A B2B Buyer’s Guide to Heavy Duty L Brackets: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for heavy duty l brackets

In the competitive landscape of industrial and commercial applications, sourcing heavy duty L brackets that meet stringent performance and durability standards can pose significant challenges for B2B buyers. Whether you’re in Nigeria, Saudi Arabia, or any region across Europe and South America, ensuring that the brackets you choose can support substantial loads while withstanding environmental factors is crucial for the integrity of your projects. This comprehensive guide delves into the diverse types of heavy duty L brackets available in the market, their various applications, and critical considerations for supplier vetting.

From the materials used in production to the specific weight capacities of each bracket, our guide empowers you to make informed purchasing decisions tailored to your business needs. We will explore cost considerations, installation tips, and the latest trends in design and functionality, ensuring you are well-equipped to navigate the complexities of international sourcing.

Understanding the unique requirements of different markets is essential, especially when dealing with varying standards and regulations across regions. By leveraging the insights provided in this guide, B2B buyers can confidently select the right heavy duty L brackets that enhance safety, reliability, and efficiency in their operations, ultimately driving greater value for their projects and businesses.

Understanding heavy duty l brackets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heavy Duty Steel L Brackets | Made from thick steel; high weight capacity; corrosion-resistant coatings available | Warehousing, industrial shelving, furniture | Pros: Extremely durable, suitable for heavy loads. Cons: Heavier and may require more robust installation. |

| Stainless Steel L Brackets | Rust-resistant; aesthetic brushed finish; available in various sizes and thicknesses | Kitchen installations, commercial displays | Pros: Corrosion-resistant, visually appealing. Cons: Higher cost compared to other materials. |

| Heavy Duty Corner Braces | Triangular design for added stability; available in multiple lengths; high load ratings | Structural support in construction, cabinetry | Pros: Provides excellent support for corners. Cons: May not be as versatile in application as flat brackets. |

| Adjustable L Brackets | Feature adjustable arms for customizable shelf heights; typically lighter materials | Retail displays, temporary installations | Pros: Flexibility in design; easy to install. Cons: Lower weight capacity than fixed options. |

| Floating L Brackets | Concealed installation for a clean look; designed for aesthetic applications | Residential interiors, modern furniture | Pros: Enhances visual appeal; saves space. Cons: Limited load capacity; requires precise installation. |

What are the Characteristics of Heavy Duty Steel L Brackets?

Heavy duty steel L brackets are known for their exceptional strength and durability, making them ideal for applications that require substantial load-bearing capabilities. Typically constructed from thick steel, these brackets often feature corrosion-resistant coatings to enhance longevity in various environments. They are widely used in warehousing, industrial shelving, and furniture applications, where reliability is paramount. When purchasing, buyers should consider the specific load capacity and installation requirements, as heavier brackets may necessitate more robust mounting hardware.

Illustrative image related to heavy duty l brackets

How Do Stainless Steel L Brackets Differ from Other Types?

Stainless steel L brackets stand out due to their resistance to rust and corrosion, making them suitable for environments exposed to moisture, such as kitchens and commercial displays. They come in various sizes and thicknesses, allowing for flexibility in design. The aesthetic appeal of a brushed finish also makes them a popular choice for visible installations. B2B buyers should weigh the higher costs associated with stainless steel against the long-term benefits of durability and maintenance savings.

Why Choose Heavy Duty Corner Braces for Structural Support?

Heavy duty corner braces feature a triangular design that provides superior stability and load distribution, making them essential in construction and cabinetry applications. Available in multiple lengths and capable of supporting significant weights, these braces are ideal for reinforcing corners in furniture and structural frameworks. Buyers should consider the load ratings and installation methods, ensuring they select the right thickness and size for their specific needs.

What Advantages Do Adjustable L Brackets Offer?

Adjustable L brackets are designed with movable arms that allow for customizable shelf heights, making them particularly useful in retail displays and temporary installations. Typically made from lighter materials, they are easy to install and reposition. However, their weight capacity may not match that of fixed brackets, which is a critical consideration for buyers looking for versatile yet reliable solutions.

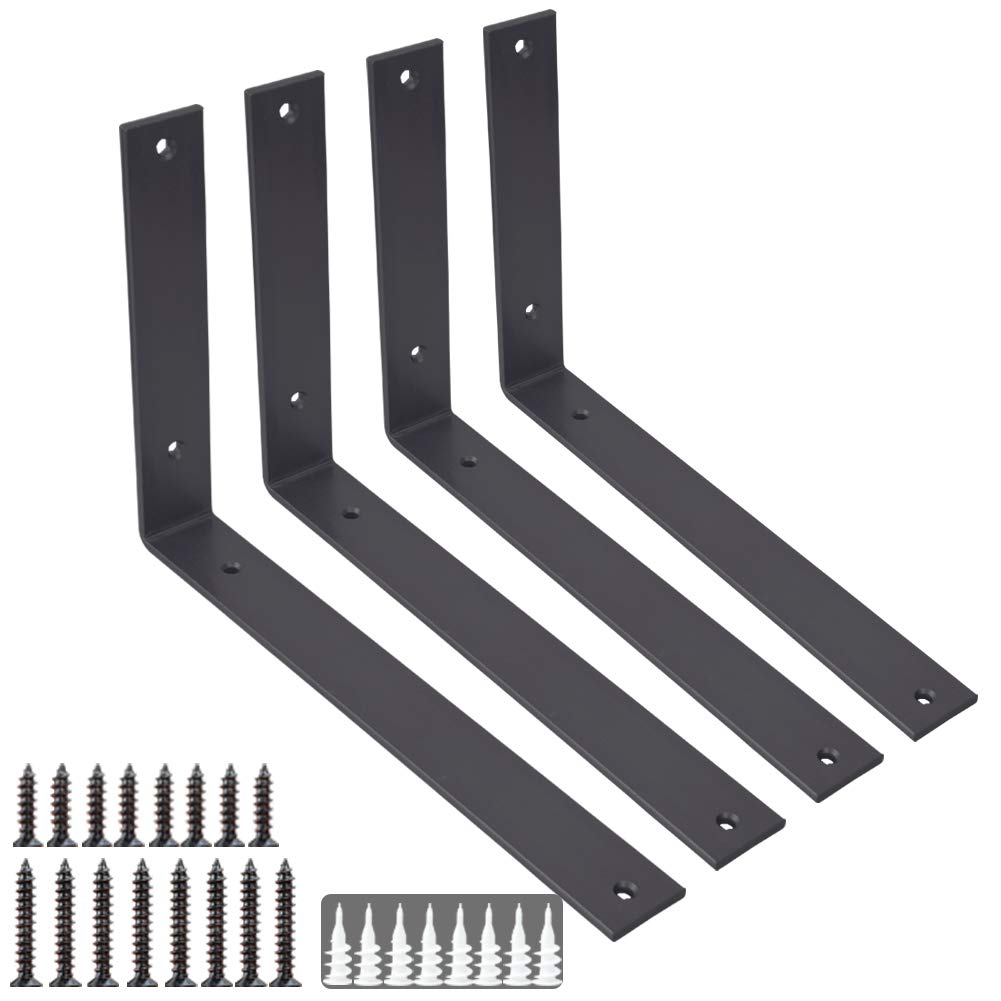

Illustrative image related to heavy duty l brackets

How Do Floating L Brackets Enhance Aesthetic Appeal?

Floating L brackets provide a sleek, modern look by concealing their installation, which is particularly desirable in residential interiors and contemporary furniture design. While they offer a clean aesthetic, these brackets typically have limited load capacities, necessitating careful consideration of the intended application. Buyers should ensure precise installation to maximize their effectiveness while balancing aesthetic desires with functional requirements.

Key Industrial Applications of heavy duty l brackets

| Industry/Sector | Specific Application of heavy duty l brackets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Renovation | Supporting heavy shelves in commercial spaces | Ensures structural integrity and safety in installations | Material strength, corrosion resistance, and load capacity |

| Retail & Display | Mounting display units for merchandise | Enhances product visibility while ensuring stability | Aesthetic design, weight capacity, and ease of installation |

| Manufacturing | Securing machinery and equipment | Provides durable support for operational efficiency | High load ratings, material durability, and compliance with safety standards |

| Hospitality | Installing shelving in kitchens and storage areas | Maximizes space utilization and improves organization | Resistance to moisture, ease of cleaning, and load capacity |

| Automotive | Supporting heavy parts in repair shops | Increases workshop efficiency and safety | Weight limits, compatibility with existing structures, and ease of installation |

How Are Heavy Duty L Brackets Used in Construction and Renovation?

In the construction and renovation sector, heavy duty L brackets are vital for supporting heavy shelves and fixtures in commercial spaces. They provide the necessary structural integrity to hold substantial loads, which is crucial for safety compliance. Buyers in this industry should prioritize brackets made from durable materials that can withstand environmental factors, particularly in regions with high humidity or temperature fluctuations, like parts of Africa and the Middle East.

What Role Do Heavy Duty L Brackets Play in Retail and Display?

In retail environments, heavy duty L brackets are used to mount display units securely. This enhances product visibility while ensuring that the displays remain stable and safe for customer interaction. Retailers must consider the aesthetic appeal of the brackets, as well as their load capacity, to maintain a professional appearance. Sourcing brackets that are easy to install and have a finished look is essential for maintaining the overall store design, particularly in competitive markets in Europe and South America.

How Are Heavy Duty L Brackets Essential in Manufacturing?

In manufacturing settings, heavy duty L brackets are employed to secure machinery and equipment. This ensures that operational processes run smoothly and safely, minimizing the risk of accidents. Businesses should focus on sourcing brackets with high load ratings and those made from materials that meet industry safety standards. For manufacturers in regions such as Nigeria and Saudi Arabia, understanding local compliance regulations is crucial when selecting the right brackets for their operations.

Illustrative image related to heavy duty l brackets

How Do Heavy Duty L Brackets Enhance Hospitality Operations?

In the hospitality industry, heavy duty L brackets are often installed in kitchens and storage areas to support shelving. This maximizes space utilization and improves organization, which is essential for efficient operations. Buyers should look for brackets that are resistant to moisture and easy to clean, as these attributes are critical in food service environments. Additionally, ensuring that the brackets can support the weight of kitchen equipment and supplies is vital for maintaining operational efficiency.

What Benefits Do Heavy Duty L Brackets Offer in Automotive Applications?

In automotive repair shops, heavy duty L brackets are used to support heavy parts and tools, enhancing workshop efficiency and safety. These brackets must be capable of bearing significant loads while being compatible with existing structures. Automotive businesses should prioritize sourcing brackets that offer high weight limits and are easy to install, as this can significantly reduce downtime during repairs. Understanding the specific requirements of automotive applications is essential for ensuring safety and functionality in the workspace.

3 Common User Pain Points for ‘heavy duty l brackets’ & Their Solutions

Scenario 1: The Challenge of Insufficient Load Capacity

The Problem: Many B2B buyers face difficulties when selecting heavy-duty L brackets that can adequately support their specific applications, especially in industries such as construction, warehousing, or retail. A common frustration arises when brackets do not meet the necessary weight capacities for heavy shelves, leading to structural failures or the need for costly replacements. This often occurs when buyers overlook the weight specifications or do not fully understand the implications of shelf materials and bracket thickness on load-bearing capabilities.

Illustrative image related to heavy duty l brackets

The Solution: To overcome this issue, it is crucial for buyers to conduct thorough assessments of their shelving needs before purchasing heavy-duty L brackets. Start by identifying the maximum weight each shelf will hold, considering not only the weight of the items but also any potential dynamic loads (e.g., movement during handling). When sourcing brackets, opt for those with clear load capacity ratings, ensuring they exceed your requirements by at least 20-30% for safety. For instance, if a shelf will hold 300 lbs, choose brackets rated for at least 375 lbs. Additionally, consider the material and thickness of the brackets; thicker brackets generally provide better support and stability. Buyers should consult with suppliers for detailed specifications and potentially request samples to verify performance under real-world conditions.

Scenario 2: Installation Complications Leading to Structural Issues

The Problem: Another common challenge for B2B buyers is the installation process of heavy-duty L brackets, which can become complex, especially in commercial settings where speed is essential. Improper installation can lead to misalignment, inadequate support, or even damage to the wall or shelving units, causing operational delays and safety hazards. This is particularly relevant in regions where building materials and wall compositions can vary significantly.

The Solution: To mitigate installation issues, it is advisable to utilize a systematic approach. First, ensure that your installation team is equipped with the right tools and understands the specific requirements for the materials they are working with. For instance, when mounting on drywall, locate wall studs using a stud finder and use appropriate mounting screws (like #12 tapered wood screws or lag screws). Provide training on using laser levels to ensure brackets are installed straight and evenly. Additionally, consider creating a comprehensive installation guide tailored to your specific environment, incorporating best practices and common pitfalls. Engaging with a supplier that offers technical support and installation services can also provide valuable assistance, ensuring that brackets are installed correctly and safely.

Scenario 3: Material Corrosion and Longevity Concerns

The Problem: In various regions, particularly those with high humidity or corrosive environments, buyers often encounter issues with bracket durability. Corrosion can significantly weaken heavy-duty L brackets, leading to premature failures. This is a critical concern for businesses in sectors like food and beverage, pharmaceuticals, or outdoor retail, where environmental conditions can rapidly degrade materials.

The Solution: To address corrosion concerns, it is essential to select heavy-duty L brackets made from high-quality, corrosion-resistant materials such as stainless steel or powder-coated finishes. When sourcing these brackets, verify their resistance ratings against specific environmental factors. It’s also beneficial to conduct regular maintenance checks on installed brackets to ensure they remain free from rust and corrosion. Implementing a preventive maintenance schedule, including periodic inspections and cleaning, can prolong the lifespan of the brackets. For businesses operating in particularly harsh environments, consider investing in brackets that have additional protective coatings or treatments, which can provide extra durability against corrosion and wear. Consulting with manufacturers about the best options for your specific conditions can lead to more informed decisions and ultimately save costs on replacements and repairs.

Strategic Material Selection Guide for heavy duty l brackets

When selecting heavy-duty L brackets for various applications, the choice of material significantly influences performance, durability, and suitability for specific environments. This guide analyzes four common materials used in manufacturing heavy-duty L brackets: steel, stainless steel, aluminum, and plastic composites. Each material has unique properties, advantages, and limitations, which are critical for international B2B buyers to consider.

What Are the Key Properties of Steel in Heavy-Duty L Brackets?

Steel is a widely used material for heavy-duty L brackets due to its high strength and load-bearing capacity. It typically has excellent temperature resistance, making it suitable for various environments. However, standard carbon steel is prone to corrosion, which can limit its application in humid or outdoor settings unless it is treated or coated.

Pros: Steel brackets are generally cost-effective and can support heavy loads, making them ideal for industrial and commercial applications. They are also relatively easy to manufacture and can be produced in various sizes and shapes.

Cons: The main drawback of steel is its susceptibility to rust and corrosion without protective coatings. This can lead to a shorter lifespan in adverse conditions, requiring additional maintenance.

Impact on Application: Steel brackets are suitable for heavy loads in dry environments but may require additional treatment for outdoor use, such as galvanization.

How Does Stainless Steel Compare for Heavy-Duty L Brackets?

Stainless steel is known for its corrosion resistance and durability, making it an excellent choice for heavy-duty L brackets exposed to moisture or chemicals. It maintains its strength at elevated temperatures and is less likely to rust compared to carbon steel.

Pros: The primary advantage of stainless steel is its longevity and low maintenance requirements. It is also aesthetically pleasing, which can be important for visible applications.

Cons: The main limitation is the higher cost compared to carbon steel. Additionally, stainless steel can be more challenging to machine, which may increase manufacturing complexity.

Impact on Application: Stainless steel brackets are ideal for environments with high humidity or exposure to corrosive substances, such as kitchens or outdoor settings.

What Are the Benefits of Using Aluminum for Heavy-Duty L Brackets?

Aluminum is lightweight and resistant to corrosion, making it a popular choice for applications where weight reduction is crucial. It has a good strength-to-weight ratio and performs well under moderate loads.

Pros: The lightweight nature of aluminum makes it easy to handle and install. It also does not rust, which is advantageous for outdoor applications.

Cons: Aluminum has a lower load-bearing capacity compared to steel and stainless steel, which may limit its use in heavy-duty applications. It can also be more expensive than carbon steel.

Impact on Application: Aluminum brackets are suitable for lightweight shelving and installations where corrosion resistance is essential, but they may not be ideal for extremely heavy loads.

Illustrative image related to heavy duty l brackets

How Do Plastic Composites Perform in Heavy-Duty L Brackets?

Plastic composites, often reinforced with materials like fiberglass, offer a unique alternative for heavy-duty L brackets. They are lightweight, resistant to corrosion, and can be molded into complex shapes.

Pros: The main advantage of plastic composites is their resistance to corrosion and moisture, making them suitable for various environments. They are also non-conductive, which can be beneficial in electrical applications.

Cons: The major limitation is their lower load-bearing capacity compared to metals. They may also be less durable under extreme temperatures and can degrade over time when exposed to UV light.

Impact on Application: Plastic composite brackets are ideal for applications where weight and corrosion resistance are critical, but they may not be suitable for heavy-duty industrial uses.

Summary Table of Material Selection for Heavy-Duty L Brackets

| Material | Typical Use Case for Heavy Duty L Brackets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Industrial shelving, heavy-duty supports | High strength and load-bearing capacity | Prone to corrosion without treatment | Low |

| Stainless Steel | Outdoor and corrosive environments | Excellent corrosion resistance and durability | Higher cost and manufacturing complexity | High |

| Aluminum | Lightweight shelving, portable applications | Lightweight and corrosion-resistant | Lower load capacity compared to steel | Medium |

| Plastic Composites | Non-metal applications, electrical use | Corrosion resistance and lightweight | Lower load capacity and potential UV degradation | Medium |

This material selection guide provides international B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in heavy-duty L brackets. Understanding these factors will help in making informed purchasing decisions that align with specific application requirements and environmental conditions.

Illustrative image related to heavy duty l brackets

In-depth Look: Manufacturing Processes and Quality Assurance for heavy duty l brackets

What Are the Main Stages in the Manufacturing Process of Heavy Duty L Brackets?

The manufacturing process of heavy-duty L brackets involves several critical stages that ensure durability and functionality. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality raw materials, typically steel or stainless steel, known for their strength and corrosion resistance. These materials undergo rigorous testing to ensure they meet specific mechanical properties. Suppliers often provide certificates of compliance to verify material standards.

-

Forming Techniques: After preparation, the materials are shaped using various forming techniques such as stamping, bending, or laser cutting. Stamping involves using a die to cut the metal into the desired shape, while bending is often performed with hydraulic presses. Laser cutting allows for precise dimensions and clean edges, which are crucial for maintaining structural integrity.

-

Assembly: In this stage, the formed components are assembled into the final L bracket design. This may involve welding or bolting parts together, depending on the design specifications and required load capacity. Automated assembly lines can enhance efficiency and consistency, reducing the likelihood of human error.

-

Finishing Processes: The final stage involves applying protective coatings, such as powder coating or galvanization, to prevent rust and enhance aesthetic appeal. These finishes are critical for brackets intended for outdoor or industrial use, where exposure to harsh environments is a concern.

How Does Quality Assurance Ensure the Reliability of Heavy Duty L Brackets?

Quality assurance (QA) is paramount in the manufacturing of heavy-duty L brackets, ensuring that each product meets industry standards and customer expectations. Several international and industry-specific standards guide this process.

-

International Standards: Compliance with ISO 9001 is essential for manufacturers targeting international markets. This standard outlines a framework for quality management systems, emphasizing continuous improvement and customer satisfaction. For heavy-duty L brackets, adherence to ISO standards helps ensure consistent quality across production batches.

-

Industry-Specific Certifications: In addition to ISO, certain products may require compliance with CE marking or API standards, particularly if they are used in construction or industrial applications. These certifications indicate that the product meets essential health, safety, and environmental requirements.

-

Quality Control Checkpoints: The quality control process typically includes several checkpoints:

– Incoming Quality Control (IQC): This initial inspection verifies that raw materials meet specified standards before they are used in production.

– In-Process Quality Control (IPQC): During manufacturing, ongoing inspections ensure that processes adhere to established guidelines and specifications.

– Final Quality Control (FQC): After assembly and finishing, the final products undergo rigorous testing to confirm they meet load capacity requirements and are free from defects.

What Testing Methods Are Commonly Used for Heavy Duty L Brackets?

Several testing methods are employed to ensure the performance and reliability of heavy-duty L brackets. These methods help verify that the brackets can withstand specified loads without failure.

-

Load Testing: This involves applying a predetermined weight to the bracket to assess its strength and stability. Manufacturers often conduct both static and dynamic load tests to simulate real-world conditions.

-

Fatigue Testing: This testing evaluates how the brackets perform under repeated loading and unloading cycles. It helps identify potential points of failure over time, ensuring longevity and reliability.

-

Corrosion Resistance Testing: Especially for brackets intended for outdoor or industrial use, manufacturers may conduct salt spray tests or other corrosion tests to evaluate the effectiveness of protective coatings.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those sourcing from international suppliers, verifying the quality control processes is critical to ensure product reliability.

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality control checkpoints, and compliance with international standards. These audits provide insights into the supplier’s commitment to quality.

-

Requesting Quality Reports: Buyers can request detailed quality assurance reports that outline the results of IQC, IPQC, and FQC. These documents should include testing results and any corrective actions taken to address non-conformities.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections are particularly valuable for buyers in regions like Africa and South America, where local quality assurance standards may differ.

What Are the Nuances of Quality Control for International B2B Buyers?

Understanding the nuances of quality control is essential for B2B buyers operating in diverse markets. Key considerations include:

-

Regional Standards: Different regions may have varying quality standards and regulations. For example, European buyers may prioritize CE marking, while buyers in the Middle East may focus on local compliance requirements. Familiarity with these standards helps buyers navigate the complexities of international procurement.

-

Cultural Differences: Cultural attitudes toward quality and business practices can vary significantly. Building strong relationships with suppliers through effective communication and understanding local business customs can enhance collaboration and quality outcomes.

-

Logistics and Supply Chain Considerations: International logistics can impact quality control. Delays or mishandling during shipping can lead to product damage. Therefore, it’s vital for buyers to understand the logistics capabilities of their suppliers and incorporate quality checks during the shipping process.

In conclusion, a thorough understanding of manufacturing processes and quality assurance for heavy-duty L brackets not only enhances product reliability but also builds trust in supplier relationships. B2B buyers must prioritize quality and compliance to ensure that their sourcing efforts yield durable and dependable products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘heavy duty l brackets’

This guide aims to provide international B2B buyers with a practical checklist for sourcing heavy-duty L brackets. By following these steps, you can ensure that you make informed purchasing decisions that meet your project’s needs.

Illustrative image related to heavy duty l brackets

Step 1: Define Your Technical Specifications

Before you start sourcing, it’s essential to establish the technical requirements for your heavy-duty L brackets. Consider factors such as load capacity, dimensions, and material type. Knowing whether you need brackets for commercial or residential applications will help you filter suppliers effectively.

- Load Capacity: Determine the maximum weight the brackets must support.

- Dimensions: Specify the required length and thickness based on your shelving or structural needs.

- Material: Common options include stainless steel for corrosion resistance or iron for durability.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in heavy-duty L brackets. Look for suppliers with a solid track record in your region, particularly in Africa, South America, the Middle East, and Europe.

- Supplier Reviews: Read customer feedback and case studies to gauge reliability.

- Industry Experience: Prioritize suppliers with experience in your specific sector, as they may understand your unique requirements better.

Step 3: Evaluate Product Quality

Quality should be a top priority when sourcing heavy-duty L brackets. Request samples or detailed product specifications to assess the materials and construction methods used.

- Corrosion Resistance: Ensure the brackets are treated or coated to prevent rust, especially in humid environments.

- Design Features: Look for added features like countersunk mounting holes for easier installation and improved aesthetics.

Step 4: Verify Supplier Certifications

It’s crucial to confirm that your chosen suppliers meet industry standards and certifications. This step ensures the reliability and safety of the products you are purchasing.

- Quality Certifications: Look for ISO certifications or other relevant standards that indicate a commitment to quality.

- Compliance: Ensure that the products comply with local regulations, especially if you are importing them into your country.

Step 5: Request Competitive Quotes

Once you have identified potential suppliers, request quotes to compare pricing and terms. Be specific about your requirements to receive accurate estimates.

Illustrative image related to heavy duty l brackets

- Bulk Discounts: Inquire about pricing tiers for larger orders to maximize cost savings.

- Shipping Costs: Factor in shipping and handling fees, as these can significantly impact overall costs.

Step 6: Assess Customer Support and Warranty Options

Evaluate the level of customer support provided by the supplier, as well as any warranty options available for the products.

- Support Channels: Ensure there are multiple ways to reach customer service, such as phone, email, or live chat.

- Warranty Terms: Review warranty policies to understand what is covered and for how long, providing peace of mind in your investment.

Step 7: Finalize Your Order and Establish Payment Terms

After selecting a supplier, finalize your order while ensuring that payment terms are clear and mutually agreeable.

- Payment Methods: Confirm acceptable payment methods and any upfront costs.

- Order Confirmation: Get a written confirmation detailing the order specifics, including delivery timelines and return policies.

By following this checklist, you can streamline your sourcing process for heavy-duty L brackets, ensuring that you choose the right products and suppliers for your needs.

Comprehensive Cost and Pricing Analysis for heavy duty l brackets Sourcing

When sourcing heavy duty L brackets, understanding the cost structure and pricing nuances is essential for international B2B buyers. Here, we break down the critical components that influence pricing and offer actionable insights tailored to buyers in regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Heavy Duty L Brackets?

1. Materials

The choice of materials significantly affects the overall cost of heavy duty L brackets. Common materials include steel and stainless steel, with variations in thickness impacting strength and weight capacity. For instance, a 3/8″ thick steel bracket typically has a higher load capacity and durability compared to a 1/4″ counterpart, but it also comes at a higher price point. Corrosion-resistant coatings can further add to material costs but are essential for longevity, especially in humid or saline environments.

Illustrative image related to heavy duty l brackets

2. Labor and Manufacturing Overhead

Labor costs vary by region and can substantially influence the pricing of heavy duty L brackets. In countries with higher labor costs, such as those in Europe, the production expenses will be reflected in the final price. Additionally, manufacturing overhead, which includes utilities, equipment maintenance, and factory operations, must be accounted for. Efficient production processes can help mitigate these costs.

3. Tooling and Quality Control (QC)

Tooling costs involve the initial setup for production, including molds and machinery needed to manufacture specific bracket designs. Quality control is crucial for ensuring that brackets meet specified load capacities and safety standards. Buyers should inquire about QC processes and certifications, as these factors impact both cost and the reliability of the product.

4. Logistics and Transportation Costs

Shipping plays a vital role in the total cost structure, especially for international buyers. Factors such as the distance from the manufacturer, shipping method, and associated duties and tariffs can significantly affect pricing. Understanding Incoterms is critical; for instance, a DDP (Delivered Duty Paid) arrangement can simplify customs processes for buyers but may come with higher upfront costs.

5. Supplier Margin

Suppliers typically include a profit margin in their pricing. This margin can vary based on the supplier’s position in the market, their brand reputation, and the level of customer service they provide. It’s advisable for buyers to compare multiple suppliers to find the best balance of price and service.

Illustrative image related to heavy duty l brackets

What Influences the Pricing of Heavy Duty L Brackets?

1. Volume and Minimum Order Quantity (MOQ)

Volume purchases often lead to lower unit costs. Suppliers may offer discounts for bulk orders, which can be a significant factor for businesses looking to source large quantities. Understanding MOQ is essential; some suppliers may require higher minimums to justify production runs.

2. Specifications and Customization

Customization, such as specific sizes, shapes, or finishes, can affect pricing. While standard brackets may be more cost-effective, custom designs tailored to unique applications will generally incur additional costs. Buyers should weigh the necessity of customization against potential price increases.

3. Quality and Certifications

Brackets that meet international standards or possess specific quality certifications may come at a premium. However, investing in higher-quality products can lead to lower total costs in the long run due to reduced failure rates and replacement needs.

What Are Some Buyer Tips for Sourcing Heavy Duty L Brackets?

1. Negotiation Tactics

Engaging in price negotiations can yield favorable outcomes. Consider leveraging bulk purchasing or long-term contracts to secure better pricing. Building a relationship with suppliers can also lead to better terms and potential discounts.

2. Understanding Total Cost of Ownership (TCO)

When evaluating suppliers, consider not only the purchase price but also the TCO, which includes installation, maintenance, and potential replacement costs. Higher-quality brackets may have a higher upfront cost but can save money over time.

3. Navigating Pricing Nuances for International Buyers

International buyers should be aware of fluctuating currency exchange rates and their impact on pricing. Additionally, understanding local regulations and import duties is crucial for accurately calculating landed costs.

Disclaimer on Indicative Prices

Prices for heavy duty L brackets can vary widely based on the factors discussed. Always seek multiple quotes and conduct thorough due diligence to ensure that you are getting the best value for your specific needs.

Illustrative image related to heavy duty l brackets

Alternatives Analysis: Comparing heavy duty l brackets With Other Solutions

When evaluating solutions for structural support in various applications, heavy duty L brackets stand out for their strength and versatility. However, understanding alternative solutions can help B2B buyers make informed decisions tailored to specific project requirements. This analysis compares heavy duty L brackets with two viable alternatives: heavy duty corner braces and floating shelf brackets.

| Comparison Aspect | Heavy Duty L Brackets | Heavy Duty Corner Braces | Floating Shelf Brackets |

|---|---|---|---|

| Performance | High weight capacity, typically 250-425 lbs | Moderate to high capacity, 220-440 lbs | High capacity, 450-750 lbs |

| Cost | Generally low, $16-$36 per bracket | Moderate, $18-$61 per set | Higher, $32-$75 per bracket |

| Ease of Implementation | Simple installation with screws | Requires precise mounting | Installation can be complex due to hidden mounting |

| Maintenance | Low maintenance; durable materials | Low; however, alignment is critical | Low; less visible wear and tear |

| Best Use Case | Shelving and structural support in homes | Corner support for furniture or shelving | Aesthetic installations without visible brackets |

What are the Benefits and Drawbacks of Heavy Duty Corner Braces?

Heavy duty corner braces are ideal for providing additional support at right angles, making them particularly useful in furniture assembly and shelving units. Their triangular design offers structural integrity, but they typically have a lower weight capacity compared to heavy duty L brackets. Installation requires careful alignment to ensure strength, which may add complexity to the process. Additionally, while the cost is reasonable, it can still be higher than L brackets, especially for larger projects.

How Do Floating Shelf Brackets Compare to Heavy Duty L Brackets?

Floating shelf brackets offer a sleek, modern aesthetic by allowing shelves to appear as if they are floating without visible support. These brackets can bear significant weight, often between 450 to 750 lbs, making them suitable for heavy items. However, their installation can be more complicated as they often require hidden mounting, which can be challenging for those unfamiliar with precise drilling and alignment. The cost is generally higher than heavy duty L brackets, which might be a consideration for budget-conscious projects.

How Should B2B Buyers Choose the Right Solution?

When selecting the right solution for structural support, B2B buyers should consider the specific requirements of their project, including weight capacity, installation complexity, and aesthetic preferences. Heavy duty L brackets are a versatile choice for straightforward applications where strength is paramount. In contrast, heavy duty corner braces are more suitable for situations requiring additional right-angle support. Floating shelf brackets, while more costly and complex to install, are perfect for projects where aesthetics are a top priority. By weighing these factors, buyers can make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for heavy duty l brackets

What Are the Key Technical Properties of Heavy Duty L Brackets?

Heavy-duty L brackets are essential components in various construction and furniture applications. Understanding their technical specifications can help B2B buyers select the right products for their projects.

-

Material Grade

Heavy-duty L brackets are typically made from materials such as stainless steel, iron, or galvanized steel. The choice of material impacts the bracket’s strength, durability, and resistance to corrosion. For instance, stainless steel brackets are ideal for outdoor or humid environments, while iron may be more suitable for indoor applications. Selecting the right material ensures longevity and performance, minimizing the risk of structural failure. -

Load Capacity

Load capacity refers to the maximum weight that a bracket can support. This is critical in applications where safety and stability are paramount, such as in shelving or structural support. Heavy-duty L brackets can have load capacities ranging from 250 lbs to over 600 lbs, depending on their size and material thickness. Buyers must match the load capacity to their specific needs to prevent accidents and ensure the effectiveness of the installation. -

Thickness and Dimensions

The thickness of a bracket affects its strength and rigidity. Common thicknesses include 1/4 inch and 3/8 inch. Additionally, brackets come in various lengths, typically ranging from 6 inches to 18 inches. The dimensions must align with the intended application—larger or thicker brackets are recommended for heavier loads or wider shelves. Proper sizing is essential for achieving optimal support and stability. -

Mounting Hole Configuration

The configuration and number of mounting holes can significantly influence installation ease and strength. Many heavy-duty L brackets feature countersunk holes, which allow for a flush fit and reduce the risk of protruding screws. A good mounting configuration ensures that the bracket is securely fastened to the wall or surface, enhancing load-bearing capabilities. -

Finish and Coating

The finish of a heavy-duty L bracket is important for corrosion resistance and aesthetic appeal. Options like powder coating or brushed stainless steel can provide additional protection against environmental factors. A proper finish not only extends the lifespan of the bracket but also improves its appearance, making it suitable for visible installations in residential or commercial settings.

What Common Trade Terms Should B2B Buyers Know When Purchasing Heavy Duty L Brackets?

Familiarity with industry terminology can streamline the purchasing process for heavy-duty L brackets and ensure clarity in communication between buyers and suppliers.

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end product. In the context of heavy-duty L brackets, OEM suppliers may provide customized solutions tailored to specific applications or requirements. Understanding this term helps buyers identify potential suppliers who can meet specialized needs. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell in a single order. This is crucial for businesses looking to manage inventory costs effectively. Knowing the MOQ can help buyers plan their purchasing strategies and avoid overstocking or underordering. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. Using an RFQ can ensure that buyers receive competitive pricing and detailed information about the products they are interested in. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers engaging in cross-border purchases, as they dictate who is responsible for shipping, insurance, and tariffs. -

Lead Time

Lead time refers to the time it takes from placing an order to its delivery. This term is critical for project planning and inventory management. Understanding lead times can help businesses align their procurement processes with project timelines and avoid delays. -

Certification Standards

Certification standards, such as ISO or ASTM, indicate that the products meet specific quality and safety criteria. These certifications are essential for ensuring that heavy-duty L brackets perform reliably in their intended applications, providing peace of mind for buyers regarding product quality.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing heavy-duty L brackets, ensuring they select products that meet their specific needs and requirements.

Navigating Market Dynamics and Sourcing Trends in the heavy duty l brackets Sector

What Are the Key Market Dynamics and Trends Influencing the Heavy Duty L Brackets Sector?

The heavy-duty L brackets market is experiencing significant growth driven by various global factors. The increasing demand for durable shelving solutions in industrial and commercial settings, coupled with a growing emphasis on home improvement projects, is pushing the market forward. With the rise of e-commerce platforms, international B2B buyers can access a broader range of products, allowing them to compare prices and quality effortlessly. Emerging technologies, such as 3D printing and advanced materials, are also reshaping the industry, enabling manufacturers to create customized solutions that meet specific load-bearing requirements.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe (e.g., Nigeria, Saudi Arabia) are increasingly focused on sourcing products that offer high weight capacities and are easy to install. The trend towards modular designs in construction and furniture is influencing the demand for versatile, heavy-duty brackets that can support various applications, from shelving to structural reinforcement. Additionally, companies are prioritizing suppliers that can provide reliable delivery times and competitive pricing, particularly in emerging markets where logistics can be a challenge.

How Is Sustainability and Ethical Sourcing Impacting the Heavy Duty L Brackets Market?

Sustainability and ethical sourcing are becoming pivotal in the heavy-duty L brackets sector. As environmental concerns rise, buyers are increasingly demanding products that minimize ecological impact. This has led to a surge in the use of sustainable materials, such as recycled metals and eco-friendly coatings, which not only enhance durability but also reduce carbon footprints.

Ethical supply chains are also gaining importance, with buyers preferring suppliers that adhere to fair labor practices and transparent sourcing processes. Certifications such as ISO 14001 for environmental management and other green certifications are now essential for companies looking to establish credibility in the market. By choosing suppliers that prioritize sustainability, B2B buyers can contribute to environmental preservation while also meeting regulatory requirements and consumer expectations.

What Is the Historical Context of Heavy Duty L Brackets in the B2B Space?

The evolution of heavy-duty L brackets can be traced back to the early days of construction and furniture design, where they served as essential components for stability and support. Initially made from basic metals, advancements in manufacturing processes have led to the introduction of high-strength materials and finishes that enhance performance and longevity. Over the years, the design of these brackets has evolved, with manufacturers incorporating features such as corrosion resistance and aesthetic appeal to meet the needs of modern consumers.

Today, heavy-duty L brackets are not only functional but also play a crucial role in the design of residential and commercial spaces, reflecting a blend of utility and style. As the market continues to innovate, B2B buyers can expect even more tailored solutions that address specific load capacities and installation requirements, further driving the sector’s growth.

Frequently Asked Questions (FAQs) for B2B Buyers of heavy duty l brackets

-

How do I select the right heavy duty L brackets for my project?

Selecting the right heavy duty L brackets involves assessing the weight capacity, material, and dimensions required for your specific application. Consider the type of shelf or structure you intend to support; heavier materials like stone or metal may require thicker brackets (1/4″ or 3/8″). Review the manufacturer’s specifications for weight limits and installation guidelines. Additionally, ensure that the brackets can be securely mounted to wall studs or other structural supports to guarantee stability and safety. -

What is the maximum load capacity for heavy duty L brackets?

The maximum load capacity for heavy duty L brackets varies based on their size and thickness. For instance, a 10″ long, 3/8″ thick bracket can support up to 425 lbs, while two 8″ long, 1/4″ thick brackets may hold 470 lbs. It’s crucial to verify the specific load ratings from your supplier and ensure that the appropriate mounting hardware is used to secure the brackets properly. Always consider a safety margin by choosing brackets with a higher capacity than your expected load. -

Can I customize heavy duty L brackets for my specific needs?

Yes, many suppliers offer customization options for heavy duty L brackets. You can request specific sizes, thicknesses, and finishes tailored to your project requirements. Additionally, some manufacturers may accommodate requests for extra mounting holes or unique designs. When inquiring about customization, be clear about your specifications and intended use, as this will help the supplier provide the best solution for your needs. -

What are the minimum order quantities (MOQs) for heavy duty L brackets?

Minimum order quantities (MOQs) for heavy duty L brackets can vary significantly depending on the manufacturer or supplier. Typically, MOQs may range from a few dozen to several hundred units. When sourcing internationally, be sure to confirm the MOQ with the supplier upfront, as it can impact your budgeting and inventory management. If you require smaller quantities, consider discussing this with the supplier, as they may offer flexibility for first-time orders or samples. -

What payment terms should I expect when sourcing heavy duty L brackets?

Payment terms for heavy duty L brackets can vary by supplier and region. Common terms include net 30, net 60, or upfront payment for first-time orders. When dealing with international suppliers, expect to negotiate terms that may include partial payment upfront and the remainder upon delivery. Ensure to clarify any additional fees, such as shipping or customs duties, to avoid unexpected costs. It’s advisable to use secure payment methods that protect both parties in the transaction. -

How do I verify the quality of heavy duty L brackets from suppliers?

To verify the quality of heavy duty L brackets, request product samples and review certifications such as ISO or ASTM standards. Check for customer reviews and ratings, and ask for references from previous clients. Additionally, inquire about the materials used and any quality assurance processes the supplier follows. Conducting a factory audit or using third-party inspection services can also help ensure that the products meet your standards before placing a bulk order. -

What logistics considerations should I keep in mind when importing heavy duty L brackets?

When importing heavy duty L brackets, consider shipping costs, delivery times, and potential customs duties. Work closely with your supplier to understand their shipping methods and timelines. Ensure that you have the necessary import licenses and documentation to facilitate smooth customs clearance. Additionally, evaluate the reliability of shipping carriers and consider insurance options to protect your shipment against loss or damage during transit. -

Are there any specific regulations for importing heavy duty L brackets to my country?

Yes, importing heavy duty L brackets may be subject to specific regulations depending on your country. This can include compliance with safety standards, material certifications, and import tariffs. Research the import regulations for your region, particularly if you are in Africa, South America, the Middle East, or Europe. It’s advisable to consult with a customs broker or trade advisor to ensure compliance and avoid potential delays or penalties during the import process.

Top 5 Heavy Duty L Brackets Manufacturers & Suppliers List

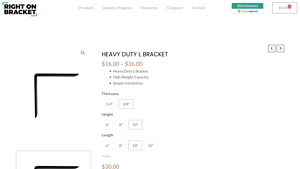

1. Right On Bracket – Heavy Duty L Bracket

Domain: rightonbracket.com

Registered: 2017 (8 years)

Introduction: {‘name’: ‘Heavy Duty L Bracket’, ‘price_range’: ‘$16.00 – $36.00’, ‘thickness_options’: [‘1/4″‘, ‘3/8″‘], ‘height_options’: [‘6″‘, ‘8″‘, ’10″‘], ‘length_options’: [‘6″‘, ‘8″‘, ’10″‘, ’12″‘], ‘weight_capacity’: {’10” long 3/8″ thick bracket’: ‘425 lbs’, ‘two 8″ long 1/4″ thick brackets’: ‘470 lbs’}, ‘installation_tips’: ‘Mounting hardware not included. Recommended #12 tapered wood screws or 1/4″ la…

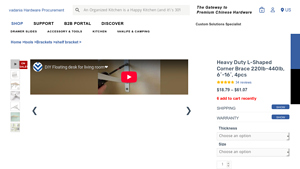

2. Vadania – Heavy Duty L-Shaped Corner Brace

Domain: vadania.com

Registered: 2019 (6 years)

Introduction: {“Product Name”: “Heavy Duty L-Shaped Corner Brace”, “Max Load”: “220lb-440lb”, “Size Options”: [“6″”, “8””, “10””, “12””, “14””, “16””], “Quantity”: “4pcs”, “Material”: “Quality Stainless Steel”, “Finish”: “Brushed, Anti-rust & corrosion”, “Mount Hole Diameter”: “6.3mm/0.25inch”, “Design”: “Triangle for sturdy construction”, “Thickness Options”: [{“Thickness”: “0.12”/3mm”, “Max Load”: “220lb/100k…

3. MSC Direct – Heavy-Duty Support Solutions

Domain: mscdirect.com

Registered: 1996 (29 years)

Introduction: This company, MSC Direct – Heavy-Duty Support Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Osborne Wood – Heavy Duty L Brackets

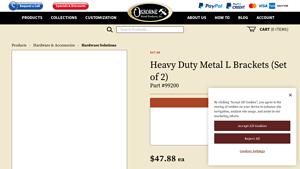

Domain: osbornewood.com

Registered: 1997 (28 years)

Introduction: Product Name: Pair of Heavy Duty L Brackets

Price: $47.88

Part Number: 99200

Set: Set of 2

Material: Heavy Duty Metal

5. Etsy – Heavy Duty Steel L Shaped Support Bracket

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Heavy Duty Steel L Shaped Support Bracket, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for heavy duty l brackets

How Can Effective Strategic Sourcing Enhance Your Heavy Duty L Bracket Procurement?

In the competitive landscape of international sourcing for heavy duty L brackets, strategic sourcing emerges as a critical approach for B2B buyers. By prioritizing quality, durability, and cost-effectiveness, businesses can ensure they select brackets that not only meet their structural needs but also enhance operational efficiency. The insights gathered from diverse markets, particularly in Africa, South America, the Middle East, and Europe, highlight the importance of understanding local requirements and supplier capabilities.

Moreover, leveraging technology for procurement processes, such as utilizing digital platforms for supplier evaluation and order fulfillment, can significantly streamline operations. Buyers should also consider factors such as corrosion resistance and load capacity, which are vital in ensuring the longevity and reliability of the brackets in various applications.

Looking ahead, as industries continue to evolve, the demand for robust and versatile heavy duty L brackets will only increase. International buyers are encouraged to engage with suppliers who demonstrate a commitment to innovation and customer service. Embrace strategic sourcing today to secure high-quality products that will support your projects and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to heavy duty l brackets

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.