Everything You Need to Know About Lost Wax Casting Near Me Sourcing in 2025

Introduction: Navigating the Global Market for lost wax casting near me

In today’s competitive landscape, sourcing reliable lost wax casting near me presents a significant challenge for B2B buyers, particularly those navigating the intricacies of international markets across Africa, South America, the Middle East, and Europe. As manufacturers and designers strive to create high-quality products, understanding the nuances of lost wax casting becomes essential. This guide offers an in-depth exploration of various casting methods, applications across industries, and critical factors such as supplier vetting and cost considerations.

International B2B buyers often grapple with the complexities of finding local casting partners that align with their specific needs. This comprehensive resource equips you with the insights necessary to make informed purchasing decisions, whether you are a jeweler in Nigeria seeking exquisite gold pieces or a designer in Vietnam looking for sustainable casting solutions.

Throughout this guide, you will discover actionable tips for evaluating casting companies, understanding the latest technologies in lost wax casting, and identifying potential pitfalls to avoid. By leveraging the information contained within, you can streamline your sourcing process, enhance product quality, and ultimately drive your business success in the global market. Join us as we navigate the world of lost wax casting and uncover the opportunities that await your business.

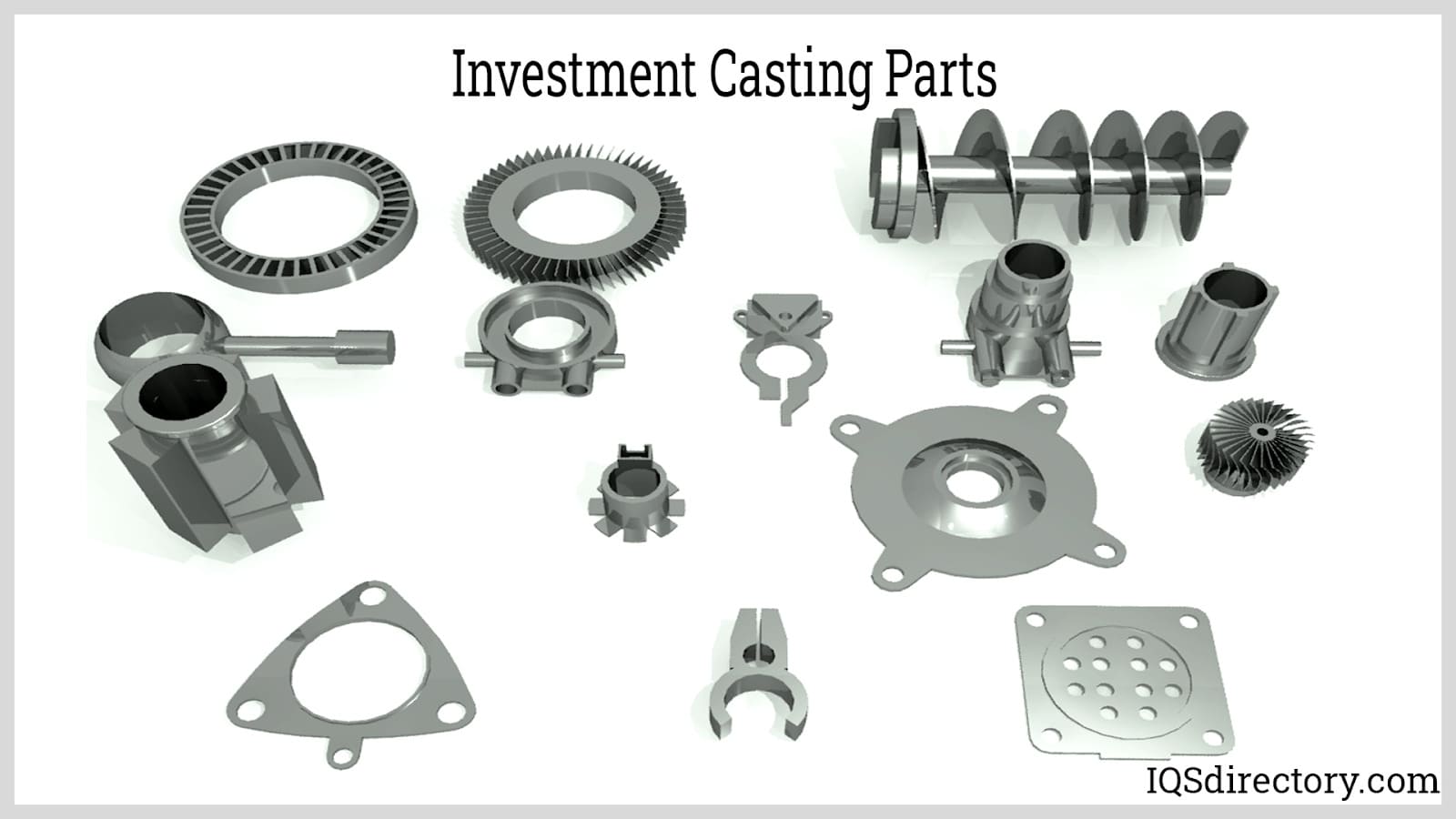

Understanding lost wax casting near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Jewelry Casting | Focuses on intricate designs with high precision. | Custom jewelry manufacturing, retail stores. | Pros: High detail, ideal for unique pieces. Cons: Longer lead times. |

| Industrial Casting | Utilizes larger molds for mass production. | Automotive, aerospace, and machinery parts. | Pros: Cost-effective for large volumes. Cons: Less detail compared to jewelry casting. |

| Art Casting | Tailored for sculptures and artistic pieces. | Art galleries, collectors, and designers. | Pros: Creative freedom, accommodates various materials. Cons: May require specialized expertise. |

| Prototype Casting | Used for creating prototypes before mass production. | Product development and testing. | Pros: Quick turnaround, allows for design adjustments. Cons: Not suitable for final production. |

| Medical Device Casting | Focuses on biocompatible materials for medical applications. | Medical device manufacturers. | Pros: High precision, adheres to strict regulations. Cons: Higher costs due to material standards. |

What Are the Characteristics of Jewelry Casting in Lost Wax Casting?

Jewelry casting is one of the most popular types of lost wax casting, particularly favored for its ability to produce intricate designs with fine details. This method is ideal for custom jewelry manufacturing, where unique pieces are in high demand. B2B buyers in the jewelry sector should consider the level of detail they require and the expected lead times, as this type often involves longer processing periods due to its meticulous nature.

How Does Industrial Casting Differ from Other Types?

Industrial casting is characterized by its capability to produce larger components and parts, often at a mass scale. This variation is commonly used in industries such as automotive and aerospace, where the demand for durable and precise parts is essential. B2B buyers looking for cost-effective solutions for high-volume production will find this method advantageous, although they may sacrifice some level of detail compared to jewelry casting.

What Makes Art Casting Unique?

Art casting is designed for sculptors and artists, allowing for the creation of artistic pieces that may require a high degree of customization. This method provides significant creative freedom and can accommodate a variety of materials. B2B buyers in the art and design sectors should prioritize finding a casting partner with experience in artistic applications, as this often requires specialized knowledge and techniques.

Why Choose Prototype Casting for Product Development?

Prototype casting is particularly beneficial for companies in the product development phase. This method allows businesses to create quick prototypes, facilitating design testing and adjustments before moving to mass production. B2B buyers should consider the importance of speed and flexibility in their casting needs, as this type is specifically tailored for rapid iteration.

How Is Medical Device Casting Regulated?

Medical device casting focuses on producing components that meet stringent biocompatibility standards. This variation is crucial for manufacturers in the medical field, where precision and compliance with regulations are paramount. Buyers in this sector should be prepared for potentially higher costs associated with the materials and processes required to meet industry standards, but the investment is essential for ensuring product safety and efficacy.

Key Industrial Applications of lost wax casting near me

| Industry/Sector | Specific Application of lost wax casting near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Jewelry Manufacturing | Custom jewelry design and production | High precision and intricate designs for unique pieces | Quality of wax models, turnaround time, and metal options |

| Aerospace | Production of complex engine components | Lightweight yet durable parts that meet strict standards | Certification of materials, precision, and compliance with regulations |

| Medical Devices | Creation of surgical instruments and implants | Biocompatibility and precision in critical applications | Material certifications, quality assurance processes, and lead times |

| Art and Sculpture | Casting of artistic sculptures and installations | Ability to replicate fine details and artistic vision | Experience with artistic projects, material options, and finishing capabilities |

| Automotive | Manufacturing of engine parts and components | Enhanced performance and durability in vehicles | Compatibility with existing designs, material quality, and production capacity |

How is Lost Wax Casting Used in Jewelry Manufacturing?

In the jewelry manufacturing sector, lost wax casting is integral for creating custom pieces tailored to specific designs. This method allows artisans to achieve high levels of detail and precision, essential for producing intricate jewelry items. For international buyers, particularly from regions like Africa and South America, sourcing quality wax models and ensuring a rapid turnaround are crucial. Additionally, understanding the variety of metal options available, such as gold or silver, can significantly influence the final product’s appeal and marketability.

What Role Does Lost Wax Casting Play in Aerospace Applications?

In the aerospace industry, lost wax casting is used to produce complex engine components that require lightweight and durable materials. The casting process ensures that these parts meet stringent industry standards for safety and performance. International buyers must consider the certification of materials used and the precision of the casting process, as any defects can have critical implications. Collaborating with suppliers who have experience in aerospace applications is vital to ensure compliance with regulatory requirements.

How is Lost Wax Casting Applied in Medical Device Manufacturing?

Lost wax casting plays a pivotal role in the medical device industry by enabling the production of surgical instruments and implants that require high precision and biocompatibility. The casting process allows manufacturers to create complex geometries that are essential for functional medical devices. For international buyers, especially from the Middle East and Europe, sourcing partners must have robust quality assurance processes and certifications to ensure that the products meet health and safety regulations.

In What Ways is Lost Wax Casting Beneficial for Art and Sculpture?

Artists and sculptors utilize lost wax casting to replicate their intricate designs into durable materials, allowing for the creation of both small-scale and large installations. This method provides artists with the flexibility to achieve fine details, capturing their artistic vision accurately. For B2B buyers in the art sector, it is important to work with suppliers who have experience in handling artistic projects and can offer various finishing options to enhance the final piece’s aesthetic.

How Does Lost Wax Casting Support Automotive Component Manufacturing?

In the automotive industry, lost wax casting is crucial for producing engine parts and components that require both strength and durability. The method allows manufacturers to create complex shapes that enhance vehicle performance. For international buyers, sourcing considerations should include compatibility with existing designs, the quality of the materials used, and the supplier’s production capacity to meet demand efficiently. Ensuring a reliable supply chain is essential for maintaining production schedules and quality standards.

3 Common User Pain Points for ‘lost wax casting near me’ & Their Solutions

Scenario 1: Difficulty Finding Reliable Local Casting Services

The Problem: B2B buyers often struggle to locate reputable lost wax casting services in their vicinity. This issue is particularly pronounced in regions with fewer established casting companies or where traditional business directories may not list updated information. Buyers may end up contacting businesses that have outdated contact details, leading to wasted time and resources. Moreover, the lack of online presence for some casting companies complicates the search process, making it challenging to assess their capabilities and customer reviews.

The Solution: To effectively navigate this challenge, buyers should leverage a multi-faceted approach to sourcing casting services. Start by utilizing specific search terms such as “lost wax casting [your city]” or “jewelry casting services near me” on search engines. Additionally, consider joining industry-specific forums and social media groups where local artisans and businesses share recommendations. This grassroots approach can often reveal hidden gems that may not appear in standard searches. Furthermore, once potential companies are identified, prioritize reaching out directly to inquire about their experience, capabilities, and to request samples of previous work. Establishing a personal connection can also provide insights into their reliability and service quality.

Scenario 2: Concerns About Quality and Consistency in Casting

The Problem: Buyers frequently encounter anxiety over the quality and consistency of the casting results, especially when working with new suppliers. Variability in cast quality can lead to significant financial losses, especially if the castings are intended for high-end jewelry or industrial applications. Inconsistent finishes, porosity, and design inaccuracies can tarnish a buyer’s reputation and impact customer satisfaction.

The Solution: To mitigate quality concerns, it’s essential to conduct thorough due diligence before engaging with a casting service. Begin by requesting detailed information about their casting process, technology used, and quality assurance measures. Ask for samples of past work, and if possible, visit their facilities to observe their operations firsthand. Establish clear specifications and expectations for the casting project, and consider implementing a trial run of smaller orders before committing to larger production volumes. This approach not only helps in assessing the quality but also fosters a collaborative relationship with the supplier, allowing for better communication and adjustments during the casting process.

Illustrative image related to lost wax casting near me

Scenario 3: Long Turnaround Times Affecting Production Schedules

The Problem: Many B2B buyers face delays in turnaround times from casting services, which can disrupt their production schedules and lead to missed deadlines. In industries where time-to-market is critical, such as fashion and jewelry design, prolonged casting times can have cascading effects on the overall project timeline, affecting customer relationships and financial performance.

The Solution: To address turnaround time issues, buyers should clearly communicate their project timelines and urgency upfront when discussing potential partnerships with casting companies. Inquire about standard processing times and any potential bottlenecks in their workflow. Some companies may offer expedited services for an additional fee, which can be a worthwhile investment for critical projects. Additionally, consider establishing a preferred vendor relationship with a reliable casting company, which may lead to prioritized service and faster response times. Keeping an open line of communication regarding order status and production updates can further help in managing expectations and ensuring timely delivery.

Strategic Material Selection Guide for lost wax casting near me

What Are the Key Materials Used in Lost Wax Casting?

Lost wax casting is a versatile manufacturing process that allows for the creation of intricate designs in various materials. Understanding the properties, advantages, and limitations of these materials is crucial for B2B buyers looking to optimize their production processes. Below, we analyze four common materials used in lost wax casting, focusing on their suitability for international buyers from diverse regions.

Which Metals Are Commonly Used in Lost Wax Casting?

1. Gold (Various Karats)

Key Properties: Gold is highly malleable and ductile, with excellent corrosion resistance and a melting point around 1,064°C (1,947°F).

Pros & Cons: Gold castings are known for their luxurious finish and high market value. However, they can be expensive due to the cost of raw materials, and the casting process can be complex, requiring skilled labor to ensure quality.

Impact on Application: Gold is ideal for high-end jewelry and decorative items, where aesthetics and durability are paramount.

Considerations for International Buyers: Compliance with international standards such as ASTM and local regulations regarding precious metals is essential. Buyers from regions like Africa and the Middle East may prefer specific karat values based on local market trends.

Illustrative image related to lost wax casting near me

2. Silver (Sterling Silver)

Key Properties: Sterling silver is an alloy containing 92.5% silver and 7.5% other metals (usually copper), providing good strength and a melting point of approximately 893°C (1,639°F).

Pros & Cons: Silver is more affordable than gold, making it a popular choice for mid-range jewelry. However, it is prone to tarnishing and may require regular maintenance to retain its luster.

Impact on Application: Silver is suitable for both jewelry and functional items, but tarnishing can affect its appeal in markets where aesthetics are critical.

Considerations for International Buyers: Buyers should ensure compliance with silver content standards (e.g., ASTM, JIS) and consider local preferences for finishes that minimize tarnishing.

3. Brass

Key Properties: Brass is an alloy of copper and zinc, known for its good corrosion resistance and a melting point around 900°C (1,652°F).

Pros & Cons: Brass offers a gold-like appearance at a lower cost, making it an attractive option for costume jewelry. However, it is less durable than precious metals and can tarnish over time.

Impact on Application: Brass is often used for decorative items and lower-cost jewelry, appealing to budget-conscious consumers.

Considerations for International Buyers: Compliance with material safety standards is crucial, especially in regions with stringent regulations on metal content. Buyers should also be aware of local market preferences for brass finishes.

4. Platinum

Key Properties: Platinum is a dense, malleable metal with a high melting point of about 1,768°C (3,214°F) and exceptional corrosion resistance.

Illustrative image related to lost wax casting near me

Pros & Cons: Platinum is highly durable and hypoallergenic, making it ideal for fine jewelry. However, its high cost and the complexity of working with it can be significant drawbacks.

Impact on Application: Platinum is favored for high-end jewelry, particularly engagement and wedding rings, where durability and prestige are essential.

Considerations for International Buyers: Buyers should ensure that their suppliers adhere to international standards for platinum purity and consider the higher costs associated with sourcing this material.

Summary Table of Materials for Lost Wax Casting

| Material | Typical Use Case for lost wax casting near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Gold (Various Karats) | High-end jewelry and decorative items | Luxurious finish and high market value | Expensive and complex casting process | High |

| Silver (Sterling Silver) | Jewelry and functional items | More affordable than gold | Prone to tarnishing | Medium |

| Brass | Decorative items and costume jewelry | Gold-like appearance at lower cost | Less durable and can tarnish | Low |

| Platinum | Fine jewelry, especially engagement rings | Highly durable and hypoallergenic | High cost and complex to work with | High |

This guide provides a comprehensive overview of materials utilized in lost wax casting, tailored for international B2B buyers. Understanding these materials will enable businesses to make informed decisions that align with their production needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for lost wax casting near me

What Are the Key Stages in the Lost Wax Casting Manufacturing Process?

The lost wax casting process is a sophisticated method widely used in the jewelry and industrial sectors. It encompasses several distinct stages, from material preparation to finishing, ensuring the creation of high-quality metal parts.

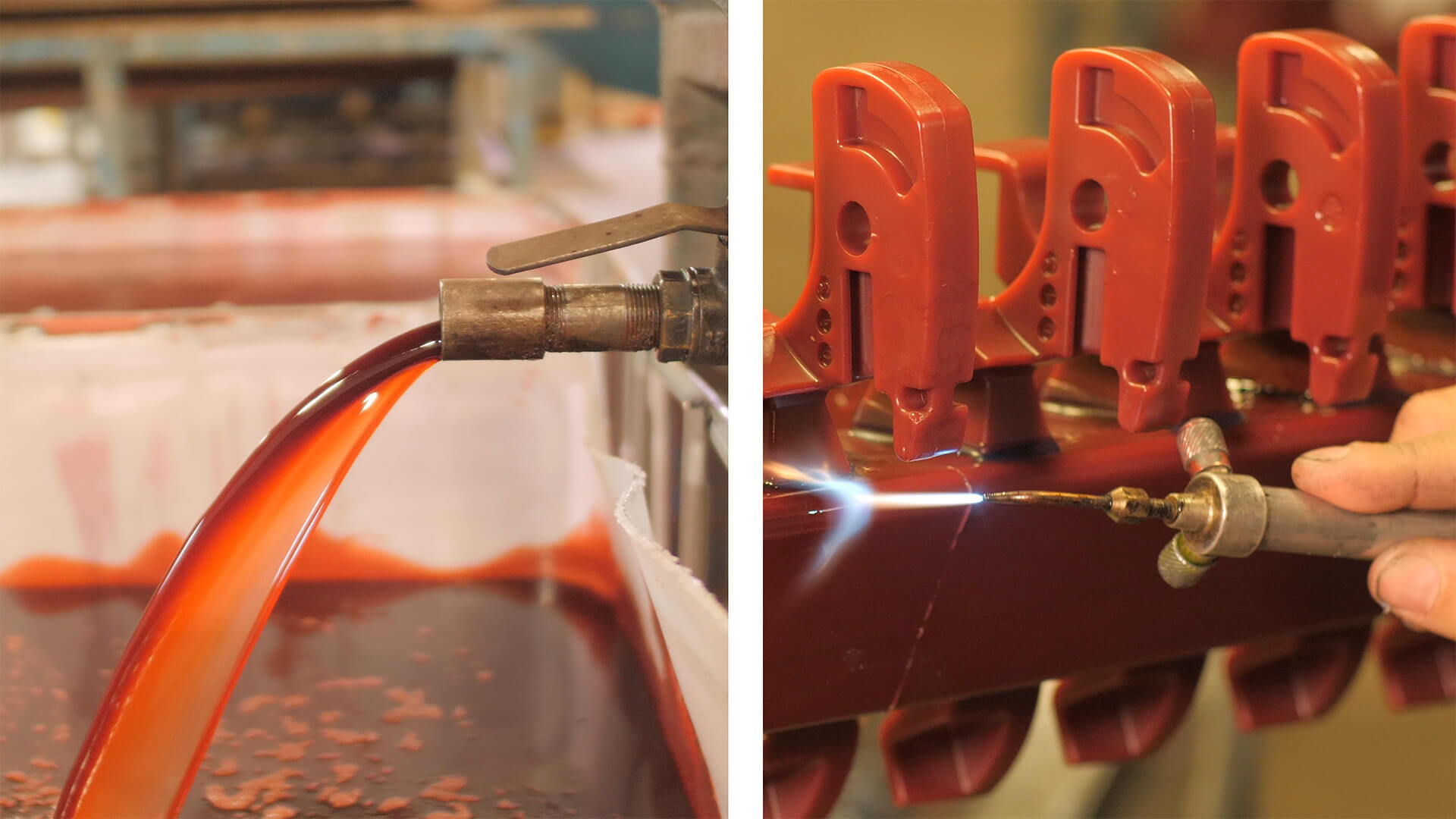

Illustrative image related to lost wax casting near me

-

Material Preparation: The initial step involves selecting the appropriate materials for casting. This typically includes wax or resin to create the model, as well as the metal to be cast (gold, silver, platinum, etc.). The wax models must adhere to industry standards for quality and compatibility.

-

Forming the Mold: Once the model is ready, it is encased in a special plaster or ceramic material to create a mold. This process involves heating the mold to harden it and then melting the wax to leave a hollow cavity. Advanced techniques, such as 3D printing, can also be utilized to produce intricate designs with precision.

-

Metal Pouring: After the mold is prepared, molten metal is poured into the cavity. The temperature and timing of this step are critical, as they affect the final product’s integrity and surface quality. Techniques such as vacuum casting can be employed to minimize air pockets and improve the casting quality.

-

Finishing: Once the metal cools and solidifies, the mold is broken to reveal the cast piece. This stage includes cleaning, polishing, and applying any desired surface treatments. Finishing touches enhance the aesthetic appeal and durability of the final product.

-

Assembly (if applicable): In some cases, multiple parts may need to be assembled to create a final product. This could involve soldering, setting stones, or other methods to ensure a cohesive and functional piece.

How Is Quality Assurance Implemented in Lost Wax Casting?

Quality assurance (QA) is crucial in ensuring that the final castings meet the specified standards. The process typically involves several checkpoints throughout the manufacturing cycle.

-

International Standards Compliance: Many manufacturers adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards ensures that the processes are documented, consistent, and continuously improved.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): Raw materials, including wax, metal, and mold materials, are inspected upon arrival. This step ensures that only materials meeting specified quality criteria are used in production.

– In-Process Quality Control (IPQC): During the casting process, periodic checks are conducted to monitor parameters such as temperature, pressure, and timing. This helps identify any deviations from the set standards early on.

– Final Quality Control (FQC): After the casting is complete, each piece undergoes a thorough inspection. This includes dimensional checks, visual inspections for defects, and sometimes testing for material properties. -

Common Testing Methods: Various testing methods may be employed to verify the quality of the castings. These include:

– Non-Destructive Testing (NDT): Techniques like ultrasonic testing or X-ray inspection can reveal internal defects without damaging the part.

– Mechanical Testing: Hardness and tensile strength tests assess the material properties of the castings to ensure they meet the required specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be diligent in verifying the quality control practices of their suppliers. Here are several strategies to ensure quality:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and compliance with international standards. This firsthand observation is invaluable in determining the supplier’s commitment to quality.

-

Requesting Quality Reports: Buyers should request detailed quality assurance reports from suppliers. These documents should outline the processes followed, test results, and compliance with relevant standards. Suppliers should be willing to provide this information to build trust.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These organizations can conduct random checks, ensuring that the products meet the agreed specifications.

-

Certification Verification: Buyers should verify any claimed certifications (like ISO 9001 or CE) by checking with the certifying bodies. This step helps ensure that the supplier adheres to recognized quality standards.

-

References and Reviews: Seeking references from other B2B partners or checking online reviews can provide insights into the supplier’s reliability and quality standards. Engaging with other businesses in similar industries can reveal valuable information regarding supplier performance.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from various international markets must navigate specific nuances in quality control that may differ from local practices. Here are a few considerations:

-

Cultural Differences: Understanding cultural attitudes toward quality and business practices is essential. In some regions, personal relationships may heavily influence quality assurance practices.

-

Regulatory Compliance: Buyers must be aware of the regulatory requirements in their region. Certain countries may have stricter import regulations regarding quality, particularly for products like jewelry that could involve precious metals.

-

Language Barriers: Clear communication is vital. Buyers should ensure that specifications and quality expectations are explicitly outlined and understood by the supplier, potentially using translation services if necessary.

-

Logistical Challenges: International shipping can pose risks to product quality. Buyers should discuss packaging and shipping methods with suppliers to minimize damage during transit.

By understanding the manufacturing processes and the importance of quality assurance in lost wax casting, B2B buyers can make informed decisions when selecting suppliers, ultimately ensuring the quality and reliability of the products they purchase.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lost wax casting near me’

To successfully procure lost wax casting services, B2B buyers must approach the sourcing process methodically. This guide provides a structured checklist to streamline your search for reliable casting suppliers, ensuring that your investment yields high-quality results.

Step 1: Define Your Technical Specifications

Begin by outlining your specific requirements for the lost wax casting process. This includes the type of metal you need (gold, silver, platinum, etc.), the complexity of the design, and the desired finish. Clear specifications help potential suppliers understand your needs and provide accurate quotes.

- Design Complexity: Consider whether you are working with simple shapes or intricate designs, as this will affect the casting process.

- Metal Type: Different metals may require specific handling and expertise, so it’s crucial to specify your preferences.

Step 2: Research Local Suppliers

Use search engines and industry directories to identify casting companies in your vicinity. This step is vital for minimizing shipping costs and lead times, which can significantly impact your project timeline.

- Keywords: Use search terms like “lost wax casting [your city/region]” or “jewelry casting near me” to find local options.

- Company Listings: Explore online directories or forums where casting companies are listed, and consider reaching out for recommendations.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet the suppliers you’ve identified. Request company profiles, case studies, and references from other businesses in your industry or region to gain insights into their reliability and quality.

Illustrative image related to lost wax casting near me

- Quality Assurance: Inquire about their quality control processes to ensure that the final product meets your standards.

- Customer Feedback: Look for reviews or testimonials from previous clients to gauge their satisfaction with the supplier’s services.

Step 4: Verify Certifications and Standards

Ensure that your chosen supplier adheres to industry standards and possesses relevant certifications. This step is crucial for ensuring compliance with quality and ethical sourcing practices.

- ISO Certifications: Look for suppliers with ISO certifications, as they indicate adherence to international quality management standards.

- Sustainability Practices: Verify whether they follow environmentally friendly practices, especially if you are concerned about ethical sourcing.

Step 5: Request Samples and Quotes

Once you’ve narrowed down your options, request samples of previous work and detailed quotes from potential suppliers. This will help you assess the quality of their craftsmanship and the competitiveness of their pricing.

- Sample Evaluation: Analyze the quality of the samples to see if they meet your expectations.

- Cost Breakdown: Request a detailed quote that outlines all costs involved, including any additional fees for design modifications or expedited services.

Step 6: Discuss Timelines and Delivery Options

Communication regarding project timelines is critical. Confirm the expected turnaround times and delivery options with your selected supplier to ensure they align with your project deadlines.

- Lead Times: Understand their typical production times based on your order size and complexity.

- Shipping Arrangements: Discuss shipping methods and insurance coverage to protect your investment during transit.

Step 7: Establish a Communication Plan

Finally, set up a clear communication plan with your supplier to facilitate smooth collaboration throughout the casting process. Regular updates can help address any potential issues proactively.

- Point of Contact: Designate a point of contact for both parties to streamline communication.

- Regular Check-ins: Schedule periodic updates to track progress and resolve any questions that may arise.

By following these steps, B2B buyers can effectively source lost wax casting services that meet their specific needs, ensuring high-quality outcomes for their projects.

Comprehensive Cost and Pricing Analysis for lost wax casting near me Sourcing

What Are the Key Cost Components in Lost Wax Casting?

When considering lost wax casting, several cost components must be evaluated to understand the overall pricing structure. The primary elements include:

-

Materials: The choice of metal significantly affects costs. Precious metals like gold, platinum, and silver are more expensive than brass or bronze. Additionally, the cost of wax or resin used for creating the initial model also contributes to the material expenses.

-

Labor: Skilled labor is essential for the lost wax casting process. The expertise required for creating molds, pouring metal, and finishing products can lead to higher labor costs, especially if the casting company employs highly experienced artisans.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and equipment depreciation. Companies with advanced technology may have higher overhead due to the investment in specialized machinery.

-

Tooling: Depending on the complexity of the design, tooling costs can vary. Custom molds or specialized tools will increase upfront costs but can improve efficiency in mass production.

-

Quality Control (QC): Rigorous quality checks are necessary to ensure that the final product meets industry standards and client specifications. QC processes add to labor costs and may require additional time.

-

Logistics: Shipping and handling can become significant, especially for international orders. The costs associated with transporting materials to and from the foundry should not be overlooked.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure business sustainability. This margin can vary based on the supplier’s reputation, service quality, and market demand.

What Influences Pricing for Lost Wax Casting?

Several factors can influence the pricing of lost wax casting services:

-

Volume and Minimum Order Quantity (MOQ): Higher volume orders often receive discounted rates. Establishing a long-term relationship with a supplier can also lead to better pricing structures.

-

Specifications and Customization: Unique designs or specifications can increase costs. Customization may require more labor and materials, influencing the final price.

-

Material Quality and Certifications: The quality of metals used and any necessary certifications (e.g., conflict-free sourcing) can affect pricing. Buyers should be aware that higher quality often comes at a premium.

-

Supplier Factors: The supplier’s location, reputation, and capabilities can influence costs. Companies with advanced technology and skilled labor may charge more but offer higher quality and faster turnaround times.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) relevant to the transaction is crucial. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can impact the total cost.

What Are Effective Buyer Tips for Sourcing Lost Wax Casting Services?

B2B buyers should consider the following tips to enhance cost-efficiency in sourcing lost wax casting:

-

Negotiation: Engage in discussions with suppliers to negotiate prices, especially if you have a long-term project or multiple orders. Suppliers may be more flexible with pricing for established clients.

-

Evaluate Total Cost of Ownership: Consider not only the upfront costs but also the long-term expenses associated with the casting service. This includes labor for finishing, logistics, and potential rework costs due to quality issues.

-

Understand Pricing Nuances for International Sourcing: For buyers in regions such as Africa, South America, the Middle East, and Europe, be aware of the additional costs associated with international shipping, customs duties, and potential tariffs. Building relationships with local suppliers can mitigate some of these costs.

-

Request Detailed Quotes: When reaching out to suppliers, request comprehensive quotes that break down costs. This will help in understanding where savings can be made and ensure transparency.

Conclusion

Understanding the cost structure and pricing influencers for lost wax casting is essential for international B2B buyers. By focusing on the key cost components, recognizing pricing influencers, and applying effective sourcing strategies, buyers can make informed decisions that align with their business objectives. Always keep in mind that the prices can vary widely based on the aforementioned factors, so it’s prudent to obtain multiple quotes and conduct thorough research before committing to a supplier.

Alternatives Analysis: Comparing lost wax casting near me With Other Solutions

Exploring Alternatives to Lost Wax Casting

When considering jewelry production or metal fabrication, lost wax casting is a popular method known for its precision and ability to create intricate designs. However, various alternative methods also exist, each with unique advantages and drawbacks. This section evaluates lost wax casting against two notable alternatives: 3D Printing and Die Casting. Understanding these options will help B2B buyers make informed decisions that align with their specific requirements.

| Comparison Aspect | Lost Wax Casting Near Me | 3D Printing | Die Casting |

|---|---|---|---|

| Performance | High precision and detail | Excellent for complex geometries | Good for high-volume production |

| Cost | Moderate to high | Variable; lower for small batches | Lower per unit in large quantities |

| Ease of Implementation | Requires skilled artisans | User-friendly with CAD software | Requires specialized equipment |

| Maintenance | Moderate; skilled labor needed | Low; requires software updates | High; molds need frequent replacement |

| Best Use Case | Custom, detailed pieces | Prototyping, complex designs | Mass production, uniform parts |

What Are the Advantages and Disadvantages of 3D Printing?

3D printing, or additive manufacturing, allows for the creation of complex designs directly from digital files. This method excels in prototyping and small batch production, making it ideal for businesses that need rapid iterations or customization. The primary advantage lies in its flexibility and reduced material waste. However, the cost can escalate for larger production runs, and the surface finish may require additional post-processing to meet quality standards.

Illustrative image related to lost wax casting near me

How Does Die Casting Compare to Lost Wax Casting?

Die casting is a manufacturing process that forces molten metal into a mold under high pressure. This technique is particularly effective for producing large quantities of uniform parts, making it a preferred choice for mass production. The cost per unit decreases significantly with scale, which benefits manufacturers looking to optimize their budgets. However, the initial setup cost for molds can be high, and the process is less suitable for intricate designs compared to lost wax casting, which can accommodate fine details more effectively.

Conclusion: How to Choose the Right Solution for Your Needs

In selecting the right casting method, B2B buyers should consider the specific requirements of their projects. For intricate, custom designs, lost wax casting remains a strong choice due to its high level of detail. If speed and flexibility are priorities, especially in prototyping, 3D printing may be the better option. Conversely, for companies focused on mass production of standard parts, die casting offers a cost-effective solution. Ultimately, understanding the unique benefits and limitations of each method will empower buyers to make decisions that best support their business objectives.

Essential Technical Properties and Trade Terminology for lost wax casting near me

What Are the Essential Technical Properties of Lost Wax Casting?

When engaging with lost wax casting services, understanding the key technical properties is vital for ensuring high-quality outcomes that meet your business needs. Here are several critical specifications to consider:

-

Material Grade

The material grade refers to the quality and composition of the metal used in the casting process, such as gold, silver, or brass. Different grades have varying levels of purity and physical properties, which can impact the final product’s durability and appearance. For B2B buyers, selecting the appropriate material grade is crucial as it affects both the aesthetic qualities of the jewelry and its market value. -

Tolerance

Tolerance is the permissible limit of variation in a physical dimension of a cast piece. In lost wax casting, maintaining tight tolerances is essential for ensuring that components fit together precisely, especially in intricate designs. For businesses, understanding tolerance levels can prevent costly rework and ensure that products meet client specifications. -

Surface Finish

The surface finish refers to the texture and smoothness of the casted item. Different finishes, such as polished or matte, can significantly affect the product’s visual appeal and marketability. A high-quality finish not only enhances the aesthetic but also adds to the perceived value of the jewelry, making it crucial for B2B buyers to specify desired finishes upfront. -

Casting Process Efficiency

This property pertains to the speed and effectiveness of the casting process, which can vary among service providers. Efficient processes can reduce lead times and lower costs, making it an important consideration for businesses that require timely delivery. Understanding the efficiency of a casting service can help buyers optimize their supply chain and inventory management. -

Yield Rate

The yield rate is the percentage of usable product produced from a casting batch. High yield rates indicate fewer defects and less waste, which is beneficial for cost management. For B2B buyers, knowing the yield rate helps in evaluating the overall value of a casting service, as lower waste translates to lower costs.

What Are Common Trade Terms in Lost Wax Casting?

Familiarizing yourself with industry terminology can facilitate better communication and negotiation with casting service providers. Here are several essential trade terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of lost wax casting, understanding OEM relationships can help businesses identify reliable partners for producing customized components. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of products that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to ensure that their order sizes align with their production needs and budget constraints. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to submit price quotes for specific products or services. For buyers in lost wax casting, issuing an RFQ can help in comparing costs and evaluating the quality of different service providers. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping agreements. Understanding these terms is crucial for B2B transactions, as they dictate who is responsible for shipping costs, insurance, and risk during transportation. -

Lead Time

Lead time is the amount of time taken from placing an order to receiving the finished product. Knowing the lead time is vital for B2B buyers to effectively plan their production schedules and meet customer demands. -

Casting Defects

Casting defects are flaws that occur during the casting process, such as porosity or surface irregularities. Being aware of common defects helps buyers understand quality control measures and select casting services that minimize these issues.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when seeking lost wax casting services, ensuring alignment with their production goals and market demands.

Navigating Market Dynamics and Sourcing Trends in the lost wax casting near me Sector

What Are the Current Trends Driving the Lost Wax Casting Market for International B2B Buyers?

The lost wax casting market is experiencing significant transformation, driven by globalization and technological advancements. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for customized and high-quality casting solutions is on the rise. Key trends include the adoption of digital tools such as 3D printing and CAD software, which streamline the design process and reduce lead times. As businesses seek more efficient production methods, suppliers that offer instant pricing tools and rapid prototyping services are gaining a competitive edge.

Moreover, the market is witnessing a surge in demand for niche applications, such as artisanal jewelry and bespoke metalwork. This shift is encouraging casting companies to diversify their service offerings, including polishing, stone setting, and finishing options that meet specific client needs. The integration of automated quality assurance processes is also becoming a standard, allowing for consistent product quality and enhanced customer satisfaction.

Furthermore, as supply chains evolve, international buyers are increasingly looking for local partners to mitigate risks associated with long-distance logistics. This trend emphasizes the importance of establishing reliable local sources for lost wax casting services, ensuring that buyers can respond quickly to market demands and maintain operational efficiency.

How Is Sustainability Shaping Sourcing Decisions in the Lost Wax Casting Industry?

Sustainability has emerged as a critical factor influencing B2B sourcing decisions in the lost wax casting sector. The environmental impact of metal casting processes, including energy consumption and waste generation, is prompting buyers to seek suppliers that prioritize eco-friendly practices. The use of recycled metals, sustainable wax materials, and environmentally responsible casting methods are becoming essential criteria for procurement.

Ethical sourcing is also gaining traction, with buyers increasingly demanding transparency in their supply chains. Companies that can demonstrate their commitment to ethical practices—such as fair labor conditions and responsible sourcing of raw materials—are likely to attract more international clients. Certifications related to green manufacturing and ethical sourcing can serve as a competitive advantage, enhancing a company’s reputation and appeal to conscientious buyers.

Additionally, the push for sustainability is leading to innovations in casting technologies that reduce emissions and waste. For instance, some casting companies are investing in energy-efficient furnaces and exploring alternative materials that minimize environmental impact. As a result, buyers are encouraged to prioritize partnerships with suppliers who align with their sustainability goals, ensuring that their sourcing practices contribute positively to the environment.

What Is the Historical Context of Lost Wax Casting Relevant to Today’s B2B Landscape?

The lost wax casting technique, with roots tracing back over 5,000 years, has evolved significantly to meet contemporary market demands. Originally utilized in ancient civilizations for creating intricate jewelry and religious artifacts, the process has been refined through centuries of craftsmanship and innovation. Today, it stands as a hallmark of precision and quality in metalworking, particularly within the jewelry industry.

The modern adaptation of lost wax casting incorporates advanced technologies such as 3D printing, which allows for more complex designs and faster production times. This evolution reflects a broader trend in manufacturing where traditional techniques blend seamlessly with cutting-edge technology. For B2B buyers, understanding this historical context not only provides insight into the craftsmanship involved but also highlights the value of partnering with suppliers who respect traditional methods while embracing modern advancements.

Illustrative image related to lost wax casting near me

This historical perspective is crucial for international buyers seeking to source high-quality lost wax castings, as it underscores the importance of experience, skill, and innovation in selecting the right casting partner. As the market continues to evolve, leveraging this rich history can inform sourcing decisions and foster deeper relationships with suppliers committed to excellence.

Frequently Asked Questions (FAQs) for B2B Buyers of lost wax casting near me

-

How do I find a reliable lost wax casting supplier near me?

To find a reliable lost wax casting supplier, start by researching local and international companies with a strong reputation. Utilize online directories, industry forums, and social media platforms to gather recommendations. Look for suppliers that provide detailed information about their services, including their casting capabilities and experience in your specific industry. It’s also beneficial to reach out to existing customers for testimonials. If local options are limited, consider expanding your search to international suppliers, ensuring they have experience with the specific materials and designs relevant to your needs. -

What is the best metal for lost wax casting jewelry?

The best metal for lost wax casting jewelry often depends on the desired aesthetic and functional properties. Common choices include gold (in various karats), silver, and platinum, each offering unique qualities such as durability, luster, and hypoallergenic properties. For budget-conscious projects, brass or bronze may also be suitable alternatives. Consider the final use of the jewelry and customer preferences when selecting the metal. Collaborating with your casting supplier can help determine the most appropriate metal based on your design and market trends. -

What are the minimum order quantities (MOQs) for lost wax casting services?

Minimum order quantities (MOQs) for lost wax casting services can vary significantly between suppliers. Some may accept small orders for prototypes or custom pieces, while others might require larger batches to justify production costs. Typically, MOQs can range from a few pieces to several dozen, depending on the complexity of the design and the materials used. It’s essential to communicate your needs with potential suppliers to understand their policies and negotiate terms that suit your production requirements. -

How can I ensure quality assurance in lost wax casting?

To ensure quality assurance in lost wax casting, it’s crucial to partner with a supplier that has a robust quality control process. Inquire about their inspection methods, such as dimensional checks, surface finish evaluations, and material testing. Request samples or prototypes before committing to larger orders, allowing you to assess craftsmanship and adherence to your specifications. Additionally, consider suppliers who offer guarantees or recasting services if the initial products do not meet your quality standards, ensuring your investment is protected. -

What are the common payment terms for international lost wax casting orders?

Payment terms for international lost wax casting orders can vary based on the supplier and the nature of the agreement. Common options include upfront payment, partial payments upon order confirmation, and balance upon delivery. Some suppliers may also accept letters of credit or other financing options for larger orders. It’s advisable to clarify payment terms during the negotiation process, ensuring transparency and aligning with your budget constraints and cash flow management strategies. -

What customization options are available for lost wax casting?

Lost wax casting offers extensive customization options, allowing for unique designs tailored to your specifications. Customization can include variations in metal types, finishes, and the incorporation of gemstones or intricate detailing. Discuss your design requirements with the casting supplier, who can advise on feasible options based on their capabilities. Additionally, consider the use of 3D printing technology for creating complex models, which can enhance the precision and creativity of your final product. -

How do logistics and shipping work for international lost wax casting orders?

Logistics and shipping for international lost wax casting orders involve several key considerations, including shipping methods, costs, and insurance. Discuss with your supplier their shipping options, which may include air freight for quicker delivery or sea freight for larger shipments. Ensure all shipments are fully insured to protect against loss or damage during transit. It’s also important to understand customs regulations in your country to avoid delays or additional fees upon arrival. -

What factors should I consider when vetting a lost wax casting supplier?

When vetting a lost wax casting supplier, consider their experience, reputation, and capacity to handle your specific projects. Review their portfolio to assess the quality of their previous work, and seek references from other clients. Evaluate their communication responsiveness and willingness to collaborate on design iterations. Additionally, inquire about their production timelines, quality assurance processes, and flexibility in meeting your order requirements. This comprehensive approach will help ensure you partner with a supplier that aligns with your business goals.

Top 6 Lost Wax Casting Near Me Manufacturers & Suppliers List

1. Vijay’s NYC – Metal Casting Services

Domain: vijays.nyc

Registered: 2018 (7 years)

Introduction: Metal Casting services at Vijay’s NYC include high-quality metal castings in Precious or Semi-Precious metals using the lost-wax casting method. Available metals include Yellow Gold (10K, 14K, 18K, 22K), White Gold (10K, 14K, 18K), Pink Gold (10K, 14K, 18K), Platinum (950), Silver (925-Sterling), and Brass. Customers can supply their own wax/resin models for casting, provided they meet industry st…

2. Global Gold & Silver – Certified Jewelry Casting Services

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: Top Jewelry Casting services in New York, NY include: 1. Global Gold & Silver – Certified professionals, free estimates, response time 3 hrs, response rate 100%. 2. Carrera Casting – Eco-friendly, no minimum orders, casts 50 different alloys daily, offers rubber jewelry molds, CAD design, 3D-printing, and 3D-scanning, response time 10 mins, response rate 100%. 3. J Patch Designs by Karen – Establi…

3. City Casting Corp – Jewelry & Sculpture Manufacturing

Domain: citycastingnyc.com

Registered: 2015 (10 years)

Introduction: City Casting Corp. manufactures in-house jewelry and sculptures using lost wax casting. They offer services including casting in precious and base metals of all karats and colors, CAD design and printing, molding for production, laser engraving, and finishing. They handle projects of all sizes and have been in business since 1984.

4. Casting House – Jewelry Casting Services

Domain: castinghouse.com

Registered: 1998 (27 years)

Introduction: Casting House offers jewelry casting services for custom and mass production of jewelry designs. The casting process includes steps such as wax model preparation, investment, burnout, melting, casting using techniques like centrifugal, vacuum-assisted, pressure casting, and torch casting, and divesting. They provide access to over 40 precious metals including variations of platinum, gold, white go…

5. JCCO – Jewelry Casting Services

Domain: jccojewelrycastingservices.com

Registered: 2007 (18 years)

Introduction: JCCO ENTERPRISES offers jewelry casting services with the following key details: 1. **Materials**: Casting available in 10K, 14K, 18K (yellow, white, rose, green) gold, .925 sterling silver, and platinum. 2. **Services Offered**: – Gold Casting Service Labor Price: $11.00 per casting – Sterling Silver Casting Service Labor Price: $2.75 per casting – Platinum Casting Service Labor Price: $12.00 per…

6. Hobbyist Wax Carvings – Custom Casting Services

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Hobbyist wax carvings, casting services for one-off pieces, materials: silver, gold, brass, no finishing services required, concerns about shipping fragile items, recommendations for casting houses, preference for local casting houses for shorter delivery times.

Strategic Sourcing Conclusion and Outlook for lost wax casting near me

In the dynamic landscape of lost wax casting, strategic sourcing emerges as a pivotal element for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. By leveraging local expertise and global networks, businesses can access high-quality casting services tailored to their specific needs. The advantages of proximity to casting companies include reduced shipping costs, faster turnaround times, and improved communication, which ultimately enhance project efficiency.

As you evaluate potential casting partners, prioritize firms that offer comprehensive services, including advanced technology and quality assurance processes. Establishing relationships with reputable casting companies can not only streamline your supply chain but also foster innovation in your product designs.

Looking ahead, the demand for customized and sustainable casting solutions is expected to grow, driven by evolving market trends and consumer preferences. Embrace this opportunity by exploring casting companies that align with your values and operational goals. Take the next step towards optimizing your sourcing strategy by conducting thorough research and reaching out to local experts in lost wax casting. Your commitment to quality and efficiency will set your business apart in an increasingly competitive global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.