Choosing Your Brush With Nylon Bristles: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for brush with nylon bristles

In today’s competitive landscape, sourcing high-quality brushes with nylon bristles presents significant challenges for international B2B buyers. From ensuring compliance with industry standards to selecting the right specifications for diverse applications, the process can be daunting. This guide serves as a comprehensive resource, addressing various brush types, their applications across multiple industries, effective supplier vetting strategies, and insights into cost considerations.

By delving into the nuances of nylon bristle brushes, this guide empowers decision-makers from Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Vietnam—to make informed purchasing choices. Understanding the unique attributes of nylon bristles, such as their durability and ease of maintenance, enables buyers to select products that meet their specific needs, whether for industrial cleaning, personal care, or specialized applications.

Furthermore, we will explore the importance of supplier relationships, highlighting best practices for evaluating and selecting reliable manufacturers. With actionable insights and expert recommendations, this guide aims to equip B2B buyers with the tools necessary to navigate the global market effectively, ensuring they secure quality products that enhance their operations and meet customer demands.

Understanding brush with nylon bristles Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Industrial Bore Brushes | Large diameter, FDA-compliant nylon bristles | Cleaning in food service, pharmaceuticals | Pros: High durability; Cons: Limited to specific cleaning tasks. |

| Detailing Brushes | Small, precision nylon bristles for intricate work | Automotive, electronics, jewelry cleaning | Pros: Excellent for fine detail; Cons: May require multiple sizes for different tasks. |

| Utility Brushes | Versatile design with stiff nylon bristles | Janitorial services, material handling | Pros: Multi-functional; Cons: May not be suitable for delicate surfaces. |

| Hairbrushes | Combination of boar and nylon bristles for hair care | Personal grooming, salons | Pros: Effective for various hair types; Cons: Higher price point for premium brands. |

| ESD Safe Brushes | Anti-static nylon bristles to prevent electrostatic discharge | Electronics manufacturing, cleanrooms | Pros: Essential for sensitive environments; Cons: May have limited availability. |

What are Industrial Bore Brushes and Their Key Characteristics?

Industrial bore brushes feature large diameters and are often made with FDA-compliant nylon bristles. They are specifically designed for cleaning the walls and bottoms of holes, making them ideal for applications in food service and pharmaceuticals where hygiene is paramount. Buyers should consider the size and compatibility with existing equipment, as these brushes typically attach to standard broom threads for ease of use.

Illustrative image related to brush with nylon bristles

How Do Detailing Brushes Stand Out in Their Applications?

Detailing brushes are characterized by their small, precision nylon bristles, which allow for intricate cleaning tasks. Commonly used in the automotive and electronics industries, these brushes are essential for removing dust and debris from hard-to-reach areas. When purchasing, businesses should evaluate the variety of sizes available to ensure they can meet the specific needs of their cleaning tasks.

What Makes Utility Brushes Versatile for Various Industries?

Utility brushes are designed with stiff nylon bristles and offer a versatile solution for a range of applications, including janitorial services and material handling. Their robust construction makes them suitable for heavy-duty cleaning tasks, though they may not be ideal for delicate surfaces. Buyers should assess the bristle stiffness and overall design to match the intended use.

Why Are Hairbrushes with Nylon Bristles Popular in Personal Grooming?

Hairbrushes that combine boar and nylon bristles are popular for their effectiveness in personal grooming and salon settings. The nylon bristles help detangle hair while the boar bristles distribute natural oils for a healthy shine. B2B buyers in the beauty industry should consider the quality and brand reputation, as premium options often come with a higher price point but provide enhanced performance.

How Do ESD Safe Brushes Protect Sensitive Equipment?

ESD safe brushes feature anti-static nylon bristles designed to prevent electrostatic discharge, making them crucial in electronics manufacturing and cleanroom environments. These brushes help maintain a safe working atmosphere by minimizing the risk of static-related damage to sensitive components. When sourcing these brushes, buyers should check for compliance with industry standards to ensure optimal performance in critical applications.

Key Industrial Applications of brush with nylon bristles

| Industry/Sector | Specific Application of brush with nylon bristles | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Cleaning and sanitizing equipment | Ensures compliance with health regulations, reducing contamination risks | FDA compliance, durability, ease of cleaning |

| Aerospace | Cleaning precision parts | Maintains high standards of safety and performance in critical applications | Material specifications, anti-static properties |

| Automotive | Surface preparation before painting | Enhances paint adhesion and finish quality | Bristle stiffness, compatibility with solvents |

| Electronics | Dust removal from sensitive components | Protects against malfunctions and extends product lifespan | ESD-safe materials, precision sizing |

| Janitorial Services | General cleaning in commercial environments | Increases efficiency and effectiveness of cleaning operations | Handle material, bristle durability, size variations |

How is ‘brush with nylon bristles’ utilized in the food processing industry?

In the food processing sector, brushes with nylon bristles are essential for cleaning and sanitizing equipment, surfaces, and utensils. They help remove food residues and contaminants, ensuring compliance with stringent health regulations. These brushes are typically FDA compliant, allowing businesses to maintain high hygiene standards. International buyers should prioritize sourcing brushes that are durable and easy to clean, as these features contribute to long-term cost savings and operational efficiency.

What role do nylon bristle brushes play in the aerospace industry?

In aerospace applications, brushes with nylon bristles are used for cleaning precision parts and assemblies. Their non-abrasive nature allows for effective cleaning without damaging sensitive components. This is crucial in maintaining safety and performance standards in aircraft manufacturing and maintenance. Buyers in this sector must consider material specifications to ensure the brushes meet rigorous industry standards, including anti-static properties to prevent damage to electronic components.

How do nylon bristle brushes benefit the automotive industry?

Within the automotive industry, brushes with nylon bristles are utilized for surface preparation before painting. They effectively remove dust and debris, enhancing paint adhesion and ensuring a high-quality finish. This application is vital for maintaining aesthetic and protective qualities of vehicles. Buyers should focus on the bristle stiffness and compatibility with various solvents to ensure optimal performance and longevity in their cleaning processes.

In what ways are nylon bristle brushes important for electronics?

In the electronics sector, brushes with nylon bristles are critical for dust removal from sensitive components. Their non-conductive properties help protect against electrostatic discharge (ESD), which can damage delicate electronic parts. International buyers should prioritize sourcing brushes that meet ESD-safe standards and are available in precise sizes to accommodate various applications, ensuring effective maintenance of electronic devices.

How do janitorial services utilize nylon bristle brushes?

Janitorial services frequently employ brushes with nylon bristles for general cleaning tasks in commercial environments. These brushes are effective in scrubbing floors, walls, and equipment, increasing the efficiency of cleaning operations. Buyers should consider handle material and bristle durability when sourcing, as these factors can significantly impact the brushes’ effectiveness and lifespan in demanding cleaning situations.

3 Common User Pain Points for ‘brush with nylon bristles’ & Their Solutions

Scenario 1: Inconsistent Quality of Nylon Bristles

The Problem: B2B buyers often face challenges with the inconsistency in the quality of nylon bristles used in brushes. This inconsistency can lead to varying performance levels, affecting the end product quality in industries such as manufacturing, automotive, and food services. Buyers may receive brushes that either shed bristles or fail to perform the intended cleaning or application tasks effectively, resulting in increased operational costs and dissatisfaction among end-users.

The Solution: To mitigate these issues, it is crucial for buyers to establish strong relationships with reputable suppliers who prioritize quality control in their manufacturing processes. When sourcing brushes, request detailed product specifications and certifications, such as FDA compliance or ISO standards, which indicate adherence to quality benchmarks. Moreover, consider conducting sample tests of brushes before placing bulk orders. This allows you to evaluate the bristle integrity, flexibility, and effectiveness in real-world applications, ensuring that the brushes meet your specific operational requirements.

Scenario 2: Difficulty in Selecting the Right Nylon Brush for Specific Applications

The Problem: Many buyers struggle with identifying the appropriate nylon bristle brush for their particular cleaning or application needs. Different industries, such as pharmaceuticals or food processing, have specific requirements regarding brush design, bristle stiffness, and compliance with hygiene standards. This confusion can lead to the purchase of unsuitable products, resulting in inefficiencies and potential compliance issues.

The Solution: To address this challenge, buyers should invest time in understanding the specific applications and requirements of their industry. Utilize resources such as technical datasheets and product catalogs from manufacturers that clearly outline the use cases for each type of nylon brush. Additionally, engaging with industry experts or attending trade shows can provide valuable insights into the latest innovations and best practices in brush technology. By aligning your brush selection with the operational needs, you can enhance productivity and ensure compliance with industry standards.

Scenario 3: High Replacement Costs Due to Brush Wear and Tear

The Problem: Another common pain point for B2B buyers is the high cost associated with frequent brush replacements due to wear and tear, especially in high-volume environments. Brushes with nylon bristles may degrade quickly under heavy use, leading to increased maintenance costs and downtime, which can significantly affect overall business operations.

The Solution: To combat this issue, buyers should focus on selecting high-durability nylon brushes that are specifically designed for prolonged use in demanding environments. Look for brushes that feature reinforced bristles or those treated to enhance resistance to abrasion and chemicals. Additionally, implementing a routine maintenance schedule, including proper cleaning and storage of brushes, can extend their lifespan. Educating staff on best practices for brush usage can also minimize damage and ensure optimal performance, ultimately reducing the frequency and cost of replacements.

Strategic Material Selection Guide for brush with nylon bristles

What Are the Key Materials Used in Brushes with Nylon Bristles?

When selecting a brush with nylon bristles for industrial or commercial applications, the choice of materials significantly impacts performance, durability, and compliance with industry standards. Below is an analysis of four common materials used in the construction of these brushes, focusing on their properties, advantages and disadvantages, and considerations for international B2B buyers.

Illustrative image related to brush with nylon bristles

1. Nylon Bristles

Key Properties: Nylon bristles are known for their resilience and flexibility. They can withstand high temperatures up to 80°C (176°F) and are resistant to various chemicals, making them suitable for a wide range of applications.

Pros & Cons: Nylon bristles offer excellent durability and resistance to wear, which is crucial for brushes used in demanding environments. However, they can be more expensive than other bristle materials, and their performance may degrade at extreme temperatures or when exposed to certain solvents.

Impact on Application: Nylon bristles are ideal for cleaning, scrubbing, and applying coatings in industries such as automotive, aerospace, and food service due to their compatibility with various media, including oils and solvents.

Considerations for International Buyers: Compliance with standards such as FDA regulations for food-grade applications is essential. Buyers in regions like Europe and the Middle East may also need to consider REACH compliance for chemical safety.

2. Plastic Handles (Polypropylene or Acetal)

Key Properties: Plastic handles made from polypropylene or acetal are lightweight, resistant to moisture, and can handle temperatures up to 100°C (212°F).

Pros & Cons: These materials are cost-effective and easy to mold into various shapes, allowing for ergonomic designs. However, they may not be as durable as metal handles and can be prone to cracking under extreme conditions.

Impact on Application: Plastic handles are suitable for applications where weight and moisture resistance are critical, such as in janitorial services or food processing.

Illustrative image related to brush with nylon bristles

Considerations for International Buyers: Buyers should ensure that the plastic materials used comply with local regulations regarding food safety and environmental impact, especially in regions with stringent plastic waste regulations.

3. Metal Handles (Aluminum or Stainless Steel)

Key Properties: Metal handles, particularly those made from aluminum or stainless steel, offer high strength and durability, withstanding heavy use and exposure to harsh environments.

Pros & Cons: Metal handles provide excellent longevity and resistance to corrosion, making them suitable for outdoor or industrial applications. However, they can be heavier and more expensive than plastic alternatives.

Impact on Application: These handles are ideal for heavy-duty brushes used in industrial cleaning, automotive, and construction sectors, where durability is paramount.

Considerations for International Buyers: Compliance with standards like ASTM for material quality is crucial. Buyers in regions such as Africa and South America should also consider the availability of metal recycling facilities when selecting metal handles.

Illustrative image related to brush with nylon bristles

4. Rubber Cushioning

Key Properties: Rubber cushioning, often used in the base of brushes, provides shock absorption and enhances user comfort. It can withstand a range of temperatures and is resistant to wear.

Pros & Cons: The cushioning improves the ergonomics of the brush, reducing hand fatigue during prolonged use. However, rubber can degrade over time, especially when exposed to UV light or extreme temperatures.

Impact on Application: Rubber cushioning is beneficial in applications requiring frequent use, such as personal care or cleaning brushes, where user comfort is essential.

Considerations for International Buyers: Buyers should verify that the rubber materials comply with local health and safety regulations, particularly in the cosmetic and food industries.

Summary Table of Material Selection for Brushes with Nylon Bristles

| Material | Typical Use Case for brush with nylon bristles | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon Bristles | Cleaning, scrubbing, and applying coatings | Excellent durability and flexibility | Performance degradation at extremes | Medium |

| Plastic Handles (Polypropylene or Acetal) | Janitorial services, food processing | Cost-effective and lightweight | Less durable than metal | Low |

| Metal Handles (Aluminum or Stainless Steel) | Heavy-duty industrial cleaning | High strength and corrosion resistance | Heavier and more expensive | High |

| Rubber Cushioning | Personal care, cleaning brushes | Ergonomic and comfortable | Degradation over time | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, ensuring they can make informed decisions based on performance needs, compliance standards, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for brush with nylon bristles

What Are the Key Stages in Manufacturing Brushes with Nylon Bristles?

The manufacturing of brushes with nylon bristles involves several critical stages that ensure both functionality and quality. Understanding these processes can help B2B buyers identify reliable suppliers and make informed purchasing decisions.

Material Preparation: What Materials Are Used for Nylon Bristle Brushes?

The initial stage of manufacturing begins with the selection of high-quality materials. Nylon is chosen for its durability, flexibility, and resistance to moisture and chemicals. Depending on the brush design, other materials, such as wood, plastic, or metal for handles and bases, are also selected.

Once the materials are sourced, they undergo a thorough inspection to verify their quality. This involves checking for defects, such as inconsistencies in the nylon strands and structural integrity of the handles. For nylon bristles, specific grades of nylon, often classified by their tensile strength and elasticity, are preferred to ensure optimal performance.

Forming: How Are Nylon Bristles Integrated into the Brush Design?

The forming stage includes several key techniques. The nylon bristles are typically extruded to achieve uniform length and diameter. This process ensures that each bristle meets the required specifications for stiffness and flexibility.

After extrusion, the bristles are cut to the desired length and bundled together. The next step involves attaching the bristles to the brush head, which can be performed using various methods such as tufting or embedding. In tufting, the bristles are inserted into pre-drilled holes in the brush head and secured with adhesive or by mechanical means.

Assembly: What Processes Are Involved in Finalizing Brush Production?

Once the bristles are secured, the brush undergoes assembly, where the handle is attached to the brush head. Depending on the design, this may involve screws, adhesives, or molding processes. Each brush is then subjected to a preliminary quality check to ensure that it meets design specifications.

In some cases, additional features, such as ergonomic handles or specialized designs for specific applications (e.g., cleaning, grooming), may be integrated during this stage. This customization can enhance the brush’s functionality and appeal to a broader range of markets.

Finishing: What Are the Final Touches Applied to the Brushes?

The finishing stage is crucial for both aesthetics and performance. This includes processes such as polishing, coating, and labeling. Brushes may be coated with protective finishes to enhance durability and resistance to wear and tear.

Labeling is also an essential part of this stage, particularly for international markets. Proper labeling, including compliance with regulations such as CE marking for Europe or FDA compliance for food-related applications, is crucial for marketability and legal compliance.

Illustrative image related to brush with nylon bristles

How Is Quality Assurance Implemented in Brush Manufacturing?

Quality assurance is a fundamental aspect of the manufacturing process, especially in industries where performance and safety are paramount.

What International Standards Govern the Quality of Nylon Bristle Brushes?

Manufacturers often adhere to international quality standards, such as ISO 9001, which outlines criteria for a quality management system. This certification indicates that the manufacturer has established processes to ensure consistent quality in their products.

Additionally, industry-specific standards may apply. For example, brushes intended for the food service industry may need to comply with FDA regulations in the United States, while those sold in Europe may require CE marking. Understanding these standards helps B2B buyers assess the credibility of suppliers.

What Are the Key Quality Control Checkpoints in Brush Production?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to identify defects early. These include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival. Buyers should ensure that suppliers have robust IQC processes to prevent defective materials from entering production.

-

In-Process Quality Control (IPQC): During the manufacturing process, random samples are tested for compliance with specifications. This may include checking bristle density, handle strength, and overall dimensions.

-

Final Quality Control (FQC): Once the brushes are assembled, they undergo final inspections to ensure they meet quality standards. This may involve functional testing, such as evaluating bristle flexibility and attachment strength.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain high-quality standards, B2B buyers should conduct thorough due diligence. This may involve:

-

Supplier Audits: Regular audits of supplier facilities can provide insights into their manufacturing processes and adherence to quality standards. Buyers can assess whether suppliers are following ISO 9001 guidelines and other relevant certifications.

-

Quality Reports: Requesting detailed quality control reports can help buyers understand how frequently defects occur and how they are addressed. These reports should include data from IQC, IPQC, and FQC stages.

-

Third-Party Inspections: Engaging independent inspectors can add an extra layer of assurance. These experts can verify compliance with international standards and provide unbiased assessments of product quality.

What Are the Unique Quality Assurance Challenges for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, may face unique challenges when ensuring quality.

-

Regulatory Compliance: Different regions have varying regulations regarding product quality and safety. Buyers must ensure that suppliers are compliant with local laws, which may involve additional testing or certification.

-

Cultural Differences in Quality Standards: Expectations regarding quality may vary significantly across cultures. B2B buyers should communicate clearly with suppliers about their specific quality requirements to avoid misunderstandings.

-

Logistics and Supply Chain Issues: Delays in shipping and customs can impact the timely delivery of quality products. Buyers should work closely with suppliers to establish reliable logistics and contingency plans.

In conclusion, understanding the manufacturing processes and quality assurance measures for brushes with nylon bristles is crucial for B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, alongside robust quality control practices, buyers can ensure they procure high-quality products that meet their specific needs.

Illustrative image related to brush with nylon bristles

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brush with nylon bristles’

In the competitive landscape of B2B procurement, sourcing a brush with nylon bristles requires careful consideration and strategic planning. This guide provides a step-by-step checklist to help international buyers streamline their purchasing process, ensuring they select the right product and supplier for their specific needs.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the nylon bristle brush based on your intended application. Consider factors such as bristle stiffness, diameter, and the specific type of nylon used, as these will affect performance and durability. Documenting these specifications will help you communicate effectively with suppliers and ensure compatibility with your operational requirements.

Step 2: Research Market Trends and Applications

Understanding current market trends can provide insights into the most suitable types of brushes for your industry. Analyze applications across various sectors, such as automotive, medical, or food service, to identify the specific features that enhance performance in those areas. This knowledge will allow you to make informed decisions and choose brushes that meet industry standards.

Illustrative image related to brush with nylon bristles

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to thoroughly vet potential suppliers. Request detailed company profiles, including their experience, production capabilities, and certifications such as ISO standards. Additionally, seek references from other buyers in your industry to gauge their reliability and product quality, ensuring you partner with a trustworthy manufacturer.

Step 4: Request Samples for Testing

Always request product samples before placing a bulk order. Testing samples allows you to evaluate the brush’s performance in real-world conditions, ensuring it meets your quality expectations. Pay attention to factors like bristle retention, flexibility, and ease of cleaning, which can significantly impact usability and longevity.

Step 5: Verify Compliance with Regulations

Ensure that the brushes comply with relevant industry regulations and standards, particularly if they will be used in sensitive environments like healthcare or food processing. Check for certifications such as FDA compliance for medical-grade brushes, as this will be crucial for maintaining safety and quality in your operations.

Illustrative image related to brush with nylon bristles

Step 6: Analyze Pricing and Terms of Sale

Review pricing structures, payment terms, and minimum order quantities from various suppliers. Look for volume discounts and consider the total cost of ownership, which includes shipping and potential tariffs. A transparent pricing model can help you budget effectively and avoid unexpected costs down the line.

Step 7: Establish a Quality Assurance Process

Once you have selected a supplier, set up a quality assurance process to monitor product quality consistently. Define key performance indicators (KPIs) and establish protocols for receiving inspections and regular audits. This proactive approach will help maintain product integrity and foster a strong relationship with your supplier.

By following this checklist, B2B buyers can confidently navigate the sourcing process for brushes with nylon bristles, ensuring they make informed decisions that align with their operational needs and industry standards.

Comprehensive Cost and Pricing Analysis for brush with nylon bristles Sourcing

When considering the sourcing of brushes with nylon bristles, understanding the comprehensive cost structure and pricing dynamics is essential for B2B buyers. This analysis outlines key cost components, pricing influencers, and strategic buyer tips tailored for international markets, particularly those in Africa, South America, the Middle East, and Europe.

Illustrative image related to brush with nylon bristles

What Are the Key Cost Components in Sourcing Nylon Bristle Brushes?

-

Materials: The primary cost driver is the raw materials used to manufacture nylon bristles. High-quality nylon, which is often FDA compliant for food applications, can command a premium price. Additionally, handles may be made from various materials like plastic or wood, impacting overall costs.

-

Labor: Labor costs depend significantly on the manufacturing location. Regions with higher labor costs will naturally increase the price of the brushes. However, countries with lower labor costs may offer competitive pricing, although they might compromise on quality.

-

Manufacturing Overhead: This includes utilities, facility costs, and general operational expenses. Efficient manufacturing processes can help reduce overhead, thereby lowering the price of the final product.

-

Tooling: Customization often requires specific tooling, which can increase initial costs. For standard products, tooling costs may be amortized over larger production runs, making them more cost-effective.

-

Quality Control (QC): Rigorous quality control processes ensure that products meet safety and performance standards. While this can add to the cost, it is crucial for maintaining product integrity, especially in regulated industries.

-

Logistics: Shipping costs can vary significantly based on the origin and destination of the product. Factors like distance, shipping method, and Incoterms will influence logistics costs.

-

Margin: Suppliers will typically apply a markup to cover their costs and profit margins. Understanding the standard margins within your industry can assist in negotiating better pricing.

How Do Pricing Influencers Affect the Cost of Nylon Bristle Brushes?

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract volume discounts, making it essential for buyers to assess their needs and negotiate MOQs that align with their purchasing capacity.

-

Specifications and Customization: Custom brushes designed for specific applications or industries can lead to increased costs due to additional material, tooling, and labor requirements. Buyers should weigh the benefits of customization against the associated costs.

-

Material Quality and Certifications: Brushes made from high-quality, certified materials (e.g., FDA-compliant nylon) generally incur higher costs but offer better performance and safety assurance. Buyers should prioritize quality over cost in regulated industries.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their proven track record, while new or less-known suppliers might offer lower prices but come with risks.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers in shipping, which can significantly affect total costs, especially in terms of logistics and insurance.

What Tips Can Help Buyers Negotiate Better Prices for Nylon Bristle Brushes?

-

Leverage Total Cost of Ownership (TCO): Consider not only the purchase price but also the long-term costs associated with quality, durability, and maintenance. A higher upfront cost may lead to lower overall expenses.

-

Negotiate Terms: Engage in discussions about payment terms, delivery schedules, and potential discounts for early payment or bulk orders. Flexibility can often yield significant savings.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing, enhanced service, and priority access to new products or innovations.

-

Stay Informed: Keep abreast of market trends, material price fluctuations, and competitor offerings to strengthen your negotiating position.

-

Cultural Sensitivity: When dealing with suppliers from diverse regions, understanding cultural nuances in negotiation can facilitate smoother transactions and foster goodwill.

Conclusion

In summary, a comprehensive understanding of the cost structure and pricing dynamics for nylon bristle brushes is essential for B2B buyers. By considering the key components and influencers, and applying strategic negotiation techniques, buyers can effectively manage costs while ensuring quality and compliance. Keep in mind that prices can vary widely based on numerous factors, so it’s wise to conduct thorough market research before finalizing any procurement decisions.

Alternatives Analysis: Comparing brush with nylon bristles With Other Solutions

Exploring Alternative Solutions to Brushes with Nylon Bristles

In the quest for effective cleaning and grooming solutions, the brush with nylon bristles stands out for its versatility and performance. However, buyers often explore alternatives that may better suit their specific needs. This section provides a comparative analysis of brushes with nylon bristles against two viable alternatives: foam applicators and synthetic microfiber cloths.

Comparison Table

| Comparison Aspect | Brush With Nylon Bristles | Foam Applicator | Synthetic Microfiber Cloth |

|---|---|---|---|

| Performance | Excellent for detangling and grooming, distributes oils evenly | Good for applying products, limited in scrubbing capabilities | Superior dust and dirt trapping, versatile for various surfaces |

| Cost | Moderate (£145.40 per unit) | Low (£5-£20 per unit) | Moderate (£10-£30 per unit) |

| Ease of Implementation | Easy to use, requires minimal training | Very easy to use, no training needed | Simple to use, often requires specific cleaning solutions |

| Maintenance | Requires regular cleaning; may need replacement over time | Low maintenance; can be rinsed and reused | Machine washable, durable, but may need regular replacement |

| Best Use Case | Ideal for hair grooming and styling | Best for applying creams and lotions | Great for dusting, wiping surfaces, and cleaning |

Detailed Breakdown of Alternatives

Foam Applicator

Foam applicators are lightweight tools designed primarily for the application of creams and lotions. They excel in scenarios where a smooth, even application is critical, such as in cosmetics or coatings. The pros of foam applicators include their low cost and ease of use, making them accessible for a variety of industries, including beauty and automotive. However, they are less effective for scrubbing or detangling, which may limit their usability in more demanding cleaning tasks.

Illustrative image related to brush with nylon bristles

Synthetic Microfiber Cloth

Synthetic microfiber cloths have gained popularity for their exceptional cleaning capabilities, particularly in dust and dirt trapping. These cloths can be used dry or damp, making them versatile for various applications, from cleaning surfaces to polishing. Their primary advantage is the ability to capture microscopic particles, which brushes may miss. Additionally, microfiber cloths are machine washable and durable, providing a cost-effective solution over time. However, they may require specific cleaning solutions for optimal performance, and their effectiveness can diminish if not maintained properly.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between a brush with nylon bristles and its alternatives, B2B buyers should consider their specific use cases, budget constraints, and maintenance requirements. A brush with nylon bristles may be ideal for tasks involving grooming and detangling, particularly in the beauty industry. In contrast, foam applicators and synthetic microfiber cloths may serve better in applications where product application or surface cleaning is paramount. By assessing these factors, buyers can make informed decisions that align with their operational goals and enhance efficiency.

Essential Technical Properties and Trade Terminology for brush with nylon bristles

What Are the Key Technical Properties of a Brush with Nylon Bristles?

When selecting a brush with nylon bristles for industrial or commercial applications, understanding its technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

-

Material Grade

The primary component of nylon bristle brushes is the nylon material, often specified by its grade (e.g., Nylon 6, Nylon 6.12). The grade impacts the brush’s durability, flexibility, and resistance to chemicals or temperature fluctuations. For B2B buyers, selecting the right material grade ensures that the brush will withstand specific conditions in industrial settings, enhancing longevity and performance. -

Bristle Diameter

The bristle diameter, measured in millimeters or inches, affects the brush’s cleaning effectiveness and surface compatibility. A thicker bristle diameter provides more abrasion, making it suitable for heavy-duty cleaning tasks, while thinner bristles are better for delicate surfaces. Buyers should match the bristle diameter to their specific cleaning or application needs to optimize efficiency. -

Brush Dimensions

The overall dimensions of the brush, including length, width, and height, are critical for determining its application. For instance, a larger brush may be more efficient for sweeping large areas, while a smaller brush is ideal for precision work. Understanding the dimensions helps in selecting brushes that fit specific tools or machines. -

FDA Compliance

For applications in food processing or medical industries, brushes must comply with FDA regulations. This certification ensures that the materials used do not contaminate products or surfaces. B2B buyers in regulated industries must prioritize FDA-compliant brushes to adhere to safety and quality standards. -

Temperature Resistance

Some nylon brushes are designed to withstand high or low temperatures. This property is particularly important in industries such as automotive or aerospace, where brushes may come into contact with heated surfaces. Knowing the temperature tolerance can prevent damage to both the brush and the materials being cleaned. -

Bristle Stiffness

The stiffness of the bristles can vary significantly and affects the brush’s application. Stiffer bristles are more effective for heavy scrubbing, while softer bristles are better for more gentle applications. Selecting the correct stiffness ensures optimal performance without damaging surfaces.

What Are Common Trade Terms Related to Brushes with Nylon Bristles?

Understanding industry terminology is essential for effective communication and negotiation in the B2B space. Here are some common terms relevant to brushes with nylon bristles:

Illustrative image related to brush with nylon bristles

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of brushes, an OEM might produce nylon bristle brushes that are sold under different brand names. Understanding OEM relationships can help buyers source high-quality products tailored to their specifications. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is important for B2B buyers as it affects inventory management and cost efficiency. Knowing the MOQ helps in planning purchases and ensuring that production needs are met without overstocking. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. It is a crucial step in the procurement process, allowing buyers to compare offers from different vendors and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of international trade rules that define the responsibilities of buyers and sellers in the shipment of goods. Familiarity with Incoterms is vital for B2B buyers engaged in international trade, as they dictate shipping costs, risks, and logistics responsibilities. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is essential for supply chain management, as it impacts production schedules and inventory levels. -

Custom Design

Custom design refers to the ability to create brushes tailored to specific requirements or applications. Many manufacturers offer customization options, allowing buyers to specify dimensions, materials, and bristle types to meet unique operational needs. This flexibility can enhance efficiency and performance in specialized applications.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when procuring brushes with nylon bristles, ensuring they meet their operational requirements effectively.

Navigating Market Dynamics and Sourcing Trends in the brush with nylon bristles Sector

What Are the Key Market Dynamics and Trends Influencing the Brush with Nylon Bristles Sector?

The global market for brushes with nylon bristles is experiencing significant growth, driven by diverse applications across multiple industries, including automotive, healthcare, and personal care. The increasing demand for high-quality, durable cleaning tools is a critical driver, as industries seek efficient solutions to enhance productivity and maintain hygiene standards. Emerging technologies in manufacturing, such as automation and advanced materials, are reshaping sourcing strategies, making it easier for international B2B buyers to access innovative products tailored to their specific needs.

In regions like Africa, South America, the Middle East, and Europe, there is a notable shift towards customization and specialization in brush production. Buyers are increasingly looking for suppliers who can provide tailored solutions, whether it’s for specific applications in food processing or for personal grooming products. Furthermore, e-commerce platforms and digital marketplaces are simplifying the procurement process, allowing buyers to compare products and prices seamlessly.

Illustrative image related to brush with nylon bristles

Another emerging trend is the increasing importance of compliance with international quality standards, such as ISO certifications. B2B buyers are now prioritizing suppliers who not only meet these standards but also demonstrate a commitment to innovation and customer service. This trend is particularly pronounced in competitive markets like Saudi Arabia and Vietnam, where businesses seek to differentiate themselves through superior product offerings.

How Is Sustainability Shaping the Sourcing of Brushes with Nylon Bristles?

Sustainability has become a cornerstone of sourcing practices in the brush with nylon bristles sector. As environmental concerns grow, B2B buyers are increasingly focused on the environmental impact of their purchases. This includes the sourcing of materials, production processes, and the end-of-life disposal of products. Buyers are now more inclined to partner with suppliers who prioritize eco-friendly materials, such as recycled nylon or biodegradable alternatives.

The importance of ethical supply chains cannot be overstated. Companies are under pressure to ensure that their sourcing practices align with sustainability goals, which often include transparency and social responsibility. Certifications such as the Global Recycled Standard (GRS) and the Forest Stewardship Council (FSC) are becoming essential for suppliers aiming to appeal to conscientious buyers. These certifications not only demonstrate compliance with environmental standards but also build trust with end consumers.

Moreover, the demand for ‘green’ certifications is reshaping product development. B2B buyers are looking for brushes that not only perform well but also come with assurances of minimal environmental impact. This has led to innovations in product design and manufacturing processes, making it easier for buyers to source responsibly.

What Is the Historical Context of the Brush with Nylon Bristles Sector?

The evolution of brushes with nylon bristles dates back to the mid-20th century when nylon was first introduced as a synthetic alternative to natural bristles. Initially popularized for its durability and versatility, nylon quickly became the material of choice for various applications, ranging from household cleaning to industrial uses. As production techniques advanced, manufacturers began to explore the benefits of combining nylon with other materials, such as boar bristles, to enhance performance.

Illustrative image related to brush with nylon bristles

Over the decades, the brush sector has adapted to changing consumer preferences and technological advancements. The rise of personal grooming trends in the late 20th century led to a surge in demand for high-quality hairbrushes, further establishing nylon as a preferred material due to its ability to withstand heat and humidity. Today, the brush with nylon bristles sector is marked by a focus on innovation, sustainability, and customization, reflecting the broader trends shaping the global marketplace. This historical context provides valuable insights for B2B buyers looking to navigate the current landscape and make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of brush with nylon bristles

-

How do I choose the right nylon bristle brush for my application?

Selecting the appropriate nylon bristle brush hinges on understanding your specific needs. Consider factors such as the brush size, bristle stiffness, and the intended application—whether for cleaning, painting, or industrial use. For instance, a softer bristle may be ideal for delicate surfaces, while stiffer bristles are better suited for heavy-duty cleaning. Additionally, ensure the brush is compatible with any machinery or tools you plan to use. Reviewing product specifications and consulting with suppliers can provide clarity on which brush will best meet your requirements. -

What are the benefits of using nylon bristles in brushes?

Nylon bristles offer several advantages, including durability, resistance to chemicals, and flexibility. These properties make them ideal for a variety of applications, from industrial cleaning to personal grooming. Nylon bristles maintain their shape over time and do not absorb water, which prevents bacterial growth. Furthermore, they are available in various stiffness levels, allowing for tailored solutions based on specific cleaning or application needs, ensuring optimal performance across different environments. -

What is the minimum order quantity (MOQ) for nylon bristle brushes?

The MOQ for nylon bristle brushes can vary significantly between suppliers and product types. Typically, manufacturers may set an MOQ ranging from 100 to 1,000 units, depending on production costs and inventory considerations. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you’re testing new products or entering a new market. Establishing a clear understanding of MOQ can help avoid overstock issues and optimize your supply chain. -

How can I ensure quality assurance when sourcing nylon bristle brushes?

To ensure quality assurance, request samples from potential suppliers before making bulk purchases. Evaluate the brush’s performance, durability, and material quality. Additionally, inquire about the supplier’s quality control processes, certifications (such as ISO standards), and customer reviews. Conducting factory audits or using third-party inspection services can further verify compliance with international standards. Establishing a clear return policy can also protect your investment in case the products do not meet your expectations. -

What payment terms should I expect when ordering nylon bristle brushes internationally?

Payment terms for international orders can vary widely. Common practices include advance payment, partial payments (e.g., 30% upfront, 70% before shipping), or net 30/60 terms upon receipt of goods. Discuss payment methods such as bank transfers, letters of credit, or online payment platforms, ensuring they are secure and suitable for both parties. Additionally, consider currency fluctuations and transaction fees when negotiating terms, as these can impact overall costs. -

What logistics considerations should I keep in mind when importing nylon bristle brushes?

When importing nylon bristle brushes, consider shipping methods, customs regulations, and potential tariffs. Opt for reliable freight forwarders who can navigate the complexities of international shipping and provide tracking services. Understand the import duties applicable in your country and ensure all documentation is complete to prevent delays. Additionally, factor in delivery times and logistics costs to calculate your total landed cost, which will help in budgeting and pricing strategies. -

Can I customize nylon bristle brushes with my branding?

Yes, many manufacturers offer customization options for nylon bristle brushes, including branding through logos, colors, and specific dimensions. Customization can enhance brand visibility and cater to your target market’s preferences. Discuss your requirements with suppliers, including minimum order quantities for customized products. Keep in mind that customization may affect lead times and costs, so plan accordingly to align with your marketing strategies. -

What industries commonly use nylon bristle brushes?

Nylon bristle brushes are widely utilized across various industries, including automotive, aerospace, food service, and healthcare. In automotive applications, they are often employed for cleaning and detailing. In food service, FDA-compliant nylon brushes are essential for sanitization and cleaning equipment. Understanding the specific industry applications can help you tailor your product offerings and marketing strategies to meet the needs of your target audience effectively.

Top 7 Brush With Nylon Bristles Manufacturers & Suppliers List

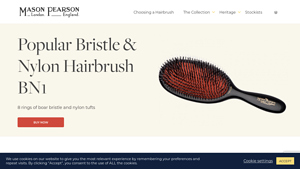

1. Mason Pearson – Popular Bristle & Nylon Hairbrush BN1

Domain: masonpearson.com

Registered: 1997 (28 years)

Introduction: Product Name: Popular Bristle & Nylon Hairbrush BN1

Price: £145.40

Bristle Composition: 8 rings of boar bristle and nylon tufts

Specifications:

– Rubber Cushion: Dry Natural Rubber (DNR)

– Handle and Base: Cellulose acetate plastic

– Bristles: Boar bristle & nylon tufts

– Logo: Elegantly embedded with hot foil

Size:

– Length: 9 inches / 22.86 cm

– Width: 3 inches / 7.62 cm

– Head: 5.12 inches / 13…

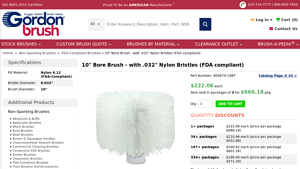

2. Gordon Brush – 10 Bore Brush with Nylon Bristles

Domain: gordonbrush.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “10” Bore Brush – with .032″ Nylon Bristles (FDA compliant)”, “Part Number”: “900674-10BT”, “Fill Material”: “Nylon 6.12 (FDA-Compliant)”, “Bristle Diameter”: “0.032””, “Brush Diameter”: “10””, “Price”: “$222.06 each”, “Package Quantity”: “sold in packages of 3 for $666.18”, “Quantity Discounts”: [{“1+ packages”: “$222.06 each (price per package $666.18)”}, {“34+ packages”: “$210….

3. Hairbrush – Nylon Bristle Clusters

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Hairbrush with nylon bristle clusters, available in normal or compact size. Previously found in standard drugstores in Taiwan about 20 years ago and 40 years ago at a normal price. Not commonly seen in the US or Europe.

4. Cleaner Supply – Nylon Bristle Coat Brush 14 1/4

Domain: cleanersupply.com

Registered: 1997 (28 years)

Introduction: Nylon Bristle Coat Brush 14 1/4″

5. Morocco Method – Mixed Boar Bristle & Nylon Brush

Domain: shop.morroccomethod.com

Registered: 1999 (26 years)

Introduction: Mixed Pure Boar Bristle & Nylon Brush – Small

Price: $30.00

Size: 7″ x 2″

Features:

– Several rings of pure boar bristles and nylon tufts

– Pneumatic rubber cushion for efficient brushing

– Hand-polished plastic handle for ergonomic comfort

– Ideal for travel and on-the-go brushing

– Suitable for thick hair and stronger scalps

– Daily brushing promotes scalp health by increasing blood flow and di…

6. Crown Affair – The Brush No. 001

Domain: crownaffair.com

Registered: 2007 (18 years)

Introduction: {“name”: “The Brush No. 001”, “type”: “boar and nylon bristle brush”, “material”: “handcrafted beechwood, ethically sourced boar bristles, high-quality nylon”, “features”: [“distributes natural oils from scalp to strands”, “stimulates scalp”, “mixed tension brushing for effective detangling”, “pneumatic breathing hole for flexibility”], “recommended_for”: “all hair textures, especially medium to t…

7. Target – Top-Rated Nylon Bristle Hair Brushes

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Top-Rated Nylon Bristle Hair Brushes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for brush with nylon bristles

In today’s competitive landscape, strategic sourcing of brushes with nylon bristles can significantly enhance operational efficiency and product quality across various industries. Key takeaways highlight the importance of selecting suppliers who prioritize quality materials, such as FDA-compliant nylon, and demonstrate robust manufacturing practices. By leveraging high-quality nylon bristles, businesses can ensure durability, performance, and compliance with industry standards, which is particularly crucial for sectors such as food service, healthcare, and aerospace.

Moreover, international buyers from Africa, South America, the Middle East, and Europe should focus on building long-term partnerships with reliable suppliers to optimize their supply chains and reduce costs. This proactive approach not only secures a consistent quality of products but also fosters innovation and responsiveness to market demands.

As the global market evolves, staying ahead requires agility and informed decision-making. We encourage B2B buyers to explore diverse sourcing options and consider the strategic advantages of integrating nylon bristle brushes into their operations. The future of your business could hinge on these choices, paving the way for sustainable growth and enhanced customer satisfaction. Embrace the opportunity to refine your sourcing strategies today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.