Everything You Need to Know About Decorative Metal Trim Moulding Sourcing in 2025

Introduction: Navigating the Global Market for decorative metal trim moulding

In today’s competitive landscape, sourcing decorative metal trim moulding can pose significant challenges for international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe. With a variety of materials, finishes, and applications available, navigating this market requires a keen understanding of industry standards and supplier capabilities. This guide aims to empower decision-makers by providing a comprehensive overview of decorative metal trim moulding, covering essential aspects such as types, applications, and cost considerations, as well as effective strategies for vetting suppliers.

As the demand for aesthetically pleasing and durable architectural elements grows, the importance of selecting high-quality moulding cannot be overstated. Buyers must consider not only the visual appeal but also the functional benefits that different materials offer, such as corrosion resistance and ease of installation. This guide will explore various product categories, including aluminum, copper, and tin-plated options, alongside insights into market trends that can influence purchasing decisions.

By equipping B2B buyers with actionable insights and best practices, this resource aims to facilitate informed decisions that align with their specific project requirements and budget constraints. Whether you are a contractor, architect, or retailer, understanding the nuances of decorative metal trim moulding will enhance your ability to deliver exceptional results to your clients and drive business success.

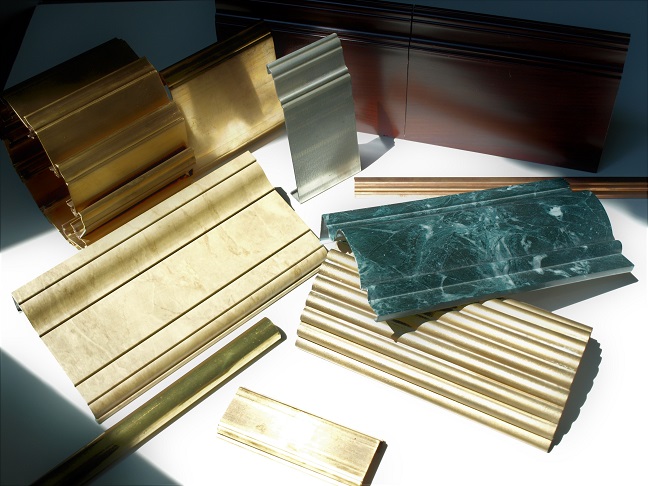

Understanding decorative metal trim moulding Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aluminum Trim Moulding | Lightweight, corrosion-resistant, versatile | Commercial interiors, signage, furniture | Pros: Durable, easy to install. Cons: Can be more expensive than PVC. |

| Copper Trim Moulding | Unique aesthetic, natural patina over time | High-end residential, art installations | Pros: Attractive, antimicrobial properties. Cons: Higher cost, requires maintenance. |

| Tin Plated Steel Moulding | Strong, rust-resistant, affordable | Industrial settings, decorative accents | Pros: Cost-effective, good durability. Cons: Limited aesthetic appeal compared to other metals. |

| Decorative Angle Moulding | L-shaped design for edge protection | Cabinetry, countertops, wall finishes | Pros: Provides clean lines, versatile. Cons: Can be tricky to install for beginners. |

| Cove Moulding | Curved profile, enhances visual flow | Ceiling transitions, wall finishes | Pros: Softens transitions, aesthetically pleasing. Cons: May require specialized installation tools. |

What Are the Characteristics of Aluminum Trim Moulding?

Aluminum trim moulding stands out for its lightweight nature and resistance to corrosion, making it a popular choice in various commercial applications. This type of moulding is highly versatile, often used in interiors for framing, signage, and furniture accents. When purchasing, B2B buyers should consider factors such as thickness, finish options, and compatibility with other materials. Its durability ensures a long lifespan, although it may come at a slightly higher price point compared to alternatives like PVC.

Why Choose Copper Trim Moulding for High-End Projects?

Copper trim moulding is revered for its unique aesthetic appeal, developing a natural patina over time that adds character to high-end residential projects and art installations. Its antimicrobial properties make it suitable for environments where hygiene is paramount. Buyers should evaluate the cost and maintenance requirements, as copper can be more expensive and may require periodic cleaning to maintain its appearance. The investment is often justified by the distinctive charm it brings to upscale designs.

What Advantages Does Tin Plated Steel Moulding Offer?

Tin plated steel moulding is recognized for its strength and affordability, making it an ideal choice for industrial settings and decorative accents. Its rust-resistant properties ensure longevity, while its cost-effectiveness makes it accessible for large-scale projects. Buyers should consider the aesthetic implications, as its appearance may not match the elegance of other metals. However, its practicality in demanding environments often outweighs this drawback.

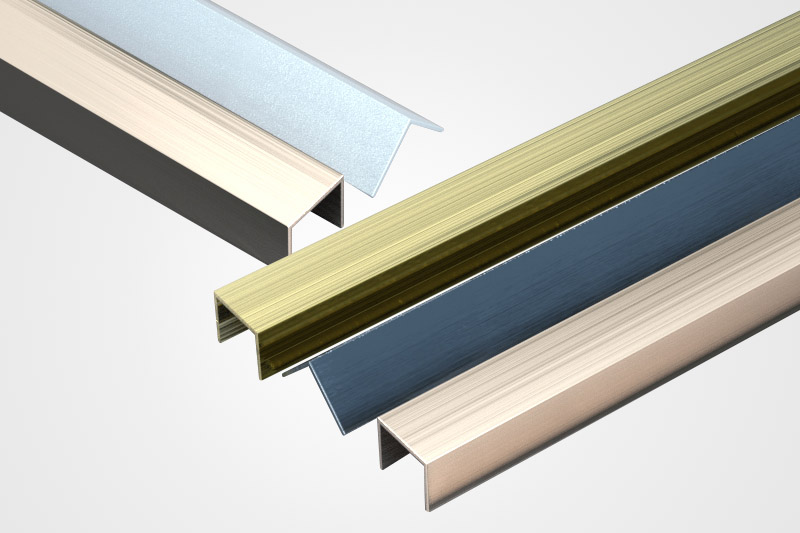

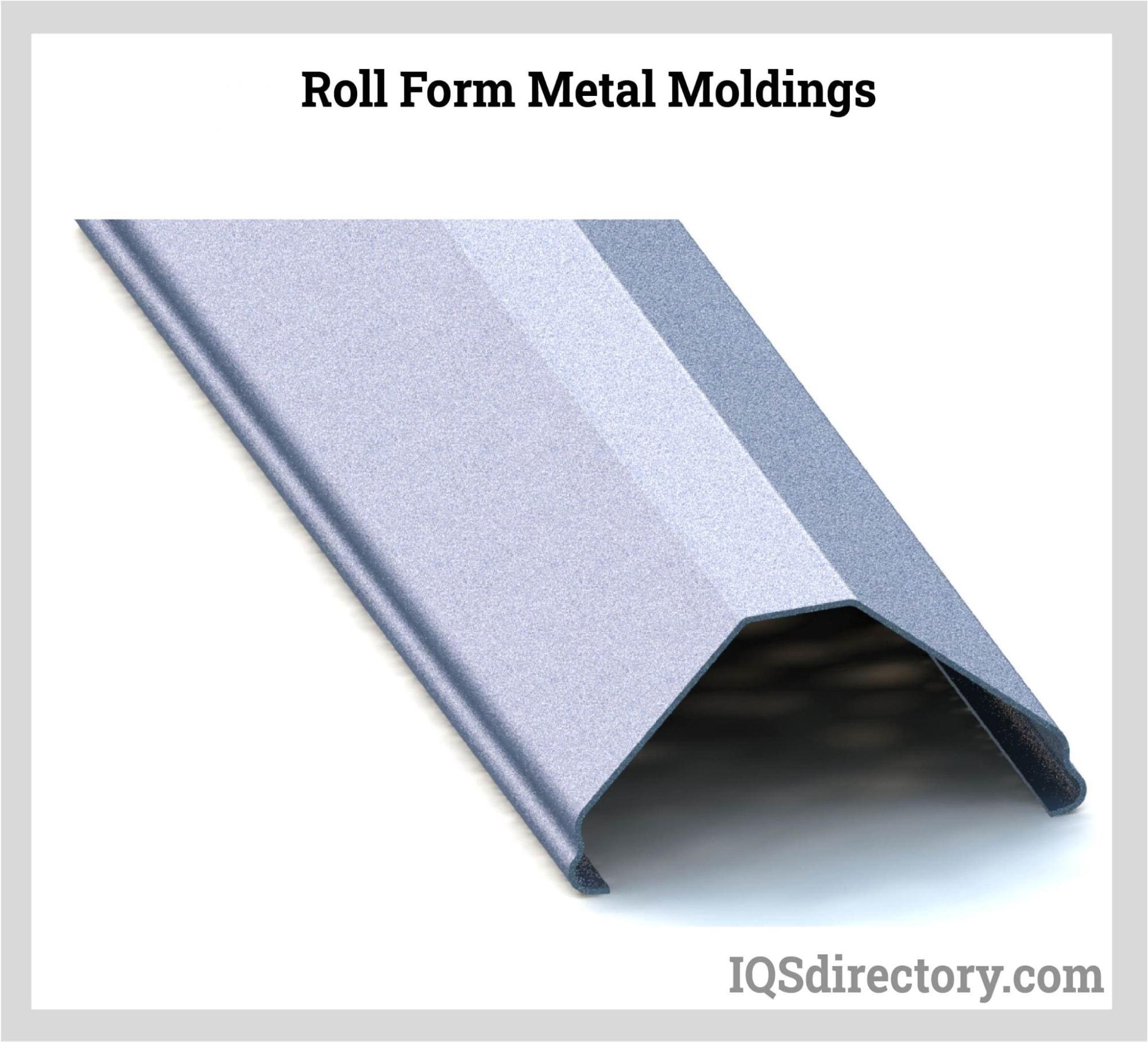

Illustrative image related to decorative metal trim moulding

How Does Decorative Angle Moulding Enhance Edges?

Decorative angle moulding features an L-shaped design that serves both functional and aesthetic purposes. It is commonly used for protecting edges on cabinetry and countertops, as well as enhancing wall finishes. B2B buyers should assess installation complexity, as it may require precise cutting and fitting. The clean lines offered by angle moulding can significantly elevate the visual appeal of a space, making it a valuable addition to any project.

Why Is Cove Moulding a Popular Choice for Visual Flow?

Cove moulding, with its curved profile, is designed to enhance visual transitions between walls and ceilings, providing a softening effect that is both elegant and functional. It is frequently used in residential and commercial spaces to create a seamless look. Buyers should consider the installation process, as specialized tools may be necessary for achieving perfect curves. Despite the potential challenges, the aesthetic benefits of cove moulding make it a sought-after option for enhancing interior spaces.

Key Industrial Applications of decorative metal trim moulding

| Industry/Sector | Specific Application of Decorative Metal Trim Moulding | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Used in the finishing of residential and commercial buildings, such as around windows and doors. | Enhances aesthetic appeal while providing durability and protection against weather elements. | Considerations include compliance with local building codes and availability of custom designs. |

| Furniture Manufacturing | Applied in the production of upscale furniture, particularly in decorative edges and accents. | Adds value through enhanced design, appealing to premium market segments. | Look for suppliers who offer a variety of finishes and customization options. |

| Automotive | Incorporated in vehicle interiors and exteriors for trims and embellishments. | Increases perceived value and brand differentiation through stylish design elements. | Ensure suppliers can meet stringent industry standards for quality and safety. |

| Retail Fixtures | Utilized in the design of display cases and shelving units. | Improves product presentation and enhances the shopping experience, driving sales. | Seek suppliers that can provide sustainable materials and quick turnaround times. |

| Architectural Design | Used in bespoke architectural features such as moldings and cornices in high-end projects. | Provides a unique aesthetic that can elevate project value and client satisfaction. | Important to partner with suppliers who understand the nuances of architectural applications. |

In the construction industry, decorative metal trim moulding is vital for finishing touches in both residential and commercial projects. It is commonly installed around windows and doors, enhancing the overall aesthetic while providing protection against the elements. For international buyers, particularly in regions like Africa and the Middle East, compliance with local building codes and the availability of custom designs are crucial factors when sourcing these materials.

Within the furniture manufacturing sector, decorative metal trim moulding is employed to create upscale furniture pieces with distinctive edges and accents. This application not only elevates the design but also appeals to consumers looking for premium quality. Buyers in South America and Europe should prioritize suppliers who offer a wide range of finishes and customization options to meet diverse market demands.

The automotive industry leverages decorative metal trim moulding for both interior and exterior applications, contributing to the vehicle’s overall style and perceived value. The use of high-quality trim can differentiate a brand in a competitive market. International buyers must ensure that their suppliers adhere to stringent quality and safety standards, particularly in regions like Germany where regulations are strict.

In retail fixtures, decorative metal trim moulding plays a significant role in the design of display cases and shelving units. Its application improves product presentation, thereby enhancing the shopping experience and potentially driving sales. Buyers should look for suppliers that offer sustainable materials and quick turnaround times to keep up with the fast-paced retail environment.

Finally, in architectural design, decorative metal trim moulding is often used in bespoke features like moldings and cornices, particularly in high-end projects. This application not only adds a unique aesthetic but can also elevate the project’s overall value. For buyers in Europe and the Middle East, partnering with suppliers who understand the intricacies of architectural applications is essential for achieving desired results.

3 Common User Pain Points for ‘decorative metal trim moulding’ & Their Solutions

Scenario 1: Sourcing Quality Decorative Metal Trim Moulding

The Problem: B2B buyers often struggle to find high-quality decorative metal trim moulding that meets their specific project requirements. This challenge is exacerbated in regions where suppliers may not carry a wide selection of materials or styles. Inconsistent quality across different vendors can lead to delays in project timelines and increased costs, as buyers may have to order multiple samples or even replace subpar products after installation.

The Solution: To navigate this issue effectively, buyers should prioritize establishing relationships with reputable suppliers who specialize in decorative metal trim moulding. Conduct thorough research to identify suppliers with a strong track record of quality and customer service. Request product samples to evaluate the finish and durability before making large purchases. Additionally, leverage trade shows or industry exhibitions to meet suppliers face-to-face, allowing for discussions about custom requirements and bulk pricing options. This proactive approach not only ensures quality but also builds a reliable supply chain that can adapt to future needs.

Scenario 2: Understanding Specifications and Application Requirements

The Problem: Another common pain point for B2B buyers is the complexity involved in specifying and applying decorative metal trim moulding correctly. Many buyers may not fully understand the various types of moulding available or how to select the right profiles for specific applications, leading to miscalculations or the use of inappropriate materials. This confusion can result in costly mistakes during installation, ultimately affecting the overall aesthetics and functionality of the project.

The Solution: To mitigate this issue, buyers should invest time in training or consulting with industry experts who can provide insights into the specifications of decorative metal trim moulding. Understanding the differences in profiles, materials, and finishes is crucial. Buyers can also utilize resources such as detailed product catalogs or online guides that outline the best applications for each type of moulding. Creating a checklist of project requirements, including dimensions, intended use, and desired finish, can help streamline the selection process. Collaborating with architects or designers during the early planning stages ensures that the chosen trim not only complements the overall design but also meets structural and regulatory requirements.

Scenario 3: Dealing with Installation Challenges

The Problem: Installation of decorative metal trim moulding can often present significant challenges, especially for B2B buyers managing large-scale projects. Issues such as misalignment, improper fastening, and the need for specialized tools can lead to frustration and delays. Additionally, inadequate installation can compromise the durability and appearance of the moulding, resulting in costly rework and customer dissatisfaction.

Illustrative image related to decorative metal trim moulding

The Solution: To address installation challenges, buyers should prioritize hiring experienced contractors or tradespeople familiar with decorative metal trim moulding. Providing clear installation guidelines and ensuring that all necessary tools are available can enhance efficiency on-site. Additionally, consider offering training sessions for installation teams to familiarize them with the specific requirements of the moulding being used. Providing a comprehensive installation manual that includes troubleshooting tips can further empower teams to resolve minor issues independently. For complex installations, engaging with the supplier for guidance or even on-site support can be invaluable, ensuring that the project meets quality standards and is completed on time.

Strategic Material Selection Guide for decorative metal trim moulding

What Are the Key Properties of Common Materials Used in Decorative Metal Trim Moulding?

When selecting materials for decorative metal trim moulding, it is essential to consider various factors that affect performance, durability, and suitability for specific applications. Here, we analyze four commonly used materials: aluminum, stainless steel, copper, and tin-plated steel.

Aluminum: A Lightweight and Versatile Choice

Aluminum is a popular choice for decorative metal trim due to its lightweight nature and excellent corrosion resistance. It performs well in various environmental conditions, making it suitable for both indoor and outdoor applications. Aluminum can withstand temperatures up to 400°F (204°C) and is resistant to rust, which is particularly advantageous in humid or coastal regions.

Pros: Aluminum is cost-effective, easy to fabricate, and can be finished in various colors and textures. It is also recyclable, aligning with sustainability goals.

Cons: While durable, aluminum may not be as strong as other metals, which can be a limitation in high-impact applications. Additionally, it may require protective coatings in harsh environments to maintain its aesthetic appeal.

Impact on Application: Aluminum is compatible with a wide range of media, including paints and adhesives, making it versatile for different decorative applications.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with relevant standards such as DIN and ASTM for aluminum products, particularly regarding thickness and finish.

Stainless Steel: Strength and Aesthetic Appeal

Stainless steel is renowned for its strength, durability, and aesthetic appeal, making it an excellent choice for high-end decorative trim. It offers exceptional corrosion resistance, particularly in environments exposed to moisture or chemicals. Stainless steel can handle temperatures exceeding 1000°F (538°C), making it suitable for various applications.

Illustrative image related to decorative metal trim moulding

Pros: Its robust nature ensures longevity, and it requires minimal maintenance. The sleek finish of stainless steel adds a modern touch to any design.

Cons: The primary drawback is its higher cost compared to other materials. Additionally, stainless steel can be challenging to work with due to its hardness, requiring specialized tools for fabrication.

Impact on Application: Stainless steel is particularly effective in commercial settings where durability and aesthetics are paramount, such as restaurants and hotels.

Considerations for International Buyers: Buyers should be aware of the specific grades of stainless steel that meet local standards, such as JIS in Japan or ASTM in the U.S., to ensure compliance and performance.

Copper: Timeless Elegance with Unique Properties

Copper is celebrated for its rich color and ability to develop a unique patina over time. It offers excellent thermal and electrical conductivity, making it suitable for decorative applications where aesthetic appeal is essential.

Illustrative image related to decorative metal trim moulding

Pros: Copper is naturally antimicrobial, making it a hygienic option for environments like kitchens and hospitals. Its malleability allows for intricate designs.

Cons: Copper is relatively expensive and may require regular maintenance to prevent tarnishing. It is also less resistant to corrosion compared to aluminum and stainless steel.

Impact on Application: Copper is often used in high-end residential applications, such as decorative accents in cabinetry and architectural features.

Considerations for International Buyers: Compliance with local regulations regarding copper content and recycling should be considered, especially in regions where environmental regulations are stringent.

Tin-Plated Steel: Cost-Effective and Functional

Tin-plated steel combines the strength of steel with a protective layer of tin, offering good corrosion resistance at a lower cost. It is suitable for applications where aesthetics are less critical than functionality.

Pros: This material is affordable and provides decent durability for indoor applications. It can be easily painted or coated for decorative purposes.

Cons: Tin-plated steel is less durable than other metals and may not perform well in outdoor environments. The tin layer can wear off over time, exposing the steel beneath.

Illustrative image related to decorative metal trim moulding

Impact on Application: Commonly used in budget-conscious projects, tin-plated steel is ideal for decorative trim in residential settings where cost is a significant factor.

Considerations for International Buyers: Buyers should check for compliance with local standards regarding coating thickness and corrosion resistance to ensure product longevity.

Summary Table of Material Selection for Decorative Metal Trim Moulding

| Material | Typical Use Case for decorative metal trim moulding | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Indoor and outdoor decorative trim | Lightweight and corrosion-resistant | Less strong than other metals | Medium |

| Stainless Steel | High-end commercial and residential applications | Exceptional durability and aesthetics | Higher cost and fabrication complexity | High |

| Copper | Decorative accents in high-end residential settings | Unique patina and antimicrobial properties | Expensive and requires maintenance | High |

| Tin-Plated Steel | Budget-conscious residential applications | Cost-effective and functional | Less durable and prone to corrosion | Low |

This strategic material selection guide provides B2B buyers with actionable insights into the properties, advantages, and limitations of various materials used in decorative metal trim moulding, helping them make informed purchasing decisions.

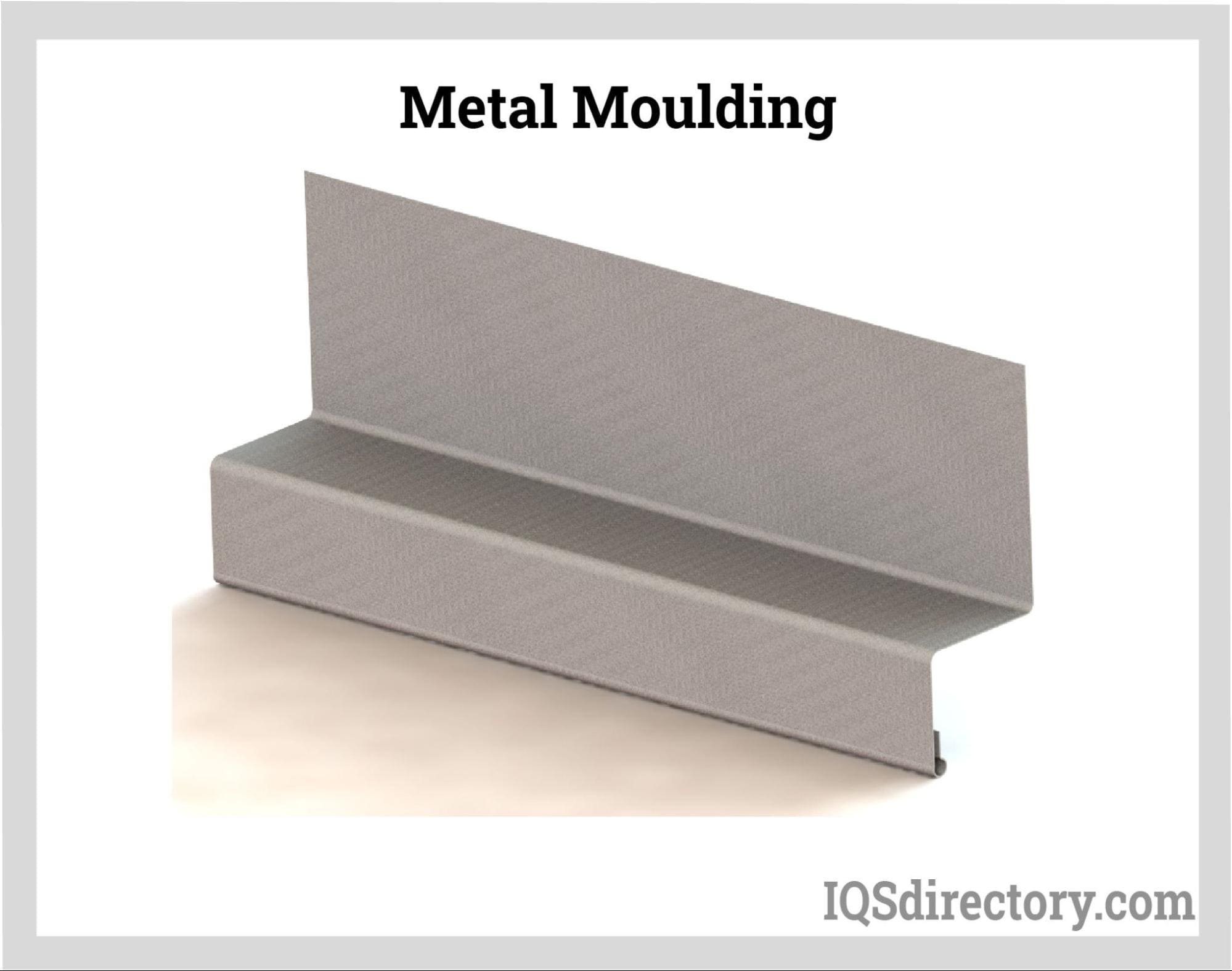

In-depth Look: Manufacturing Processes and Quality Assurance for decorative metal trim moulding

What Are the Key Stages in the Manufacturing Process of Decorative Metal Trim Moulding?

The manufacturing of decorative metal trim moulding involves several critical stages to ensure the final product meets aesthetic and functional requirements.

-

Material Preparation: The process begins with the selection of raw materials, which typically include aluminum, copper, and tin-plated steel. Each material is chosen based on its properties such as durability, corrosion resistance, and weight. The raw materials are sourced from certified suppliers to ensure quality. Once received, they undergo inspection for compliance with specifications.

-

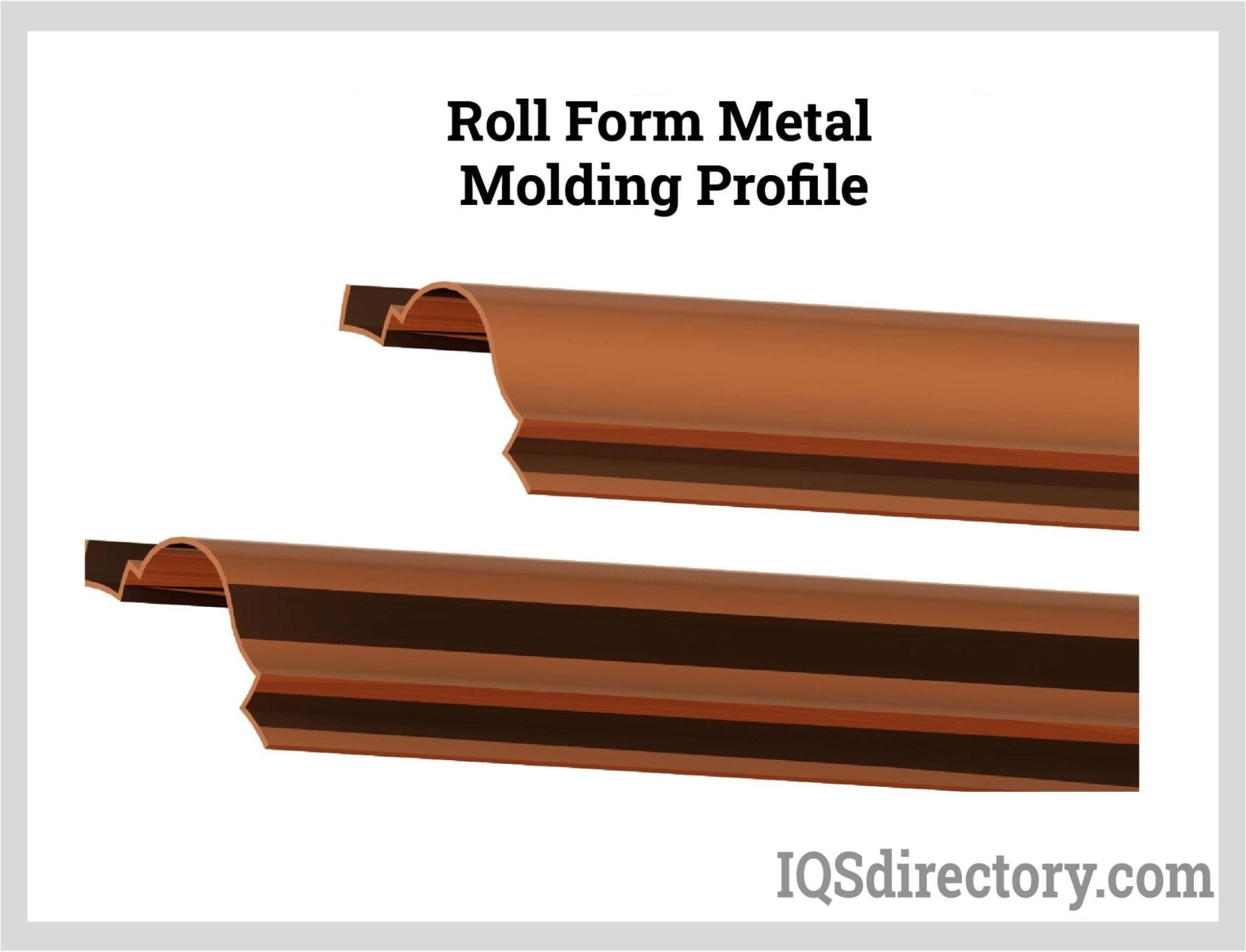

Forming Techniques: Various forming techniques are employed, including extrusion, stamping, and roll forming.

– Extrusion is commonly used for creating complex shapes, allowing for consistent profiles with minimal waste.

– Stamping is ideal for producing intricate designs and can be performed at high speeds, making it efficient for mass production.

– Roll Forming is employed for longer lengths of moulding, providing uniformity and precision. -

Assembly: In this stage, components are assembled based on design specifications. This may include welding or fastening different parts together. Automated assembly lines are often utilized to enhance efficiency and accuracy, especially for large-scale orders.

-

Finishing: The finishing process is crucial for both aesthetics and protection. Techniques such as anodizing, powder coating, and painting are used to enhance the appearance and durability of the moulding. Each method has its benefits:

– Anodizing increases corrosion resistance and allows for a variety of color finishes.

– Powder Coating provides a robust layer of protection against scratches and environmental factors.

– Painting can offer a wide range of colors and textures to meet specific customer needs.

How Is Quality Assurance Implemented in Decorative Metal Trim Moulding Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the products meet international standards and customer expectations.

-

International Standards: Many manufacturers adhere to international standards such as ISO 9001, which outlines the criteria for quality management systems. Compliance with these standards demonstrates a commitment to quality and continuous improvement. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply depending on the intended application of the moulding.

-

Quality Control Checkpoints: Effective quality control involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial stage verifies the quality of raw materials before they enter production. Suppliers must provide documentation and test reports to confirm material specifications.

– In-Process Quality Control (IPQC): During manufacturing, random samples are tested to ensure adherence to design specifications and identify any deviations early in the process.

– Final Quality Control (FQC): Once production is complete, a thorough inspection is conducted. This includes dimensional checks, surface finish assessments, and functional testing. -

Common Testing Methods: Various testing methods are utilized to validate the quality of decorative metal trim moulding:

– Dimensional Testing: Ensures that the moulding meets specified measurements and tolerances.

– Corrosion Resistance Testing: Evaluates how well the product withstands environmental conditions.

– Adhesion Testing: For coated products, this assesses the durability of the finish.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is vital to ensure product reliability.

-

Supplier Audits: Conducting audits of potential suppliers is an effective way to assess their manufacturing processes and quality control systems. This includes reviewing their compliance with international standards and inspecting their facilities.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can provide insights into their QA practices. These reports should include information on testing methods, results, and any corrective actions taken for non-conformities.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These agencies can perform inspections at various stages of production, ensuring that the products meet required standards before shipment.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers face unique challenges regarding quality control that must be addressed to mitigate risks.

-

Regulatory Compliance: Understanding the regulatory landscape in different regions is crucial. For instance, products sold in Europe must comply with CE marking requirements, which may not be applicable in other markets. Buyers should ensure that their suppliers are familiar with and comply with these regulations.

-

Cultural and Language Barriers: These can affect communication regarding quality expectations. Establishing clear specifications and maintaining open lines of communication can help bridge these gaps.

-

Logistical Challenges: Transportation and customs procedures can impact product quality. Ensuring that suppliers have robust packaging and shipping practices can help minimize damage during transit.

Conclusion

In the competitive landscape of decorative metal trim moulding, understanding the manufacturing processes and implementing rigorous quality assurance measures is essential for international B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing, alongside robust quality control practices, manufacturers can deliver high-quality products that meet diverse market demands. Buyers should proactively engage with suppliers to verify their QA processes, ensuring that they receive products that not only meet specifications but also provide lasting value.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘decorative metal trim moulding’

In the competitive landscape of decorative metal trim moulding, making informed procurement decisions is essential for B2B buyers. This guide provides a structured approach to sourcing, ensuring you acquire quality products that meet your specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements for decorative metal trim moulding. This includes dimensions, material types (such as aluminum, copper, or stainless steel), and finish preferences. A well-defined specification helps streamline communication with suppliers and minimizes the risk of receiving incorrect products.

Step 2: Research Market Trends

Stay informed about current trends in decorative metal trim moulding. Understanding market demand can influence your purchasing decisions, especially regarding style and functionality. Look for innovations in design and materials that may appeal to your target market or offer competitive advantages.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it’s crucial to conduct a thorough evaluation. Request detailed company profiles, product samples, and references from existing clients. Pay attention to their production capabilities, lead times, and reliability to ensure they can meet your demands consistently.

- Key Questions to Ask:

- What is their production capacity?

- Can they provide case studies or testimonials?

Step 4: Verify Certifications and Compliance

Ensure that suppliers comply with relevant industry standards and certifications. This is especially important for international buyers who may be subject to different regulations. Certifications can indicate a supplier’s commitment to quality and safety, giving you confidence in your procurement choices.

Illustrative image related to decorative metal trim moulding

- Look for:

- ISO certifications

- Local compliance with environmental regulations

Step 5: Request Samples for Quality Assessment

Always request samples of the decorative metal trim moulding before making a bulk order. This allows you to assess the quality of materials, craftsmanship, and finish. Comparing samples from multiple suppliers can help you make an informed decision based on tangible evidence rather than just specifications.

Step 6: Negotiate Pricing and Terms

Once you’ve identified a suitable supplier, engage in negotiations to secure the best pricing and payment terms. Consider factors such as order volume, long-term partnerships, and shipping costs. Clear agreements can prevent misunderstandings and foster positive supplier relationships.

- Important Negotiation Points:

- Bulk order discounts

- Payment terms and conditions

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful sourcing process. Set up regular check-ins with your chosen supplier to monitor production progress and address any potential issues. Establishing strong communication channels can enhance collaboration and ensure timely delivery of your orders.

Illustrative image related to decorative metal trim moulding

By following these steps, B2B buyers can navigate the sourcing process for decorative metal trim moulding with confidence, ensuring they select high-quality products that meet their business needs.

Comprehensive Cost and Pricing Analysis for decorative metal trim moulding Sourcing

What Are the Key Cost Components in Decorative Metal Trim Moulding Sourcing?

Understanding the cost structure of decorative metal trim moulding is essential for B2B buyers to make informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly influences the overall cost. Common materials include aluminum, copper, and steel, each with varying price points based on market demand and availability. For instance, aluminum is often preferred for its lightweight nature and resistance to corrosion, while copper may be chosen for its aesthetic appeal despite its higher cost.

-

Labor: Labor costs encompass the workforce involved in manufacturing and finishing the moulding. This includes skilled labor for intricate designs and craftsmanship, which can vary by region, impacting the total cost.

-

Manufacturing Overhead: Overhead costs cover utilities, facility maintenance, and other operational expenses associated with production. Efficient production processes can help mitigate these costs.

-

Tooling: Custom tooling for specific designs can add to the initial costs. However, reusable tooling may provide cost savings over time, especially for high-volume orders.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the moulding meets industry standards, which can incur additional costs but ultimately enhances product reliability and buyer satisfaction.

-

Logistics: Shipping and handling costs are critical, particularly for international buyers. Factors such as shipping distance, weight, and customs duties can significantly affect the final price.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market dynamics can help buyers assess whether the margin is reasonable.

How Do Price Influencers Impact Decorative Metal Trim Moulding Pricing?

Several factors influence the pricing of decorative metal trim moulding, making it crucial for buyers to consider these elements:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for larger orders. Negotiating favorable terms based on anticipated order volume can lead to significant savings.

-

Specifications and Customization: Custom designs and specific material requirements can increase costs. It’s essential to balance customization needs with budget constraints.

-

Materials and Quality Certifications: The quality of materials and any certifications (e.g., ISO, ASTM) can influence pricing. Higher-quality materials may come at a premium but can provide better durability and aesthetic value.

-

Supplier Factors: Supplier reputation, location, and production capabilities can affect pricing. Established suppliers with a track record of quality may charge higher prices, while newer or less reputable suppliers might offer lower prices but at a risk of quality issues.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) dictate responsibilities between buyers and sellers, affecting total costs. Understanding terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is vital for accurate pricing assessments.

What Are Effective Buyer Tips for Cost-Efficient Sourcing?

To maximize value and minimize costs when sourcing decorative metal trim moulding, buyers should consider the following strategies:

-

Negotiate Wisely: Leverage volume and long-term relationships in negotiations. Building rapport with suppliers can lead to better pricing and terms.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term costs, including maintenance, installation, and potential replacements. High-quality moulding may have a higher upfront cost but lower lifetime costs.

-

Understand Pricing Nuances for International Transactions: Different regions have varying pricing structures influenced by local economies, tariffs, and logistics. Buyers from Africa, South America, the Middle East, and Europe should be aware of these factors to avoid unexpected costs.

-

Stay Informed on Market Trends: Regularly monitor market trends and commodity prices. Fluctuations in raw material costs can impact pricing, and being informed allows for timely purchasing decisions.

By understanding these cost components, price influencers, and effective sourcing strategies, B2B buyers can navigate the complexities of decorative metal trim moulding sourcing more effectively. Always consider indicative prices as they can fluctuate based on market conditions and supplier negotiations.

Alternatives Analysis: Comparing decorative metal trim moulding With Other Solutions

Introduction to Alternative Solutions for Decorative Metal Trim Moulding

When considering decorative metal trim moulding for architectural and design projects, it is essential to explore viable alternatives that can meet similar aesthetic and functional needs. Various materials and methods exist, each offering unique advantages and disadvantages. In this section, we will compare decorative metal trim moulding with two prominent alternatives: PVC moulding and wood trim. This analysis will aid international B2B buyers in making informed decisions tailored to their specific requirements.

Comparison Table

| Comparison Aspect | Decorative Metal Trim Moulding | PVC Moulding | Wood Trim |

|---|---|---|---|

| Performance | High durability, rust-resistant, ideal for moisture-rich environments | Good moisture resistance, but less durable than metal | Excellent aesthetics, but susceptible to rot |

| Cost | Generally higher initial cost | Lower cost, budget-friendly | Variable cost; can be high for premium wood |

| Ease of Implementation | Requires specialized tools for cutting and installation | Easy to cut and install; lightweight | Moderate; may need professional installation |

| Maintenance | Low maintenance; resistant to wear | Low maintenance; easy to clean | Requires regular upkeep to prevent damage |

| Best Use Case | Commercial applications, high-end residential designs | Budget-friendly projects, DIY installations | Traditional aesthetics, residential interiors |

Detailed Breakdown of Alternatives

1. PVC Moulding

PVC moulding is a popular alternative due to its affordability and ease of installation. It is lightweight, making it easier to handle and cut without specialized tools. PVC is moisture-resistant, making it suitable for environments like bathrooms and kitchens. However, while it is durable, it may not match the longevity of metal trim, especially in high-traffic or commercial spaces. Its aesthetic appeal can also be less sophisticated compared to metal options, which might deter buyers looking for a premium finish.

2. Wood Trim

Wood trim offers unmatched aesthetic qualities, providing a classic and warm look that many buyers prefer for residential interiors. It can be stained or painted to match various design schemes, making it highly versatile. However, wood is susceptible to issues such as rot, warping, and insect damage, especially in humid climates. While it can be more expensive depending on the type of wood, the investment may be justified for projects that prioritize visual appeal over durability. Maintenance is more demanding, requiring regular treatments to maintain its integrity.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate trim solution involves assessing specific project requirements, including budget, desired aesthetics, and environmental factors. Decorative metal trim moulding is ideal for those seeking a durable and sophisticated finish, particularly in commercial settings. Conversely, PVC moulding serves as a cost-effective choice for DIY projects, while wood trim caters to those prioritizing traditional aesthetics. By weighing these alternatives against their unique needs, B2B buyers can make strategic decisions that enhance their project outcomes and satisfy client expectations.

Essential Technical Properties and Trade Terminology for decorative metal trim moulding

What Are the Key Technical Properties of Decorative Metal Trim Moulding?

Understanding the essential technical properties of decorative metal trim moulding is crucial for B2B buyers. These specifications not only influence the aesthetic and functional aspects of the product but also impact procurement decisions.

1. Material Grade

The material grade refers to the specific type of metal used in the trim moulding, such as aluminum, copper, or stainless steel. Each material has unique properties, including weight, strength, corrosion resistance, and aesthetic appeal. For buyers, selecting the appropriate material grade ensures that the trim will meet both functional and decorative requirements, especially in environments with varying humidity and temperature conditions.

2. Tolerance

Tolerance defines the allowable variation in the dimensions of the moulding. This specification is critical for ensuring that the trim fits perfectly within the intended application, whether it be in architectural designs or furniture manufacturing. A tighter tolerance often indicates higher quality and precision, which can reduce installation time and costs, making it an important consideration for B2B transactions.

Illustrative image related to decorative metal trim moulding

3. Finish Type

The finish type refers to the surface treatment applied to the moulding, such as anodizing, powder coating, or plating. The choice of finish affects the trim’s durability, maintenance requirements, and visual appeal. For buyers, understanding the finish type is essential for ensuring that the product aligns with their design vision while also providing the necessary protection against wear and tear.

4. Load-Bearing Capacity

This property indicates the maximum weight that the trim can support without deforming or failing. It is particularly important for mouldings used in structural applications or where heavy loads are expected. Buyers should evaluate the load-bearing capacity to ensure that the moulding will perform adequately in its intended use, thereby reducing the risk of product failure.

5. Corrosion Resistance

Corrosion resistance measures the material’s ability to withstand degradation from environmental factors such as moisture, salt, and chemicals. This property is vital for decorative trim used in outdoor applications or in areas with high humidity. Understanding corrosion resistance helps buyers select products that will maintain their appearance and functionality over time, reducing long-term maintenance costs.

What Are Common Trade Terminologies Related to Decorative Metal Trim Moulding?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms relevant to decorative metal trim moulding:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components that are used in another company’s end products. In the context of decorative metal trim moulding, buyers may engage with OEMs for customized designs that fit specific applications. Understanding OEM relationships can help buyers secure better pricing and tailored solutions.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is critical for buyers as it affects inventory costs and cash flow. Negotiating favorable MOQs can lead to better pricing and more efficient supply chain management.

Illustrative image related to decorative metal trim moulding

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for a specific quantity of goods. It is a vital tool for buyers to compare offers and negotiate better deals. Crafting a clear RFQ can lead to more accurate quotes and improved supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in shipping and delivery. Familiarity with these terms helps buyers understand shipping costs, risks, and logistics involved in procurement, particularly when dealing with international suppliers.

5. Lead Time

Lead time is the period between placing an order and receiving the product. In the context of decorative metal trim moulding, understanding lead times helps buyers plan their projects effectively and manage timelines. Shorter lead times can enhance operational efficiency and customer satisfaction.

Conclusion

In the competitive landscape of decorative metal trim moulding, grasping the essential technical properties and trade terminologies is vital for B2B buyers. This knowledge not only aids in making informed purchasing decisions but also fosters stronger supplier relationships and project success.

Navigating Market Dynamics and Sourcing Trends in the decorative metal trim moulding Sector

What Are the Key Trends Shaping the Decorative Metal Trim Moulding Market?

The decorative metal trim moulding sector is witnessing significant transformation, driven by both aesthetic and functional demands across various industries. Global drivers include an increasing emphasis on interior aesthetics in residential and commercial spaces, as well as a growing preference for durable materials that withstand wear and tear. In regions such as Europe and the Middle East, where design innovation is a priority, decorative metal trims are becoming essential for enhancing architectural features.

Emerging B2B technologies, such as 3D modeling and digital fabrication, are revolutionizing the way manufacturers create and supply these products. Buyers can now engage in more customized solutions, enabling them to meet specific design requirements without the constraints of traditional manufacturing methods. Additionally, e-commerce platforms are facilitating seamless sourcing experiences, allowing international buyers from Africa and South America to access a wider range of products and suppliers, thus increasing market competitiveness.

As the market matures, sustainability is becoming a key consideration. Buyers are increasingly looking for suppliers who prioritize eco-friendly materials and manufacturing processes, which aligns with global sustainability goals. This trend not only influences purchasing decisions but also shapes supplier relationships and product development strategies.

How Can Sustainability and Ethical Sourcing Be Integrated into B2B Practices?

Sustainability and ethical sourcing are gaining momentum in the decorative metal trim moulding sector, as businesses recognize their environmental impact and the importance of responsible supply chains. The production of metal trim involves energy-intensive processes and the use of raw materials that can deplete natural resources. Therefore, sourcing from manufacturers that utilize recycled materials or implement energy-efficient practices is crucial for reducing the overall carbon footprint of these products.

Moreover, certifications such as LEED (Leadership in Energy and Environmental Design) and FSC (Forest Stewardship Council) can provide assurance to buyers regarding the sustainability of their purchases. These certifications not only enhance a company’s reputation but also appeal to environmentally conscious consumers and businesses.

Ethical sourcing practices extend beyond material selection; they encompass fair labor practices and transparency in supply chains. Buyers should prioritize suppliers who demonstrate a commitment to ethical treatment of workers and who provide visibility into their sourcing processes. This not only fosters trust but also aligns with the growing consumer demand for corporate social responsibility.

What Is the Historical Context of Decorative Metal Trim Moulding?

The evolution of decorative metal trim moulding dates back to ancient civilizations, where metals were used for both functional and decorative purposes in architecture. Over centuries, the techniques and materials have advanced significantly. Initially, artisans crafted these trims by hand, utilizing materials such as bronze and brass for their durability and aesthetic appeal.

In the modern era, the introduction of manufacturing technologies has transformed the sector. The rise of aluminum and stainless steel in the mid-20th century provided cost-effective and versatile alternatives, leading to widespread adoption in both residential and commercial applications. Today, decorative metal trim moulding combines traditional craftsmanship with innovative designs, appealing to a global market that values both heritage and modernity. This historical context is essential for B2B buyers, as it reflects the ongoing interplay between functionality, design, and sustainability within the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of decorative metal trim moulding

-

How do I ensure the quality of decorative metal trim moulding from suppliers?

To guarantee the quality of decorative metal trim moulding, start by researching potential suppliers extensively. Request samples to evaluate the material and craftsmanship firsthand. Ensure they provide certifications, such as ISO or ASTM, which validate their adherence to industry standards. Additionally, consider third-party quality assurance inspections before shipment, particularly for large orders. Establishing a clear communication channel for quality expectations and specifications can further mitigate risks. -

What is the best material for decorative metal trim moulding?

The best material for decorative metal trim moulding largely depends on the intended application and aesthetic preferences. Aluminum is lightweight, rust-resistant, and versatile, making it suitable for both indoor and outdoor use. Copper offers a unique aesthetic with a warm tone and develops a beautiful patina over time, ideal for high-end applications. Tin-plated steel is durable and economical for projects requiring a classic look. Evaluate the project’s environmental conditions and design requirements to make an informed choice. -

How can I customize decorative metal trim moulding for my project?

Customization options for decorative metal trim moulding often include unique profiles, finishes, and dimensions. Many suppliers offer bespoke services that allow you to specify the design features you need. When approaching a supplier, provide detailed drawings or specifications and inquire about their capabilities for custom orders. Be prepared for potential minimum order quantities and lead times, and discuss pricing implications for customized products to ensure they align with your budget. -

What should I consider regarding minimum order quantities (MOQ) for metal trim moulding?

Minimum order quantities (MOQ) can vary significantly among suppliers and may depend on the type of moulding and customization involved. It’s essential to inquire about MOQ when sourcing to understand the financial implications, especially for smaller businesses or projects. Some suppliers may allow flexibility, particularly for first-time orders or samples. Always clarify the MOQ and negotiate terms to find a supplier who can accommodate your needs without compromising on quality or service. -

What payment terms are typically offered by suppliers of decorative metal trim moulding?

Payment terms can vary widely based on the supplier’s policies and the buyer’s relationship with them. Common terms include net 30, net 60, or upfront payments, especially for international transactions. For first-time orders, suppliers may require full payment in advance. Consider discussing payment options such as letters of credit or escrow services to protect your interests. Establishing a good rapport with the supplier can often lead to more favorable terms over time. -

How do I vet suppliers for international sourcing of decorative metal trim moulding?

Vetting suppliers is crucial for successful international sourcing. Start by checking their business credentials, such as registration and compliance with local regulations. Look for reviews and testimonials from previous clients to gauge their reliability and quality. Request references and contact them to gain insights into their experiences. Additionally, consider conducting a factory audit or using third-party inspection services to verify production capabilities and quality control processes. -

What logistics considerations should I keep in mind when importing metal trim moulding?

When importing decorative metal trim moulding, logistics considerations include shipping methods, customs regulations, and delivery timelines. Determine the best shipping options based on your budget and urgency, whether by air or sea. Familiarize yourself with the import duties and tariffs applicable in your country to avoid unexpected costs. Additionally, ensure that the supplier provides proper documentation for customs clearance, including invoices, packing lists, and certificates of origin. -

What are common challenges in international trade for decorative metal trim moulding, and how can I overcome them?

Common challenges in international trade include language barriers, cultural differences, and varying quality standards. To overcome these, invest time in understanding the local market and establishing clear communication with suppliers. Utilize bilingual representatives or translation services when necessary. Building strong relationships with your suppliers can help mitigate misunderstandings and foster collaboration. Additionally, consider joining trade associations or networks to gain insights and support in navigating international trade complexities.

Top 6 Decorative Metal Trim Moulding Manufacturers & Suppliers List

1. Decorative Ceiling Tiles – Metal Trim & Molding Options

Domain: decorativeceilingtiles.net

Registered: 2007 (18 years)

Introduction: Metal Trim and Molding options include Aluminum, Copper, and Tin Plated Steel. Various types of ceiling tiles and moldings are available for purchase, including faux wood beams, wall panels, acoustic panels, and ceiling planks. Products can be ordered in bulk, with specific categories for installation methods (Drop In, Glue Up, Nail Up, Peel and Stick) and materials (Copper, PVC, Tin Plated Steel,…

2. Dahlstrom – Decorative Metal Mouldings

Domain: dahlstromrollform.com

Registered: 1999 (26 years)

Introduction: Dahlstrom Metal Mouldings are decorative metal mouldings, casings, chair rails, and interior design trim, known for their historical significance and modern applications. They are used in notable buildings like the Empire State Building and Rockefeller Center. Key features include:

– Fire Resistance: Metal mouldings do not contribute fuel or smoke in fires, making them suitable for public spaces.

…

3. Pinterest – Decorative Metal Trim

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Metal Ribbon, Metal Trim, Decorative Metal Strip, Filigree Decorative Strip, Rustic Cream Finish, for Furniture – Shelves – Crowns – Frames – Etsy UK

4. Johnson Roll Forming – Key Products

Domain: johnsonrollforming.com

Registered: 2004 (21 years)

Introduction: Key Product Details: 1. Metal Mouldings (Moldings) 2. Aluminum Moulding (Molding) 3. Profiles, Special Shapes & Sections 4. Channels: U-Channels, J-Channels, C-Channels, Box Channels, Hat Channels, Strut Channels 5. Specialty Tubing: Shelf Support Tubing, Open Seam, Open Buttseam, Tubing with Gap Lock Seam, Flanged & Finned Seam Tubing, Hemmed Seam Tubing, Split Seam & Butt Seam Tubing, Telescopic…

5. Brownwood Inc – Decorative Aluminum Trim Products

Domain: brownwoodinc.com

Registered: 2008 (17 years)

Introduction: Accent Trim products include various types of decorative aluminum components such as:

– .25” Decorative Aluminum Bar (MSRP: $75.35)

– .25″ Decorative Aluminum Bar Sample Kit (MSRP: $66.60)

– .438″ Wide x .25″ Thick Angled Aluminum Bar (MSRP: $86.36)

– .5” Decorative Aluminum L-Channel (MSRP: $45.62)

– .5″ Aluminum L-Channel Sample Kit (MSRP: $37.74)

– .75” Decorative Aluminum Strapping (MSRP: $51….

6. Outwater – Metal Like Decorative Trim

Domain: outwater.com

Registered: 1995 (30 years)

Introduction: This company, Outwater – Metal Like Decorative Trim, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for decorative metal trim moulding

In the rapidly evolving market of decorative metal trim moulding, strategic sourcing emerges as a critical component for international B2B buyers. By leveraging global supply chains, businesses can access a diverse range of materials such as aluminum, copper, and tin-plated steel, each offering unique aesthetic and functional benefits. Buyers from regions like Africa, South America, the Middle East, and Europe should prioritize partnerships with reliable suppliers that provide quality assurance and customization options to meet specific project demands.

The increasing trend towards sustainable and durable materials further emphasizes the importance of sourcing practices that align with environmental considerations. By selecting products that are not only visually appealing but also resistant to wear and tear, companies can enhance their offerings while reducing long-term costs.

Illustrative image related to decorative metal trim moulding

As we look ahead, the decorative metal trim moulding sector is poised for growth, driven by innovation and design trends. B2B buyers are encouraged to stay informed about emerging technologies and market shifts that could impact their sourcing strategies. Engaging with industry experts and attending trade shows can provide valuable insights and foster relationships that are vital for future success. Embrace this opportunity to elevate your sourcing strategy and position your business at the forefront of the decorative metal trim moulding market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to decorative metal trim moulding

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.