Choosing Your Tire Stopper: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for tire stopper

In today’s globalized economy, sourcing high-quality tire stoppers presents a significant challenge for international B2B buyers. Whether you’re managing a logistics hub in Brazil or overseeing parking facilities in Saudi Arabia, the need for reliable and effective tire stoppers—commonly known as wheel stops or parking curb blocks—cannot be overstated. These essential safety devices not only protect vehicles from damage but also enhance the overall functionality of parking areas, making them a critical investment for businesses across various sectors.

This comprehensive guide delves into the multifaceted world of tire stoppers, offering insights into the different types available, their specific applications, and the best practices for supplier vetting. We will also explore cost considerations, helping you to navigate pricing structures and understand what to expect in terms of quality and performance. By providing actionable information tailored to the unique needs of international buyers, this guide empowers you to make informed purchasing decisions that will enhance safety and efficiency in your operations.

As we journey through this guide, you will gain valuable knowledge that will aid in overcoming common sourcing hurdles, ensuring you find the right tire stopper solutions to meet your business needs, whether you are in Africa, South America, the Middle East, or Europe. Prepare to elevate your procurement strategy and secure the best products for your operations.

Understanding tire stopper Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rubber Wheel Stops | Durable, flexible material; often weather-resistant | Parking lots, warehouses, retail spaces | Pros: Cost-effective, easy installation. Cons: May degrade over time in extreme conditions. |

| Concrete Curb Stops | Heavy-duty, long-lasting; can withstand heavy loads | Industrial sites, commercial properties | Pros: Extremely durable, suitable for heavy vehicles. Cons: Higher initial cost, difficult to relocate. |

| Plastic Parking Blocks | Lightweight, often eco-friendly; various colors | Temporary events, residential areas | Pros: Easy to move, affordable. Cons: Less durable than rubber or concrete options. |

| Metal Wheel Stops | Strong, often with high visibility; resistant to damage | Airports, shipping facilities | Pros: Highly durable, can withstand impacts. Cons: Higher cost, potential rusting if not coated. |

| Spike Wheel Stops | Features spikes for enhanced grip; often rubber-based | Outdoor facilities, construction sites | Pros: Prevents vehicle movement, good for security. Cons: Can be harsh on tires, may require more maintenance. |

What Are Rubber Wheel Stops and Their B2B Advantages?

Rubber wheel stops are popular due to their flexibility and durability. Made from weather-resistant materials, these stops are ideal for varied climates, making them suitable for parking lots, warehouses, and retail spaces. B2B buyers appreciate their cost-effectiveness and ease of installation, allowing for quick deployment. However, it’s crucial to consider that they may degrade over time, especially in extreme weather conditions, necessitating potential replacements.

Illustrative image related to tire stopper

How Do Concrete Curb Stops Compare in Durability?

Concrete curb stops are known for their heavy-duty nature, making them a preferred choice for industrial sites and commercial properties. Their ability to withstand significant loads makes them suitable for environments with heavy vehicles. While they offer exceptional durability, the higher initial cost and difficulty in relocation can be drawbacks for businesses looking for flexibility in their parking solutions.

What Are the Benefits of Using Plastic Parking Blocks?

Plastic parking blocks are lightweight and often eco-friendly, appealing to businesses focused on sustainability. Their versatility makes them suitable for temporary events or residential areas. Buyers find them affordable and easy to move, which is an advantage for businesses that require flexible parking solutions. However, they are generally less durable than rubber or concrete options, which may lead to higher long-term costs if replacements are needed frequently.

When to Choose Metal Wheel Stops for Your Business?

Metal wheel stops are designed for high visibility and can resist damage, making them ideal for environments like airports and shipping facilities. Their strength ensures they can withstand impacts, providing a robust solution for busy areas. While their durability is a significant advantage, the higher cost and potential for rusting if not properly coated should be considered by buyers looking for long-term solutions.

Why Consider Spike Wheel Stops for Enhanced Security?

Spike wheel stops are designed for enhanced grip and security, commonly used in outdoor facilities and construction sites. Their rubber-based materials often feature spikes that prevent vehicle movement, making them a secure option. While they provide excellent security, businesses should weigh the potential harshness on tires and the increased maintenance requirements, ensuring they align with their operational needs.

Illustrative image related to tire stopper

Key Industrial Applications of tire stopper

| Industry/Sector | Specific Application of tire stopper | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation | Parking lots for commercial vehicles | Enhances safety and prevents vehicle damage | Durability, size specifications, and compliance with local regulations |

| Logistics & Warehousing | Loading docks and truck parking areas | Optimizes space utilization and improves workflow | Load capacity, visibility (color options), and installation ease |

| Retail | Shopping center parking lots | Increases customer safety and satisfaction | Aesthetic design, weather resistance, and customization options |

| Manufacturing | Factory parking and loading zones | Reduces accidents and enhances operational efficiency | Material strength, anti-slip features, and maintenance requirements |

| Public Infrastructure | Public parking spaces and municipal areas | Supports urban planning and enhances safety | Compliance with safety standards, environmental considerations, and cost-effectiveness |

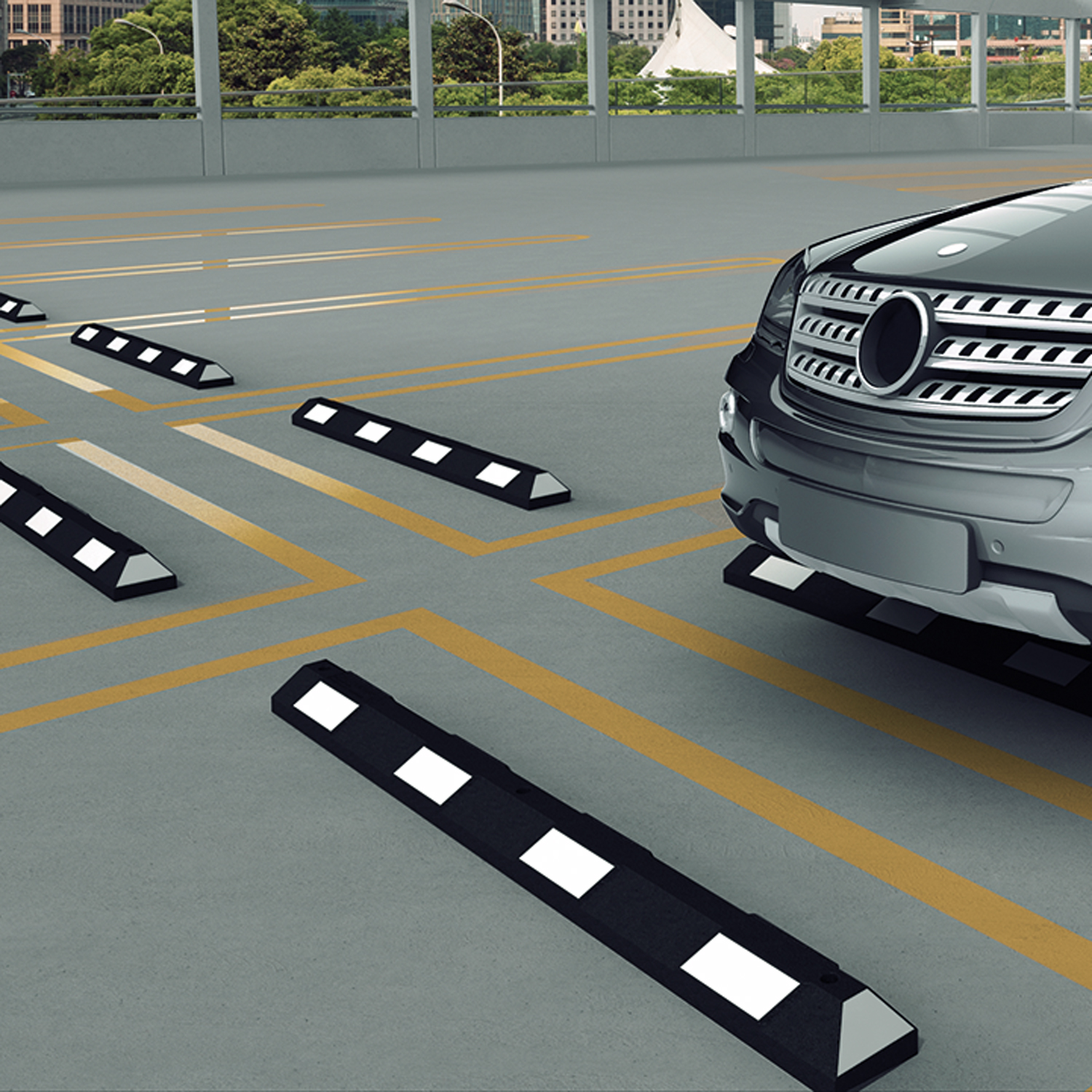

How is a Tire Stopper Used in Transportation Applications?

In the transportation sector, tire stoppers are vital for managing parking lots specifically designed for commercial vehicles. They provide a clear boundary that helps prevent vehicle overrun, thereby reducing the risk of damage to surrounding property and ensuring the safety of pedestrians. Buyers in this sector should focus on durable materials that can withstand heavy loads and extreme weather conditions, especially in regions like Africa and the Middle East where environmental factors can be severe.

What Role Do Tire Stoppers Play in Logistics and Warehousing?

In logistics and warehousing, tire stoppers are strategically placed in loading docks and truck parking areas to optimize space and improve operational flow. By clearly marking parking boundaries, they help minimize the risk of accidents and facilitate efficient loading and unloading processes. When sourcing tire stoppers for these applications, businesses must consider load capacity and visibility features, ensuring that the products are both functional and compliant with safety regulations in their respective countries.

Why are Tire Stoppers Important for Retail Environments?

Retail environments benefit significantly from the use of tire stoppers in shopping center parking lots. They not only enhance safety for customers by preventing vehicle collisions but also improve the overall shopping experience. Retailers should prioritize aesthetic design and weather resistance when sourcing tire stoppers, as these factors contribute to the visual appeal and longevity of the product, particularly in diverse climatic conditions seen in South America and Europe.

How Do Tire Stoppers Enhance Safety in Manufacturing Facilities?

In manufacturing settings, tire stoppers are essential for defining parking zones and loading areas, which helps reduce accidents and streamline operations. Proper placement of these stoppers ensures that vehicles do not encroach on pedestrian walkways, thereby enhancing workplace safety. Buyers in the manufacturing sector should look for tire stoppers with high material strength and anti-slip features to maintain safety standards and reduce maintenance needs.

What Are the Benefits of Tire Stoppers in Public Infrastructure?

Tire stoppers play a crucial role in public infrastructure by supporting urban planning and enhancing the safety of public parking spaces. They help direct traffic flow and ensure that vehicles are parked in designated areas, which is particularly important in densely populated urban areas. Sourcing considerations for public projects should include compliance with local safety standards and environmental factors, ensuring that the tire stoppers contribute positively to community safety and aesthetics.

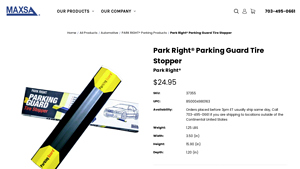

Illustrative image related to tire stopper

3 Common User Pain Points for ‘tire stopper’ & Their Solutions

Scenario 1: Inconsistent Quality Leads to Safety Concerns

The Problem: One of the major challenges B2B buyers face when sourcing tire stoppers is the inconsistency in quality. Poorly manufactured tire stoppers can lead to safety hazards, such as vehicles rolling over them or not providing adequate stopping power. This inconsistency is especially concerning for businesses operating in high-traffic areas or those that have a responsibility to ensure the safety of their employees and customers. In regions like Africa and South America, where regulations may not be as strictly enforced, the temptation to cut costs can lead to the procurement of subpar products, increasing the risk of accidents.

The Solution: To mitigate this issue, buyers should prioritize sourcing tire stoppers from reputable manufacturers with a proven track record of quality. Request detailed specifications, including materials used, weight, and durability tests. Implement a quality assurance process that involves thorough inspections upon delivery. Buyers can also consider establishing long-term relationships with suppliers who demonstrate consistent quality and are willing to provide samples for testing before bulk orders. Additionally, integrating third-party quality certifications can serve as a benchmark for reliability, ensuring that the products not only meet but exceed safety standards.

Scenario 2: Installation Challenges Affect Performance

The Problem: Another common pain point for B2B buyers is the difficulty in the installation of tire stoppers. Many businesses underestimate the importance of proper installation, which can significantly affect the performance of tire stoppers. Improperly installed stoppers can lead to misalignment, reduced effectiveness, and potential damage to vehicles. This problem is exacerbated in regions with diverse terrain, where environmental factors can impact the longevity and functionality of tire stoppers.

The Solution: To address installation challenges, buyers should seek comprehensive installation guides and training from suppliers. This can include on-site installation services or video tutorials that demonstrate the correct procedures. Additionally, investing in high-quality installation accessories, such as lag bolts and mounting spikes, can enhance the stability and effectiveness of the tire stoppers. Buyers should also consider the specific environmental conditions of their location—such as weather and soil type—when choosing the appropriate installation method, ensuring that the tire stoppers remain securely in place even under adverse conditions.

Scenario 3: Budget Constraints Limit Choices

The Problem: Budget constraints are a significant issue for many businesses, particularly in emerging markets where cost management is crucial. Buyers often find themselves torn between the need for high-quality tire stoppers and the pressure to stick to a limited budget. This dilemma can lead to decisions that compromise safety and quality, ultimately resulting in higher costs due to replacements or repairs.

The Solution: To navigate budget constraints effectively, B2B buyers should conduct a comprehensive cost-benefit analysis when selecting tire stoppers. Instead of focusing solely on the initial purchase price, they should evaluate the total cost of ownership, which includes durability, maintenance, and replacement frequency. Exploring bulk purchasing options can also lead to significant savings. Buyers should not hesitate to negotiate terms with suppliers, as many manufacturers are willing to offer discounts for larger orders or long-term contracts. Additionally, considering alternative materials that provide similar durability at a lower cost can be a practical approach. Engaging in conversations with suppliers about innovative solutions tailored to budget constraints can help businesses find a balance between quality and affordability.

Strategic Material Selection Guide for tire stopper

What Materials Are Commonly Used for Tire Stoppers and Their Key Properties?

When selecting materials for tire stoppers, it’s essential to consider their properties, advantages, and limitations to ensure optimal performance in various environments. Here, we analyze four common materials: rubber, concrete, plastic, and metal.

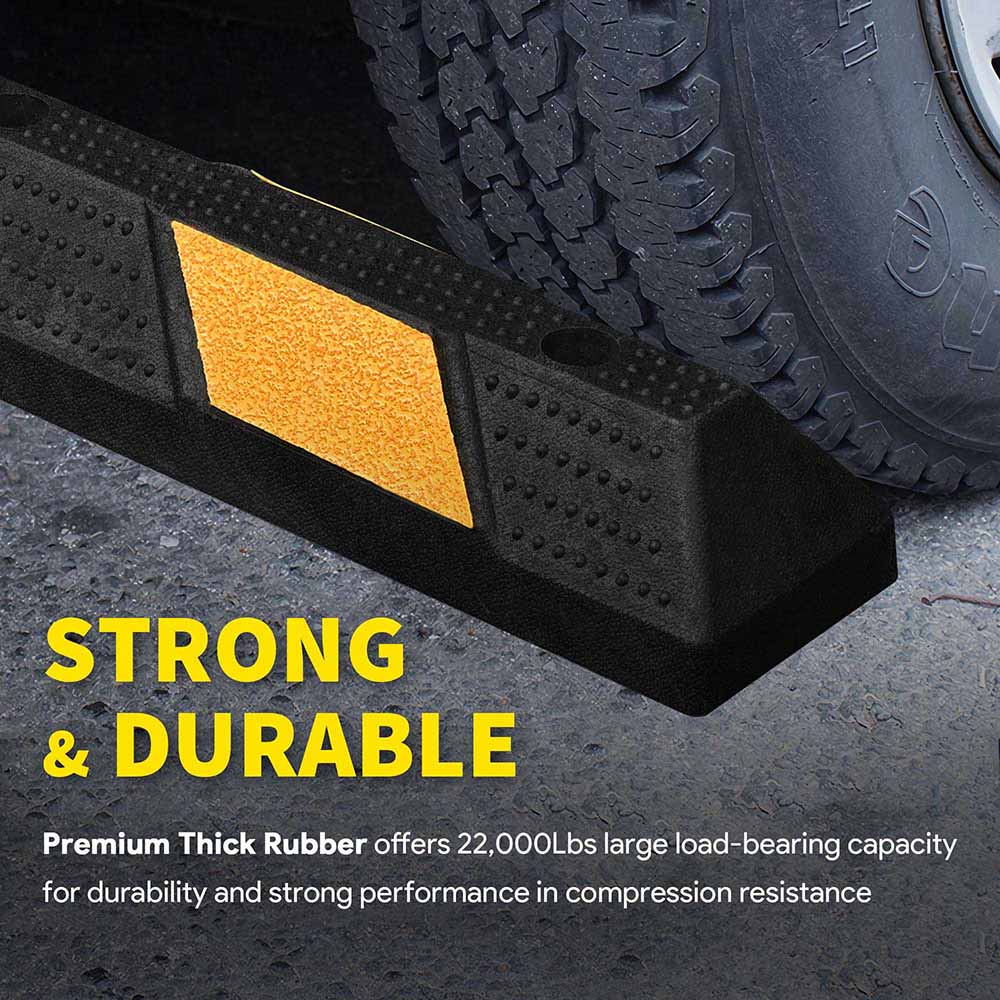

How Does Rubber Perform as a Material for Tire Stoppers?

Rubber is a widely-used material for tire stoppers due to its excellent shock absorption and flexibility. It typically has a high resistance to wear and can withstand a range of temperatures, making it suitable for outdoor applications. Rubber tire stoppers can also be designed with spikes or grooves to enhance grip and prevent slippage.

Pros: Rubber is durable and cost-effective, with a relatively simple manufacturing process. It is lightweight, making it easy to transport and install.

Cons: However, rubber can degrade over time when exposed to UV light and extreme weather conditions, which may limit its lifespan in harsh environments.

Impact on Application: Rubber tire stoppers are compatible with various surfaces, including asphalt and concrete, but may not be ideal for areas with high chemical exposure.

Considerations for International Buyers: Compliance with safety standards, such as ASTM and EN, is crucial. Buyers should also consider local weather conditions when selecting rubber products, especially in regions like Africa and the Middle East where UV exposure is significant.

What Benefits Does Concrete Offer for Tire Stoppers?

Concrete is another popular choice for tire stoppers, known for its robustness and longevity. It can withstand heavy loads and is resistant to various environmental factors, including moisture and temperature fluctuations.

Illustrative image related to tire stopper

Pros: Concrete tire stoppers are highly durable and can last for many years without significant wear. They are also available in various shapes and sizes, allowing for customization.

Cons: The primary drawback is their weight, which makes installation more challenging. Additionally, concrete can crack under extreme pressure or impact.

Impact on Application: Concrete is suitable for high-traffic areas, such as commercial parking lots, where durability is paramount. However, it may not be suitable for temporary installations due to its permanence.

Considerations for International Buyers: Buyers should ensure that the concrete used complies with local building codes and standards, such as DIN or JIS. In regions with seismic activity, like parts of South America, additional reinforcement may be necessary.

How Does Plastic Compare as a Material for Tire Stoppers?

Plastic tire stoppers are gaining popularity due to their lightweight nature and versatility. They are often made from recycled materials, making them an eco-friendly option.

Pros: Plastic is resistant to corrosion and UV damage, ensuring a longer lifespan in various environmental conditions. They are also easy to install and can be produced in vibrant colors for visibility.

Cons: However, plastic tire stoppers may not withstand heavy loads as effectively as rubber or concrete, leading to potential deformation under pressure.

Impact on Application: Plastic is ideal for light-duty applications, such as residential parking areas or temporary installations.

Considerations for International Buyers: Buyers should check for compliance with environmental regulations, especially in Europe, where sustainability is a significant concern. Additionally, they should consider the load ratings specified by manufacturers.

What Role Does Metal Play in Tire Stopper Applications?

Metal tire stoppers, often made from steel or aluminum, provide a robust solution for high-traffic areas. They are known for their strength and durability.

Pros: Metal tire stoppers can withstand extreme conditions and heavy loads, making them suitable for industrial applications. They are also resistant to corrosion when treated properly.

Cons: The primary drawback is their susceptibility to rust if not adequately coated, and they can be more expensive than other materials.

Impact on Application: Metal is best suited for environments where heavy machinery or vehicles are present, such as warehouses or loading docks.

Considerations for International Buyers: Compliance with international standards for load-bearing and safety is crucial. Buyers in humid regions, like parts of South America, should prioritize corrosion-resistant finishes.

Illustrative image related to tire stopper

Summary of Material Selection for Tire Stoppers

| Material | Typical Use Case for Tire Stopper | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Residential and light commercial parking | Excellent shock absorption | Degrades under UV exposure | Low |

| Concrete | High-traffic commercial areas | Highly durable | Heavy and difficult to install | Medium |

| Plastic | Temporary and light-duty applications | Lightweight and eco-friendly | May deform under heavy loads | Low |

| Metal | Industrial applications | Extremely strong and durable | Susceptible to rust without treatment | High |

This guide provides a comprehensive overview of material options for tire stoppers, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for tire stopper

What Are the Main Stages in the Manufacturing Process of Tire Stoppers?

The manufacturing of tire stoppers, also known as parking curb blocks or wheel stops, involves several critical stages that ensure the final product meets safety and quality standards. Understanding these processes is essential for B2B buyers aiming to source high-quality products.

Material Preparation: What Materials Are Used in Tire Stopper Production?

The first step in manufacturing tire stoppers is material preparation. Common materials include recycled rubber, concrete, and plastic. Each material offers unique benefits: rubber is durable and flexible, concrete provides stability and weight, while plastic is lightweight and resistant to weathering. Suppliers often source materials from certified vendors to ensure compliance with international standards.

Illustrative image related to tire stopper

In this phase, raw materials are inspected for quality, and any necessary treatments are applied. For instance, rubber may undergo a vulcanization process to enhance its durability and elasticity. Buyers should inquire about the source and quality of materials used, as this directly impacts the longevity and performance of the tire stoppers.

How Are Tire Stoppers Formed?

The next stage is forming, where raw materials are shaped into the desired tire stopper profile. This process varies depending on the material used:

- Rubber: In rubber production, materials are mixed and poured into molds. The curing process then solidifies the shape and ensures the product can withstand vehicle weight and environmental conditions.

- Concrete: Concrete is mixed, poured into forms, and allowed to set. Reinforcement bars may be added for additional strength. This method is particularly common for larger or heavy-duty tire stoppers.

- Plastic: For plastic stoppers, the material is often heated and injected into molds. This method allows for complex shapes and consistent quality.

Each forming technique requires precision to ensure uniformity and structural integrity. Buyers should seek suppliers who utilize advanced machinery and experienced personnel to maintain high production standards.

What Does the Assembly Process Involve?

For tire stoppers that require additional features, such as reflective strips or anchoring systems, the assembly process is crucial. This stage may involve:

Illustrative image related to tire stopper

- Attaching reflective tape or paint for visibility.

- Installing mounting hardware, such as spikes or bolts, to secure the stoppers in place.

- Conducting final inspections to ensure all components meet specifications.

Assembly operations should be performed in a clean environment to prevent contamination. Buyers should verify that suppliers have quality controls in place during this stage to ensure that all components function effectively together.

What Are the Finishing Touches in Tire Stopper Manufacturing?

The finishing stage includes surface treatments and quality checks. This can involve:

- Applying paint or coatings to enhance visibility and protect against UV damage.

- Conducting surface smoothing to eliminate imperfections.

- Performing final inspections to assess aesthetic and functional qualities.

Finishing processes are essential for ensuring that the tire stoppers not only perform well but also look appealing. B2B buyers should ask about the finishing techniques used, as these can significantly influence the product’s durability and visual appeal.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance is a vital aspect of tire stopper manufacturing, particularly for international buyers. Understanding relevant standards and quality checkpoints can help businesses make informed purchasing decisions.

What International Standards Are Relevant for Tire Stoppers?

Several international standards govern the quality of tire stoppers. Key standards include:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring that manufacturers consistently produce quality products.

- CE Marking: For products sold in the European Union, CE marking indicates compliance with safety and health standards.

- API Standards: Relevant for companies that use tire stoppers in industrial settings, API standards provide guidelines for performance and safety.

B2B buyers should confirm that their suppliers comply with these standards, as this reflects their commitment to quality and safety.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is implemented at various stages of the manufacturing process. Key checkpoints include:

Illustrative image related to tire stopper

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during production help identify defects early in the process.

- Final Quality Control (FQC): The completed products undergo thorough inspections to ensure they meet all specifications before shipping.

These QC checkpoints are critical for maintaining high standards throughout the manufacturing process. Buyers should inquire about the specific QC measures employed by their suppliers.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to quality standards, B2B buyers should implement several verification strategies:

What Types of Audits and Inspections Are Recommended?

- Supplier Audits: Conducting regular audits of suppliers can help assess their manufacturing processes and quality management systems.

- Third-Party Inspections: Engaging independent inspection agencies to evaluate products before shipment can provide an additional layer of assurance.

- Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes and any issues encountered.

These measures are particularly important for buyers in regions such as Africa, South America, the Middle East, and Europe, where quality assurance practices may vary significantly.

What Nuances Should International Buyers Consider?

International buyers should be aware of potential nuances in quality assurance practices. For example, differences in regulatory requirements between regions can impact the certification and testing of tire stoppers. Additionally, language barriers may pose challenges in understanding quality documentation.

To navigate these complexities, buyers should establish clear communication with suppliers and consider engaging local representatives who understand regional standards and practices.

Conclusion

Understanding the manufacturing processes and quality assurance practices for tire stoppers is essential for B2B buyers seeking reliable products. By focusing on material preparation, forming, assembly, and finishing stages, alongside robust quality control measures, businesses can ensure they are sourcing high-quality tire stoppers that meet international standards. Engaging in thorough verification and audit processes will further enhance confidence in supplier capabilities, ultimately leading to safer and more efficient parking solutions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tire stopper’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure tire stoppers, essential for enhancing parking safety and efficiency. With a global market encompassing regions such as Africa, South America, the Middle East, and Europe, it’s vital to navigate the sourcing process effectively. This checklist will help you identify the right suppliers, assess product quality, and ensure compliance with local standards.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clarify the technical requirements for the tire stoppers you need. Consider factors such as size, material, and weight capacity. This step is crucial because precise specifications ensure that the products meet your operational needs and safety standards.

- Material Choices: Look for durable materials like rubber or plastic that can withstand environmental conditions.

- Dimensions: Ensure the size fits the parking layout and vehicle types you accommodate.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers. This involves looking at their experience, reputation, and product range. Understanding your options helps mitigate risks associated with poor-quality products.

- Industry Experience: Prioritize suppliers with a proven track record in manufacturing tire stoppers.

- Customer Reviews: Check online reviews and testimonials to gauge customer satisfaction.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications and comply with international safety standards. Certifications can indicate quality assurance and adherence to safety regulations, which is vital for minimizing liability.

- ISO Certifications: Look for ISO 9001 for quality management systems.

- Local Compliance: Ensure they meet any specific regional regulations, especially if you are importing.

Step 4: Request Product Samples

Always request samples before placing a bulk order. Testing samples allows you to assess the quality, durability, and functionality of the tire stoppers. It is an essential step to confirm that the products meet your expectations.

- Testing Procedures: Evaluate the samples under real-world conditions to ensure they perform as required.

- Fit and Finish: Inspect for any defects or inconsistencies in the product design.

Step 5: Discuss Terms and Conditions

Engage in discussions about pricing, payment terms, and delivery schedules. Clear communication on these aspects can prevent misunderstandings and ensure smoother transactions.

- Bulk Discounts: Inquire about pricing structures for larger orders.

- Lead Times: Confirm delivery timelines to align with your project schedules.

Step 6: Assess After-Sales Support

Inquire about the after-sales services offered by the supplier. Reliable after-sales support can be crucial for maintenance and troubleshooting, ensuring your operations remain uninterrupted.

- Warranty Terms: Understand the warranty period and conditions for product replacement or repair.

- Customer Support: Evaluate the availability of support channels for quick resolution of any issues.

Step 7: Finalize Your Purchase Agreement

Once you are satisfied with the supplier and product, finalize the purchase agreement. Ensure all terms discussed are documented to protect both parties and facilitate a smooth transaction.

- Contract Clauses: Include clauses on delivery, payment, and liability to safeguard your interests.

- Review Process: Have legal counsel review the contract to ensure compliance with local laws.

By following this checklist, you can navigate the procurement process for tire stoppers efficiently, ensuring that you select the best products from reputable suppliers while minimizing risks.

Comprehensive Cost and Pricing Analysis for tire stopper Sourcing

What Are the Key Cost Components in Sourcing Tire Stoppers?

When sourcing tire stoppers, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components typically include:

-

Materials: The choice of materials significantly impacts pricing. Common materials include rubber, plastic, and concrete, each with varying costs. Rubber, for instance, tends to be more expensive but offers better durability and performance, making it a preferred option for many commercial applications.

-

Labor: Labor costs can vary based on the region and the complexity of manufacturing processes. In regions with higher labor costs, such as parts of Europe, the overall price may be elevated. Conversely, sourcing from areas with lower labor costs could yield more competitive pricing.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can help minimize overhead costs, which can be a significant part of the overall pricing structure.

-

Tooling: For customized or specialized tire stoppers, tooling costs can be substantial. This includes molds and dies necessary for production. Buyers should consider these costs when requesting unique designs or specifications.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and safety, which can add to the overall cost. Buyers should inquire about the QC measures suppliers have in place to ensure product quality.

-

Logistics: Shipping and handling costs can greatly influence the final price. Factors such as distance, shipping methods, and freight costs should be factored into the sourcing strategy.

-

Margin: Supplier profit margins can vary widely based on market conditions, competition, and the supplier’s business model. Understanding typical margins in the industry can help buyers assess the fairness of the pricing.

How Do Price Influencers Affect Tire Stopper Costs?

Several factors can influence the pricing of tire stoppers:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Suppliers often provide discounts for bulk orders, making it advantageous for buyers who can commit to larger quantities.

-

Specifications/Customization: Customized products typically come at a premium. Buyers should weigh the benefits of customization against cost implications to ensure they meet their needs without overspending.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO or safety standards) can increase costs but may offer greater long-term value through enhanced durability and safety.

-

Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established suppliers may charge more due to their track record and customer service, while newer suppliers might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for international buyers, as they dictate the responsibilities of buyers and sellers in shipping. The choice of terms can influence overall costs, including insurance and transportation fees.

What Are the Best Practices for Negotiating Tire Stopper Prices?

When negotiating prices for tire stoppers, consider the following strategies:

-

Research and Benchmarking: Understanding market prices and competitor offerings allows for more effective negotiations. Buyers should gather data on standard costs to leverage during discussions.

-

Focus on Total Cost of Ownership (TCO): Evaluate the total cost, including maintenance, durability, and potential replacements. A higher initial price for a more durable product may result in lower long-term costs.

-

Request Multiple Quotes: Obtaining quotes from various suppliers can provide a clearer picture of the market and help identify the best deal.

-

Build Relationships: Developing strong relationships with suppliers can lead to better pricing and terms over time. Consider long-term partnerships that may yield loyalty discounts or favorable terms.

-

Be Aware of Pricing Nuances: International buyers should consider currency fluctuations, import duties, and taxes, which can significantly affect the final cost.

Conclusion

Sourcing tire stoppers involves a comprehensive understanding of cost components, pricing influences, and effective negotiation tactics. By considering these elements, international B2B buyers can make strategic sourcing decisions that align with their operational needs and budget constraints. Always remember to request indicative pricing and verify details with suppliers to ensure transparency and accuracy in your procurement process.

Alternatives Analysis: Comparing tire stopper With Other Solutions

Understanding Alternatives to Tire Stoppers in Vehicle Management

In the realm of vehicle management, tire stoppers serve a vital purpose in ensuring safe and efficient parking. However, buyers may also consider alternative solutions that can achieve similar objectives. Understanding these alternatives allows businesses to make informed decisions based on performance, cost, and specific application needs.

| Comparison Aspect | Tire Stopper | Concrete Wheel Stops | Parking Sensors |

|---|---|---|---|

| Performance | Highly effective at preventing vehicle movement and damage | Durable and stable, ideal for heavy-duty use | Provides real-time feedback and alerts for parking guidance |

| Cost | Generally low-cost, approx. $25-$50 per unit | Moderate to high, approx. $100-$300 per unit | Higher initial investment, typically $200-$500 per unit |

| Ease of Implementation | Easy to install with minimal tools required | Requires more labor for installation, often needing concrete setting | Installation complexity varies; may require professional setup |

| Maintenance | Low maintenance, occasional cleaning needed | Low maintenance but may require checks for stability | Requires regular calibration and potential software updates |

| Best Use Case | Ideal for standard parking lots and residential areas | Best for commercial parking lots with heavy vehicles | Suitable for high-traffic areas needing precise parking management |

What Are the Pros and Cons of Concrete Wheel Stops as an Alternative?

Concrete wheel stops are a robust alternative to tire stoppers. Made from durable concrete, they offer excellent stability and can withstand the weight of heavy vehicles, making them ideal for commercial applications. One of the primary advantages of concrete wheel stops is their longevity; they are less likely to suffer from wear and tear compared to rubber options. However, their installation can be more labor-intensive and costly, requiring concrete work that might not be feasible for all businesses. Additionally, they may not be as visible as rubber alternatives, potentially leading to safety concerns if not properly marked.

How Do Parking Sensors Compare to Tire Stoppers?

Parking sensors represent a modern technological solution for managing vehicle parking. They provide real-time feedback, allowing drivers to park more efficiently and safely. The primary advantage of parking sensors is their ability to guide drivers with visual or auditory signals, reducing the likelihood of collisions or parking errors. However, the initial investment can be significantly higher, and ongoing maintenance is necessary to ensure the system remains operational. Furthermore, parking sensors may require professional installation, adding to the complexity and costs involved.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right vehicle management solution requires careful consideration of specific business needs, budget constraints, and the environment in which the solution will be implemented. Tire stoppers are an excellent choice for cost-effective and easy-to-install options, especially in residential or low-traffic areas. Conversely, businesses that manage heavy vehicles or require enhanced visibility may benefit from concrete wheel stops. For those seeking advanced technology, parking sensors offer an innovative approach to parking management but come with higher costs and installation complexities. By evaluating these alternatives against their operational requirements, B2B buyers can make informed decisions that enhance safety and efficiency in their vehicle management practices.

Essential Technical Properties and Trade Terminology for tire stopper

What Are the Key Technical Properties of Tire Stoppers?

When considering tire stoppers, understanding their technical properties is crucial for ensuring safety, durability, and compliance with regulations. Here are some essential specifications to consider:

Illustrative image related to tire stopper

-

Material Grade

– Tire stoppers are commonly made from rubber, plastic, or concrete. The material grade determines their resistance to wear, weather conditions, and chemical exposure. For instance, high-grade rubber provides better durability and flexibility, making it suitable for outdoor use in various climates. Selecting the right material ensures longevity and reduces replacement costs. -

Dimensions and Weight Tolerance

– The size and weight of a tire stopper affect its stability and effectiveness in preventing vehicle movement. Standard dimensions often range from 3 to 6 feet in length, with weights varying according to material. Understanding weight tolerance helps in selecting the right stopper for different vehicle types and parking applications, ensuring they withstand vehicular pressure without displacement. -

Load-Bearing Capacity

– This specification indicates the maximum weight a tire stopper can support. It is critical for businesses with heavy vehicles or frequent traffic, such as logistics companies or construction sites. A higher load-bearing capacity reduces the risk of damage and enhances safety, preventing accidents caused by stopper failure. -

Installation Features

– Tire stoppers may come with additional installation features such as mounting spikes or bolts. These components enhance stability by securing the stoppers to the ground, which is vital in high-traffic areas. Understanding installation options allows buyers to choose products that meet their specific site requirements, facilitating easier setup and maintenance. -

Color and Visibility

– The color of tire stoppers, often featuring bright hues and reflective stripes, plays a crucial role in visibility, especially at night or in low-light conditions. Enhanced visibility helps reduce accidents by alerting drivers to parking boundaries. For businesses, selecting brightly colored stoppers can improve overall safety in parking facilities.

What Are Common Trade Terms Related to Tire Stoppers?

Familiarity with industry jargon can aid B2B buyers in making informed decisions. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of tire stoppers, buyers might seek OEM products for guaranteed compatibility and quality assurance. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for businesses to manage inventory efficiently and avoid overstocking. Knowing the MOQ helps in budgeting and planning purchases. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and terms for a specific product. For tire stoppers, issuing an RFQ allows buyers to compare prices and features from different suppliers, facilitating better purchasing decisions. -

Incoterms (International Commercial Terms)

– These are standardized terms used in international trade to define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms helps businesses understand shipping costs, risks, and logistics, ensuring smooth transactions. -

Lead Time

– This term refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for project planning, especially in construction or logistics, where timely delivery of tire stoppers can impact operations. -

Bulk Pricing

– This refers to the reduced price per unit when purchasing large quantities of a product. For businesses needing multiple tire stoppers, understanding bulk pricing can lead to significant cost savings, making it a critical consideration for budget-conscious buyers.

By grasping these technical properties and trade terms, international B2B buyers can enhance their purchasing strategies for tire stoppers, ensuring that their choices align with safety, functionality, and budgetary constraints.

Navigating Market Dynamics and Sourcing Trends in the tire stopper Sector

What Are the Current Market Dynamics and Key Trends in the Tire Stopper Sector?

The tire stopper market is experiencing significant growth, driven by an increase in urbanization and the expansion of commercial spaces. In regions like Africa, South America, the Middle East, and Europe, rapid infrastructural development is creating a heightened demand for effective parking solutions. Businesses are increasingly prioritizing safety and operational efficiency, leading to a surge in the adoption of high-quality tire stoppers. As international B2B buyers, understanding these dynamics is crucial for making informed procurement decisions.

Emerging technologies are reshaping the sourcing landscape. Smart parking solutions, which integrate tire stoppers with sensors and IoT capabilities, are gaining traction. These innovations not only enhance safety but also streamline parking management, appealing to businesses looking to optimize their operations. Additionally, the rise of e-commerce has made it easier for buyers to access a diverse range of tire stopper products globally, allowing for better price comparison and quality assessment.

Another noteworthy trend is the shift towards bulk purchasing and long-term partnerships with suppliers. Companies are looking to secure better pricing and reliability by committing to larger orders, thereby mitigating supply chain disruptions. This trend is particularly pronounced in emerging markets, where businesses are keen to establish stable supply lines to support their growth.

How Important Is Sustainability and Ethical Sourcing in the Tire Stopper Market?

Sustainability is becoming a key factor in the procurement process for tire stoppers. As environmental concerns grow, businesses are increasingly seeking products that minimize ecological impact. This includes sourcing tire stoppers made from recycled or eco-friendly materials, which not only reduces waste but also appeals to environmentally conscious consumers. B2B buyers are advised to prioritize suppliers who demonstrate a commitment to sustainable practices.

Ethical sourcing is equally important, particularly in regions where labor standards may vary. Buyers should conduct due diligence to ensure that their suppliers adhere to fair labor practices and maintain transparent supply chains. Certifications such as ISO 14001 (Environmental Management) or the Global Recycled Standard (GRS) can serve as indicators of a supplier’s commitment to sustainability and ethical sourcing.

Incorporating sustainability into procurement strategies not only helps in meeting regulatory requirements but can also enhance a company’s brand reputation. Consumers and clients are increasingly favoring businesses that prioritize environmental responsibility, making it a critical consideration for B2B buyers.

How Has the Tire Stopper Sector Evolved Over Time?

The tire stopper sector has evolved significantly from simple concrete blocks to innovative, multifunctional products. Initially designed solely for vehicle restraint, modern tire stoppers now incorporate features such as reflective strips for enhanced visibility and materials that withstand extreme weather conditions. The introduction of rubber and recycled plastic options has also transformed the market, providing more durable and eco-friendly alternatives.

Historically, tire stoppers were predominantly used in commercial settings; however, their application has expanded to residential areas, public parks, and even event venues. This evolution reflects broader trends in urban planning and vehicle management, where the emphasis is on safety, efficiency, and sustainability. Understanding this historical context can provide B2B buyers with insights into product development and consumer preferences, ultimately guiding more informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of tire stopper

-

How do I ensure the tire stopper meets safety regulations in my country?

To ensure compliance with safety regulations, first research the specific guidelines and standards applicable in your country or region. Many countries have established regulations for parking equipment, including tire stoppers. Work with suppliers who can provide documentation that demonstrates their products meet these standards. Additionally, consider seeking certifications from recognized bodies that validate the quality and safety of the tire stoppers. -

What is the best material for tire stoppers in outdoor applications?

For outdoor applications, rubber is often the best material for tire stoppers due to its durability and resistance to weather elements. Rubber tire stoppers can withstand UV rays, rain, and temperature variations, making them ideal for long-term use in parking lots and other outdoor areas. Some manufacturers also offer recycled rubber options, which are environmentally friendly and cost-effective. -

How do I determine the right size tire stopper for my needs?

The appropriate size of a tire stopper depends on the type of vehicle and the parking layout. Standard lengths are typically between 3 to 6 feet, but it’s essential to consider the dimensions of the vehicles that will use the parking space. Additionally, assess the intended use, such as whether it’s for standard cars, larger vehicles, or specific applications like RV parking. Consulting with suppliers for guidance based on your specific requirements can also be beneficial. -

What are common customization options for tire stoppers?

Many manufacturers offer customization options for tire stoppers, including size, color, and branding. Custom colors can enhance visibility, while branding options allow companies to display their logo. Some suppliers may also provide features like embedded reflectors for increased nighttime visibility or added spikes for enhanced stability. Be sure to communicate your specific needs with potential suppliers during the sourcing process. -

What is the typical minimum order quantity (MOQ) for tire stoppers?

The minimum order quantity for tire stoppers can vary significantly between suppliers. Generally, MOQs range from 1 to several dozen units, depending on the manufacturer and the specific product. For bulk purchases, suppliers often offer more favorable pricing. It’s advisable to inquire directly with potential suppliers about their MOQ policies to find a solution that fits your project requirements. -

What payment terms should I expect when sourcing tire stoppers internationally?

Payment terms for international orders can vary widely based on supplier policies and the buyer’s location. Common terms include upfront payment, a deposit with the balance due upon shipment, or net payment terms (e.g., net 30 or net 60 days). Always discuss and negotiate payment terms before finalizing the order to ensure clarity and avoid potential disputes. -

How do I vet suppliers for tire stoppers effectively?

To vet suppliers, start by researching their reputation in the industry. Look for reviews, testimonials, and case studies from previous clients. Request samples of their products to assess quality firsthand. Additionally, verify their certifications and compliance with international standards. Establishing clear communication and discussing your specific needs can also help gauge their responsiveness and reliability. -

What logistics considerations should I keep in mind when importing tire stoppers?

When importing tire stoppers, consider shipping methods, lead times, and customs regulations. Evaluate whether air freight or sea freight is more cost-effective based on your timeline. Be aware of any import duties, taxes, or tariffs that may apply in your country. Collaborating with a logistics provider experienced in handling international shipments can streamline the process and ensure compliance with all necessary regulations.

Top 3 Tire Stopper Manufacturers & Suppliers List

1. InPro Corp – Tire Stop

Domain: inprocorp.com

Registered: 1996 (29 years)

Introduction: Product: Tire Stop

Application: Exterior

Cover Type: Roof/Deck

Mounting Position: Surface Mount

Floor Thickness: 0″ [0mm] (No finish, e.g., concrete deck)

Available Lengths: T1800: 6′ (1.8M) and T500: 22″ (.5m)

Material: Made of environmentally responsible shredded tires, diverting 1 (TRSTP 500) to 3.4 (TRSTP 1800) tires from the landfill with every piece ordered.

Features:

– Highly resilient mat…

2. Traffic Sign Store – Parking Lot Tire Stop

Domain: trafficsignstore.com

Registered: 2002 (23 years)

Introduction: {‘product_name’: ‘Parking Lot Tire Stop’, ‘product_code’: ‘WST-1-Tirestop’, ‘price’: ‘$72.50’, ‘shipping_weight’: ‘45.00 pounds’, ‘dimensions’: ’72 inches long, 6 inches wide, 4.25 inches tall’, ‘color_options’: [‘Yellow’, ‘White’, ‘Blue’, ‘Green’, ‘Red’], ‘material’: ’40-pound Black Rubber’, ‘shipping_info’: ‘Free Shipping on sign orders of $200 or more (applies only to sign sizes less than 30×30…

3. Maxsain Innovations – Park Right Parking Guard Tire Stopper

Domain: maxsainnovations.com

Registered: 2003 (22 years)

Introduction: {“product_name”: “Park Right Parking Guard Tire Stopper”, “MSRP”: “$24.95”, “SKU”: “37355”, “UPC”: “850004980163”, “weight”: “1.25 LBS”, “dimensions”: {“width”: “3.50 in”, “height”: “15.90 in”, “depth”: “1.20 in”}, “features”: [“Helps park in the same spot every time”, “3M adhesive for secure mounting”, “Reflective tape for high visibility”, “Raised bump for adherence to garage floor”, “Fluorescen…

Strategic Sourcing Conclusion and Outlook for tire stopper

In the realm of strategic sourcing for tire stoppers, understanding the nuances of quality, pricing, and supply chain dynamics is essential for international B2B buyers. Sourcing high-quality tire stoppers not only enhances safety and efficiency in parking environments but also contributes to overall operational effectiveness. By prioritizing reliable suppliers and understanding market trends, businesses can secure products that meet their specific needs while optimizing their procurement processes.

As you navigate the diverse markets in Africa, South America, the Middle East, and Europe, consider the varying demands and standards that influence purchasing decisions. Building strong relationships with manufacturers and distributors in these regions can lead to favorable terms and reliable supply chains.

Looking ahead, the demand for innovative and durable tire stoppers is expected to grow, driven by urbanization and increased vehicle usage. This presents a significant opportunity for B2B buyers to invest in high-quality products that ensure safety and compliance with local regulations. Engage with suppliers who understand your market needs and are prepared to offer tailored solutions. Take the next step in elevating your procurement strategy by exploring partnerships that align with your business goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.