A Deep Dive into The Carbide End Mill Store Solution

Introduction: Navigating the Global Market for the carbide end mill store

In the fast-evolving landscape of global manufacturing, sourcing high-quality carbide end mills can pose a significant challenge for B2B buyers. The intricacies of selecting the right tools—whether for precision machining in Germany or mass production in Nigeria—require not just product knowledge but also a keen understanding of supplier dynamics and market trends. This guide aims to demystify the carbide end mill market by providing a comprehensive overview of various types, applications, and key factors to consider when vetting suppliers.

From high-performance standard length end mills to specialized geometries tailored for unique machining tasks, the guide covers a diverse array of products essential for enhancing operational efficiency. It delves into critical aspects such as cost analysis, quality assurance, and the impact of local market conditions on pricing and availability. For international buyers from regions like Africa, South America, the Middle East, and Europe, this resource empowers informed purchasing decisions by equipping them with the insights needed to navigate supplier relationships and optimize their procurement strategies.

By understanding the nuances of the carbide end mill market, buyers can not only secure the best tools for their operations but also foster long-term partnerships with reliable suppliers. This guide is your essential tool for thriving in a competitive global market, ensuring that you make well-informed choices that drive your business success.

Understanding the carbide end mill store Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Length End Mills | Common sizes, versatile for general machining | General milling, prototyping | Pros: Widely available, cost-effective. Cons: Limited for specialized tasks. |

| Long and Extra Long End Mills | Extended reach for deep cuts, various diameters | Deep cavity machining, aerospace | Pros: Ideal for deep cuts. Cons: Can be less rigid, prone to deflection. |

| Miniature End Mills | Small diameter, high precision for intricate work | Micro machining, electronics manufacturing | Pros: Excellent for detail work. Cons: Fragile, requires careful handling. |

| Stub End Mills | Shorter length, thicker shank for increased rigidity | High-speed machining, heavy material removal | Pros: More durable, reduced chatter. Cons: Limited depth of cut. |

| Specialty Profile End Mills | Custom shapes and geometries for specific applications | Unique machining needs, specialized industries | Pros: Tailored solutions. Cons: Higher cost, longer lead times. |

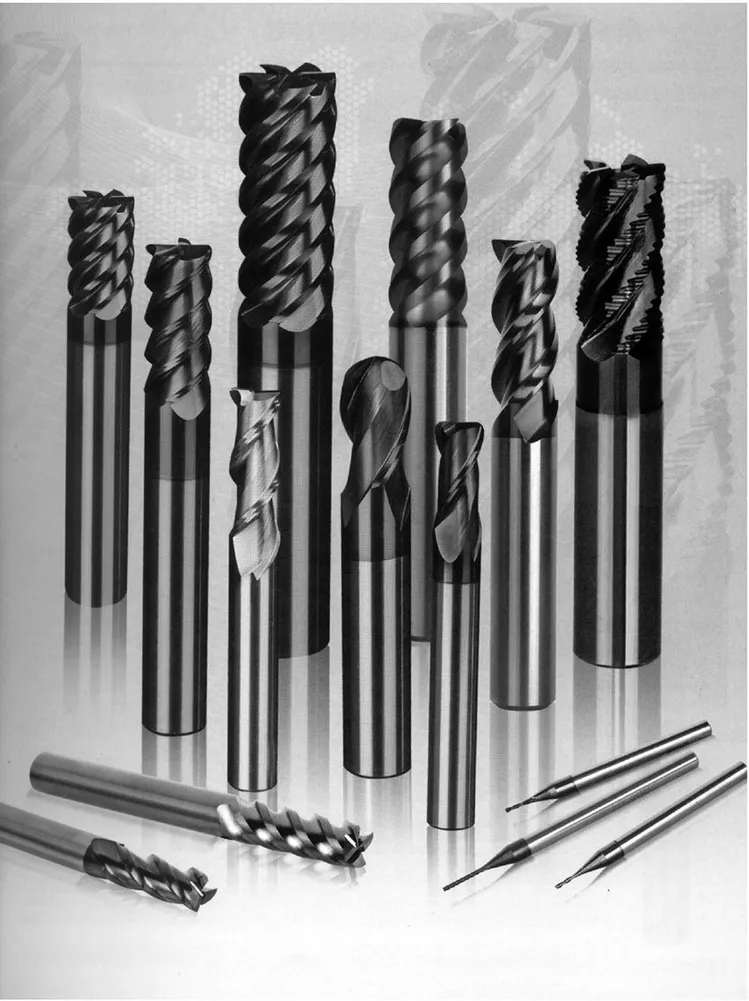

What Are the Characteristics of Standard Length End Mills?

Standard length end mills are the most common type used in various machining processes. They are designed with a balance between length and diameter, making them suitable for general milling tasks across industries. These end mills are available in a wide range of sizes and materials, including solid carbide, which enhances their durability and cutting performance. When purchasing, buyers should consider the specific material being machined, as different coatings and geometries can significantly affect performance and tool life.

How Do Long and Extra Long End Mills Differ in Application?

Long and extra long end mills feature extended lengths that allow them to reach deeper into workpieces without the need for additional setups. This makes them particularly useful in applications such as cavity machining in aerospace and automotive components. Buyers should be cautious about the rigidity of these tools, as longer lengths may lead to increased deflection during operation. It’s essential to assess the machine’s capabilities and the material’s hardness to ensure optimal performance.

Illustrative image related to the carbide end mill store

Why Choose Miniature End Mills for Precision Work?

Miniature end mills are designed for high precision tasks, often used in micro machining applications where intricate details are required. Their small diameters allow for tight tolerances and fine features in components, making them ideal for industries such as electronics and medical device manufacturing. Buyers should consider the fragility of these tools; while they provide exceptional detail, they require careful handling and may have limited tool life in harsher environments.

What Advantages Do Stub End Mills Offer?

Stub end mills are characterized by their shorter length and thicker shank, providing increased rigidity and stability during machining. They are particularly effective in high-speed machining applications and are well-suited for heavy material removal tasks. Buyers should consider the trade-off between depth of cut and tool durability, as stub end mills excel in maintaining structural integrity but may not reach as deep as longer variants.

When Should You Consider Specialty Profile End Mills?

Specialty profile end mills are tailored for specific machining requirements, featuring unique shapes and geometries designed to meet particular industry needs. These tools are invaluable for applications that require a custom approach, such as mold making or complex component manufacturing. While they offer significant advantages in specialized tasks, buyers should be prepared for higher costs and longer lead times associated with custom tooling solutions.

Key Industrial Applications of the carbide end mill store

| Industry/Sector | Specific Application of the carbide end mill store | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision machining of aircraft components | Enhanced performance and safety in aircraft operations | Certification compliance, material specifications, and delivery timelines |

| Automotive | Manufacturing engine parts and transmission systems | Improved durability and efficiency of vehicles | Tool geometry, coating options, and compatibility with materials used |

| Oil and Gas | Drilling and milling of complex components | Increased operational efficiency and reduced downtime | Resistance to wear, corrosion, and specific machining capabilities |

| Medical Devices | Fabrication of surgical instruments and implants | High precision and reliability in critical applications | Biocompatibility, surface finish, and regulatory requirements |

| Electronics Manufacturing | Production of circuit boards and connectors | Enhanced precision and reduced production costs | Tolerance specifications, tooling life, and material compatibility |

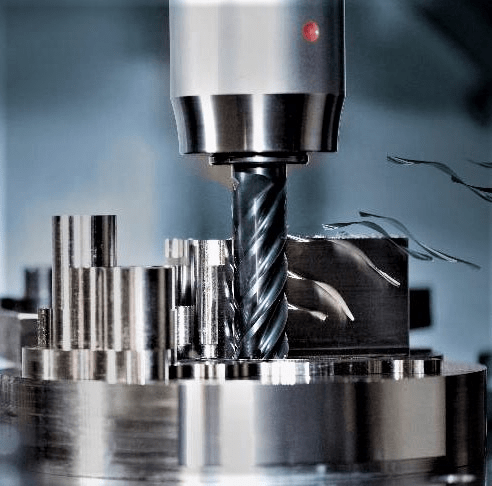

How is the carbide end mill store utilized in aerospace applications?

In the aerospace sector, the carbide end mill store is essential for the precision machining of aircraft components such as turbine blades and fuselage parts. These components require extreme accuracy and durability due to the high-stress environments they operate in. The carbide end mills available are designed to handle tough materials like titanium and high-strength aluminum alloys, ensuring safety and performance. International buyers must consider certifications like AS9100 and specific material requirements when sourcing these tools to meet stringent industry standards.

Illustrative image related to the carbide end mill store

What role does the carbide end mill store play in automotive manufacturing?

Automotive manufacturers utilize carbide end mills for machining engine parts, transmission systems, and other critical components. The durability and cutting efficiency of carbide tools significantly enhance the production of high-performance vehicles. Buyers from regions like Europe and South America should focus on the geometry and coatings of the end mills to optimize performance and tool life, especially when working with diverse materials like cast iron and aluminum alloys commonly used in automotive applications.

How does the carbide end mill store support oil and gas drilling operations?

In the oil and gas industry, the carbide end mill store provides tools for drilling and milling complex components used in extraction and refining processes. The tools are engineered to withstand harsh environments, offering resistance to wear and corrosion. Buyers in the Middle East and Africa must prioritize sourcing end mills that meet specific machining capabilities and can handle the unique challenges of drilling operations, such as high temperatures and pressures.

Why is the carbide end mill store crucial for medical device manufacturing?

The medical device sector relies on the carbide end mill store for the fabrication of surgical instruments and implants, where precision and reliability are paramount. Carbide end mills are used to achieve the necessary tolerances and surface finishes required for biocompatible materials. International buyers, particularly from developing regions, should ensure that sourced tools comply with medical device regulations and standards, such as ISO 13485, to guarantee the safety and effectiveness of their products.

How does the carbide end mill store enhance electronics manufacturing?

In electronics manufacturing, the carbide end mill store supplies tools for producing circuit boards and connectors, where precision is critical. The use of high-quality carbide end mills leads to improved accuracy and reduced production costs, which is vital in a competitive market. Buyers from Europe and South America need to consider factors such as tolerance specifications and the compatibility of tooling with various materials to ensure optimal results in their manufacturing processes.

Illustrative image related to the carbide end mill store

3 Common User Pain Points for ‘the carbide end mill store’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right End Mill for Specific Applications

The Problem: B2B buyers often face the daunting task of choosing the correct carbide end mill for their specific manufacturing processes. With a vast array of options, including different geometries, sizes, and coatings, making the right decision can be overwhelming. This challenge is exacerbated when buyers are also dealing with international shipping and regulatory compliance, particularly in regions like Africa and the Middle East, where access to local expertise may be limited. A miscalculation can lead to production delays, increased costs, and unsatisfactory end products.

The Solution: To effectively navigate this challenge, buyers should leverage the comprehensive resources available at the carbide end mill store. Start by utilizing the online product selection tools, such as the end mill size charts and the speeds and feeds calculator. These tools provide essential data to help determine the most suitable end mill based on the material type, desired finish, and machine capabilities. Additionally, reaching out to the store’s customer service can provide personalized recommendations based on specific project requirements. Buyers should also consider ordering samples to test performance before committing to larger purchases, ensuring that the selected tools meet their operational needs.

Scenario 2: Managing Supply Chain Disruptions and Lead Times

The Problem: Global supply chain disruptions have made timely delivery of carbide end mills a significant concern for many B2B buyers. Lengthy lead times can halt production lines and cause significant financial losses. Buyers from regions such as South America and Europe may encounter additional challenges, such as customs delays and varying import regulations, which can complicate the procurement process even further.

The Solution: To mitigate supply chain risks, B2B buyers should establish a proactive purchasing strategy. This includes maintaining a buffer stock of essential cutting tools to cushion against unexpected delays. Collaborating closely with suppliers like the carbide end mill store can provide insights into inventory levels and expected shipping timelines. Buyers should also inquire about expedited shipping options or local distribution centers that can facilitate quicker access to tools. Regular communication with suppliers regarding potential delays and updates can help buyers plan their production schedules more effectively.

Scenario 3: Understanding and Utilizing Tool Performance Data Effectively

The Problem: Many B2B buyers lack the technical expertise to interpret tool performance data, which can result in inefficient machining processes and increased operational costs. For example, buyers in industries such as aerospace or automotive manufacturing require precise machining standards but may struggle to apply the recommended speeds and feeds data effectively. This gap in knowledge can lead to improper tool usage, resulting in tool wear, decreased productivity, and compromised part quality.

The Solution: Buyers should invest in training sessions or workshops that focus on tool performance metrics and their implications for machining operations. The carbide end mill store often provides resources and guidance on how to interpret and apply this data effectively. Utilizing the store’s technical support can also help buyers understand the nuances of tool performance, allowing them to optimize their processes. Additionally, buyers should document their machining experiences and outcomes to refine their understanding over time, ultimately leading to improved efficiency and cost savings in their manufacturing operations.

Strategic Material Selection Guide for the carbide end mill store

What are the Key Materials Used in Carbide End Mills?

When selecting carbide end mills, understanding the materials involved is crucial for optimizing performance and ensuring compatibility with specific applications. Here, we analyze four common materials used in the production of carbide end mills, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Solid Carbide

Key Properties:

Solid carbide end mills are known for their high hardness and wear resistance, which allows them to perform well at elevated temperatures. They typically have a temperature rating of up to 1000°C and are resistant to deformation under pressure.

Pros & Cons:

The primary advantage of solid carbide is its durability and ability to maintain sharp cutting edges over extended periods. However, they can be brittle, making them susceptible to chipping and breakage under high-impact conditions. Additionally, solid carbide tools are generally more expensive than their HSS counterparts.

Impact on Application:

Solid carbide end mills are ideal for machining hard materials, such as titanium and stainless steel, due to their superior hardness. They are also suited for high-speed machining applications.

Considerations for International Buyers:

Buyers from regions like Nigeria and Germany should ensure compliance with international standards such as ASTM and DIN, which can affect the quality and performance of solid carbide tools. Additionally, understanding local material preferences can influence purchasing decisions.

2. High-Speed Steel (HSS)

Key Properties:

HSS end mills have good toughness and can withstand high temperatures (up to 600°C) without losing hardness. They are less brittle than carbide, making them suitable for a variety of machining processes.

Illustrative image related to the carbide end mill store

Pros & Cons:

HSS tools are generally more affordable and easier to manufacture than solid carbide tools. However, they wear out faster and require more frequent sharpening, which can lead to increased operational costs over time.

Impact on Application:

HSS end mills are versatile and can be used for machining softer materials like aluminum and brass. They are often preferred for general-purpose applications.

Considerations for International Buyers:

In regions with varying machining standards, such as South America and the Middle East, HSS tools may be favored for their cost-effectiveness. Buyers should be aware of local preferences for tool materials based on the types of materials they commonly work with.

Illustrative image related to the carbide end mill store

3. Cobalt Steel

Key Properties:

Cobalt steel end mills feature enhanced hardness and heat resistance compared to standard HSS, withstanding temperatures of up to 800°C. They are less prone to wear and can maintain cutting performance over longer periods.

Pros & Cons:

The key advantage of cobalt steel is its ability to cut through tougher materials without losing edge integrity. However, it is more expensive than standard HSS and can still be more brittle than carbide.

Impact on Application:

Cobalt steel is particularly effective for machining high-temperature alloys and other hard materials, making it suitable for aerospace and automotive applications.

Considerations for International Buyers:

B2B buyers in Europe and Africa should consider the availability of cobalt steel tools in their local markets. Compliance with environmental regulations regarding cobalt mining and processing may also influence purchasing decisions.

4. Carbide-Tipped

Key Properties:

Carbide-tipped end mills combine a carbide cutting edge with a steel body, providing a balance of hardness and toughness. They can operate at temperatures similar to solid carbide tools while retaining the flexibility of steel.

Illustrative image related to the carbide end mill store

Pros & Cons:

These tools offer a cost-effective solution for high-performance applications, as they are less expensive than solid carbide while still providing excellent cutting capabilities. However, the bond between the carbide tip and steel body can be a point of failure if not manufactured correctly.

Impact on Application:

Carbide-tipped end mills are suitable for a variety of materials, including softer metals and composites, making them versatile for different machining tasks.

Considerations for International Buyers:

In regions like South America and the Middle East, where cost considerations are paramount, carbide-tipped tools may be preferred. Buyers should also verify the manufacturing standards to ensure quality and performance.

Summary Table

| Material | Typical Use Case for the carbide end mill store | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Solid Carbide | Machining hard materials like titanium | High durability and wear resistance | Brittle and prone to chipping | High |

| High-Speed Steel | General-purpose machining of softer materials | Cost-effective and easy to manufacture | Wears out faster, requires sharpening | Low |

| Cobalt Steel | Machining high-temperature alloys | Enhanced hardness and heat resistance | More expensive and brittle | Medium |

| Carbide-Tipped | Versatile applications across various materials | Cost-effective with good performance | Potential bond failure | Medium |

This strategic material selection guide provides B2B buyers with essential insights to make informed decisions when sourcing carbide end mills, ensuring optimal performance and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for the carbide end mill store

What Are the Key Stages in the Manufacturing Process of Carbide End Mills?

The manufacturing process of carbide end mills is intricate and requires precision at each stage to ensure high-quality outputs. The main stages involved include material preparation, forming, assembly, and finishing.

Illustrative image related to the carbide end mill store

-

Material Preparation: The journey of a carbide end mill begins with the selection of high-grade tungsten carbide powder, which is known for its hardness and durability. This powder is typically mixed with cobalt, which acts as a binder, to create a composite material that possesses excellent wear resistance. The mixture is then subjected to a process called granulation, where it is processed into granules suitable for pressing.

-

Forming: The granules are compacted into specific shapes using high-pressure pressing techniques. This process forms the basic geometry of the end mill. The compacted shapes are then subjected to a sintering process, where they are heated in a controlled atmosphere furnace at high temperatures. This step causes the particles to fuse together, resulting in a solid carbide body.

-

Assembly: After sintering, the end mills undergo a series of machining operations, including grinding and sharpening. This ensures that the cutting edges are precisely formed and meet the necessary specifications. Additionally, features such as flutes and cutting geometries are refined during this stage, which significantly impacts the performance of the end mills.

-

Finishing: The final stage involves surface treatments such as coating, which can enhance the performance and lifespan of the end mills. Common coatings include titanium nitride (TiN) and zirconium nitride (ZrN), which provide additional hardness and reduce friction during machining operations. This finishing step is crucial for preparing the end mills for the demanding conditions of industrial applications.

How Is Quality Assurance Implemented in Carbide End Mill Manufacturing?

Quality assurance (QA) in carbide end mill manufacturing is vital to ensure that products meet international standards and customer expectations. Various methods and checkpoints are employed throughout the manufacturing process.

-

International Standards and Certifications: Compliance with international standards such as ISO 9001 is essential for manufacturers. This standard outlines the requirements for a quality management system (QMS) that can enhance customer satisfaction by ensuring consistent quality. Additionally, certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant depending on the application of the end mills.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): Before production begins, raw materials undergo rigorous testing to verify their quality. This includes checking the composition and properties of tungsten carbide and cobalt.

– In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is conducted at various stages, such as during the pressing and sintering processes. This ensures that any deviations from specifications are promptly addressed.

– Final Quality Control (FQC): After the end mills are finished, they undergo comprehensive testing, which may include dimensional inspections, hardness testing, and performance evaluations. This step ensures that the final products meet the required standards before they are shipped. -

Common Testing Methods: Manufacturers utilize various testing methods to ensure the quality of carbide end mills. These may include:

– Dimensional Measurement: Using precision tools to measure the geometry and dimensions of the end mills.

– Hardness Testing: Employing methods such as Rockwell or Vickers hardness tests to assess the hardness of the carbide material.

– Cutting Tests: Performing practical cutting tests to evaluate the performance of the end mills under operational conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial to ensure reliability and performance. Here are actionable insights:

-

Supplier Audits: Conducting audits of potential suppliers can provide firsthand insights into their manufacturing processes and quality control systems. This can include visiting the manufacturing facility to observe practices, equipment, and certifications in place.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can help buyers understand the effectiveness of their QC processes. These reports should include data on testing results, compliance with international standards, and any corrective actions taken in case of non-conformities.

-

Third-party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. These inspections can verify compliance with international standards and assess the overall quality of the end mills before shipment.

-

Certifications and Compliance Documents: Buyers should request copies of relevant certifications and compliance documents from suppliers. This may include ISO certifications, CE marking, and any industry-specific certifications that apply to the end mills being purchased.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate several nuances related to quality control when sourcing carbide end mills:

-

Understanding Regional Standards: Different regions may have varying standards and regulations concerning manufacturing and quality assurance. For instance, EU buyers may prioritize CE compliance, while buyers in the Middle East may focus on local certifications.

-

Language and Communication Barriers: When sourcing from suppliers in different countries, language differences may pose challenges in understanding quality control processes. Clear communication is essential, and buyers should consider using interpreters or bilingual representatives when necessary.

-

Cultural Differences in Quality Perception: Different cultures may have varying expectations regarding quality. Buyers should be aware of these differences and ensure that their quality expectations are clearly communicated to suppliers.

-

Logistics and Shipping Considerations: The quality of end mills can be affected during shipping, especially over long distances. Buyers should ensure that suppliers have robust packaging and shipping processes to minimize damage during transit.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing carbide end mills, ultimately leading to improved operational efficiencies and product performance in their respective industries.

Illustrative image related to the carbide end mill store

Practical Sourcing Guide: A Step-by-Step Checklist for ‘the carbide end mill store’

Introduction

This practical sourcing guide aims to assist international B2B buyers in efficiently procuring carbide end mills from reputable suppliers, particularly from ‘the carbide end mill store.’ The following checklist outlines essential steps to ensure you select the best products and suppliers that meet your specific needs, enhancing your manufacturing processes and product quality.

-

Define Your Technical Specifications

Before initiating the sourcing process, it’s crucial to clearly outline your technical requirements. Identify the specific types of carbide end mills you need, including dimensions, coatings, and geometries. This clarity will help you communicate effectively with suppliers and ensure that the products match your operational needs. -

✅ Research Potential Suppliers

Conduct thorough research to identify potential suppliers, focusing on those with a strong reputation in the industry. Look for suppliers that specialize in carbide end mills and have positive reviews from clients in your region. Utilize online directories, trade publications, and industry forums to gather information about supplier reliability and product quality. -

Evaluate Supplier Certifications

Supplier certifications are a key indicator of quality assurance. Verify that potential suppliers hold relevant industry certifications, such as ISO 9001, which demonstrates their commitment to quality management. Additionally, check for any specific certifications related to carbide tools to ensure they meet international manufacturing standards. -

✅ Request Product Samples

Before making a bulk purchase, request samples of the carbide end mills you intend to procure. Testing samples will allow you to assess the product’s performance, durability, and suitability for your applications. Ensure that the samples are representative of the products you plan to order, as this will provide a clearer picture of what to expect. -

Analyze Pricing and Terms

While cost is a significant factor, it should not be the only consideration. Compare pricing structures among different suppliers, taking note of any additional costs such as shipping, taxes, and duties. Also, review the payment terms and conditions to ensure they align with your budget and cash flow requirements. -

✅ Verify Customer Support and After-Sales Service

Quality customer support can significantly impact your sourcing experience. Assess the responsiveness of potential suppliers by reaching out with inquiries. Additionally, inquire about their after-sales support, including warranty policies and return procedures, to ensure you will receive assistance if issues arise after purchase. -

✅ Establish Long-Term Relationships

Building a long-term relationship with your suppliers can lead to better pricing, priority access to new products, and improved service. Discuss future collaboration opportunities and express your interest in developing a partnership. A strong relationship can provide stability and support as your business needs evolve.

By following these steps, you can confidently navigate the sourcing process for carbide end mills, ensuring that you select a supplier that meets your business’s specific needs and standards.

Comprehensive Cost and Pricing Analysis for the carbide end mill store Sourcing

What are the Key Cost Components in Sourcing Carbide End Mills?

When sourcing carbide end mills, understanding the cost structure is essential for effective budgeting and procurement. The primary cost components include:

-

Materials: The cost of high-quality carbide and other materials significantly influences the final price. Premium materials can enhance durability and performance but will also increase upfront costs.

-

Labor: Skilled labor is required for manufacturing carbide end mills. Labor costs can vary based on geographical location and the expertise level of workers involved in the production process.

-

Manufacturing Overhead: This includes expenses related to utilities, equipment maintenance, and factory space. Efficient manufacturing processes can help reduce overhead costs, which can be passed on to the buyer.

-

Tooling: The initial investment in tooling for carbide end mill production can be substantial. Custom tooling may be necessary for specific designs, affecting overall costs.

-

Quality Control (QC): Rigorous QC processes ensure that the end mills meet industry standards. This adds to the cost but is crucial for maintaining quality and reliability, particularly in high-stakes applications.

-

Logistics: Shipping and handling costs vary based on the supplier’s location and the destination. International buyers should factor in import duties and taxes that may apply.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the margin can help buyers negotiate better deals.

How Do Price Influencers Affect Carbide End Mill Costs?

Several factors can influence the pricing of carbide end mills, impacting the total cost for buyers:

-

Volume/MOQ: Higher order volumes often lead to reduced per-unit costs. Buyers should consider negotiating minimum order quantities (MOQs) to benefit from bulk pricing.

-

Specifications and Customization: Custom specifications can lead to increased costs due to specialized tooling and manufacturing processes. Buyers should assess whether the added value justifies the higher price.

-

Material Quality and Certifications: End mills made from higher-grade materials or with specific certifications (e.g., ISO standards) typically command higher prices. Buyers must weigh the importance of these factors against their specific needs.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more for their products, but they often provide better quality assurance and customer service.

-

Incoterms: The agreed-upon terms of delivery (e.g., FOB, CIF) can influence pricing by determining who bears shipping and insurance costs. Buyers should understand these terms to avoid unexpected expenses.

What Tips Can Help Buyers Optimize Costs?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe can employ several strategies to optimize costs when sourcing carbide end mills:

-

Negotiation: Effective negotiation with suppliers can lead to better pricing, especially for bulk orders. Buyers should prepare to discuss their requirements and leverage competitive quotes.

-

Cost Efficiency: Understanding the Total Cost of Ownership (TCO) is crucial. This includes not just the purchase price but also maintenance, downtime, and operational efficiency. Investing in higher-quality end mills may lead to lower TCO over time.

-

Pricing Nuances for International Buyers: International buyers should be aware of exchange rates, shipping times, and potential tariffs. Establishing relationships with local distributors may also facilitate smoother transactions and reduce costs.

-

Market Research: Keeping abreast of market trends and competitor pricing can empower buyers to make informed decisions. Utilizing online resources and industry reports can provide valuable insights.

Conclusion

In summary, a comprehensive understanding of cost components, price influencers, and strategic negotiation can significantly enhance the sourcing process for carbide end mills. By considering these factors, buyers can optimize their procurement strategies, ensuring they receive high-quality products at competitive prices. Always remember to factor in all elements of costs, including logistics and potential tariffs, to achieve a truly cost-effective solution.

Alternatives Analysis: Comparing the carbide end mill store With Other Solutions

In the competitive landscape of industrial metal cutting tools, buyers are often faced with numerous options that promise quality and efficiency. The Carbide End Mill Store is a prominent player in this market, but potential customers should be aware of viable alternatives that may also meet their operational needs. This analysis compares The Carbide End Mill Store with two notable alternatives: 6gTools and Carbide Depot, focusing on key aspects that are critical for B2B buyers.

| Comparison Aspect | The Carbide End Mill Store | 6gTools | Carbide Depot |

|---|---|---|---|

| Performance | High-quality, diverse range of carbide tools for various applications | Offers robust performance with a focus on customer service and tool variety | Specializes in high-performance end mills across multiple categories |

| Cost | Competitive pricing, with a focus on value for quality | Generally lower prices, particularly for bulk orders | Varies widely, often higher for premium offerings |

| Ease of Implementation | User-friendly website with effective search algorithms | Easy navigation, but may lack advanced filtering options | Comprehensive site but can be overwhelming due to extensive product range |

| Maintenance | Minimal maintenance required; tools are durable | Similar durability; however, customer service may impact maintenance support | Varies by product; some require more frequent replacement |

| Best Use Case | Ideal for machine shops needing a variety of end mills | Best for budget-conscious buyers looking for a range of cutting tools | Suitable for specialized applications needing high-performance tools |

What are the Advantages and Disadvantages of 6gTools as an Alternative?

6gTools positions itself as a strong contender by emphasizing customer service and a diverse product range. One of its primary advantages is the lower price point, especially attractive for bulk orders, making it ideal for businesses looking to manage costs. However, while their website is user-friendly, it may lack the advanced filtering options that some buyers prefer for precision searches. This can potentially lead to longer search times for specific products.

How Does Carbide Depot Compare in Terms of Performance and Cost?

Carbide Depot specializes in high-performance end mills, making it an excellent choice for businesses that require specialized tools for demanding applications. Their product range includes various types of end mills, catering to niche markets. However, this specialization often comes at a premium price, which may not align with the budgets of all buyers. Additionally, while they offer a comprehensive product catalog, the site can be overwhelming, potentially complicating the selection process for users unfamiliar with specific tool types.

Illustrative image related to the carbide end mill store

How Should B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right solution depends on several factors, including budget constraints, specific performance requirements, and the complexity of the projects at hand. Buyers from regions such as Africa, South America, the Middle East, and Europe should consider not only the cost and performance but also the supplier’s reliability and support options. The Carbide End Mill Store offers a balanced approach with high-quality tools and competitive pricing, while alternatives like 6gTools and Carbide Depot provide unique advantages that may better suit specific operational needs. Ultimately, understanding the nuances of each option will empower B2B buyers to make informed decisions that align with their business goals.

Essential Technical Properties and Trade Terminology for the carbide end mill store

What Are the Key Technical Properties of Carbide End Mills?

Understanding the technical specifications of carbide end mills is crucial for B2B buyers to make informed purchasing decisions. Here are some essential properties to consider:

1. Material Grade

Carbide end mills are typically made from solid carbide, a composite of tungsten carbide and cobalt. This material is known for its hardness and durability, allowing for high-speed machining and longer tool life. For B2B buyers, selecting the right material grade ensures optimal performance in their specific applications, reducing downtime and increasing productivity.

2. Flute Count

The number of flutes on an end mill impacts chip removal and surface finish. End mills can have two, three, or four flutes, with each configuration suited for different machining operations. A two-flute end mill allows for better chip removal in deeper cuts, while a four-flute design provides a smoother finish in shallower cuts. Understanding flute count helps buyers select tools that meet their machining requirements effectively.

3. Coating

Coatings such as TiN (Titanium Nitride) and TiAlN (Titanium Aluminum Nitride) enhance the performance of carbide end mills by reducing friction and improving wear resistance. Coated end mills can withstand higher temperatures and are less prone to oxidation. For international buyers, choosing the right coating can significantly impact tool longevity and machining efficiency, particularly in demanding environments.

4. Cutting Diameter and Length

The cutting diameter and length of an end mill determine its suitability for various applications. Standard sizes range from micro end mills to larger diameters for heavy machining. Buyers must consider these dimensions to ensure compatibility with their machinery and the specifics of the workpiece being machined.

Illustrative image related to the carbide end mill store

5. Tolerance

Tolerance refers to the allowable deviation from a specified dimension. In precision machining, tight tolerances are critical for ensuring part quality and functionality. Understanding tolerance specifications helps B2B buyers select the right end mills for their precision needs, minimizing the risk of defects and rework.

Which Trade Terms Are Commonly Used in the Carbide End Mill Industry?

Familiarizing yourself with industry jargon is essential for effective communication and negotiation. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then branded by another company. In the context of carbide end mills, buyers may seek OEM suppliers for customized solutions tailored to their specific machinery or processes.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it affects inventory management and overall project costs. Buyers should evaluate their needs against suppliers’ MOQs to optimize procurement strategies.

3. RFQ (Request for Quotation)

An RFQ is a document sent by potential buyers to suppliers to request pricing and terms for specific products. This process is essential for obtaining competitive pricing and understanding supplier capabilities, particularly for bulk purchases of carbide end mills.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers navigate the complexities of global sourcing and ensures clarity in contractual agreements.

5. Lead Time

Lead time is the period between placing an order and receiving the product. For carbide end mills, understanding lead time is critical for project scheduling and inventory management. Buyers should inquire about lead times to ensure timely delivery and avoid production delays.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions, streamline their procurement processes, and ultimately enhance their operational efficiency.

Illustrative image related to the carbide end mill store

Navigating Market Dynamics and Sourcing Trends in the the carbide end mill store Sector

What Are the Key Market Dynamics and Sourcing Trends in the Carbide End Mill Sector?

The global carbide end mill market is experiencing significant transformation driven by technological advancements, evolving manufacturing processes, and increasing demand for precision machining. Key trends include the integration of automation and Industry 4.0 technologies, which enhance operational efficiency and reduce lead times. International buyers from regions like Africa, South America, the Middle East, and Europe are increasingly prioritizing suppliers who can offer high-quality, durable tools that meet stringent performance standards. Additionally, the rise of e-commerce platforms is reshaping sourcing strategies, allowing buyers to access a broader range of products and suppliers with ease.

In terms of market dynamics, buyers are increasingly looking for customization options and specialized geometries tailored to specific applications. This trend is particularly pronounced in industries such as aerospace, automotive, and medical devices, where precision is paramount. Moreover, manufacturers are focusing on developing carbide end mills with advanced coatings to enhance tool life and performance, which is an important consideration for buyers seeking cost-effective solutions. The global supply chain landscape is also evolving, with an emphasis on local sourcing to mitigate risks associated with geopolitical uncertainties and transportation disruptions.

How Does Sustainability and Ethical Sourcing Impact the Carbide End Mill Store?

Sustainability and ethical sourcing are becoming essential considerations for B2B buyers in the carbide end mill sector. The environmental impact of manufacturing processes, including resource extraction and waste generation, has prompted many companies to adopt greener practices. Buyers are increasingly seeking suppliers who demonstrate a commitment to sustainable manufacturing methods, such as using recycled materials and minimizing energy consumption.

Furthermore, ethical supply chains are critical in ensuring compliance with international labor standards and environmental regulations. Buyers are encouraged to verify the credentials of their suppliers, looking for certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety. By prioritizing suppliers who adhere to these standards, buyers can ensure that their sourcing practices contribute positively to the environment and society.

The demand for ‘green’ certified materials is also on the rise, with buyers showing interest in carbide end mills produced using eco-friendly processes. Adopting sustainable sourcing strategies not only aligns with corporate social responsibility goals but can also enhance brand reputation and customer loyalty in an increasingly environmentally conscious market.

What Is the Evolution of the Carbide End Mill Store Sector?

The carbide end mill store sector has evolved significantly over the past few decades. Initially characterized by traditional brick-and-mortar suppliers, the industry has transitioned to a more diversified landscape that includes online platforms and global suppliers. This evolution has been fueled by advancements in manufacturing technologies, including computer numerical control (CNC) machining and sophisticated coating techniques, which have enhanced product quality and performance.

In the early days, the focus was primarily on standard tool offerings; however, the demand for customization and specialized tools has driven suppliers to innovate continuously. The advent of e-commerce has further transformed the sector, enabling buyers to access a wide array of products and suppliers worldwide, thereby increasing competition and improving pricing dynamics. As the industry continues to grow, maintaining a focus on quality, sustainability, and technological advancements will be crucial for suppliers aiming to meet the evolving needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of the carbide end mill store

1. How do I select the right carbide end mill for my application?

Choosing the right carbide end mill involves understanding your specific machining requirements, including material type, desired finish, and machining parameters. Begin by assessing the material you’ll be cutting—different end mills are designed for various metals, plastics, and composites. Consider factors like flute count, diameter, and length, which affect the tool’s performance. Using a speeds and feeds calculator can help optimize cutting conditions. Additionally, consulting with suppliers for recommendations based on your application can ensure you select the most effective tool.

2. What are the key factors to consider when vetting a carbide end mill supplier?

When vetting a carbide end mill supplier, prioritize their reputation, product quality, and customer service. Look for suppliers with a proven track record and positive customer reviews, especially from international clients. Evaluate their product range to ensure they offer tools suited for your specific needs. Additionally, inquire about their manufacturing processes, quality assurance measures, and certifications. Good communication and responsiveness can also indicate a supplier’s commitment to customer satisfaction, which is crucial for long-term partnerships.

3. What customization options are available for carbide end mills?

Many suppliers offer customization options for carbide end mills to meet specific requirements. Customization can include altering dimensions, coating types, and flute geometries to optimize performance for particular materials or applications. Discuss your needs with the supplier’s technical team, who can provide insights on the best modifications for your projects. Keep in mind that customized tools may have longer lead times and different pricing structures compared to standard options, so plan accordingly.

Illustrative image related to the carbide end mill store

4. What is the minimum order quantity (MOQ) for carbide end mills?

Minimum order quantities for carbide end mills can vary significantly between suppliers. Some may require a minimum of 10 pieces, while others may allow smaller orders for specific products. When sourcing from international suppliers, it’s essential to clarify the MOQ upfront, as this can impact your purchasing strategy and inventory management. If you need a small quantity, inquire if the supplier can accommodate special requests or if they offer stock items without an MOQ.

5. What payment terms should I expect when buying carbide end mills internationally?

Payment terms for international purchases of carbide end mills typically include options such as advance payment, letters of credit, or payment upon delivery. Suppliers may offer different terms based on your business relationship, order size, and payment history. It’s crucial to discuss and agree upon payment terms before finalizing your order to avoid misunderstandings. Additionally, consider the costs associated with currency exchange and transaction fees, which can affect the overall price.

6. How does quality assurance work for carbide end mills?

Quality assurance for carbide end mills involves rigorous testing and inspection processes to ensure that each tool meets industry standards. Suppliers often implement quality control measures, including dimensional checks, performance testing, and surface inspections. Ask suppliers about their QA processes, certifications, and warranty policies to ensure that you’re receiving high-quality products. Additionally, consider requesting samples for testing before placing large orders to evaluate performance firsthand.

7. What logistics and shipping options are available for international orders?

Logistics and shipping options for international orders of carbide end mills may include air freight, sea freight, and courier services, each with different cost and delivery time implications. Discuss shipping options with your supplier, as they often have established relationships with logistics providers that can offer competitive rates. Ensure you understand the shipping costs, customs duties, and delivery timelines, and consider using a freight forwarder if you’re unfamiliar with international shipping regulations.

Illustrative image related to the carbide end mill store

8. How can I ensure timely delivery of my carbide end mill orders?

To ensure timely delivery of carbide end mill orders, maintain clear communication with your supplier regarding lead times and shipping options. Place orders well in advance of when you need the tools to accommodate potential delays. Additionally, consider establishing a consistent ordering schedule or setting up a standing order for frequently used tools. Regularly check in with your supplier for updates on your order status and discuss any concerns proactively to mitigate delays.

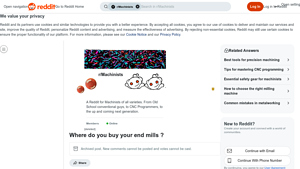

Top 8 The Carbide End Mill Store Manufacturers & Suppliers List

1. End Mill Man – High Performance End Mills

Domain: endmillman.com

Registered: 2018 (7 years)

Introduction: End Mills: HP End Mills, Turbo Roughers, Variable Helix Hot Mills, Extreme SKY-5, HP-4, Variable Helix Aluminum HP Series, Square End, Radius End, Ball End, HEM Multi-Flute HP, 5 Flute High Performance, 6 Flute High Performance. Length Options: Standard Length Square, Standard Length Ball, Radius End, Double Ended, Stub Length, Extended Reach, Long/X-Long Square End, Long/X-Long Ball End, Super Lo…

2. IQS Directory – Carbide End Mills

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: The Carbide End Mill Store offers a comprehensive range of carbide end mills, drills, reamers, taps, and other industrial cutting tools. Their carbide end mills are made from high-quality materials, ensuring durability and longevity, with a variety of sizes, coatings, and geometries available. All products are made in the USA. They provide same-day shipping for most orders and custom tooling servi…

3. Carbide Depot – End Mills and Tooling Solutions

Domain: carbidedepot.com

Registered: 1998 (27 years)

Introduction: Carbide End Mills, Endmills for Sale, Categories include Inserts, Boring Bars, Carbide Burrs, Carbide Drilling, Indexable Drilling, Carbide Milling Cutters, Rotary Holders, Shims/Shim Seats, Spare Parts, Taps, Threadmills, Toolholders. Types include High Performance, Standard Length Single End, Long Single End, Extra Long Single End, Stub Single End, Miniature Routers, Specialty Profiles, Standard…

4. CGS Tool – Premium Carbide End Mills

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: CGS Tool Premium Carbide End Mills, High Performance Solid Carbide End Mills, variable helix, variable pitch, high helix, finishing, 100% positive feedback, 49K items sold, 455 followers, various sizes including 1/8″, 3/16″, 1/4″, 3/8″, 1/2″, 5/16″, refurbished options available, prices ranging from $4.15 to $140.00, coatings include uncoated and ALTiN, multiple flute options including 2-flute, 3-…

5. HongSheng – Carbide End Mills

Domain: hongsheng.aliexpress.com

Registered: 2006 (19 years)

Introduction: This company, HongSheng – Carbide End Mills, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Hobby Machinist – End Mills

Domain: hobby-machinist.com

Registered: 2010 (15 years)

Introduction: 1. **All Industrial** – Offers good no-name end mills, often in lots of 4, 5, or 10 on eBay at competitive prices with fast shipping. Noted for conventional end mills, especially those under 1/2″.

2. **Niagara Cutter** – Recommended for quality end mills, available on eBay. Known for various types including HSS, cobalt, and carbide.

3. **Lakeshore Carbide** – Mentioned positively by users for …

7. End Mill Discount – Carbide End Mills

Domain: endmilldiscount.com

Registered: 1999 (26 years)

Introduction: End Mill Discount offers a wide range of carbide end mills including: All Purpose Carbide End Mills, Square End Mills (1/32 – 1/2 and 33/64 – 1), Ball End Mills (1/32 – 1/2 and 33/64 – 1), Stub Length End Mills, Metric End Mills, Long Length Mills, X-Long and XX-Long Mills, Left Handed End Mills, Corner Radius Mills, Roughing Mills, High Performance Mills & Drills, Micro Tools, Superbee Cutters, C…

8. End Mills – Suppliers and Insights

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: End mills, suppliers mentioned include MSC, Kennametal, Helical, Harvey, Fraisa, Sandvik, Walter, and McMaster. Users discuss purchasing experiences, convenience, and pricing strategies.

Strategic Sourcing Conclusion and Outlook for the carbide end mill store

In conclusion, the strategic sourcing of carbide end mills is essential for optimizing manufacturing efficiency and product quality. By leveraging high-quality suppliers such as Titan USA, Harvey Tool, and M.A. Ford, international buyers can ensure they receive tools that enhance performance and durability. Understanding key factors like inventory management, technical specifications, and customer support will empower buyers to make informed decisions that align with their operational goals.

As global markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for reliable metal cutting tools will continue to grow. B2B buyers should prioritize partnerships with suppliers that offer comprehensive product lines and excellent service, as these relationships are crucial for long-term success.

Looking ahead, the carbide end mill store will remain a pivotal resource for manufacturers aiming to streamline their operations. We encourage buyers to explore innovative sourcing strategies and engage with trusted suppliers to elevate their manufacturing capabilities. By doing so, they can not only meet current demands but also position themselves for future growth in a competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.