The Definitive Guide to Class 200 Pvc: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for class 200 pvc

Navigating the complexities of sourcing Class 200 PVC can be a daunting task for international B2B buyers, particularly when considering the diverse applications and specifications required across various industries. This guide aims to demystify the global market for Class 200 PVC, providing actionable insights into its types, applications, and the essential factors to consider when vetting suppliers. Buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—will find valuable information tailored to their unique procurement challenges.

Understanding the nuances of Class 200 PVC is critical for ensuring that the right products are sourced for projects requiring high-pressure applications, such as irrigation systems, plumbing, and industrial uses. This guide will explore the different grades of PVC, compare them with other pipe ratings, and highlight best practices for selecting suppliers who meet international quality standards. Additionally, we will discuss cost considerations, logistics, and the importance of establishing long-term supplier relationships to optimize your procurement strategy.

By equipping B2B buyers with comprehensive knowledge and actionable strategies, this guide empowers informed purchasing decisions that can enhance operational efficiency and project outcomes. With the right insights, navigating the global market for Class 200 PVC becomes not just manageable, but a strategic advantage in a competitive landscape.

Understanding class 200 pvc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Class 200 PVC Pipe | Maximum pressure rating of 200 psi | Irrigation, water distribution | Pros: High pressure capacity; versatile. Cons: Heavier than lower classes. |

| Class 200 PVC Fittings | Specialized fittings designed for Class 200 pipes | Plumbing, industrial applications | Pros: Seamless integration; durable. Cons: Higher cost compared to standard fittings. |

| Class 200 PVC Sheet | Rigid, flat sheets made from Class 200 PVC | Fabrication, signage, construction | Pros: Versatile applications; easy to fabricate. Cons: Limited to flat surfaces. |

| Class 200 PVC Ducts | Designed for air and gas applications | HVAC systems, exhaust systems | Pros: Lightweight; corrosion-resistant. Cons: Not suitable for high-temperature applications. |

| Class 200 PVC Couplings | Connectors that join two pipes securely | Water management, irrigation | Pros: Reliable connections; easy to install. Cons: May require additional fittings for complex systems. |

What are the Key Characteristics of Class 200 PVC Pipe?

Class 200 PVC pipe is primarily recognized for its maximum pressure rating of 200 psi, making it suitable for various applications, particularly in irrigation and water distribution systems. Its robust structure allows it to withstand significant stress, which is crucial for projects requiring reliable performance under pressure. When considering purchasing Class 200 PVC pipe, buyers should evaluate the specific pressure requirements of their applications to ensure compatibility.

How Do Class 200 PVC Fittings Enhance System Integrity?

Class 200 PVC fittings are designed specifically for use with Class 200 pipes, ensuring a secure and leak-proof connection. These fittings come in various shapes and sizes, allowing for versatile configurations in plumbing and industrial applications. Buyers should consider the compatibility of fittings with their existing systems, as well as the potential for higher costs compared to standard fittings, which may affect budget considerations.

In What Scenarios is Class 200 PVC Sheet Most Suitable?

Class 200 PVC sheets are rigid, flat materials ideal for fabrication, signage, and construction applications. Their versatility allows them to be easily cut and shaped, making them suitable for custom projects. Businesses should assess their specific fabrication needs and consider the limitations of using flat sheets, as they may not be suitable for three-dimensional applications.

What are the Advantages of Using Class 200 PVC Ducts in HVAC Systems?

Class 200 PVC ducts are lightweight and corrosion-resistant, making them an excellent choice for HVAC systems and exhaust applications. Their design allows for efficient airflow while maintaining structural integrity. When selecting ducts, buyers should consider the temperature limitations, as Class 200 PVC is not suitable for high-temperature environments, which could affect performance and longevity.

How Do Class 200 PVC Couplings Simplify Installation?

Class 200 PVC couplings are essential for joining two pipes securely, facilitating smooth water management and irrigation systems. Their ease of installation reduces labor costs and time, making them a preferred choice for contractors. However, buyers should be aware that complex systems may require additional fittings, potentially increasing the overall project cost.

Key Industrial Applications of class 200 pvc

| Industry/Sector | Specific Application of class 200 pvc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Irrigation systems for crop production | High pressure rating allows for efficient water distribution, reducing waste. | Ensure compatibility with local water regulations and pressure requirements. |

| Water Treatment | Non-potable water systems | Durable and corrosion-resistant, minimizing maintenance costs. | Verify chemical compatibility for specific treatment processes. |

| Construction | Plumbing and drainage systems | Lightweight, easy to install, and cost-effective compared to metal alternatives. | Assess local building codes and standards for PVC usage. |

| Mining | Slurry transport pipes | Robust design to handle abrasive materials, reducing downtime and maintenance. | Consider sourcing from suppliers with experience in mining applications. |

| HVAC | Ventilation and exhaust systems | Excellent resistance to temperature fluctuations and chemicals, ensuring longevity. | Look for suppliers offering custom lengths and fittings for specific configurations. |

How is Class 200 PVC Utilized in Agriculture for Irrigation Systems?

In agriculture, class 200 PVC is widely used for irrigation systems due to its high pressure rating of 200 psi, which allows for efficient water distribution across large fields. This capability ensures that crops receive adequate moisture, enhancing yield while minimizing water waste. Buyers from regions like Africa and South America should consider local water regulations and pressure requirements when sourcing, as these factors can significantly influence system design and implementation.

What Role Does Class 200 PVC Play in Water Treatment Applications?

Class 200 PVC is an ideal choice for non-potable water systems in water treatment facilities. Its durability and resistance to corrosion make it a cost-effective solution that reduces maintenance expenses over time. For international buyers, particularly in the Middle East, it’s crucial to verify the chemical compatibility of the PVC with specific treatment processes to ensure long-term performance and compliance with local environmental regulations.

How is Class 200 PVC Beneficial for Construction Plumbing?

In the construction industry, class 200 PVC is often utilized in plumbing and drainage systems. Its lightweight nature makes installation faster and less labor-intensive compared to traditional metal pipes, resulting in lower overall project costs. Buyers in Europe, especially in countries like Germany, should assess local building codes and standards to ensure compliance when incorporating class 200 PVC into their projects.

In What Ways is Class 200 PVC Used in Mining Operations?

Mining operations benefit from class 200 PVC pipes, particularly in transporting slurries, which consist of water mixed with minerals. The robust design of class 200 PVC allows it to withstand the abrasive nature of these materials, thereby reducing downtime and maintenance needs. Companies sourcing PVC for mining should prioritize suppliers with experience in this sector to ensure reliability and performance under challenging conditions.

Why is Class 200 PVC Preferred in HVAC Systems?

In HVAC applications, class 200 PVC is used for ventilation and exhaust systems due to its excellent resistance to temperature fluctuations and various chemicals. This property enhances the longevity of the systems, reducing the need for frequent replacements. Businesses looking to source class 200 PVC for HVAC should seek suppliers that offer custom lengths and fittings to meet specific configuration needs, ensuring optimal system performance.

3 Common User Pain Points for ‘class 200 pvc’ & Their Solutions

Scenario 1: Navigating Pressure Ratings for Optimal Application

The Problem: B2B buyers often struggle with understanding the pressure ratings associated with Class 200 PVC. This confusion can lead to selecting the wrong pipe for a specific application, risking failure in crucial water supply systems. For instance, a contractor might choose Class 200 for a project requiring a sustained pressure of 220 psi, not realizing that this could lead to catastrophic failure if the pipe cannot handle the pressure for extended periods.

The Solution: To mitigate this issue, it’s essential to have a clear understanding of the pressure requirements of your application. Begin by conducting a thorough assessment of the system’s needs, including peak and sustained pressure levels. When sourcing Class 200 PVC, ensure that the specifications align with these requirements. Use reliable suppliers who provide detailed pressure ratings and performance data. Additionally, implement a factor of safety in your calculations; for instance, if your application requires 180 psi, opting for Class 200 PVC is a prudent choice, as it is rated for 200 psi and can handle unexpected surges. Always consult pressure rating charts and, if possible, work with an engineer to verify your selections.

Scenario 2: Ensuring Compatibility with Existing Infrastructure

The Problem: Compatibility issues often arise when integrating Class 200 PVC into existing systems. Buyers may face challenges when the dimensions or fittings of Class 200 do not align with pre-installed piping or fixtures. For instance, a buyer may purchase Class 200 PVC with the expectation that it will easily connect to older piping systems, only to find that the fittings are incompatible, leading to delays and increased costs.

The Solution: To address compatibility issues, it is crucial to perform a comprehensive compatibility assessment before making purchases. Measure the outside diameters and wall thicknesses of existing piping systems to ensure that the Class 200 PVC fits without the need for extensive modifications. When sourcing, look for suppliers who offer a wide range of fittings and connectors specifically designed for Class 200 PVC. It may also be beneficial to use adapters or transition fittings that can accommodate different pipe standards. Maintaining open communication with suppliers about your existing infrastructure will enable them to recommend the most suitable products, thereby streamlining the installation process and reducing potential setbacks.

Scenario 3: Dealing with Supply Chain Disruptions

The Problem: Supply chain disruptions can significantly impact the availability of Class 200 PVC, especially for international buyers in regions like Africa or South America. This can lead to project delays, cost overruns, and the inability to meet contractual obligations. For example, a construction company may order a large quantity of Class 200 PVC, only to face unexpected delays due to shipping issues, which affects the entire project timeline.

The Solution: To combat supply chain vulnerabilities, diversify your supply sources. Establish relationships with multiple suppliers across different geographical locations to reduce dependence on a single source. Consider local manufacturers or distributors for Class 200 PVC to minimize shipping times and costs. Additionally, implement a robust inventory management system that allows for forecasting and planning based on historical data and market trends. Keeping a buffer stock of critical materials can also provide a safety net during supply chain disruptions. Finally, maintain clear communication with suppliers to stay informed about potential delays and proactively adjust project timelines as necessary. This strategic approach can help ensure that your projects proceed smoothly, even in the face of unforeseen challenges.

Strategic Material Selection Guide for class 200 pvc

What Are the Key Properties of Class 200 PVC?

Class 200 PVC (Polyvinyl Chloride) is engineered for high-pressure applications, boasting a maximum sustained pressure rating of 200 psi. This material is particularly advantageous in environments requiring robust performance, such as irrigation systems, potable water distribution, and various industrial applications. The inherent corrosion resistance of PVC makes it suitable for transporting a wide range of fluids, from non-potable water to chemical solutions. Additionally, Class 200 PVC can withstand temperatures up to 140°F (60°C), making it versatile for different climates, especially in regions with fluctuating temperatures.

What Are the Advantages and Disadvantages of Class 200 PVC?

Pros: Class 200 PVC is lightweight, which simplifies transportation and installation. Its resistance to corrosion and chemical degradation ensures longevity, reducing maintenance costs over time. Furthermore, its smooth interior surface minimizes flow resistance, enhancing fluid transport efficiency.

Cons: While Class 200 PVC is durable, it can be more expensive than lower-rated PVC options, which may deter budget-conscious buyers. Additionally, it is less flexible than other materials, which can complicate installation in tight spaces or intricate layouts.

How Does Class 200 PVC Impact Specific Applications?

The impact of Class 200 PVC on applications is significant. It is particularly well-suited for agricultural irrigation systems, where high-pressure water delivery is essential. The material’s compatibility with various media, including fertilizers and other chemicals, makes it a preferred choice in agricultural settings. However, it is crucial for buyers to consider local regulations regarding the use of PVC in potable water systems, as some regions may have stringent compliance standards.

What Should International B2B Buyers Consider When Selecting Class 200 PVC?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding local compliance and standards is vital. For example, in Europe, adherence to DIN standards is crucial, while ASTM standards are prevalent in the United States. Buyers should also consider the availability of fittings and connectors compatible with Class 200 PVC in their local markets to ensure seamless integration into existing systems. Furthermore, regional preferences for materials may vary, influencing the overall cost and availability of Class 200 PVC.

Summary Table of Material Selection for Class 200 PVC

| Material | Typical Use Case for Class 200 PVC | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Class 200 PVC | High-pressure irrigation systems | Excellent corrosion resistance | Higher cost compared to lower-rated PVC | Medium |

| Schedule 40 PVC | General plumbing applications | Widely available and easy to source | Lower pressure rating (up to 140 psi) | Low |

| Schedule 80 PVC | Industrial applications with higher pressures | Greater wall thickness for added strength | Heavier and more expensive than Class 200 PVC | High |

| CPVC (Chlorinated PVC) | Hot water systems | Higher temperature tolerance (up to 200°F) | More expensive and less common in some regions | High |

This guide provides actionable insights for B2B buyers considering Class 200 PVC, ensuring informed decisions that align with their specific application needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for class 200 pvc

What Are the Main Stages of Manufacturing Class 200 PVC?

The manufacturing of Class 200 PVC pipes involves several critical stages, each designed to ensure the final product meets stringent performance and quality standards. Understanding these processes can help B2B buyers make informed decisions when sourcing materials.

How Is Material Prepared for Class 200 PVC Production?

The manufacturing process begins with material preparation, primarily involving the selection and blending of PVC resin with additives. These additives may include stabilizers, lubricants, and colorants, which enhance the pipe’s durability, flexibility, and UV resistance. The mixture is then processed through a compounding stage, where it is heated and mixed in a controlled environment to ensure uniformity.

After compounding, the material is extruded into a continuous profile. The extrusion process involves forcing the molten PVC through a die, shaping it into the desired pipe form. This stage is critical for achieving the correct dimensions and physical properties essential for Class 200 PVC pipes, which are rated for a maximum sustained pressure of 200 psi.

What Forming Techniques Are Employed in Class 200 PVC Manufacturing?

Once the material is extruded, it undergoes a cooling process, usually through a water bath or air-cooling system, to solidify its shape. This is followed by cutting the continuous pipe into specified lengths. The forming techniques used are essential for ensuring the pipes maintain their strength and integrity under pressure.

In addition to standard extrusion, some manufacturers may employ advanced techniques such as co-extrusion or multi-layer extrusion, which can enhance the pipe’s characteristics by incorporating different materials or layers. These methods can improve resistance to chemical exposure or physical stress, making the pipes suitable for a broader range of applications.

What Quality Assurance Measures Are Implemented During Production?

Quality assurance (QA) is integral to the manufacturing of Class 200 PVC pipes. It ensures that the products not only meet regulatory standards but also fulfill customer expectations regarding performance and safety.

Which International Standards Govern Class 200 PVC Quality?

Manufacturers of Class 200 PVC must adhere to various international standards, such as ISO 9001, which outlines requirements for a quality management system. Compliance with ISO standards indicates that a manufacturer has established processes to ensure consistent quality and continuous improvement.

In Europe, CE marking is essential for products sold within the EU, signifying conformity with health, safety, and environmental protection standards. Other industry-specific standards, such as those from the American Petroleum Institute (API), may also apply depending on the intended use of the PVC pipes, especially in applications involving oil and gas.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is performed at multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before they enter production. Suppliers must provide certifications and test reports for the materials used in manufacturing.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to monitor variables such as temperature, pressure, and material consistency. This helps identify any deviations from standard operating procedures in real time.

-

Final Quality Control (FQC): After production, each batch of Class 200 PVC pipes undergoes rigorous testing to ensure they meet dimensional specifications and pressure ratings. Common tests include hydrostatic pressure tests, impact resistance tests, and dimensional checks.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, should take proactive steps to verify the QC processes of their suppliers. Here are effective strategies:

What Steps Can Buyers Take for Supplier Audits?

Conducting supplier audits is a crucial step in ensuring quality. Buyers should request access to the manufacturer’s quality management documentation, including their ISO certifications and internal QC procedures. Audits can be performed either by the buyer’s internal team or by third-party inspection agencies to provide an unbiased assessment.

How Can Buyers Utilize Quality Reports and Third-Party Inspections?

Buyers should insist on receiving detailed quality reports for each batch of PVC pipes, which should include test results and certifications. Engaging third-party inspection services can provide additional assurance of quality compliance. These services often conduct random sampling and testing to confirm that products meet specified standards.

What Are the Nuances of QC and Certification for International Buyers?

International buyers must navigate various nuances related to QC and certification. Different countries may have distinct regulatory requirements and standards for PVC pipes, which can impact the approval process for materials.

How Do Local Standards Affect International Sourcing?

For instance, European buyers may require CE marking, while buyers in the Middle East might need to comply with local standards such as the Gulf Cooperation Council (GCC) certifications. Understanding these requirements is vital to avoid delays in customs or potential penalties for non-compliance.

What Should Buyers Know About Documentation and Traceability?

Documentation is key in international trade. Buyers should ensure that their suppliers maintain comprehensive records of all manufacturing processes, quality tests, and compliance certifications. This traceability is critical not only for regulatory compliance but also for addressing any potential quality issues that may arise after the sale.

Conclusion

Manufacturing Class 200 PVC pipes involves a detailed process that emphasizes quality assurance at every stage. For B2B buyers, understanding these manufacturing and QC processes is essential for sourcing reliable products that meet international standards. By taking proactive measures to verify supplier quality and compliance, businesses can mitigate risks and ensure that they receive high-quality materials for their projects.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘class 200 pvc’

In the competitive landscape of international procurement, sourcing Class 200 PVC pipe requires a strategic approach to ensure quality, compliance, and value for your investment. This guide provides a step-by-step checklist tailored for B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for identifying the right Class 200 PVC pipe for your project. Consider the intended application, required pressure ratings (up to 200 psi), and dimensions. Documenting these specifications will help streamline the sourcing process and facilitate communication with potential suppliers.

Step 2: Research Regulatory Compliance

Understanding local and international regulations regarding PVC pipe is critical. Ensure that the Class 200 PVC you intend to purchase meets industry standards, such as ASTM D1785 or ISO certifications relevant to your region. Compliance not only ensures safety but also prevents potential legal issues during installation and use.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record in delivering high-quality PVC products and consider their certifications and adherence to manufacturing standards.

- Check for ISO Certification: Suppliers with ISO 9001 certification indicate a commitment to quality management systems.

- Assess Product Range: A supplier offering a diverse range of PVC products may better meet your future needs.

Step 4: Request Samples for Quality Assessment

Once you have shortlisted potential suppliers, request samples of Class 200 PVC pipe. Conduct thorough quality assessments to evaluate the pipe’s physical properties, such as wall thickness and flexibility. Testing for compliance with pressure ratings and durability is essential to ensure the product meets your technical specifications.

Step 5: Negotiate Pricing and Terms

Engage in discussions regarding pricing, payment terms, and delivery schedules. Understanding the total cost of ownership, including shipping and potential tariffs, is vital for budget planning. Don’t hesitate to negotiate; many suppliers expect some level of discussion regarding pricing.

- Consider Volume Discounts: Inquire about bulk purchase discounts or loyalty programs that can reduce costs.

- Clarify Payment Terms: Aim for favorable payment terms that align with your cash flow requirements.

Step 6: Confirm Logistics and Delivery Schedules

Discuss logistics with your chosen supplier to ensure timely delivery of your Class 200 PVC pipes. Confirm shipping methods, lead times, and any customs requirements specific to your region. Ensuring that the supplier can meet your project timelines is crucial for maintaining workflow and avoiding delays.

Step 7: Establish a Follow-Up Plan

After procurement, maintain communication with your supplier to address any post-purchase concerns. Establishing a follow-up plan will help you manage any issues related to product performance or compliance. Keeping the lines of communication open can lead to better service and potential future collaborations.

By following this structured checklist, B2B buyers can effectively navigate the complexities of sourcing Class 200 PVC pipe, ensuring that they secure quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for class 200 pvc Sourcing

What Are the Key Cost Components in Class 200 PVC Sourcing?

Understanding the cost structure of Class 200 PVC is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

-

Materials: The primary raw material for Class 200 PVC is polyvinyl chloride (PVC) resin. Prices for PVC resin can fluctuate based on market demand and crude oil prices, which significantly impact the overall cost. Additionally, the cost may vary depending on the grade of PVC used, which influences durability and pressure ratings.

-

Labor: Labor costs encompass wages for skilled and unskilled workers involved in manufacturing, quality control, and logistics. Countries with higher labor costs may see an increase in the overall pricing structure.

-

Manufacturing Overhead: This includes utilities, maintenance of equipment, and other indirect costs that support the manufacturing process. Efficient manufacturing processes can help mitigate these costs, leading to better pricing for buyers.

-

Tooling: This refers to the costs associated with molds and machinery required for producing Class 200 PVC pipes. Initial tooling investments can be significant, but they are amortized over large production runs, making them less impactful per unit in high-volume orders.

-

Quality Control (QC): Ensuring product quality is vital, particularly for applications requiring specific pressure ratings. QC processes may add to the cost but are necessary to avoid costly failures and maintain compliance with international standards.

-

Logistics: This encompasses transportation, warehousing, and distribution costs. For international buyers, shipping costs can vary significantly based on distance, mode of transport, and local tariffs. Understanding Incoterms is essential for clarifying responsibilities and costs in the shipping process.

-

Margin: Manufacturers typically add a profit margin to cover their costs and ensure business viability. This margin can vary based on market competition and supplier relationships.

What Influences Pricing in Class 200 PVC Purchases?

Several factors can influence pricing, impacting how international B2B buyers approach their sourcing strategies.

-

Volume and Minimum Order Quantity (MOQ): Higher volume orders often lead to lower per-unit costs due to economies of scale. Negotiating favorable terms based on order size is critical.

-

Specifications and Customization: Custom requirements, such as specific dimensions or certifications, can increase costs. Buyers should weigh the necessity of custom features against their budgets.

-

Material Quality and Certifications: Pipes that meet specific international standards, like ISO or ASTM certifications, may come at a premium. However, investing in higher-quality materials can reduce long-term costs associated with failures or replacements.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can impact pricing. Establishing a good relationship with suppliers can lead to better terms and pricing flexibility.

-

Incoterms: Understanding Incoterms is essential for international transactions. They dictate the responsibilities of buyers and sellers concerning shipping costs, insurance, and risk, which can affect the final pricing structure.

What Tips Can Help Buyers Optimize Their Class 200 PVC Sourcing?

Buyers can leverage several strategies to enhance their sourcing effectiveness:

-

Negotiation Skills: Developing strong negotiation skills can help secure better pricing and terms. Buyers should be prepared to discuss volume discounts, payment terms, and delivery schedules.

-

Total Cost of Ownership (TCO): Consider the long-term costs associated with sourcing Class 200 PVC, including maintenance, potential failures, and logistics. A lower upfront price may not always equate to better value.

-

Understanding Pricing Nuances: International buyers should be aware of currency fluctuations, local tariffs, and import duties that can affect final costs. Staying informed about market trends can help in making strategic sourcing decisions.

-

Supplier Evaluation: Conduct thorough evaluations of potential suppliers, assessing their production capacity, quality assurance processes, and delivery timelines. Establishing partnerships with reliable suppliers can lead to cost savings and improved supply chain resilience.

Conclusion

Sourcing Class 200 PVC involves navigating a complex web of cost components and pricing influencers. By understanding these factors and employing strategic sourcing techniques, international B2B buyers can optimize their purchasing decisions, ensuring they achieve both quality and cost-effectiveness in their projects.

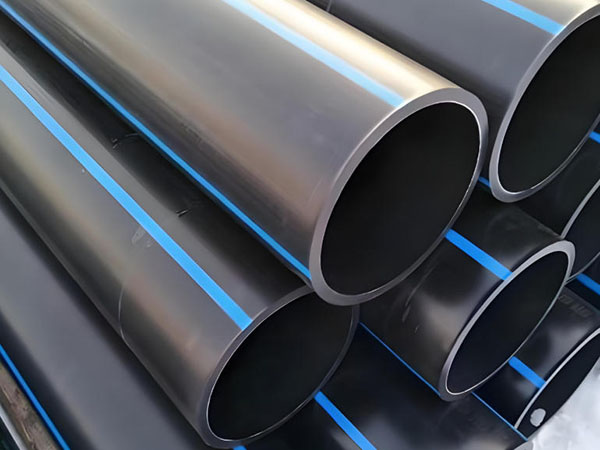

Alternatives Analysis: Comparing class 200 pvc With Other Solutions

When considering piping solutions for various applications, it’s crucial to explore alternatives that could meet specific operational needs. Class 200 PVC is widely recognized for its durability and pressure handling capabilities, but other materials and methods may also provide suitable solutions depending on the context. This analysis compares Class 200 PVC against two viable alternatives: HDPE (High-Density Polyethylene) and Copper Pipes.

| Comparison Aspect | Class 200 PVC | HDPE (High-Density Polyethylene) | Copper Pipes |

|---|---|---|---|

| Performance | Max sustained pressure of 200 psi; suitable for various fluid transport applications. | Flexible and resistant to corrosion; can handle high pressures and extreme temperatures. | Excellent thermal conductivity; high pressure and temperature resistance. |

| Cost | Generally lower upfront costs; widely available. | Moderate costs; can be more expensive due to installation complexity. | Higher initial costs; price volatility due to copper market fluctuations. |

| Ease of Implementation | Easy to install; lightweight and can be cut with simple tools. | Requires specialized welding or fusion techniques for installation. | Requires skilled labor for soldering and fitting; can be cumbersome. |

| Maintenance | Low maintenance; resistant to UV and chemical degradation. | Low maintenance but may require monitoring for wear over time. | Requires regular inspection for corrosion and leaks; potential for higher maintenance costs. |

| Best Use Case | Ideal for low to moderate pressure applications, such as irrigation and drainage systems. | Best for applications requiring flexibility, such as in urban environments or areas with ground movement. | Suitable for potable water systems and heating applications due to its thermal properties. |

What Are the Advantages and Disadvantages of HDPE Compared to Class 200 PVC?

HDPE pipes are highly versatile and known for their resistance to corrosion and chemicals. Their flexibility allows for installation in challenging terrains and reduces the likelihood of breakage under stress. However, the installation of HDPE can be complex, requiring specialized equipment and skilled labor, which may increase overall project costs. Despite this, HDPE’s long-term durability and lower maintenance needs often make it a preferred choice for extensive underground piping systems.

How Do Copper Pipes Compare to Class 200 PVC in Terms of Performance?

Copper pipes are prized for their thermal conductivity and long lifespan, making them a go-to for heating and hot water applications. They can handle high pressures and temperatures, which is beneficial in industrial settings. However, copper’s higher cost and susceptibility to corrosion in certain environments can lead to increased maintenance and replacement costs. Additionally, the installation process for copper piping is labor-intensive, requiring skilled professionals, which can escalate project expenses.

Conclusion: How Can B2B Buyers Choose the Right Piping Solution?

Selecting the appropriate piping solution hinges on multiple factors, including application requirements, budget constraints, and installation capabilities. Class 200 PVC offers an economical and straightforward option for many fluid transport needs, particularly in irrigation and drainage. However, if flexibility and resistance to harsh conditions are paramount, HDPE may be more suitable. For applications requiring high thermal performance, copper remains a strong contender despite its higher cost. By assessing the specific requirements of their projects and considering long-term performance and maintenance factors, B2B buyers can make informed decisions that align with their operational goals.

Illustrative image related to class 200 pvc

Essential Technical Properties and Trade Terminology for class 200 pvc

What Are the Key Technical Properties of Class 200 PVC?

Class 200 PVC pipe is widely recognized for its robust performance in various applications, particularly in irrigation and drainage systems. Understanding its essential technical properties can significantly influence procurement decisions for B2B buyers.

-

Material Grade

Class 200 PVC is made from high-quality polyvinyl chloride (PVC), which offers excellent durability and resistance to corrosion. This material is lightweight yet strong, making it suitable for high-pressure applications where reliability is critical. B2B buyers should prioritize this property to ensure the longevity and effectiveness of their piping systems. -

Pressure Rating

The pressure rating for Class 200 PVC is 200 psi, indicating its ability to sustain high-pressure applications without failure. This is particularly important for buyers in regions with varying water pressures or those involved in agricultural irrigation systems. Understanding pressure ratings helps in selecting the right materials for specific operational demands, minimizing the risk of pipe burst and subsequent downtime. -

Nominal Size and Dimensions

Class 200 PVC pipes are available in various nominal sizes, allowing flexibility in design and installation. The nominal size corresponds to the pipe’s inside diameter, which can affect flow rates and compatibility with existing systems. B2B buyers should be aware of these dimensions when planning their projects to ensure seamless integration with other components. -

Chemical Resistance

PVC exhibits excellent resistance to a wide range of chemicals, including acids, bases, and salts. This property is crucial for industries dealing with corrosive substances, ensuring that the pipe maintains integrity over time. Buyers should consider this aspect to avoid costly replacements or repairs due to chemical degradation. -

Temperature Tolerance

Class 200 PVC can typically withstand temperatures up to 140°F (60°C) without losing its structural integrity. This temperature tolerance is vital for applications where heat exposure is a concern, such as in hot water systems or environments with fluctuating temperatures. Understanding this property allows buyers to make informed choices about where and how to use Class 200 PVC effectively. -

Compliance and Standards

Class 200 PVC pipes often meet specific industry standards and regulations, such as ASTM D2241, which governs the specifications for PVC pipes. Compliance with these standards assures buyers of quality and performance, making it easier to align with regional regulations and avoid legal complications.

What Are Common Trade Terms Associated with Class 200 PVC?

Familiarity with industry jargon is essential for B2B buyers to navigate procurement and supply chain processes effectively.

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components or products that are used in another company’s end product. Understanding OEM relationships can help buyers source high-quality Class 200 PVC pipes that meet specific requirements for their projects. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts purchasing decisions, inventory management, and overall project budgeting. Knowing the MOQ helps buyers plan their orders accordingly. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and availability for specific products. Utilizing RFQs enables buyers to compare offers from different suppliers, ensuring they secure the best possible deal on Class 200 PVC. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and obligations associated with the procurement of Class 200 PVC. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for project planning and ensuring that materials arrive when needed, avoiding delays in project timelines. -

Certification

Certification indicates that a product meets specific industry standards or regulations. For Class 200 PVC, certifications can assure buyers of quality and compliance with safety standards, which is particularly important for construction and agricultural applications.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance project efficiency and minimize risks associated with procurement.

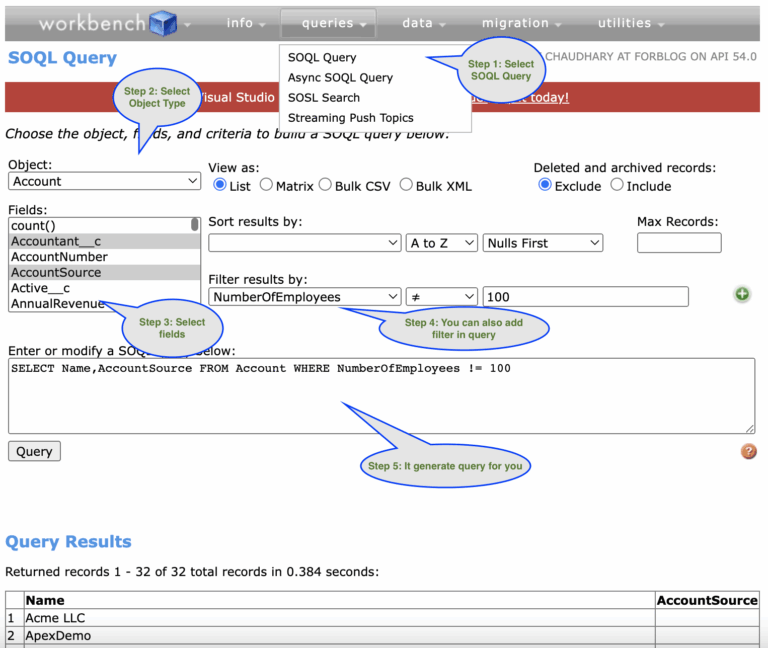

Navigating Market Dynamics and Sourcing Trends in the class 200 pvc Sector

What Are the Key Market Drivers Influencing the Class 200 PVC Sector?

The global market for Class 200 PVC is being shaped by several key drivers, including increasing infrastructure development, growing demand for efficient irrigation systems, and the rising need for water management solutions, particularly in developing regions such as Africa and South America. As urbanization accelerates, countries are investing heavily in water supply and sewage systems, which boosts the demand for reliable and high-pressure piping solutions like Class 200 PVC.

Illustrative image related to class 200 pvc

Additionally, advancements in B2B technology are transforming sourcing practices. Digital platforms are enabling buyers to access a wider range of suppliers, facilitating price comparisons, and enhancing negotiation capabilities. The rise of e-commerce in the construction and plumbing sectors allows international buyers to source materials more efficiently, often at lower costs. Furthermore, the integration of data analytics is assisting companies in forecasting demand, optimizing inventory, and streamlining supply chains.

Emerging trends also indicate a shift towards modular construction techniques, which require versatile and durable materials. As Class 200 PVC pipes are lightweight and easy to transport, they are increasingly favored in prefabricated construction processes. In regions like the Middle East, where rapid urban development is common, this trend is particularly pronounced, presenting lucrative opportunities for B2B buyers.

How Is Sustainability and Ethical Sourcing Impacting the Class 200 PVC Market?

Sustainability is becoming a cornerstone of B2B sourcing strategies, particularly in the Class 200 PVC sector. As environmental concerns rise, buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. The production of PVC can have significant environmental impacts, from the sourcing of raw materials to the energy-intensive manufacturing processes. Therefore, ethical sourcing is critical for companies looking to align with global sustainability goals.

Buyers are encouraged to seek suppliers who utilize recycled materials in their PVC products or those that adhere to ‘green’ certifications, such as the Green Building Council’s LEED certification. These certifications not only enhance the credibility of the products but also ensure compliance with stringent environmental regulations in various regions, particularly in Europe and North America.

Moreover, the demand for low-impact materials is prompting manufacturers to innovate. Companies are developing PVC options that are free from harmful additives and that can be recycled more efficiently at the end of their lifecycle. This not only reduces the environmental footprint but also appeals to eco-conscious buyers who are willing to pay a premium for sustainable products.

What Is the Historical Context of Class 200 PVC Development?

The evolution of Class 200 PVC can be traced back to the broader development of PVC as a material for plumbing and construction applications. Initially introduced in the 1930s, PVC gained popularity due to its durability, resistance to corrosion, and cost-effectiveness compared to traditional materials like metal and concrete. The introduction of class ratings, such as Class 200, emerged as the need for standardized pressure ratings became apparent, particularly in irrigation and construction sectors.

Over the decades, advancements in manufacturing processes and material science have led to improved formulations of PVC that enhance its strength and longevity. The Class 200 rating, which denotes a maximum sustained pressure of 200 psi, has become a standard in applications requiring reliable and high-performance piping solutions. This evolution reflects the industry’s response to growing demands for efficiency, reliability, and sustainability in infrastructure development worldwide.

As B2B buyers navigate the Class 200 PVC market, understanding these historical trends and current dynamics is crucial for making informed sourcing decisions that align with both business goals and environmental responsibilities.

Frequently Asked Questions (FAQs) for B2B Buyers of class 200 pvc

-

How do I select the right class 200 PVC pipe for my project?

Selecting the right class 200 PVC pipe involves understanding your project’s specific requirements, such as the pressure rating and application. Class 200 PVC is rated for a maximum sustained pressure of 200 psi, making it suitable for irrigation, non-potable water transport, and various industrial applications. Assess your pressure needs and ensure the diameter fits your system’s flow requirements. Additionally, consult local building codes and regulations that might dictate specific material standards for your region. -

What are the advantages of using class 200 PVC over other types?

Class 200 PVC offers several advantages, including higher pressure ratings compared to standard PVC pipes like Schedule 40. This makes it ideal for applications that experience higher pressure demands, such as irrigation systems and industrial settings. It is lightweight, resistant to corrosion, and easy to install. Additionally, its uniform outside diameter allows for compatibility with various fittings, simplifying installation and reducing the risk of leaks. -

What should I consider when vetting suppliers for class 200 PVC?

When vetting suppliers, consider their industry experience, reputation, and product certifications. Request samples to assess quality and ensure they meet international standards. Check for compliance with regulations relevant to your region, such as ISO certifications. Additionally, inquire about their production capabilities, lead times, and customer service responsiveness. A reliable supplier should also provide clear documentation on material specifications and safety data sheets. -

What are the typical minimum order quantities (MOQs) for class 200 PVC pipes?

Minimum order quantities for class 200 PVC pipes can vary significantly depending on the supplier and the specific product dimensions. Typically, MOQs range from a few hundred to several thousand units. It’s advisable to discuss your requirements with potential suppliers to negotiate favorable terms. If you are testing a new supplier, some may offer flexibility in MOQs to build a relationship, especially if you plan to make recurring orders. -

What payment terms are common for international B2B transactions involving class 200 PVC?

Common payment terms for international B2B transactions may include options such as Letters of Credit (LC), advance payments, or payment upon delivery. Many suppliers prefer a 30% deposit upfront with the balance due upon shipment. Always clarify payment terms before finalizing an agreement to avoid misunderstandings. Additionally, consider discussing options for escrow services, which can provide extra security for both parties. -

How can I ensure the quality of class 200 PVC pipes before shipment?

To ensure quality, request a Certificate of Compliance from the supplier, which confirms that the pipes meet specified standards. You can also arrange for third-party quality inspections at the manufacturing facility prior to shipment. This can include checking dimensions, pressure testing, and verifying material specifications. Establishing a clear quality assurance process in your contract will help mitigate risks associated with substandard materials. -

What logistics considerations should I keep in mind when importing class 200 PVC?

When importing class 200 PVC, consider shipping methods, customs regulations, and potential tariffs. Ensure that the supplier provides all necessary documentation for customs clearance, including commercial invoices, packing lists, and certificates of origin. Additionally, factor in shipping times and costs, and consider partnering with a logistics provider experienced in handling construction materials to streamline the process. -

Can class 200 PVC be customized for specific applications?

Yes, class 200 PVC can often be customized in terms of length, diameter, and even color, depending on the supplier’s capabilities. Some manufacturers offer options for specific fittings or joint types to better suit unique project requirements. When requesting customization, provide detailed specifications and discuss your needs early in the negotiation process to ensure the supplier can meet your expectations.

Top 4 Class 200 Pvc Manufacturers & Suppliers List

1. PVC Guy – Schedule 40 PVC

Domain: pvcguy.com

Registered: 2016 (9 years)

Introduction: Schedule 40 PVC: 1. Standard (STD) rating, commonly used in residential plumbing. 2. Wall thickness varies with pipe size; strength decreases as size increases. 3. Widely available and stocked in hardware stores. 4. Used for most plumbing applications. 5. Notable for its affordability and availability. 6. Pressure rating varies by size, requiring tables for specific applications. Class 200 PVC: 1….

2. Reddit – Pipe Comparison Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Sch 40 pipe is more expensive but recommended for pressurized systems due to its durability. Class 200 pipe is cheaper and rated for 200 psi, suitable for non-pressurized use, but not recommended for constant pressure applications. Users advise against using Class 200 pipe if it will be under pressure, citing potential for cracks or leaks.

3. TroubleFreePool – Class 200 PVC Autofill Line

Domain: troublefreepool.com

Registered: 2007 (18 years)

Introduction: Class 200 PVC used on autofill line; rated for 200 psi; thinner wall compared to Schedule 40 PVC; concerns about longevity and durability; installed under concrete patio/deck; potential issues with earthquakes; accessible only if deck is removed.

4. PlumbersStock – 4 Class 200 PVC Pipe

Domain: plumbersstock.com

Registered: 2007 (18 years)

Introduction: {“Product”:”4″ Class 200 (CL 200) PVC Pipe”,”Material”:”PVC”,”Length”:”5′”,”Diameter”:”4″”,”Connection Type”:”Glued”,”Use”:”Water”,”Weight”:”1.83 lbs.”,”Applications”:”Irrigation, residential or commercial sprinkler systems”,”Pressure Rating”:”200 psi”}

Strategic Sourcing Conclusion and Outlook for class 200 pvc

Strategic sourcing of Class 200 PVC offers international buyers a robust solution for a variety of applications, particularly in irrigation and construction. Understanding the unique specifications and advantages of Class 200 PVC—such as its pressure rating of 200 psi—enables businesses to make informed purchasing decisions that enhance operational efficiency and reduce long-term costs.

By prioritizing strategic sourcing, companies can leverage competitive pricing, ensure consistent quality, and foster relationships with reliable suppliers. Buyers in regions like Africa, South America, the Middle East, and Europe, including Germany and Brazil, are positioned to benefit from the growing demand for sustainable materials and innovative solutions in their respective markets.

Illustrative image related to class 200 pvc

As the global landscape evolves, it is essential to remain proactive in sourcing high-quality Class 200 PVC products. Embrace the opportunity to connect with trusted suppliers who can meet your project specifications and help you navigate the complexities of international procurement. Equip your business for success by prioritizing strategic sourcing today, and position yourself as a leader in your industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.