Choosing Your Steam Systems: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for steam systems

In an increasingly interconnected world, navigating the complexities of sourcing efficient steam systems can pose significant challenges for international B2B buyers. The need for reliable steam generation and distribution is paramount, especially for industries across Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam. This guide serves as a comprehensive resource, detailing the various types of steam systems, their applications, and key considerations for selecting the right equipment and suppliers.

From understanding the intricacies of steam boilers—be it firetube or watertube designs—to exploring the essential components of an effective steam distribution network, this guide equips buyers with the knowledge necessary to make informed purchasing decisions. We delve into vital topics such as supplier vetting, maintenance requirements, and cost factors, ensuring that you can assess potential partners with confidence.

Moreover, this resource highlights the importance of optimizing steam efficiency and safety, addressing common pitfalls that can lead to operational inefficiencies. By leveraging the insights provided in this guide, B2B buyers will be empowered to enhance their steam system operations, ultimately leading to improved productivity and reduced costs. Embrace the opportunity to streamline your sourcing process and elevate your steam system strategy in the global market.

Understanding steam systems Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Firetube Boiler | Combustible fuel within tubes; heat surrounds water | Food processing, manufacturing | Pros: Simpler design, lower initial cost. Cons: Limited steam pressure capacity, less efficient at high loads. |

| Watertube Boiler | Water contained in tubes; heated by external combustion | Power generation, chemical plants | Pros: Higher pressure capabilities, better efficiency. Cons: More complex design, higher maintenance costs. |

| Electric Steam Boiler | Uses electric elements to heat water; compact design | Pharmaceuticals, laboratories | Pros: High efficiency, no emissions. Cons: Higher operating costs, limited capacity for large-scale operations. |

| Condensing Steam System | Recovers heat from exhaust; improves overall efficiency | District heating, industrial processes | Pros: Energy savings, reduced emissions. Cons: Initial investment can be high, requires careful design. |

| Combined Heat and Power (CHP) | Simultaneously generates electricity and useful heat | Large industrial facilities, hospitals | Pros: Maximizes energy use, lowers fuel costs. Cons: Complex systems, higher upfront costs. |

What Are the Characteristics and Suitability of Firetube Boilers for B2B Buyers?

Firetube boilers feature a design where the combustion gases pass through tubes that are submerged in water. This makes them ideal for applications with lower pressure requirements, such as food processing and manufacturing. Buyers should consider the initial lower capital cost and simpler maintenance of firetube boilers, but they should also note that these systems may not be suitable for high-load situations due to limitations in steam pressure and efficiency.

How Do Watertube Boilers Stand Out in Industrial Applications?

Watertube boilers differ from firetube models by containing water in the tubes, which are heated externally. This design allows for higher pressure outputs and efficiency, making them suitable for power generation and chemical processing. B2B buyers should evaluate the operational efficiency and capacity of watertube boilers against their more complex maintenance needs and higher initial costs, especially in environments where consistent high pressure is required.

Why Are Electric Steam Boilers Gaining Popularity in Specific Sectors?

Electric steam boilers utilize electric heating elements to produce steam, offering a compact and efficient option for applications in pharmaceuticals and laboratories. Their key advantages include higher efficiency and zero emissions, making them a cleaner alternative. However, buyers must weigh the higher operational costs and limited capacity against their specific steam requirements and environmental goals.

What Advantages Do Condensing Steam Systems Offer for Energy Efficiency?

Condensing steam systems are designed to recover heat from exhaust gases, significantly improving overall energy efficiency. These systems are particularly beneficial in district heating and industrial processes, where energy savings can lead to reduced operational costs. Buyers should consider the initial investment and the need for precise system design, as the benefits can outweigh the costs in the long term.

How Does Combined Heat and Power (CHP) Technology Maximize Energy Use?

CHP systems generate both electricity and useful heat simultaneously, making them an excellent choice for large industrial facilities and hospitals that require significant energy. The primary advantage lies in maximizing energy utilization and reducing fuel costs. However, the complexity of CHP systems and their higher upfront costs necessitate careful consideration by B2B buyers, particularly in terms of long-term savings versus initial investments.

Key Industrial Applications of steam systems

| Industry/Sector | Specific Application of steam systems | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Steam heating for cooking and sterilization | Ensures food safety, improves product quality | Compliance with food safety standards, energy efficiency, reliability of supply |

| Pharmaceuticals | Steam for sterilization and process heating | Guarantees product purity, enhances process efficiency | Regulatory compliance, steam quality, and pressure control |

| Textile Manufacturing | Steam for dyeing and finishing processes | Improves color consistency, reduces processing times | Quality of steam, system efficiency, and maintenance support |

| Power Generation | Steam for turbine operation | High energy efficiency, reliable power generation | Boiler capacity, fuel type compatibility, and emissions control |

| Chemical Processing | Steam for heating and reaction processes | Enhances reaction rates, increases production capacity | Quality of steam, safety features, and energy costs |

How Are Steam Systems Used in the Food and Beverage Industry?

In the food and beverage sector, steam systems are pivotal for cooking, heating, and sterilization processes. Steam is utilized to ensure food safety by effectively killing bacteria and pathogens during cooking. Moreover, it plays a crucial role in maintaining product quality by providing consistent temperatures during processing. For international buyers, particularly in regions like Africa and South America, sourcing steam systems that meet stringent food safety regulations is essential. Additionally, energy efficiency and reliability are key considerations to minimize operational costs.

What Role Do Steam Systems Play in Pharmaceuticals?

In the pharmaceutical industry, steam systems are integral for sterilization and heating processes. Steam is used to sterilize equipment and products, ensuring that pharmaceuticals meet stringent purity standards. The ability to maintain consistent steam quality and pressure is crucial for effective sterilization. Buyers in this sector should prioritize suppliers that provide systems compliant with regulatory standards and offer robust monitoring capabilities. The importance of safety and reliability cannot be overstated, especially in regions with varying infrastructure quality.

How Are Steam Systems Utilized in Textile Manufacturing?

Steam systems are extensively employed in textile manufacturing for processes such as dyeing and finishing. The use of steam facilitates uniform dye application, leading to improved color consistency and reduced processing times. For B2B buyers, sourcing steam solutions that can deliver high-quality steam at the required pressure is vital for optimizing production efficiency. Additionally, considerations around maintenance support and energy costs are critical, particularly for manufacturers in emerging markets like Vietnam and Nigeria, where operational efficiency can significantly impact competitiveness.

What Advantages Do Steam Systems Offer in Power Generation?

In power generation, steam systems are essential for operating turbines that convert thermal energy into electricity. High-pressure steam enhances energy efficiency and reliability in power generation processes. Buyers in this sector must consider the capacity of boilers, compatibility with various fuel types, and emissions control technologies to meet environmental regulations. As energy demands grow in regions like the Middle East, investing in efficient steam systems can provide a competitive edge in the energy market.

How Are Steam Systems Applied in Chemical Processing?

Steam is widely used in chemical processing for heating and facilitating various chemical reactions. By providing consistent and controlled heat, steam enhances reaction rates and increases overall production capacity. B2B buyers in this sector should focus on sourcing steam systems that ensure high-quality steam and include safety features to prevent operational hazards. Additionally, understanding energy costs and the potential for energy recovery can significantly improve the economic viability of steam systems in chemical applications, especially in developing markets.

3 Common User Pain Points for ‘steam systems’ & Their Solutions

Scenario 1: Inefficient Steam Distribution Leading to Energy Loss

The Problem: Many B2B buyers encounter challenges with inefficient steam distribution systems, which can lead to significant energy losses. This inefficiency often stems from poorly designed pipe layouts, insufficient insulation, or outdated components that fail to deliver steam at the required quality and pressure. For businesses operating in energy-intensive industries, such as food processing or textiles, this can lead to increased operational costs and reduced productivity.

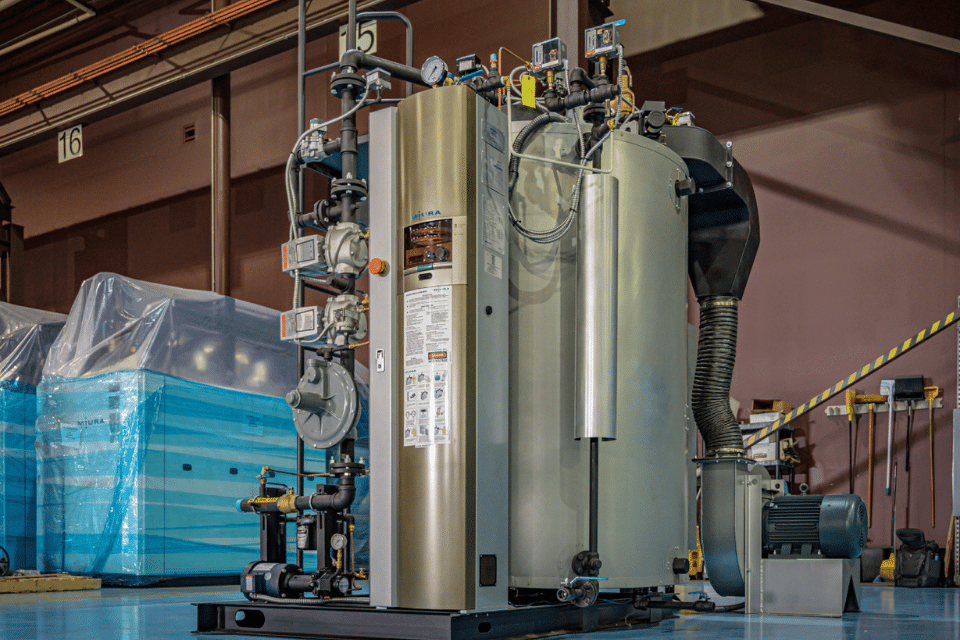

Illustrative image related to steam systems

The Solution: To combat these issues, it’s crucial to conduct a comprehensive audit of the steam distribution system. This includes evaluating the layout of pipes to ensure they are optimally designed for steam flow, minimizing bends and unnecessary extensions that can cause pressure drops. Additionally, investing in high-quality insulation materials can significantly reduce heat loss. Implementing regular maintenance schedules is essential to replace any outdated or failing components, such as steam traps and valves, that may be contributing to inefficiency. Partnering with suppliers who offer advanced steam system technology, such as pressure-reducing valves with built-in separators, can also enhance steam quality and energy efficiency.

Scenario 2: Condensate Management Issues Affecting Performance

The Problem: A common pain point for businesses utilizing steam systems is the inadequate management of condensate. Poor condensate removal can lead to water hammer, reduced system efficiency, and even equipment damage. This is especially critical in industries where steam is used for heating or processing, as the presence of excess condensate can disrupt operations and lead to costly downtimes.

The Solution: Implementing a robust condensate return system is key to resolving these issues. Buyers should focus on designing condensate lines that facilitate easy drainage and ensure proper gradient alignment to promote gravity flow. The use of steam traps is essential; they should be strategically placed to efficiently remove condensate while preventing steam loss. Regular monitoring and maintenance of these traps will help identify blockages or failures early. Additionally, consider integrating advanced monitoring technology that provides real-time data on condensate flow and temperature, allowing for proactive management of the steam system.

Scenario 3: Safety Risks Due to Inadequate Pressure Management

The Problem: Safety is a paramount concern in steam system operations, particularly regarding pressure management. Inadequate pressure control can lead to dangerous situations, including equipment failures or even catastrophic accidents. B2B buyers must ensure that their steam systems are designed and maintained to operate safely within specified pressure limits, especially in regions with stringent safety regulations.

The Solution: To mitigate these risks, it is crucial to invest in a comprehensive pressure management strategy. This includes installing pressure-reducing valves (PRVs) at critical points in the system to ensure that downstream equipment operates within safe pressure limits. Regular calibration of pressure gauges and safety valves is essential for reliable operation. Buyers should also consider implementing automated monitoring systems that can alert operators to any anomalies in pressure levels. Training staff on emergency procedures and conducting regular safety drills will further enhance the safety of steam operations. Partnering with suppliers who provide robust safety equipment and support can also ensure compliance with local regulations and best practices.

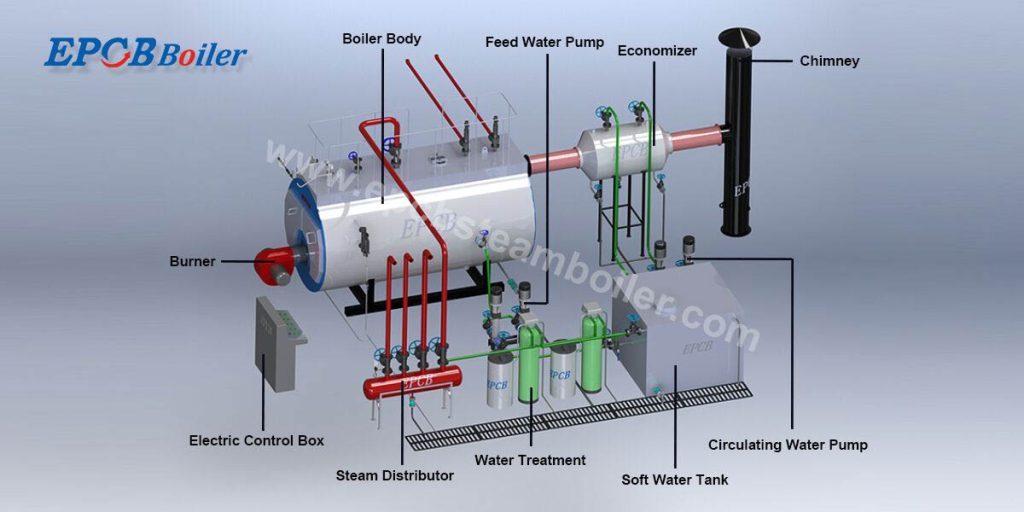

Illustrative image related to steam systems

Strategic Material Selection Guide for steam systems

When selecting materials for steam systems, it is essential to consider the specific requirements of the application, including temperature and pressure ratings, corrosion resistance, and overall durability. Here, we analyze four common materials used in steam systems, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Carbon Steel in Steam Systems?

Carbon steel is a prevalent choice for steam piping due to its high strength and good thermal conductivity. It typically has a temperature rating of up to 400°C (752°F) and can handle pressures up to 20 bar (290 psi). Its corrosion resistance can be enhanced with coatings or galvanization, making it suitable for various environments.

Pros and Cons: Carbon steel is relatively inexpensive and widely available, making it a cost-effective option for large installations. However, it is susceptible to corrosion, especially in high-moisture environments, which can lead to maintenance issues over time.

Impact on Application: Carbon steel is compatible with steam and water but may not be suitable for systems involving aggressive chemicals. Buyers should consider the local climate and environmental conditions when selecting this material.

International Considerations: Compliance with ASTM standards is crucial, as many regions, including Africa and South America, have specific regulations regarding material specifications. Buyers should also be aware of local sourcing options to ensure timely procurement.

How Does Stainless Steel Perform in Steam Applications?

Stainless steel is known for its excellent corrosion resistance and high-temperature performance, typically rated for temperatures up to 800°C (1472°F) and pressures exceeding 50 bar (725 psi). The material’s chromium content provides a protective oxide layer, making it ideal for harsh environments.

Pros and Cons: The primary advantage of stainless steel is its durability and longevity, reducing the need for frequent replacements. However, it comes at a higher cost compared to carbon steel, which may impact budget-sensitive projects.

Impact on Application: Stainless steel is suitable for high-purity applications, such as food processing and pharmaceuticals, where contamination must be minimized. Its resistance to scaling and corrosion makes it a preferred choice for steam systems in these sectors.

International Considerations: Buyers in Europe and the Middle East should ensure compliance with DIN and JIS standards, as these regions often have stringent regulations regarding material quality and safety.

What are the Benefits of Copper in Steam Systems?

Copper is often used in smaller steam systems and for specific applications like heat exchangers due to its excellent thermal conductivity and resistance to corrosion. It can typically withstand temperatures up to 200°C (392°F) and moderate pressures.

Pros and Cons: The primary advantage of copper is its ability to transfer heat efficiently, leading to energy savings. However, it is more expensive than carbon steel and may not be suitable for high-pressure applications.

Impact on Application: Copper is ideal for low-pressure steam systems and applications requiring rapid heat transfer. Its compatibility with steam and water makes it a versatile option, but it should be avoided in systems with aggressive chemicals.

International Considerations: Compliance with ASTM standards is critical, especially for buyers in Africa and South America, where local regulations may dictate specific material requirements.

Why Choose PVC for Steam Systems?

Polyvinyl Chloride (PVC) is not commonly used for steam systems due to its lower temperature and pressure ratings, typically around 60°C (140°F) and 6 bar (87 psi). However, it is often utilized in condensate drainage systems.

Pros and Cons: PVC is lightweight, easy to install, and cost-effective, making it suitable for non-pressurized applications. On the downside, its limited temperature and pressure ratings restrict its use in high-performance steam systems.

Impact on Application: PVC is ideal for condensate lines where steam is not present, but it should never be used for carrying steam directly due to its thermal limitations.

International Considerations: Buyers should ensure compliance with local standards, as PVC specifications can vary significantly across regions, particularly in Europe and the Middle East.

Illustrative image related to steam systems

Summary Table of Material Selection for Steam Systems

| Material | Typical Use Case for steam systems | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General steam piping | Cost-effective and widely available | Susceptible to corrosion | Low |

| Stainless Steel | High-purity applications (food, pharma) | Excellent corrosion resistance and durability | Higher cost compared to carbon steel | High |

| Copper | Heat exchangers, low-pressure systems | Superior thermal conductivity | Expensive and limited high-pressure use | Med |

| PVC | Condensate drainage systems | Lightweight and easy to install | Low temperature and pressure ratings | Low |

This strategic material selection guide provides B2B buyers with critical insights into the properties, advantages, and limitations of various materials used in steam systems, facilitating informed decision-making tailored to specific regional requirements and applications.

In-depth Look: Manufacturing Processes and Quality Assurance for steam systems

What Are the Key Manufacturing Processes for Steam Systems?

The manufacturing of steam systems involves several critical stages that ensure the final product meets the rigorous demands of various industrial applications. Understanding these stages can help B2B buyers assess potential suppliers and the quality of the systems they provide.

What Are the Main Stages in the Manufacturing Process of Steam Systems?

-

Material Preparation: The first step in manufacturing steam systems is sourcing and preparing the raw materials. Common materials include carbon steel, stainless steel, and alloys, selected based on their thermal and mechanical properties. Suppliers must ensure that materials comply with international standards such as ASTM or ASME. Proper documentation of material certification is crucial to verify compliance.

-

Forming: This stage includes various techniques such as welding, bending, and machining to shape the components of the steam system. For instance, pipe sections may be formed using processes like hot or cold bending, depending on the design specifications. Advanced techniques, such as laser cutting and CNC machining, are often employed to ensure precision and reduce waste.

-

Assembly: After forming, components are assembled into complete steam systems. This stage may involve integrating valves, pressure gauges, and safety devices. Proper alignment and secure fastening are essential to prevent leaks and ensure system integrity. Use of standardized fittings and components can further enhance compatibility and performance.

-

Finishing: The final stage involves surface treatment and finishing processes to enhance durability and corrosion resistance. Techniques such as galvanizing, powder coating, or painting are commonly used. This not only improves the aesthetic appeal but also extends the lifespan of steam systems, especially in harsh environments.

How Is Quality Assurance Implemented in Steam System Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of steam systems, ensuring that every component meets safety and performance standards. An effective QA program will help B2B buyers feel confident in their purchasing decisions.

What International Standards Apply to Steam System Manufacturing?

International standards play a vital role in guiding manufacturers in producing safe and reliable steam systems. Key standards include:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS), focusing on continuous improvement and customer satisfaction.

- CE Marking: For products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: The American Petroleum Institute (API) provides standards specifically for components used in steam and other industrial systems, ensuring they meet stringent quality criteria.

What Are the Key Quality Control Checkpoints in Steam System Production?

Quality control (QC) checkpoints are crucial in maintaining high standards throughout the manufacturing process. Typical checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications and standards.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections and tests are conducted to monitor the quality of components and assemblies. This may include dimensional checks and visual inspections.

- Final Quality Control (FQC): Once the steam system is fully assembled, a comprehensive inspection is performed. This includes pressure testing, leak detection, and functional testing to verify that the system operates as intended.

How Can B2B Buyers Verify the Quality Control Processes of Suppliers?

B2B buyers should take proactive steps to verify a supplier’s QC processes to ensure they are sourcing high-quality steam systems.

What Audits and Reports Should Buyers Request?

- Supplier Audits: Conducting audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control systems. Buyers should look for evidence of certifications, adherence to standards, and the presence of an effective QMS.

- Quality Reports: Requesting documentation of QC processes, including inspection reports and testing results, can help verify that the supplier adheres to industry standards.

How Important Are Third-Party Inspections in Quality Assurance?

Engaging third-party inspection agencies can add an additional layer of assurance regarding the quality of steam systems. These agencies provide unbiased evaluations of manufacturing processes and final products, often issuing certificates that confirm compliance with relevant standards. This is particularly important for buyers in regions such as Africa and South America, where local regulations may vary.

What Nuances Should International B2B Buyers Be Aware of in Quality Assurance?

When sourcing steam systems internationally, particularly from regions like the Middle East and Europe, B2B buyers should consider several nuances:

- Regulatory Compliance: Different regions have distinct regulations regarding manufacturing standards and safety. Understanding these regulations is crucial to ensure compliance and avoid potential legal issues.

- Cultural Differences: Business practices and expectations around quality may vary significantly. Building strong relationships with suppliers and understanding their quality philosophies can enhance collaboration and outcomes.

- Logistics and Supply Chain Challenges: International shipping can introduce risks such as damage during transit or delays that affect the delivery schedule. Buyers should work closely with suppliers to implement robust logistics strategies to mitigate these risks.

Conclusion

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures in the production of steam systems is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with rigorous quality control checkpoints and adherence to international standards, buyers can make informed purchasing decisions. Verifying supplier QC processes through audits, reports, and third-party inspections further ensures that the steam systems they procure will meet their operational requirements and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘steam systems’

Introduction

This practical sourcing guide is designed for B2B buyers looking to procure steam systems. It provides a structured checklist to help you navigate the complexities of sourcing, ensuring you select the right system that meets your operational needs while adhering to safety and efficiency standards.

Illustrative image related to steam systems

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your procurement process. Consider factors such as steam pressure requirements, capacity, and the intended application of the steam. This clarity will help you communicate effectively with suppliers and ensure that the steam system you choose aligns with your operational demands.

- Key Considerations:

- Maximum and minimum operating pressures.

- Required steam quality (dry or wet).

- Compatibility with existing infrastructure.

Step 2: Assess Your Budget and Total Cost of Ownership

Understanding your budget is crucial for making informed purchasing decisions. However, it’s not just about the initial purchase price; consider the total cost of ownership, which includes installation, maintenance, and operational costs over the system’s lifespan. This comprehensive view will help you avoid hidden costs that can arise later.

- Factors to Evaluate:

- Initial costs versus long-term savings.

- Maintenance requirements and associated costs.

- Energy efficiency ratings that may reduce operational costs.

Step 3: Research and Verify Supplier Credentials

Selecting a reputable supplier is vital for ensuring quality and reliability. Research potential suppliers, looking for certifications, industry experience, and customer reviews. This step mitigates risks associated with subpar products and services.

- Checklist for Verification:

- Look for ISO or other relevant certifications.

- Request case studies or testimonials from similar industries.

- Ensure they have a robust customer support system in place.

Step 4: Evaluate System Design and Integration Capabilities

Understanding how the steam system will integrate with your existing infrastructure is essential. Evaluate the design options provided by suppliers, ensuring they can accommodate your current setup and future expansion needs.

Illustrative image related to steam systems

- Key Points to Assess:

- Flexibility in system design to adapt to changing operational needs.

- Compatibility with existing equipment (boilers, valves, etc.).

- Provision for future upgrades or expansions.

Step 5: Request Detailed Proposals and Quotes

Once you have shortlisted potential suppliers, request detailed proposals and quotes. This documentation should include technical specifications, pricing, delivery timelines, and warranty information. A thorough comparison will help you make an informed decision.

- What to Look For:

- Clarity in pricing (including hidden fees).

- Detailed timelines for delivery and installation.

- Warranty and service agreements that protect your investment.

Step 6: Conduct Site Visits and Product Demonstrations

If possible, arrange site visits to the supplier’s facilities or request product demonstrations. This hands-on experience can provide insights into the supplier’s capabilities and the performance of their steam systems.

- Benefits of Site Visits:

- Verify the quality of manufacturing processes.

- Assess the level of expertise in handling steam systems.

- Observe how the supplier manages customer installations.

Step 7: Finalize Contracts with Clear Terms

Once you have selected a supplier, ensure that the contract clearly outlines all terms and conditions, including payment schedules, delivery expectations, and service agreements. A well-defined contract protects both parties and minimizes misunderstandings.

- Important Elements to Include:

- Payment milestones tied to project phases.

- Penalties for delays or non-compliance.

- Clear definitions of warranties and service obligations.

By following this structured checklist, B2B buyers can effectively navigate the procurement process for steam systems, ensuring a reliable and efficient solution that meets their operational needs.

Comprehensive Cost and Pricing Analysis for steam systems Sourcing

What are the Key Cost Components in Sourcing Steam Systems?

When sourcing steam systems, understanding the cost structure is vital for effective budgeting and decision-making. The primary components include:

-

Materials: The quality and type of materials significantly influence the cost. For steam systems, this typically involves high-grade steel or alloys resistant to corrosion and high temperatures. Sourcing materials that meet international standards can mitigate future maintenance costs.

-

Labor: Skilled labor is required for both installation and ongoing maintenance. Labor costs can vary widely based on geographical location and the complexity of the steam system being installed. In regions like Africa and South America, labor may be more affordable, but the expertise might vary.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities and rent for manufacturing facilities. Understanding the manufacturer’s operational efficiency can provide insight into pricing strategies.

-

Tooling: Initial tooling costs can be significant, especially for custom components. Buyers should consider whether they need standard or bespoke parts, as customization can substantially increase costs.

-

Quality Control (QC): Ensuring compliance with international quality standards is critical, particularly in regions with stringent regulations. Investing in robust QC processes can prevent costly failures down the line.

-

Logistics: Shipping costs can be a major factor, especially for international buyers. Understanding the Incoterms used in contracts can help buyers anticipate additional fees related to transportation, insurance, and tariffs.

-

Margin: Suppliers typically include a profit margin in their pricing. Buyers should seek transparency regarding this margin and assess whether it reflects the quality and service provided.

How Do Price Influencers Impact Steam Systems Sourcing?

Several factors can influence the pricing of steam systems significantly:

-

Volume/MOQ: Bulk purchases can lead to significant discounts. Buyers should negotiate minimum order quantities (MOQs) that align with their operational needs while maximizing savings.

-

Specifications and Customization: Custom specifications can drive up costs. It is important for buyers to clearly define their requirements to avoid unnecessary modifications later in the process.

-

Materials and Quality Certifications: The choice of materials and certifications (such as ISO or ASME) can affect pricing. Higher-grade materials often command higher prices but can lead to lower long-term operational costs due to enhanced durability and efficiency.

-

Supplier Factors: The supplier’s reputation, experience, and location can influence pricing. Established suppliers may charge a premium for their reliability and service, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The terms of sale affect the total cost of ownership. Understanding whether costs include freight, insurance, and customs duties is critical for accurate budgeting.

What Buyer Tips Can Enhance Cost-Efficiency in Steam Systems Sourcing?

Buyers can employ several strategies to enhance cost-efficiency when sourcing steam systems:

-

Negotiate Effectively: Leverage volume discounts and long-term contracts to negotiate better pricing. Building relationships with suppliers can also lead to preferential pricing and terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the upfront costs but also the long-term operational costs associated with maintenance, efficiency, and potential downtime. A seemingly lower-priced system may incur higher costs over its lifecycle.

-

Be Aware of Pricing Nuances in International Markets: For buyers in regions like Nigeria and Vietnam, it’s crucial to account for local economic conditions, currency fluctuations, and import tariffs that can affect overall costs.

-

Request Detailed Quotations: Ensure quotations break down costs clearly. This transparency allows for better comparison between suppliers and can highlight areas where costs may be reduced.

-

Plan for Future Needs: Consider scalability in your sourcing strategy. Investing in a system that can grow with your operations can prevent future expenditure on additional systems or upgrades.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on specific circumstances such as market conditions, supplier negotiations, and individual project requirements. Always consult with suppliers for precise quotations tailored to your needs.

Alternatives Analysis: Comparing steam systems With Other Solutions

Understanding Alternatives to Steam Systems for Industrial Applications

In industrial settings, steam systems have long been a reliable solution for heating and power generation. However, with advancements in technology and a growing focus on efficiency and sustainability, several alternative solutions have emerged. This analysis explores viable alternatives to steam systems, providing insights into their performance, cost, ease of implementation, maintenance requirements, and best-use scenarios.

| Comparison Aspect | Steam Systems | Electric Heating Systems | Hot Water Systems |

|---|---|---|---|

| Performance | High thermal efficiency; can deliver high temperatures and pressures. | Quick heat-up time; suitable for smaller applications. | Efficient for moderate heating needs; lower temperature than steam. |

| Cost | Higher initial investment; ongoing fuel costs can vary. | Generally lower installation costs; electricity rates influence operational costs. | Moderate installation costs; often cost-effective in terms of energy consumption. |

| Ease of Implementation | Requires significant infrastructure; complex installation. | Easier to install; minimal infrastructure needed. | Requires plumbing but generally simpler than steam systems. |

| Maintenance | Regular maintenance required; potential for leaks and pressure issues. | Low maintenance; fewer moving parts. | Moderate maintenance; requires inspection of water quality and heating elements. |

| Best Use Case | Ideal for high-demand applications like manufacturing and food processing. | Best for small-scale heating applications or where space is limited. | Suitable for residential heating or commercial applications with moderate heat demands. |

In-Depth Analysis of Alternative Solutions

Electric Heating Systems

Electric heating systems utilize electricity to generate heat, often through resistive heating elements. Their primary advantage lies in their simplicity and ease of installation, making them ideal for small-scale applications such as laboratories or small manufacturing units. However, they may not be suitable for high-demand processes requiring significant heat, and operational costs can fluctuate based on local electricity rates.

Illustrative image related to steam systems

Hot Water Systems

Hot water systems operate by heating water to a desired temperature, which can then be circulated for heating or processing. They are particularly effective in applications where lower temperatures are sufficient, such as in residential heating or certain food processing methods. While installation costs are generally moderate, they may not provide the high thermal efficiency or quick heat-up times of steam systems. Maintenance requirements are manageable, focusing primarily on water quality and system integrity.

Choosing the Right Solution for Your Needs

When selecting between steam systems and their alternatives, B2B buyers should consider several factors, including the specific thermal demands of their applications, budget constraints, and operational efficiency goals. Steam systems excel in high-demand environments requiring consistent and high-quality heat, while electric and hot water systems may offer cost-effective solutions for smaller or less intensive applications. Ultimately, the right choice will depend on a comprehensive assessment of the operational context, economic considerations, and long-term sustainability objectives. By carefully evaluating these alternatives, businesses can enhance their operational efficiency and align their heating solutions with their strategic goals.

Essential Technical Properties and Trade Terminology for steam systems

What Are the Key Technical Properties of Steam Systems?

Understanding the essential technical properties of steam systems is critical for B2B buyers who aim to ensure efficiency, safety, and performance in their operations. Below are some of the most important specifications to consider:

1. Material Grade

Steam systems are typically constructed from materials such as carbon steel, stainless steel, or alloy steel. The material grade affects durability, resistance to corrosion, and the ability to withstand high temperatures and pressures. For instance, carbon steel is commonly used for lower pressure systems, while stainless steel is preferred for high-pressure and corrosive environments. Selecting the right material can significantly impact the longevity and maintenance costs of the system.

2. Working Pressure

The working pressure refers to the maximum pressure at which the steam system operates. It is influenced by factors such as the boiler’s maximum safe working pressure and the operational requirements of the equipment using the steam. Understanding the working pressure is crucial for system design, as it determines the size of pipes and the type of components required. Operating under optimal pressure minimizes energy loss and enhances system efficiency.

Illustrative image related to steam systems

3. Temperature Rating

This specification indicates the maximum temperature that steam can reach within the system. The temperature rating is essential for ensuring the steam system operates safely and efficiently. Exceeding this temperature can lead to equipment failure or safety hazards. Buyers must ensure that all components are rated for the intended operating temperature to avoid costly downtimes and potential risks.

4. Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions and performance criteria in steam system components. This is particularly important for fittings, valves, and pipes, where precise dimensions are critical for maintaining system integrity and preventing leaks. Ensuring that components meet specified tolerance levels helps maintain operational efficiency and safety.

5. Insulation Thickness

Proper insulation of steam pipes is vital for minimizing heat loss during distribution. The thickness of insulation impacts both energy efficiency and operating costs. Insufficient insulation can lead to significant energy losses, increasing fuel consumption and operational expenses. Buyers should consider insulation specifications that align with their energy efficiency goals.

What Are Common Trade Terms in Steam Systems?

Familiarity with industry terminology is essential for effective communication and negotiation in the steam systems market. Below are several key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the steam system industry, buyers often seek OEM parts to ensure compatibility and reliability. Understanding this term can help in sourcing high-quality components that meet specific operational requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to sell. This term is crucial for buyers to understand when negotiating contracts, as it can affect inventory management and purchasing decisions. Knowing the MOQ helps businesses budget effectively and manage supply chain logistics.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers requesting pricing and terms for specific products or services. This process is essential for comparing offers and making informed purchasing decisions. Buyers should be detailed in their RFQs to receive accurate and competitive quotes.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers assess shipping costs, insurance, and risk management. Familiarity with Incoterms can streamline negotiations and ensure clarity in contracts.

5. Pressure Reducing Valve (PRV)

A PRV is a critical component in steam systems that regulates steam pressure before it reaches the equipment. Understanding how PRVs work is essential for ensuring the safety and efficiency of the steam distribution system. Buyers should be aware of the specifications and functionalities of PRVs to maintain optimal system performance.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions that enhance operational efficiency and safety in their steam systems.

Navigating Market Dynamics and Sourcing Trends in the steam systems Sector

What Are the Current Market Dynamics and Key Trends in the Steam Systems Sector?

The global steam systems market is experiencing a transformative phase driven by several key factors. Increasing industrialization and the need for energy-efficient processes are propelling demand for advanced steam distribution systems, especially in emerging markets such as Africa and South America. Countries like Nigeria and Vietnam are investing heavily in infrastructure, thus creating opportunities for B2B buyers to source high-quality steam systems that can enhance operational efficiency.

In addition to energy efficiency, automation and digitalization are becoming pivotal trends in steam system management. The integration of IoT technologies allows for real-time monitoring and predictive maintenance, which significantly reduces downtime and operational costs. B2B buyers are encouraged to seek suppliers who offer smart steam solutions, as these can provide valuable insights into system performance and energy consumption, leading to informed decision-making.

Sourcing trends are also shifting towards suppliers who can deliver customized solutions tailored to specific industry needs. Buyers are increasingly looking for manufacturers that can provide flexible and scalable systems that adapt to changing operational demands. This trend is complemented by a rising emphasis on local sourcing, where companies prefer suppliers within their regions to reduce lead times and transportation costs.

How Do Sustainability and Ethical Sourcing Impact the Steam Systems Market?

Sustainability is now a core consideration for international B2B buyers in the steam systems sector. The environmental impact of steam systems, particularly in terms of energy consumption and emissions, is under scrutiny. Buyers are increasingly seeking solutions that not only meet operational needs but also align with their sustainability goals.

The importance of ethical supply chains cannot be overstated. Buyers are encouraged to partner with manufacturers who prioritize responsible sourcing of materials and adhere to environmental regulations. This includes selecting suppliers who utilize sustainable practices, such as using recycled materials or renewable energy in production processes.

Certifications and standards play a crucial role in ensuring that products meet environmental and ethical benchmarks. Look for suppliers that hold ‘green’ certifications, such as ISO 14001 for environmental management systems or Energy Star ratings for energy efficiency. These certifications not only enhance the credibility of the product but also provide assurance to buyers that they are making responsible choices that contribute positively to the environment.

Illustrative image related to steam systems

What Is the Brief Evolution of Steam Systems and Their Relevance Today?

The evolution of steam systems can be traced back to the Industrial Revolution, where steam power became the backbone of manufacturing processes. Initially, steam boilers were simple vessels that converted water into steam for mechanical power. Over the decades, advancements in technology have transformed steam systems into sophisticated solutions that enhance efficiency and safety.

Today, steam systems are integral to various industries, including food processing, pharmaceuticals, and energy generation. The focus has shifted from merely producing steam to optimizing its use through effective distribution and recovery systems. This evolution reflects the industry’s response to the dual pressures of increasing productivity and minimizing environmental impact, making steam systems more relevant than ever in the context of modern industrial demands.

By understanding these market dynamics and sourcing trends, international B2B buyers can make informed decisions that align with their operational goals and sustainability objectives, ultimately driving success in their respective industries.

Frequently Asked Questions (FAQs) for B2B Buyers of steam systems

-

How do I solve steam quality issues in my system?

To address steam quality issues, first assess the steam generation and distribution process. Ensure that your boiler is operating at optimal efficiency and that the steam is adequately superheated. Regularly inspect your steam lines for leaks or condensation that could introduce moisture into the steam. Utilizing separators and proper drainage systems will help manage condensate and maintain steam purity. Additionally, consider implementing regular maintenance schedules and employing quality control measures to enhance the overall performance of your steam system. -

What is the best steam boiler type for industrial applications?

The best steam boiler type for industrial applications often depends on your specific requirements. Firetube boilers are generally favored for their simplicity and lower initial costs, making them suitable for applications with moderate steam demands. Conversely, watertube boilers are ideal for high-pressure and high-capacity needs, offering greater efficiency and flexibility. Assess your steam load requirements, fuel type, and available space before making a decision. Consulting with a steam system expert can further help tailor the choice to your operational needs. -

What factors should I consider when sourcing steam systems internationally?

When sourcing steam systems internationally, consider factors such as supplier reputation, product certifications, and compliance with local regulations. Evaluate the supplier’s experience in your industry and their ability to provide customized solutions. Quality assurance processes and after-sales support are also crucial. Additionally, understand the logistics involved, including shipping costs, delivery timelines, and import duties, to ensure that your procurement process runs smoothly and efficiently. -

How can I vet suppliers for steam systems?

To vet suppliers for steam systems, start by reviewing their credentials and experience in the industry. Request references from previous clients and check for certifications such as ISO or ASME. Conduct site visits, if possible, to assess their manufacturing capabilities and quality control processes. Additionally, compare product warranties and after-sales support services. Engaging in direct communication to discuss your specific needs can also reveal their responsiveness and commitment to customer service. -

What customization options are available for steam systems?

Customization options for steam systems can vary widely based on supplier capabilities. Common customizations include the boiler size, pressure ratings, fuel type, and specific control systems tailored to your operational requirements. Some suppliers may offer bespoke solutions, such as enhanced safety features or integrated monitoring systems. Discussing your specific needs with potential suppliers will help you identify the best customization options available to optimize performance and efficiency. -

What are typical minimum order quantities (MOQs) for steam systems?

Minimum order quantities (MOQs) for steam systems can vary by supplier and the complexity of the system. For standard systems, MOQs may range from one unit to several, depending on the manufacturer’s production capabilities. Custom systems usually have higher MOQs due to the specialized nature of the components involved. It’s essential to clarify MOQs during the procurement process to ensure alignment with your project requirements and budget. -

What payment terms should I expect when purchasing steam systems?

Payment terms for purchasing steam systems typically vary based on supplier policies and the size of the order. Common arrangements include upfront payments, partial payments upon order confirmation, and the remainder upon delivery. Some suppliers may offer financing options or extended payment terms for larger orders. It’s vital to negotiate terms that provide financial flexibility while ensuring the supplier’s confidence in fulfilling the contract. -

How do I ensure quality assurance for steam systems?

To ensure quality assurance for steam systems, establish clear specifications and standards during the procurement process. Request documentation related to quality control measures, including certifications and testing protocols. Arrange for factory inspections or third-party audits to verify compliance with international standards. Additionally, implementing a robust post-purchase evaluation process, including performance monitoring and feedback collection, will help maintain quality over time and address any issues promptly.

Top 2 Steam Systems Manufacturers & Suppliers List

1. HFMMagazine – Hospital Steam Systems

Domain: hfmmagazine.com

Registered: 1997 (28 years)

Introduction: Hospital steam systems are essential for sterilization and humidification in healthcare facilities. They utilize saturated or dry steam, which is recognized for its reliability and effectiveness in sterilizing medical devices. Steam systems can support various functions including heating, hot water, food service, and laundry. Key benefits include close control of temperature and pressure, energy e…

2. Experitec – Fisher™ FIELDVUE™ Control Solutions

Domain: experitec.com

Registered: 2002 (23 years)

Introduction: Fisher™ FIELDVUE™ Product Lineup, Fisher™ Whisper™ Technology, Plantweb Insight™ Valve Health App, Control Valves, Regulators, Pressure Relief & Safety Valves, Isolation and Shut off Valves, Actuators, Controllers and Instruments, Tank Vents and Hatches, Bulk Storage and Transport Equipment, Steam Traps, Valves and Level Gauges, Flame and Detonation Arrestors, Nuclear Flow Controls, Check Valves.

Strategic Sourcing Conclusion and Outlook for steam systems

In navigating the complexities of steam systems, strategic sourcing emerges as a pivotal element for businesses aiming to enhance efficiency and reduce operational costs. By investing in high-quality steam distribution systems and reliable boiler technology, companies can ensure that steam is delivered at the right pressure and quality, ultimately optimizing their production processes. The integration of effective condensate management and pressure reduction strategies not only improves energy efficiency but also promotes sustainability by minimizing waste.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe evaluate their steam system needs, it is essential to prioritize suppliers that offer comprehensive support services, including installation, maintenance, and training. These partnerships can significantly impact operational uptime and reliability.

Looking ahead, the steam systems market is poised for innovation, with advancements in technology and sustainability driving new solutions. As industries evolve, embracing these changes will be crucial for maintaining a competitive edge. Engage with trusted suppliers and invest in the latest technologies to future-proof your steam systems and unlock new opportunities for growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.