A Deep Dive into Cooling Tower Types Solution

Introduction: Navigating the Global Market for cooling tower types

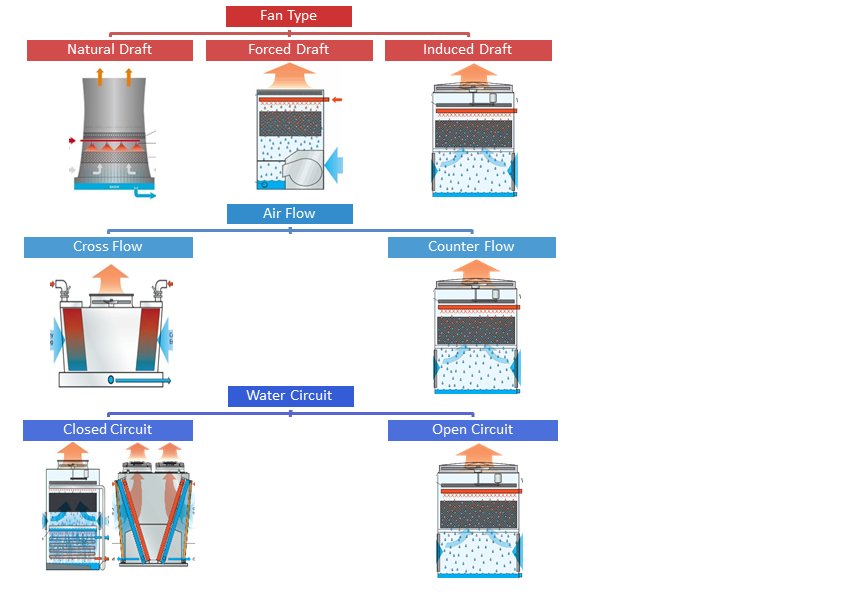

In today’s competitive industrial landscape, sourcing the right cooling tower types is crucial for optimizing operational efficiency and minimizing energy costs. With a myriad of options available, from crossflow to counterflow designs, making an informed choice can be daunting for international B2B buyers, particularly those operating in diverse environments such as Africa, South America, the Middle East, and Europe, including nations like Brazil and Germany. This comprehensive guide aims to demystify the world of cooling towers by exploring various types, their specific applications across industries, and essential factors to consider when vetting suppliers.

Navigating the complexities of cooling tower selection involves understanding key components, cost implications, and the benefits of each type in relation to specific operational needs. This guide will empower decision-makers by providing actionable insights into performance metrics and maintenance considerations, ultimately facilitating smarter purchasing decisions. Whether you are looking to enhance your commercial HVAC systems or streamline manufacturing processes, our in-depth analysis ensures that you are equipped with the knowledge to select the most suitable cooling tower for your requirements. As global markets evolve, understanding these critical aspects will position your business for success in a rapidly changing environment.

Understanding cooling tower types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

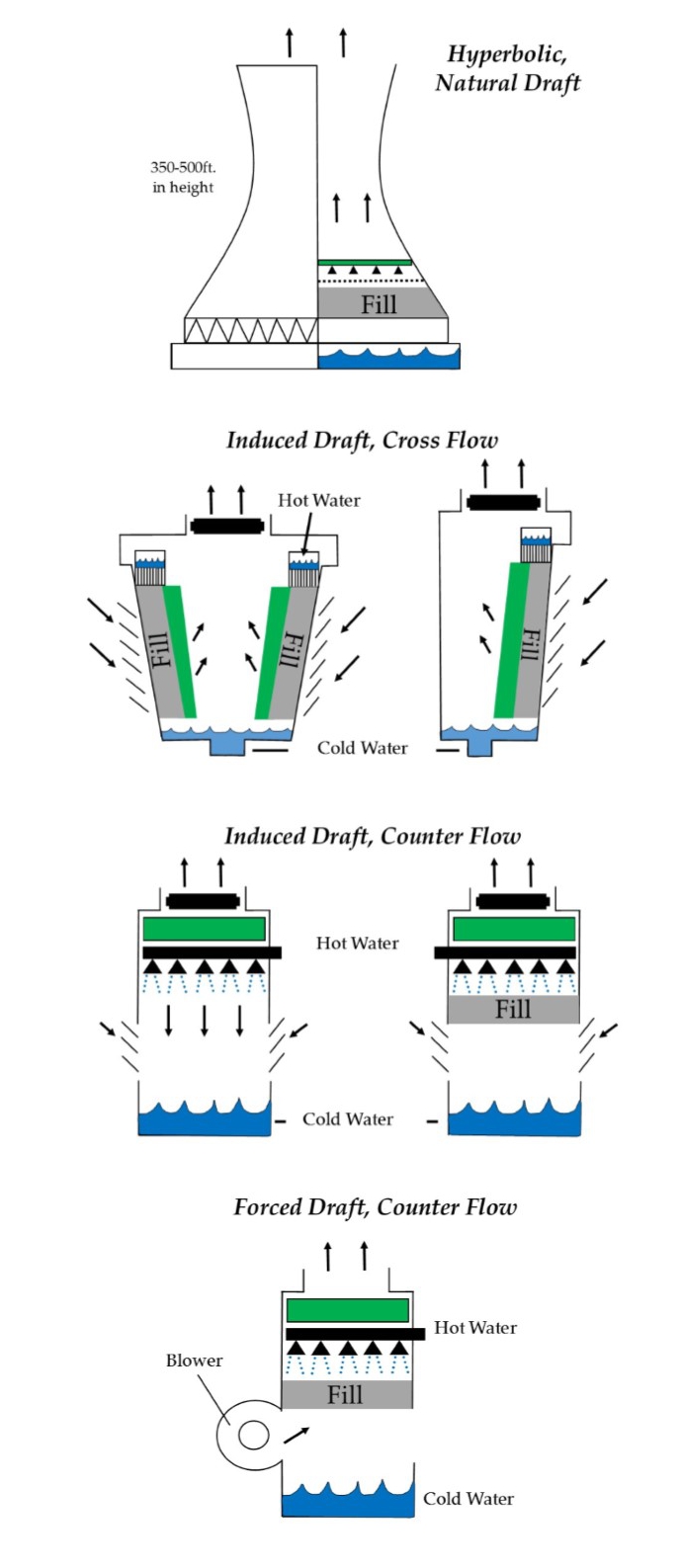

| Crossflow Cooling Towers | Air enters from the sides; uses gravitational flow of water | HVAC systems, industrial processes | Pros: Cost-effective, simple maintenance. Cons: Prone to freezing and clogging. |

| Counterflow Cooling Towers | Air flows upward; uses pressurized spray nozzles for water | Power generation, chemical processing | Pros: Efficient heat transfer, less risk of freezing. Cons: Higher energy costs, potential noise issues. |

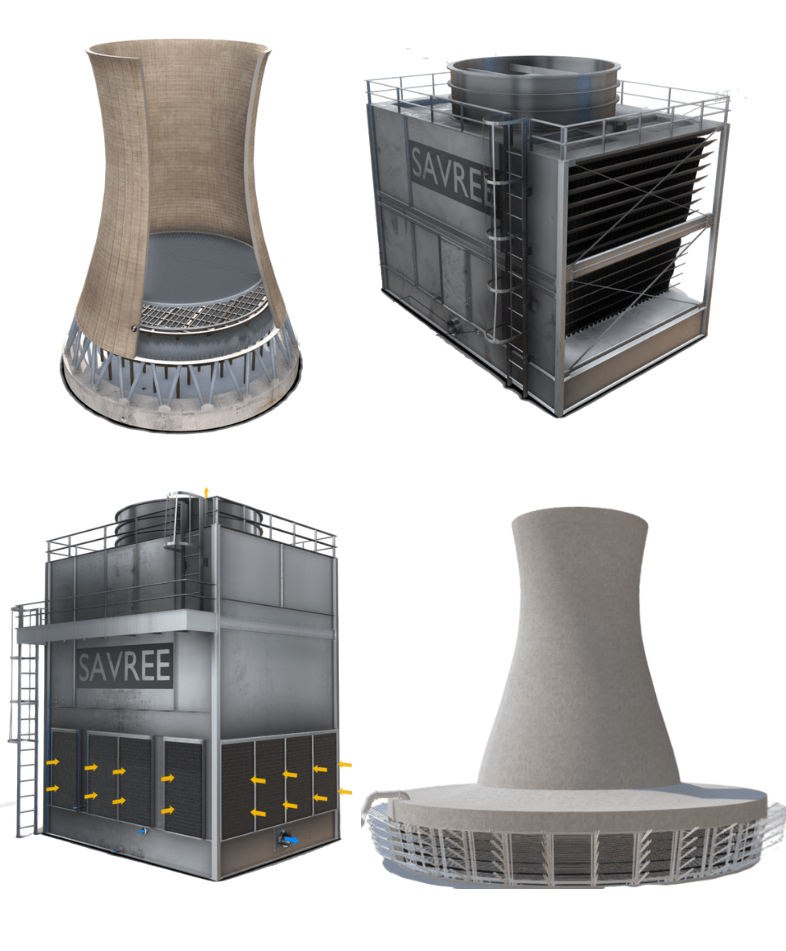

| Natural Draft Cooling Towers | Utilizes natural convection; often has a hyperbolic design | Large-scale power plants, industrial cooling | Pros: Low operational costs, strong structural integrity. Cons: Limited to specific designs and applications. |

| Induced Draft Cooling Towers | Fans at the top pull air through; prevents air recirculation | Heavy industrial operations, HVAC systems | Pros: High air velocity, efficient cooling. Cons: More complex and costly to maintain. |

| Forced Draft Cooling Towers | Fans located at the base push air into the tower | Small-scale and indoor applications | Pros: Good for high-pressure applications. Cons: Less efficient, higher operational costs. |

What Are the Characteristics of Crossflow Cooling Towers?

Crossflow cooling towers are designed with air entering from the sides, allowing gravity to assist in the downward flow of hot water. This design makes them relatively simple and cost-effective to maintain, making them suitable for HVAC systems and various industrial processes. However, their open design can lead to issues with freezing and clogging, especially in environments with high dust or debris.

How Do Counterflow Cooling Towers Operate and Where Are They Used?

Counterflow cooling towers feature a design where air flows upwards against the downward flow of water, utilizing pressurized spray nozzles for water distribution. This configuration allows for efficient heat transfer, making them ideal for power generation and chemical processing applications. Although they are efficient, buyers should consider the higher energy costs and potential noise issues associated with this type.

What Advantages Do Natural Draft Cooling Towers Offer?

Natural draft cooling towers leverage natural convection for airflow, often characterized by their hyperbolic shape. This design enhances airflow and structural integrity while minimizing operational costs. They are typically used in large-scale power plants and industrial cooling applications. However, their reliance on specific designs limits their versatility in various settings.

Why Choose Induced Draft Cooling Towers for Heavy Industrial Use?

Induced draft cooling towers employ fans at the top to pull air through the system, effectively preventing recirculation. This method allows for high air velocity and efficient cooling, making them suitable for heavy industrial operations and HVAC systems. However, they can be more complex and costly to maintain, which is a critical consideration for B2B buyers.

What Are the Key Considerations for Forced Draft Cooling Towers?

Forced draft cooling towers utilize fans at the base to push air into the system, making them particularly effective for small-scale and indoor applications. Their design tolerates high pressure well, but they tend to be less efficient compared to other types, leading to higher operational costs. Buyers should weigh the advantages of high-pressure tolerance against the potential for increased energy expenses.

Key Industrial Applications of cooling tower types

| Industry/Sector | Specific Application of cooling tower types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Generation | Cooling systems for thermal power plants | Enhances efficiency and reliability of energy production | Capacity to handle high thermal loads; energy efficiency ratings |

| Chemical Manufacturing | Heat management in chemical processing | Prevents overheating, ensuring process stability | Material compatibility; ease of maintenance |

| HVAC Systems | Cooling for large commercial buildings | Improves indoor air quality and system efficiency | Size and design for space; noise levels; energy consumption |

| Food and Beverage | Process cooling in food production | Maintains product quality and safety | Hygiene standards; energy efficiency; regulatory compliance |

| Data Centers | Cooling for IT equipment and server farms | Reduces risk of equipment failure and downtime | Scalability; energy efficiency; environmental impact |

How Are Cooling Towers Used in Power Generation?

In power generation, cooling towers are essential for dissipating heat generated by thermal power plants. These towers manage high thermal loads, ensuring the efficient operation of turbines and boilers. Buyers in this sector should prioritize cooling towers with high capacity and energy efficiency ratings, as they directly impact the operational costs and environmental compliance of the facility. Additionally, understanding local climate conditions, particularly in regions like the Middle East, can influence the choice of cooling tower type.

What Role Do Cooling Towers Play in Chemical Manufacturing?

In the chemical manufacturing industry, cooling towers are critical for heat management during various chemical processes. They prevent overheating, which can compromise process stability and product quality. B2B buyers must consider the compatibility of cooling tower materials with chemicals used in their processes to avoid corrosion or contamination. Furthermore, ease of maintenance is crucial for minimizing downtime and ensuring consistent production, especially in regions like South America, where supply chain logistics can pose challenges.

How Are Cooling Towers Integrated into HVAC Systems?

Cooling towers are a vital component of HVAC systems in large commercial buildings, where they help regulate indoor temperatures and improve air quality. By efficiently removing heat from the building, these towers contribute to the overall energy efficiency of the HVAC system, leading to lower operational costs. Buyers should assess the size and design of cooling towers to fit specific building layouts, as well as consider noise levels to ensure compliance with local regulations, particularly in urban environments in Europe.

Why Are Cooling Towers Important in Food and Beverage Production?

In the food and beverage industry, cooling towers play a crucial role in maintaining temperature control during production processes, ensuring product safety and quality. They help prevent spoilage and ensure compliance with health regulations. Buyers should prioritize cooling towers that meet hygiene standards and offer energy-efficient operations to minimize costs. Additionally, regulatory compliance is essential, particularly in regions with strict food safety laws, such as Germany.

How Do Cooling Towers Benefit Data Centers?

Cooling towers are integral to data centers, where they help dissipate heat generated by IT equipment and server farms. Effective cooling reduces the risk of equipment failure and minimizes downtime, which is critical for maintaining service levels. B2B buyers should focus on the scalability of cooling solutions to accommodate future growth and the energy efficiency of the systems to reduce operational costs. Environmental impact considerations are also increasingly important, especially in markets like Africa, where sustainability is a growing concern.

3 Common User Pain Points for ‘cooling tower types’ & Their Solutions

Scenario 1: Choosing the Right Cooling Tower Type for Specific Needs

The Problem: B2B buyers often grapple with selecting the appropriate cooling tower type for their operations, particularly when faced with diverse applications and environmental conditions. For instance, a chemical processing plant in Brazil may require robust cooling solutions that can handle high heat loads, while a data center in Germany may prioritize energy efficiency and noise reduction. This mismatch can lead to operational inefficiencies, increased costs, and potential equipment failures if the wrong type is selected.

The Solution: To address this challenge, buyers should conduct a thorough needs assessment that considers their specific operational requirements, including heat load calculations, available space, and environmental factors. Engaging with manufacturers or consultants who specialize in cooling tower design can provide insights into the most suitable options. For instance, a counterflow cooling tower may be ideal for environments needing efficient heat transfer with limited space, while crossflow towers may work well for larger industrial applications. Buyers should also look into energy efficiency ratings and maintenance requirements to ensure long-term cost-effectiveness.

Scenario 2: Addressing Maintenance and Operational Challenges

The Problem: Regular maintenance of cooling towers can be a significant pain point for B2B buyers, especially in regions with harsh environmental conditions. For example, cooling towers in the Middle East may suffer from sand and dust accumulation, leading to decreased performance and increased maintenance costs. Neglecting maintenance can result in operational downtime, higher energy consumption, and even safety hazards due to overheating equipment.

The Solution: To mitigate these maintenance challenges, buyers should implement a proactive maintenance strategy that includes regular inspections and cleaning schedules tailored to their specific environment. Choosing cooling tower models with easily accessible components can facilitate quicker maintenance and reduce labor costs. Additionally, investing in advanced monitoring systems that track performance metrics can help identify issues before they escalate. For example, integrating sensors that measure water quality and airflow can provide real-time data, enabling timely interventions and minimizing operational disruptions.

Scenario 3: Managing Water Usage and Environmental Compliance

The Problem: B2B buyers are increasingly facing pressure to manage water usage effectively and comply with environmental regulations. In regions like South America, where water scarcity is becoming a pressing issue, companies may find themselves in a bind when their cooling tower operations require excessive water consumption. This not only raises operational costs but also poses risks of non-compliance with local regulations aimed at conserving water resources.

The Solution: To overcome this pain point, buyers should explore cooling tower types that offer superior water efficiency. For instance, closed-circuit cooling towers can significantly reduce water loss through evaporation and are an excellent choice for industries concerned about water usage. Additionally, implementing a water recycling system can help in reusing water within the cooling system, thus reducing the overall demand. Buyers should also stay informed about local regulations and consider partnering with environmental consultants to ensure compliance while optimizing their cooling tower operations. Regular audits and sustainability assessments can further enhance their commitment to responsible water management.

By addressing these common pain points with tailored solutions, B2B buyers can optimize their cooling tower systems, reduce operational risks, and enhance overall efficiency.

Strategic Material Selection Guide for cooling tower types

When selecting materials for cooling towers, it’s essential to consider their properties, advantages, and limitations in relation to specific applications. The choice of material can significantly impact the performance, durability, and overall cost-effectiveness of cooling tower systems. Below, we analyze four common materials used in cooling tower construction, focusing on their suitability for various environments and applications.

What Are the Key Properties of Fiberglass Reinforced Plastic (FRP) in Cooling Towers?

Fiberglass Reinforced Plastic (FRP) is widely used in cooling tower construction due to its excellent corrosion resistance and lightweight nature. FRP can withstand temperatures up to 60°C (140°F) and pressures of around 0.5 MPa (72 psi). Its inherent resistance to chemicals makes it suitable for various industrial applications, particularly in environments where corrosive substances are present.

Pros: FRP is highly durable and requires minimal maintenance. Its lightweight nature allows for easier installation and transportation, making it a cost-effective option for many projects.

Cons: However, FRP can be more expensive than traditional materials like steel, and its manufacturing process can be complex, leading to longer lead times.

Impact on Application: FRP’s compatibility with various cooling media makes it an excellent choice for industries such as chemical processing and power generation.

International Considerations: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM D638 for tensile properties. In Europe, DIN standards may apply, influencing material selection.

How Does Stainless Steel Compare for Cooling Tower Applications?

Stainless steel is another popular choice for cooling towers, known for its high strength and excellent corrosion resistance, particularly in high-temperature applications. It can handle temperatures exceeding 150°C (302°F) and pressures up to 1.0 MPa (145 psi), making it suitable for demanding environments.

Pros: The durability of stainless steel is unmatched, providing a long service life with minimal maintenance. Its aesthetic appeal also makes it a preferred choice for visible installations.

Illustrative image related to cooling tower types

Cons: The primary drawback is the cost; stainless steel is generally more expensive than FRP or plastic alternatives. Additionally, its weight can complicate installation.

Impact on Application: Stainless steel is particularly effective in environments with high humidity or exposure to chemicals, making it ideal for HVAC systems and industrial applications.

International Considerations: Buyers should verify compliance with relevant standards, such as ASTM A240 for stainless steel sheet and plate, to ensure quality and performance in their specific markets.

What Are the Advantages of Using Galvanized Steel in Cooling Towers?

Galvanized steel is a cost-effective option for cooling towers, providing reasonable corrosion resistance through a protective zinc coating. It can typically withstand temperatures up to 70°C (158°F) and pressures around 0.5 MPa (72 psi).

Pros: The affordability of galvanized steel makes it an attractive option for budget-conscious projects. Its strength and structural integrity are also significant advantages.

Cons: However, galvanized steel is less durable than stainless steel and can be prone to corrosion in harsh environments, particularly where chemicals are present.

Illustrative image related to cooling tower types

Impact on Application: This material is suitable for less demanding applications where cost is a primary concern, such as in some commercial HVAC systems.

International Considerations: Buyers should ensure that the galvanized coating meets local standards, such as JIS G3302 in Japan or EN ISO 1461 in Europe, to ensure longevity and performance.

How Does Polyvinyl Chloride (PVC) Perform in Cooling Tower Applications?

Polyvinyl Chloride (PVC) is often used for fill media and piping in cooling towers due to its excellent chemical resistance and lightweight properties. PVC can handle temperatures up to 60°C (140°F) and is suitable for low-pressure applications.

Illustrative image related to cooling tower types

Pros: Its resistance to corrosion and chemicals makes PVC a popular choice for cooling towers in various industries. Additionally, its lightweight nature facilitates easy installation.

Cons: However, PVC is less durable under extreme temperatures and may not be suitable for high-pressure applications.

Impact on Application: PVC is often used in applications where water quality is a concern, such as in food processing or pharmaceutical industries.

International Considerations: Buyers should ensure compliance with standards such as ASTM D1784 for PVC pipe and fittings, particularly in regulated industries.

Summary Table of Material Selection for Cooling Towers

| Material | Typical Use Case for cooling tower types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Fiberglass Reinforced Plastic | Chemical processing, power generation | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Stainless Steel | HVAC systems, industrial applications | High durability and aesthetic appeal | Expensive, heavier than alternatives | High |

| Galvanized Steel | Commercial HVAC systems | Cost-effective and strong | Prone to corrosion in harsh environments | Medium |

| Polyvinyl Chloride | Food processing, pharmaceutical sectors | Lightweight and chemically resistant | Less durable under extreme conditions | Medium |

This guide provides a comprehensive overview of material options for cooling towers, helping international B2B buyers make informed decisions based on their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cooling tower types

What Are the Main Stages of Manufacturing Cooling Towers?

The manufacturing process for cooling towers involves several critical stages, each contributing to the overall quality and efficiency of the final product. Understanding these stages can help B2B buyers assess the capabilities of their suppliers and ensure they receive reliable equipment.

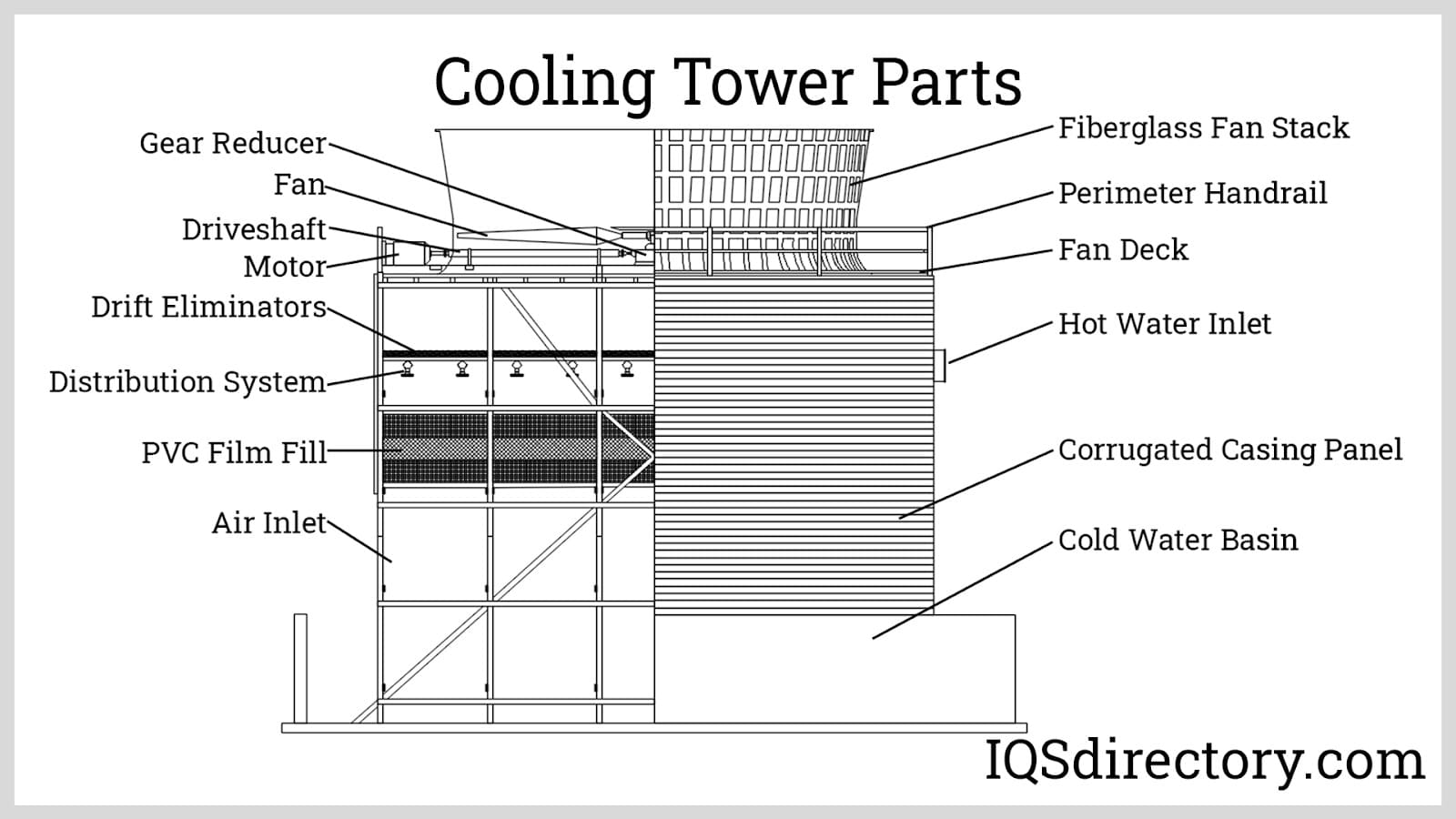

Material Preparation: What Materials Are Used?

The process begins with material selection, typically involving metals such as galvanized steel, stainless steel, or fiberglass-reinforced plastic (FRP). Each material has specific benefits; for example, stainless steel offers corrosion resistance, while FRP provides lightweight durability. The selected materials undergo cutting and shaping to meet the design specifications, ensuring that they can withstand the operational pressures of cooling systems.

Forming: How Are Cooling Towers Shaped?

Once the materials are prepared, they undergo various forming techniques. These may include bending, welding, and stamping to create the structural components of the cooling tower. Advanced technologies, such as CNC machining, are often employed to achieve high precision in component shapes. For example, the fill media, which maximizes water-air contact, is typically manufactured using specialized molds that define its texture and surface area.

Assembly: What Techniques Are Used?

The assembly stage involves integrating all components, including the fill media, fans, distribution systems, and basins, into a cohesive unit. Techniques such as robotic welding or manual assembly are common, depending on the complexity of the design. Quality control checkpoints are integrated into this stage, where components are inspected for fit and function before proceeding to the next step.

Finishing: How Are Cooling Towers Prepared for Use?

Finishing processes are crucial for enhancing durability and performance. This may include surface treatments like galvanization or powder coating to protect against corrosion and environmental factors. Additionally, pre-assembly testing is often conducted to ensure that each cooling tower meets specific operational standards before being shipped to clients.

Illustrative image related to cooling tower types

What Quality Assurance Measures Are Essential in Cooling Tower Manufacturing?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for cooling towers. It ensures that products meet international standards and client specifications, minimizing the risk of operational failures.

Which International Standards Should Buyers Consider?

For B2B buyers, understanding the relevant international quality standards is crucial. ISO 9001 is the most recognized standard for quality management systems, ensuring that manufacturers adhere to consistent quality practices. Additionally, industry-specific certifications, such as CE marking in Europe and API standards for industrial products, are critical indicators of compliance and quality.

What Are the QC Checkpoints Throughout the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor compliance with design specifications and quality standards.

- Final Quality Control (FQC): Before shipping, the completed cooling towers undergo rigorous testing and inspection to confirm their performance and safety.

These checkpoints help identify and rectify issues early in the production process, ensuring that the final product meets high-quality standards.

What Common Testing Methods Are Used to Ensure Quality?

To guarantee the reliability and efficiency of cooling towers, manufacturers employ various testing methods:

- Hydrostatic Testing: This method checks for leaks by filling the cooling tower with water and pressurizing it to ensure that no water escapes.

- Performance Testing: This involves running the cooling tower under simulated operational conditions to assess its cooling capacity and efficiency.

- Vibration Analysis: For towers with mechanical components, vibration analysis can identify potential issues with fans and motors, ensuring smooth operation.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control measures of their suppliers. Here are some effective strategies:

Illustrative image related to cooling tower types

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality assurance practices of potential suppliers. This firsthand evaluation can reveal the robustness of their QC measures.

- Requesting Quality Reports: Suppliers should provide documentation of their quality control processes and results from recent tests. This transparency can help buyers gauge the reliability of the products.

- Engaging Third-Party Inspectors: Hiring independent inspectors to evaluate the manufacturing facilities and processes can provide an unbiased assessment of quality control measures.

What Are the QC and Certification Nuances for International B2B Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is essential. Different markets may have varying requirements for certifications, and buyers must ensure that their suppliers comply with local regulations.

- Regional Standards: Buyers should familiarize themselves with regional standards that may influence product certification. For instance, European buyers may prioritize CE marking, while clients in the Middle East might focus on local regulatory compliance.

- Cultural Considerations: Understanding cultural attitudes towards quality and business practices can impact supplier relationships. Building trust through regular communication and transparency can enhance collaboration.

Conclusion: Why Is Understanding Manufacturing and Quality Assurance Crucial for B2B Buyers?

In summary, a comprehensive understanding of the manufacturing processes and quality assurance measures for cooling towers is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, along with rigorous quality control checkpoints and testing methods, buyers can make informed decisions. Ensuring compliance with international standards and conducting thorough supplier evaluations will lead to successful procurement and long-term operational efficiency in their cooling systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cooling tower types’

Introduction

This practical sourcing guide is designed to assist B2B buyers in navigating the complexities of procuring cooling tower types. With diverse options available, understanding your specific needs and the unique features of each cooling tower can lead to more informed purchasing decisions that enhance operational efficiency and reduce costs.

Step 1: Define Your Technical Specifications

Identifying your technical requirements is the first step in sourcing a cooling tower. Consider factors such as the volume of water to be cooled, the temperature differential, and the specific application—be it HVAC, industrial processes, or power generation.

– Load Requirements: Assess peak load conditions to determine the necessary cooling capacity.

– Environmental Conditions: Take into account the local climate, as this influences cooling tower performance.

Step 2: Evaluate Cooling Tower Types

Understanding the various types of cooling towers is essential for selecting the right one for your application. Familiarize yourself with crossflow, counterflow, natural draft, induced draft, and forced draft cooling towers to identify which type aligns best with your needs.

– Operational Efficiency: Consider how each type operates under your specific conditions and the potential energy costs associated with them.

– Maintenance Needs: Some designs may require more frequent maintenance, impacting long-term operational costs.

Step 3: Assess Compliance and Regulations

Ensure that the cooling towers you are considering comply with local and international standards, particularly regarding safety and environmental regulations. This step is crucial to avoid legal issues and ensure smooth operations.

– Certification Verification: Look for certifications from recognized bodies that validate the quality and safety of the cooling towers.

– Regulatory Requirements: Familiarize yourself with local regulations that may dictate specific cooling tower designs or operational practices.

Step 4: Shortlist Potential Suppliers

Once you have defined your specifications and evaluated cooling tower types, compile a list of potential suppliers. Focus on vendors who specialize in your required cooling tower type and have a proven track record.

– Industry Experience: Suppliers with experience in your industry can provide valuable insights and tailored solutions.

– Reputation and Reviews: Check online reviews, testimonials, and case studies from other customers in similar sectors to gauge reliability.

Step 5: Request Detailed Proposals

Engage shortlisted suppliers by requesting detailed proposals that include technical specifications, pricing, lead times, and warranty information. This step allows you to compare offerings comprehensively.

– Customization Options: Inquire about customization capabilities to ensure the solution fits your specific operational needs.

– Total Cost of Ownership: Evaluate not just the upfront costs but also long-term maintenance and operational expenses.

Step 6: Conduct Site Visits or Virtual Tours

If feasible, arrange site visits or virtual tours of the suppliers’ facilities to assess their production capabilities and quality control processes. This step helps to build trust and provides a clearer understanding of their operational standards.

– Quality Assurance Practices: Observe how they manage quality assurance and testing processes.

– Facility Infrastructure: Evaluate their manufacturing capabilities and technology to ensure they can meet your production requirements.

Step 7: Finalize Contracts and Agreements

Once you have selected a supplier, work on finalizing contracts that clearly outline terms of delivery, payment schedules, warranties, and service agreements. This step is critical to protect your interests and ensure transparency.

– Negotiation of Terms: Ensure that all terms are agreeable, including any service level agreements (SLAs) for ongoing support.

– Contingency Plans: Discuss contingency measures in case of delays or product issues to safeguard your operations.

By following this step-by-step checklist, B2B buyers can make informed decisions when procuring cooling tower types, ultimately enhancing their operational efficiency and sustainability.

Comprehensive Cost and Pricing Analysis for cooling tower types Sourcing

What Are the Key Cost Components in Sourcing Cooling Towers?

When evaluating the cost structure of cooling towers, several key components must be considered. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials significantly impacts the overall cost. For instance, cooling towers can be constructed from materials like galvanized steel, stainless steel, or high-density polyethylene (HDPE). Each material has its own cost implications, durability, and maintenance requirements, which can affect long-term operational costs.

-

Labor: Labor costs vary depending on the complexity of the cooling tower design and the skill level required for assembly and installation. Regions with higher labor costs will naturally see increased pricing.

-

Manufacturing Overhead: This includes costs associated with the facility where the cooling towers are produced, such as utilities, depreciation of machinery, and indirect labor. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: The initial setup for manufacturing cooling towers, including molds and specialized equipment, adds to the upfront costs. Custom designs may require additional investment in tooling.

-

Quality Control (QC): Ensuring that cooling towers meet industry standards and certifications can add to the cost. This includes testing procedures and compliance with regulations, which are particularly crucial for international buyers.

-

Logistics: Transporting cooling towers from the manufacturer to the buyer’s location can incur significant costs, especially for larger units. Factors like distance, shipping methods, and customs duties must be factored into the overall pricing.

-

Margin: Suppliers typically include a margin that reflects their business model and market conditions. This margin can vary widely based on the supplier’s reputation, quality of service, and market demand.

How Do Price Influencers Impact Cooling Tower Costs?

Several factors can influence the pricing of cooling towers beyond the basic cost components. Understanding these influencers can help buyers negotiate better deals.

-

Volume/MOQ: Purchasing in bulk or meeting minimum order quantities (MOQs) can lead to significant cost savings. Suppliers often provide tiered pricing structures that reward larger orders.

-

Specifications and Customization: Customized cooling towers tailored to specific operational needs may incur additional costs. Buyers should balance the need for customization with cost-efficiency.

-

Materials: The choice of materials directly impacts pricing. High-quality, durable materials may have a higher upfront cost but can lead to lower Total Cost of Ownership (TCO) due to reduced maintenance and longer lifespan.

-

Quality and Certifications: Cooling towers that meet international standards and certifications may carry a premium price. However, these certifications often ensure reliability and safety, which can be crucial in certain industries.

-

Supplier Factors: The reputation and reliability of the supplier play a significant role in pricing. Established suppliers may charge more due to their proven track record but often provide better after-sales support and warranty services.

-

Incoterms: Understanding Incoterms is vital for international buyers. These terms define the responsibilities of buyers and sellers in shipping, insurance, and tariffs, which can affect the overall cost.

What Are the Best Practices for Negotiating Cooling Tower Prices?

Buyers looking to optimize their sourcing of cooling towers should consider the following negotiation tips:

-

Conduct Market Research: Understanding the market price range for the required cooling tower type can empower buyers during negotiations.

-

Evaluate Total Cost of Ownership: Focus on the long-term costs associated with cooling towers rather than just the initial purchase price. This includes maintenance, energy efficiency, and potential downtime costs.

-

Be Clear on Specifications: Clearly outline the required specifications and seek multiple quotes to compare pricing effectively. This transparency can also facilitate more accurate estimates from suppliers.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Suppliers are often willing to negotiate for repeat customers.

-

Consider Local Suppliers: For buyers in Africa, South America, the Middle East, and Europe, sourcing from local suppliers can reduce shipping costs and lead times, making the overall procurement process more efficient.

Disclaimer for Indicative Prices

Prices for cooling towers can vary widely based on the factors discussed above. The provided insights are meant to serve as a guideline, and potential buyers should conduct thorough market research and engage with suppliers directly to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing cooling tower types With Other Solutions

Introduction to Alternative Cooling Solutions

In industrial applications, effective heat management is crucial for optimizing processes and ensuring equipment longevity. While cooling towers are a widely adopted solution for dissipating excess heat, there are alternative technologies that can also achieve similar outcomes. Understanding these alternatives allows B2B buyers to make informed decisions tailored to their operational needs, budget constraints, and environmental considerations.

Illustrative image related to cooling tower types

Comparison Table of Cooling Tower Types and Alternatives

| Comparison Aspect | Cooling Tower Types | Evaporative Coolers | Chillers |

|---|---|---|---|

| Performance | High efficiency in large-scale heat removal; suitable for continuous operation. | Effective in moderate climates; efficiency drops in high humidity. | Consistent cooling irrespective of external conditions; energy-efficient in colder climates. |

| Cost | Higher initial investment; long-term savings on energy and maintenance. | Lower upfront cost; potential for higher operational costs in humid environments. | Higher installation and operational costs; significant energy consumption. |

| Ease of Implementation | Requires considerable space and infrastructure; more complex setup. | Generally easier to install; compact designs available. | Complex installation; requires skilled technicians for setup and maintenance. |

| Maintenance | Regular maintenance needed to prevent clogging and ensure efficiency. | Low maintenance; periodic cleaning required. | High maintenance needs; regular servicing essential for optimal performance. |

| Best Use Case | Large industrial applications, power plants, and HVAC systems. | Commercial applications in dry climates; suitable for smaller spaces. | Ideal for temperature-sensitive environments like pharmaceuticals and food processing. |

Detailed Breakdown of Alternatives

What Are Evaporative Coolers and Their Benefits?

Evaporative coolers, also known as swamp coolers, utilize the natural process of evaporation to cool air. They work best in dry climates, where they can significantly lower temperatures while using less energy than traditional cooling methods. However, their effectiveness diminishes in high humidity conditions, making them less versatile compared to cooling towers. The initial investment is typically lower, but operational costs can increase in humid environments due to reduced efficiency.

How Do Chillers Compare in Cooling Applications?

Chillers are another alternative that provides reliable cooling through a refrigeration cycle. They are particularly beneficial in environments where precise temperature control is essential, such as in pharmaceuticals or data centers. While they offer consistent performance regardless of external conditions, they can be costly to operate due to high energy consumption. Installation can also be complex, requiring specialized knowledge and equipment. The long-term operational costs should be carefully evaluated against the initial investment to determine the best fit for specific applications.

Conclusion: Choosing the Right Cooling Solution

When selecting a cooling solution, B2B buyers must consider various factors, including performance requirements, cost constraints, and specific operational contexts. Cooling towers may offer the best solution for large-scale operations needing high efficiency, while evaporative coolers could be a cost-effective choice for smaller, dry environments. Chillers are ideal for applications requiring precise temperature control but come with higher costs. By assessing their unique needs and the characteristics of each alternative, buyers can make informed decisions that align with their operational goals and budgets.

Essential Technical Properties and Trade Terminology for cooling tower types

What are the Key Technical Properties of Cooling Towers for B2B Buyers?

When evaluating cooling towers, understanding their technical specifications is crucial for making informed procurement decisions. Here are several essential properties that B2B buyers should consider:

-

Material Grade

The material grade of a cooling tower significantly influences its durability and performance. Common materials include galvanized steel, stainless steel, and FRP (Fiberglass Reinforced Plastic). Higher-grade materials provide better corrosion resistance, making them suitable for harsh industrial environments. Selecting the appropriate material ensures longevity, reducing replacement costs and downtime. -

Cooling Capacity

Measured in tons or BTUs (British Thermal Units), cooling capacity indicates the amount of heat a cooling tower can dissipate. This specification is critical for ensuring that the cooling system can handle the thermal load of the process it supports. Overestimating or underestimating this capacity can lead to inefficiencies, increased energy costs, and equipment failures. -

Water Flow Rate

Expressed in gallons per minute (GPM), the water flow rate determines how effectively the cooling tower can circulate water for cooling. A higher flow rate can enhance heat transfer efficiency but may require larger pumps and more energy. Understanding the required flow rate is essential for optimizing system design and energy consumption. -

Noise Level

Measured in decibels (dB), the noise level of a cooling tower is particularly important in urban or noise-sensitive environments. Induced draft towers tend to be noisier than crossflow models. Selecting a cooling tower with acceptable noise levels can prevent regulatory issues and improve workplace comfort. -

Efficiency Ratings

The efficiency of a cooling tower is often indicated by its Thermal Performance, which reflects how effectively it can transfer heat. Higher efficiency ratings translate to lower operational costs and reduced environmental impact. B2B buyers should prioritize models that meet or exceed industry standards for energy efficiency. -

Footprint and Dimensions

The physical dimensions and footprint of a cooling tower are vital in determining its installation requirements and compatibility with existing infrastructure. A compact design may be necessary for facilities with limited space, while larger operations might benefit from more extensive models that offer higher capacities.

What are Common Trade Terms Related to Cooling Towers?

Familiarity with industry jargon can facilitate smoother negotiations and transactions. Here are several essential terms relevant to cooling towers:

-

OEM (Original Equipment Manufacturer)

An OEM refers to companies that produce components or systems that are used in another company’s end products. In the context of cooling towers, OEM specifications ensure that parts are compatible and meet quality standards. Buyers should evaluate OEM credentials when sourcing replacement parts or new systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage budgets and inventory effectively. Suppliers with lower MOQs can be advantageous for businesses looking to test products without committing to large purchases. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products or services. This document helps standardize the procurement process, ensuring that all potential vendors provide comparable proposals. Including detailed specifications in an RFQ can lead to more accurate and competitive quotes. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers in shipping agreements. Familiarity with Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for understanding shipping costs, risks, and insurance during international transactions. -

Lead Time

Lead time refers to the duration between placing an order and receiving the product. It encompasses manufacturing, shipping, and delivery times. Knowing the lead time helps buyers plan their projects and manage operational timelines effectively. -

Field-Erected vs. Factory-assembled

These terms distinguish between cooling towers built on-site (field-erected) and those manufactured in a factory and shipped as complete units (factory-assembled). Understanding the implications of each option can influence project timelines, costs, and installation complexity.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of cooling tower procurement more efficiently, ensuring they choose the right systems for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the cooling tower types Sector

What Are the Key Market Drivers and Trends in the Cooling Tower Types Sector?

The global cooling tower market is experiencing significant growth, driven by various industrial applications, including HVAC systems, power generation, and manufacturing processes. The increasing demand for energy-efficient cooling solutions is particularly pronounced in regions like Africa, South America, the Middle East, and Europe. In these areas, rapid industrialization and urbanization are pushing the need for reliable cooling technologies. Furthermore, the rise of data centers and the telecommunications sector has created a surge in demand for effective cooling systems, as these industries generate substantial heat.

Emerging technologies are also shaping the landscape. Innovations in smart cooling systems, which leverage IoT for monitoring and optimization, are gaining traction among international B2B buyers. These advancements not only enhance operational efficiency but also contribute to cost savings. Additionally, the trend toward modular and prefabricated cooling towers is becoming popular, allowing for quicker installation and scalability, which is especially advantageous in developing markets.

Illustrative image related to cooling tower types

B2B buyers should also be aware of the regulatory landscape, as governments increasingly impose stringent environmental standards. These regulations can influence sourcing decisions, making it essential to stay informed about compliance requirements in different regions.

How Can Sustainability and Ethical Sourcing Impact Cooling Tower Procurement?

Sustainability is becoming a cornerstone of procurement strategies in the cooling tower sector. The environmental impact of cooling towers, particularly in terms of water consumption and energy efficiency, cannot be overlooked. With rising concerns about climate change and resource scarcity, international buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainability.

Ethical sourcing practices are equally important, as they ensure that materials used in cooling tower construction are obtained responsibly. Buyers should seek suppliers who offer ‘green’ certifications and materials, such as recyclable or sustainably sourced components. For instance, using high-performance fill media made from recycled PVC can significantly reduce environmental footprints.

Furthermore, integrating lifecycle assessments into procurement processes can help buyers evaluate the long-term sustainability of cooling tower solutions. By focusing on energy-efficient designs and materials with minimal environmental impact, companies can contribute to a more sustainable industrial ecosystem while also enhancing their brand reputation.

Illustrative image related to cooling tower types

What Is the Historical Context of Cooling Towers for B2B Buyers?

The evolution of cooling tower technology can be traced back to the early 20th century, when these systems were primarily employed in steam power plants. Initially, cooling towers were simple structures that relied on natural draft principles. Over the decades, advancements in materials and engineering led to the development of more efficient designs, such as induced and forced draft cooling towers.

By the late 20th century, the focus shifted towards enhancing thermal performance and energy efficiency, spurred by rising energy costs and environmental regulations. The introduction of modular designs and advanced materials has further transformed the landscape, making cooling towers more adaptable and efficient. This historical context is vital for B2B buyers, as understanding past trends can inform better decision-making regarding modern cooling solutions that meet current and future industrial demands.

Conclusion

In summary, international B2B buyers navigating the cooling tower types sector must consider market dynamics, sustainability, and historical context when sourcing solutions. By staying informed about emerging trends and prioritizing ethical sourcing, companies can not only enhance operational efficiencies but also contribute positively to environmental sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of cooling tower types

1. How do I select the right cooling tower type for my industrial application?

Selecting the right cooling tower type hinges on several factors, including your specific cooling needs, available space, and environmental conditions. For instance, crossflow cooling towers are cost-effective and easier to maintain, making them suitable for many applications. Conversely, counterflow towers are more efficient but may require larger pumps and higher energy costs. Consider factors such as airflow direction, water distribution methods, and local climate conditions before making a decision. Consulting with manufacturers can provide insights tailored to your operational needs.

2. What are the key components to consider when sourcing cooling towers?

When sourcing cooling towers, focus on essential components such as fill media, fans, and distribution systems. The fill media impacts heat transfer efficiency, while the type of fans (induced or forced draft) affects operational costs and noise levels. Additionally, evaluate the distribution system—whether pressurized or gravity-fed—as this influences water distribution uniformity. Understanding these components will help you assess different models and select one that aligns with your specific requirements and budget.

3. What is the average lead time for cooling tower orders?

Lead times for cooling tower orders can vary significantly based on factors such as the type of tower, customization options, and supplier location. Typically, standard models may have lead times of 6 to 12 weeks, while customized solutions could take longer, potentially extending to 16 weeks or more. It’s crucial to communicate your timeline clearly with suppliers and consider ordering in advance to account for any unforeseen delays in manufacturing or shipping, especially when dealing with international logistics.

4. Are there minimum order quantities (MOQs) for cooling towers?

Minimum order quantities (MOQs) for cooling towers can differ between suppliers. Some manufacturers may require a minimum order of one unit for standard models, while others might have MOQs for custom designs due to the costs associated with production setup. It’s advisable to discuss MOQs upfront with potential suppliers, as this can impact your purchasing strategy, especially if you are operating in a smaller-scale market or require multiple units for different applications.

5. How can I ensure quality assurance (QA) when purchasing cooling towers?

To ensure quality assurance when purchasing cooling towers, consider suppliers with established reputations and certifications such as ISO 9001. Request documentation of previous projects and customer references to gauge their reliability. Additionally, inquire about their QA processes, including testing standards and inspection protocols. Conducting a site visit or arranging for a factory audit can further confirm the supplier’s commitment to quality, especially for large international orders.

Illustrative image related to cooling tower types

6. What payment terms should I expect when sourcing cooling towers internationally?

Payment terms can vary widely when sourcing cooling towers internationally. Common options include a deposit upfront (often 30-50%) with the balance due before shipment or upon delivery. Some suppliers may also offer letters of credit or payment through escrow services for added security. Always clarify payment terms during negotiations and consider the risks associated with international transactions, such as currency fluctuations and banking fees, which may affect your overall budget.

7. What are the logistics considerations for importing cooling towers?

When importing cooling towers, logistics considerations include shipping methods, customs clearance, and potential tariffs or taxes. Evaluate whether you will use air freight for faster delivery or sea freight for cost savings. Ensure that your supplier provides all necessary documentation for customs, including invoices and packing lists. Additionally, work with logistics providers who have experience in handling industrial equipment, as they can navigate the complexities of international shipping and ensure timely delivery.

8. How can I customize a cooling tower to meet my specific needs?

Customizing a cooling tower involves discussing your specific operational requirements with the manufacturer. Key customization options include size, materials, fan types, and control systems. For instance, if you operate in a high-dust environment, you might require additional filtration systems. Collaborate closely with the supplier to ensure all your specifications are documented and that they can meet your cooling efficiency, space constraints, and budgetary requirements.

Top 8 Cooling Tower Types Manufacturers & Suppliers List

1. Chardon Labs – Cooling Towers

Domain: chardonlabs.com

Registered: 1997 (28 years)

Introduction: Cooling towers are heat exchangers used in various industries to cool processes and prevent overheating. They operate by exposing hot water to cool air, facilitating evaporation to dissipate heat. Key components include fill media (film-type and splash-type), fans and motors (axial and centrifugal), distribution systems (pressurized spray and gravity), and basins/sump tanks. There are five main ty…

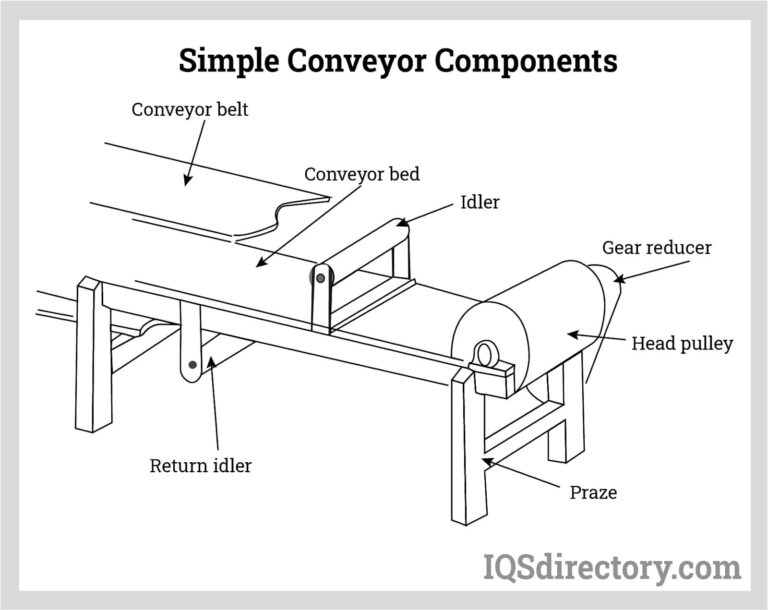

2. IQS Directory – Cooling Towers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Cooling towers are specialized heat exchangers that remove excess heat from water via latent heat dissipation through evaporation. Key terms include: Cooling Range (temperature difference between inlet and outlet), Cooling Load (heat removal rate), Make-up (fresh water volume to replenish evaporated water), Drift (small water droplets carried away), Plume (exiting warm air and water vapor), Approa…

3. Sensorex – Water Quality Sensors

Domain: sensorex.com

Registered: 1996 (29 years)

Introduction: Sensorex offers over 2000 sensor packages for various water quality parameters including pH, Oxidation Reduction Potential (ORP), Conductivity (EC), Dissolved Oxygen (DO), Free Chlorine (FCL), Chlorine Dioxide (CLD), and UV Transmittance (UVT). The company also provides a full line of sensor accessories and transmitters, along with expert technical support for custom designs and off-the-shelf prod…

4. Tower Water – Cooling Tower Solutions

Domain: towerwater.com

Registered: 2009 (16 years)

Introduction: The three main types of cooling towers are: 1. Crossflow Cooling Towers: – Common due to ease of maintenance. – Water cascades down while air flows horizontally. – Expensive to install but easy to manage. – Susceptible to frost damage in cold regions. 2. Counterflow Cooling Towers: – Air flows upward against the descending water. – Uses more energy, leading to higher utility costs. – More compact …

5. French & Company – Cooling Towers

Domain: frenchandcompany.com

Registered: 2000 (25 years)

Introduction: Cooling towers are industrial systems used to release heat back into the air, commonly utilized in factories, warehouses, chemical plants, power stations, and HVAC systems. They can be adjusted for performance, structure, drift, and plume abatement. Types of cooling towers include: 1. Factory Assembled Cooling Towers: These are pre-assembled at factories and can be shipped intact or assembled on-s…

6. Perfect Cooling Towers – Advanced Cooling Solutions

Domain: perfectcoolingtowers.com

Registered: 2009 (16 years)

Introduction: Types of cooling towers: Natural draft, Mechanical draft, Cross-flow, Counter-flow. Features: Non-Corrosive Cooling Tower, unique design one piece casing, advanced technology, emphasis on performance and low maintenance, conservative thermal ratings, long life construction. Capable of withstanding temperatures of at least 120ºF (48.9ºC). Evaporation loss: 1% total mass of water lost for every 10°F…

7. Marley Flow Control – Cooling Towers

Domain: marleyflow.com.au

Introduction: Cooling towers are essential for plants and facilities, offering cost-effective and energy-efficient solutions. Marley Flow Control, an Australian-owned brand since 2002, specializes in manufacturing cooling towers with a wide range of products available for order. Key features include: 1. Types of cooling towers: – Forced draft: Centrifugal fans at the base push air through the tower. – Induced d…

8. Facebook – Natural Draft Cooling Towers

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Natural Draft Cooling Towers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for cooling tower types

How Can Strategic Sourcing Enhance Your Cooling Tower Selection Process?

In conclusion, understanding the diverse types of cooling towers is crucial for international B2B buyers seeking to optimize their operations. Each cooling tower type—whether crossflow, counterflow, natural draft, induced draft, or forced draft—offers unique advantages tailored to specific industrial needs. By strategically sourcing the right cooling tower, businesses can enhance efficiency, reduce operational costs, and minimize environmental impact.

The significance of strategic sourcing cannot be overstated; it empowers organizations to identify suppliers who not only meet quality standards but also align with sustainability goals and provide long-term value. As industries evolve and the demand for efficient cooling solutions grows, leveraging strategic sourcing will be key to staying competitive in the global market.

As you navigate your purchasing decisions, consider how these insights can guide you towards selecting the most suitable cooling tower for your specific application. Engage with trusted suppliers who understand the nuances of your industry and can offer tailored solutions. By doing so, you position your business for future success in a rapidly changing landscape, particularly in regions like Africa, South America, the Middle East, and Europe.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.