The Definitive Guide to Braided Metal: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for braided metal

Navigating the global market for braided metal can be a daunting challenge for B2B buyers, particularly those sourcing high-quality materials for diverse applications across industries. With the increasing demand for durable and flexible solutions, understanding the nuances of braided metal—ranging from stainless steel cables to braided hoses—becomes crucial for making informed procurement decisions. This guide offers a comprehensive overview of braided metal products, detailing various types, applications, and industry standards, while also providing insights on effective supplier vetting and cost considerations.

As international buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Nigeria, face unique market dynamics, this guide is designed to empower you with actionable insights. You will learn how to evaluate suppliers based on quality compliance and regulatory standards, ensuring that you can confidently source braided metal that meets your specific needs. By the end of this guide, you will be equipped with the knowledge to navigate the complexities of the market, optimize your purchasing strategy, and ultimately drive value for your organization. Whether you are involved in manufacturing, construction, or any industry requiring reliable braided metal solutions, this guide serves as your essential resource for success.

Understanding braided metal Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel Braided Wire | High tensile strength, corrosion-resistant, flexible | Aerospace, robotics, medical devices | Pros: Durable, versatile; Cons: Higher cost than alternatives |

| Copper Braided Wire | Excellent conductivity, high flexibility | Electrical wiring, grounding applications | Pros: Superior electrical performance; Cons: Prone to corrosion |

| Brass Braided Cord | Aesthetic appeal, moderate strength | Interior design, decorative lighting | Pros: Attractive finish; Cons: Limited load capacity |

| Steel Braided Hose | Corrugated core, high pressure tolerance | Fluid transfer, industrial machinery | Pros: Robust and durable; Cons: Heavier than alternatives |

| PTFE Coated Braided Wire | Chemical resistance, low friction | Chemical processing, food industry | Pros: Non-stick, versatile; Cons: More expensive than standard options |

What Are the Key Characteristics of Stainless Steel Braided Wire?

Stainless steel braided wire is characterized by its high tensile strength and flexibility, making it suitable for demanding applications in industries such as aerospace and medical devices. Its resistance to corrosion ensures longevity, especially in challenging environments. When purchasing, consider the wire diameter and breaking strength to ensure it meets specific application requirements.

Why Choose Copper Braided Wire for Electrical Applications?

Copper braided wire offers exceptional electrical conductivity and flexibility, making it ideal for applications such as electrical wiring and grounding. Its lightweight nature facilitates ease of installation. However, buyers should be mindful of its susceptibility to corrosion, especially in humid or corrosive environments, and may need to consider protective coatings.

How Does Brass Braided Cord Enhance Aesthetic Appeal?

Brass braided cord is often chosen for its aesthetic appeal, making it popular in interior design and decorative lighting applications. While it provides moderate strength, it is not intended for heavy-duty applications. Buyers should evaluate the visual impact and the specific load requirements of their projects to ensure suitability.

What Makes Steel Braided Hose a Reliable Choice?

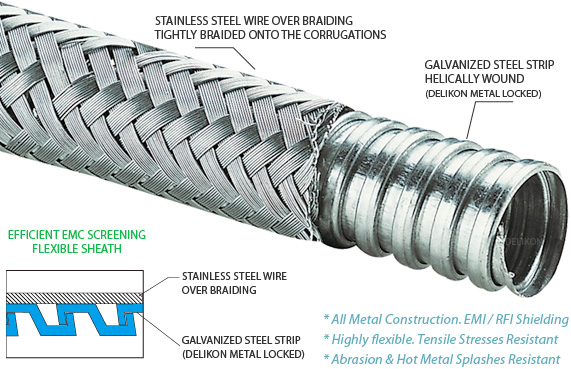

Steel braided hose is designed with a corrugated stainless-steel core that provides high pressure tolerance, making it ideal for fluid transfer in industrial machinery. Its robust nature ensures durability in demanding environments. Buyers should consider the hose’s diameter and pressure ratings to match their operational needs effectively.

Why Is PTFE Coated Braided Wire Preferred in Chemical Processing?

PTFE coated braided wire offers excellent chemical resistance and low friction, making it particularly suitable for chemical processing and the food industry. Its non-stick properties facilitate cleaning and maintenance. Buyers should weigh the benefits of its resistance against the higher cost compared to standard braided wires, ensuring it aligns with their operational budget.

Illustrative image related to braided metal

Key Industrial Applications of braided metal

| Industry/Sector | Specific Application of braided metal | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Aircraft control cables and systems | Enhanced safety and reliability in flight operations | Certifications (e.g., ISO 9001), corrosion resistance, and weight specifications are critical. |

| Medical Devices | Guide wires and catheter systems | Improved precision and flexibility in surgical procedures | Compliance with medical standards (ISO 13485), material biocompatibility, and custom fabrication options. |

| Robotics | Flexible connections in robotic arms | Increased durability and performance in automation tasks | Compatibility with existing systems, tensile strength, and flexibility ratings must be assessed. |

| Electrical Engineering | Braided electrical cords for lighting and appliances | Aesthetic appeal and enhanced durability in design | Voltage ratings, gauge sizes, and UL certifications are essential for safety and compliance. |

| Oil & Gas | Steel braided hoses for fluid transfer | Resistance to high pressure and temperature fluctuations | Compliance with industry regulations, compatibility with various fluids, and durability against environmental factors. |

How is Braided Metal Used in Aerospace Applications?

In the aerospace industry, braided metal is primarily utilized in aircraft control cables and systems. These cables must withstand extreme conditions while ensuring safety and reliability during flight operations. Buyers in this sector should prioritize sourcing braided metal that meets strict certification standards, such as ISO 9001, and offers corrosion resistance. The lightweight nature of braided metal also contributes to overall fuel efficiency, making it a preferred choice for manufacturers aiming to enhance aircraft performance.

What Role Does Braided Metal Play in Medical Devices?

Braided metal is crucial in the medical sector, particularly in the production of guide wires and catheter systems. These components require exceptional flexibility and precision to navigate the human body during surgical procedures. For international buyers, ensuring compliance with medical standards, such as ISO 13485, is vital. Additionally, sourcing materials that are biocompatible and provide custom fabrication options can significantly impact the effectiveness and safety of medical devices.

How is Braided Metal Applied in Robotics?

In robotics, braided metal is often used for flexible connections in robotic arms, where durability and performance are paramount. The adaptability of braided metal allows for intricate movements, crucial for automation tasks across various industries. Buyers should evaluate compatibility with existing robotic systems and the tensile strength of the braided components. Flexibility ratings are also important, as they influence the overall functionality and lifespan of the robotic application.

What are the Benefits of Braided Electrical Cords in Electrical Engineering?

Braided metal is increasingly popular in electrical engineering, especially for creating braided electrical cords used in lighting and appliances. These cords not only provide enhanced durability but also contribute to the aesthetic appeal of modern designs. B2B buyers should pay attention to essential factors such as voltage ratings, gauge sizes, and UL certifications to ensure safety and compliance with electrical standards. The unique look of braided cords can also differentiate products in a competitive marketplace.

How is Braided Metal Used in the Oil & Gas Industry?

In the oil and gas sector, steel braided hoses are essential for fluid transfer applications, especially in high-pressure environments. These hoses offer superior resistance to temperature fluctuations and are designed to withstand harsh operational conditions. Buyers must consider industry regulations and ensure compatibility with various fluids to maintain safety and efficiency. Durability against environmental factors is also a key consideration when sourcing braided metal for oil and gas applications.

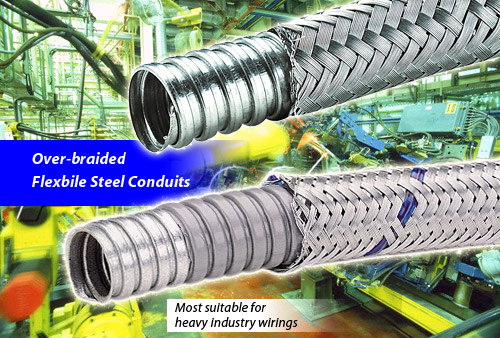

Illustrative image related to braided metal

3 Common User Pain Points for ‘braided metal’ & Their Solutions

Scenario 1: Difficulty in Specifying the Right Braided Metal for Diverse Applications

The Problem:

B2B buyers often face challenges in selecting the appropriate braided metal for their specific applications, especially when dealing with various industries such as aerospace, automotive, or electronics. For instance, a buyer in the medical device sector may require braided stainless steel cables that offer both strength and flexibility, but they may not be familiar with the technical specifications such as tensile strength, corrosion resistance, or compliance standards like ISO 13485. This lack of knowledge can lead to costly mistakes, including purchasing the wrong materials that do not meet regulatory or performance requirements.

The Solution:

To navigate this complexity, buyers should invest time in thoroughly understanding their application requirements and the properties of different braided metal options. Start by consulting with manufacturers or suppliers who specialize in braided metal products and can provide detailed technical specifications. Create a checklist of essential criteria, including the environment in which the braided metal will be used (e.g., exposure to chemicals or extreme temperatures), required strength, and compliance needs. Engaging in discussions with engineers or technical experts can also provide insights into best practices for material selection, ensuring that you choose the right product that meets both functional and regulatory standards.

Scenario 2: Concerns Over Quality and Compliance of Braided Metal Products

The Problem:

Quality assurance is a significant concern for B2B buyers, particularly when sourcing braided metal from international suppliers. Buyers may worry about the integrity of the materials, potential defects, or whether the products comply with international safety and quality standards. For instance, a company based in Nigeria sourcing stainless steel braided hoses for industrial applications might be unsure if the supplier adheres to ISO standards or if the materials meet local regulations, potentially exposing them to legal liabilities or operational failures.

The Solution:

To mitigate quality concerns, buyers should establish a robust supplier evaluation process. This includes verifying the supplier’s certifications, such as ISO 9001 or ISO 13485, and requesting detailed compliance documents like RoHS or REACH statements. It’s also beneficial to perform on-site audits or request samples for quality testing before making bulk purchases. Building long-term relationships with trusted suppliers can enhance transparency and reliability. Additionally, consider utilizing third-party inspection services to verify the quality of braided metal products before they are shipped, ensuring they meet the necessary standards.

Illustrative image related to braided metal

Scenario 3: Challenges with Custom Fabrication and Sourcing Specific Braided Metal Designs

The Problem:

In many industries, standard braided metal products may not suffice, leading to the need for custom solutions tailored to specific applications. For example, an engineering firm in Saudi Arabia may require custom-diameter braided cables that can handle unique load capacities for a specialized project. The challenge arises when suppliers do not offer the flexibility to accommodate custom orders, resulting in delays and increased costs.

The Solution:

Buyers should proactively communicate their specific needs to suppliers during the sourcing process. When seeking custom fabrication, provide clear specifications, including desired dimensions, material grades, and performance criteria. Look for suppliers that specialize in custom orders and have proven capabilities in fabricating braided metal products. Additionally, consider engaging in collaborative design processes with suppliers to develop prototypes before committing to large orders. This approach not only ensures that the final product meets your specifications but also can streamline the production timeline, minimizing delays and optimizing costs.

Strategic Material Selection Guide for braided metal

What Are the Key Properties of Stainless Steel Braided Metal?

Stainless steel is a popular choice for braided metal applications due to its excellent mechanical properties and resistance to corrosion. This material typically withstands temperatures up to 1000°F (538°C) and can handle high-pressure environments, making it suitable for various industrial applications, including aerospace, automotive, and medical devices. Its inherent resistance to rust and oxidation ensures longevity and reliability in harsh environments.

Pros & Cons: The durability of stainless steel braided metal is a significant advantage, providing both strength and flexibility. However, the cost of stainless steel is relatively high compared to other materials, which may impact budget-sensitive projects. Additionally, manufacturing processes can be complex, requiring specialized equipment and expertise.

Illustrative image related to braided metal

Impact on Application: Stainless steel braided metal is compatible with a wide range of media, including gases, liquids, and corrosive substances. This versatility makes it an ideal choice for applications in chemical processing and food industries.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with international standards such as ASTM and ISO. Additionally, understanding local market preferences for material specifications is crucial for successful procurement.

How Does Copper Braided Metal Compare in Terms of Performance?

Copper braided metal is known for its excellent electrical conductivity and thermal properties, making it a preferred choice for electrical applications. It can typically operate at temperatures up to 200°F (93°C) and is suitable for low to medium-pressure applications.

Pros & Cons: The key advantage of copper is its superior conductivity, which is essential for electrical applications. However, copper is prone to corrosion, particularly in humid environments, which can limit its use in certain applications. The cost of copper can also fluctuate significantly based on market conditions.

Impact on Application: Copper braided metal is particularly well-suited for grounding and bonding applications, where electrical performance is critical. However, its susceptibility to oxidation may necessitate additional protective measures in certain environments.

Considerations for International Buyers: Buyers should be aware of the varying standards for electrical applications across different regions. Compliance with UL and IEC standards is essential for ensuring safety and reliability in electrical systems.

What Are the Advantages of Using Brass Braided Metal?

Brass braided metal combines the properties of copper and zinc, offering good corrosion resistance and moderate strength. It typically performs well in temperatures up to 300°F (149°C) and is suitable for low-pressure applications.

Pros & Cons: The corrosion resistance of brass makes it an attractive option for applications in marine environments. However, brass is generally less durable than stainless steel and may not be suitable for high-stress applications. Its cost is moderate, making it a viable option for budget-conscious projects.

Impact on Application: Brass braided metal is commonly used in plumbing and HVAC systems due to its resistance to corrosion and ability to handle water and air media effectively.

Considerations for International Buyers: When sourcing brass braided metal, compliance with local standards such as DIN and JIS is crucial. Buyers should also consider the availability of brass in their region, as it may vary significantly.

Illustrative image related to braided metal

What Role Does Aluminum Braided Metal Play in Various Applications?

Aluminum braided metal is lightweight and offers good corrosion resistance, typically withstanding temperatures up to 400°F (204°C). It is often used in applications where weight savings are crucial, such as in aerospace and automotive industries.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which can reduce overall system weight. However, it is less durable than stainless steel and may not perform well under high-pressure conditions. The cost of aluminum is generally lower than that of stainless steel but can be higher than copper.

Impact on Application: Aluminum braided metal is suitable for applications requiring flexibility and lightweight solutions, such as in electrical conduits and protective sleeves.

Illustrative image related to braided metal

Considerations for International Buyers: Buyers should ensure that aluminum braided metal complies with relevant standards for their specific applications. Understanding regional preferences for material types can also aid in making informed purchasing decisions.

| Material | Typical Use Case for braided metal | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Aerospace, automotive, medical devices | High strength and corrosion resistance | Higher cost and complex manufacturing | High |

| Copper | Electrical grounding and bonding | Superior electrical conductivity | Prone to corrosion in humid environments | Medium |

| Brass | Plumbing and HVAC systems | Good corrosion resistance | Less durable than stainless steel | Medium |

| Aluminum | Aerospace and automotive applications | Lightweight and flexible | Less durable under high pressure | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for braided metal

What Are the Main Stages in the Manufacturing Process of Braided Metal?

The manufacturing process for braided metal involves several key stages, each critical to producing high-quality products that meet industry specifications.

-

Material Preparation: The first step involves sourcing high-grade raw materials, typically stainless steel or other alloys suitable for specific applications. The materials undergo stringent quality checks to ensure they meet required tensile strength and corrosion resistance. This stage may also include cutting the metal strands into appropriate lengths and cleaning them to remove any surface contaminants.

-

Forming: In this phase, the prepared materials are shaped into the desired configurations. This often involves techniques like twisting or braiding the metal strands together. The braiding process can be performed using automated machines designed to ensure uniform tension and consistency in the braid pattern, which is essential for maintaining strength and flexibility.

-

Assembly: Following the forming process, the braided metal is assembled into final products. This may include the addition of fittings or connectors, depending on the application. For example, in braided electrical cords, components such as plugs and insulation may be integrated at this stage. Each assembly is carefully inspected to ensure it meets design specifications.

-

Finishing: The final stage involves surface treatment and finishing processes. This can include polishing, coating, or applying protective layers to enhance durability and aesthetic appeal. The finishing process not only improves the product’s appearance but also contributes to its resistance to environmental factors, such as moisture and chemicals.

Which Key Techniques Are Used in Braided Metal Production?

Several techniques are employed throughout the manufacturing process to ensure the quality and performance of braided metal products.

-

Precision Braiding Machines: These machines are equipped with advanced technology to create intricate braiding patterns while maintaining consistent tension. This precision is crucial for ensuring that the final product meets the required specifications for strength and flexibility.

-

Quality Control Automation: Many manufacturers utilize automated quality control systems that monitor critical parameters throughout the production process. These systems can detect deviations in real-time, allowing for immediate corrective actions.

-

Welding and Joining Techniques: For applications requiring a robust connection between components, advanced welding techniques may be used. These methods ensure that joints are strong enough to withstand operational stresses.

What International Standards Are Relevant to Quality Assurance in Braided Metal?

Quality assurance in the production of braided metal is governed by various international standards, which help ensure products meet global market expectations.

-

ISO 9001: This standard outlines requirements for a quality management system (QMS) and is widely recognized across industries. Compliance with ISO 9001 signifies that a manufacturer has implemented effective quality management processes and is committed to continuous improvement.

-

CE Marking: For products marketed within the European Union, CE marking indicates conformity with health, safety, and environmental protection standards. Manufacturers must ensure that their braided metal products comply with relevant directives to obtain this certification.

-

API Standards: In industries such as oil and gas, adherence to American Petroleum Institute (API) standards is crucial. These standards provide specifications for quality and performance, particularly for braided hoses used in high-pressure applications.

What Are the Quality Control Checkpoints in Braided Metal Manufacturing?

Quality control is integral to the manufacturing process, and several checkpoints are established to maintain high standards.

Illustrative image related to braided metal

-

Incoming Quality Control (IQC): At this initial stage, raw materials are inspected upon arrival. This includes verifying material specifications, checking for defects, and ensuring compliance with purchase order requirements.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor quality at various stages. This includes checking the integrity of the braiding process, ensuring dimensional accuracy, and verifying that assembly components are correctly fitted.

-

Final Quality Control (FQC): Once the products are completed, they undergo a final inspection. This includes testing for tensile strength, flexibility, and other performance metrics. Documentation of these tests is crucial for traceability and compliance with international standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability.

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facilities, review quality control processes, and evaluate compliance with international standards. This firsthand insight can significantly influence purchasing decisions.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can provide insights into their quality management practices, testing methodologies, and compliance with standards.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent entities can evaluate product quality, conduct random sampling, and verify adherence to specified standards before shipment.

What Nuances Should International Buyers Be Aware of Regarding Quality Control?

International buyers must navigate various nuances when it comes to quality control in braided metal manufacturing.

-

Cultural Differences: Understanding the cultural context of suppliers can impact communication regarding quality expectations. Establishing clear and open lines of communication is vital for successful partnerships.

-

Documentation Requirements: Different regions may have varying documentation requirements for imports. Buyers should familiarize themselves with these to avoid delays in customs clearance or compliance issues.

-

Regulatory Compliance: Each market may have specific regulations governing the use of braided metal products. Buyers must ensure that their suppliers are compliant with these regulations to mitigate risks and ensure market entry.

By understanding the manufacturing processes and quality assurance protocols, B2B buyers can make informed decisions, ensuring they source high-quality braided metal products that meet their operational needs.

Illustrative image related to braided metal

Practical Sourcing Guide: A Step-by-Step Checklist for ‘braided metal’

To assist B2B buyers in successfully procuring braided metal, this practical sourcing guide outlines essential steps to ensure that your purchasing decisions are informed, strategic, and effective. Braided metal products are utilized across various industries, including aerospace, robotics, and electrical applications, making it crucial to approach sourcing with diligence.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. This includes material type (e.g., stainless steel, brass, or copper), diameter, strength, and any regulatory compliance needed. Specific specifications will help streamline the supplier selection process and ensure that the products meet your operational needs.

Step 2: Research Suppliers Thoroughly

Invest time in identifying and researching potential suppliers. Look for companies with a strong reputation in the market and those that specialize in braided metal products. Utilize platforms like LinkedIn, industry directories, and trade shows to gather information. Pay attention to their experience, market presence, and customer reviews to gauge reliability.

Step 3: Verify Supplier Certifications

Ensure that your chosen suppliers possess the necessary certifications and compliance documents. This may include ISO certifications, RoHS compliance, and material safety data sheets (MSDS). Certification validates a supplier’s adherence to industry standards, which is critical for quality assurance and regulatory requirements.

Step 4: Request Samples for Evaluation

Before placing a bulk order, request samples of the braided metal products. This allows you to assess the quality, performance, and suitability for your specific applications. Evaluate factors such as flexibility, tensile strength, and overall finish. It’s vital to conduct thorough testing to avoid costly mistakes after procurement.

Step 5: Discuss Customization Options

Engage with suppliers regarding customization possibilities. Depending on your project’s unique requirements, you may need specific lengths, coatings, or additional features. Understanding the supplier’s capability to accommodate custom orders can significantly impact your project’s success and overall efficiency.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, initiate negotiations on pricing, payment terms, and delivery schedules. Transparency in these discussions can foster a stronger partnership. Consider factors such as minimum order quantities, bulk discounts, and shipping costs to ensure you are getting the best overall deal.

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful supplier relationship. Ensure that you establish clear lines of communication regarding order status, lead times, and any potential issues. Regular updates and feedback can help mitigate misunderstandings and lead to a more efficient procurement process.

By following these steps, B2B buyers can navigate the complexities of sourcing braided metal effectively, ensuring they secure the right products from reliable suppliers for their specific needs.

Illustrative image related to braided metal

Comprehensive Cost and Pricing Analysis for braided metal Sourcing

What Are the Key Cost Components in Braided Metal Sourcing?

When considering the sourcing of braided metal, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The type of metal used—such as stainless steel, brass, or copper—will significantly impact pricing. Stainless steel, for example, is often more expensive due to its corrosion resistance and strength. The diameter and construction (e.g., 1×7 vs. 7×7 strands) also influence material costs.

-

Labor: Labor costs vary based on the complexity of the braiding process and the expertise required. Customizations, such as unique lengths or specifications, may necessitate skilled labor, thereby increasing overall costs.

-

Manufacturing Overhead: This includes expenses such as utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce these overhead costs, making it beneficial to assess suppliers based on their production capabilities.

-

Tooling: The initial investment in tooling can be substantial, particularly for custom orders. Suppliers often pass these costs onto buyers, especially for low-volume orders. Understanding the tooling requirements can help buyers negotiate better pricing.

-

Quality Control (QC): Compliance with international standards and certifications (like ISO) can add to costs but is essential for maintaining product integrity. Buyers should factor in these costs when evaluating suppliers, as higher quality assurance can lead to long-term savings.

-

Logistics: Shipping and handling costs can vary significantly based on the supplier’s location and the chosen Incoterms. International shipments may incur additional tariffs and customs fees, which should be considered in the total cost analysis.

-

Margin: Supplier margins can vary widely based on market conditions, demand, and competition. Buyers should compare multiple suppliers to understand the market pricing and identify the best deals.

What Influences Pricing in Braided Metal Sourcing?

Several factors can influence the pricing of braided metal, and understanding these can help buyers make more strategic decisions.

-

Volume/MOQ: Minimum order quantities (MOQs) can impact pricing, with larger orders often resulting in discounts. Buyers should assess their needs carefully to avoid excess inventory while maximizing cost efficiency.

-

Specifications and Customization: Custom specifications can lead to increased costs due to the additional labor and materials required. Buyers should clearly outline their requirements to get accurate quotes.

-

Materials and Quality: The choice of materials and the quality certifications required will affect pricing. Higher-quality materials that comply with stringent standards typically come at a premium but may offer long-term benefits.

-

Supplier Factors: The supplier’s reputation, experience, and operational efficiency can all impact pricing. Established suppliers may offer better quality assurance and reliability but may also charge higher prices.

-

Incoterms: Understanding the implications of Incoterms is crucial for international buyers. Different terms can affect who bears the risk and cost of shipping, which can significantly alter the total cost of ownership.

What Are Some Buyer Tips for Cost-Efficient Sourcing?

To maximize cost efficiency in braided metal sourcing, buyers should consider the following tips:

-

Negotiate Smartly: Leverage volume purchases and long-term relationships to negotiate better terms with suppliers. Don’t hesitate to ask for discounts on larger orders or for agreeing to exclusive contracts.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors such as longevity, maintenance, and compliance costs. A higher upfront cost may be justified by lower operational costs over time.

-

Understand Pricing Nuances for International Buyers: When sourcing from suppliers in other regions, be aware of currency fluctuations, import taxes, and shipping costs. These can significantly impact the final price.

-

Conduct Thorough Market Research: Stay informed about market trends and pricing changes. Regularly reviewing multiple suppliers will help you understand competitive pricing and identify opportunities for savings.

-

Request Samples: Before committing to large orders, ask for samples to evaluate quality. This can prevent costly mistakes and ensure that the product meets your specifications.

By considering these cost components, price influencers, and buyer tips, international B2B buyers can make informed decisions when sourcing braided metal, ensuring they achieve the best value for their investment.

Alternatives Analysis: Comparing braided metal With Other Solutions

When evaluating braided metal solutions, it’s essential to consider alternatives that can meet similar needs in various applications. Understanding the strengths and weaknesses of each option helps B2B buyers make informed decisions that align with their operational requirements and budgets.

Illustrative image related to braided metal

| Comparison Aspect | Braided Metal | Plastic Coated Wire | Solid Copper Wire |

|---|---|---|---|

| Performance | High tensile strength and flexibility, resistant to environmental factors | Moderate strength, less durable under harsh conditions | Excellent conductivity, but lacks flexibility and durability in dynamic applications |

| Cost | Generally higher due to material quality | Lower initial cost, but may require replacements more frequently | Moderate cost, with varying prices depending on purity and thickness |

| Ease of Implementation | Requires specialized tools for cutting and installation | Easy to work with, can be cut with standard tools | Easy to install, but may require soldering for connections |

| Maintenance | Low maintenance; resistant to corrosion | May degrade over time, requiring periodic replacements | Low maintenance but susceptible to corrosion if not properly insulated |

| Best Use Case | Ideal for high-stress applications like aerospace and robotics | Suitable for low-stress, indoor environments | Best for electrical applications needing high conductivity without significant movement |

How Does Plastic Coated Wire Compare to Braided Metal?

Plastic coated wire is often chosen for its lower cost and ease of installation. It is suitable for applications where flexibility and high tensile strength are less critical, such as in indoor lighting or home appliances. However, it may not perform well in extreme temperatures or corrosive environments, leading to a shorter lifespan. While it is easy to work with and does not require specialized tools, the trade-off is that it may need more frequent replacements, which can increase long-term costs.

What Are the Benefits and Drawbacks of Solid Copper Wire?

Solid copper wire is renowned for its excellent electrical conductivity, making it the preferred choice for many electrical applications. It is easy to install and typically requires minimal maintenance. However, its rigidity can be a disadvantage in applications where flexibility is needed. Additionally, solid copper is more susceptible to corrosion if exposed to moisture without proper insulation. This makes it less ideal for high-stress or outdoor applications compared to braided metal, which offers superior durability and resistance to environmental factors.

Conclusion: Which Solution is Right for Your Needs?

Selecting the right wire or cable solution depends on several factors, including the specific application, environmental conditions, and budget constraints. For high-performance needs in demanding industries such as aerospace or robotics, braided metal is often the best choice due to its strength and durability. However, for less demanding applications, plastic coated wire or solid copper wire may provide sufficient performance at a lower cost. B2B buyers should assess their unique requirements carefully and consider both the short-term and long-term implications of their choice to ensure they select the most effective solution.

Essential Technical Properties and Trade Terminology for braided metal

What Are the Key Technical Properties of Braided Metal?

Braided metal is a versatile material used across various industries, providing strength and flexibility that single-strand wires cannot match. Understanding its technical properties is essential for B2B buyers looking to make informed purchasing decisions.

What Are the Essential Material Grades for Braided Metal?

-

Material Grade: Common grades for braided metal include 304 and 316 stainless steel. Grade 304 is known for its excellent corrosion resistance and is suitable for general applications, while Grade 316 offers higher resistance to pitting and is preferred in marine and chemical environments. Choosing the right grade ensures that the braided metal meets the specific demands of your application, such as exposure to corrosive substances.

-

Tensile Strength: This specification measures the maximum stress that the braided metal can withstand while being stretched or pulled before breaking. For example, a 0.019″ diameter wire may have a minimum breaking strength of 40 lbs, making it suitable for applications requiring significant durability. Understanding tensile strength helps buyers select the right product based on load requirements.

-

Diameter and Construction: The diameter of braided wire can range from 0.006″ to 0.032″, and its construction may vary (e.g., 1×7 or 7×7). A larger diameter typically indicates greater strength but may also affect flexibility. Knowing the right diameter and construction type is crucial for ensuring compatibility with existing systems and performance expectations.

-

Voltage Rating and Temperature Tolerance: For electrical applications, braided metal cords come with specific voltage ratings (e.g., 300 volts) and temperature tolerances (e.g., 105 degrees Celsius). These specifications ensure that the braided metal can safely handle the electrical load and environmental conditions it will encounter, thus preventing failures or hazards.

-

Compliance and Certification: Many braided metal products are certified to industry standards such as UL or ISO 13485, which indicates compliance with safety and quality regulations. Buyers should prioritize products with the necessary certifications to ensure reliability and market acceptance.

What Are Common Trade Terms in the Braided Metal Industry?

Navigating the braided metal market requires familiarity with specific trade terminology. Here are some key terms to understand:

Illustrative image related to braided metal

-

OEM (Original Equipment Manufacturer): This term refers to companies that manufacture products that are sold under another company’s brand. Understanding OEM relationships can help buyers identify reliable sources for high-quality braided metal components tailored to their needs.

-

MOQ (Minimum Order Quantity): This is the smallest number of units a supplier is willing to sell. Knowing the MOQ helps buyers assess whether a supplier’s offerings align with their purchasing capabilities and project requirements, especially for custom or specialized products.

-

RFQ (Request for Quotation): An RFQ is a document that buyers send to suppliers to request pricing and availability for specific products. This process is critical for ensuring competitive pricing and negotiating terms that meet the buyer’s budget and timeline.

-

Incoterms (International Commercial Terms): These are a set of rules that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is essential for clarifying shipping costs, delivery responsibilities, and risk management in cross-border transactions.

-

Lead Time: This term refers to the time it takes for a supplier to fulfill an order from the moment it is placed until it is delivered. Knowing the lead time helps buyers plan their supply chain and production schedules effectively.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing braided metal products, ensuring they select materials that meet their performance and compliance needs.

Navigating Market Dynamics and Sourcing Trends in the braided metal Sector

What Are the Current Market Dynamics and Key Trends Affecting the Braided Metal Sector?

The braided metal sector is experiencing notable growth, driven by advancements in technology and increasing demand across various industries, including aerospace, medical, and automotive. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe engage in sourcing, they must understand the dynamics at play. Key trends include the rising adoption of stainless steel braided wires and cables due to their superior strength and flexibility compared to traditional materials. This trend is particularly relevant for applications requiring high durability and resistance to corrosion.

Moreover, the integration of digital technologies in sourcing processes is reshaping how buyers interact with suppliers. E-commerce platforms and digital marketplaces are facilitating faster transactions and improved supply chain transparency. Additionally, the increasing focus on customization and on-demand manufacturing is allowing B2B buyers to procure tailored solutions that meet specific project requirements. This shift towards agility and adaptability is essential for maintaining competitive advantage in a rapidly evolving marketplace.

How Can Sustainability and Ethical Sourcing Influence B2B Decisions in the Braided Metal Industry?

Sustainability is becoming a critical factor in the procurement strategies of B2B buyers in the braided metal sector. The environmental impact of metal production and processing is significant, leading to a heightened focus on ethical sourcing practices. Buyers are increasingly seeking suppliers that demonstrate a commitment to sustainability through the use of recycled materials and adherence to environmental regulations.

Certifications such as ISO 14001 and compliance with RoHS (Restriction of Hazardous Substances) are becoming essential criteria in supplier evaluation. Furthermore, the demand for ‘green’ materials—those produced with minimal environmental impact—continues to rise, prompting suppliers to innovate in their offerings. This shift not only meets regulatory requirements but also aligns with the growing consumer preference for sustainable products, providing a competitive edge for businesses that prioritize ethical sourcing.

What Is the Historical Context of the Braided Metal Sector That B2B Buyers Should Consider?

The braided metal sector has evolved significantly over the past century, transitioning from rudimentary manufacturing techniques to advanced production processes. Initially utilized in basic applications, braided metal wires and cables have developed into critical components in sophisticated technologies, including telecommunications and medical devices. The introduction of stainless steel as a primary material marked a turning point, offering enhanced durability and resistance to environmental factors.

As industries have transformed, so too have the applications for braided metal products. Today, B2B buyers benefit from a wealth of options, including custom fabrication and specialized designs that cater to diverse needs. Understanding this historical evolution can provide valuable insights into current market offerings and future innovations, enabling buyers to make informed decisions that align with their strategic objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of braided metal

-

How do I choose the right type of braided metal for my application?

Choosing the right braided metal depends on several factors, including the mechanical strength required, environmental conditions, and specific application needs. For instance, stainless steel braided cables are ideal for applications needing high tensile strength and resistance to corrosion, making them suitable for industries like aerospace and medical. Additionally, consider the diameter and construction type, as these affect flexibility and load-bearing capacity. Always consult with suppliers for samples and technical specifications to ensure compatibility with your intended use. -

What are the key advantages of using stainless steel braided wires?

Stainless steel braided wires offer numerous advantages, including exceptional strength, flexibility, and resistance to corrosion. They are particularly useful in applications involving harsh environments, such as marine or industrial settings. The braided structure enhances flexibility, allowing for easier installation in confined spaces. Additionally, these wires can withstand higher temperatures and pressures compared to traditional materials, making them a reliable choice for critical applications in sectors like robotics and electronics. -

What are the common applications for braided metal cables?

Braided metal cables are widely utilized across various industries, including aerospace, automotive, medical, and robotics. In aerospace, they are used in control systems and harnesses due to their lightweight and strength. Medical applications often involve guide wires and surgical instruments, benefiting from their flexibility and durability. In the automotive sector, they are employed for fuel lines and electrical wiring, where resistance to abrasion and heat is crucial. Identifying your industry’s specific requirements will help in selecting the appropriate braided metal product. -

How can I ensure quality and compliance when sourcing braided metal?

To ensure quality and compliance, start by sourcing from reputable suppliers who provide certifications such as ISO 13485 or RoHS compliance. Request detailed product specifications, including material certifications and test reports, to verify compliance with industry standards. Additionally, consider conducting factory visits or audits to assess manufacturing processes and quality control measures. Establishing clear communication with your supplier regarding your quality expectations will also facilitate smoother transactions and reduce risks. -

What is the typical minimum order quantity (MOQ) for braided metal products?

Minimum order quantities (MOQs) for braided metal products can vary significantly based on the supplier and the specific product type. Generally, MOQs may range from a few meters for standard items to larger quantities for custom orders. It’s advisable to discuss your needs with potential suppliers, as some may offer flexibility on MOQs for first-time buyers or repeat customers. Understanding your demand forecast will help in negotiating favorable terms with suppliers. -

What payment terms are common in international transactions for braided metal sourcing?

Payment terms can vary widely depending on the supplier and the nature of the transaction. Common terms include advance payment, letters of credit, and net 30/60/90 days. For international transactions, it’s crucial to establish secure payment methods that mitigate risks, such as using escrow services or third-party payment platforms. Negotiating terms that align with your cash flow while ensuring supplier confidence in transaction security is key to building a successful partnership. -

How do I vet suppliers for braided metal products?

Vetting suppliers involves assessing their credibility, quality standards, and reliability. Start by checking references and reviews from previous clients, as well as their industry reputation. It’s also beneficial to request samples and certifications to evaluate product quality. Additionally, consider visiting the supplier’s facility if possible, or utilizing third-party inspection services to ensure they meet your quality requirements. Establishing clear communication and understanding their production capabilities will further enhance your evaluation process. -

What logistics considerations should I keep in mind when importing braided metal?

When importing braided metal products, consider factors like shipping methods, customs regulations, and lead times. Evaluate the most efficient shipping options based on cost and urgency, and be aware of any import duties or tariffs that may apply. It’s essential to collaborate with logistics partners experienced in international trade to navigate customs clearance smoothly. Additionally, maintaining open communication with suppliers regarding shipping schedules will help manage expectations and ensure timely delivery of products.

Top 9 Braided Metal Manufacturers & Suppliers List

1. Component Supply Company – Key Product Details for Braided Wire & Cable

Domain: componentsupplycompany.com

Registered: 2009 (16 years)

Introduction: Key Product Details for Braided Wire & Cable: 1. Material: Stainless Steel 2. Diameter Range: 0.006″ to 0.032″ 3. Available Lengths: 10-ft, 25-ft, 100-ft spools 4. Construction Types: 1×7, 7×7 5. Minimum Breaking Strengths: Ranging from 5 lbs to 120 lbs depending on diameter and construction 6. Product Codes: MCXU-17-006-10, MCXU-17-006-25, MCXU-17-006-C, MCXU-17-019-10, MCXU-17-019-25, MCXU-17-01…

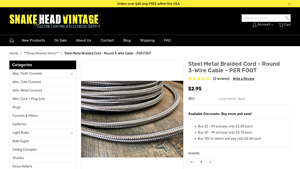

2. Snakehead Vintage – Steel Metal Braided Cord

Domain: snakeheadvintage.com

Registered: 2012 (13 years)

Introduction: Steel Metal Braided Cord – Round 3-Wire Cable – PER FOOT

Price: $2.95 per foot

SKU: cord-metal-steel

Current Stock: 4722

Discounts:

– Buy 25 – 49: $2.85 each

– Buy 50 – 99: $2.75 each

– Buy 100 or above: $2.65 each

Description: Authentic metal braided electrical cords, perfect for industrial or elegant aesthetics. Suitable for DIY lighting and interior design. 3-wire, 18 gauge (18/3) strand…

3. WireCare – Flexo® Tinned Copper

Domain: wirecare.com

Registered: 2000 (25 years)

Introduction: Metal & Shielding braided sleeving products provide protection and management for wires and cables, offering EMI, RFI, and ESD protection. Key products include:

– Flexo® Tinned Copper: EMI, RFI, ESD Protection, complies with CID A-A-59569.

– Flexo® Tinned Copper Flat: Point-To-Point Ground Path, complies with CID A-A-59569.

– Flexo® Stainless Steel 304: Virtually indestructible, won’t rust.

– …

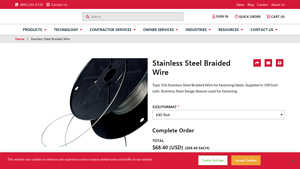

4. Markserv – Stainless Steel Braided Wire

Domain: markserv.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “Stainless Steel Braided Wire”, “material”: “Type 316 Stainless Steel”, “length”: “100 feet”, “usage”: “Used to fix valve & instrument tags”, “part_number”: “#15747”, “price”: “$68.40 (USD)”, “features”: [“Durable mounting option”, “Easy installation”], “recommended_products”: [{“name”: “Stainless Steel Swage Sleeves”, “description”: “For use with Stainless Steel Braided Wire, com…

5. Adobe Stock – Metal Braid Assets

Domain: stock.adobe.com

Registered: 1986 (39 years)

Introduction: Metal Braid Images – 24,376 Stock Photos, Vectors, and Videos available on Adobe Stock. Includes options for free trials to access images and videos. Categories include images, videos, audio, templates, and 3D assets. Users can sort and filter results, and there are options for premium content.

6. Swagelok – Flexible and Braided Metal Core Hose

Domain: products.swagelok.com

Registered: 1996 (29 years)

Introduction: Convoluted, Flexible and Braided Metal Core Hose from Swagelok. Available in various series including Flexible Metal Hose (FJ, FL, FM), High-Pressure Metal Hose (FX), and Vacuum-Insulated Metal Hose (FV). Designed for diverse applications in industries such as chemicals, clean energy, food and beverage, industrial machinery, life sciences, metals and mining, oil and gas, power, pulp and paper, res…

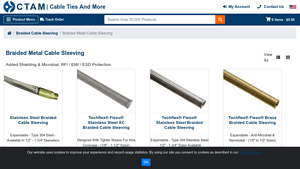

7. Cable Ties and More – Braided Cable Sleeving Solutions

Domain: cabletiesandmore.com

Registered: 2006 (19 years)

Introduction: Metal Braided Sleeving, Metal Cable Sleeves, General Purpose Braided Cable Sleeving, Heavy Duty Braided Cable Sleeving, Flame Retardant Braided Cable Sleeving, Automotive Braided Cable Sleeving, Advanced Engineering Braided Sleeving, High Temperature Fiberglass Sleeving, Special Application Braided Sleeving, Electrical Insulation Cable Sleeves.

8. Setrab USA – sūsa Stainless Steel Braided Hose

Domain: setrabusa.com

Registered: 1998 (27 years)

Introduction: {‘product_name’: ‘sūsa Stainless Steel Braided Hose’, ‘brand’: ‘Setrab USA’, ‘part_number’: ’21-SSN06-3′, ‘original_price’: ‘$24.39’, ‘current_price’: ‘$20.74’, ‘available_lengths’: [‘3 ft’, ‘6 ft’, ’12 ft’, ’24 ft’, ’48 ft’], ‘available_sizes’: [‘-6’, ‘-8’, ‘-10’, ‘-12’, ‘-16’], ‘construction’: ‘true double-braided stainless hose’, ‘material’: ‘chlorinated polyethylene (CPE) synthetic rubber, rei…

9. WireMasters – Metal Braid AA59569

Domain: wiremasters.com

Registered: 1998 (27 years)

Introduction: Metal Braid AA59569 | QQB575 | WireMasters offers braided shielding products for aerospace and defense systems. Available in tubular round or flat forms, these braids are constructed from tin, nickel, or silver-coated copper. They provide 95% or more shield coverage when placed over the equivalent diameter of the inside diameter of the tubular braid, reducing mechanical abrasion and stresses on wi…

Strategic Sourcing Conclusion and Outlook for braided metal

In today’s competitive global market, strategic sourcing of braided metal products is pivotal for organizations aiming to enhance efficiency and quality in their operations. The diverse applications of braided metal—from medical devices to industrial machinery—underscore its importance across various sectors. By leveraging reliable suppliers, businesses can ensure they receive materials that meet stringent quality standards, such as ISO certifications and compliance with regulations like RoHS and REACH.

For international buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, the ability to source braided metal effectively not only reduces costs but also mitigates supply chain risks. Engaging with suppliers who offer customization options, small quantity orders, and robust customer support can significantly enhance product development timelines and market responsiveness.

As industries continue to evolve, the demand for high-quality, flexible, and durable materials will only increase. Now is the time to evaluate your sourcing strategies and consider partnerships that will position your business for future growth. Explore the vast potential of braided metal solutions to innovate and differentiate your offerings in an ever-changing marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.