Pressure Transducer Types Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for pressure transducer types

In an increasingly interconnected global market, sourcing the right pressure transducer types can be a daunting challenge for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. The diversity in industrial applications—from oil and gas to pharmaceuticals—demands a nuanced understanding of the various transducer technologies available. This comprehensive guide aims to demystify the landscape of pressure transducers, detailing the different types, their specific applications, and the key factors to consider when evaluating suppliers.

By addressing essential aspects such as cost, performance metrics, and supplier vetting processes, this guide empowers international buyers to make informed purchasing decisions. Whether you’re navigating the complexities of choosing between strain gauge, capacitive, or piezoresistive transducers, our insights will help you align your procurement strategies with your operational needs.

This resource not only serves as a roadmap for selecting the best pressure transducer for your specific application but also provides actionable intelligence that can enhance your supply chain efficiency. As global demand continues to rise, understanding these critical components will position your business for success in an ever-evolving marketplace.

Understanding pressure transducer types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Strain Gauge | High accuracy, suitable for narrow pressure ranges | Oil & gas, pharmaceuticals, HVAC | Pros: High precision, versatile. Cons: Sensitive to temperature variations. |

| Capacitive | Measures capacitance changes; ideal for low-pressure ranges | Research labs, aerospace, HVAC | Pros: High sensitivity, good for dynamic measurements. Cons: Limited range, can be affected by humidity. |

| Piezoelectric | Generates voltage when pressure is applied | Automotive, industrial machinery | Pros: Fast response time, good for dynamic pressure changes. Cons: Not suitable for static pressure measurements. |

| Differential | Measures the difference between two pressures | Flow measurement, HVAC systems | Pros: Accurate flow rate measurement. Cons: Complexity in installation and calibration. |

| Optical | Utilizes light to measure pressure changes | Biomedical applications, high-tech industries | Pros: Non-contact measurement, high accuracy. Cons: Higher cost, sensitive to environmental conditions. |

What are the Characteristics of Strain Gauge Pressure Transducers?

Strain gauge pressure transducers are widely recognized for their high accuracy and reliability, especially in narrow-span measurements. These devices function by measuring the deformation of a strain gauge when subjected to pressure, making them suitable for applications in sectors like oil and gas, pharmaceuticals, and HVAC systems. When purchasing, buyers should consider the transducer’s sensitivity to temperature fluctuations and potential drift over time, which may impact long-term accuracy.

How Do Capacitive Pressure Transducers Work?

Capacitive pressure transducers operate by detecting changes in capacitance caused by diaphragm movement under pressure. They are particularly effective in low-pressure applications, making them ideal for research laboratories and aerospace industries. For B2B buyers, the high sensitivity of capacitive transducers is a significant advantage, though their limited pressure range and susceptibility to humidity must be carefully evaluated during selection.

What are the Advantages of Piezoelectric Pressure Transducers?

Piezoelectric pressure transducers are unique in their ability to generate an electrical charge when pressure is applied, which allows for rapid response times. This makes them ideal for applications in automotive and industrial machinery where dynamic pressure changes are common. Buyers should note that while piezoelectric transducers excel in transient measurements, they are not suited for static pressure readings, which can limit their applicability in certain environments.

Why Choose Differential Pressure Transducers?

Differential pressure transducers are designed to measure the difference between two pressure points, making them essential for flow measurement in HVAC systems and other industrial applications. Their ability to provide accurate flow rate data is a primary advantage for B2B buyers; however, the complexity involved in their installation and calibration should be considered, as it may require specialized knowledge and resources.

What are the Features of Optical Pressure Transducers?

Optical pressure transducers use light to measure pressure changes, offering non-contact measurement capabilities that are highly beneficial in biomedical and high-tech applications. Their high accuracy is a major selling point, but the higher cost and sensitivity to environmental conditions may deter some buyers. When considering optical transducers, businesses should assess whether the precision justifies the investment, particularly in specialized applications.

Key Industrial Applications of pressure transducer types

| Industry/Sector | Specific Application of pressure transducer types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Monitoring pipeline pressure and flow rates | Ensures operational safety and efficiency, reducing leaks and downtime | Need for high accuracy and durability in extreme environments |

| Food & Beverage | Control of pressure in packaging processes | Maintains product quality and extends shelf life | Compliance with health and safety standards, reliability in hygiene-sensitive applications |

| Water Treatment | Monitoring pressure in filtration systems | Enhances system performance and reduces maintenance costs | Ability to withstand corrosive environments and varying pressures |

| Pharmaceuticals | Pressure monitoring in sterile environments | Ensures product integrity and compliance with regulatory standards | Need for high accuracy and reliability, especially in critical applications |

| HVAC Systems | Pressure control in heating and cooling systems | Optimizes energy efficiency and comfort for end-users | Compatibility with existing systems and ability to handle variable conditions |

How Are Pressure Transducer Types Used in the Oil & Gas Industry?

In the oil and gas sector, pressure transducers are critical for monitoring pipeline pressure and flow rates. They help detect leaks and prevent catastrophic failures, ensuring both operational safety and efficiency. B2B buyers in this industry must prioritize high accuracy and durability, as these devices often operate in extreme environments, including high temperatures and corrosive conditions. Sourcing reliable pressure transducers can significantly reduce downtime and maintenance costs.

What Role Do Pressure Transducer Types Play in Food & Beverage Applications?

In the food and beverage industry, pressure transducers are utilized in packaging processes to control pressure levels. This is vital for maintaining product quality and extending shelf life, thereby enhancing consumer satisfaction. Buyers should consider compliance with health and safety standards, as well as the reliability of transducers in hygiene-sensitive applications. The right pressure transducer can streamline operations and reduce waste, translating to significant cost savings.

How Are Pressure Transducer Types Essential in Water Treatment?

Pressure transducers in water treatment applications monitor pressure in filtration systems, which is crucial for optimizing performance and reducing maintenance costs. By providing real-time data, these devices help operators make informed decisions about system adjustments. Buyers in this sector need transducers that can withstand corrosive environments and varying pressure levels, ensuring long-term reliability and efficiency in water purification processes.

Why Are Pressure Transducer Types Important in Pharmaceuticals?

In pharmaceutical manufacturing, pressure transducers are used to monitor pressure in sterile environments, crucial for ensuring product integrity and compliance with stringent regulatory standards. These devices must offer high accuracy and reliability, as any deviation can compromise product quality. B2B buyers should focus on sourcing transducers designed for critical applications, where precision is paramount, and any failure can lead to significant financial losses and compliance issues.

How Do Pressure Transducer Types Enhance HVAC Systems?

Pressure transducers play a vital role in HVAC systems by controlling pressure levels in heating and cooling processes. This optimization leads to improved energy efficiency and enhanced comfort for end-users. Buyers should ensure that the selected transducers are compatible with existing systems and can handle variable conditions, as HVAC applications often involve fluctuating pressures. Investing in quality pressure transducers can lead to long-term operational savings and improved system performance.

3 Common User Pain Points for ‘pressure transducer types’ & Their Solutions

Scenario 1: Navigating Pressure Transducer Selection Challenges

The Problem: B2B buyers often struggle with selecting the appropriate pressure transducer type for their specific applications. With a myriad of options available—such as strain gauge, capacitive, and piezoresistive transducers—understanding the nuances of each type can be overwhelming. This confusion can lead to costly mistakes, such as purchasing a transducer that does not meet the required specifications for pressure range, accuracy, or environmental conditions. Buyers might also face pressure to meet tight project deadlines, compounding the stress of making the right choice.

The Solution: To alleviate these challenges, buyers should start by conducting a thorough needs assessment that outlines the specific application requirements, including pressure range, temperature conditions, and the type of fluid being measured. Engaging with manufacturers or suppliers who provide detailed technical specifications and application notes can be beneficial. Additionally, investing time in comparative analysis tools or product selection guides can streamline the decision-making process. Buyers should also consider reaching out for expert consultations to clarify doubts and ensure alignment with operational needs. Finally, leveraging user reviews and case studies can provide real-world insights into how different transducer types perform in similar applications.

Scenario 2: Managing Calibration and Maintenance Issues

The Problem: Pressure transducers require regular calibration to ensure accuracy and reliability. B2B buyers may encounter issues when transducers drift out of calibration due to environmental factors such as temperature fluctuations or vibrations in industrial settings. This can lead to erroneous readings, impacting operational efficiency and product quality. Furthermore, the process of recalibrating can be time-consuming, requiring equipment downtime and potentially disrupting production schedules.

The Solution: To effectively manage calibration and maintenance, buyers should implement a proactive maintenance schedule that includes regular checks and recalibration of pressure transducers based on the manufacturer’s recommendations. Investing in calibration equipment or services can also minimize downtime. Utilizing transducers with built-in self-diagnostic features can help identify calibration needs before they affect performance. Moreover, training staff on proper handling and installation techniques can significantly reduce the risk of calibration drift caused by improper use. Establishing a partnership with suppliers for ongoing support and calibration services can further enhance reliability and performance.

Scenario 3: Addressing Compatibility with Existing Systems

The Problem: Many B2B buyers face compatibility issues when integrating new pressure transducer types into existing systems, especially in industries where legacy systems are prevalent. This can lead to signal transmission problems, incorrect readings, or even equipment failures. Buyers may find themselves in a difficult position, having to choose between upgrading entire systems or compromising on the transducer technology they wish to use.

The Solution: To navigate compatibility challenges, buyers should prioritize transducers that offer flexible output options compatible with their existing systems, such as 4-20 mA or digital signals. Before making a purchase, conducting a comprehensive compatibility assessment is crucial. This includes checking the communication protocols, electrical requirements, and physical dimensions of the transducers against the current infrastructure. In cases where compatibility is a concern, considering modular systems or adapters can bridge the gap without necessitating a complete overhaul. Engaging with suppliers who provide integration support or custom solutions can also help ensure seamless compatibility and operation, ultimately safeguarding the investment in new technology.

Strategic Material Selection Guide for pressure transducer types

What Are the Key Materials Used in Pressure Transducers?

When selecting pressure transducers for various applications, understanding the materials used in their construction is crucial. Different materials offer unique properties that can significantly affect performance, durability, and suitability for specific environments. Below is an analysis of four common materials used in pressure transducer manufacturing.

How Do Stainless Steel Properties Benefit Pressure Transducers?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 1200°F (650°C) and can handle pressures exceeding 10,000 psi, depending on the grade.

Pros & Cons: The durability of stainless steel makes it ideal for harsh environments, especially in industries like oil and gas or food processing. However, its higher cost compared to other materials can be a drawback for budget-sensitive projects. Manufacturing complexity can also increase due to the need for specialized machining processes.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive fluids and gases. This versatility makes it suitable for applications in various sectors, including chemical processing and pharmaceuticals.

Illustrative image related to pressure transducer types

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers from regions like Africa and South America should ensure that the selected stainless steel grade meets local regulations to avoid issues during importation.

What Advantages Do Silicon-Based Materials Offer for Pressure Transducers?

Key Properties: Silicon-based materials, particularly silicon carbide, exhibit excellent thermal stability and are capable of operating in extreme conditions, with temperature ratings up to 600°F (315°C) and pressures around 1000 psi.

Pros & Cons: Silicon-based transducers are cost-effective and lightweight, making them suitable for applications where weight is a critical factor. However, their brittleness can limit their use in high-impact environments, and they may not be as durable as metals.

Impact on Application: These materials are particularly effective for low-pressure applications and are often used in automotive and aerospace sectors. Their compatibility with non-corrosive fluids makes them ideal for specific applications.

Illustrative image related to pressure transducer types

Considerations for International Buyers: Buyers should be aware of the varying standards for silicon-based materials across different regions. Ensuring compliance with local regulations and certifications is crucial for smooth procurement.

How Does Polymeric Material Enhance Pressure Transducer Performance?

Key Properties: Polymeric materials, such as polyimide and PTFE, offer excellent chemical resistance and can operate at temperatures up to 400°F (204°C). They are also lightweight and flexible.

Pros & Cons: The primary advantage of polymers is their resistance to a wide variety of chemicals, making them suitable for corrosive environments. However, they typically have lower pressure ratings (up to 500 psi) and may not perform as well under extreme temperatures compared to metals.

Impact on Application: Polymeric pressure transducers are commonly used in laboratory settings and in applications involving aggressive chemicals. Their flexibility allows for integration into compact systems.

Considerations for International Buyers: Buyers should check for compliance with relevant standards such as JIS or ASTM, especially when sourcing from regions with stringent regulations. Understanding the specific chemical compatibility is also vital.

What Role Does Titanium Play in Pressure Transducer Manufacturing?

Key Properties: Titanium is renowned for its high strength-to-weight ratio and exceptional corrosion resistance, particularly in aggressive environments. It can withstand temperatures up to 800°F (427°C) and pressures exceeding 15,000 psi.

Pros & Cons: The main advantage of titanium is its durability and resistance to corrosion, making it ideal for marine or chemical applications. However, the high cost and complex manufacturing processes can be prohibitive for some projects.

Impact on Application: Titanium transducers are particularly suited for applications in the aerospace and medical industries, where reliability and performance are critical. Their compatibility with a wide range of media enhances their utility.

Illustrative image related to pressure transducer types

Considerations for International Buyers: Buyers should ensure that titanium components meet international quality standards, as non-compliance can lead to significant delays in project timelines, especially in regulated industries.

Summary Table of Material Selection for Pressure Transducers

| Material | Typical Use Case for pressure transducer types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Oil & gas, food processing | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Silicon-Based | Automotive, aerospace | Lightweight and cost-effective | Brittle, limited impact resistance | Medium |

| Polymeric | Laboratory, chemical processing | Chemical resistance and flexibility | Lower pressure ratings | Low |

| Titanium | Aerospace, medical applications | High strength and corrosion resistance | High cost and complex manufacturing | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in pressure transducers, facilitating informed purchasing decisions tailored to specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for pressure transducer types

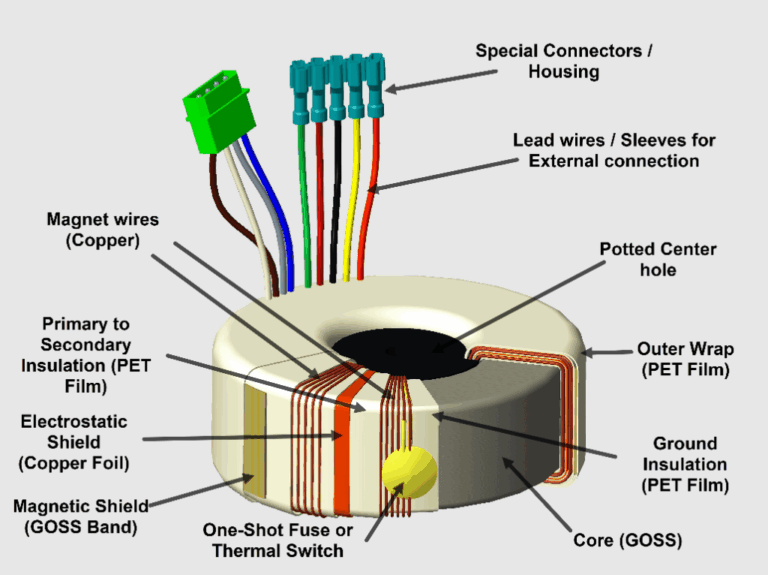

What Are the Main Stages of Manufacturing Pressure Transducers?

The manufacturing of pressure transducers involves several critical stages that ensure the final product meets industry standards for performance and reliability. Each stage incorporates specific techniques and methodologies tailored to the unique requirements of various types of pressure transducers, such as strain gauge, capacitive, and piezoelectric sensors.

Material Preparation: What Materials Are Used?

The first step in the manufacturing process is material selection and preparation. Common materials include stainless steel, silicon, and various polymers. For strain gauge transducers, high-quality silicon wafers are utilized for their sensitivity and accuracy. In contrast, stainless steel is preferred for its durability and resistance to corrosion in harsh environments. During this stage, materials are often subjected to cleaning and inspection to ensure they are free from contaminants that could affect performance.

Forming: How Are Components Shaped?

Once materials are prepared, they are shaped into components through various forming techniques. For instance, diaphragms are typically manufactured using precision stamping or laser cutting, ensuring tight tolerances. In the case of piezoelectric transducers, the piezoelectric elements are often machined into specific shapes to enhance their sensitivity. Forming techniques may also involve heat treatment to enhance material properties, such as strength and flexibility.

Assembly: What Does the Assembly Process Entail?

The assembly stage involves integrating the various components into a complete pressure transducer. This may include bonding strain gauges to diaphragms, assembling electronic circuits, and installing protective housings. Advanced assembly techniques, such as automated soldering and ultrasonic welding, are employed to ensure consistent quality and performance. Attention to detail is crucial during this stage, as any misalignment or improper assembly can lead to inaccurate readings or equipment failure.

Finishing: How Are Transducers Prepared for Market?

The final stage in manufacturing pressure transducers is finishing, which includes testing, calibration, and packaging. Each transducer undergoes rigorous testing to ensure it meets specified performance metrics. Calibration is performed using standardized pressure sources to verify accuracy. Finally, products are packaged in protective materials that prevent damage during shipping and handling, ensuring they arrive at the buyer’s location in optimal condition.

What Quality Assurance Processes Are Essential for Pressure Transducers?

Quality assurance (QA) is critical in the manufacturing of pressure transducers, as it ensures that products are reliable, accurate, and meet customer expectations. International and industry-specific standards guide these QA processes.

Which International Standards Should Buyers Be Aware Of?

One of the primary standards relevant to pressure transducer manufacturing is ISO 9001. This standard focuses on quality management systems and is widely recognized across industries. Compliance with ISO 9001 ensures that manufacturers have established processes for consistent quality and continuous improvement. Additionally, regional certifications such as CE marking for the European market and API standards for the oil and gas industry may apply, depending on the application of the transducers.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that each stage meets predefined quality criteria. These checkpoints typically include:

- Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing to identify and rectify issues in real-time.

- Final Quality Control (FQC): Comprehensive testing of finished products to verify performance against specifications, including pressure testing, temperature testing, and environmental simulations.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying the quality assurance processes of suppliers is essential for minimizing risk. Here are actionable steps buyers can take:

What Should Buyers Look for in Supplier Audits?

Conducting supplier audits is one effective way to assess quality assurance practices. Buyers should request audits that evaluate compliance with relevant standards, such as ISO 9001 and other industry-specific certifications. This audit should cover manufacturing processes, material sourcing, and testing protocols.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality assurance practices. These inspectors can verify compliance with international standards and perform independent testing of pressure transducers. Buyers should seek detailed reports from these inspections to ensure that the products meet their requirements.

What Are the Common Testing Methods Used in QC?

Common testing methods used in quality control for pressure transducers include:

- Calibration Testing: Ensures that the transducer’s output is accurate across its specified range.

- Environmental Testing: Assesses performance under various environmental conditions, such as temperature fluctuations and humidity.

- Durability Testing: Evaluates the transducer’s ability to withstand mechanical stress and vibration.

What Are the Unique QC and Certification Nuances for International Buyers?

International buyers must navigate specific nuances in quality control and certification, particularly when sourcing from diverse regions. Understanding local regulations, certifications, and quality expectations is crucial. For example, in some countries, additional certifications may be required for products intended for use in hazardous environments, such as those found in the oil and gas sector.

Buyers should also be aware of potential language barriers and cultural differences that may affect communication with suppliers. Establishing clear expectations and ensuring that documentation is readily available in a language understood by both parties can help mitigate misunderstandings.

Conclusion: How Can Buyers Ensure Quality in Pressure Transducers?

In summary, the manufacturing processes and quality assurance for pressure transducers are intricate and multi-faceted. By understanding the stages of manufacturing, the importance of quality control, and how to verify supplier practices, B2B buyers can make informed decisions that lead to successful procurement of reliable pressure transducers tailored to their specific needs. This diligence not only enhances operational efficiency but also supports long-term partnerships with trustworthy suppliers across the globe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pressure transducer types’

Introduction

When sourcing pressure transducers, it’s essential to have a structured approach to ensure you select the right type that meets your specific application needs. This guide provides a step-by-step checklist designed for B2B buyers, helping you navigate the complexities of pressure transducer procurement effectively.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. Consider factors such as the type of pressure measurement needed (absolute, gauge, or differential), the pressure range, and the environment in which the transducer will operate. Understanding these specifications will streamline the selection process and help suppliers provide the most suitable options.

- Pressure Type: Determine if you need absolute, gauge, or differential pressure measurement.

- Operating Environment: Consider temperature, humidity, and potential exposure to corrosive substances.

Step 2: Research Different Pressure Transducer Types

Gain a solid understanding of the various types of pressure transducers available on the market. Familiarize yourself with technologies such as strain gauge, capacitive, piezoresistive, and optical transducers. Each type has distinct advantages and limitations that may influence your choice.

- Strain Gauge: Ideal for narrow spans and differential pressure measurements.

- Capacitive: Suitable for low vacuum applications and can provide high accuracy.

Step 3: Evaluate Potential Suppliers

Once you have identified your needs, begin evaluating potential suppliers. Look for companies with a proven track record in your industry and those that offer robust customer support. Request company profiles, product catalogs, and case studies to assess their capabilities.

Illustrative image related to pressure transducer types

- Experience in Your Sector: Ensure the supplier has experience with applications similar to yours.

- Customer Testimonials: Seek feedback from other businesses that have worked with the supplier.

Step 4: Verify Compliance and Certifications

Ensure that the suppliers you are considering adhere to relevant industry standards and possess necessary certifications. This step is critical to guarantee the quality and reliability of the pressure transducers.

- ISO Certifications: Look for suppliers with ISO 9001 or other relevant certifications that demonstrate quality management.

- Industry-Specific Standards: Check for compliance with standards such as ATEX for hazardous environments or FDA regulations for food and pharmaceutical applications.

Step 5: Request Samples or Demonstrations

Before finalizing your purchase, request samples or product demonstrations to validate performance claims. Testing the transducers in your operational environment can provide invaluable insights into their functionality and reliability.

- Test in Real Conditions: Ensure the sample is tested under the same conditions it will face in actual use.

- Performance Metrics: Evaluate key performance indicators such as accuracy, response time, and durability.

Step 6: Discuss Warranty and After-Sales Support

A robust warranty and comprehensive after-sales support can significantly influence your long-term satisfaction with the product. Inquire about warranty terms and the availability of technical support or maintenance services.

- Warranty Duration: Look for warranties that cover a significant period, indicating supplier confidence in their product.

- Technical Assistance: Ensure the supplier offers accessible technical support for troubleshooting and maintenance.

Step 7: Compare Pricing and Terms

Finally, gather pricing information and compare terms from multiple suppliers. While cost is a critical factor, also consider the overall value, including quality, support, and reliability.

- Total Cost of Ownership: Factor in installation, maintenance, and potential downtime costs.

- Payment Terms: Negotiate favorable payment conditions that align with your financial strategy.

By following this checklist, you can make informed decisions when sourcing pressure transducers that will meet your operational needs effectively and efficiently.

Comprehensive Cost and Pricing Analysis for pressure transducer types Sourcing

What Are the Key Cost Components in Pressure Transducer Sourcing?

When sourcing pressure transducers, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials greatly influences the cost. High-quality materials for sensitive applications, such as stainless steel for corrosive environments, will be more expensive than standard options. Additionally, specialized materials for high-accuracy sensors will add to the cost.

-

Labor: Skilled labor is necessary for manufacturing pressure transducers, particularly those that require precision assembly and calibration. Labor costs can vary significantly based on the region, with countries in Africa and South America often having lower labor costs compared to Europe.

-

Manufacturing Overhead: This includes expenses related to the facilities, equipment, and utilities necessary for production. A higher overhead can result in increased pricing, especially for manufacturers with advanced technologies and stringent quality measures.

-

Tooling: The initial investment in tooling can be substantial, particularly for custom or specialized transducers. This cost is often amortized over larger production runs, making it essential to consider minimum order quantities (MOQs) when negotiating.

-

Quality Control (QC): Rigorous QC processes are vital in ensuring reliability and accuracy. The costs associated with testing and certification can significantly impact the overall price, particularly for transducers that must meet specific regulatory standards or industry certifications.

-

Logistics: Shipping and handling costs vary based on the destination, shipping method, and Incoterms. For international buyers, understanding the logistics costs, including tariffs and duties, is crucial for budgeting.

-

Margin: Supplier profit margins can vary based on their market position, competition, and the complexity of the transducer. Buyers should be aware of these margins when evaluating pricing.

How Do Price Influencers Affect Pressure Transducer Costs?

Several factors can influence the pricing of pressure transducers, impacting how buyers approach sourcing.

-

Volume/MOQ: Suppliers often offer better pricing for larger orders. Understanding the minimum order quantities can help buyers negotiate better terms and reduce unit costs.

-

Specifications and Customization: Custom features, such as specific pressure ranges or output types, can increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Materials and Quality Certifications: Higher quality and certified materials can lead to increased costs, but they may also offer long-term savings through improved reliability and performance. It’s essential to weigh these factors when making purchasing decisions.

-

Supplier Factors: The reputation and reliability of suppliers can significantly affect pricing. Well-established suppliers may charge a premium for their products due to perceived quality and service levels.

-

Incoterms: The choice of Incoterms can impact total costs. Understanding the implications of different terms (e.g., FOB, CIF) is essential for budgeting and can influence negotiation strategies.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

B2B buyers can employ several strategies to ensure cost-efficient sourcing of pressure transducers.

-

Negotiation: Always negotiate pricing and terms with suppliers. Leverage volume commitments and long-term relationships to secure better deals.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider factors such as maintenance, reliability, and the lifespan of the transducers.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import tariffs, and local market conditions that can affect pricing. Establishing relationships with local distributors can provide additional insights and potentially lower costs.

-

Research and Comparison: Always compare multiple suppliers to ensure competitive pricing. Utilize online resources and industry networks to gather information on market rates and supplier performance.

Disclaimer on Indicative Prices

Prices for pressure transducers can vary widely based on the factors discussed above. It is essential to conduct thorough market research and engage with suppliers directly for the most accurate and current pricing information.

Alternatives Analysis: Comparing pressure transducer types With Other Solutions

Understanding Alternatives to Pressure Transducer Types

When assessing the best solutions for pressure measurement in industrial settings, it is crucial to explore alternatives to pressure transducers. While pressure transducers are widely utilized for their accuracy and versatility, other technologies can provide similar functionalities under specific conditions. This section compares pressure transducer types with two viable alternatives: mechanical pressure gauges and piezoelectric pressure sensors.

Comparison of Pressure Measurement Solutions

| Comparison Aspect | Pressure Transducer Types | Mechanical Pressure Gauges | Piezoelectric Pressure Sensors |

|---|---|---|---|

| Performance | High accuracy and repeatability; suitable for a wide range of pressures. | Moderate accuracy; can be limited in dynamic applications. | Excellent for dynamic pressure changes; very sensitive. |

| Cost | Higher initial investment; long-term savings on maintenance and accuracy. | Lower initial cost; less durable over time. | Moderate cost; varies based on sensitivity and range. |

| Ease of Implementation | Requires calibration and setup; more complex integration. | Easy to install and operate; minimal setup required. | Requires careful handling and calibration; can be complex. |

| Maintenance | Low maintenance; periodic recalibration needed. | Regular maintenance required; prone to wear and tear. | Low maintenance; however, sensitive to environmental conditions. |

| Best Use Case | Suitable for automated processes and where precise measurement is critical. | Ideal for simple, local pressure measurements in static applications. | Best for dynamic measurements in rapidly changing environments. |

In-Depth Analysis of Alternatives

Mechanical Pressure Gauges

Mechanical pressure gauges, such as Bourdon tube gauges, are traditional devices that measure pressure through mechanical means. They are relatively inexpensive and straightforward to install, making them a popular choice for many applications. However, their accuracy can be limited, especially in dynamic pressure situations, and they may not provide the reliability required for automated systems. Furthermore, mechanical gauges can suffer from wear and tear, leading to increased maintenance needs over time.

Piezoelectric Pressure Sensors

Piezoelectric pressure sensors utilize the piezoelectric effect to measure pressure changes. These sensors are highly sensitive and can capture rapid pressure fluctuations, making them suitable for dynamic applications such as automotive and aerospace industries. While they offer excellent performance, piezoelectric sensors can be more complex to implement and require careful calibration. Additionally, they can be sensitive to environmental factors, which may limit their application in harsh conditions.

Conclusion: How to Choose the Right Pressure Measurement Solution

Selecting the appropriate pressure measurement solution depends on various factors, including application requirements, budget constraints, and operational environments. For B2B buyers, understanding the specific needs of their operations is essential. If high accuracy and the ability to integrate into automated systems are paramount, pressure transducers may be the best option. Conversely, for simpler applications where cost is a significant concern, mechanical gauges could suffice. Lastly, for industries requiring rapid response to pressure changes, piezoelectric sensors may be the optimal choice despite their complexity. Each solution has its advantages and trade-offs, and careful evaluation will lead to the best decision for effective pressure management.

Essential Technical Properties and Trade Terminology for pressure transducer types

What Are the Key Technical Properties of Pressure Transducers?

When selecting pressure transducers, understanding their technical properties is crucial for ensuring optimal performance and reliability in various industrial applications. Here are some essential specifications that B2B buyers should consider:

-

Material Grade

– The material used in pressure transducers significantly impacts their durability and suitability for specific environments. Common materials include stainless steel for corrosion resistance and polymers for lightweight applications. Choosing the right material ensures longevity and reduces the risk of failure in harsh conditions, making it a critical factor for industries such as petrochemicals and food processing. -

Accuracy

– Accuracy indicates how closely a transducer’s output matches the actual pressure. It is typically expressed as a percentage of the full scale (e.g., ±0.5% FS). High accuracy is vital for applications requiring precise pressure measurements, such as in laboratory settings or sensitive manufacturing processes. Lower accuracy can lead to costly errors and inefficiencies. -

Tolerance

– Tolerance refers to the permissible limits of variation in the output signal or measurement. Understanding tolerance levels helps businesses anticipate performance under varying conditions. Tight tolerance is essential in applications where precision is non-negotiable, such as in aerospace or medical devices. -

Temperature Range

– The operational temperature range defines the limits within which the pressure transducer can function effectively. This is particularly important for industries that experience extreme temperatures, such as oil and gas extraction. Transducers that can withstand wider temperature ranges offer greater flexibility and adaptability to diverse operational environments. -

Response Time

– This specification indicates how quickly a pressure transducer can respond to changes in pressure. A fast response time is crucial in dynamic environments where pressure fluctuations occur rapidly. For instance, in automotive applications, quick response times can enhance safety and performance by allowing real-time adjustments. -

Signal Output Type

– The signal output type (e.g., analog, digital, or pneumatic) affects how the transducer communicates with control systems. Analog outputs like 4-20 mA are common in industrial applications due to their reliability over long distances. Understanding the output type is essential for ensuring compatibility with existing equipment and systems.

What Common Trade Terms Should B2B Buyers Know About Pressure Transducers?

Familiarity with industry jargon can significantly enhance communication and negotiation processes in B2B transactions. Here are some key terms relevant to pressure transducers:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. When sourcing pressure transducers, knowing whether you are dealing with an OEM can help determine product quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory planning. Buyers should negotiate this term based on their specific needs to avoid excess inventory costs. -

RFQ (Request for Quotation)

– An RFQ is a formal process where buyers request pricing and terms from suppliers. This process is crucial for comparing offers from multiple vendors, ensuring competitive pricing, and gaining insights into supplier capabilities. -

Incoterms (International Commercial Terms)

– These are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk management, and delivery responsibilities, which is vital for global supply chain efficiency. -

Calibration

– Calibration is the process of adjusting a transducer to ensure its measurements are accurate. Regular calibration is essential for maintaining performance standards in critical applications. Buyers should inquire about calibration services and intervals when selecting a supplier. -

Certification

– Certification refers to the approval of a product based on established standards (e.g., ISO, CE). Certified pressure transducers are often more reliable and can meet regulatory requirements, making certification a key consideration for compliance-driven industries.

Understanding these technical properties and trade terms not only aids in making informed purchasing decisions but also fosters better communication and collaboration with suppliers, ultimately leading to enhanced operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the pressure transducer types Sector

What Are the Key Market Dynamics and Trends in the Pressure Transducer Types Sector?

The global pressure transducer market is experiencing significant growth driven by increasing demand across various industries, including oil and gas, automotive, aerospace, and medical sectors. Key factors fueling this expansion include the rise of automation and control systems, which necessitate precise pressure measurement. Additionally, the growing emphasis on process optimization and efficiency has spurred investments in advanced sensing technologies. B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly keen on sourcing pressure transducers that offer high accuracy and reliability while being cost-effective.

Emerging technologies such as IoT and Industry 4.0 are transforming the landscape of pressure measurement. These advancements allow for real-time monitoring and data analytics, enhancing decision-making processes for businesses. Furthermore, the trend toward miniaturization of devices is gaining traction, with manufacturers focusing on developing compact and efficient pressure transducers that can seamlessly integrate into existing systems. International buyers should also consider the impact of regional regulations and standards, which can influence sourcing decisions. Understanding local market needs and compliance requirements is crucial for successful procurement in diverse international markets.

How Important Are Sustainability and Ethical Sourcing in the Pressure Transducer Types Sector?

As sustainability becomes a focal point for businesses worldwide, the pressure transducer industry is not left behind. The environmental impact of manufacturing processes and the materials used in pressure transducers has led to a growing demand for sustainable and ethically sourced products. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their carbon footprint and employing eco-friendly practices.

One way to achieve this is through the use of ‘green’ certifications and materials. Buyers should look for transducers made from recyclable materials or those that utilize less harmful production methods. Additionally, transparency in the supply chain is essential; ethical sourcing ensures that materials are obtained responsibly, minimizing environmental degradation and promoting social responsibility. By prioritizing sustainability, businesses not only comply with regulatory requirements but also enhance their brand reputation, appealing to a growing segment of environmentally-conscious consumers.

What Is the Historical Context of Pressure Transducer Development That Influences Today’s Market?

The evolution of pressure transducers has been marked by significant technological advancements since their inception. Initially, mechanical methods such as U-tube manometers and Bourdon tubes dominated the market. However, the limitations of these early devices in terms of accuracy and integration capabilities led to the development of electronic pressure transducers in the mid-20th century.

The introduction of strain gauge technology revolutionized the industry, allowing for more precise and reliable measurements. Over the decades, the shift from mechanical to solid-state sensors has paved the way for modern applications, including differential pressure measurement and real-time monitoring systems. This historical context is essential for B2B buyers, as understanding the evolution of pressure transducer technologies can guide procurement decisions, ensuring they select devices that meet current industry standards and technological requirements.

Frequently Asked Questions (FAQs) for B2B Buyers of pressure transducer types

-

How do I select the right pressure transducer for my application?

Selecting the right pressure transducer involves understanding your specific application requirements. Consider factors such as the type of pressure to be measured (absolute, gauge, or differential), the pressure range, environmental conditions (temperature, humidity, and potential exposure to corrosive substances), and the required accuracy and reliability. Additionally, assess the type of output signal needed (analog or digital) and compatibility with existing systems. Collaborating with suppliers for technical support can also help ensure you make the most informed decision. -

What are the key differences between gauge, absolute, and differential pressure transducers?

Gauge pressure transducers measure pressure relative to atmospheric pressure and are ideal for applications where atmospheric variations are minimal. Absolute pressure transducers measure pressure relative to a perfect vacuum, making them suitable for applications requiring high precision. Differential pressure transducers measure the difference between two pressure points, commonly used in flow measurement applications. Understanding these distinctions helps in choosing the right transducer type based on the specific measurement needs of your process. -

What customization options should I consider when sourcing pressure transducers?

When sourcing pressure transducers, consider customization options such as specific pressure ranges, output signal types, materials (for corrosive or high-temperature environments), and connector types. Additionally, you may need features like built-in temperature compensation or enhanced accuracy levels. Discussing your requirements with potential suppliers can lead to tailored solutions that meet your unique operational needs, ensuring optimal performance and longevity of the transducer in your application. -

What are the typical minimum order quantities (MOQ) for pressure transducers?

Minimum order quantities for pressure transducers can vary widely among suppliers, often ranging from a single unit to several hundred, depending on the manufacturer and product type. For custom or specialized transducers, MOQs may be higher due to the need for dedicated production runs. It’s essential to communicate your needs with suppliers early in the negotiation process to determine their flexibility and whether they can accommodate smaller orders, especially for trial runs or initial project phases. -

What payment terms are common for international B2B transactions involving pressure transducers?

Payment terms for international transactions involving pressure transducers typically include options like advance payment, letter of credit, or net 30/60/90 days after delivery. It’s crucial to clarify these terms upfront to avoid misunderstandings. Many suppliers may also offer discounts for early payments or larger orders. Ensuring clear communication about payment methods and terms can facilitate smoother transactions and build trust between you and your supplier. -

How do I ensure quality assurance when sourcing pressure transducers?

To ensure quality assurance when sourcing pressure transducers, request detailed product specifications and certifications from suppliers, such as ISO 9001 or other relevant industry standards. Consider conducting a factory audit or requesting samples for testing before placing larger orders. Establishing a clear quality control process, including acceptance criteria and testing procedures, will help maintain product integrity and reliability throughout the supply chain. -

What logistics considerations should I keep in mind when importing pressure transducers?

When importing pressure transducers, consider logistics factors such as shipping methods, customs regulations, and potential tariffs or duties that may apply. Choose a reliable freight forwarder familiar with your region’s import regulations to streamline the process. Additionally, ensure that the supplier provides adequate packaging to prevent damage during transit. Planning for lead times and potential delays can help you maintain production schedules without disruption. -

How can I effectively vet suppliers of pressure transducers?

Effectively vetting suppliers of pressure transducers involves researching their reputation, checking references, and reviewing customer testimonials. Assess their manufacturing capabilities, quality control processes, and compliance with industry standards. Engaging in direct communication to discuss your specific needs can also provide insight into their responsiveness and expertise. Consider starting with a small order to evaluate their performance before committing to larger purchases, ensuring a reliable partnership for your sourcing needs.

Top 4 Pressure Transducer Types Manufacturers & Suppliers List

1. Dwyer Omega – Pressure Transducers

Domain: dwyeromega.com

Registered: 2022 (3 years)

Introduction: Pressure transducers come in various designs for industrial and laboratory applications, including industrial, liquid, and micro pressure transducers. They typically feature a cylinder-shaped center housing a diaphragm and measurement pressure chamber, with a pressure port for signal transmission. Types of pressure measurement include absolute, gauge, and differential pressure. Differential pressu…

2. IQS Directory – Pressure Transducers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Pressure transducers convert applied pressure into an electrical signal for industrial applications. Key components include an elastic material (typically a diaphragm made from metal, rubber, plastic, or leather) and an electrical mechanism that detects deformation and translates it into an electrical signal. Different referencing pressures include: 1. Absolute Pressure: Measured relative to a per…

3. Ashcroft – Pressure Transducer

Domain: blog.ashcroft.com

Registered: 1995 (30 years)

Introduction: A pressure transducer, also known as a pressure transmitter or pressure sensor, is an electronic device that measures and monitors the pressure of air, gas, or liquid in industrial systems. Key features include:

– Converts pressure measurements to electrical signals (current or voltage), with common outputs of 4 to 20 mA, 0-5 Vdc, 0-10 Vdc, and millivolt per volt.

– Pressure range from 0-0.1 inc…

4. TE – Measurement Types for Pressure Transducers

Domain: te.com

Registered: 1992 (33 years)

Introduction: This company, TE – Measurement Types for Pressure Transducers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for pressure transducer types

What Are the Key Insights for Sourcing Pressure Transducers?

In summary, selecting the right pressure transducer is crucial for optimizing industrial processes and ensuring accurate measurements. B2B buyers should prioritize understanding the specific applications and environments in which these transducers will be utilized. From strain gauge to capacitance transducers, each type offers distinct advantages and limitations that can significantly impact performance and reliability.

Strategic sourcing in this domain not only enhances operational efficiency but also mitigates risks associated with inaccurate measurements or equipment failures. By collaborating with reputable suppliers who offer a range of pressure transducer types, businesses can ensure they are equipped with the most suitable technology tailored to their needs.

How Can International Buyers Prepare for Future Trends?

As industries evolve, the demand for advanced pressure measurement solutions will only increase. Buyers in Africa, South America, the Middle East, and Europe should stay informed about emerging technologies and innovations in pressure transducer design. Engaging with suppliers who prioritize research and development will be essential for maintaining a competitive edge.

Take proactive steps today by assessing your current pressure measurement needs and exploring partnerships with trusted manufacturers. By doing so, you will not only secure reliable products but also position your organization for future growth and success in an increasingly competitive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to pressure transducer types

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.