Everything You Need to Know About Fixed Machine Guard Sourcing in 2025

Introduction: Navigating the Global Market for fixed machine guard

In today’s global marketplace, sourcing fixed machine guards presents a significant challenge for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The need for effective machine safety solutions is paramount as industries strive to protect their workforce while complying with stringent safety regulations. Fixed machine guards are vital components in ensuring that hazardous machinery remains secure and inaccessible during operations. However, understanding the various types, applications, and compliance requirements can be daunting.

This comprehensive guide provides an in-depth exploration of fixed machine guards, covering their diverse types—from robust fixed guards to advanced presence-sensing solutions—and their applications across different industrial sectors. We will delve into the critical aspects of supplier vetting to ensure quality and reliability, discuss cost considerations, and highlight best practices for integrating these safety measures into your operations.

By equipping international B2B buyers with actionable insights and expert knowledge, this guide empowers you to make informed purchasing decisions. Whether you are operating in a manufacturing facility in Nigeria or a tech hub in Vietnam, understanding the nuances of fixed machine guards will enhance workplace safety and operational efficiency, ultimately leading to a more secure and productive environment for your workforce.

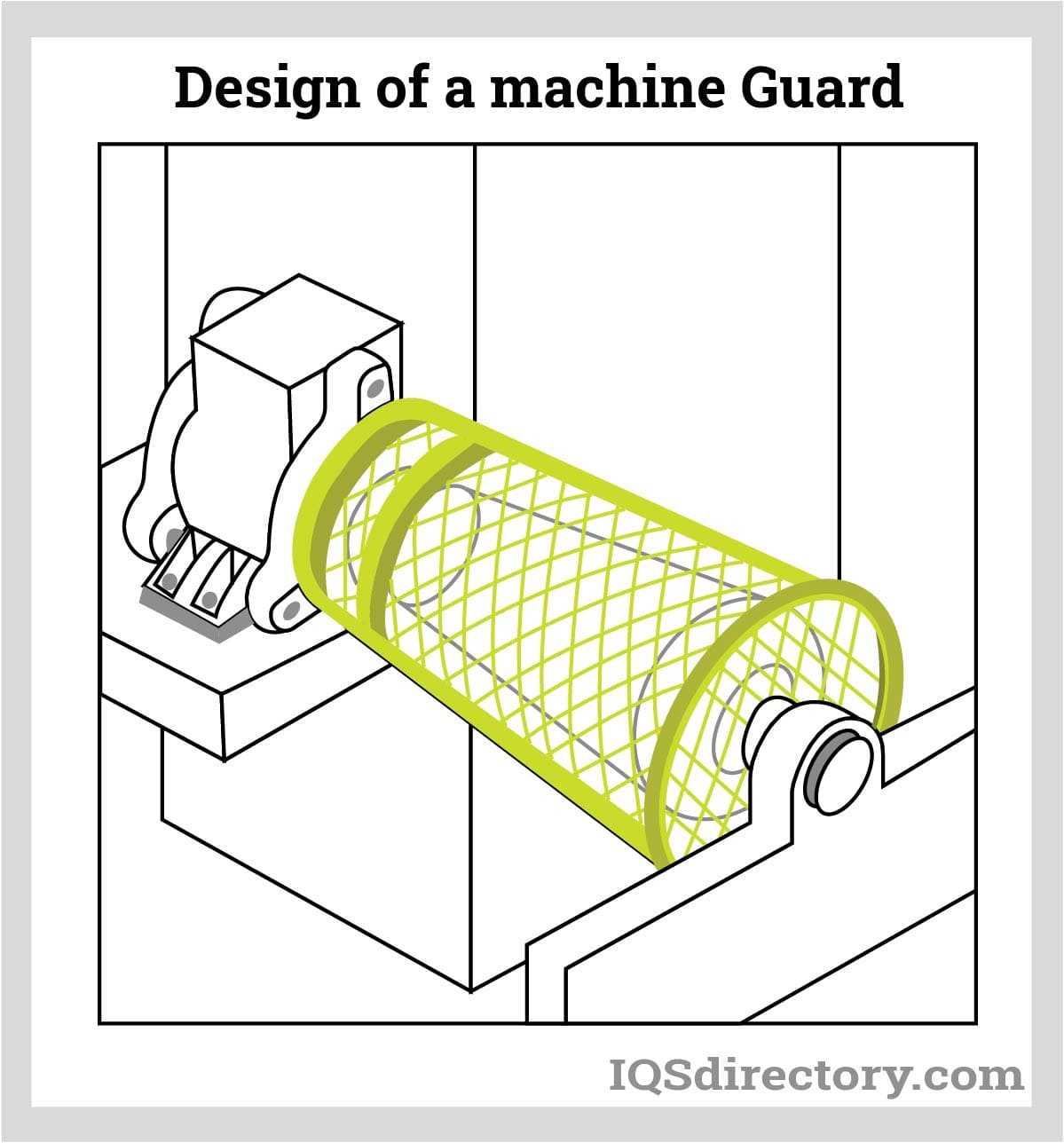

Understanding fixed machine guard Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Metal Guards | Permanently attached, typically made of robust metals | Manufacturing, Heavy machinery | Pros: Durable, high protection level. Cons: Limited access for maintenance. |

| Fixed Polycarbonate Guards | Transparent materials allowing visibility while providing protection | Food processing, Pharmaceuticals | Pros: Clear view of operations, lightweight. Cons: Less impact resistance compared to metal. |

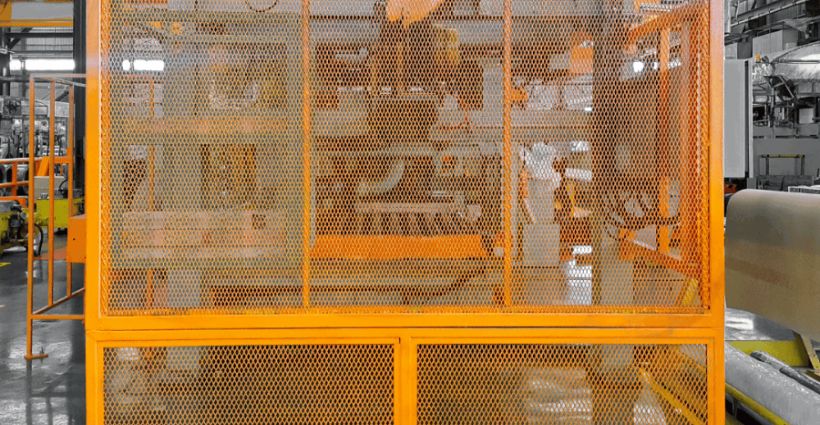

| Fixed Mesh Guards | Made from wire mesh, allowing airflow while preventing access | Robotics, Automated assembly lines | Pros: Good visibility, lightweight, and easy to install. Cons: May not provide full protection against small debris. |

| Fixed Panel Guards | Solid panels that can be customized for specific machinery needs | Industrial equipment, CNC machines | Pros: Tailored solutions for specific applications. Cons: Can be cumbersome to remove for maintenance. |

| Fixed Perimeter Guards | Encloses entire work areas to restrict access | Warehouses, Multi-machine environments | Pros: Comprehensive safety barrier. Cons: Requires more space and can limit workflow. |

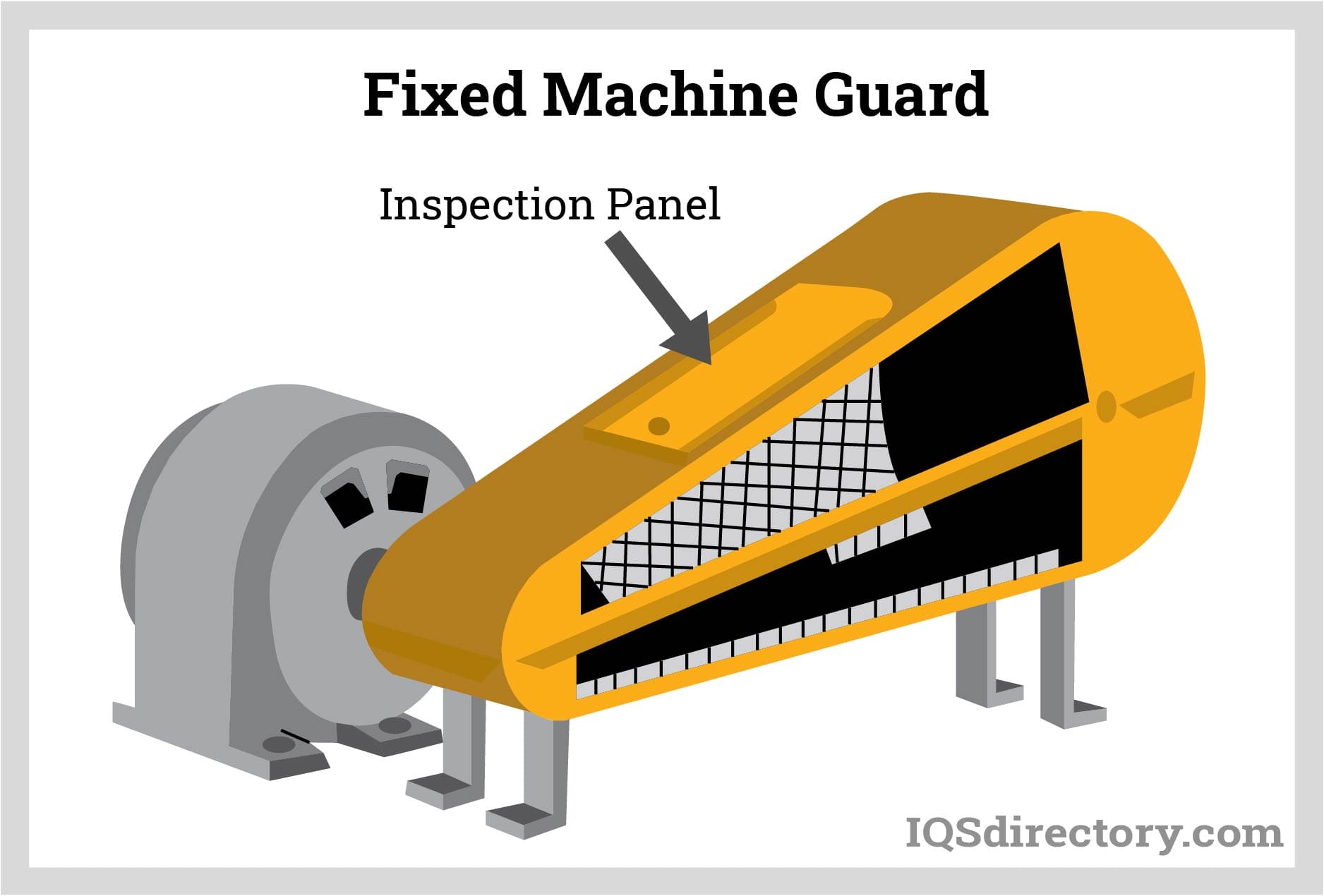

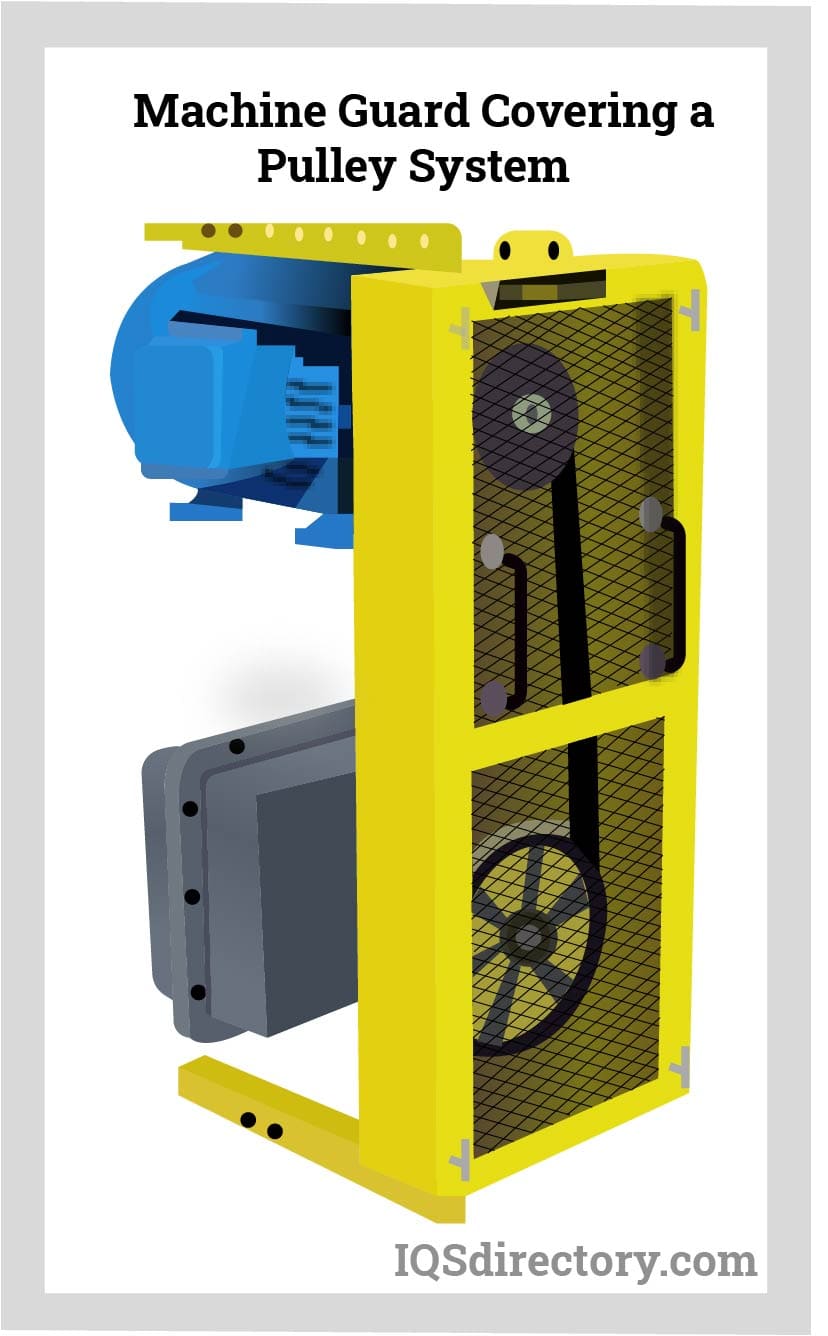

What Are the Characteristics of Fixed Metal Guards?

Fixed metal guards are robust barriers permanently attached to machinery, designed to offer high levels of protection. Commonly utilized in manufacturing and heavy machinery sectors, these guards are crafted from durable materials such as steel or aluminum. B2B buyers should consider their long-lasting nature and ability to withstand harsh environments, making them ideal for high-risk areas. However, their fixed nature can limit access for maintenance, necessitating a well-defined operational procedure to ensure safety during machine servicing.

How Do Fixed Polycarbonate Guards Compare in Suitability?

Fixed polycarbonate guards are a popular choice in industries such as food processing and pharmaceuticals, where visibility into the machine’s operations is crucial. These guards are lightweight and transparent, allowing operators to monitor processes without compromising safety. When purchasing, B2B buyers should evaluate their environments to ensure that the material can withstand the specific hazards present. While polycarbonate guards offer excellent visibility, they may not provide the same level of impact resistance as metal options, which is a critical consideration for high-risk applications.

What Advantages Do Fixed Mesh Guards Offer?

Fixed mesh guards are designed to provide a balance between visibility and safety, making them suitable for robotics and automated assembly lines. Their construction from wire mesh allows for airflow while preventing unauthorized access to hazardous areas. B2B buyers should assess the specific operational needs and safety requirements of their facilities, as mesh guards may not be suitable for environments with small debris hazards. The lightweight design and ease of installation are notable advantages, but potential buyers should ensure they meet safety standards for their intended use.

Illustrative image related to fixed machine guard

Why Choose Fixed Panel Guards for Custom Applications?

Fixed panel guards offer customizable solutions tailored to specific machinery and operational needs, particularly in industrial equipment and CNC machine applications. They provide a solid barrier against hazards, ensuring worker safety while allowing for machine functionality. When considering these guards, B2B buyers should focus on the customization options available, as well as the installation and maintenance requirements. While they provide significant protection, fixed panel guards can be cumbersome to remove, necessitating clear protocols for safe maintenance access.

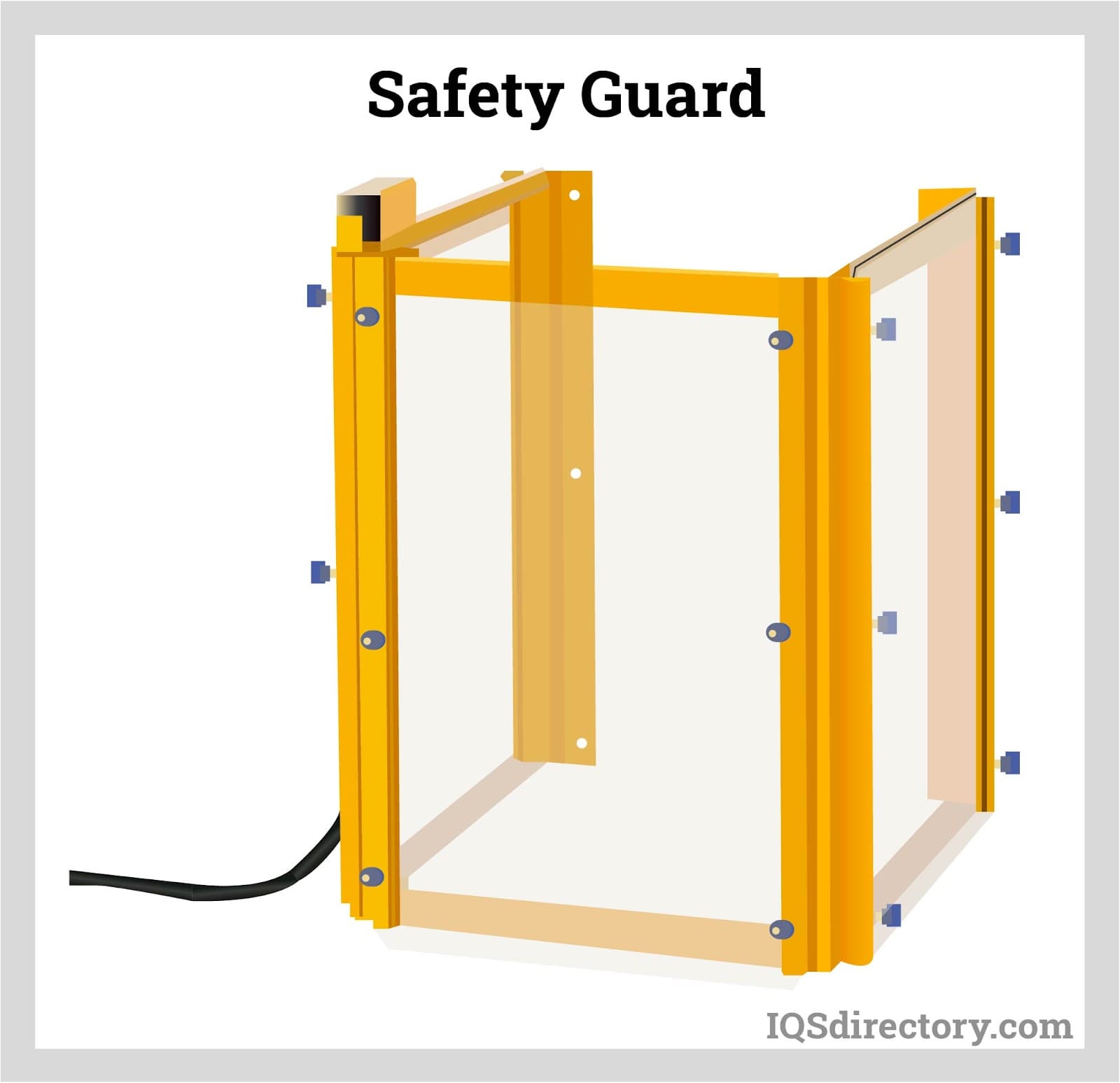

How Do Fixed Perimeter Guards Enhance Workplace Safety?

Fixed perimeter guards are designed to restrict access to entire work areas, making them ideal for warehouses and environments with multiple machines operating simultaneously. These comprehensive safety barriers help prevent unauthorized entry into hazardous zones, significantly enhancing workplace safety. B2B buyers should evaluate the spatial requirements and workflow implications of installing perimeter guards, as they can occupy substantial space and potentially limit movement. While they offer strong protection, it’s essential to balance safety with operational efficiency when considering this option.

Key Industrial Applications of fixed machine guard

| Industry/Sector | Specific Application of Fixed Machine Guard | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Enclosing hazardous machinery | Protects workers from injury, ensuring compliance with safety regulations | Durability of materials, compliance with local safety standards |

| Food Processing | Guarding slicing and packaging machines | Reduces contamination risk and enhances worker safety | Food-grade materials, easy to clean, and maintenance access |

| Automotive | Protecting assembly line equipment | Minimizes downtime due to accidents, boosts productivity | Customization options for various machinery, robust construction |

| Mining | Securing conveyors and crushing equipment | Prevents access to dangerous areas, enhances operational safety | Adaptability to harsh environments, strong impact resistance |

| Construction | Shielding power tools and heavy machinery | Reduces the likelihood of accidents, improving site safety | Compliance with international safety standards, ease of installation |

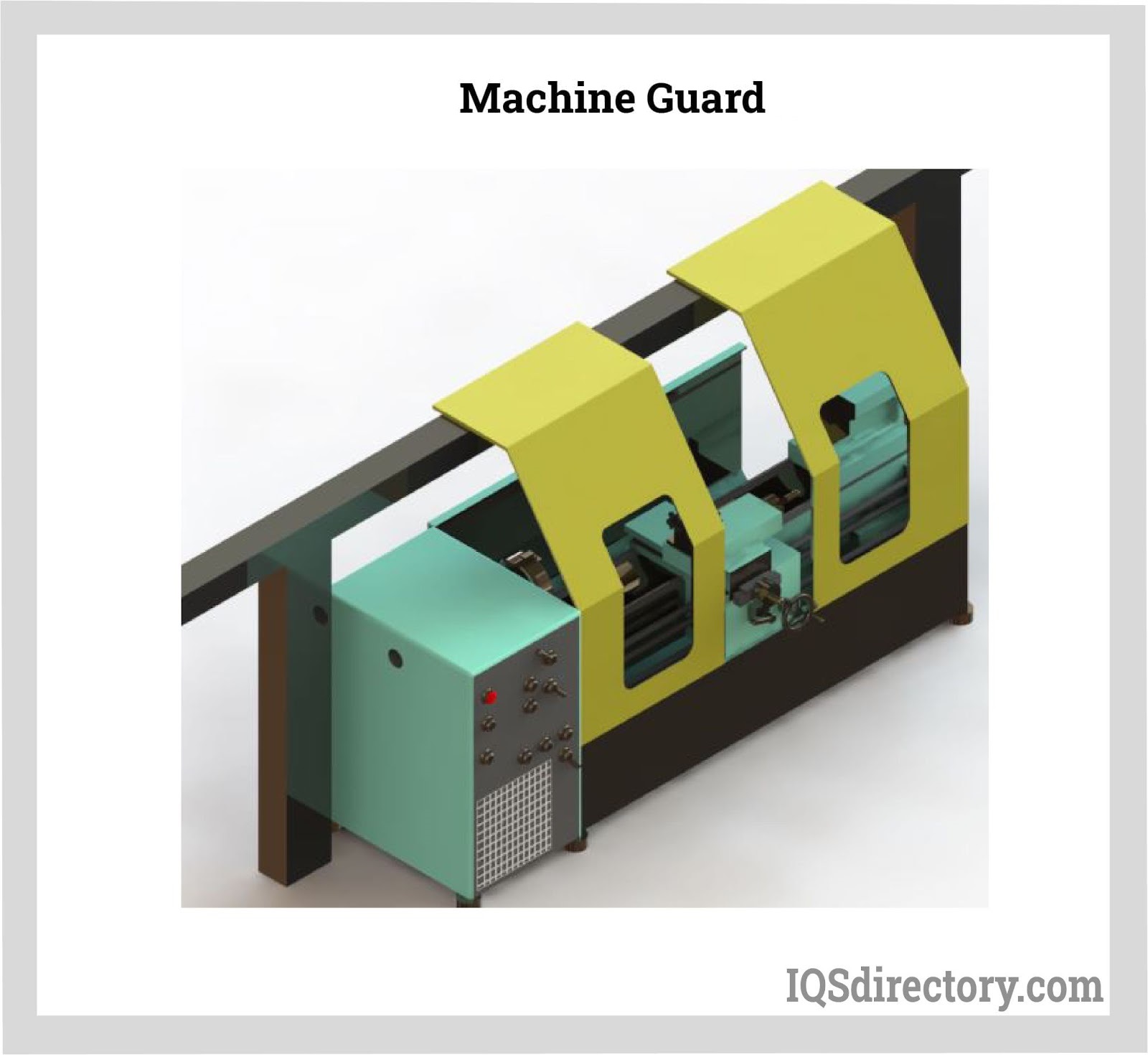

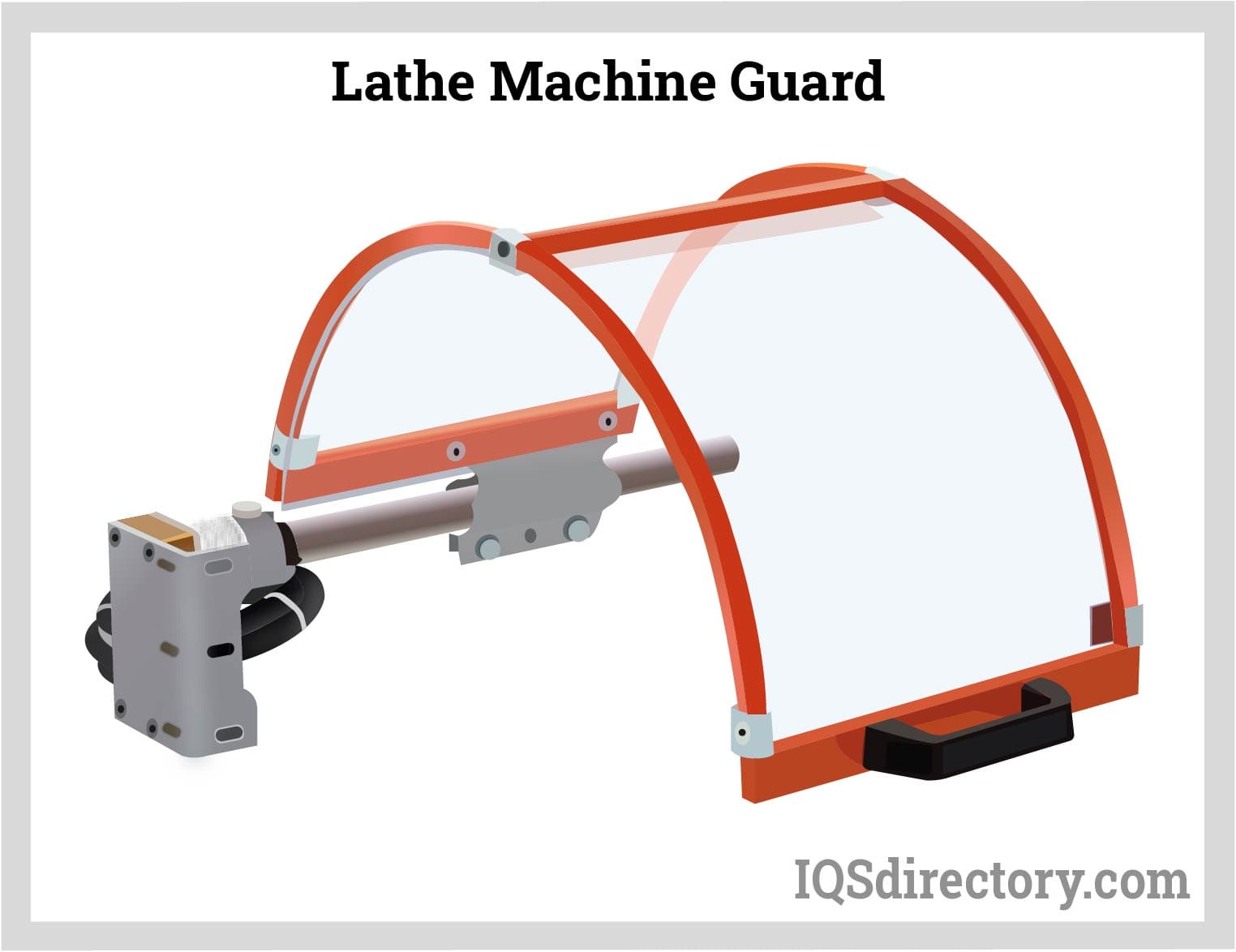

How is Fixed Machine Guard Used in Manufacturing?

In the manufacturing sector, fixed machine guards are essential for enclosing hazardous machinery, such as lathes, milling machines, and robotic arms. These guards prevent unauthorized access to dangerous areas, significantly reducing the risk of workplace injuries. Buyers in this sector should consider the durability of materials, ensuring they can withstand the rigors of a manufacturing environment, as well as compliance with local safety regulations, which can vary widely across regions in Africa, South America, the Middle East, and Europe.

What are the Benefits of Fixed Machine Guard in Food Processing?

In food processing, fixed machine guards are commonly used to enclose slicing and packaging machines. Their primary role is to protect workers from sharp blades and moving parts while minimizing contamination risks. Buyers must prioritize food-grade materials that are easy to clean and maintain, as hygiene is paramount in this industry. Additionally, they should ensure that the guards allow for quick access for maintenance without compromising safety.

Illustrative image related to fixed machine guard

How Does Fixed Machine Guard Enhance Safety in Automotive Industries?

In the automotive industry, fixed machine guards are utilized to protect assembly line equipment, including robotic arms and conveyor systems. By minimizing the risk of accidents, these guards help maintain a high level of productivity and compliance with safety regulations. Buyers should look for customization options that fit various machinery types and robust construction to withstand the demands of high-volume production environments.

What Role Does Fixed Machine Guard Play in Mining Operations?

Fixed machine guards are critical in mining, where they secure conveyors and crushing equipment from unauthorized access. By preventing entry into hazardous areas, these guards enhance operational safety and reduce the likelihood of accidents that can lead to costly downtime. Buyers in this sector should consider sourcing guards that are adaptable to harsh environments and offer strong impact resistance, given the rugged nature of mining operations.

How are Fixed Machine Guards Used in Construction Sites?

In construction, fixed machine guards are employed to shield power tools and heavy machinery from accidental contact. This application is vital for reducing workplace accidents and ensuring a safer environment for workers. When sourcing fixed guards for construction, buyers should ensure compliance with international safety standards and seek solutions that are easy to install and adjust, as site conditions can change frequently.

3 Common User Pain Points for ‘fixed machine guard’ & Their Solutions

Scenario 1: Inconsistent Compliance with Safety Regulations

The Problem: Many B2B buyers face challenges ensuring that their fixed machine guards comply with local and international safety regulations. This inconsistency can lead to hefty fines, increased liability, and, most importantly, a higher risk of workplace accidents. Buyers often struggle to interpret complex safety standards, such as those set by OSHA or local equivalents, and may find it difficult to verify that their guards meet these requirements. This uncertainty can create tension between management and safety teams, as well as jeopardize employee safety.

The Solution: To overcome compliance challenges, B2B buyers should prioritize sourcing fixed machine guards from reputable suppliers who provide detailed documentation regarding safety standards. When specifying guards, ensure they are designed to meet or exceed relevant industry regulations. Conduct regular audits of the machine guarding system, and develop a formal checklist based on applicable regulations to verify compliance. Additionally, investing in training for safety personnel on current regulations will bolster understanding and ensure that compliance is consistently maintained. Collaborating with safety consultants can also provide peace of mind, ensuring that the guarding solutions implemented are fully compliant and tailored to the specific risks present in the workplace.

Illustrative image related to fixed machine guard

Scenario 2: Difficulty in Accessing Machinery for Maintenance

The Problem: Fixed machine guards, while essential for safety, can make routine maintenance and machine adjustments cumbersome. B2B buyers often encounter frustration when their employees struggle to remove guards for necessary maintenance, leading to downtime and potential operational delays. Workers may resort to unsafe practices to bypass guards, increasing the risk of accidents and injuries. This scenario creates a tension between maintaining safety and operational efficiency.

The Solution: To alleviate this issue, B2B buyers should invest in fixed machine guards that are designed with user-friendly access features. Look for guards that incorporate features such as quick-release mechanisms or removable panels that still comply with safety regulations. Additionally, develop a clear protocol for maintenance that outlines safe procedures for removing guards, including training employees on the importance of following these protocols. Regularly scheduled maintenance should be built into operational timelines, ensuring that guards are removed and replaced safely and efficiently. By prioritizing design that balances safety with accessibility, organizations can streamline maintenance processes while maintaining a secure work environment.

Scenario 3: Lack of Customization for Unique Machinery

The Problem: In many industrial settings, machinery can be highly specialized, requiring tailored solutions for fixed machine guards. Buyers often face the challenge of finding standard guards that do not fit properly or that fail to address specific hazards associated with their unique equipment. This can lead to inadequate protection, increased risk of injury, and potential operational inefficiencies, as off-the-shelf solutions may not effectively mitigate the risks presented.

Illustrative image related to fixed machine guard

The Solution: To effectively address the need for customized fixed machine guards, buyers should engage with manufacturers who specialize in bespoke guarding solutions. Collaborate with safety engineers to analyze the specific hazards associated with the machinery in question, and work together to design guards that provide optimal protection. During the sourcing process, inquire about the manufacturer’s ability to create custom solutions and their experience with similar machinery. Furthermore, implement a feedback loop with operators who interact with the guards daily to gather insights on their functionality and effectiveness. This collaborative approach not only ensures that the guards meet safety standards but also enhances operational efficiency by providing the necessary protection tailored to the unique requirements of each machine.

Strategic Material Selection Guide for fixed machine guard

When selecting materials for fixed machine guards, it is crucial to consider the specific requirements of the application, including environmental conditions, regulatory compliance, and the nature of the machinery being guarded. Below, we analyze four common materials used in the construction of fixed machine guards, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Steel for Fixed Machine Guards?

Steel is a widely used material for fixed machine guards due to its strength and durability. It typically offers high tensile strength, making it suitable for environments where heavy impacts may occur. Steel can withstand high temperatures and pressures, making it ideal for applications involving heavy machinery or processes that generate heat.

Illustrative image related to fixed machine guard

Pros and Cons of Steel:

– Pros: High durability, excellent strength-to-weight ratio, and good resistance to wear and tear.

– Cons: Prone to corrosion if not properly treated, which can be a significant concern in humid or corrosive environments. It can also be heavier than other materials, increasing manufacturing and installation complexity.

Impact on Application: Steel’s robustness makes it suitable for guarding heavy machinery in industries such as manufacturing and mining. However, it may require additional protective coatings or treatments to enhance corrosion resistance, especially in coastal or high-humidity regions.

How Does Aluminum Compare as a Material for Fixed Machine Guards?

Aluminum is another popular choice for fixed machine guards, especially in applications where weight is a concern. It is lightweight yet strong, providing a good balance between durability and ease of handling. Aluminum also offers excellent corrosion resistance, which is beneficial in various environments.

Pros and Cons of Aluminum:

– Pros: Lightweight, corrosion-resistant, and easier to fabricate and install compared to steel.

– Cons: Generally less strong than steel, which may limit its use in high-impact applications. It can also be more expensive than steel, depending on the alloy used.

Impact on Application: Aluminum is ideal for applications in industries such as food processing and pharmaceuticals, where corrosion resistance is critical. International buyers should consider the specific alloy used, as it can affect performance in different environments.

Illustrative image related to fixed machine guard

What Are the Benefits of Polycarbonate for Fixed Machine Guards?

Polycarbonate is a high-performance thermoplastic known for its impact resistance and transparency. This material is often used in environments where visibility is essential, allowing operators to monitor machinery without compromising safety.

Pros and Cons of Polycarbonate:

– Pros: Excellent impact resistance, lightweight, and allows for visibility of machinery operation.

– Cons: May not withstand extreme temperatures or heavy impacts as effectively as metals. It can also be susceptible to scratching, which may affect visibility over time.

Impact on Application: Polycarbonate is suitable for applications in environments where visibility is crucial, such as in assembly lines or automated processes. Buyers should ensure that the polycarbonate used meets relevant safety standards for impact resistance.

What Role Does Stainless Steel Play in Fixed Machine Guards?

Stainless steel is an alloy known for its corrosion resistance and aesthetic appeal. It is often used in environments where hygiene is paramount, such as food and beverage processing or pharmaceutical manufacturing.

Illustrative image related to fixed machine guard

Pros and Cons of Stainless Steel:

– Pros: Excellent corrosion resistance, strong and durable, and easy to clean, making it suitable for hygienic environments.

– Cons: Higher cost compared to regular steel and may require specialized welding techniques for assembly.

Impact on Application: Stainless steel is ideal for applications requiring high levels of cleanliness and corrosion resistance. International buyers should verify compliance with specific standards, such as ASTM or DIN, to ensure material suitability for their operations.

Summary Table of Material Selection for Fixed Machine Guards

| Material | Typical Use Case for Fixed Machine Guard | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery guarding | High durability and strength | Prone to corrosion | Medium |

| Aluminum | Food processing, lightweight applications | Lightweight and corrosion-resistant | Less strong than steel | High |

| Polycarbonate | Visibility-required environments | Excellent impact resistance | Susceptible to scratching | Medium |

| Stainless Steel | Hygienic applications | Corrosion-resistant and easy to clean | Higher cost than regular steel | High |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on the specific needs of their operations and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for fixed machine guard

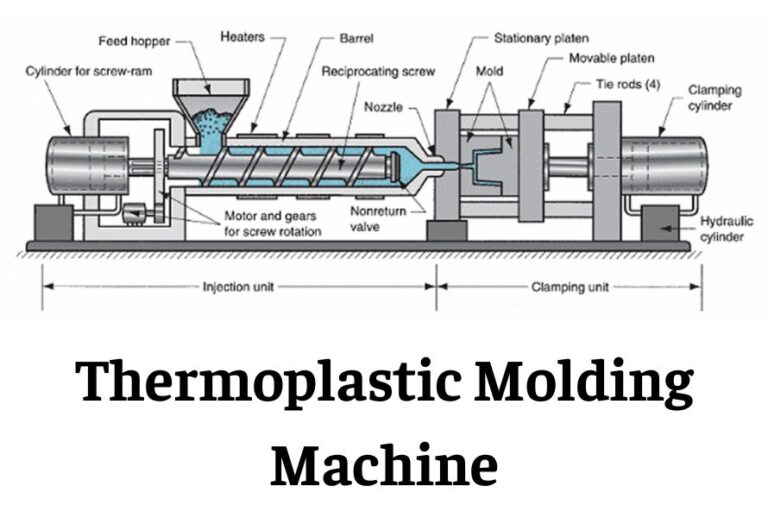

What Are the Key Stages in the Manufacturing Process of Fixed Machine Guards?

Manufacturing fixed machine guards involves several stages that ensure the final product meets safety and quality standards. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Fixed Machine Guards?

The manufacturing process begins with the selection of appropriate materials, typically robust metals or polycarbonate, known for their durability and resistance to impacts. Material preparation involves cutting sheets or bars to specified dimensions, which may be achieved through methods such as laser cutting or water jet cutting. This ensures precision and minimizes waste. Additionally, materials undergo inspections to check for defects or inconsistencies before proceeding to the next stage.

What Techniques Are Used for Forming Fixed Machine Guards?

In the forming stage, the prepared materials are shaped into the required configurations. Common techniques include bending, stamping, and welding. Bending is often used for creating angles and curves that fit the machinery’s design, while stamping is employed for more complex shapes. Welding is critical for assembling parts securely, ensuring that the guard can withstand the forces it may encounter during operation. Advanced manufacturing technologies, like CNC machining, are increasingly being utilized for enhanced precision.

How Is the Assembly of Fixed Machine Guards Conducted?

Once the individual components are formed, the assembly process begins. This stage typically involves attaching various parts, such as panels, posts, and fasteners, to create a complete guard. During assembly, manufacturers focus on ensuring that all connections are secure and that the guard complies with design specifications. Quality control measures are often integrated into this stage to catch any potential issues before the product moves to the finishing phase.

Illustrative image related to fixed machine guard

What Finishing Techniques Are Applied to Fixed Machine Guards?

Finishing processes are essential for enhancing the durability and aesthetic appeal of fixed machine guards. Common techniques include powder coating, painting, or galvanizing. Powder coating not only provides a protective layer against corrosion but also allows for customization in color and texture. This stage may also involve additional inspections to ensure that the finish is uniform and free from defects, as any imperfections could compromise the guard’s effectiveness.

What Quality Assurance Measures Are Essential for Fixed Machine Guards?

Quality assurance (QA) is critical in the manufacturing of fixed machine guards to ensure compliance with safety standards and customer expectations. Various international and industry-specific standards guide these QA processes.

Which International Standards Govern Quality Assurance for Fixed Machine Guards?

ISO 9001 is a widely recognized international standard that outlines the requirements for a quality management system. Compliance with ISO 9001 ensures that manufacturers maintain a consistent level of quality in their products and processes. Additionally, CE marking is crucial in the European market, indicating that the product meets safety, health, and environmental protection standards. For specific industries, adherence to standards such as API (American Petroleum Institute) may also be necessary, particularly in sectors like oil and gas.

What Are the Key Quality Control Checkpoints in Manufacturing Fixed Machine Guards?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to maintain high standards. These checkpoints typically include:

Illustrative image related to fixed machine guard

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): During production, ongoing inspections are conducted to identify any defects or deviations from quality standards.

- Final Quality Control (FQC): After assembly and finishing, the final product undergoes a comprehensive inspection to verify that it meets all safety and quality specifications before shipment.

What Common Testing Methods Are Used for Fixed Machine Guards?

Testing methods vary but often include visual inspections, dimensional checks, and stress tests. Visual inspections help identify any surface imperfections or structural issues, while dimensional checks ensure that the guard conforms to the required specifications. Stress tests assess the guard’s ability to withstand operational forces, simulating real-world conditions to ensure reliability.

How Can B2B Buyers Verify the Quality Control Practices of Their Suppliers?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to ensuring product reliability and safety.

What Steps Can Buyers Take to Audit Suppliers’ Quality Control Systems?

Buyers can conduct on-site audits of potential suppliers to review their manufacturing processes, quality assurance protocols, and compliance with international standards. During these audits, buyers should assess documentation, observe production practices, and verify that the supplier has a robust quality management system in place.

Illustrative image related to fixed machine guard

How Can Buyers Utilize Reports and Third-Party Inspections?

Requesting quality reports from suppliers can provide insights into their manufacturing processes and compliance with established standards. Third-party inspections, conducted by accredited organizations, can further validate the supplier’s adherence to quality control practices. These inspections often involve a thorough evaluation of manufacturing processes and product samples, offering an objective assessment of quality.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating quality control nuances in international trade can be complex. Buyers should be aware of varying regional standards and certifications that may affect product acceptance in their local markets. Understanding the specific requirements for machine guards in different countries, such as the importance of CE marking in Europe or compliance with local safety regulations in Africa and South America, is vital.

Moreover, establishing clear communication with suppliers regarding quality expectations and standards is essential for successful international transactions. This proactive approach ensures that buyers receive products that meet their operational needs and regulatory requirements.

In conclusion, understanding the manufacturing processes and quality assurance measures for fixed machine guards is crucial for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and robust quality control practices, buyers can ensure they partner with reliable suppliers who prioritize safety and compliance in their operations.

Illustrative image related to fixed machine guard

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fixed machine guard’

This guide provides a comprehensive checklist for B2B buyers looking to procure fixed machine guards. Fixed guards are essential for ensuring the safety of machinery operations by preventing unauthorized access to hazardous areas. The following steps will help streamline your sourcing process, ensuring you select the right products and suppliers for your needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications required for your fixed machine guards. Consider the type of machinery involved, the hazards present, and the environment in which the guards will be used. Specifications should include dimensions, materials (e.g., metal or polycarbonate), and any additional features, such as impact resistance.

Step 2: Research Regulatory Compliance Standards

Understanding the relevant safety standards is crucial for ensuring compliance and protecting your workforce. Familiarize yourself with local and international regulations, such as OSHA guidelines in the United States or equivalent standards in your region. Ensure that any fixed machine guard you consider meets these requirements to avoid legal repercussions and enhance workplace safety.

Illustrative image related to fixed machine guard

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure they meet your needs. Request detailed company profiles, product catalogs, and case studies relevant to your industry. Additionally, seek references from other buyers in similar sectors to gauge the supplier’s reliability and quality of service.

Step 4: Verify Material Quality and Durability

The materials used in fixed machine guards significantly impact their performance and longevity. Look for suppliers that use high-quality materials capable of withstanding the specific hazards associated with your machinery. Request samples or certifications that demonstrate the guard’s durability, such as resistance to impacts, corrosion, and other environmental factors.

Step 5: Assess Installation and Maintenance Support

Consider the installation and maintenance requirements associated with the fixed machine guards. Inquire whether the supplier offers installation services or comprehensive guidance on setup. Additionally, evaluate the availability of maintenance support and whether the supplier provides training for your staff on proper usage and upkeep of the guards.

Step 6: Analyze Cost-Effectiveness

While price is an important consideration, it should not be the sole factor in your decision-making process. Analyze the total cost of ownership, which includes initial purchase price, installation, maintenance, and potential downtime costs. A more expensive guard may offer better durability and protection, leading to long-term savings and enhanced safety.

Step 7: Request Proposals and Compare Options

Once you have identified potential suppliers, request detailed proposals that include pricing, delivery timelines, and warranty information. Compare these proposals against your specifications and budget constraints. Pay attention to additional services offered, such as customization options, to ensure you select the best fit for your operational needs.

By following these steps, you can make informed decisions when sourcing fixed machine guards, ensuring the safety of your machinery operations while complying with relevant regulations.

Comprehensive Cost and Pricing Analysis for fixed machine guard Sourcing

What Are the Key Cost Components for Fixed Machine Guards?

When sourcing fixed machine guards, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts the price. Common materials include steel, aluminum, or polycarbonate, each with varying costs based on durability, strength, and weight. For instance, steel offers robustness but is heavier, affecting logistics costs.

-

Labor: Labor costs encompass the workforce required for manufacturing and assembly. Skilled labor may command higher wages, particularly in regions where skilled labor is in high demand.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can lower overhead, but initial investments in technology may be high.

-

Tooling: The initial cost of tooling—such as molds or dies—can be substantial, especially for custom designs. Buyers should consider these costs when evaluating pricing, particularly if they require bespoke solutions.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the guards meet safety standards, which is essential for compliance. While this adds to the overall cost, it mitigates risks associated with product failure.

-

Logistics: Shipping and handling costs vary significantly based on distance, shipping methods, and the volume of the order. Buyers must factor in these costs when assessing total expenditures.

-

Margin: Supplier margins can differ based on market positioning and competitiveness. Understanding the margin expectations of suppliers can aid in negotiation.

How Do Price Influencers Affect Fixed Machine Guard Costs?

Several factors can influence the pricing of fixed machine guards, impacting overall procurement costs.

Illustrative image related to fixed machine guard

-

Volume/MOQ: Bulk purchases typically yield lower unit prices due to economies of scale. Minimum Order Quantities (MOQ) can also dictate pricing structures, so negotiating favorable terms can lead to cost savings.

-

Specifications/Customization: Custom designs tailored to specific machinery or operational needs will generally incur higher costs. Standardized products are usually more cost-effective, so buyers should assess whether customization is necessary.

-

Materials: The choice of materials not only affects the initial cost but also the longevity and maintenance needs of the guards. Higher-quality materials might come with a higher upfront cost but can reduce long-term maintenance expenses.

-

Quality and Certifications: Products that meet international safety standards often come at a premium. Certifications can enhance trust and compliance, making them a worthy investment for safety-conscious buyers.

-

Supplier Factors: Supplier reputation, reliability, and geographical location can influence pricing. Local suppliers might offer lower logistics costs, while suppliers with a strong track record may command higher prices.

-

Incoterms: Understanding Incoterms is vital for international buyers, as they define responsibilities regarding shipping, insurance, and tariffs. Clarity on these terms can prevent unexpected costs.

What Negotiation and Cost-Efficiency Strategies Should Buyers Consider?

To maximize cost-efficiency when sourcing fixed machine guards, buyers can adopt several strategies:

-

Engage in Negotiation: Leverage volume purchases and long-term partnerships to negotiate better terms and prices. Establishing a relationship with suppliers can also lead to favorable conditions.

-

Assess Total Cost of Ownership (TCO): Instead of focusing solely on purchase price, consider the TCO, which includes maintenance, durability, and compliance costs. This broader perspective can lead to more informed purchasing decisions.

-

Understand Pricing Nuances for International Transactions: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and local market conditions that can affect pricing.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers can provide a clearer picture of market pricing and help identify competitive offers.

Conclusion

Understanding the comprehensive cost structure and pricing influences of fixed machine guards is essential for international B2B buyers. By analyzing these factors and employing effective negotiation strategies, buyers can enhance their procurement efficiency and ensure compliance with safety standards while managing costs effectively.

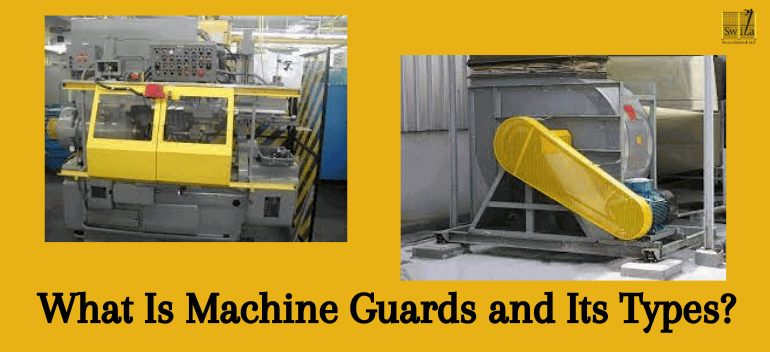

Alternatives Analysis: Comparing fixed machine guard With Other Solutions

In industrial settings, ensuring worker safety is paramount, and fixed machine guards are one of the most common solutions employed to prevent accidents. However, there are various alternatives that can also provide effective safety measures. This analysis compares fixed machine guards with other viable solutions, helping B2B buyers make informed decisions about safety implementations in their operations.

Illustrative image related to fixed machine guard

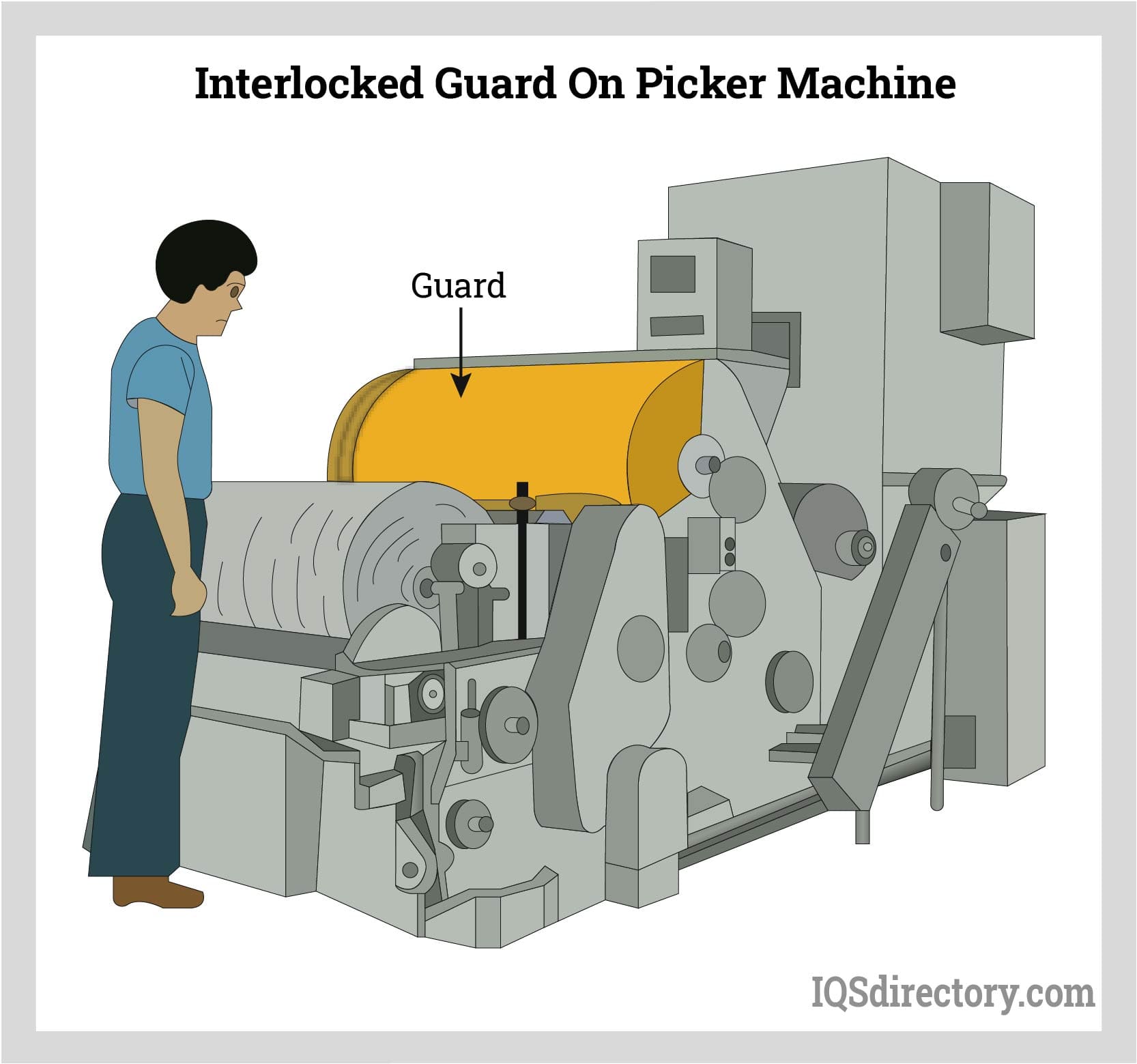

| Comparison Aspect | Fixed Machine Guard | Interlocked Machine Guard | Presence-Sensing Machine Guard |

|---|---|---|---|

| Performance | High; prevents access to hazards | High; shuts down machine when guard is removed | High; stops machine upon detecting presence |

| Cost | Generally low; one-time installation | Moderate; requires more complex installation | Higher; involves advanced technology |

| Ease of Implementation | Easy; straightforward installation | Moderate; requires technical setup | Complex; needs integration with machine controls |

| Maintenance | Low; minimal upkeep required | Moderate; requires regular checks to ensure functionality | Higher; needs periodic calibration and testing |

| Best Use Case | Machines needing infrequent access | Machines requiring frequent access for maintenance | High-risk areas with potential for human error |

What are Interlocked Machine Guards and Their Pros and Cons?

Interlocked machine guards are designed to enhance safety by automatically shutting down machinery when the guard is removed. This feature is particularly beneficial for operations requiring regular access to machinery for maintenance or adjustments. The main advantage of interlocked guards is that they significantly reduce the risk of accidental machine startup, thus protecting workers. However, they come at a moderate cost and require more technical expertise for installation and maintenance compared to fixed guards.

How Do Presence-Sensing Machine Guards Work and What are Their Advantages and Disadvantages?

Presence-sensing machine guards utilize advanced technologies like light curtains or pressure-sensitive mats to detect the presence of a person or object near hazardous areas. When an object is detected, the machine automatically stops, preventing potential accidents. These guards are particularly effective in high-risk environments where human error is a significant concern. Despite their high performance, presence-sensing guards can be costly due to the technology involved and may require complex integration with existing machinery, which can complicate the implementation process.

Conclusion: Which Safety Solution is Right for Your Business?

Choosing the right machine guarding solution depends on several factors, including the specific operational requirements, budget constraints, and the level of risk present in the work environment. For situations where access to machinery is infrequent, fixed machine guards may be the most cost-effective and straightforward option. Conversely, if regular access is necessary, interlocked guards might be more suitable. For high-risk areas where human presence poses significant dangers, presence-sensing technology can provide enhanced safety but at a higher cost and complexity. By carefully assessing these aspects, B2B buyers can select the most effective safety solution tailored to their operational needs.

Essential Technical Properties and Trade Terminology for fixed machine guard

What Are the Key Technical Properties of Fixed Machine Guards?

Understanding the technical properties of fixed machine guards is essential for B2B buyers to ensure compliance, safety, and efficiency in their operations. Here are some critical specifications to consider:

Illustrative image related to fixed machine guard

1. Material Grade

The material grade of fixed machine guards typically ranges from steel to polycarbonate. Steel guards are preferred for their durability and resistance to impact, while polycarbonate offers visibility and lightweight benefits. Selecting the right material is crucial for ensuring that the guard can withstand the operational environment and potential hazards, which is vital for minimizing workplace injuries.

2. Load-Bearing Capacity

This specification indicates how much weight the guard can support without compromising its structural integrity. A higher load-bearing capacity ensures that the guard can endure various operational stresses, such as impacts or vibrations from machinery. This property is particularly important in heavy industries where machinery operates under high loads, as it contributes to long-term safety and reliability.

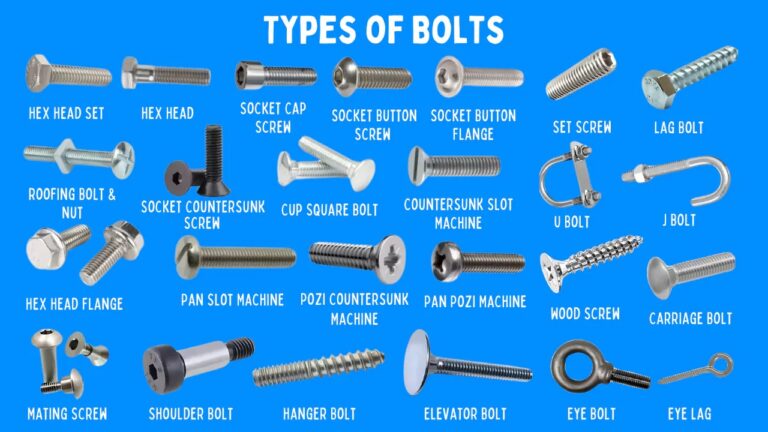

3. Fastening Mechanism

The fastening mechanism of a fixed guard must be robust and secure to prevent unauthorized removal. Common options include bolts, screws, or specialized locking systems. The choice of fastening is vital for ensuring that the guard remains in place, thereby enhancing worker safety and preventing accidental access to hazardous areas.

4. Tolerance Levels

Tolerance levels refer to the allowable deviation in dimensions during manufacturing. High precision in tolerance is essential for ensuring that the guard fits correctly and functions as intended. Poor tolerances can lead to gaps that may expose workers to hazards, highlighting the importance of sourcing guards from reputable manufacturers who adhere to strict quality standards.

5. Compliance with Safety Standards

Fixed machine guards must comply with international safety standards such as ISO 14120 or local regulations. Compliance ensures that the guards are designed and tested to provide adequate protection against machine hazards. Understanding these standards is critical for B2B buyers, as non-compliance can result in legal liabilities and increased insurance costs.

Illustrative image related to fixed machine guard

What Are Common Trade Terms Related to Fixed Machine Guards?

Familiarity with industry jargon can significantly enhance communication and negotiation processes in B2B transactions. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are used in another company’s end products. For fixed machine guards, knowing the OEM can help buyers ensure that they are sourcing high-quality components that meet specific standards.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell in a single order. Understanding MOQ is essential for B2B buyers as it can influence purchasing decisions and inventory management strategies. Buyers should consider their operational needs and forecast demand when evaluating MOQs.

3. RFQ (Request for Quotation)

An RFQ is a formal document requesting a price quote from suppliers for specific products or services. This term is significant in the procurement process, as it allows buyers to compare prices, terms, and conditions from multiple vendors, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international contracts to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers engaged in cross-border transactions, as they help mitigate risks and ensure smooth logistics.

Illustrative image related to fixed machine guard

5. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the goods. This term is critical for supply chain management, especially in industries where downtime can be costly. Understanding lead times helps buyers plan their operations and inventory more effectively.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that they procure the right fixed machine guards that enhance workplace safety and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the fixed machine guard Sector

What Are the Key Market Dynamics Impacting Fixed Machine Guard Purchases?

The fixed machine guard market is experiencing significant growth, driven by heightened safety regulations and an increasing focus on workplace safety across industries. Countries in Africa, South America, the Middle East, and Europe are amplifying their investments in manufacturing, which directly correlates with a greater need for effective machine safety solutions. Emerging technologies such as smart sensors and IoT-enabled monitoring systems are also reshaping sourcing trends, allowing buyers to integrate advanced safety measures into their operations. International B2B buyers are increasingly seeking suppliers who can provide not only compliant products but also innovative solutions that enhance operational efficiency.

Illustrative image related to fixed machine guard

Additionally, the shift towards automation in manufacturing is influencing the demand for fixed machine guards. As industries adopt robotics and automated processes, the need to safeguard these machines against human interaction becomes critical. In markets like Nigeria and Vietnam, where industrial growth is accelerating, suppliers must be agile, offering customized solutions that meet local safety standards while being cost-effective. Collaboration with local distributors who understand regional regulations can provide significant advantages in navigating these dynamics.

How Can Sustainability and Ethical Sourcing Impact Fixed Machine Guard Procurement?

Sustainability is becoming a pivotal consideration for B2B buyers in the fixed machine guard sector. As companies worldwide face pressure to reduce their environmental impact, sourcing from suppliers that prioritize eco-friendly materials and practices is crucial. Buyers should look for manufacturers that utilize recyclable materials, such as high-grade steel or polycarbonate, which offer durability while minimizing environmental harm.

Furthermore, the importance of ethical supply chains cannot be overstated. Buyers must ensure that their suppliers adhere to fair labor practices and responsible sourcing methods. Certifications like ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as benchmarks for evaluating potential suppliers. By prioritizing sustainability and ethical sourcing, companies not only improve their corporate image but also align with global trends towards greener operations, which can enhance their market competitiveness.

Illustrative image related to fixed machine guard

What Is the Historical Context of Fixed Machine Guards in Industrial Safety?

The evolution of fixed machine guards can be traced back to the industrial revolution when machinery began to dominate manufacturing processes. Initially, safety measures were minimal, often leading to accidents and injuries among workers. Over the decades, as awareness of workplace safety grew, regulations emerged, leading to the development of more robust safety standards.

By the late 20th century, organizations such as OSHA began implementing guidelines that mandated the use of machine guards. This pivotal shift ensured that fixed guards became an integral part of machinery design, focusing on preventing unauthorized access to hazardous areas. Today, fixed machine guards are recognized not only as safety devices but as critical components that enhance productivity and operational reliability in manufacturing environments. Understanding this evolution helps B2B buyers appreciate the importance of investing in high-quality, compliant safety solutions that protect both workers and equipment.

Frequently Asked Questions (FAQs) for B2B Buyers of fixed machine guard

-

How do I choose the right fixed machine guard for my operations?

Choosing the right fixed machine guard involves assessing the specific machinery and operational environment. Consider the types of hazards present, the frequency of access needed, and the materials used for construction. Fixed guards should be robust and securely attached to prevent unauthorized access. Collaborate with suppliers who understand local safety regulations and can provide tailored solutions that meet your operational needs. Conduct a risk assessment to ensure compliance with international safety standards, which is crucial for protecting workers and minimizing liability. -

What are the key safety standards for fixed machine guards?

Fixed machine guards must comply with established safety standards, which vary by region. For instance, in the U.S., OSHA guidelines outline requirements for design, installation, and maintenance. Internationally, standards from organizations like ISO or ANSI may apply. Ensure that your chosen supplier adheres to these standards to guarantee the effectiveness and reliability of the guards. Request documentation that verifies compliance to enhance workplace safety and reduce the risk of penalties during inspections. -

What customization options are available for fixed machine guards?

Many suppliers offer customization options for fixed machine guards to suit specific applications. You can request modifications in size, shape, and materials based on the machinery and operational requirements. Some manufacturers also provide features such as color coding, branding, or additional safety elements like visibility strips. Discuss your needs with potential suppliers to explore available customization options that enhance both safety and functionality. -

What is the minimum order quantity (MOQ) for fixed machine guards?

Minimum order quantities (MOQ) for fixed machine guards can vary significantly among suppliers. Some manufacturers may have a low MOQ for standard products, while custom designs may require higher quantities. It’s essential to clarify MOQ details during initial discussions with suppliers to ensure they align with your procurement strategy. If you’re looking to test a new design, inquire if suppliers can accommodate smaller orders or provide prototypes. -

What payment terms should I expect when sourcing fixed machine guards?

Payment terms for fixed machine guards typically depend on the supplier’s policies and the size of the order. Common practices include upfront payments, deposits with the balance due upon delivery, or net payment terms (e.g., 30, 60, or 90 days). Ensure you discuss payment options and negotiate terms that suit your cash flow requirements. Additionally, consider using secure payment methods to protect your investment, especially when dealing with international suppliers. -

How do I vet suppliers for fixed machine guards?

Vetting suppliers for fixed machine guards involves evaluating their experience, reputation, and compliance with safety standards. Request references from previous clients, check online reviews, and review their certifications related to safety and quality. Conduct site visits if possible, or request virtual tours of their manufacturing facilities. Assess their responsiveness and willingness to provide technical support, as these factors can indicate their commitment to quality and customer service. -

What logistics considerations should I be aware of when importing fixed machine guards?

When importing fixed machine guards, consider logistics factors such as shipping methods, customs clearance, and lead times. Understand the costs associated with freight, duties, and taxes in your region. Work with a logistics provider experienced in handling industrial equipment to ensure timely delivery and compliance with local regulations. Additionally, ensure that your supplier provides adequate packaging to protect the guards during transit, as damage can lead to increased costs and delays. -

What quality assurance measures should I expect from suppliers?

Quality assurance measures for fixed machine guards should include regular inspections, testing for durability, and adherence to safety standards. Ask suppliers about their quality control processes, including any certifications they hold (e.g., ISO 9001). A reliable supplier should provide documentation of quality checks and be open to third-party audits. Establish clear communication regarding your quality expectations and ensure that they can meet your operational standards consistently.

Top 8 Fixed Machine Guard Manufacturers & Suppliers List

1. Axelent – Machine Guards

Domain: axelent.com

Registered: 2002 (23 years)

Introduction: Axelent is a leading manufacturer of machine guards, providing a complete system that meets current directives and standards. Key product details include: 1. Fixed Guards: Designed to prevent access to hazards, suitable for areas accessed less than once per week. 2. Compliance: Must be strong enough for expected hazards, removable only with tools, and fasteners must remain with the guard. 3. Safet…

2. Axelent – Machine Guards

Domain: axelentusa.com

Registered: 2004 (21 years)

Introduction: Axelent is a leading manufacturer of machine guards, offering a complete system that meets current directives and standards. Key product categories include: 1. **Panels** – Mesh panels for industry and warehouse environments. 2. **Posts** – Support structures for machine guarding systems. 3. **Doors** – Access points integrated into guarding systems. 4. **Locks & Switches** – Safety mechanisms for…

3. Sandbaggy – High Profile Machine Safety Guard

Domain: sandbaggy.com

Registered: 2010 (15 years)

Introduction: {“Product Name”: “High Profile Machine Safety Guard”, “Dimensions”: {“Height”: “24 inches”, “Length”: “48 inches”}, “Material”: “Steel”, “Tube Diameter”: “4.5 inches”, “Color”: “Yellow with Black Stripes”, “Coating”: “Powder Coated”, “Mounting Plate Dimensions”: {“Width”: “8 inches”, “Length”: “8 inches”, “Thickness”: “1/16 inch”}, “Hole Diameter”: “5/8 inch”, “Weight”: “39 lbs”, “Price”: {“1 pcs”…

4. Uline – Low Profile Machine Guard

Domain: uline.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Low Profile Machine Guard”, “Model Number”: “H-7688F”, “Dimensions”: {“Width”: “9 inches”, “Length”: “48 inches”, “Diameter”: “4.5 inches”, “Height”: “9 inches”}, “Mounting Plate Dimensions”: {“Size”: “8 x 8 inches”, “Holes”: {“Size”: “1 1/4 x 7/8 inches”, “Distance Between Holes (Center to Center)”: “6 inches”, “Distance Between Hole & Corner of Plate”: “7/8 inches”}}, “Weight”:…

5. Safety Matters – Machine Guards

Domain: safetymattersweekly.com

Registered: 2016 (9 years)

Introduction: Machine guards are safety devices used to protect employees from unguarded or inadequately guarded machines. They prevent direct contact with moving parts and protect against flying chips, kickbacks, and splashing of harmful liquids. There are two main types of machine guards: fixed guards, which provide constant protection and can only be adjusted by authorized personnel, and interlocking guards,…

6. Pilz – Fixed Guards

7. Belt Conveyor Guarding – Barrier Guards

Domain: conveyorguarding.com

Registered: 2005 (20 years)

Introduction: Belt Conveyor Guarding specializes in ergonomic, user-friendly fixed machine guarding. Key product types include: 1. Barrier Guards – Enclose rotating machine applications, commonly used for tail sections on conveyors, with a modular bolt-together design requiring no welding or cutting. 2. Component Guards – Placed on or around individual machines to prevent contact with rotating hazards, applicab…

8. OSHAcademy – Machine Safeguarding Course

Domain: oshacademy.com

Registered: 2006 (19 years)

Introduction: 154 Machine Safeguarding: Basic course covers various types of machine guards including Fixed Guards, Adjustable Guards, and Interlocked Guards. Fixed Guards are permanent parts of machines made from durable materials, providing simplicity and permanence. Adjustable Guards offer flexibility for different stock sizes, while Interlocked Guards ensure safety by shutting off the machine when opened. T…

Strategic Sourcing Conclusion and Outlook for fixed machine guard

Why Is Strategic Sourcing Essential for Fixed Machine Guards?

In the evolving landscape of global manufacturing, the strategic sourcing of fixed machine guards emerges as a critical component in ensuring workplace safety and operational efficiency. By prioritizing high-quality materials and compliance with international safety standards, businesses can significantly reduce the risk of workplace accidents and enhance productivity. The integration of fixed guards not only protects workers from hazards but also fosters a culture of safety, which is increasingly valued by stakeholders across industries.

Illustrative image related to fixed machine guard

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe look to enhance their safety protocols, leveraging strategic sourcing can yield substantial long-term benefits. Collaborating with reputable suppliers who prioritize innovation and sustainability will ensure that organizations remain competitive while adhering to stringent safety regulations.

Looking ahead, the demand for advanced machine guarding solutions will continue to rise as industries evolve. Buyers are encouraged to engage with manufacturers who are committed to continuous improvement and customization of their products. By making informed sourcing decisions today, businesses can not only safeguard their workforce but also pave the way for a more resilient and efficient operational future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to fixed machine guard