Choosing Your Rotary Vane: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for rotary vane

In today’s competitive landscape, sourcing reliable rotary vane pumps can be a daunting challenge for international B2B buyers, especially those operating in diverse industries across Africa, South America, the Middle East, and Europe. These essential components, integral to various applications—from automotive systems to food and beverage processing—require a nuanced understanding of functionality, efficiency, and market availability. This comprehensive guide aims to demystify the complexities surrounding rotary vane pumps by exploring their types, applications, and operational advantages, while also providing insights on supplier vetting and cost considerations.

By equipping buyers with actionable knowledge, this guide empowers organizations to make informed purchasing decisions that align with their operational needs and budgetary constraints. Whether you’re in Nigeria seeking efficient solutions for water treatment or in Saudi Arabia looking to enhance your automotive manufacturing processes, understanding the nuances of rotary vane pumps is crucial. With this resource, you’ll gain clarity on the best practices for sourcing, ensuring that your investments lead to enhanced productivity and reliability in your operations.

Understanding rotary vane Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Sliding Vane Pumps | Vanes slide in and out to create chambers for fluid movement. | Beverage dispensers, automotive applications | Pros: Efficient for varying fluid viscosities; Cons: Can wear faster with abrasive materials. |

| Flexible Vane Pumps | Vanes maintain contact with the rotor walls, suitable for viscous liquids. | Food, pharmaceutical, and cosmetic industries | Pros: Ideal for transporting delicate products; Cons: May require more maintenance than other types. |

| Dry Rotary Vane Pumps | Operate without lubrication, using graphite vanes to minimize wear. | Semiconductor manufacturing, vacuum applications | Pros: No oil contamination; Cons: Limited to specific applications due to wear resistance. |

| Oil-Lubricated Vane Pumps | Utilize oil to enhance sealing and cooling, extending lifespan. | Industrial applications requiring high reliability | Pros: Longer lifespan and efficient sealing; Cons: Oil contamination can limit use in sensitive applications. |

| Oscillating Vane Pumps | Use an oscillating motion to draw in and compress liquids. | Chemical processing, vacuum filtration | Pros: Effective for low-viscosity fluids; Cons: More complex design may lead to higher costs. |

What Are the Characteristics of Sliding Vane Pumps?

Sliding vane pumps are characterized by their ability to create distinct chambers for fluid movement through the sliding action of the vanes. This design allows them to handle a variety of liquid viscosities, making them particularly useful in the beverage and automotive sectors for applications such as carbonated drink dispensers and power steering systems. When considering a purchase, B2B buyers should evaluate the pump’s efficiency in terms of energy consumption and its durability against abrasive materials, which can affect long-term performance.

How Do Flexible Vane Pumps Stand Out in the Market?

Flexible vane pumps are designed to maintain constant contact with the rotor walls, making them ideal for transporting viscous liquids without compromising product integrity. These pumps are widely used in the food and pharmaceutical industries, where maintaining the quality of sensitive liquids, such as creams and yogurts, is paramount. Buyers should assess the compatibility of these pumps with their specific liquid types and consider the potential for increased maintenance needs due to the nature of their design.

Why Choose Dry Rotary Vane Pumps for Specific Applications?

Dry rotary vane pumps operate without lubrication, relying on graphite vanes that minimize wear while maintaining efficiency. They are particularly suited for applications in semiconductor manufacturing and other clean environments where oil contamination is a concern. B2B buyers should weigh the advantages of reduced maintenance against the potential limitations in handling highly abrasive or thick liquids, which may necessitate a different pump type for certain applications.

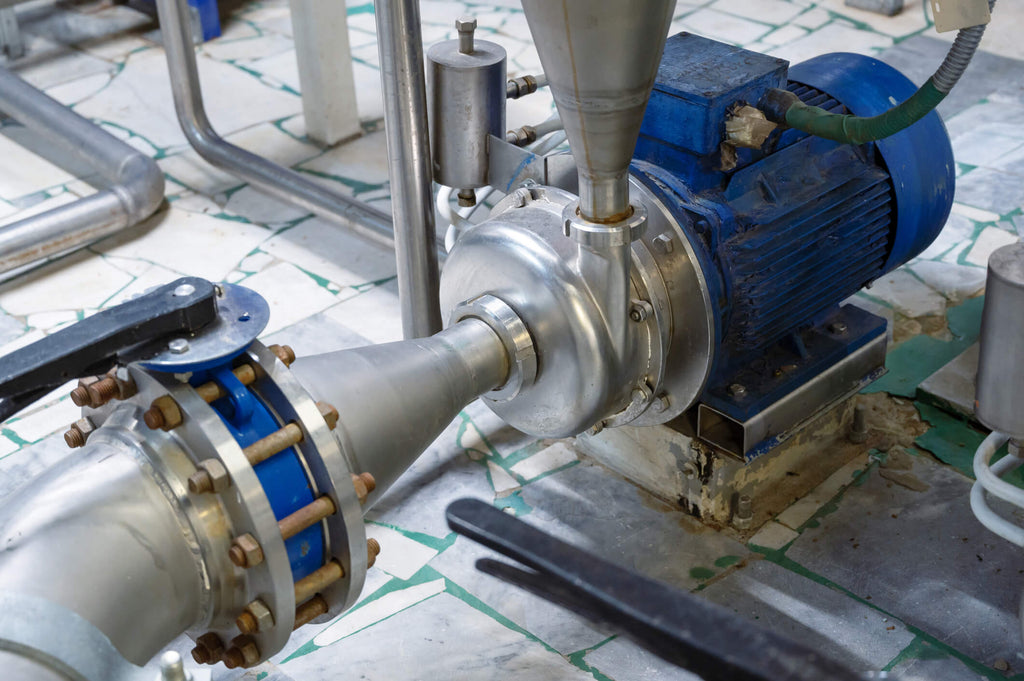

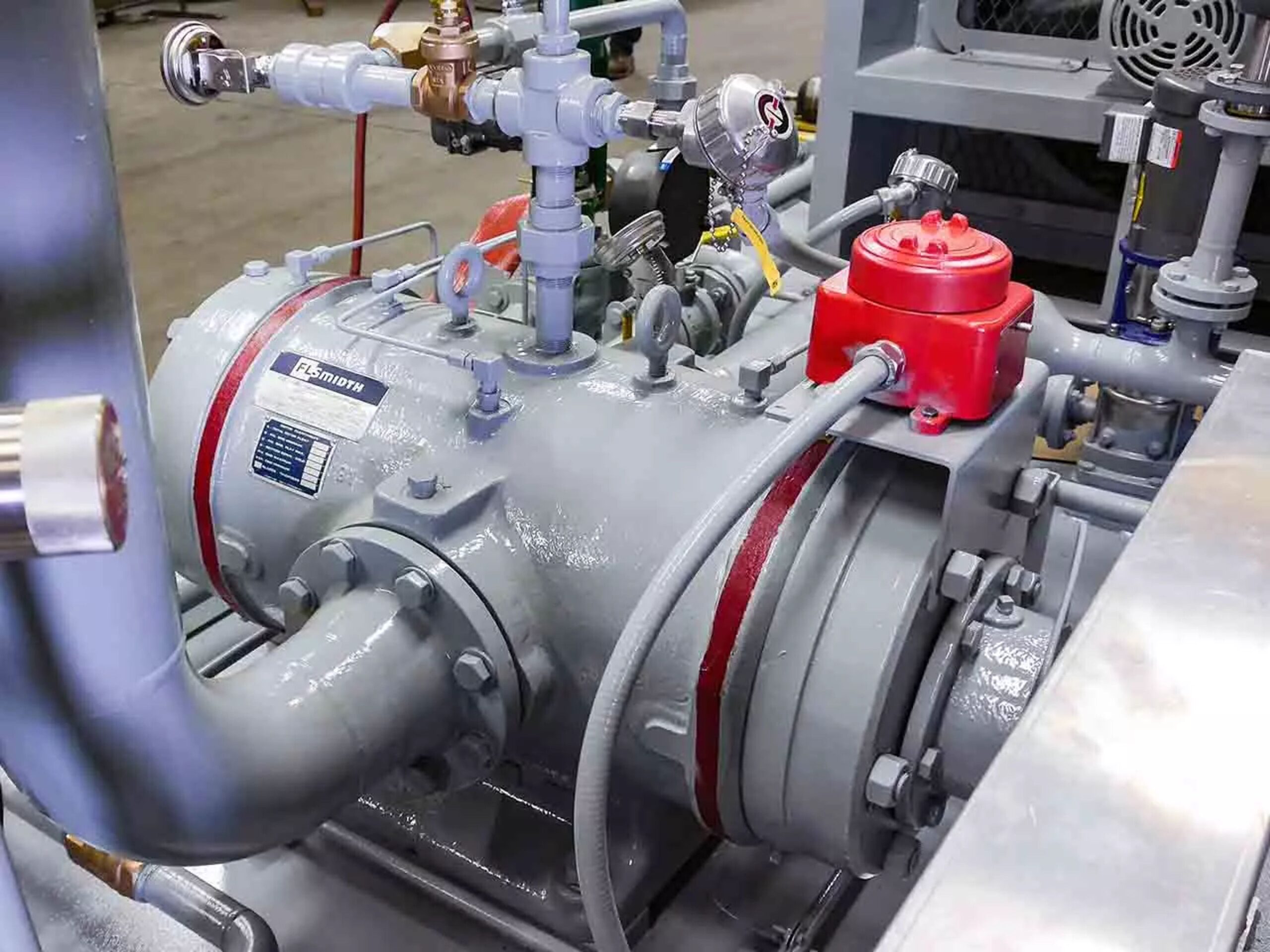

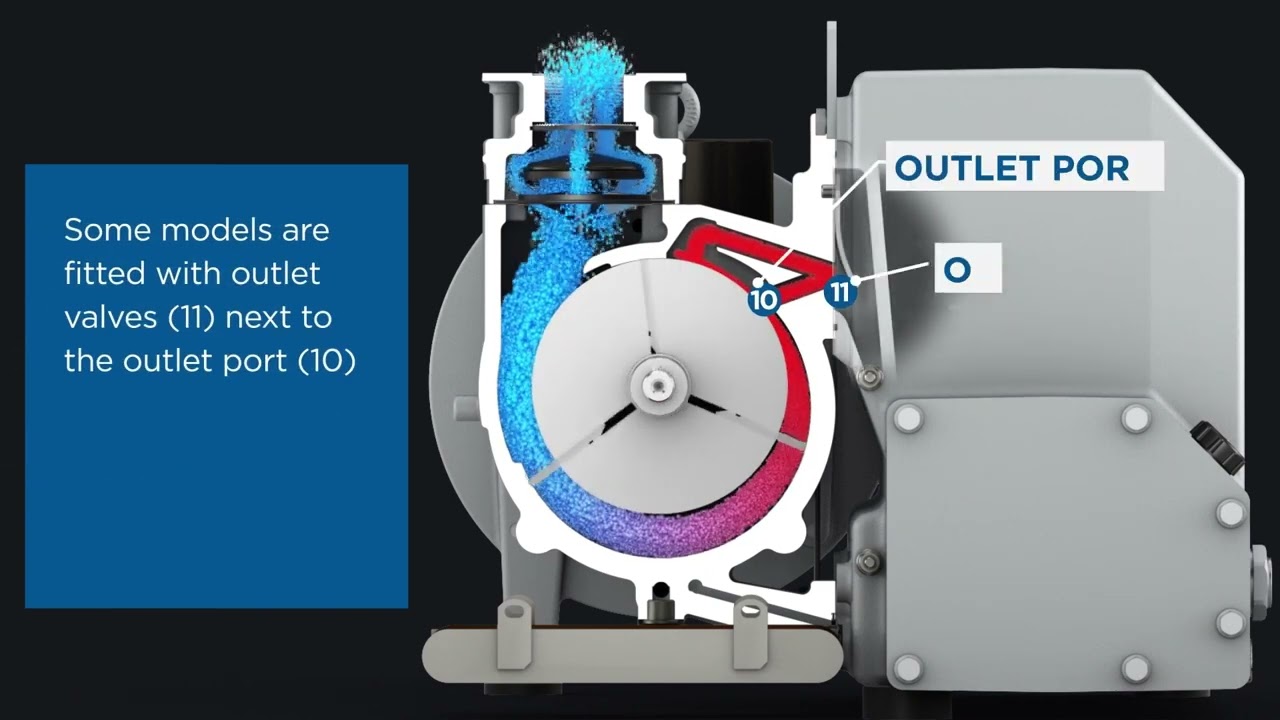

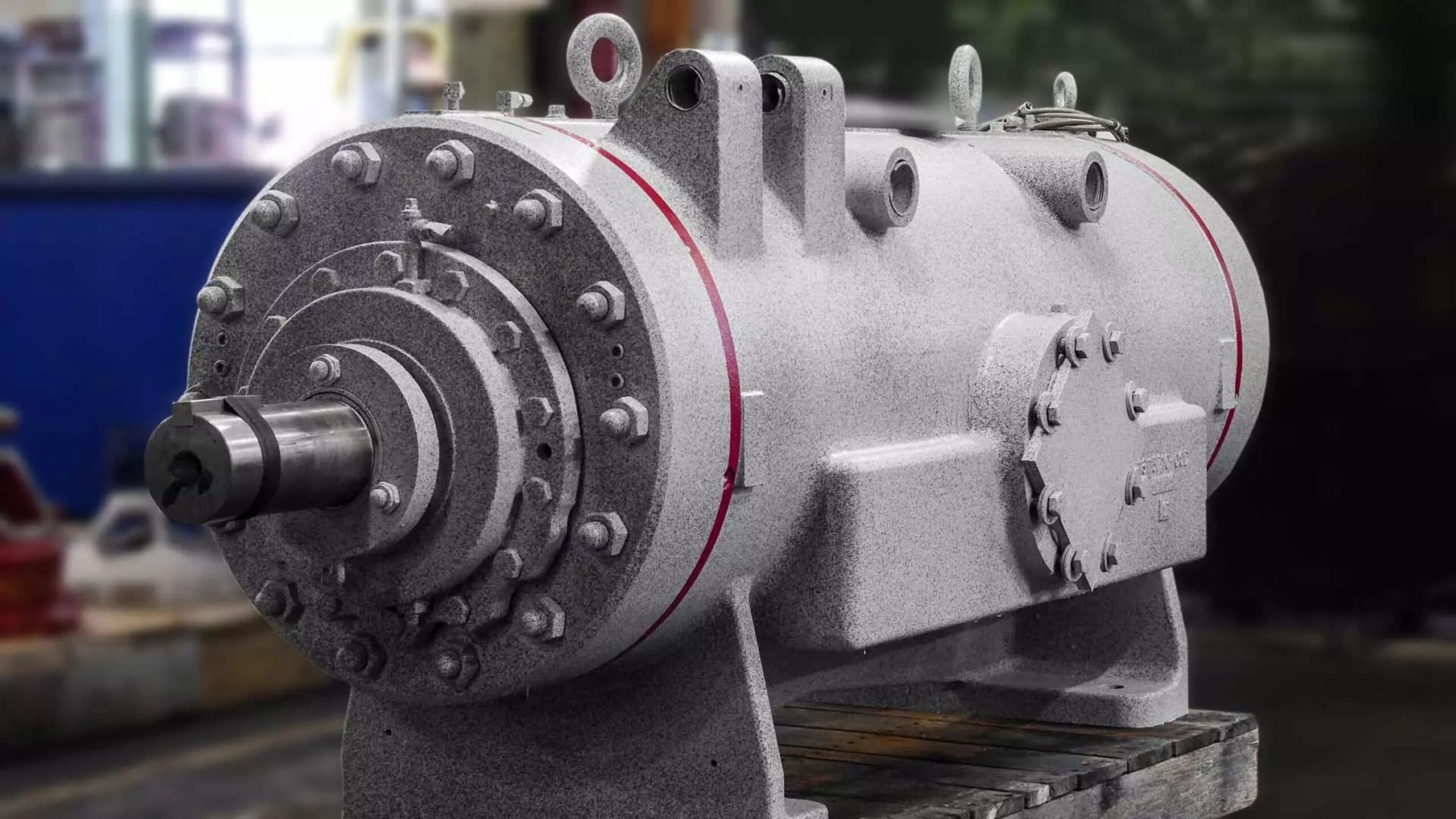

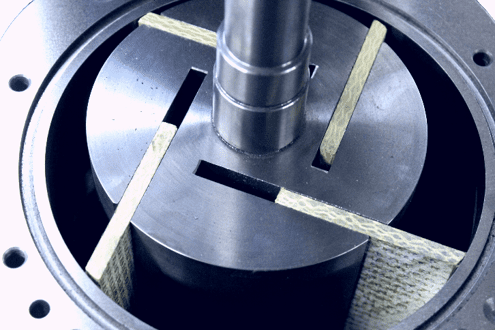

Illustrative image related to rotary vane

What Are the Benefits of Oil-Lubricated Vane Pumps?

Oil-lubricated rotary vane pumps utilize oil to enhance sealing and cooling, significantly extending the lifespan of the pump. They are commonly employed in industrial applications that demand high reliability and consistent performance. Buyers should consider the trade-offs between the benefits of improved efficiency and the risk of oil contamination, which can restrict their use in sensitive environments. Evaluating the specific operational needs and the potential impact of oil on the application is crucial for informed purchasing decisions.

How Do Oscillating Vane Pumps Function and What Are Their Uses?

Oscillating vane pumps operate through a unique motion that draws in and compresses liquids, making them effective for low-viscosity fluids in chemical processing and vacuum filtration. Their design can be more complex, which may lead to higher initial costs. B2B buyers should analyze the specific requirements of their applications, as well as the balance between upfront investment and long-term operational efficiency, to determine if oscillating vane pumps are the right fit.

Key Industrial Applications of rotary vane

| Industry/Sector | Specific Application of rotary vane | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Power steering fluid transport | Ensures reliable steering performance and safety in vehicles. | Need for high durability and resistance to wear. |

| Food and Beverage | Carbonated beverage dispensing | Maintains carbonation levels and product quality. | Compliance with food safety standards is crucial. |

| Chemical Processing | Chemical vapor deposition | Enables the production of thin films for semiconductors. | Requires pumps that handle corrosive materials safely. |

| Water Treatment | Pressurized water supply for filtration | Essential for efficient filtration and purification processes. | Must meet local regulations for water quality. |

| Pharmaceutical Manufacturing | Transport of viscous liquids | Preserves the integrity of sensitive formulations. | Need for pumps that minimize contamination risks. |

How is Rotary Vane Used in the Automotive Industry?

In the automotive sector, rotary vane pumps are integral for transporting power steering fluid, ensuring that steering systems operate smoothly and reliably. By creating a consistent flow of fluid, these pumps enhance vehicle safety and performance. For buyers in Africa and the Middle East, sourcing robust rotary vane pumps that can withstand harsh operating conditions is critical. Additionally, the demand for pumps that offer low maintenance and high durability is paramount, especially in regions with limited access to replacement parts.

Illustrative image related to rotary vane

What Role Does Rotary Vane Play in Food and Beverage Applications?

In the food and beverage industry, rotary vane pumps are utilized for dispensing carbonated beverages, where maintaining the right carbonation level is essential for product quality. They facilitate the transport of liquids without compromising the integrity of the product, making them ideal for applications in espresso machines and fountain drink dispensers. Buyers from South America and Europe must ensure that the pumps meet stringent food safety regulations and are made from non-corrosive materials to avoid contamination.

How is Rotary Vane Applied in Chemical Processing?

Rotary vane pumps are pivotal in chemical processing, particularly in applications like chemical vapor deposition (CVD), which is essential for producing thin films used in semiconductor manufacturing. These pumps must handle corrosive materials and operate under varying pressure conditions, making it crucial for buyers to consider the material compatibility and reliability of the pumps. For international buyers, understanding local regulations regarding chemical handling and safety is essential to ensure compliance and operational efficiency.

What is the Importance of Rotary Vane in Water Treatment?

In water treatment facilities, rotary vane pumps are used to supply pressurized water for filtration processes, particularly in reverse osmosis systems. Their ability to create a consistent flow is vital for maintaining effective filtration and ensuring water quality. Buyers from regions like Africa should focus on pumps that are energy-efficient and capable of operating under varying water conditions. Additionally, compliance with local water quality regulations is a critical consideration when sourcing these pumps.

How Does Rotary Vane Benefit Pharmaceutical Manufacturing?

In pharmaceutical manufacturing, rotary vane pumps are used to transport viscous liquids, such as creams and gels, ensuring that the integrity of sensitive formulations is preserved during processing. The ability to handle varying viscosities without damaging the product is crucial. Buyers in the pharmaceutical sector must prioritize pumps that minimize contamination risks and adhere to strict industry standards. Ensuring that the pumps are easy to clean and maintain is also essential for compliance with regulatory requirements.

Illustrative image related to rotary vane

3 Common User Pain Points for ‘rotary vane’ & Their Solutions

Scenario 1: Struggling with Consistent Performance in Viscous Liquid Applications

The Problem: B2B buyers in industries such as food and beverage or pharmaceuticals often face challenges when using rotary vane pumps to transport viscous liquids. These pumps, while effective, can struggle with maintaining consistent performance, leading to fluctuations in flow rates and potential product quality issues. This inconsistency can result in operational delays, increased waste, and ultimately, customer dissatisfaction. Buyers may also be concerned about the wear and tear on the pump components due to the high viscosity of the liquids being handled.

The Solution: To overcome this issue, it is crucial to select the right type of rotary vane pump specifically designed for viscous applications. Buyers should consider investing in flexible vane pumps, as they maintain contact with the rotor walls, allowing for effective liquid trapping and consistent flow. Additionally, implementing pre-filtration systems can help mitigate the impact of solids within the viscous liquids, thus protecting the pump from abrasion and prolonging its lifespan. Regular maintenance and monitoring of pump performance should also be prioritized to ensure optimal operation and early identification of potential issues.

Scenario 2: Navigating High Maintenance Costs and Downtime

The Problem: Many B2B buyers experience high maintenance costs and unplanned downtime associated with rotary vane pumps, especially when used in demanding environments. The cost of repairs, coupled with lost productivity during downtime, can significantly affect the overall efficiency and profitability of operations. Buyers often feel trapped in a cycle of frequent repairs and replacements, which can erode their confidence in the technology.

The Solution: To address these challenges, buyers should focus on choosing rotary vane pumps that are designed for durability and reliability. Selecting pumps with robust materials and seals can greatly reduce maintenance needs. Furthermore, implementing a preventive maintenance schedule can help identify wear and tear before it leads to failure. Educating staff on proper operational techniques, such as avoiding dry running conditions and ensuring appropriate lubrication, can also mitigate damage and extend the life of the pump. Collaborating with suppliers that offer strong technical support and warranty programs can provide additional peace of mind.

Scenario 3: Ensuring Compatibility with Diverse Fluids

The Problem: In a global marketplace, B2B buyers often deal with a variety of fluids, each with unique properties and requirements. Many buyers find that their rotary vane pumps are not compatible with all the fluids they need to handle, which can lead to inefficiencies and additional costs when switching between products. This lack of versatility can limit operational flexibility and hinder the ability to scale operations.

The Solution: To ensure compatibility with diverse fluids, buyers should conduct thorough research on the specifications of rotary vane pumps before making a purchase. It is essential to choose pumps that can handle a wide range of fluid viscosities and chemical compositions, such as those with adjustable vanes or multiple configuration options. Consulting with manufacturers or suppliers can provide insights into which pump models are best suited for various applications. Additionally, investing in modular or multi-purpose rotary vane pumps can enhance operational flexibility, allowing for seamless transitions between different fluids without the need for extensive system modifications. Regular training for operational staff on the specific requirements and characteristics of the fluids being handled can also minimize compatibility issues and enhance overall efficiency.

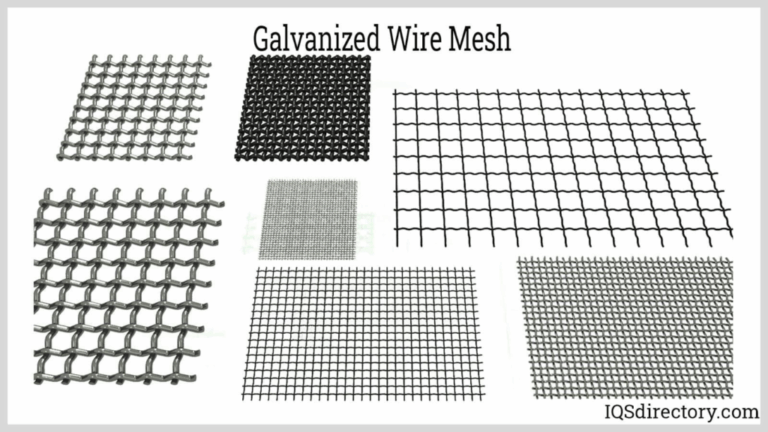

Strategic Material Selection Guide for rotary vane

What Materials Are Commonly Used in Rotary Vane Manufacturing?

When selecting materials for rotary vanes, it’s essential to consider the specific application requirements, including pressure, temperature, and the nature of the fluids being handled. Below are analyses of four common materials used in rotary vane construction, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Aluminum in Rotary Vane Applications?

Aluminum is a lightweight metal known for its excellent corrosion resistance and good thermal conductivity. It typically operates effectively at moderate temperatures and pressures, making it suitable for various applications, including automotive and light industrial uses.

Pros: Aluminum is relatively inexpensive and easy to manufacture, allowing for cost-effective production of rotary vanes. Its lightweight nature contributes to reduced energy consumption in applications where weight is a critical factor.

Cons: While aluminum is durable, it may not withstand high-pressure environments or extreme temperatures as well as other materials. Additionally, it can be susceptible to wear when in contact with abrasive substances.

Impact on Application: Aluminum is compatible with non-corrosive fluids and gases but may not be the best choice for applications involving harsh chemicals or high-viscosity liquids.

International Considerations: Buyers in regions like Africa and South America should ensure compliance with local standards (e.g., ASTM or DIN) when sourcing aluminum vanes, as quality can vary significantly across manufacturers.

How Does Steel Perform as a Material for Rotary Vanes?

Steel, particularly stainless steel, is favored for its strength and resistance to corrosion. It can handle higher pressures and temperatures, making it suitable for more demanding applications, such as industrial pumps and heavy machinery.

Pros: Steel offers excellent durability and longevity, making it a reliable choice for high-performance rotary vanes. Its ability to withstand extreme conditions enhances operational safety and efficiency.

Cons: The primary drawback of steel is its higher cost compared to aluminum and its heavier weight, which can increase energy consumption in certain applications. Manufacturing complexity can also be higher due to the need for specialized machining.

Impact on Application: Steel is ideal for applications involving aggressive fluids, such as chemicals or high-viscosity materials, where other materials might fail.

International Considerations: In regions like the Middle East, where harsh environments can accelerate corrosion, selecting high-grade stainless steel that meets specific standards is crucial for ensuring long-term performance.

What Advantages Do Composite Materials Offer in Rotary Vane Design?

Composite materials, such as reinforced plastics or carbon fiber, have gained popularity due to their lightweight and high-strength properties. These materials can be engineered to provide excellent resistance to chemicals and temperature variations.

Pros: Composites can be tailored for specific applications, providing flexibility in design and performance. They are generally resistant to corrosion and can operate effectively in a variety of environments.

Cons: The manufacturing process for composites can be complex and costly, potentially leading to higher prices. Additionally, they may not be suitable for high-pressure applications unless specifically designed for that purpose.

Impact on Application: Composites are particularly effective in food processing and pharmaceutical applications where contamination must be avoided.

International Considerations: Buyers should be aware of the certifications and standards required for composite materials in their respective regions, ensuring they meet safety and quality regulations.

Why Is Rubber an Important Material for Rotary Vane Seals?

Rubber is often used for sealing applications in rotary vane pumps due to its elasticity and ability to create tight seals. It is crucial in preventing leaks and maintaining efficiency.

Pros: Rubber seals are cost-effective and can be easily replaced, making maintenance simpler. They provide excellent resistance to a variety of fluids and gases, enhancing the overall reliability of the pump.

Cons: Rubber may degrade over time when exposed to extreme temperatures or certain chemicals, necessitating regular inspection and replacement.

Impact on Application: The choice of rubber type can significantly affect the performance of the rotary vane, particularly in applications involving aggressive or high-temperature fluids.

International Considerations: Buyers should ensure that the rubber used complies with international standards for chemical resistance and temperature tolerance, especially in regions with diverse environmental conditions.

Illustrative image related to rotary vane

Summary Table of Material Selection for Rotary Vanes

| Material | Typical Use Case for rotary vane | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive pumps, light industrial applications | Lightweight and cost-effective | Limited pressure and temperature range | Low |

| Steel | Industrial pumps, heavy machinery | High strength and durability | Higher cost and weight | High |

| Composite | Food processing, pharmaceuticals | Customizable and corrosion-resistant | Complex and potentially costly | Medium |

| Rubber | Seals in rotary vane applications | Cost-effective and easy to replace | Degrades under extreme conditions | Low |

This strategic material selection guide provides international B2B buyers with essential insights to make informed decisions when sourcing rotary vanes, ensuring compatibility with their specific applications and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for rotary vane

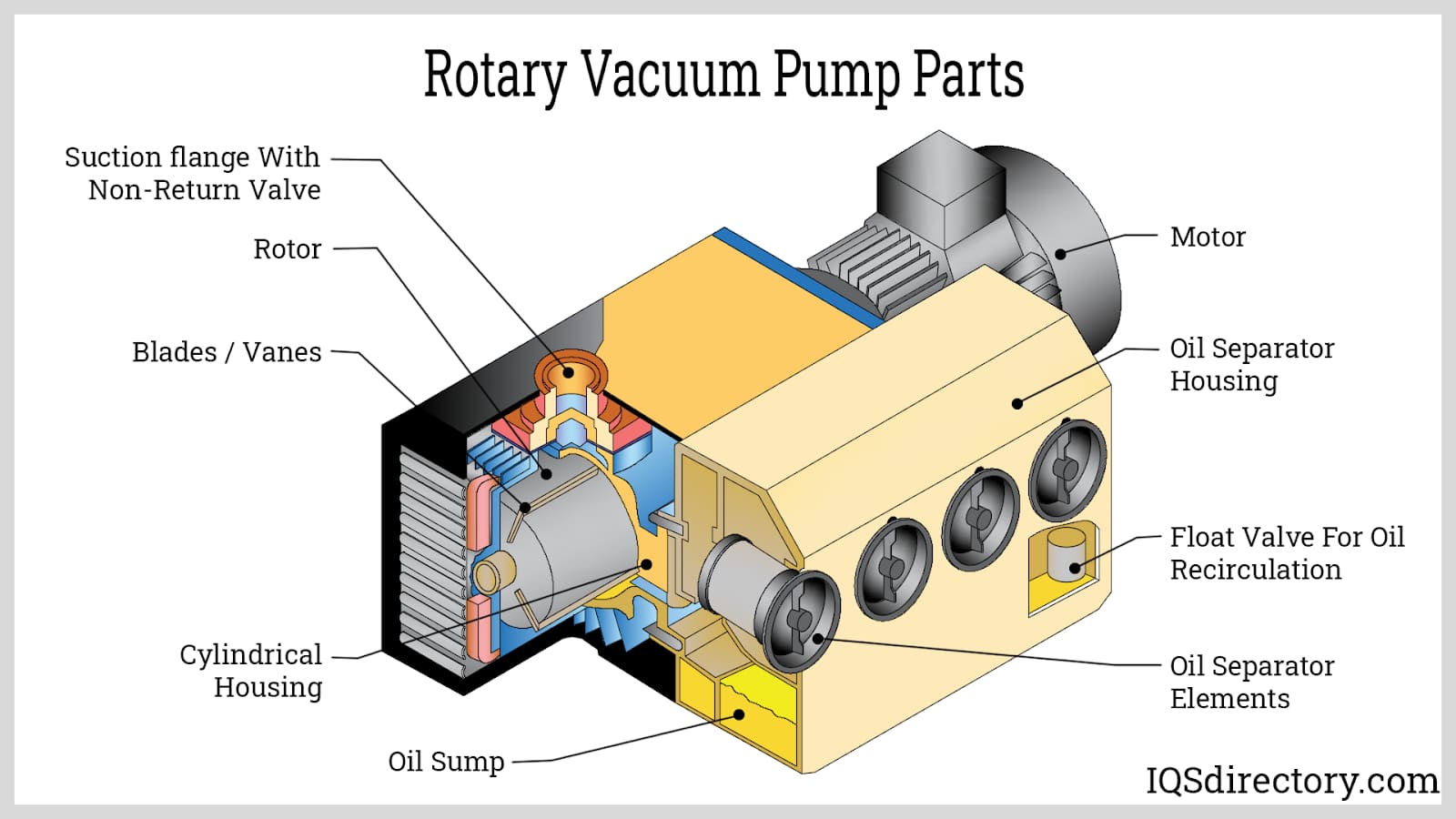

What Are the Main Stages of Manufacturing Rotary Vane Pumps?

Manufacturing rotary vane pumps involves several critical stages, each designed to ensure the final product meets high standards of quality and performance. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Rotary Vane Pumps?

The manufacturing process begins with material selection, focusing primarily on the rotor, vanes, and housing. Common materials include aluminum, stainless steel, and specialized composites that provide durability and resistance to corrosion. Quality assurance starts here, as suppliers must provide materials that meet specified standards. Material testing, such as tensile strength and corrosion resistance, is often conducted to ensure compliance with international standards.

Once materials are selected, they undergo preparation, which may involve cutting, machining, and heat treatment. Advanced machining techniques, such as CNC (Computer Numerical Control) machining, are employed for precision in creating components like the rotor and housing. This stage is crucial, as any discrepancies can lead to inefficiencies or failures in the final product.

What Techniques Are Used in Forming Rotary Vane Components?

The forming stage involves shaping the prepared materials into the required components. Techniques such as die casting, extrusion, and injection molding may be used, depending on the complexity and design of the parts.

- Die Casting: This method is often used for producing the rotor and housing, providing a high level of accuracy and a smooth finish.

- Injection Molding: Typically used for producing the vanes, this technique allows for intricate designs and consistency in component dimensions.

Forming processes must adhere to strict tolerances to ensure optimal performance of the rotary vane pump. Automated systems often support these processes, enhancing efficiency and consistency.

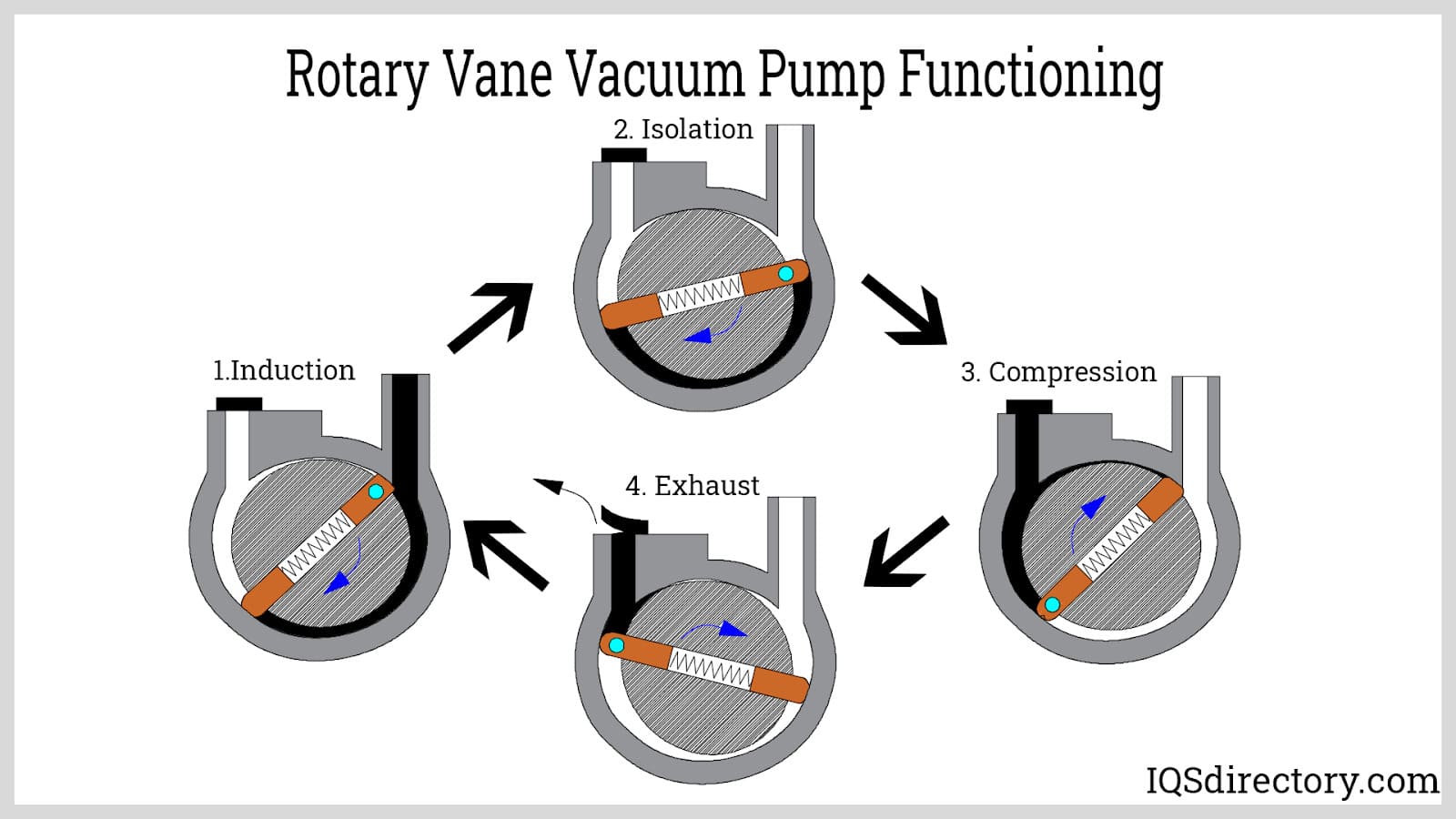

How Is the Assembly of Rotary Vane Pumps Conducted?

Once the components are formed, they move to the assembly stage. This process requires skilled technicians who follow stringent assembly protocols to ensure every part fits together correctly. Key components like the rotor, vanes, inlet, and exhaust valves are assembled in a clean environment to minimize contamination.

Illustrative image related to rotary vane

During assembly, critical alignments are checked to ensure that the vanes operate smoothly within the housing. This is where the importance of quality assurance becomes evident, as any misalignment can lead to operational failures. Torque specifications for fastening components are carefully monitored, and real-time quality checks are often integrated into this phase to catch any discrepancies.

What Finishing Processes Are Applied to Rotary Vane Pumps?

Finishing processes are essential for enhancing the performance and longevity of rotary vane pumps. These processes may include surface treatment, painting, and coating to prevent corrosion and wear. Techniques such as anodizing for aluminum components or applying protective coatings to steel parts are common.

Additionally, balancing is critical for the rotor to minimize vibrations during operation. This step is particularly important for applications requiring high precision, such as in medical devices or automotive systems.

How Is Quality Assurance Implemented in Rotary Vane Pump Manufacturing?

Quality assurance (QA) in rotary vane pump manufacturing is vital to ensure that products meet international standards and customer expectations. Implementing a robust QA system involves adhering to various standards and conducting thorough inspections at multiple checkpoints.

What Are the Relevant International Standards for Quality Assurance?

Most manufacturers align their quality management systems with ISO 9001, which sets the criteria for a quality management system. Compliance with this standard indicates that a company has established processes to ensure consistent quality in its products.

In addition to ISO 9001, industry-specific certifications such as CE marking for products sold in the European market, and API (American Petroleum Institute) standards for pumps used in the oil and gas sector, are also significant. These certifications help buyers in regions like Africa, South America, the Middle East, and Europe verify the reliability and safety of the products they purchase.

What Quality Control Checkpoints Are Commonly Used?

Quality control (QC) involves several critical checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This phase includes inspections of raw materials and components upon arrival. Suppliers must provide documentation to demonstrate compliance with quality standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC involves real-time monitoring and testing of components. This may include dimensional checks, functionality tests, and visual inspections to ensure consistency.

-

Final Quality Control (FQC): After assembly, the completed rotary vane pumps undergo final testing. This includes performance testing under various conditions to ensure they meet specified operational requirements.

What Common Testing Methods Are Used for Quality Assurance?

Testing methods for rotary vane pumps can vary based on application requirements but typically include:

-

Performance Testing: Evaluates the pump’s efficiency, flow rate, and pressure capabilities.

-

Durability Testing: Assesses the pump’s ability to withstand prolonged operation under specified conditions.

-

Leak Testing: Ensures that all seals are functioning correctly and that there are no leaks in the system.

-

Vibration Analysis: Monitors vibrations during operation to identify potential issues that could affect performance.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those in regions like Nigeria, Saudi Arabia, and others, verifying the quality control processes of suppliers is crucial. Here are some strategies to ensure reliability:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality assurance practices firsthand. This is an effective way to evaluate the supplier’s adherence to quality standards.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality assurance reports, including test results and compliance certifications. Regular reporting can provide transparency into the supplier’s QA practices.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These services can conduct inspections at various stages of production and provide certification.

-

Understanding QC Nuances: Buyers should familiarize themselves with the specific quality control nuances relevant to their region and industry. This includes understanding regulatory requirements and quality standards that may differ across countries.

By taking these steps, B2B buyers can significantly reduce the risks associated with sourcing rotary vane pumps and ensure they are investing in high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rotary vane’

To successfully procure rotary vane pumps, B2B buyers need a structured approach that encompasses technical requirements, supplier evaluation, and compliance considerations. This guide will provide a detailed checklist to streamline the sourcing process, ensuring that you select the best rotary vane pump solution for your business needs.

Step 1: Define Your Technical Specifications

Establishing precise technical specifications is critical before initiating the sourcing process. Identify the specific applications for the rotary vane pump, including the type of fluids it will handle, required pressure ranges, and flow rates. Consider the environment where the pump will be installed, as this may influence the choice between oil-lubricated and dry-running pumps.

Illustrative image related to rotary vane

- Fluid Characteristics: Understand viscosity, temperature, and chemical compatibility.

- Performance Requirements: Determine the necessary pressure and flow rate to meet operational needs.

Step 2: Research Available Options

Conduct thorough market research to identify the different types of rotary vane pumps available. Familiarize yourself with the various designs, including sliding vane and flexible vane pumps, and their respective applications in industries like food and beverage, automotive, and chemical processing.

- Types of Pumps: Compare the advantages and disadvantages of oil-lubricated versus dry-running pumps.

- Industry Applications: Align pump types with your specific industry requirements to ensure optimal performance.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. A reputable supplier should demonstrate a history of reliability and product performance.

- Supplier Credentials: Look for certifications and compliance with international standards.

- Customer Feedback: Seek testimonials or case studies that highlight the supplier’s reliability and service quality.

Step 4: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that include pricing, delivery timelines, and warranty information. Ensure that the quotations align with your technical specifications to facilitate meaningful comparisons.

- Breakdown of Costs: Analyze costs for each component, including shipping and installation if applicable.

- Warranty Terms: Understand the warranty coverage and conditions to safeguard your investment.

Step 5: Assess After-Sales Support and Service

Evaluate the after-sales support offered by suppliers. Reliable after-sales service is crucial for maintenance and troubleshooting, especially in critical applications where downtime can be costly.

Illustrative image related to rotary vane

- Technical Support: Check if the supplier provides technical assistance and training for your team.

- Spare Parts Availability: Ensure that spare parts are readily available to minimize downtime.

Step 6: Verify Compliance and Certifications

Ensure that the rotary vane pumps meet relevant industry regulations and standards. Compliance with international quality standards, such as ISO certifications, is essential for ensuring product reliability and safety.

- Regulatory Requirements: Understand the specific regulations applicable to your industry and region.

- Quality Assurance: Confirm that the supplier has established quality control processes to maintain product integrity.

Step 7: Finalize the Purchase Agreement

Once all evaluations are complete, finalize the purchase agreement with the selected supplier. Ensure that all terms are clearly defined, including payment terms, delivery schedules, and return policies.

- Contract Clarity: Review the agreement for any ambiguous terms to avoid disputes later.

- Negotiation: Be open to negotiating terms that align better with your operational needs.

By following this checklist, B2B buyers can effectively navigate the procurement process for rotary vane pumps, ensuring they select a solution that meets their technical and operational requirements while establishing a strong partnership with their suppliers.

Comprehensive Cost and Pricing Analysis for rotary vane Sourcing

When sourcing rotary vane pumps, understanding the comprehensive cost structure and pricing dynamics is crucial for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. This guide breaks down the key components of cost and pricing, along with actionable insights for optimizing sourcing strategies.

What Are the Key Cost Components in Rotary Vane Manufacturing?

-

Materials: The primary materials used in rotary vane pumps include high-grade metals, plastics, and sealing materials. The selection of these materials significantly affects the durability and performance of the pump. Buyers should consider sourcing from suppliers that offer quality materials that comply with international standards to ensure longevity and reliability.

-

Labor: Labor costs vary by region and can be influenced by local wage standards and the complexity of the manufacturing process. Countries with lower labor costs may offer competitive pricing, but it’s essential to balance this with quality assurance.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, depreciation, and factory management. Efficient production processes can help minimize overhead costs, which can be a point of negotiation.

-

Tooling: Custom tooling may be necessary for specific applications or designs. The initial investment in tooling can be substantial, but it is often amortized over the production run, making it a critical factor in determining the final price.

-

Quality Control (QC): Rigorous quality control processes ensure that the pumps meet required specifications and performance standards. Investing in QC can reduce long-term costs associated with returns and maintenance, making it a vital part of the cost structure.

-

Logistics: Transportation costs can vary widely based on the origin of the pumps, the chosen shipping method, and the destination. International buyers should consider factors such as shipping routes, tariffs, and local customs regulations.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market rates and the suppliers’ cost structures can provide leverage during negotiations.

How Do Price Influencers Affect Rotary Vane Pump Costs?

Several factors influence the pricing of rotary vane pumps:

-

Volume/MOQ: Bulk orders often lead to reduced per-unit costs. Buyers should assess their demand forecasts to negotiate favorable terms, especially for high-volume purchases.

-

Specifications and Customization: Custom features or materials can increase costs. Buyers should clearly define their requirements to avoid unexpected price hikes.

-

Quality and Certifications: Pumps that meet specific industry standards or certifications (such as ISO) may command higher prices. However, these certifications can lead to enhanced reliability and reduced risk of failure.

-

Supplier Factors: The reputation, experience, and reliability of suppliers can influence pricing. Established suppliers may charge more, but they often provide better service and quality assurance.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) can significantly impact the total landed cost. Buyers should understand the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) on their overall expenses.

What Are Effective Buyer Tips for Sourcing Rotary Vane Pumps?

-

Negotiation Strategies: Engage suppliers in open discussions about pricing, delivery times, and payment terms. Highlighting long-term relationships can lead to better deals.

-

Focus on Cost-Efficiency: Look beyond the initial purchase price. Consider the Total Cost of Ownership (TCO), which includes maintenance, energy consumption, and operational efficiency over the pump’s lifespan.

-

Understand Pricing Nuances: Different regions may have varying pricing structures due to local economic conditions and supply chain logistics. Buyers in Africa and South America, for instance, should factor in local import duties and currency fluctuations.

-

Conduct Market Research: Stay informed about market trends and competitor pricing. This knowledge can empower buyers during negotiations and help them make informed decisions.

-

Request Samples or Prototypes: Before committing to large orders, request samples to evaluate quality and performance. This step can mitigate risks associated with sourcing decisions.

Conclusion

Sourcing rotary vane pumps requires a thorough understanding of cost components, pricing influencers, and effective negotiation strategies. By leveraging these insights, international B2B buyers can optimize their procurement processes, ensuring they secure the best value for their investments. Always remember that the landscape is dynamic, and staying informed about market conditions will enhance your sourcing effectiveness.

Illustrative image related to rotary vane

Alternatives Analysis: Comparing rotary vane With Other Solutions

Introduction to Alternative Solutions for Rotary Vane Pumps

When evaluating fluid and gas transfer technologies, it’s essential to consider various solutions available in the market. While rotary vane pumps offer numerous advantages, there are alternative systems that may better suit specific applications or industries. In this analysis, we will compare rotary vane pumps with two viable alternatives: diaphragm pumps and centrifugal pumps. Understanding the differences in performance, cost, implementation, maintenance, and best use cases will enable B2B buyers to make informed decisions tailored to their operational requirements.

Comparison Table of Rotary Vane Pumps and Alternatives

| Comparison Aspect | Rotary Vane | Diaphragm Pump | Centrifugal Pump |

|---|---|---|---|

| Performance | High efficiency with stable flow; ideal for viscous liquids. | Good for low to medium viscosity; can handle slurries. | Best for low viscosity fluids; flow rate varies with pressure. |

| Cost | Moderate initial investment; lower operational costs. | Typically higher upfront cost; durable but can require more maintenance. | Generally lower cost; high efficiency can lead to savings over time. |

| Ease of Implementation | Requires careful installation and setup; may need specific mounting. | Simple installation; versatile in applications. | Easy to install; widely understood technology. |

| Maintenance | Low maintenance; oil changes may be required for oil-lubricated models. | Moderate maintenance; diaphragm replacements needed. | Low maintenance; minimal wear parts. |

| Best Use Case | Ideal for applications needing precise control of viscous liquids (e.g., food, automotive). | Suitable for chemical transfer, pharmaceuticals, and food applications. | Best for water treatment, cooling systems, and large-scale fluid transfer. |

Detailed Breakdown of Alternatives

Diaphragm Pumps: Pros and Cons

Diaphragm pumps utilize a flexible diaphragm to create a vacuum that draws fluids into the chamber. They excel in applications that require handling aggressive chemicals and slurries, making them a popular choice in the pharmaceutical and food industries. The primary advantage of diaphragm pumps is their ability to operate dry without damage, enhancing their reliability. However, the initial cost is generally higher than rotary vane pumps, and they require more frequent maintenance, particularly in replacing diaphragms, which may affect overall operational efficiency.

Centrifugal Pumps: Pros and Cons

Centrifugal pumps are designed for transferring fluids at higher flow rates, making them suitable for low-viscosity applications such as water treatment and chemical processing. Their straightforward design allows for easy installation and low maintenance, as they have fewer moving parts. The downside is that they are less effective for high-viscosity liquids or applications requiring precise control, as their flow rate can vary significantly based on system pressure. This variability can lead to inefficiencies in processes where consistent flow is crucial.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate pump technology is critical for optimizing operational efficiency and cost-effectiveness. B2B buyers should assess their specific requirements, including the type of fluid being handled, the viscosity, and the operational environment. Rotary vane pumps are a solid choice for applications requiring stable flow and the ability to handle viscous liquids, while diaphragm pumps offer versatility in handling aggressive fluids. On the other hand, centrifugal pumps are ideal for high-flow, low-viscosity applications. By carefully considering these factors and the strengths and weaknesses of each option, businesses can make an informed decision that aligns with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for rotary vane

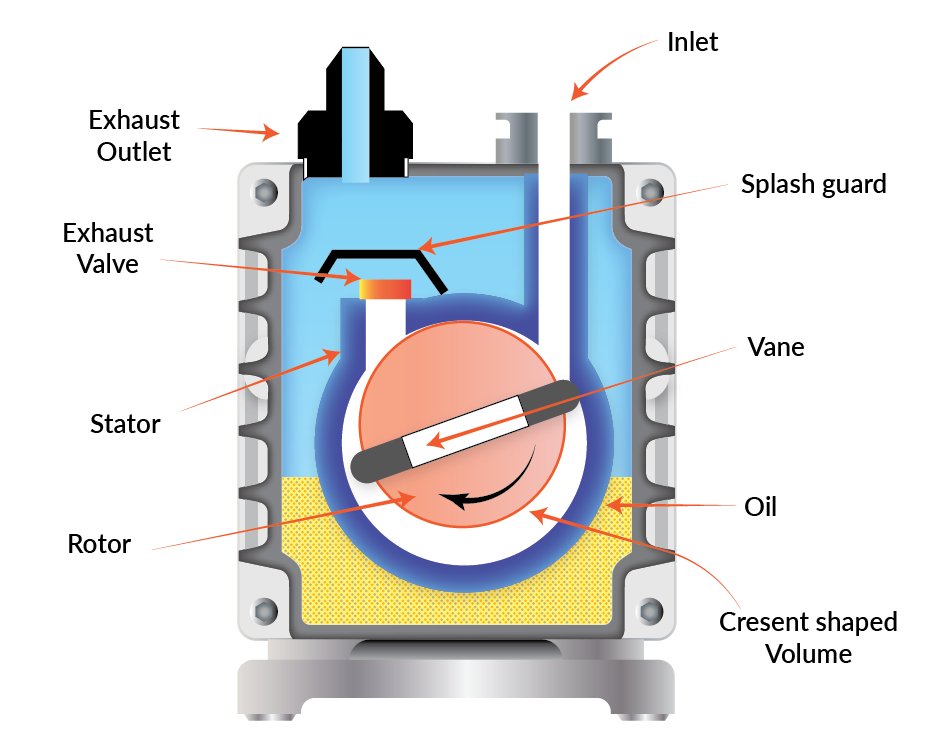

What Are the Key Technical Properties of Rotary Vane Pumps?

Understanding the technical specifications of rotary vane pumps is essential for B2B buyers to make informed purchasing decisions. Here are some critical specifications and their importance:

1. Material Grade

Rotary vane pumps are typically constructed from various materials, including aluminum, cast iron, and stainless steel. The choice of material affects the pump’s durability, corrosion resistance, and suitability for different applications. For instance, stainless steel is ideal for food and beverage applications due to its resistance to corrosion and ease of cleaning. Selecting the right material ensures longevity and reliability in demanding environments.

2. Operating Pressure

This specification indicates the maximum pressure the pump can handle during operation. Rotary vane pumps are classified into low, medium, and high-pressure categories. Understanding the operating pressure is crucial for applications that require specific pressure levels, such as automotive systems or industrial processes. Choosing a pump that matches the required operating pressure minimizes the risk of pump failure and operational inefficiencies.

3. Flow Rate

The flow rate, often measured in liters per minute (L/min), indicates how much fluid the pump can move within a specified time frame. This specification is vital for determining whether the pump can meet the demands of a particular application. A higher flow rate may be necessary for processes that require rapid fluid transfer, while lower flow rates might suffice for applications involving delicate or viscous materials.

4. Tolerance

Tolerance refers to the allowable deviation from specified dimensions in the manufacturing process. High tolerance levels ensure that the pump components fit together correctly, which is crucial for maintaining efficiency and preventing leaks. For B2B buyers, understanding tolerance specifications helps in selecting pumps that will operate effectively within their systems, minimizing downtime and maintenance costs.

5. Vane Type

Different types of vanes (sliding, flexible, external, rotating, and oscillating) influence the pump’s performance characteristics. For instance, sliding vanes are common in applications where high efficiency is needed, while flexible vanes are suited for handling viscous liquids. Knowing the vane type helps buyers choose the right pump for their specific applications, ensuring optimal performance.

Illustrative image related to rotary vane

What Are the Common Trade Terms in the Rotary Vane Industry?

Familiarity with industry jargon is essential for effective communication and negotiations. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of rotary vane pumps, knowing the OEM can help buyers ensure they are sourcing high-quality, reliable components that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, especially when planning inventory and budgeting. It helps in negotiating pricing and ensures that the supplier can meet production demands.

3. RFQ (Request for Quotation)

An RFQ is a document that an organization sends to suppliers to solicit price quotes for specific products or services. Issuing an RFQ for rotary vane pumps allows buyers to compare offers from different suppliers, ensuring they get the best price and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B transactions, particularly in international trade, as they help clarify shipping costs and responsibilities.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times for rotary vane pumps is essential for project planning and inventory management, ensuring that operations run smoothly without delays.

Understanding these technical specifications and trade terms will empower B2B buyers to make informed decisions when sourcing rotary vane pumps, ultimately enhancing their operational efficiency and product quality.

Illustrative image related to rotary vane

Navigating Market Dynamics and Sourcing Trends in the rotary vane Sector

What Are the Current Market Dynamics and Key Trends Influencing Rotary Vane Purchases?

The global market for rotary vane pumps is being significantly influenced by several key drivers, particularly the increasing demand for efficient fluid and gas handling solutions across diverse industries. As sectors such as automotive, food and beverage, and water treatment continue to expand, the necessity for reliable and versatile pumps is paramount. For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is essential.

Emerging technologies such as IoT and smart manufacturing are reshaping sourcing strategies, allowing buyers to leverage real-time data for better decision-making. This trend is particularly relevant in regions with growing industrial bases, where efficiency and operational cost reduction are critical. Additionally, the rise of e-commerce platforms is simplifying the procurement process, enabling buyers to access a wider range of suppliers and products.

Sustainability is another crucial aspect influencing purchasing decisions. Companies are increasingly prioritizing eco-friendly solutions and materials, which has led to a greater focus on sourcing pumps that meet stringent environmental standards. Overall, understanding these market dynamics and trends will empower B2B buyers to make informed sourcing decisions and foster long-term partnerships.

How Is Sustainability Reshaping the Rotary Vane Supply Chain?

Sustainability has become a central theme in the sourcing of rotary vane pumps, with increasing emphasis on minimizing environmental impact throughout the supply chain. Buyers are now expected to consider the ecological footprint of their procurement choices, influencing everything from raw material sourcing to manufacturing processes.

Illustrative image related to rotary vane

Ethical supply chains are gaining importance, particularly in regions where regulatory frameworks are evolving. Buyers are encouraged to seek suppliers who adhere to recognized sustainability certifications, such as ISO 14001, which denotes effective environmental management systems. Additionally, the use of ‘green’ materials in the manufacturing of rotary vane pumps is becoming more prevalent. This includes the adoption of recyclable components and the minimization of hazardous substances, aligning with global sustainability goals.

Investing in suppliers that prioritize sustainability not only enhances brand reputation but can also lead to cost savings through improved efficiencies and reduced waste. As international markets continue to evolve, B2B buyers must navigate these sustainability trends to ensure compliance and foster responsible sourcing practices.

What Is the Historical Context of Rotary Vane Technology for B2B Buyers?

The rotary vane pump technology has a rich history dating back to the early 20th century, evolving significantly to meet the changing demands of various industries. Initially developed for vacuum applications, these pumps have become integral to many sectors, including automotive and food processing. Over the decades, advancements in materials and design have enhanced their efficiency and reliability, allowing them to handle a broader range of fluids and gases.

For B2B buyers, understanding this evolution is crucial, as it highlights the technological advancements that have driven the current market offerings. The continuous improvements in design and manufacturing processes have led to increased durability and lower maintenance costs, making rotary vane pumps a preferred choice for many applications. Recognizing this historical context can help buyers appreciate the value and reliability of these pumps as they make sourcing decisions in today’s competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of rotary vane

-

How do I solve issues with rotary vane pump efficiency?

To enhance the efficiency of your rotary vane pump, ensure that it is properly sized for your application. Check for any obstructions or leaks in the suction line, which can hinder performance. Regular maintenance, including cleaning and replacing worn vanes, is crucial. Additionally, consider the viscosity of the fluids being pumped; using a pump designed for higher viscosities can improve efficiency. If issues persist, consult with your supplier to explore potential upgrades or modifications to your existing system. -

What is the best rotary vane pump for high-viscosity liquids?

For high-viscosity liquids, a flexible vane rotary pump is typically the best option. These pumps maintain constant contact with the rotor, allowing them to effectively handle thicker fluids without compromising flow rates. Ensure that the pump’s materials are compatible with the specific liquid you are working with to prevent corrosion or wear. Additionally, consider the pump’s pressure capabilities, as higher viscosity fluids often require more robust designs to maintain performance. -

What factors should I consider when vetting suppliers for rotary vane pumps?

When vetting suppliers, consider their industry experience, reputation, and customer reviews. Verify their certifications and compliance with international quality standards, as this is crucial for reliability. Assess their ability to provide customization options tailored to your specific needs, including sizes and materials. Additionally, inquire about their after-sales support and warranty policies, as strong customer service can significantly enhance your purchasing experience. -

What are the typical minimum order quantities (MOQs) for rotary vane pumps?

Minimum order quantities for rotary vane pumps can vary widely depending on the supplier and the specific model. Generally, MOQs can range from a few units for smaller suppliers to several dozen for larger manufacturers. Always inquire about potential flexibility in MOQs, especially if you are a first-time buyer or looking to test the market. Some suppliers may offer lower MOQs for initial orders or pilot projects, which can be beneficial for new businesses. -

What payment terms should I expect when purchasing rotary vane pumps internationally?

Payment terms can vary by supplier and region, but common practices include upfront payment, a deposit with the balance upon delivery, or net payment terms (e.g., net 30 or net 60 days). It’s essential to clarify these terms upfront to avoid misunderstandings. Consider using secure payment methods like letters of credit or escrow services for larger transactions, particularly in international dealings, to mitigate risks associated with cross-border purchases. -

How can I ensure quality assurance (QA) for rotary vane pumps?

To ensure quality assurance, request detailed specifications and test results from your supplier. Many reputable manufacturers will provide certifications that demonstrate compliance with industry standards. Consider visiting the manufacturing facility or requesting a third-party inspection prior to shipment to verify quality. Additionally, implement a thorough incoming inspection process upon delivery to check for any damage or defects, ensuring that the pumps meet your operational requirements. -

What logistics considerations should I keep in mind when importing rotary vane pumps?

When importing rotary vane pumps, consider shipping costs, lead times, and customs regulations specific to your country. Work closely with your supplier to ensure that they provide all necessary documentation for customs clearance, such as bills of lading and certificates of origin. Additionally, consider the shipping method (air vs. sea) based on urgency and cost. Be prepared for potential delays and ensure that your logistics partner is experienced in handling industrial equipment. -

How can I customize rotary vane pumps for specific applications?

Customization of rotary vane pumps can include adjustments to size, materials, and design features to meet specific application requirements. Discuss your needs with the supplier, focusing on factors such as the type of fluid, operating temperature, and pressure requirements. Some manufacturers may offer modular designs that allow for easy upgrades or modifications. Always request prototypes or sample units if possible, to test performance in your unique operational environment before finalizing your order.

Top 7 Rotary Vane Manufacturers & Suppliers List

1. Leybold – Oil Sealed Rotary Vane Pumps

Domain: leybold.com

Registered: 2001 (24 years)

Introduction: Oil sealed rotary vane pumps are designed for efficient vacuum generation. They operate by using rotating vanes within a cylindrical housing to create a vacuum. The key features include: two-stage operation for enhanced performance, compatibility with various applications such as analytical instruments, medical applications, and industrial processes, and a robust design for reliability. Leybold of…

2. Masport – Rotary Vane Pumps

Domain: masportpump.com

Registered: 1998 (27 years)

Introduction: Masport’s Rotary Vane Pumps offer versatility and durability for various applications and tank sizes. Key product details include:

– **Product Series**: H1 Series, H2 Series, H3 Series, H4 Series, H75 Series, H400W, VIPER, TITAN, HYDRA, SIDEWINDER, MAMBA, COBRA.

– **Port Sizes**: 1″, 1 1/2″, 2″, 3″, 4″.

– **CFM Ratings**: Ranging from 13 CFM to 532 CFM.

– **Tank Sizes**: Suitable for tanks from 7…

3. Fresh Water Systems – Rotary Vane Pumps

Domain: freshwatersystems.com

Registered: 1998 (27 years)

Introduction: This company, Fresh Water Systems – Rotary Vane Pumps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. SMC Pneumatics – Rotary Vane Pumps and Compressors

Domain: smcpneumatics.com

Registered: 2001 (24 years)

Introduction: Rotary Vane pumps and compressors utilize a cylindrical head with a rotor that has slots for vanes (pump blades). These pumps use centrifugal force to push the vanes against the housing wall, creating a gap that compresses gas and increases pressure, thereby creating a vacuum. They are designed to be compact, providing high performance for extended hours. Subcategories include BL-G Series, DTE Ser…

5. Pfeiffer – Rotary Vane Pumps

Domain: pfeiffer-vacuum.com

Registered: 1996 (29 years)

Introduction: Rotary Vane Pumps from Pfeiffer are robust and durable oil-lubricated vacuum solutions characterized by high pumping speeds and reliable operation across the rough and medium vacuum range. They are widely used in analytical and laboratory environments, with hermetically sealed versions minimizing contamination risks, making them ideal for processes like sterilization. The pumps cover a wide pumpin…

6. Busch – Rotary Vane Vacuum Pumps

Domain: buschvacuum.com

Registered: 2011 (14 years)

Introduction: Busch Rotary Vane Vacuum Pumps and Compressors are available in single- and two-stage versions, operable with different types of lubrication or dry-running. Key models include: R5 (single-stage oil-lubricated, proven and reliable with over 3 million units in operation), HUCKEPACK (two-stage oil-lubricated, robust for difficult applications), and SECO (single-stage dry-running, reliable for medium …

7. Fluidotech – Rotary Vane Pumps

Domain: fluidotech.it

Registered: 1998 (27 years)

Introduction: Rotary vane pumps are a type of positive displacement pump characterized by a flow rate directly proportional to speed. They feature various types of vanes (sliding, flexible, oscillating, rotating, external) and are known for dry-priming, easy maintenance, and good suction characteristics. Key components include vanes, rotor, stator, and housing. Advantages include stable low-pulsation flow, high…

Strategic Sourcing Conclusion and Outlook for rotary vane

What Are the Key Takeaways for B2B Buyers of Rotary Vane Pumps?

In the competitive landscape of rotary vane pumps, strategic sourcing emerges as a crucial factor for international buyers. Understanding the diverse applications—from automotive to food and beverage—allows companies in Africa, South America, the Middle East, and Europe to identify the right solutions tailored to their specific industry needs. Emphasizing the advantages of rotary vane pumps, such as their durability, efficiency, and low maintenance, can significantly enhance operational capabilities while minimizing costs.

How Can Strategic Sourcing Enhance Your Supply Chain?

Engaging in strategic sourcing not only secures high-quality rotary vane pumps but also fosters long-term partnerships with suppliers who understand regional market dynamics and compliance requirements. This is particularly vital in emerging markets, where local suppliers can offer insights and faster service that align with unique operational challenges.

What’s Next for International B2B Buyers?

As global demand for rotary vane pumps continues to rise, now is the ideal time for B2B buyers to reassess their sourcing strategies. By leveraging insights into pump technology and supplier capabilities, businesses can position themselves for growth and innovation. Connect with reputable suppliers today to ensure your operations are equipped with the best rotary vane solutions for tomorrow’s challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.