Everything You Need to Know About Plastic Tote Manufacturers Sourcing in 2025

Introduction: Navigating the Global Market for plastic tote manufacturers

In today’s global economy, sourcing high-quality plastic totes for diverse applications poses a significant challenge for B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. The plastic tote manufacturing landscape is vast and varied, encompassing a wide range of products from heavy-duty attached lid containers to eco-friendly options designed for sustainability. This guide serves as a comprehensive resource, delving into the different types of plastic totes available, their applications across various industries, and essential supplier vetting processes to ensure quality and reliability.

International buyers can benefit greatly from understanding the nuances of the market, including cost considerations, materials used, and the logistical aspects of importing these products. By equipping yourself with this knowledge, you can make informed purchasing decisions that align with your business needs and operational goals. Whether you’re looking to streamline warehouse operations, enhance product protection during transit, or adopt more sustainable practices, this guide is designed to empower you with actionable insights and strategies for successful sourcing.

From identifying reputable manufacturers to assessing the best fit for your specific requirements, navigating the global market for plastic tote manufacturers has never been more manageable. Embrace the opportunity to optimize your supply chain and elevate your operational efficiency with the right plastic tote solutions.

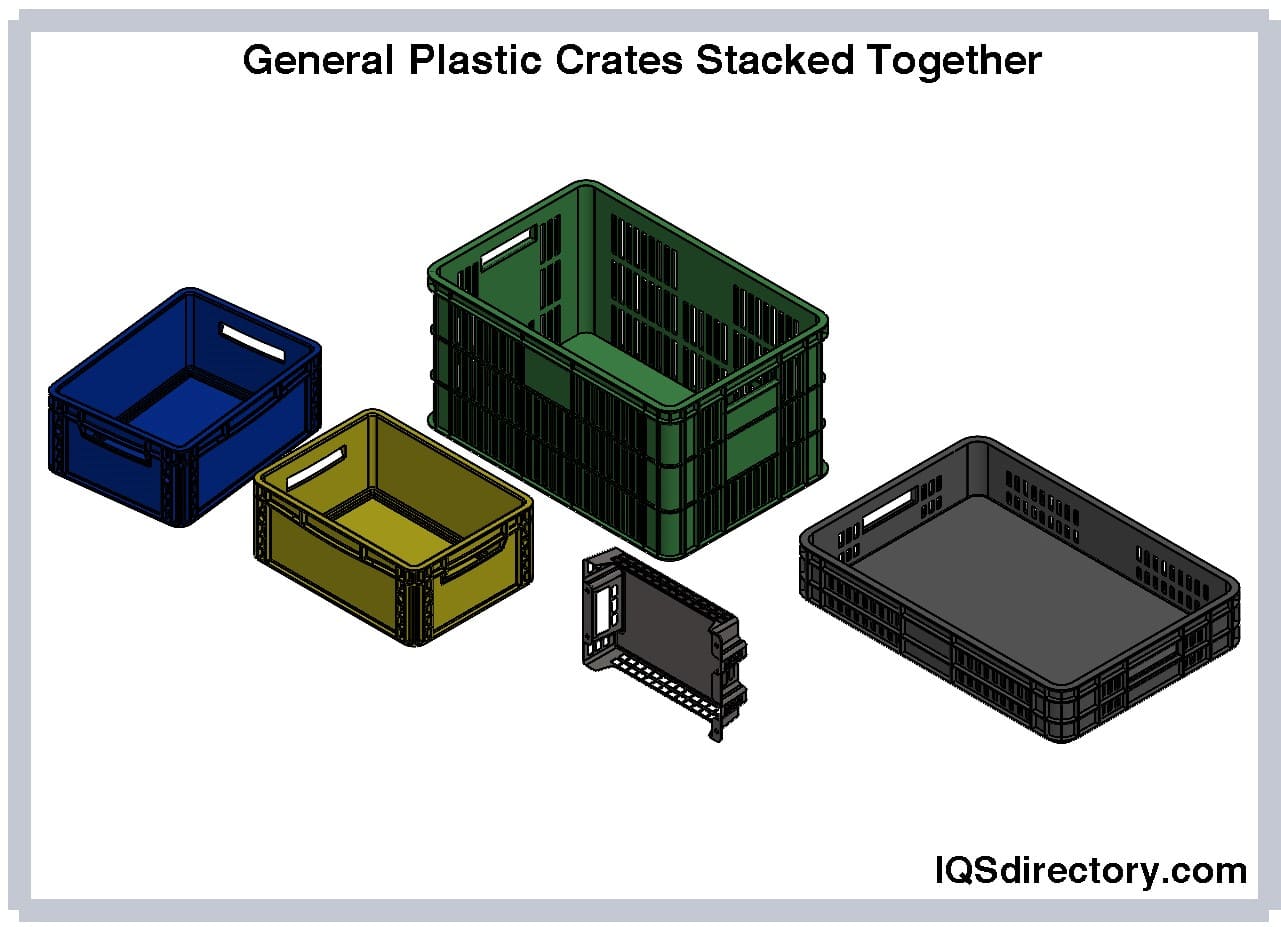

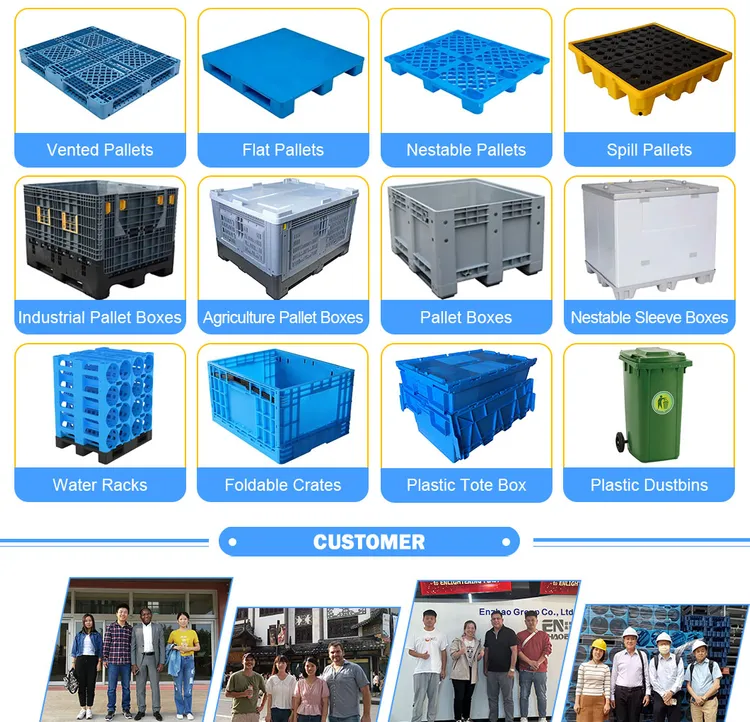

Understanding plastic tote manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heavy-Duty Attached Lid Totes | Durable, stackable, and nestable with attached lids | Warehousing, distribution, and inventory storage | Pros: High durability, excellent space-saving. Cons: Higher initial cost. |

| Nestable Totes | Designed to fit into each other when empty | Retail, e-commerce, and seasonal storage | Pros: Space-efficient, easy to transport. Cons: Limited capacity when nested. |

| Customizable Plastic Totes | Options for branding and specific sizes | Marketing, promotional events, and specialized storage | Pros: Tailored solutions, enhances brand visibility. Cons: Longer lead times for customization. |

| Eco-Friendly Plastic Totes | Made from recycled materials with a lower environmental impact | Sustainability-focused businesses and green logistics | Pros: Supports sustainability goals, often compliant with regulations. Cons: May have a higher price point. |

| Stackable Crates | Designed for maximum vertical storage without compromising stability | Manufacturing, logistics, and shipping | Pros: Efficient use of vertical space, robust design. Cons: Requires adequate ceiling height for stacking. |

What are Heavy-Duty Attached Lid Totes and Their B2B Benefits?

Heavy-duty attached lid totes are robust containers that offer exceptional durability and security for various applications. These totes typically feature molded grip handles and a stacking capacity of up to 500 lbs, making them ideal for warehousing and distribution environments. They provide excellent protection for goods and are designed for repeated use, which is beneficial for businesses that require reliable storage solutions. When purchasing, consider the load-bearing requirements and the frequency of use, as this will influence the total cost of ownership.

Illustrative image related to plastic tote manufacturers

How Do Nestable Totes Enhance Storage Solutions?

Nestable totes are engineered to fit inside one another when not in use, maximizing storage efficiency. This feature is particularly beneficial for retail and e-commerce businesses that may experience seasonal fluctuations in inventory. By allowing for easy transport and storage, these totes help reduce logistical costs. Buyers should evaluate the size and weight capacity to ensure they meet specific operational needs while considering the trade-off between nesting capability and available storage volume.

What Advantages Do Customizable Plastic Totes Offer?

Customizable plastic totes provide businesses with the opportunity to tailor storage solutions to their specific needs, including size variations and branding options. This customization is especially valuable for marketing and promotional efforts, allowing companies to enhance their brand visibility. However, buyers should be mindful of potential lead times and the minimum order quantities required for customization, as these factors can affect inventory management and cash flow.

Why Choose Eco-Friendly Plastic Totes for Sustainable Practices?

Eco-friendly plastic totes are made from recycled materials and are designed to minimize environmental impact. They are increasingly popular among businesses focused on sustainability and corporate social responsibility. While they may come at a premium price, the long-term benefits include compliance with environmental regulations and a positive brand image. Buyers should assess the materials used and ensure that they align with their sustainability goals to maximize the value of their investment.

How Do Stackable Crates Optimize Vertical Storage?

Stackable crates are designed to provide maximum vertical storage capabilities, making them ideal for warehouses and manufacturing facilities. Their robust design ensures stability when stacked, allowing businesses to utilize vertical space effectively. This can lead to significant savings in floor space and improved operational efficiency. When considering stackable crates, buyers should evaluate the height of their storage area and the weight limits to ensure safe stacking practices.

Illustrative image related to plastic tote manufacturers

Key Industrial Applications of plastic tote manufacturers

| Industry/Sector | Specific Application of plastic tote manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Supply Chain | Use of heavy-duty attached lid totes for transporting goods | Enhanced security and protection of products during transit | Assess weight capacity, nesting capabilities, and sealing options |

| Retail and E-commerce | Storing and organizing inventory in warehouses | Improved inventory management and space optimization | Consider size, stackability, and customization options |

| Agriculture | Transporting harvested produce and agricultural supplies | Durability and resistance to environmental factors | Evaluate material safety, capacity for bulk items, and hygiene |

| Manufacturing | Use in assembly lines for parts and components | Streamlined operations and reduced risk of damage | Check compatibility with existing systems and ergonomic designs |

| Food and Beverage | Storing ingredients and finished products for distribution | Compliance with health standards and temperature control | Ensure material is food-grade, easy to clean, and stackable |

How Are Plastic Totes Used in Logistics and Supply Chain Management?

In logistics and supply chain management, heavy-duty attached lid totes are utilized for the secure transportation of goods. These containers provide enhanced protection against damage during transit, which is crucial for maintaining product integrity. For international buyers, especially in regions like Africa and South America, sourcing totes that can withstand varying climatic conditions is essential. Considerations include weight capacity and the ability to nest when empty, which maximizes storage efficiency.

What Role Do Plastic Totes Play in Retail and E-commerce?

In the retail and e-commerce sectors, plastic totes are vital for storing and organizing inventory in warehouses. Their stackable design allows businesses to optimize space and improve inventory management. For B2B buyers in Europe and the Middle East, it is important to consider the size and customization options of these totes to align with specific warehouse configurations and branding requirements.

How Are Plastic Totes Beneficial in Agriculture?

In agriculture, plastic totes are employed for transporting harvested produce and agricultural supplies. Their durability ensures they can withstand harsh environmental conditions, while their design promotes hygiene and ease of cleaning. Buyers in regions with diverse agricultural practices, such as Brazil and Saudi Arabia, should evaluate the material safety and capacity of totes to handle bulk items effectively.

Why Are Plastic Totes Important in Manufacturing?

Manufacturers utilize plastic totes in assembly lines for parts and components, allowing for streamlined operations and reduced risk of damage. These totes can be tailored to fit specific operational workflows, which is particularly beneficial for international manufacturers seeking efficiency. It is critical to check the compatibility of totes with existing systems and consider ergonomic designs that facilitate ease of use.

How Do Plastic Totes Support the Food and Beverage Industry?

In the food and beverage sector, plastic totes are essential for storing ingredients and finished products, ensuring compliance with health standards. They help maintain temperature control and protect against contamination. For international buyers, particularly in regions with stringent food safety regulations, it is vital to ensure that the materials used are food-grade, easy to clean, and stackable for efficient storage.

Illustrative image related to plastic tote manufacturers

3 Common User Pain Points for ‘plastic tote manufacturers’ & Their Solutions

Scenario 1: Difficulty in Finding Customizable Plastic Tote Solutions

The Problem: Many B2B buyers face the challenge of sourcing plastic totes that meet specific size, design, or branding requirements. Off-the-shelf solutions may not fit their unique operational needs, leading to inefficiencies in storage and transportation. For instance, a logistics company in Brazil may require totes that can accommodate specific product dimensions while also needing them to feature their company logo for brand visibility. Without the ability to customize, they risk compromising their operational efficiency and brand representation.

The Solution: To effectively address this pain point, B2B buyers should prioritize manufacturers that offer customizable plastic totes. When researching potential suppliers, inquire about their ability to tailor products according to specific dimensions, colors, and branding requirements. Engage in detailed discussions to understand the manufacturing capabilities and explore options for customization, such as hot-stamping logos or selecting unique color schemes. Additionally, request samples before committing to larger orders to ensure the product meets both functional and aesthetic needs. By leveraging manufacturers that specialize in custom solutions, businesses can enhance their logistics processes while reinforcing their brand identity.

Scenario 2: Concerns Over Durability and Quality of Plastic Totes

The Problem: Buyers often grapple with the uncertainty regarding the quality and durability of plastic totes, especially when purchasing in bulk. Companies in the Middle East, for example, may operate in harsh environments where inadequate tote performance can lead to product damage or loss. Concerns about the structural integrity and lifespan of the totes can create hesitation and lead to increased operational costs due to frequent replacements.

Illustrative image related to plastic tote manufacturers

The Solution: To mitigate these concerns, B2B buyers should conduct thorough due diligence on potential plastic tote manufacturers. Look for suppliers that provide detailed specifications, including materials used (such as high-density polyethylene or polypropylene), load capacities, and stacking capabilities. Additionally, seek manufacturers that offer warranties or guarantees on their products, as this indicates confidence in their durability. Consider reviewing customer testimonials or case studies to gauge real-world performance. By selecting a manufacturer with a proven track record of delivering high-quality, durable products, buyers can ensure that their investment will withstand the demands of their operational environments.

Scenario 3: Inefficiencies in Space Utilization During Storage and Transport

The Problem: Many businesses face challenges with inefficient use of space when storing and transporting goods in plastic totes. In South America, for instance, companies may find that their existing totes do not stack or nest effectively, leading to wasted warehouse space and increased transportation costs. This inefficiency not only hampers productivity but can also significantly impact overall operational costs.

The Solution: B2B buyers should focus on sourcing plastic totes that are specifically designed for efficient stacking and nesting. When evaluating potential manufacturers, inquire about their tote designs that optimize space utilization. Look for features such as tapered sides for nesting when empty and reinforced structures for safe stacking when full. Request information about the stacking capabilities, including maximum weight limits and the number of totes that can be safely stacked. Conducting a space analysis within your warehouse can also help determine the optimal tote size and design for your specific needs. By investing in space-efficient plastic totes, companies can reduce storage footprint and transportation costs, leading to improved operational efficiency.

Strategic Material Selection Guide for plastic tote manufacturers

When selecting materials for plastic totes, manufacturers must consider a variety of factors that influence both product performance and market suitability. This analysis focuses on four common materials used in plastic tote manufacturing: High-Density Polyethylene (HDPE), Polypropylene (PP), Polyvinyl Chloride (PVC), and Acrylonitrile Butadiene Styrene (ABS). Each material has distinct properties, advantages, and limitations that can impact their application in diverse international markets.

Illustrative image related to plastic tote manufacturers

What are the Key Properties of High-Density Polyethylene (HDPE) for Plastic Totes?

HDPE is renowned for its strength and durability. It boasts a high resistance to impact, chemicals, and moisture, making it an ideal choice for various environments. HDPE can withstand temperatures ranging from -40°F to 120°F, which is suitable for both cold and warm climates. Its lightweight nature also contributes to lower shipping costs.

Pros and Cons of HDPE: The primary advantage of HDPE is its excellent durability and resistance to environmental stressors. However, its manufacturing complexity can be higher than other materials, leading to increased production costs. Furthermore, while HDPE is recyclable, it may not be as eco-friendly as other options, which could be a consideration for environmentally conscious buyers.

Impact on Application: HDPE is compatible with a wide range of media, including food products and hazardous materials, making it versatile for various industries.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local regulations regarding food safety and chemical storage. Standards such as ASTM and DIN are often referenced in product specifications, which can influence purchasing decisions.

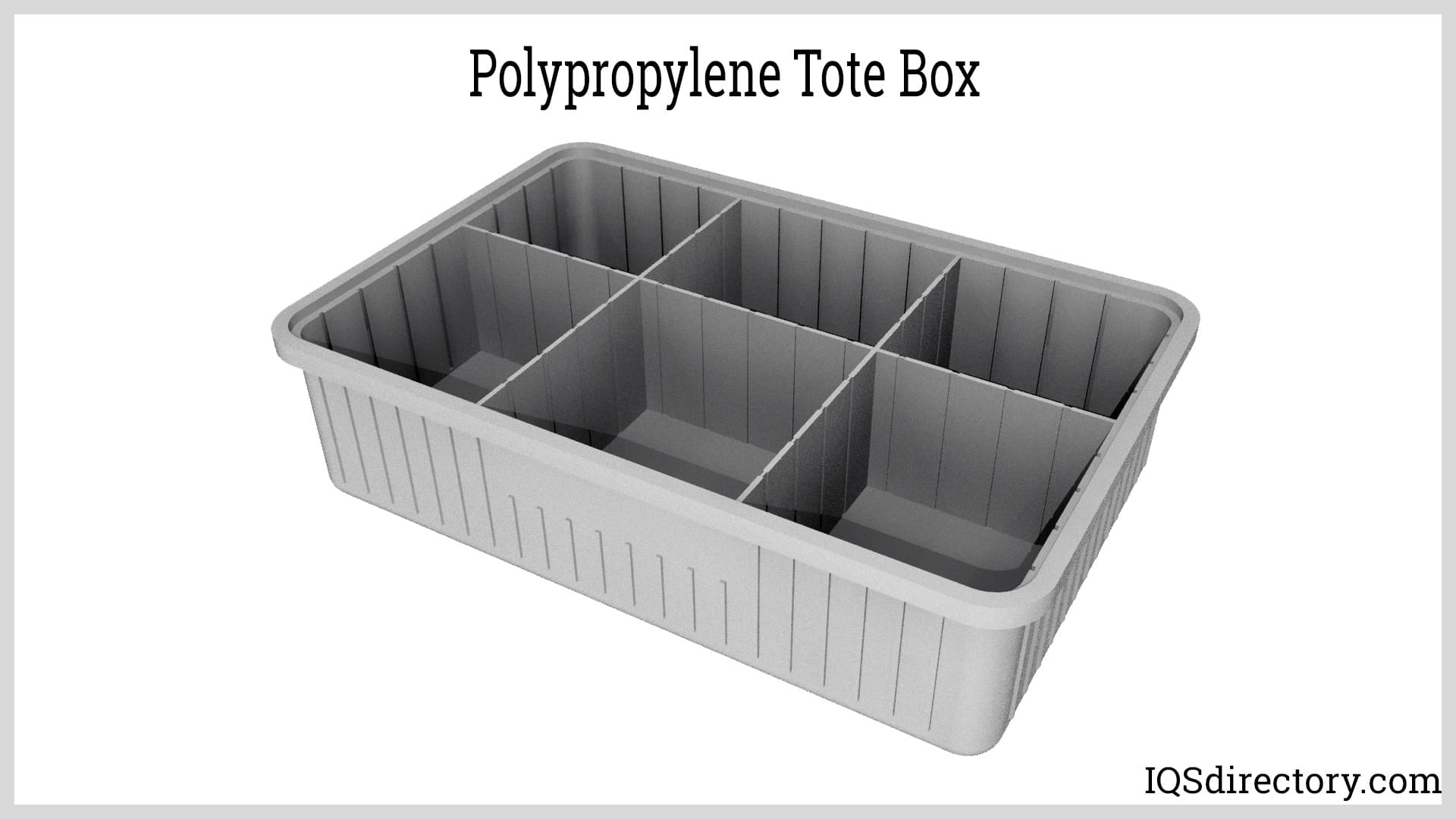

How Does Polypropylene (PP) Compare for Plastic Tote Manufacturing?

Polypropylene is another popular material due to its excellent chemical resistance and flexibility. It can handle temperatures up to 200°F, making it suitable for applications requiring heat resistance.

Pros and Cons of PP: The flexibility of PP allows for easy molding into complex shapes, which can enhance the design of totes. However, its lower impact resistance compared to HDPE can be a drawback in high-stress environments. Additionally, while generally cost-effective, the price of PP can fluctuate based on oil prices, impacting overall costs.

Impact on Application: Polypropylene is particularly effective for storing chemicals and pharmaceuticals due to its inert nature.

Considerations for International Buyers: Buyers from the Middle East and Europe may prioritize PP for its lightweight properties, which can reduce shipping costs. Compliance with specific industry standards, such as the European Union’s REACH regulation, is critical for ensuring safe usage.

What are the Advantages of Using Polyvinyl Chloride (PVC) in Plastic Totes?

PVC is known for its rigidity and strength, making it a suitable option for heavy-duty applications. It has a good resistance to environmental factors and can perform well in a variety of temperatures.

Pros and Cons of PVC: The key advantage of PVC is its durability and low cost, making it an attractive option for bulk purchases. However, it can be less flexible than HDPE and PP, which may limit its application in certain designs. Additionally, concerns about the environmental impact of PVC production and disposal may deter some buyers.

Illustrative image related to plastic tote manufacturers

Impact on Application: PVC is often used in industrial settings where heavy loads are common, providing reliable performance under pressure.

Considerations for International Buyers: Compliance with international standards such as ISO can be crucial for buyers in Europe and the Middle East, where stringent regulations govern material safety and environmental impact.

Why Choose Acrylonitrile Butadiene Styrene (ABS) for Plastic Totes?

ABS is favored for its high strength and impact resistance, making it ideal for applications requiring robust performance. It can withstand temperatures from -4°F to 176°F.

Pros and Cons of ABS: The main advantage of ABS is its excellent toughness and ability to be easily molded into complex shapes. However, it is generally more expensive than other plastics, which could deter cost-sensitive buyers. Additionally, ABS may not be suitable for high-temperature applications.

Impact on Application: ABS is often used in environments where aesthetics are important, as it can be produced in various colors and finishes.

Considerations for International Buyers: Buyers in regions with high humidity or temperature fluctuations, such as parts of Africa and Brazil, should consider the limitations of ABS in extreme conditions and ensure compliance with local standards.

Summary Table of Material Selection for Plastic Tote Manufacturers

| Material | Typical Use Case for plastic tote manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Density Polyethylene (HDPE) | Food storage, chemical containment | Excellent durability and moisture resistance | Higher manufacturing complexity | Medium |

| Polypropylene (PP) | Chemical storage, pharmaceuticals | Good chemical resistance and flexibility | Lower impact resistance | Medium |

| Polyvinyl Chloride (PVC) | Heavy-duty industrial applications | Low cost and durability | Less flexible, environmental concerns | Low |

| Acrylonitrile Butadiene Styrene (ABS) | Aesthetic applications, consumer goods | High strength and impact resistance | Higher cost, temperature limitations | High |

This guide provides B2B buyers with essential insights into material selection for plastic totes, helping them make informed decisions that align with their operational needs and compliance requirements.

Illustrative image related to plastic tote manufacturers

In-depth Look: Manufacturing Processes and Quality Assurance for plastic tote manufacturers

What Are the Key Stages in the Manufacturing Process of Plastic Totes?

The manufacturing process for plastic totes involves several critical stages that ensure the final product meets industry standards for quality and durability. Understanding these stages is essential for B2B buyers who are looking for reliable suppliers.

Material Preparation: What Types of Plastics Are Used?

The journey begins with material preparation, where high-density polyethylene (HDPE) and polypropylene are commonly used due to their strength and resistance to chemicals. The selected resin is often pelletized and subjected to pre-drying to eliminate moisture, which can affect the quality of the final product. Suppliers should provide technical data sheets (TDS) for the materials used, detailing their properties and compliance with relevant regulations.

Forming: How Are Plastic Totes Shaped?

The forming stage typically involves several techniques, primarily injection molding and blow molding. Injection molding is favored for its precision, allowing manufacturers to create complex shapes and designs with minimal waste. The process begins by melting the plastic pellets, which are then injected into molds to form the tote’s structure. Blow molding, on the other hand, is often used for creating hollow containers and is more suitable for larger totes.

Key considerations for B2B buyers include understanding the mold design and production capacity of the manufacturer. Buyers should inquire about the cycle times and the number of units produced per hour, as these factors will impact lead times and pricing.

Assembly: What Are the Common Assembly Techniques?

Following forming, the assembly stage involves integrating various components such as lids, handles, and locking mechanisms. This stage may include manual labor or automated processes, depending on the scale of production. For heavy-duty plastic totes, special attention is given to the strength of hinges and seals to ensure longevity and functionality.

B2B buyers should assess whether the manufacturer employs lean manufacturing techniques to minimize waste and maximize efficiency. Suppliers that use automation in assembly may offer better consistency and lower production costs.

Finishing: What Quality Checks Are Performed?

Finishing includes processes such as surface treatment, labeling, and packaging. Surface treatments may involve smoothing out rough edges or applying anti-slip coatings, enhancing both aesthetics and safety. Custom branding options, such as hot stamping or screen printing, can also be discussed during this phase.

What Quality Assurance Practices Should Plastic Tote Manufacturers Follow?

Quality assurance is paramount in the manufacturing of plastic totes, especially for B2B buyers who require reliable products for logistics and storage.

What International Standards Govern Quality Assurance?

Manufacturers are often required to comply with international standards such as ISO 9001, which outlines requirements for a quality management system (QMS). Compliance with CE marking is also critical for products intended for the European market, indicating conformity with health, safety, and environmental protection standards.

In addition to these standards, industry-specific certifications such as the American National Standards Institute (ANSI) can enhance credibility. Buyers should verify that potential suppliers have the necessary certifications and maintain compliance through regular audits.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to ensuring that the manufacturing process meets established standards. Common QC checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring the manufacturing process at various stages to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of finished products to confirm that they meet quality standards before shipment.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control practices of potential suppliers. Here are several strategies:

Illustrative image related to plastic tote manufacturers

What Documentation Should Buyers Request?

Buyers should request detailed documentation, including quality control reports and compliance certificates. Such documentation should outline the testing methods used and the results of previous quality assessments.

How Can Audits and Third-Party Inspections Enhance Trust?

Conducting audits of manufacturing facilities can provide deeper insights into a supplier’s operations. Buyers may also consider hiring third-party inspection services to conduct independent assessments of the manufacturing processes and product quality. This can be particularly important for international buyers from regions like Africa or South America, where supply chain complexities may arise.

What Testing Methods Ensure Product Quality and Compliance?

Manufacturers commonly employ various testing methods to ensure the integrity and performance of plastic totes. Common testing methods include:

- Mechanical Testing: Assessing tensile strength, impact resistance, and load-bearing capabilities.

- Chemical Resistance Testing: Evaluating how the plastic reacts to various chemicals, crucial for industries like food and pharmaceuticals.

- Environmental Testing: Conducting tests to ensure that products can withstand extreme temperatures and humidity, especially important for buyers in diverse climates.

B2B buyers should inquire about the specific testing methods used and request access to test results to ensure the product will meet their operational needs.

Conclusion: Ensuring Quality in Your Supply Chain

For B2B buyers, understanding the manufacturing processes and quality assurance practices of plastic tote manufacturers is essential for making informed purchasing decisions. By focusing on material preparation, forming techniques, assembly methods, and finishing processes, buyers can identify manufacturers that align with their quality expectations. Additionally, verifying adherence to international standards and QC practices will further ensure a reliable supply chain, ultimately contributing to operational success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic tote manufacturers’

This sourcing guide is designed to assist international B2B buyers in effectively procuring plastic tote manufacturers. The checklist outlines essential steps to ensure that you select a supplier that meets your business needs, maintains quality standards, and adheres to sustainability practices.

Step 1: Define Your Technical Specifications

Before initiating contact with manufacturers, clarify your specific requirements for plastic totes. Consider dimensions, weight capacity, material type, and any necessary features such as stackability or lid types. A well-defined specification will streamline your search and ensure that suppliers can meet your exact needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential manufacturers that specialize in plastic totes. Look for companies with a strong reputation in the industry, and review their product offerings and customer feedback. Utilize platforms like industry trade shows, online directories, and social media to gather insights about potential suppliers.

Step 3: Evaluate Supplier Certifications

Verify the certifications and compliance of potential suppliers to ensure they meet international standards. Look for certifications such as ISO 9001 for quality management and ISO 14001 for environmental management. These certifications indicate that a manufacturer adheres to quality and sustainability practices, which is crucial for maintaining your brand’s reputation.

Step 4: Request Samples

Before placing a large order, always request product samples to assess quality firsthand. Evaluate the durability, design, and functionality of the totes to ensure they meet your specifications. This step also allows you to gauge the supplier’s responsiveness and willingness to accommodate your needs.

Step 5: Inquire About Customization Options

If your business requires branded or customized totes, inquire about the manufacturer’s capabilities in this area. Some suppliers offer customization options such as hot-stamping or color variations. Ensure that the supplier can accommodate your branding requirements without compromising on quality.

Step 6: Assess Production Capabilities and Lead Times

Understand the manufacturer’s production capacity and lead times to ensure they can meet your delivery schedules. Ask about their current order volume and whether they can scale production to accommodate your future needs. Timely delivery is crucial for maintaining your supply chain and meeting customer expectations.

Step 7: Negotiate Terms and Finalize the Agreement

Once you have selected a supplier, negotiate terms that align with your budget and requirements. Discuss payment terms, minimum order quantities, and shipping logistics. A well-structured agreement will protect your interests and establish a clear understanding of expectations between both parties.

By following this checklist, you can streamline the sourcing process, mitigate risks, and secure a reliable partnership with plastic tote manufacturers that align with your business objectives.

Illustrative image related to plastic tote manufacturers

Comprehensive Cost and Pricing Analysis for plastic tote manufacturers Sourcing

What Are the Key Cost Components for Plastic Tote Manufacturers?

Understanding the cost structure of plastic tote manufacturing is essential for B2B buyers looking to make informed purchasing decisions. The primary components of the cost structure include:

-

Materials: The type of plastic used (e.g., high-density polyethylene, polypropylene) significantly influences costs. High-quality materials enhance durability and longevity but also raise the price. Sustainable materials or those with lower environmental impact may also come at a premium.

-

Labor: Labor costs vary by region, influenced by local wage standards and the complexity of manufacturing processes. Countries with lower labor costs may offer more competitive pricing, but this can affect product quality and lead times.

-

Manufacturing Overhead: This includes costs associated with utilities, maintenance of machinery, and facility operations. Efficient manufacturing processes can help minimize these overheads, impacting overall pricing.

-

Tooling: The initial setup for manufacturing plastic totes, including molds and dies, can be a significant upfront investment. Custom tooling for specialized products may lead to higher initial costs but can result in better margins for the manufacturer.

-

Quality Control (QC): Rigorous QC processes ensure that products meet industry standards and specifications. Investments in quality assurance can increase costs but are essential for maintaining product integrity and customer satisfaction.

-

Logistics: Shipping costs are influenced by distance, transportation modes, and the volume of orders. International shipping, especially to regions like Africa or South America, may incur additional tariffs and duties, impacting total costs.

-

Margin: Manufacturers typically build in a profit margin based on the total cost of production. This margin can vary significantly based on market demand, competition, and the perceived value of the product.

What Factors Influence Pricing for Plastic Totes?

Several factors can affect the pricing of plastic totes, making it crucial for buyers to consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to bulk pricing discounts. Understanding the MOQ can help buyers negotiate better deals, especially when planning long-term needs.

-

Specifications and Customization: Custom-designed totes may incur additional costs. Buyers should clearly outline their specifications and inquire about potential cost implications before finalizing orders.

-

Quality and Certifications: Products that meet specific industry certifications or standards (e.g., ISO, FDA compliance) may come at a premium. Buyers should weigh the value of these certifications against their operational needs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established manufacturers with a proven track record may charge more but can offer better quality assurance and customer service.

-

Incoterms: Understanding shipping terms is vital for international transactions. Incoterms dictate who bears the risk and cost at various stages of shipping, impacting the final price.

What Tips Can Help Buyers Negotiate Cost-Effective Deals?

Navigating the complexities of pricing in the plastic tote industry requires strategic negotiation and planning:

-

Leverage Total Cost of Ownership (TCO): Consider not just the upfront cost but the long-term value, including durability, maintenance, and potential savings on replacements. High-quality totes may have a higher initial cost but could save money over time.

-

Negotiate Terms: Engage suppliers in discussions about payment terms, delivery schedules, and possible discounts for early payment or bulk orders. Building a good relationship can lead to more favorable terms.

-

Research Market Prices: Understanding the market landscape can provide leverage in negotiations. Buyers should compare quotes from multiple suppliers to ensure competitive pricing.

-

Assess Logistics Costs: Evaluate the total shipping costs, including potential tariffs, to avoid surprises. Opting for suppliers closer to the point of use can reduce shipping costs and lead times.

In conclusion, understanding the cost structure and pricing dynamics of plastic tote manufacturers is essential for international B2B buyers. By considering these factors and employing strategic negotiation techniques, businesses can secure cost-effective solutions that meet their operational needs.

Illustrative image related to plastic tote manufacturers

Alternatives Analysis: Comparing plastic tote manufacturers With Other Solutions

Exploring Alternatives to Plastic Tote Manufacturers

In the quest for efficient storage and transportation solutions, plastic tote manufacturers have emerged as a popular choice for businesses across various sectors. However, as industries evolve, it is essential to consider alternative solutions that may better suit specific needs. This analysis will compare plastic totes with two viable alternatives: metal containers and cardboard boxes, examining performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Plastic Tote Manufacturers | Metal Containers | Cardboard Boxes |

|---|---|---|---|

| Performance | High durability and stackable; resistant to moisture and chemicals | Extremely durable; offers high protection; heavy-duty | Lightweight but less durable; susceptible to moisture |

| Cost | Moderate initial investment; long lifespan can reduce long-term costs | Higher upfront cost; often justified by longevity | Low initial cost; less economical over time due to replacements |

| Ease of Implementation | Easy to integrate into existing systems; various sizes available | May require modifications to storage systems | Simple to set up; flexible sizing options |

| Maintenance | Minimal; easy to clean and reuse | Requires occasional maintenance; can rust if not treated | High turnover; must be replaced frequently |

| Best Use Case | Ideal for warehousing, distribution, and recycling applications | Suitable for heavy-duty industrial applications and long-term storage | Best for short-term storage and shipping, especially in dry environments |

Detailed Breakdown of Alternatives

Metal Containers

Metal containers offer exceptional durability and are often used in heavy-duty applications. Their robust construction provides superior protection for goods, making them ideal for industries that require secure storage solutions. However, the initial investment is significantly higher compared to plastic totes. Additionally, metal containers can be heavier and may require specific handling equipment, which can complicate implementation. Despite these drawbacks, their longevity and resistance to extreme conditions make them a strong contender for industries that prioritize durability.

Cardboard Boxes

Cardboard boxes are the most economical option available, often preferred for their lightweight nature and ease of use. They are widely used for shipping and storage in various sectors due to their flexibility in sizing and stacking capabilities. However, cardboard is not as durable as plastic or metal and is prone to damage from moisture and physical stress. This can lead to higher replacement costs over time. While they are perfect for short-term use and dry environments, businesses looking for long-term solutions might find them lacking.

Conclusion: How to Choose the Right Solution for Your Needs

When evaluating storage and transportation solutions, B2B buyers must consider their specific requirements, including durability, cost, and intended use. Plastic totes offer a balanced approach with their durability and versatility, making them suitable for a wide range of applications. However, industries with heavy-duty requirements might benefit from investing in metal containers, while those focused on cost-effectiveness and short-term solutions may opt for cardboard boxes. Understanding these alternatives allows buyers to make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for plastic tote manufacturers

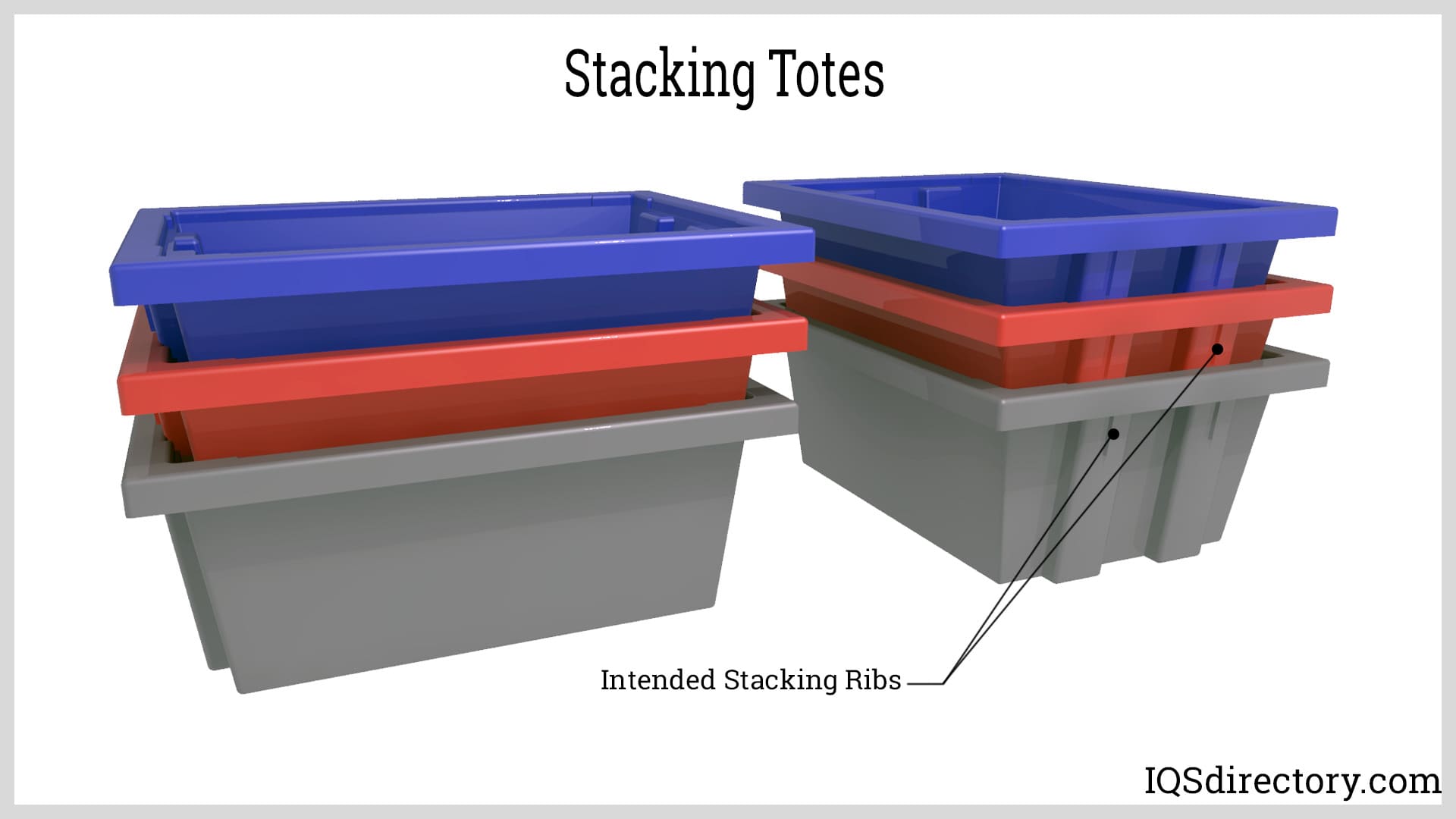

What Are the Key Technical Properties of Plastic Totes for Manufacturers?

When evaluating plastic totes, several technical specifications are crucial for ensuring they meet your operational needs. Understanding these properties helps in selecting the right product for your specific applications, whether for storage, transportation, or warehousing.

1. Material Grade

Plastic totes are primarily made from various grades of polyethylene, such as High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE). HDPE is known for its strength and durability, making it suitable for heavy-duty applications. In contrast, LDPE offers flexibility and is often used for lighter, less demanding tasks. Choosing the right material grade is essential for ensuring that the tote can withstand the intended load and environmental conditions.

2. Load Capacity

The load capacity indicates how much weight a plastic tote can safely hold without compromising its structural integrity. This specification is vital for logistics and warehousing operations, where overloading can lead to product damage or safety hazards. For example, heavy-duty totes may support loads exceeding 500 lbs, making them ideal for industrial applications.

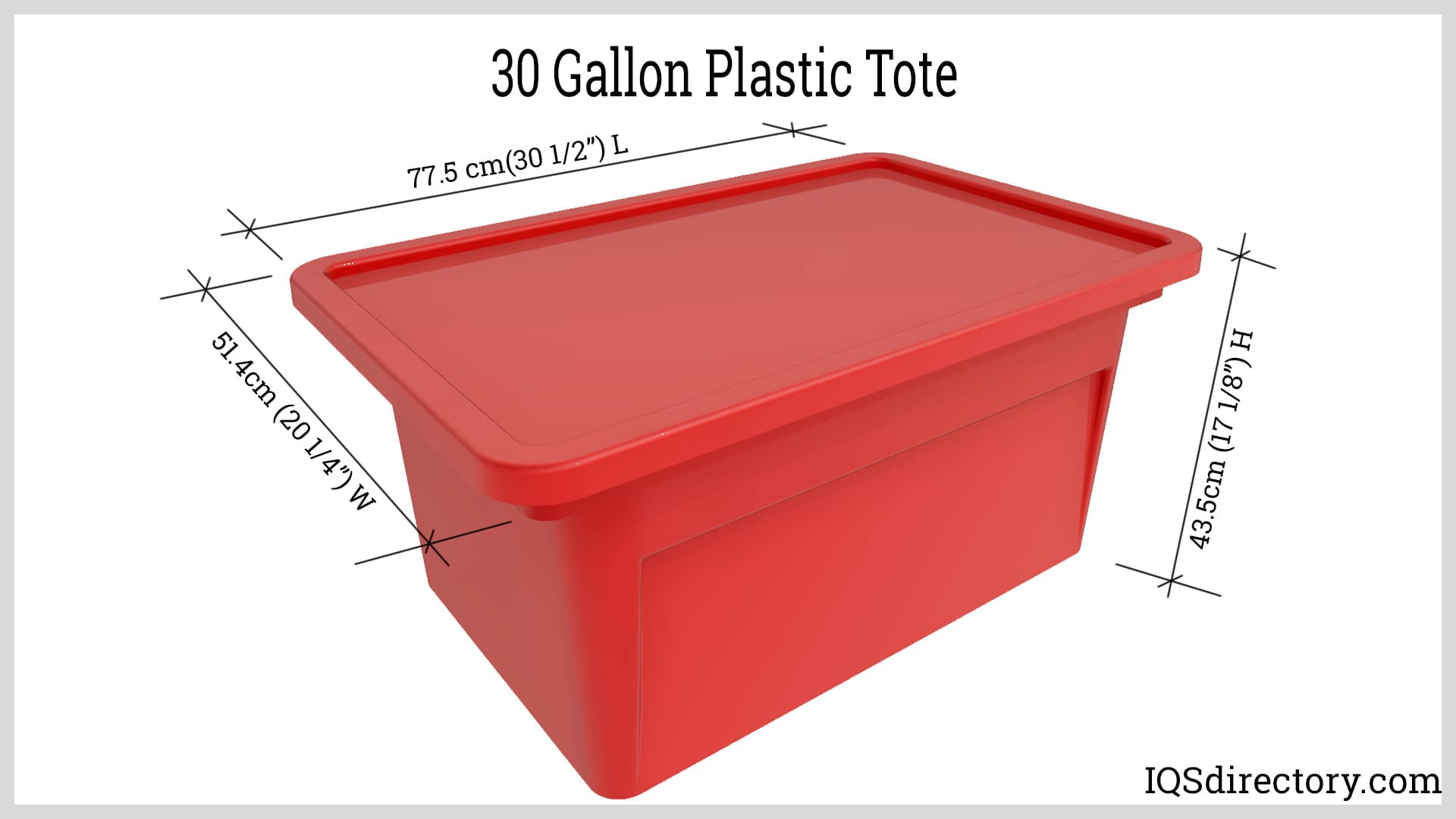

3. Dimensions and Volume

Understanding the dimensions (length, width, height) and volume of a tote is critical for optimizing storage space. This information helps buyers ensure compatibility with existing shelving systems or transport vehicles. Accurate dimensions also facilitate effective inventory management, enabling businesses to maximize space utilization.

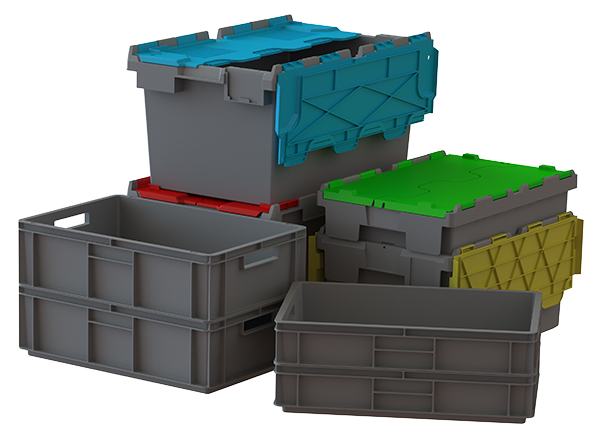

4. Stackability and Nestability

Stackability refers to the ability of totes to be securely stacked on top of one another, which is crucial for saving floor space in warehouses. Nestability allows empty totes to be nested within one another, reducing shipping costs and storage space when they are not in use. These features enhance operational efficiency and contribute to better organization in storage areas.

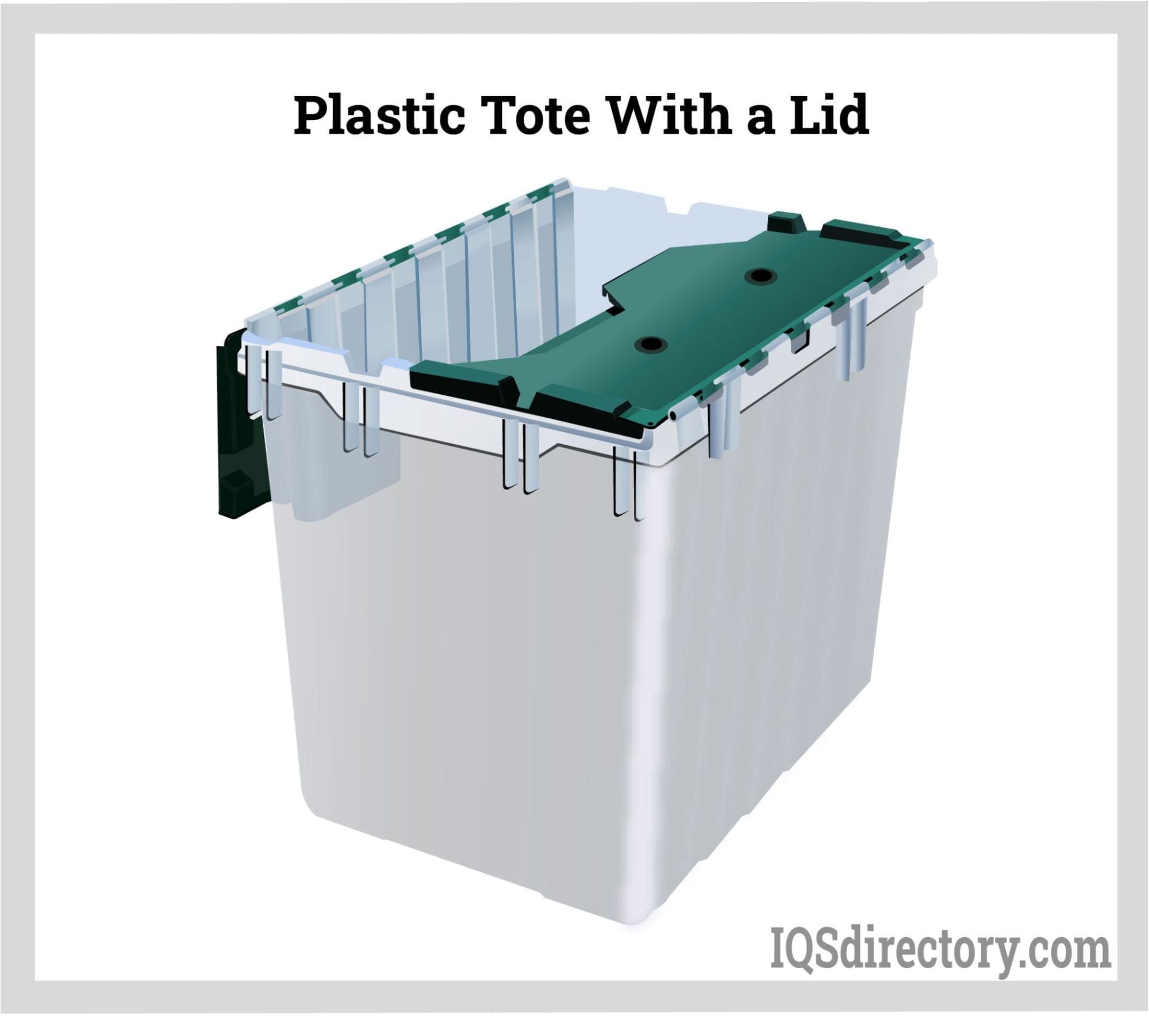

5. Sealability

Some plastic totes come equipped with features such as locking mechanisms or hasps for sealing. This is particularly important for sensitive or valuable items that require additional security during transport. Sealability ensures that contents remain protected from tampering, spillage, or contamination.

6. Environmental Impact

More manufacturers are focusing on eco-friendly options. Totes made from recycled materials or those designed for reusability can significantly lower your company’s carbon footprint. Understanding the environmental impact of the materials used can also influence purchasing decisions, especially for companies committed to sustainability.

What Are Common Trade Terms Used in the Plastic Tote Manufacturing Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of plastic totes, an OEM might design and manufacture totes that are then branded and sold by a different company. Understanding OEM relationships can help buyers identify potential partnerships or sourcing options.

Illustrative image related to plastic tote manufacturers

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers, as it can affect inventory management and overall costs. Knowing the MOQ helps you plan your purchases and avoid overstocking or understocking issues.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This process is vital for comparing costs and ensuring you receive competitive pricing. Providing detailed specifications in an RFQ can lead to more accurate and favorable quotes.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce. They outline the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is critical for international transactions, helping to clarify shipping costs and responsibilities.

5. Tare Weight

Tare weight is the weight of the container (in this case, the plastic tote) without its contents. Understanding tare weight is important for logistics and inventory management, as it allows for accurate calculations of shipping costs based on the total weight of goods being transported.

Illustrative image related to plastic tote manufacturers

6. Lead Time

Lead time refers to the amount of time it takes from placing an order to the delivery of the product. In the context of plastic totes, understanding lead times helps businesses plan their operations and manage inventory more effectively, ensuring they have the necessary materials when needed.

By familiarizing yourself with these technical properties and trade terms, you can make informed decisions that enhance your operational efficiency and improve your supply chain management.

Navigating Market Dynamics and Sourcing Trends in the plastic tote manufacturers Sector

What Are the Current Market Dynamics and Key Trends in the Plastic Tote Manufacturing Sector?

The plastic tote manufacturing sector is experiencing significant growth driven by several global factors. One of the primary drivers is the rising demand for efficient logistics and supply chain solutions. As businesses increasingly prioritize streamlined operations, plastic totes are becoming essential for storage, transportation, and inventory management across various industries, including retail, e-commerce, and manufacturing. In regions such as Africa, South America, the Middle East, and Europe, there is a noticeable shift towards automation and digitalization in warehousing, which is further propelling the demand for robust and compatible storage solutions.

Emerging technologies are also reshaping the sourcing landscape. The integration of Internet of Things (IoT) devices allows for real-time tracking and monitoring of inventory levels, enabling businesses to optimize their supply chains effectively. Additionally, advancements in plastic manufacturing techniques, such as injection molding and 3D printing, are enhancing product customization options, allowing manufacturers to cater to specific buyer needs more efficiently. International buyers from regions like Saudi Arabia and Brazil are increasingly looking for suppliers who can offer not only high-quality products but also innovative solutions that align with their operational goals.

Another trend to note is the increasing importance of supplier reliability and responsiveness. As global supply chains become more interconnected, buyers are seeking manufacturers who can ensure timely delivery and consistent quality. This dynamic is fostering partnerships that prioritize long-term collaboration over short-term transactions, enabling businesses to adapt more swiftly to market changes.

How Is Sustainability Influencing Sourcing Decisions in the Plastic Tote Manufacturing Sector?

Sustainability is becoming a pivotal factor in the sourcing strategies of international B2B buyers. The environmental impact of plastic production and disposal has prompted many businesses to seek more sustainable solutions. Manufacturers are responding by innovating with eco-friendly materials and processes, such as using recycled plastics and bio-based polymers. These alternatives not only reduce the carbon footprint but also appeal to a growing consumer base that prioritizes environmental responsibility.

Ethical sourcing is increasingly critical in the plastic tote industry. Buyers are looking for suppliers that adhere to ethical labor practices and maintain transparency throughout their supply chains. Certifications such as ISO 14001 for environmental management and FSC for responsible sourcing are becoming essential for companies aiming to prove their commitment to sustainability. By choosing certified manufacturers, international buyers can enhance their brand reputation and meet the expectations of environmentally conscious consumers.

Furthermore, the rise of circular economy principles is influencing sourcing decisions. Companies are actively seeking partnerships with manufacturers who can facilitate the recycling and repurposing of plastic totes at the end of their lifecycle. This not only minimizes waste but also provides businesses with a competitive edge in a market increasingly focused on sustainability.

What Is the Evolution of the Plastic Tote Manufacturing Sector and Its Relevance to B2B Buyers?

The plastic tote manufacturing sector has evolved significantly over the past few decades. Initially focused on basic storage solutions, the industry has transitioned to offering a diverse range of products tailored to specific applications and industries. The introduction of heavy-duty totes designed for industrial use, as well as customizable options for branding and functional enhancements, reflects the growing demands of B2B buyers.

Illustrative image related to plastic tote manufacturers

In recent years, the shift towards automation in warehouses has further influenced product design and functionality. Manufacturers are now designing totes that integrate seamlessly with automated picking systems, thereby optimizing efficiency and reducing operational costs. This evolution underscores the importance of selecting a supplier that not only understands the historical context of plastic totes but also anticipates future trends and technological advancements.

For international buyers, understanding this evolution is crucial. It allows them to make informed decisions when sourcing plastic totes that align with their operational needs while also considering sustainability and innovation. As the sector continues to grow, staying abreast of these developments will be essential for maintaining a competitive edge in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of plastic tote manufacturers

-

How do I solve challenges in sourcing reliable plastic tote manufacturers?

To effectively source reliable plastic tote manufacturers, begin by conducting thorough market research to identify potential suppliers in your desired regions, such as Africa, South America, the Middle East, and Europe. Utilize industry directories and trade platforms to find manufacturers with positive reviews and established reputations. It’s crucial to request product samples and verify certifications related to quality and safety standards. Additionally, consider visiting manufacturing facilities if possible, or engage third-party services for audits to ensure compliance and reliability. -

What is the best type of plastic tote for heavy-duty applications?

For heavy-duty applications, look for plastic totes made from high-density polyethylene (HDPE) or polypropylene, as these materials offer superior strength and durability. Heavy-duty attached lid totes are particularly effective for protecting contents during transportation and storage, as they are designed to withstand significant stacking loads. Ensure the totes have features like molded grip handles and nestable designs to maximize efficiency in both use and storage. Always check the manufacturer’s specifications for load capacities and dimensions that fit your operational needs. -

What customization options are available when ordering plastic totes?

Many manufacturers offer customization options such as sizes, colors, and branding features. You can request specific dimensions to fit your storage or transport needs and choose from various colors for easy identification. Some manufacturers also provide hot-stamping or screen-printing services for adding your logo or other branding elements to the totes. Before placing an order, confirm the lead times for customization and ensure that these options align with your operational requirements. -

What are the minimum order quantities (MOQs) for plastic totes?

Minimum order quantities (MOQs) for plastic totes can vary significantly among manufacturers, often depending on the type of tote and customization options. Standard industrial totes may have MOQs ranging from 100 to 500 units, while customized products could require larger orders. It’s advisable to discuss your specific needs with potential suppliers and negotiate MOQs that align with your budget and storage capacities. Some manufacturers may be willing to accommodate smaller orders for first-time buyers or pilot projects. -

What payment terms should I expect when dealing with plastic tote manufacturers?

Payment terms can vary widely depending on the manufacturer and the size of your order. Common arrangements include partial payments upfront (usually 30-50%) with the balance due upon delivery or net 30/60 days terms after receipt of goods. It’s essential to clarify payment methods accepted (e.g., wire transfer, credit card) and any potential financing options. For international orders, be aware of currency exchange rates and transaction fees that may affect your total costs. -

How do I ensure quality assurance (QA) when sourcing plastic totes?

To ensure quality assurance, first verify that the manufacturer adheres to industry standards and certifications, such as ISO 9001. Request detailed information on their quality control processes, including testing methods for material durability and structural integrity. Consider arranging for third-party inspections or audits to assess production practices before shipment. Additionally, maintain open communication with the supplier throughout the manufacturing process to address any concerns promptly. -

What logistics considerations should I keep in mind when importing plastic totes?

When importing plastic totes, consider factors such as shipping methods, lead times, and customs regulations. Air freight is faster but more expensive, while sea freight is cost-effective for large orders, albeit slower. Understand the import tariffs and duties applicable to your products in your country. Collaborating with a logistics partner experienced in international trade can help navigate these complexities and ensure timely delivery while minimizing costs. -

How can I assess the reliability of a plastic tote manufacturer?

To assess the reliability of a plastic tote manufacturer, start by reviewing their track record, including years in business and client testimonials. Seek references from other B2B buyers in your industry to gain insights into their experiences. Additionally, evaluate their production capabilities and technology used, as well as their response times to inquiries. A trustworthy manufacturer should be transparent about their processes and willing to provide documentation for quality certifications and compliance with international standards.

Top 5 Plastic Tote Manufacturers Manufacturers & Suppliers List

1. Correct Products – Industrial Storage Totes

Domain: correctproducts.com

Registered: 2000 (25 years)

Introduction: This company, Correct Products – Industrial Storage Totes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Versatote – Durable Plastic Tote Boxes

Domain: versatote.com

Registered: 2015 (10 years)

Introduction: Versatote is a manufacturer of robust plastic tote boxes designed for the storage and warehousing industries. Key features include:

– Designed for longevity and durability.

– Continuous development and improvement of the product range to meet customer requirements.

– Products are made with a material additive from UBQ that lowers environmental impact.

– Manufactured in a purpose-built, energy-…

3. Bonar Plastics – Plastic Bins & Insulated Containers

Domain: bonarplastics.com

Registered: 2000 (25 years)

Introduction: Plastic Bins, Boxes & Totes, Plastic & Steel Hoppers, Food Grade Liquid Totes, Polar Insulated Containers, Polar Insulated Fish Boxes, Insulated Bag-in-the-Box, Sanitary Pallets, Wine & Spirits Carts, Drums, & Containments, Ag Chem IBC Totes.

4. Plastic Containers – Key Features of Totes

Domain: plastic-containers.net

Registered: 2002 (23 years)

Introduction: Plastic totes are plastic containers used for the transportation or storage of small items. They are built in solid box shapes and can be designed to collapse for space-saving when not in use. Features include hinged or removable tops for easy access. Key features of plastic totes include:

– Available in various shapes, sizes, and colors.

– Suitable for general-purpose and specialized applications…

5. U.S. Plastic Corp. – Storage Totes and Boxes

Domain: usplastic.com

Registered: 1996 (29 years)

Introduction: U.S. Plastic Corp. offers an extensive line of storage totes and boxes suitable for various storage needs. The category includes storage containers in multiple sizes, such as totes with attached flip-top lids, dividable grid containers, and small parts containers. Notable products include Quantum® latch containers and lids, Command Center chests, Stowaway® boxes with lids, and Hefty® Hi-Rise™ stor…

Strategic Sourcing Conclusion and Outlook for plastic tote manufacturers

How Can Strategic Sourcing Enhance Your Plastic Tote Procurement?

In summary, strategic sourcing is pivotal for international B2B buyers seeking plastic totes. By focusing on quality, durability, and compatibility with existing logistics systems, companies can ensure that they invest in products that not only meet their immediate storage needs but also contribute to long-term operational efficiency. The shift towards environmentally friendly materials, as seen with manufacturers like Versatote, underscores the importance of sustainability in procurement decisions.

Buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize partnerships with manufacturers who demonstrate innovation and responsiveness to market demands. Engaging with suppliers that offer customization options, competitive pricing, and robust support will further enhance supply chain resilience.

Looking forward, the landscape for plastic tote manufacturers is ripe with opportunities. As global supply chains evolve, now is the time to assess your sourcing strategies and align them with future needs. Take action today by exploring partnerships that can help streamline your logistics operations while ensuring you remain at the forefront of industry advancements. Your strategic sourcing decisions will define your competitive edge in the coming years.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.