary for machinery operation. By automating these processes, businesses can achieve higher production rates and reduce human error. For international buyers, sourcing solenoids that meet specific pressure ratings and fluid compatibility is crucial, especially when dealing with varying environmental standards across regions like Africa and Europe.

What Role Does a Three Way Solenoid Play in Agriculture?

In agriculture, three-way solenoids are utilized in irrigation systems to control the precise distribution of water to crops. This automation allows farmers to optimize water usage, reduce waste, and ultimately increase crop yields. Buyers in regions with variable climate conditions, such as South America, should consider solenoids that can withstand harsh weather and ensure reliable operation under different soil moisture levels.

How are Three Way Solenoids Used in Oil & Gas?

The oil and gas industry relies on three-way solenoids to control the flow of gases and liquids through pipelines. These valves are essential for maintaining safety and operational efficiency, as they can quickly shut off or redirect flow in case of emergencies. When sourcing these components, businesses must prioritize durability and resistance to corrosive substances, particularly in regions like the Middle East where environmental conditions can be extreme.

What is the Importance of Three Way Solenoids in Food & Beverage?

In the food and beverage industry, three-way solenoids are critical for automating bottling and packaging processes. These valves help regulate the flow of liquids, ensuring that operations run smoothly and efficiently. For B2B buyers, compliance with food safety standards is paramount, so sourcing solenoids made from food-grade materials is essential to avoid contamination and ensure quality.

Why are Three Way Solenoids Vital in Pharmaceuticals?

In pharmaceutical manufacturing, three-way solenoids are used for fluid transfer in various production processes. Their precision is vital in maintaining the integrity of sensitive substances, reducing contamination risks. Buyers in this sector should focus on solenoids that can handle specific chemicals safely and are compliant with sterilization processes, ensuring that they meet stringent industry regulations.

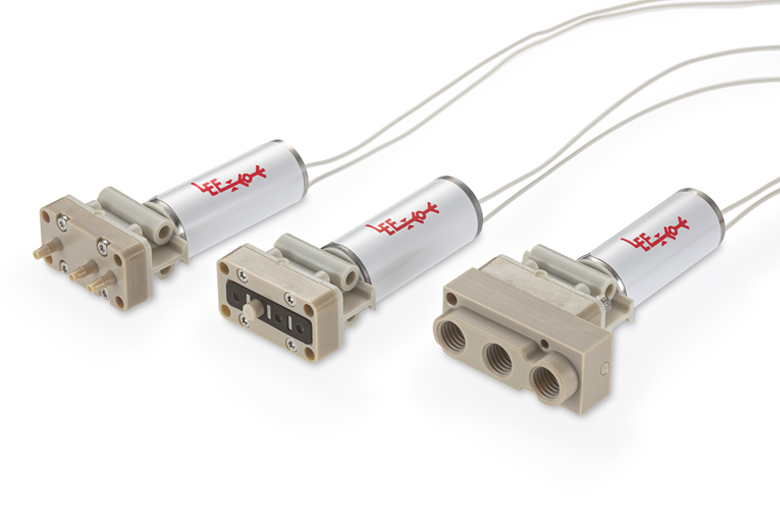

Illustrative image related to three way solenoid

3 Common User Pain Points for ‘three way solenoid’ & Their Solutions

Scenario 1: Difficulty in Sizing the Right Three-Way Solenoid Valve

The Problem: Many B2B buyers struggle with selecting the correct size of three-way solenoid valves for their specific applications. This challenge often arises from a lack of understanding of the system requirements, leading to potential issues such as improper fit, inadequate flow rates, or valve failure. When the wrong size is selected, it can result in costly downtime, increased operational expenses, and delays in project timelines.

The Solution: To effectively address sizing issues, B2B buyers should first conduct a comprehensive assessment of their system requirements, including flow rates, pressure levels, and the type of media being controlled. Consulting with technical experts from valve manufacturers can provide invaluable insights. It’s also advisable to refer to detailed sizing charts and technical specifications provided by suppliers. For instance, understanding the flow coefficient (Cv) of the valve can help in determining the appropriate size for optimal performance. Utilizing simulation tools or software for hydraulic analysis may further aid in making informed decisions. Additionally, establishing a direct line of communication with suppliers can facilitate discussions around custom sizing options, ensuring that the chosen solenoid valve aligns perfectly with operational needs.

Scenario 2: Compatibility Issues with Media

The Problem: Compatibility between the three-way solenoid valve materials and the media they control is a common concern for buyers. Using the wrong material can lead to corrosion, leaks, and ultimately, valve failure. This is particularly critical in industries dealing with aggressive chemicals, where material incompatibility can not only disrupt operations but also pose safety risks.

The Solution: B2B buyers should prioritize thorough research into the materials used in three-way solenoid valves, particularly in relation to the fluids or gases involved in their applications. Consulting chemical compatibility charts and engaging with manufacturers can help clarify which materials (such as stainless steel, brass, or plastic) are suitable for specific chemicals. Additionally, buyers should consider the environmental conditions (like temperature and pressure) that the valve will be subjected to, as these factors can significantly influence material performance. If uncertain, seeking advice from a chemical engineer or a materials specialist can provide further assurance. Investing in high-quality, industry-approved valves that are explicitly designed for chemical handling can mitigate risks and enhance operational reliability.

Scenario 3: Challenges with Installation and Maintenance

The Problem: Installation and maintenance of three-way solenoid valves can be a daunting task for many buyers, especially those who lack technical expertise. Improper installation may lead to malfunctioning systems, increased wear and tear, and higher maintenance costs. Additionally, buyers often find it challenging to maintain these valves, particularly in systems that require frequent adjustments or troubleshooting.

Illustrative image related to three way solenoid

The Solution: To overcome installation and maintenance challenges, B2B buyers should seek comprehensive installation guides and maintenance manuals provided by manufacturers. Training sessions or workshops offered by suppliers can also be beneficial, as they can equip staff with the necessary skills to handle installation and routine maintenance effectively. Furthermore, utilizing modular designs that allow for easy access to the valve components can simplify maintenance tasks. Establishing a regular maintenance schedule, including inspections and cleaning, will ensure that valves remain in optimal working condition. For more complex systems, buyers may want to consider hiring a qualified technician or engineer to oversee installation and maintenance, ensuring that best practices are followed to minimize the risk of operational issues.

Strategic Material Selection Guide for three way solenoid

What Are the Key Materials Used in Three Way Solenoid Valves?

When selecting a three-way solenoid valve, the choice of material is critical as it directly influences performance, durability, and application suitability. Below, we analyze four common materials used in the construction of three-way solenoid valves, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does Brass Perform in Three Way Solenoid Valves?

Brass is a widely used material for three-way solenoid valves due to its excellent machinability and corrosion resistance in non-corrosive environments. It typically has a temperature rating of up to 200°C and can withstand moderate pressures.

Pros: Brass valves are durable and relatively cost-effective, making them a popular choice for applications involving water and air. They are easy to manufacture and can be produced in various sizes.

Cons: Brass is not suitable for aggressive chemicals or high-temperature applications beyond its rating. Additionally, it can corrode when exposed to certain media, such as chlorinated water.

Impact on Application: Brass valves are ideal for general-purpose applications but should be avoided in chemical processing or environments with high chloride levels.

Considerations for International Buyers: Compliance with standards such as ASTM B36 for brass alloys is essential. Buyers in regions like Europe may prefer valves that meet DIN standards for quality assurance.

What Are the Benefits of Stainless Steel in Three Way Solenoid Valves?

Stainless steel is favored for its superior strength and corrosion resistance, making it suitable for harsh environments. It typically supports higher temperature and pressure ratings, often exceeding 200°C and 200 psi.

Pros: Stainless steel valves are highly durable and resistant to rust and corrosion, which makes them ideal for chemical and high-temperature applications. Their longevity reduces replacement frequency, offering long-term cost savings.

Cons: The manufacturing process for stainless steel valves can be more complex and costly than brass. Additionally, they may be heavier, which could impact installation in some applications.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive liquids and gases, making it suitable for industries like pharmaceuticals and food processing.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A312 for stainless steel pipes. In regions like Africa and South America, the availability of stainless steel may vary, impacting procurement timelines.

How Does Plastic Compare in Three Way Solenoid Valve Applications?

Plastic materials, such as PVC and polypropylene, are increasingly used in three-way solenoid valves, especially for applications involving corrosive chemicals. They generally have lower temperature ratings, often around 60°C.

Pros: Plastic valves are lightweight, resistant to corrosion, and cost-effective, making them suitable for various applications, including water treatment and chemical processing.

Illustrative image related to three way solenoid

Cons: The lower temperature and pressure ratings limit their use in high-demand applications. Additionally, plastic can be less durable than metal options, leading to shorter lifespans in some environments.

Impact on Application: Plastic valves are ideal for handling aggressive chemicals but may not perform well in high-temperature or high-pressure scenarios.

Considerations for International Buyers: Compliance with standards such as ASTM D1784 for PVC is crucial. Buyers in the Middle East should consider the effects of extreme temperatures on plastic materials.

What Role Does Aluminum Play in Three Way Solenoid Valve Design?

Aluminum offers a balance between weight and strength, making it a suitable material for three-way solenoid valves in various applications. It typically supports moderate temperature and pressure ratings.

Pros: Aluminum is lightweight, resistant to corrosion, and offers good thermal conductivity, making it suitable for diverse applications. Its cost is generally lower than stainless steel.

Cons: While aluminum is corrosion-resistant, it may not withstand harsh chemical environments as effectively as stainless steel or specialized plastics.

Impact on Application: Aluminum valves are suitable for air and water applications but may not be ideal for corrosive media.

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum alloys is important. Buyers in Europe may have specific preferences for aluminum grades that meet EU regulations.

Summary Table of Material Properties

| Material | Typical Use Case for three way solenoid | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | General-purpose applications | Cost-effective and easy to manufacture | Not suitable for aggressive chemicals | Low |

| Stainless Steel | Chemical and high-temperature applications | High durability and corrosion resistance | Higher manufacturing complexity and cost | High |

| Plastic | Corrosive chemical handling | Lightweight and cost-effective | Limited temperature and pressure ratings | Low |

| Aluminum | Air and water applications | Lightweight and good thermal conductivity | Less effective in harsh chemical environments | Medium |

This guide provides a comprehensive overview of material selection for three-way solenoid valves, helping international buyers make informed decisions based on specific application needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for three way solenoid

What Are the Main Stages of Manufacturing a Three-Way Solenoid Valve?

The manufacturing process for three-way solenoid valves involves several critical stages, each designed to ensure product reliability and performance. Understanding these stages can help international B2B buyers evaluate suppliers effectively.

Material Preparation: What Materials Are Used and How Are They Prepared?

The first stage in manufacturing three-way solenoid valves is material preparation. Common materials include brass, stainless steel, and various polymers, depending on the application and the media being controlled. Materials are sourced from certified suppliers to ensure quality.

During preparation, raw materials undergo inspection to verify they meet specified standards. This includes checking for chemical composition, mechanical properties, and surface finish. Materials that do not meet these criteria are rejected, ensuring that only high-quality components proceed to the next stage.

How Are the Components Formed and Shaped?

The forming process typically involves techniques such as machining, casting, and forging, depending on the material and design specifications. Machining is a common method used for precise shaping of valve bodies, while casting may be employed for more complex geometries.

Illustrative image related to three way solenoid

Precision is crucial during this stage, as any inaccuracies can affect the valve’s functionality. CNC (Computer Numerical Control) machines are often used to achieve the required tolerances. This technology allows for repeatable and high-precision manufacturing, which is essential for the performance of solenoid valves.

What Is Involved in the Assembly Process?

After forming, the components are assembled. This stage includes fitting the solenoid coil, valve body, seals, and actuator together. Assembly is typically performed in a controlled environment to minimize contamination and ensure the integrity of the components.

Automated assembly lines may be used to enhance efficiency, but manual assembly is also common for more complex valves. Quality checks are integrated throughout the assembly process to catch defects early, reducing the risk of faulty products reaching the market.

Illustrative image related to three way solenoid

How Is Finishing Handled to Ensure Quality?

The finishing process involves surface treatment and coating to enhance durability and resistance to corrosion. Common finishing techniques include anodizing, plating, or applying protective paints. This not only improves the aesthetic appeal but also extends the valve’s lifespan.

Finishing is closely monitored to ensure compliance with industry standards. For instance, solenoid valves used in food processing must meet stringent health and safety regulations, while those used in chemical applications may require specialized coatings to resist aggressive substances.

What Quality Assurance Standards Are Applicable to Three-Way Solenoid Valves?

Quality assurance (QA) is integral to the manufacturing process of three-way solenoid valves. Buyers should be aware of the relevant international and industry-specific standards that govern quality.

Which International Standards Should Buyers Consider?

ISO 9001 is the most recognized quality management standard globally. It emphasizes a process approach to quality management, encouraging continuous improvement and customer satisfaction. Manufacturers who are ISO 9001 certified have demonstrated their commitment to quality management systems, which is crucial for B2B buyers looking for reliable suppliers.

Additionally, certifications such as CE mark for European markets and API (American Petroleum Institute) standards for oil and gas applications are important. These certifications ensure that the products meet specific regulatory requirements and safety standards, providing buyers with confidence in their purchases.

Illustrative image related to three way solenoid

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials for compliance with specifications before they are used in production.

-

In-Process Quality Control (IPQC): During manufacturing, various tests are conducted at different stages to ensure that components meet the required standards. This can include dimensional checks and functional tests.

-

Final Quality Control (FQC): Once assembly is complete, a final inspection ensures that the product meets all specifications and standards. Functional testing of the solenoid valve is a crucial part of FQC, where the valve’s performance is assessed under operational conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying the quality control practices of suppliers is essential for ensuring product reliability and compliance with standards.

What Methods Can Be Used to Assess Supplier QC?

Buyers can employ several methods to evaluate a supplier’s quality assurance processes:

-

Supplier Audits: Conducting on-site audits allows buyers to observe the manufacturing processes, quality control measures, and compliance with international standards firsthand.

-

Quality Reports: Requesting detailed quality assurance reports from suppliers can provide insights into their QC processes, including testing results and compliance with certifications.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of a supplier’s quality control practices. These inspections often include testing samples from production runs to ensure they meet specified standards.

What Are the QC and Certification Nuances for International Buyers?

B2B buyers from diverse regions, such as Africa, South America, the Middle East, and Europe, may encounter specific challenges regarding quality assurance and certifications.

How Do Regional Standards Impact Purchasing Decisions?

Different regions may have varying standards and regulations regarding solenoid valves. For example, European buyers may prioritize CE certification, while buyers in the Middle East might focus on compliance with local standards. Understanding these nuances is crucial for making informed purchasing decisions.

Moreover, some regions may have limited access to certain certifications or third-party inspection services. Buyers should ensure that suppliers can provide the necessary documentation and proof of compliance to facilitate smooth transactions and avoid regulatory issues.

Conclusion: Why Is a Comprehensive Understanding of Manufacturing and QC Essential?

A thorough understanding of the manufacturing processes and quality assurance standards for three-way solenoid valves is vital for B2B buyers. By knowing what to look for in suppliers, buyers can ensure they receive high-quality products that meet their specific requirements and adhere to international standards. This knowledge not only aids in making informed purchasing decisions but also fosters long-term partnerships with reliable manufacturers.

Illustrative image related to three way solenoid

Practical Sourcing Guide: A Step-by-Step Checklist for ‘three way solenoid’

To assist B2B buyers in procuring three-way solenoids effectively, this guide offers a structured checklist. Each step aims to ensure that your sourcing process is thorough and aligns with your specific operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for ensuring that the solenoid valve meets your operational requirements. Consider factors such as the media (liquid or gas), pressure ratings, temperature ranges, and flow rates. Be specific about connection types and sizes, as these will affect compatibility with existing systems.

Step 2: Research Market Trends and Applications

Understanding current market trends helps you identify the best solutions for your needs. Research how different industries utilize three-way solenoids, including manufacturing, automotive, and food processing. This insight can guide you in selecting a valve that is not only suitable but also innovative, improving efficiency and performance in your applications.

Step 3: Evaluate Potential Suppliers

Before making any commitments, vet potential suppliers thoroughly. Request comprehensive company profiles, including their experience in the industry, product certifications, and customer testimonials. Look for suppliers who have successfully delivered to clients in your region or industry, as this can indicate reliability and understanding of local standards.

Step 4: Verify Product Quality and Standards

Quality assurance is paramount when sourcing solenoid valves. Ensure that the products meet international standards, such as ISO or CE certifications, which can indicate adherence to quality management systems. Request samples or detailed specifications to assess the materials used and the valve’s operational reliability.

Step 5: Check Compatibility with Your Systems

Compatibility is a vital consideration when sourcing three-way solenoids. Verify that the solenoids can integrate seamlessly with your existing systems, including electrical and mechanical interfaces. Consult with your engineering team to confirm that the specifications align with your current setups and future scalability needs.

Step 6: Assess After-Sales Support and Warranty

After-sales support can significantly impact your operational efficiency. Inquire about warranty terms, technical support availability, and maintenance services. A supplier that offers comprehensive support can help minimize downtime and ensure that your systems operate smoothly.

Step 7: Request and Compare Quotes

Finally, gather quotes from multiple suppliers to compare pricing and terms. Look beyond just the upfront cost; consider the total cost of ownership, including installation, maintenance, and potential downtime. This holistic approach will help you make an informed decision that aligns with your budget and operational goals.

By following this checklist, B2B buyers can streamline their procurement process for three-way solenoids, ensuring that they select the right products from reliable suppliers while minimizing risks and enhancing operational efficiency.

Comprehensive Cost and Pricing Analysis for three way solenoid Sourcing

What Are the Key Cost Components for Sourcing Three-Way Solenoids?

When sourcing three-way solenoid valves, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Common materials include brass, stainless steel, and various plastics. Each material has different costs and compatibility with fluids, which can affect durability and performance.

-

Labor: Labor costs can vary based on geographic location and the complexity of the manufacturing process. Skilled labor is essential for precision assembly, particularly in high-quality applications.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses related to production. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Initial tooling costs can be substantial, particularly for custom designs. However, these costs can be amortized over larger production runs, making it vital to consider volume when negotiating prices.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability, which is crucial for applications in industries such as automotive or aerospace. These measures may add to the cost but can save expenses related to product failures.

-

Logistics: Shipping and handling costs can vary widely based on the supplier’s location and the destination. International shipping often incurs additional duties and tariffs, influencing total cost.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure profitability. Understanding typical margins in your industry can aid in negotiations.

How Do Price Influencers Affect the Cost of Three-Way Solenoids?

Several factors can influence the pricing of three-way solenoid valves:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQs). Ordering in larger volumes can lead to significant cost reductions per unit due to economies of scale.

-

Specifications and Customization: Custom valves tailored to specific applications may incur higher costs due to unique designs or materials. Standardized products typically offer lower pricing.

-

Quality and Certifications: Products that meet specific international standards (e.g., ISO, CE) may have higher costs associated with compliance. However, these certifications can enhance product credibility and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers may charge more but often provide better support and quality assurance.

-

Incoterms: Understanding Incoterms is crucial for international buyers. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect total landed costs.

What Are the Best Practices for Negotiating Prices on Three-Way Solenoids?

-

Research and Benchmarking: Before entering negotiations, research market prices for similar products. Use this information to create a baseline for discussions.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but the entire lifecycle cost, including maintenance, energy consumption, and potential downtime.

-

Flexibility in Specifications: If possible, be open to alternative specifications that may reduce costs. Standardized components can often be sourced more cheaply.

-

Build Relationships with Suppliers: Strong relationships can lead to better pricing, priority service, and more favorable terms. Long-term partnerships often yield cost benefits.

-

Timing: Be mindful of market trends and seasonal fluctuations. Prices may vary based on demand cycles, so timing your purchases can lead to cost savings.

Conclusion: What to Keep in Mind When Sourcing Internationally?

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing three-way solenoids is crucial. Factors such as regional tariffs, shipping logistics, and currency fluctuations can all impact total costs. Always request detailed quotations that include all potential fees to avoid surprises.

Disclaimer: Prices for three-way solenoid valves are indicative and can vary based on the aforementioned factors. Buyers should conduct thorough due diligence and consult with multiple suppliers to ensure competitive pricing and quality.

Alternatives Analysis: Comparing three way solenoid With Other Solutions

In the world of industrial automation and fluid control, selecting the right valve technology is crucial for optimizing performance and efficiency. While the three-way solenoid valve is a popular choice for directing fluid flow, there are viable alternatives that may better suit specific applications. This analysis will compare three-way solenoid valves with two alternatives: three-way electric ball valves and pneumatic actuated valves.

| Comparison Aspect | Three Way Solenoid | Three Way Electric Ball Valve | Pneumatic Actuated Valve |

|---|---|---|---|

| Performance | High responsiveness; typically fast actuation | Good flow control; slower than solenoids | Excellent for high flow and pressure; slower response time |

| Cost | Generally lower initial cost | Higher initial investment due to motorization | Medium to high initial cost; varies with complexity |

| Ease of Implementation | Simple wiring; compact design | More complex wiring and setup | Requires air supply and more extensive setup |

| Maintenance | Low maintenance; few moving parts | Moderate maintenance; motor may require servicing | Higher maintenance; air supply system needs monitoring |

| Best Use Case | Automated systems needing quick on/off control | Applications requiring precise flow control | High-pressure systems and large scale operations |

What are the Advantages and Disadvantages of Three-Way Electric Ball Valves?

Three-way electric ball valves utilize a motorized mechanism to control the flow of media. One significant advantage of this technology is its ability to provide precise flow control, making it ideal for applications where accuracy is paramount. However, the complexity of installation and higher upfront costs can be a drawback. Maintenance may also be more frequent due to the motorized components, which could lead to increased operational costs over time.

How Do Pneumatic Actuated Valves Compare to Three-Way Solenoid Valves?

Pneumatic actuated valves are excellent for applications that require handling high pressures and large volumes of fluid. They typically offer better performance in terms of flow and pressure handling compared to solenoids. However, they require a dedicated air supply, making installation more complex. Additionally, pneumatic systems may incur higher maintenance costs due to the need for regular monitoring of the air supply system and potential wear on pneumatic components.

Conclusion: How Should B2B Buyers Select the Right Valve Solution?

When choosing between a three-way solenoid valve and its alternatives, B2B buyers should assess their specific application requirements, including flow control precision, installation complexity, and maintenance considerations. For quick and efficient on/off control in automated systems, three-way solenoid valves are often the best choice. However, if precision control or high-pressure capabilities are required, three-way electric ball valves or pneumatic actuated valves may be more appropriate. Understanding these nuances will enable buyers to make informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for three way solenoid

What Are the Key Technical Properties of a Three-Way Solenoid Valve?

Understanding the essential technical properties of three-way solenoid valves is crucial for B2B buyers aiming to make informed purchasing decisions. Here are several critical specifications:

-

Material Grade

– The material used in the construction of a three-way solenoid valve can significantly impact its performance and longevity. Common materials include brass, stainless steel, and plastic. For instance, stainless steel valves are ideal for corrosive environments due to their resistance to rust and degradation. Selecting the right material ensures compatibility with the media being controlled, which is essential for maintaining system integrity. -

Pressure Rating

– Pressure rating indicates the maximum pressure the valve can withstand without failure. This specification is vital for applications involving high-pressure fluids or gases. A valve with an inadequate pressure rating can lead to catastrophic failures, resulting in downtime and increased maintenance costs. Buyers should ensure that the pressure rating aligns with their operational requirements. -

Flow Coefficient (Cv Value)

– The flow coefficient (Cv) measures the flow capacity of the valve. A higher Cv value indicates that the valve can handle a greater flow rate with less pressure drop. This specification is essential for optimizing system efficiency and ensuring that the valve meets the flow requirements of the application. Understanding the Cv value helps in selecting the right valve for specific operational needs. -

Voltage Rating

– Voltage rating refers to the electrical specifications required to operate the solenoid. Common ratings include 12V, 24V, and 110V. Ensuring that the solenoid valve’s voltage rating matches the power supply available in the application is crucial for operational reliability and safety. -

Actuation Type

– Three-way solenoid valves can be normally closed or normally open. A normally closed valve remains shut when not energized, while a normally open valve allows flow until it is energized. Understanding the actuation type is essential for determining how the valve will integrate into a control system and affect process flow. -

Temperature Range

– The temperature range indicates the operational limits within which the valve can function effectively. Selecting a valve that operates within the required temperature range is critical for maintaining performance and preventing damage.

What Are Common Trade Terms Related to Three-Way Solenoid Valves?

Familiarity with industry jargon can facilitate smoother transactions and better communication with suppliers. Here are some key terms:

Illustrative image related to three way solenoid

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of solenoid valves, OEMs often provide custom solutions tailored to specific application needs, making it essential for buyers to understand their capabilities. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to assess whether they can meet order requirements without incurring excess inventory costs. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This is an essential step in the procurement process, allowing buyers to compare offers and negotiate favorable terms. -

Incoterms (International Commercial Terms)

– Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risk management, and delivery responsibilities, ensuring smoother cross-border transactions. -

Lead Time

– Lead time refers to the time it takes from placing an order until it is delivered. Knowing the lead time helps businesses plan their operations and manage inventory more effectively, which is crucial for maintaining production schedules. -

Compatibility

– Compatibility refers to the ability of the solenoid valve to work with various media, such as water, gas, or oil. Buyers must ensure that the selected valve is compatible with the specific fluids or gases in their applications to avoid damage and ensure safety.

Understanding these technical specifications and trade terms will empower B2B buyers to make informed decisions and engage effectively with suppliers in the global market.

Navigating Market Dynamics and Sourcing Trends in the three way solenoid Sector

What are the Key Market Dynamics and Trends Affecting the Three Way Solenoid Sector?

The three-way solenoid valve market is experiencing significant growth driven by various global factors, particularly in industrial automation, water management, and energy sectors. The increasing demand for automation in manufacturing processes is propelling the need for efficient fluid control systems, of which three-way solenoid valves are integral. Emerging economies in Africa and South America are investing in infrastructure and industrial projects, creating a burgeoning market for these products. Furthermore, advancements in Internet of Things (IoT) technologies are leading to the integration of smart solenoid valves that allow for real-time monitoring and control, enhancing operational efficiency.

International B2B buyers are increasingly looking for suppliers who can provide customizable solutions tailored to specific applications. This trend is particularly evident in markets like Germany, known for its engineering prowess, where precision and reliability are paramount. Additionally, the Middle East, with its growing industrial base, is seeing a shift towards suppliers offering innovative solutions that comply with stringent regulations and standards.

Another noteworthy trend is the growing emphasis on compatibility and versatility, as buyers seek valves that can handle various media, including water, gas, and chemicals. This need is especially relevant in sectors such as chemical processing and oil and gas, where operational flexibility is crucial. As such, suppliers must focus on providing a diverse range of products that can meet the unique demands of different industries.

How Can Sustainability and Ethical Sourcing Influence B2B Purchasing Decisions in the Three Way Solenoid Market?

Sustainability is becoming a key consideration for B2B buyers in the three-way solenoid market. The environmental impact of manufacturing processes and the longevity of products are critical factors influencing purchasing decisions. Buyers are increasingly aware of the carbon footprint associated with their supply chains and are looking for suppliers who prioritize eco-friendly practices. This includes using sustainable materials and energy-efficient manufacturing processes.

Moreover, ethical sourcing is gaining traction as businesses strive to align with corporate social responsibility (CSR) goals. Buyers are seeking suppliers who can demonstrate transparency in their supply chains, ensuring fair labor practices and minimizing environmental harm. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can serve as indicators of a supplier’s commitment to sustainability.

In the context of three-way solenoid valves, buyers may prefer products made from recyclable materials or those that use less energy during operation. Suppliers who can provide “green” certifications for their products are likely to gain a competitive edge in the market, appealing to environmentally conscious buyers. This trend not only enhances brand reputation but also ensures compliance with increasing regulatory requirements regarding sustainability.

How Has the Three Way Solenoid Valve Market Evolved Over Time?

The evolution of the three-way solenoid valve market can be traced back to the industrial revolution when automation began to reshape manufacturing processes. Initially, these valves were primarily mechanical and operated manually, but technological advancements in the late 20th century introduced electric and pneumatic solenoid valves, significantly enhancing efficiency and reliability.

With the rise of automation in industries such as automotive, oil and gas, and food processing, the demand for three-way solenoid valves surged. The introduction of electronic control systems further revolutionized the market, allowing for precise control of fluid dynamics and enabling the integration of solenoid valves into automated systems.

Today, the market continues to evolve with the advent of smart technologies. The incorporation of IoT capabilities is driving the development of intelligent solenoid valves that provide real-time data analytics, predictive maintenance, and remote control features. This ongoing evolution highlights the importance of adaptability and innovation for suppliers aiming to meet the ever-changing needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of three way solenoid

1. How do I select the right three-way solenoid valve for my application?

When selecting a three-way solenoid valve, consider the type of media (liquid or gas), pressure and temperature conditions, and the valve configuration (normally open or normally closed). It’s also essential to assess compatibility with the materials used, especially for chemical applications. Consult with suppliers to discuss your specific requirements, and they can assist in identifying the best valve for your needs. Look for valves that comply with international standards to ensure quality and reliability.

Illustrative image related to three way solenoid

2. What are the common applications for three-way solenoid valves?

Three-way solenoid valves are widely used in various applications such as fluid control in automation systems, irrigation systems, and HVAC systems. They are ideal for switching and directing the flow of liquids and gases in industrial processes. Additionally, they can be used in medical devices and food processing equipment, making them versatile components in many sectors. Understanding the specific needs of your industry will help you choose the right valve for optimal performance.

3. What is the minimum order quantity (MOQ) for three-way solenoid valves?

MOQs for three-way solenoid valves can vary significantly between manufacturers and suppliers. Typically, MOQs can range from as low as 10 units to several hundred, depending on the valve type and the supplier’s production capabilities. It’s advisable to discuss your specific requirements with potential suppliers to negotiate MOQs that align with your project needs. Bulk purchases may also offer cost savings, so consider your long-term requirements.

4. How can I ensure the quality of three-way solenoid valves before purchasing?

To ensure quality, request certifications and compliance documentation from suppliers, such as ISO certifications or CE markings. Ask for product samples to conduct your own quality tests, or inquire about third-party testing and quality assurance processes used by the manufacturer. Additionally, seek feedback from other clients or industry professionals about their experiences with the supplier’s products. Establishing a solid relationship with a reputable supplier can also be beneficial for quality assurance.

5. What payment terms should I expect when sourcing three-way solenoid valves internationally?

Payment terms can vary, but common practices include upfront payments, net 30/60/90 days, or letters of credit for larger orders. Many suppliers may require a deposit before production, especially for customized valves. It’s crucial to discuss and agree upon payment terms in advance to avoid any misunderstandings. Consider using secure payment methods to protect your transaction, and ensure that all terms are clearly outlined in the purchase agreement.

6. How can I customize three-way solenoid valves to meet my specific requirements?

Customization options for three-way solenoid valves may include modifications to size, material, or electrical specifications. Many manufacturers offer bespoke solutions to cater to unique project needs. To initiate customization, provide detailed specifications and performance requirements to the supplier. Collaborating closely with the manufacturer during the design phase can help ensure that the final product meets your expectations and operational standards.

7. What logistics considerations should I be aware of when importing three-way solenoid valves?

When importing valves, consider shipping methods, lead times, and customs regulations in your country. Work with suppliers who have experience with international logistics to facilitate smooth transportation. Ensure that all necessary documentation, such as invoices and certificates of origin, is prepared to avoid delays at customs. Additionally, factor in any potential tariffs or duties that may apply to your order, as these can affect overall costs.

8. How do I verify the reliability of a supplier for three-way solenoid valves?

To verify a supplier’s reliability, conduct thorough research, including checking their business credentials, customer reviews, and industry reputation. Request references from previous clients and inquire about their experience with product quality and service. It can also be beneficial to visit the supplier’s facilities if possible or arrange for an audit. Establishing a long-term relationship with a reputable supplier can provide additional assurance of reliability and support for your projects.

Top 6 Three Way Solenoid Manufacturers & Suppliers List

1. Electric Solenoid Valves – 3-Way Options

Domain: electricsolenoidvalves.com

Registered: 2013 (12 years)

Introduction: 3-Way Solenoid Valves available in sizes from 1/8″ to 1″. Options include: 1/4” 3-Way 110V AC Electric Solenoid Valve ($52.71), 1/4” 3-Way 12V DC Electric Solenoid Valve ($52.71), 1/4” 3-Way 24V DC Electric Solenoid Valve ($52.71), 1/8” 3-Way 110V AC Electric Solenoid Valve ($52.71), 1/8” 3-Way 12V DC Electric Solenoid Valve ($52.71), 1/8” 3-Way 24V DC Electric Solenoid Valve ($52.71), 1″ Br…

2. McMaster – Three-Way Solenoid Valves

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Three-Way Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Bezzera / Pasquini – 3-Way Solenoid Valve – 110V

Domain: pasquini.com

Registered: 1997 (28 years)

Introduction: {“name”:”3-Way Solenoid Valve – 110V”,”sku”:”8806108″,”price”:”$149.00″,”weight”:”318g”,”brand”:”Bezzera / Pasquini”,”factory_number”:”7702416R”,”item_detail”:”SOLENOID VALVE 3 WAY SIRAI 110/120V”,”inventory_quantity”:6,”shipping_required”:true,”taxable”:true,”final_sale”:true,”installation_support”:”Only for parts featured in video tutorials; otherwise, should be installed by a trained profession…

4. Emerson – Three-Way Solenoid Valves

Domain: emerson.com

Registered: 1995 (30 years)

Introduction: This company, Emerson – Three-Way Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Home Barista – 3-Way Solenoid Valve

Domain: home-barista.com

Registered: 2005 (20 years)

Introduction: 3-way solenoid valve; used in espresso machines; issues may include insufficient water flow from the drain pipe; potential clogging with coffee gunk and oils; may require backflushing with detergent; normal operation includes a clicking sound when actuated; problems can arise from low brew pressure or clogged internal channels; maintenance may involve disassembly and cleaning.

6. Solenoid Solutions Inc – 3-Way Solenoid Valves

Domain: solenoidsolutionsinc.com

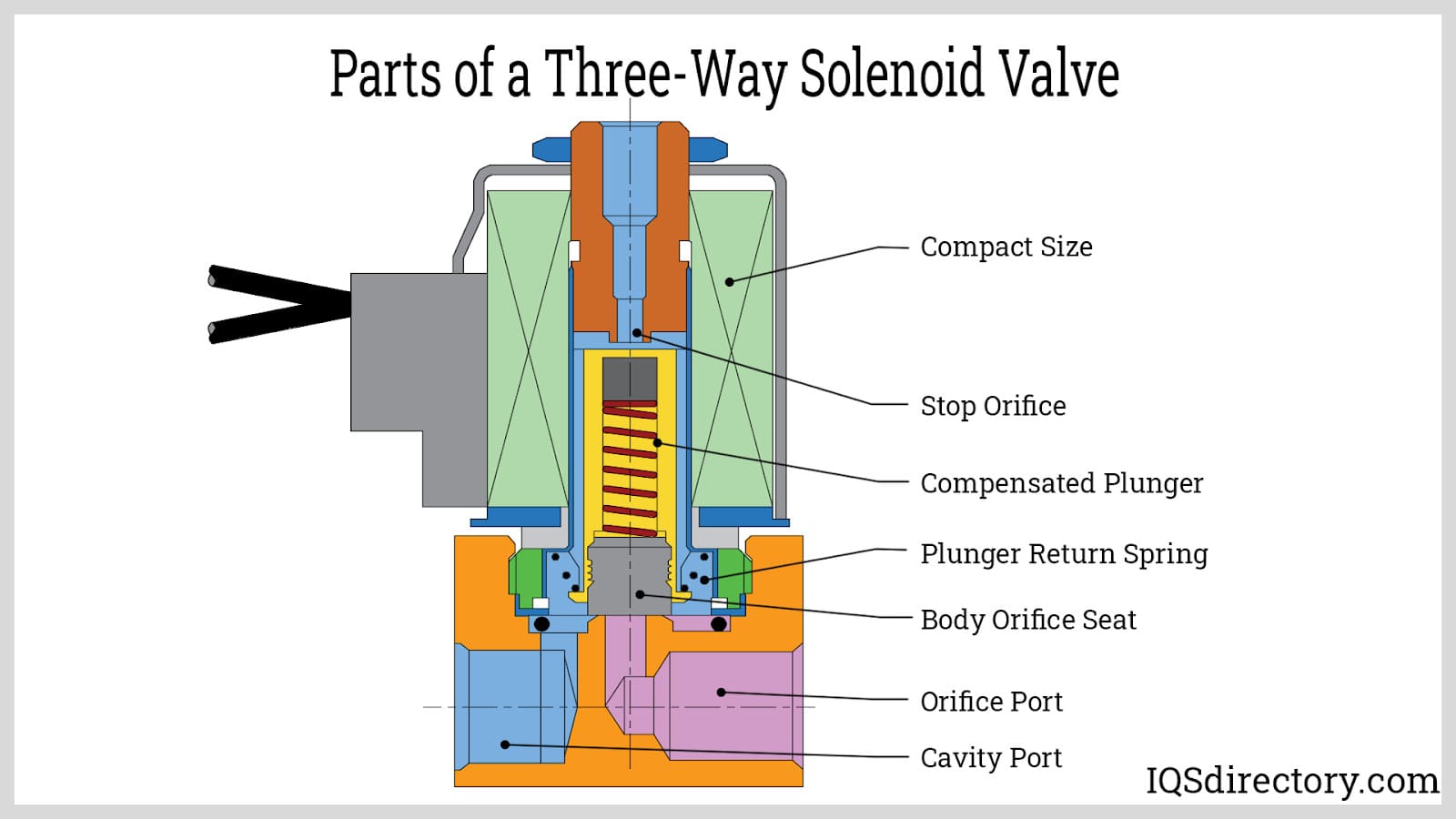

Registered: 2006 (19 years)

Introduction: Different types of 3-way solenoid valves include: 3-way normally open, 3-way normally closed, 3-way directional control, and 3-way multipurpose valves. Key features include: 3 pipe connections (cavity port, body orifice port, stop port), 2 orifices (body orifice and stop orifice), and flow control capabilities. The 3-way normally open valve allows flow from the body orifice when de-energized, whil…

Strategic Sourcing Conclusion and Outlook for three way solenoid

In conclusion, the strategic sourcing of three-way solenoid valves presents a unique opportunity for international B2B buyers to enhance operational efficiency and product reliability. Understanding the differences between normally closed and normally open configurations, as well as the compatibility of these valves with various media, is crucial for selecting the right solution tailored to specific industrial applications.

By leveraging partnerships with reputable suppliers, companies can gain access to high-quality products that meet stringent performance standards, ultimately driving innovation and automation in their operations. As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for versatile and efficient solenoid solutions is expected to rise.

Looking ahead, businesses should consider not only the immediate benefits of strategic sourcing but also the long-term value of building relationships with suppliers who can adapt to changing technological landscapes. Engage with industry experts to explore customized solutions that can elevate your processes and ensure competitive advantage. The future of automation is here—are you ready to seize it?

Illustrative image related to three way solenoid

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.