A Deep Dive into Spline Coupling Solution

Introduction: Navigating the Global Market for spline coupling

In an increasingly interconnected world, sourcing reliable spline couplings poses a significant challenge for international B2B buyers. With applications ranging from automotive to industrial machinery, selecting the right spline coupling is crucial for ensuring efficient power transmission and operational reliability. This comprehensive guide delves into the various types of spline couplings, their specific applications, and the critical factors to consider when vetting suppliers.

Buyers will gain insights into the distinctions between parallel and involute spline couplings, as well as their respective advantages and ideal use cases. Additionally, this guide addresses the complexities of cost considerations, material choices, and the importance of supplier reputation—essential elements that influence purchasing decisions.

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including Germany and Brazil, understanding the nuances of spline couplings can lead to more informed and strategic procurement choices. By empowering buyers with actionable insights and practical knowledge, this guide serves as an essential resource to navigate the global market for spline couplings effectively. Whether you are optimizing existing systems or embarking on new projects, the information provided will enhance your capacity to make educated decisions that drive your business forward.

Understanding spline coupling Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Parallel Spline Coupling | Straight teeth parallel to the shaft | Heavy machinery, automotive applications | Pros: High torque transmission; Cons: Limited flexibility in alignment. |

| Involute Spline Coupling | Curved teeth providing wider contact area | High-performance systems, aerospace, robotics | Pros: Smoother power transmission; Cons: More complex design may increase cost. |

| Flexible Spline Coupling | Allows for misalignment and vibration absorption | Pump systems, conveyor belts | Pros: Enhances durability and reduces wear; Cons: May have lower torque capacity. |

| Hexagonal Spline Coupling | Hexagonal shape for better grip and torque | Agricultural machinery, construction equipment | Pros: Strong grip; Cons: May not fit standard applications easily. |

| Keyed Spline Coupling | Combination of keyed and splined design | General machinery, manufacturing processes | Pros: Ensures secure connection; Cons: Can be heavier and bulkier. |

What Are the Characteristics of Parallel Spline Couplings?

Parallel spline couplings are characterized by their straight teeth that run parallel to the shaft. This design is particularly suited for applications requiring high torque transmission, making them ideal for heavy machinery and automotive systems. When considering a purchase, buyers should assess the torque requirements and alignment conditions of their systems, as these couplings offer limited flexibility in alignment, which could be a drawback in certain setups.

How Do Involute Spline Couplings Enhance Performance?

Involute spline couplings feature curved teeth that create a broader contact area between the inner and outer splines. This design allows for smoother power transmission, making them suitable for high-performance applications such as aerospace and robotics. B2B buyers should consider the operational demands of their systems when selecting involute couplings, as their more complex design may come at a higher cost but provides significant performance benefits.

Why Choose Flexible Spline Couplings for Your Applications?

Flexible spline couplings are designed to accommodate misalignments and absorb vibrations, making them essential for applications like pump systems and conveyor belts. Their ability to enhance durability and reduce wear is a significant advantage for businesses looking to extend equipment life. However, potential buyers should be aware that while flexible couplings provide excellent alignment compensation, they may have lower torque capacities compared to rigid alternatives.

What Advantages Do Hexagonal Spline Couplings Offer?

Hexagonal spline couplings utilize a hexagonal shape that enhances grip and torque transfer, making them particularly effective in agricultural machinery and construction equipment. Buyers should evaluate the specific requirements of their applications, as the unique shape may not be compatible with standard setups, potentially complicating integration with existing systems. However, the strong grip offered by hexagonal designs can be a decisive factor in high-torque environments.

How Do Keyed Spline Couplings Ensure Secure Connections?

Keyed spline couplings combine the features of keyed and splined designs to provide a secure connection between shafts. They are commonly used in general machinery and manufacturing processes where reliability is paramount. B2B buyers should consider the balance between security and weight, as keyed spline couplings can be heavier and bulkier than other types, which might affect overall system performance and efficiency.

Key Industrial Applications of spline coupling

| Industry/Sector | Specific Application of spline coupling | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Power transmission in drivetrains | Ensures reliable power transfer, enhancing vehicle performance | Material durability, size specifications, and torque capacity |

| Manufacturing | CNC machines and automation equipment | Improves precision in machining operations, reducing downtime | Compatibility with existing systems, precision tolerances |

| Agriculture | Agricultural machinery for power take-off (PTO) systems | Enhances efficiency in power transfer, reducing wear on components | Load ratings, environmental resistance, and ease of installation |

| Oil & Gas | Downhole drilling equipment | Facilitates efficient torque transmission in harsh environments | Corrosion resistance, temperature ratings, and custom design options |

| Heavy Machinery | Construction and mining equipment | Provides robust coupling solutions for high-torque applications | Sourcing from reliable manufacturers, compliance with international standards |

How is Spline Coupling Utilized in the Automotive Industry?

In the automotive sector, spline couplings are integral to the power transmission systems of vehicles. They connect the driveshaft to the gearbox, ensuring that torque is transmitted efficiently. This application is critical for enhancing vehicle performance, especially in high-performance models. International buyers should consider the material durability and size specifications of spline couplings to ensure compatibility with various vehicle models and to meet specific torque requirements.

What Role Does Spline Coupling Play in Manufacturing?

In manufacturing, spline couplings are commonly used in CNC machines and automation equipment to connect rotary shafts. This connection is essential for achieving high precision in machining operations, which directly impacts production efficiency. Buyers in this sector need to focus on compatibility with existing machinery and precision tolerances to avoid operational disruptions, particularly when sourcing from different international suppliers.

How is Spline Coupling Applied in Agriculture?

Agricultural machinery often employs spline couplings in power take-off (PTO) systems, which are vital for transferring power from tractors to various implements. These couplings enhance the efficiency of power transfer, reducing wear and tear on components during operation. Buyers should prioritize load ratings and environmental resistance when sourcing, as agricultural equipment often operates under challenging conditions.

Why is Spline Coupling Important in Oil & Gas?

In the oil and gas industry, spline couplings are essential for downhole drilling equipment, where they facilitate efficient torque transmission. The harsh environments faced in this sector require couplings that can withstand high pressures and corrosive materials. Buyers must consider corrosion resistance and temperature ratings when sourcing these components, ensuring reliability in critical applications.

What Benefits Does Spline Coupling Provide in Heavy Machinery?

Heavy machinery, particularly in construction and mining, relies on spline couplings for robust coupling solutions that handle high-torque applications. These couplings are crucial for maintaining operational efficiency and minimizing downtime. For international buyers, sourcing from reliable manufacturers and ensuring compliance with international standards are vital considerations to guarantee performance and safety in demanding environments.

3 Common User Pain Points for ‘spline coupling’ & Their Solutions

Scenario 1: Difficulty in Sourcing the Right Spline Coupling Type

The Problem: Many B2B buyers encounter challenges when trying to identify the correct type of spline coupling for their specific applications. With various options available—such as parallel spline and involute spline couplings—buyers often find themselves confused about the technical specifications and performance requirements needed for their machinery. This confusion can lead to costly purchasing errors, extended downtime during equipment failure, and ultimately, a significant negative impact on productivity.

The Solution: To overcome this sourcing dilemma, it is essential for buyers to engage in a detailed analysis of their operational needs. Start by consulting the equipment manufacturer’s specifications to understand the required torque capacity and alignment tolerances. Additionally, consider collaborating with a trusted supplier who specializes in spline couplings; they can provide insights based on similar applications. When placing an order, ensure to specify key details such as the shaft diameter, torque requirements, and the intended operational environment (e.g., exposure to moisture or corrosive substances). This proactive approach not only streamlines the purchasing process but also guarantees that the selected coupling will perform optimally in its intended application.

Scenario 2: Misalignment Issues Leading to Coupling Failures

The Problem: Misalignment between shafts is a frequent issue that leads to premature failure of spline couplings. For businesses operating machinery with rotating shafts, even minor misalignments can result in excessive wear and tear, increased vibration, and ultimately, costly downtime for repairs. This scenario is particularly concerning for companies in manufacturing and processing industries where operational efficiency is critical.

The Solution: To mitigate misalignment issues, it is crucial to implement routine maintenance checks and alignment verification techniques. Buyers should invest in precision alignment tools to ensure that shafts are correctly aligned before installing spline couplings. Additionally, selecting flexible spline couplings can offer some tolerance for misalignment, thereby enhancing durability. Regular training for maintenance personnel on proper installation and alignment procedures can further reduce the likelihood of misalignment-related failures, ensuring that equipment runs smoothly and efficiently.

Scenario 3: Challenges with Installation and Handling

The Problem: Installation of spline couplings can be a daunting task, especially for teams that may not have the necessary expertise. Improper installation can lead to functional issues, such as insufficient torque transmission or even complete coupling failure. This challenge is compounded in regions where access to skilled technicians is limited, creating a barrier for effective installation and maintenance of these critical components.

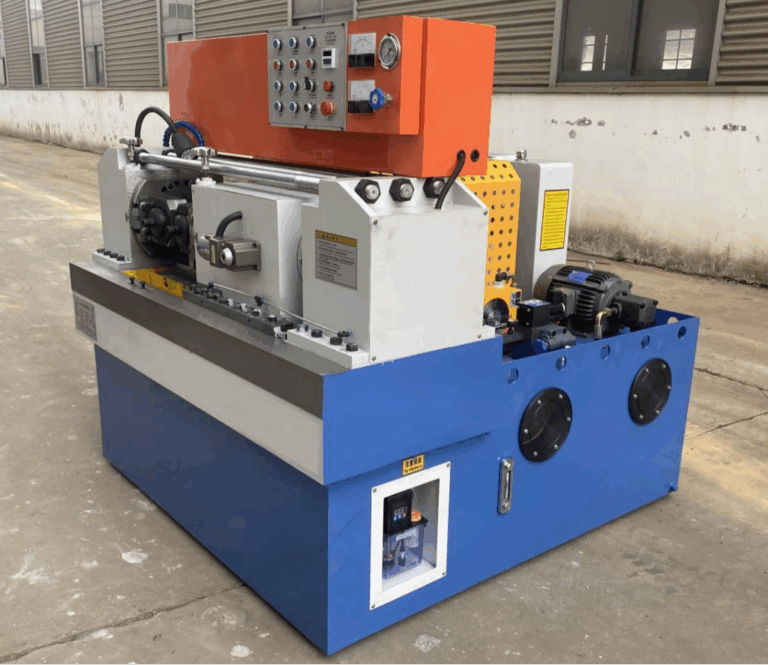

Illustrative image related to spline coupling

The Solution: To address installation challenges, companies should prioritize training and upskilling their workforce on best practices for spline coupling installation. Providing comprehensive installation guides, along with visual aids like instructional videos, can significantly enhance understanding. Furthermore, consider sourcing couplings that come with installation assistance or are designed for easy handling. For businesses operating in remote areas, establishing partnerships with local technical experts can provide the necessary support during installation phases. By investing in training and simplifying the installation process, companies can ensure that spline couplings are installed correctly, leading to improved performance and reduced maintenance costs.

Strategic Material Selection Guide for spline coupling

What are the Common Materials Used for Spline Couplings?

When selecting spline couplings, the choice of material is critical to ensuring optimal performance in various applications. Different materials offer distinct properties that can significantly affect durability, cost, and functionality. Here, we analyze four common materials used in spline couplings: steel, aluminum, magnesium, and plastic composites.

How Does Steel Perform as a Material for Spline Couplings?

Steel is a widely used material for spline couplings due to its exceptional strength and durability. It typically has a high temperature and pressure rating, making it suitable for heavy-duty applications. Steel couplings can withstand significant torque and are resistant to wear and deformation under stress.

Pros: Steel offers excellent mechanical properties, including high tensile strength and resistance to fatigue. It is also relatively cost-effective, especially in large quantities, and can be easily machined to precise specifications.

Cons: The primary drawback of steel is its susceptibility to corrosion, which can be mitigated through coatings or alloying. Additionally, steel couplings are heavier than alternatives, which may not be ideal for applications where weight is a concern.

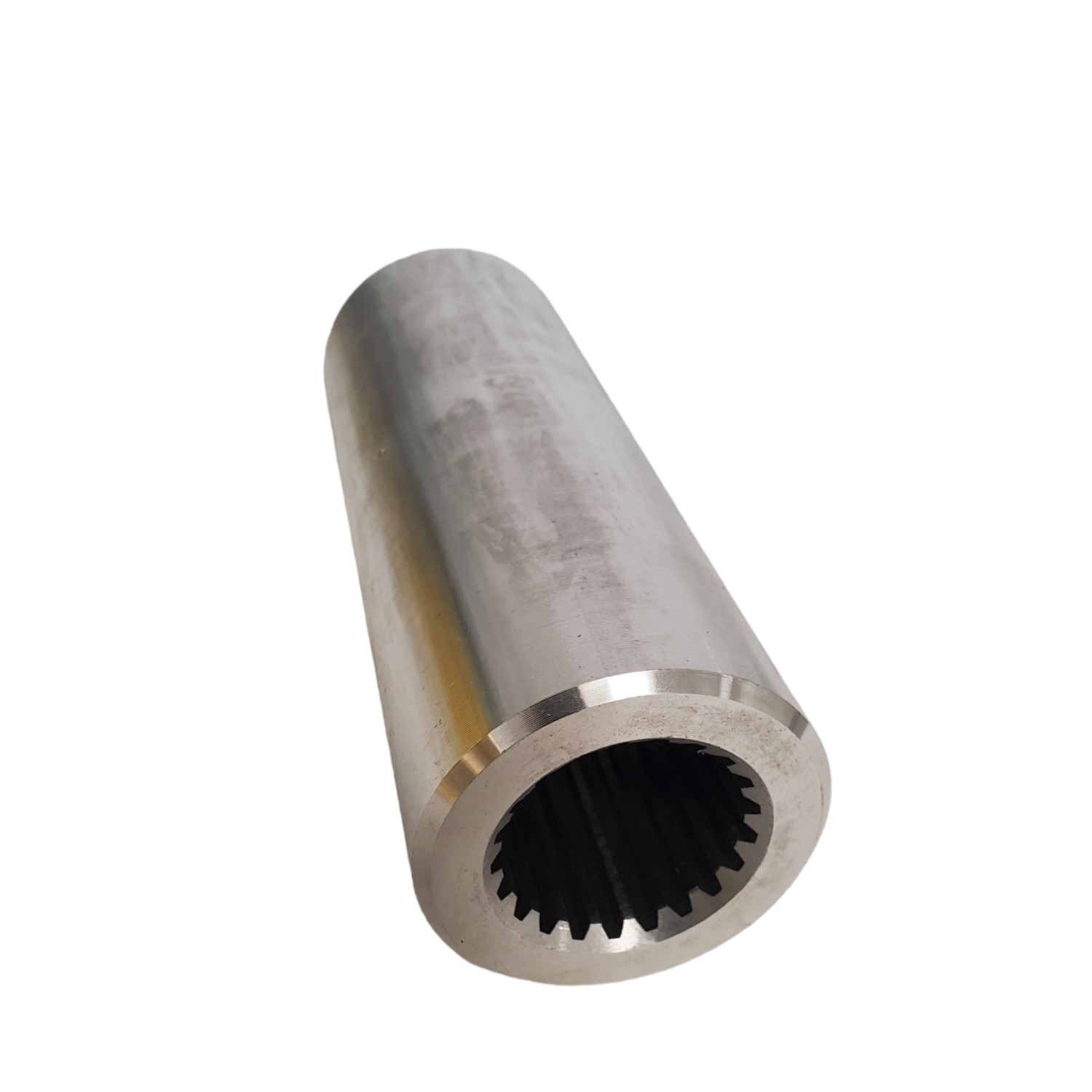

Illustrative image related to spline coupling

Impact on Application: Steel spline couplings are ideal for applications in industries such as automotive, aerospace, and heavy machinery, where high torque and durability are essential. However, they may require additional treatments for corrosion resistance, especially in humid or corrosive environments.

What are the Advantages of Aluminum in Spline Couplings?

Aluminum is another popular choice for spline couplings, particularly in applications where weight reduction is critical. It is significantly lighter than steel, which can lead to improved efficiency in rotating systems.

Pros: Aluminum offers good corrosion resistance and is easier to handle and install due to its lightweight nature. It also has decent mechanical properties, making it suitable for moderate torque applications.

Cons: The main limitation of aluminum is its lower strength compared to steel, which may not be suitable for high-torque applications. Additionally, aluminum can be more expensive than steel, particularly when high-grade alloys are required.

Impact on Application: Aluminum spline couplings are commonly used in the aerospace and automotive sectors, where weight savings can lead to improved fuel efficiency. Buyers should consider the specific torque requirements of their applications to ensure aluminum is a suitable choice.

Why Choose Magnesium for Spline Couplings?

Magnesium is an emerging choice for spline couplings due to its superior strength-to-weight ratio. It is significantly lighter than both steel and aluminum, making it an attractive option for applications requiring reduced weight without compromising strength.

Pros: Magnesium couplings are known for their excellent vibration damping properties and high corrosion resistance. They are also easier to machine, which can reduce manufacturing complexity.

Cons: The primary disadvantage of magnesium is its higher cost and limited availability compared to steel and aluminum. Additionally, it may not be suitable for extremely high-temperature applications.

Impact on Application: Magnesium spline couplings are ideal for applications in industries such as aerospace and automotive, where weight savings are crucial. International buyers should ensure compliance with relevant standards, as magnesium alloys may have specific regulatory requirements.

How do Plastic Composites Compare in Spline Couplings?

Plastic composites are increasingly being used for spline couplings, especially in applications where corrosion resistance and lightweight properties are critical. These materials can be engineered to provide specific mechanical properties tailored to the application.

Pros: Plastic composites are lightweight, resistant to corrosion, and can be produced in various shapes and sizes. They also exhibit good vibration dampening and can be cost-effective for low-torque applications.

Cons: The main limitation of plastic composites is their lower strength compared to metals, which may restrict their use in high-torque applications. They can also be sensitive to temperature fluctuations, which may affect performance.

Impact on Application: Plastic composite spline couplings are often used in marine, food processing, and chemical industries, where corrosion resistance is paramount. Buyers should ensure that the selected composite material is compatible with the specific media involved in their applications.

Summary Table of Material Selection for Spline Couplings

| Material | Typical Use Case for spline coupling | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, automotive | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Aerospace, automotive | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Magnesium | Aerospace, automotive | Excellent strength-to-weight ratio | Higher cost and limited availability | High |

| Plastic Composite | Marine, food processing, chemical | Corrosion resistant, lightweight | Lower strength, temperature sensitivity | Low |

This strategic material selection guide provides B2B buyers with essential insights into the properties and applications of various materials used in spline couplings, facilitating informed decision-making for their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for spline coupling

What Are the Main Stages of Manufacturing Spline Couplings?

The manufacturing process for spline couplings involves several critical stages that ensure the final product meets the necessary specifications for strength, durability, and performance. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Spline Couplings?

The first step in manufacturing spline couplings is the selection and preparation of raw materials. Common materials include high-strength steel, aluminum alloys, and magnesium, each chosen for their specific properties such as weight, corrosion resistance, and strength-to-weight ratios.

Once the material is selected, it undergoes processes such as cutting and heat treatment to achieve the desired mechanical properties. Heat treatment, for instance, enhances hardness and fatigue resistance, which are crucial for couplings that endure high torque and dynamic loads.

What Forming Techniques Are Used in Spline Coupling Manufacturing?

Forming is a critical phase where the raw material is shaped into the desired spline configuration. Techniques such as machining, forging, and casting are commonly employed.

-

Machining: This method involves precise cutting tools that create the internal and external splines. CNC (Computer Numerical Control) machining is often utilized for its accuracy, allowing for tight tolerances and complex designs.

-

Forging: This technique is used to enhance the material’s strength. The metal is heated and shaped using compressive forces, resulting in a denser and more durable product.

-

Casting: For certain applications, especially where lightweight components are needed, casting methods such as permanent mold casting (used in magnesium couplings) may be employed. This process can yield intricate shapes while reducing material waste.

How Are Spline Couplings Assembled?

After the individual components are formed, they are assembled. This phase may include aligning the inner and outer splines and securing them with additional features such as clamps or retaining rings.

Quality during assembly is paramount. Any misalignment can lead to significant performance issues, including premature wear or failure. Automated assembly techniques can help ensure consistency and reduce human error.

What Finishing Processes Are Applied to Spline Couplings?

The finishing stage involves surface treatments to enhance the coupling’s properties further. Common techniques include:

-

Surface Hardening: Processes such as nitriding or carburizing increase surface hardness, improving wear resistance.

-

Coating: Protective coatings may be applied to prevent corrosion, especially in environments exposed to moisture or chemicals.

-

Polishing: This improves surface finish and reduces friction, contributing to smoother operation in applications.

What Quality Assurance Measures Are Important for Spline Couplings?

Quality assurance (QA) is vital throughout the manufacturing process to ensure that spline couplings meet both international standards and specific customer requirements.

What International Standards Apply to Spline Couplings?

For manufacturers targeting international markets, adherence to recognized standards is essential. ISO 9001 is the most prominent quality management standard, focusing on ensuring consistent quality across processes. Other relevant certifications may include:

-

CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

-

API Standards: Relevant for couplings used in oil and gas applications, ensuring they meet stringent industry specifications.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial phase verifies the quality of raw materials before production begins. Materials must be tested for compliance with specified standards.

-

In-Process Quality Control (IPQC): Monitoring occurs during manufacturing, where random samples may be tested for dimensions, hardness, and surface finish to ensure ongoing compliance.

-

Final Quality Control (FQC): After assembly, finished products undergo rigorous testing to confirm they meet all design specifications and performance criteria.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are actionable steps:

What Types of Audits Should Buyers Conduct?

Conducting supplier audits is one of the most effective ways to ensure quality. Buyers should consider:

-

On-Site Audits: Visiting the manufacturing facility to assess processes, equipment, and workforce capabilities. This allows buyers to observe the QC measures in practice.

-

Documentation Reviews: Requesting access to quality management system documentation, including ISO certifications and QC process descriptions.

How Can Buyers Use Third-Party Inspections?

Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control processes. This can include:

-

Product Testing: Independent testing of samples to verify performance characteristics against specifications.

-

Quality System Audits: Evaluating the supplier’s adherence to international standards and their internal QC procedures.

What Are the QC Nuances for International B2B Buyers?

B2B buyers from various regions may face unique challenges regarding quality control. Understanding these nuances can facilitate smoother transactions:

-

Cultural Differences: Awareness of regional practices and expectations around quality can help in establishing effective communication with suppliers.

-

Regulatory Compliance: Buyers must ensure that products meet the specific regulatory requirements of their local markets, which may differ significantly from the supplier’s country.

-

Logistical Considerations: Shipping and handling practices can impact product quality. Buyers should discuss packaging and transport methods to ensure products arrive in optimal condition.

In summary, a thorough understanding of manufacturing processes and quality assurance practices for spline couplings is vital for international B2B buyers. By focusing on these aspects, buyers can ensure they partner with suppliers who not only meet their technical requirements but also adhere to rigorous quality standards, ultimately leading to successful and sustainable business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘spline coupling’

In the competitive landscape of industrial sourcing, procuring the right spline coupling is essential for ensuring efficient power transmission in various applications. This guide provides a structured approach to help B2B buyers navigate the sourcing process effectively.

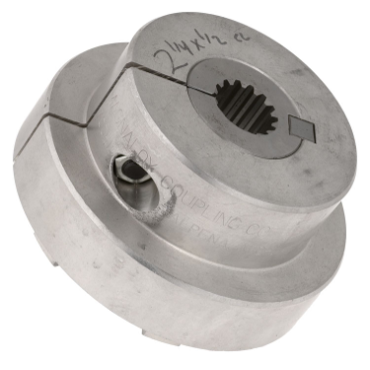

Illustrative image related to spline coupling

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the foundation of successful sourcing. Determine the type of spline coupling needed based on your application—whether it’s a parallel spline for high torque or an involute spline for smoother power transmission. Pay attention to the dimensions, load capacities, and any alignment considerations to ensure compatibility with your machinery.

Step 2: Research Available Materials

The material of the spline coupling significantly affects its performance and durability. Common materials include magnesium alloys, which offer a high strength-to-weight ratio, and steel, known for its robustness. Evaluate the operational environment; for instance, if corrosion resistance is crucial, consider couplings made from stainless steel or specially coated materials.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s vital to conduct thorough evaluations. Request detailed company profiles, product catalogs, and testimonials from other buyers in similar industries. Look for certifications that indicate adherence to international quality standards, such as ISO or ANSI, to ensure reliability and performance.

Illustrative image related to spline coupling

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the spline couplings. Testing samples allows you to assess the fit, performance, and quality of the couplings in your specific application. This step is crucial to avoid costly mistakes and ensure that the product meets your operational needs.

Step 5: Compare Pricing and Terms

After evaluating quality, compare pricing structures among different suppliers. Look beyond the initial cost; consider factors such as bulk order discounts, payment terms, and shipping costs. Understanding the total cost of ownership will help you make an informed decision that aligns with your budget.

Step 6: Check After-Sales Support and Warranty

A reliable supplier should offer robust after-sales support and warranty options. Inquire about the warranty period and what it covers, as well as the supplier’s policies on returns and repairs. Good customer support can be invaluable, especially if issues arise post-purchase.

Step 7: Finalize Your Order and Monitor Delivery

Once you have selected a supplier, finalize your order with clear specifications and timelines. Establish a communication plan for updates on the manufacturing and shipping processes. Monitoring delivery is essential to ensure that the couplings arrive on time and meet the agreed-upon specifications.

By following these steps, B2B buyers can enhance their sourcing process for spline couplings, leading to more effective procurement decisions and ultimately, smoother operations in their respective industries.

Comprehensive Cost and Pricing Analysis for spline coupling Sourcing

When sourcing spline couplings, understanding the cost structure is essential for effective budget management and strategic procurement. The pricing for spline couplings is influenced by various components that buyers need to consider to ensure they make informed purchasing decisions.

What are the Key Cost Components in Spline Coupling Production?

-

Materials: The choice of materials significantly affects the cost of spline couplings. Common materials include steel, aluminum, and magnesium alloys. High-strength materials may incur higher costs but can offer improved durability and performance, which could lead to lower long-term costs.

-

Labor: Labor costs can vary based on the manufacturing location and the complexity of the coupling design. Regions with lower labor costs may offer competitive pricing, but it’s crucial to assess the trade-off in quality and expertise.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Understanding these costs can provide insight into the supplier’s pricing strategy.

-

Tooling: Custom tooling for specific spline designs can be a significant upfront investment. Buyers should consider whether the supplier has the necessary tooling capabilities and whether these costs are included in the quoted price.

-

Quality Control (QC): Quality assurance processes are essential for ensuring that the couplings meet industry standards. Suppliers with stringent QC protocols may charge more, but this investment can lead to fewer failures and lower maintenance costs in the future.

-

Logistics: The cost of shipping and handling can vary greatly depending on the supplier’s location and the shipping terms agreed upon. International buyers should be aware of potential tariffs, customs duties, and freight costs, which can significantly impact the total procurement cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and generate revenue. This margin can vary based on market competition, demand, and supplier relationships.

What Factors Influence Pricing for Spline Couplings?

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to find a balance between inventory management and cost savings.

-

Specifications and Customization: Custom designs or specific performance requirements may increase costs. Buyers should clearly define their needs to avoid unnecessary expenses.

-

Quality Certifications: Certifications such as ISO or specific industry standards can affect pricing. Suppliers with recognized certifications might charge a premium, but this often correlates with higher reliability and performance.

-

Supplier Factors: The supplier’s reputation, experience, and market position can influence prices. Established suppliers may offer higher quality but at a premium, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the Incoterms used in the transaction is crucial. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the final price and responsibility for shipping and insurance.

What Tips Can Buyers Use to Optimize Their Spline Coupling Procurement?

-

Negotiation: Always engage in negotiations to secure better pricing. Suppliers may have flexibility in their pricing, especially for larger orders or long-term contracts.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just the initial purchase price. Consider factors like longevity, maintenance costs, and the potential for failures.

-

Pricing Nuances for International Buyers: When sourcing from different regions, consider currency fluctuations, shipping times, and import regulations. Understanding local market conditions can provide leverage in negotiations.

-

Disclaimer on Prices: Be aware that prices can fluctuate based on market conditions, material availability, and geopolitical factors. Always request updated quotes and clarify all pricing components with suppliers.

By comprehensively analyzing these cost components and pricing influencers, international B2B buyers can make strategic decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing spline coupling With Other Solutions

Introduction: Exploring Alternatives to Spline Couplings

In the realm of mechanical power transmission, selecting the right coupling technology is vital for ensuring efficiency and performance. While spline couplings are widely recognized for their ability to transmit torque between rotating shafts with minimal backlash, other alternatives exist that may better suit specific applications or budget constraints. This analysis compares spline couplings with two viable alternatives: Keyed Couplings and Flexible Couplings.

Comparison Table

| Comparison Aspect | Spline Coupling | Keyed Couplings | Flexible Couplings |

|---|---|---|---|

| Performance | High torque transmission; accommodates misalignment | Good torque transfer; limited misalignment capability | Excellent vibration dampening; compensates for misalignment |

| Cost | Moderate to high | Low to moderate | Moderate to high |

| Ease of Implementation | Requires precise machining and alignment | Simple installation; widely used | Generally easy to install but may require adjustments |

| Maintenance | Low maintenance; durable | Low maintenance; reliable | Moderate; may require periodic checks |

| Best Use Case | High-performance applications needing precision | General-purpose applications with moderate torque | Applications with vibration or significant misalignment |

Detailed Breakdown of Alternatives

Keyed Couplings

Keyed couplings are a traditional choice for connecting shafts, utilizing a key that fits into a groove on both the shaft and the coupling. This design ensures a firm connection, allowing for efficient torque transfer. One of the primary advantages of keyed couplings is their cost-effectiveness; they are typically less expensive than spline couplings. However, they do have limitations in terms of accommodating misalignment and can experience wear over time, which may necessitate more frequent maintenance in high-stress environments.

Flexible Couplings

Flexible couplings offer a unique solution by allowing for some degree of misalignment while dampening vibrations. This makes them ideal for applications where shafts may not be perfectly aligned or where operational vibrations could cause damage. Flexible couplings tend to be more complex than spline and keyed couplings, which can lead to higher installation costs. However, their ability to absorb shock loads and accommodate misalignment can extend the lifespan of connected components, making them a worthwhile investment in many scenarios.

Conclusion: Choosing the Right Coupling Solution for Your Needs

When selecting a coupling solution, B2B buyers should consider the specific requirements of their applications. Spline couplings excel in high-performance settings where precision and torque transmission are critical. Keyed couplings may be more suitable for general applications where cost is a primary concern and perfect alignment is not essential. Meanwhile, flexible couplings are the go-to option for applications involving misalignment or vibration concerns. By carefully evaluating the performance, cost, ease of implementation, and maintenance needs of each option, buyers can make informed decisions that enhance their operational efficiency and reliability.

Essential Technical Properties and Trade Terminology for spline coupling

What Are the Key Technical Properties of Spline Couplings?

When selecting spline couplings for industrial applications, understanding their technical properties is crucial. Here are some essential specifications that B2B buyers should consider:

1. Material Grade

The material of the spline coupling significantly affects its performance and durability. Common materials include carbon steel, stainless steel, and aluminum. Carbon steel offers high strength and wear resistance, making it suitable for heavy-duty applications. Stainless steel is preferred for environments exposed to moisture and corrosion, while aluminum is lightweight, enhancing efficiency in applications where weight is a concern.

2. Torque Capacity

Torque capacity is the maximum amount of torque a coupling can transmit without failure. It is vital to match the torque capacity of the coupling to the operational requirements of the machinery. Oversizing the coupling can lead to unnecessary costs, while undersizing can result in premature failure and downtime, impacting overall productivity.

3. Tolerances

Tolerances refer to the permissible limits of variation in the dimensions of the coupling. Precise tolerances are critical for ensuring proper fit and function. Inaccurate tolerances can lead to misalignment, increased wear, and inefficiencies. Manufacturers often provide detailed tolerance specifications to help buyers select the right coupling for their specific applications.

4. Spline Type

Different spline types, such as involute and parallel, serve specific applications. Involute splines offer better load distribution and smoother operation, making them ideal for high-performance systems. Parallel splines, on the other hand, are suited for applications requiring high torque transmission. Understanding these differences can help buyers choose the appropriate coupling for their machinery.

5. Misalignment Compensation

Many spline couplings are designed to accommodate slight misalignments between shafts. This feature is essential in real-world applications, where perfect alignment is often challenging to achieve. Couplings that can tolerate misalignments enhance system reliability and reduce wear on connected components.

What Are the Common Trade Terminology Terms Related to Spline Couplings?

Understanding industry jargon is crucial for effective communication and decision-making in B2B transactions. Here are some common terms associated with spline couplings:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. When sourcing spline couplings, knowing whether a product is OEM can help buyers ensure compatibility and quality, as OEM parts are typically designed to meet specific standards.

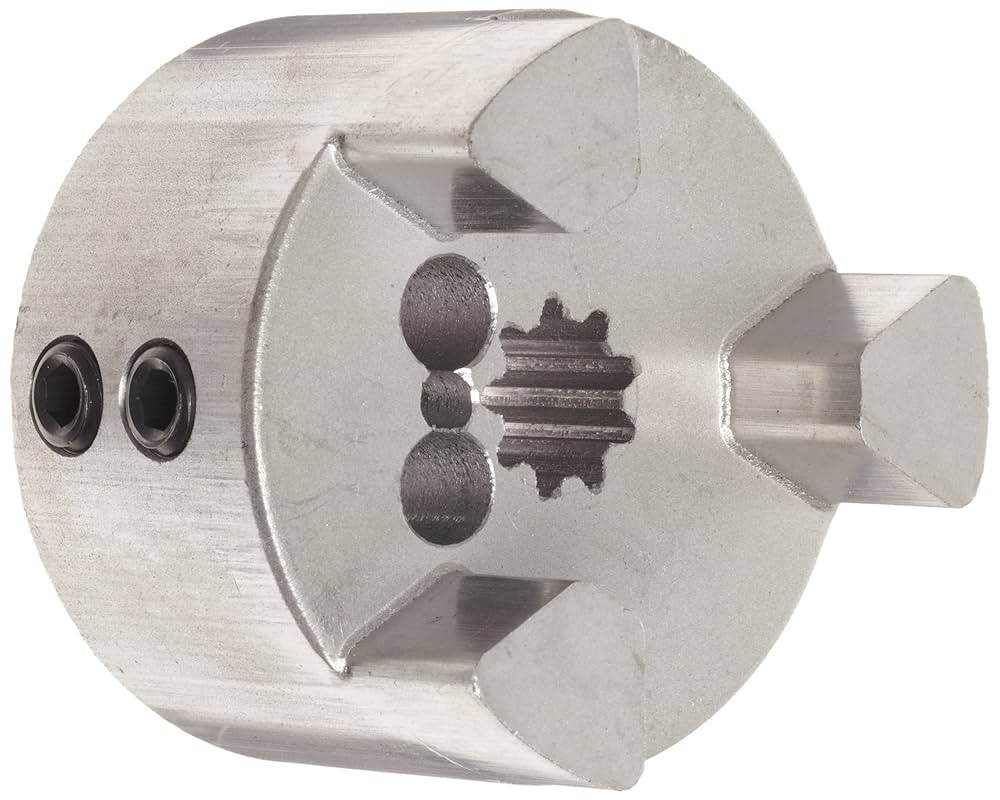

Illustrative image related to spline coupling

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for buyers to manage inventory costs and ensure they are ordering an appropriate quantity that meets their operational needs without overstocking.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. It is an essential part of the procurement process, allowing buyers to compare offers and negotiate favorable terms for spline couplings.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including who bears the costs and risks during shipping. Familiarity with these terms helps buyers understand their obligations and negotiate better shipping arrangements for spline couplings.

Illustrative image related to spline coupling

5. Lead Time

Lead time refers to the time between placing an order and receiving the product. This is critical for planning and inventory management, especially when dealing with production schedules that depend on timely delivery of spline couplings.

By understanding these technical properties and trade terminology, B2B buyers can make informed decisions when sourcing spline couplings, ensuring they select the right products for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the spline coupling Sector

What Are the Current Market Dynamics and Key Trends in the Spline Coupling Sector?

The spline coupling market is experiencing significant growth driven by various global factors, including industrial automation, the rise of renewable energy, and advancements in manufacturing technology. As industries strive for greater efficiency and productivity, the demand for reliable power transmission components like spline couplings has surged. Key trends include the increasing use of lightweight materials such as magnesium alloys, which offer enhanced strength-to-weight ratios, thereby reducing the load on bearings and extending the lifespan of machinery.

Moreover, the adoption of Industry 4.0 technologies, such as IoT and AI, is reshaping sourcing strategies. B2B buyers are increasingly seeking suppliers who can offer real-time data on product performance and inventory levels, enabling better decision-making. In regions like Africa and South America, where infrastructure development is accelerating, there is a growing emphasis on sourcing durable and adaptable spline couplings that can withstand varied environmental conditions. Conversely, European buyers, particularly in Germany, are focusing on precision-engineered products that comply with stringent quality standards, further driving innovation in the sector.

How Are Sustainability and Ethical Sourcing Changing the Spline Coupling Market?

Sustainability is becoming a critical consideration for B2B buyers in the spline coupling sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt more sustainable practices. This includes sourcing materials that have a lower carbon footprint and utilizing production methods that minimize waste and energy consumption. For instance, suppliers are increasingly offering ‘green’ certifications for their products, indicating compliance with environmental standards and responsible sourcing.

Additionally, ethical sourcing is gaining traction as buyers look to partner with manufacturers who prioritize fair labor practices and transparency in their supply chains. This trend is particularly pertinent in the Middle East and Africa, where there is a push for economic development alongside ethical considerations. By prioritizing suppliers who demonstrate a commitment to sustainability and ethical practices, B2B buyers can enhance their corporate social responsibility profiles while ensuring the long-term viability of their supply chains.

What Is the Historical Evolution of Spline Couplings and Its Relevance Today?

The evolution of spline couplings can be traced back to the early days of mechanical engineering, where the need for efficient power transmission solutions led to the development of various coupling designs. Initially, spline couplings were primarily used in heavy machinery and automotive applications. Over time, advancements in materials science and manufacturing techniques have allowed for the creation of more sophisticated designs, such as involute and parallel spline couplings, which cater to specific performance requirements.

Today, the historical significance of spline couplings is reflected in their widespread application across diverse industries, from agriculture to aerospace. This evolution highlights the importance of continuous innovation in meeting the demands of modern engineering challenges. As B2B buyers seek cutting-edge solutions, understanding the historical context of spline couplings can inform their purchasing decisions and foster a deeper appreciation for the technology that underpins their operations.

Frequently Asked Questions (FAQs) for B2B Buyers of spline coupling

-

How do I choose the right spline coupling for my application?

Choosing the right spline coupling involves evaluating several factors, including the torque requirements, shaft alignment, and environmental conditions. Identify the type of spline (parallel or involute) best suited for your needs, considering factors like the load capacity and flexibility required. Consult with suppliers for detailed specifications and, if possible, request samples to assess compatibility with your existing equipment. Additionally, consider the materials used in construction to ensure durability and resistance to corrosion, particularly in harsh environments. -

What are the common applications of spline couplings in industry?

Spline couplings are widely used in various industries, including automotive, aerospace, and manufacturing. They are particularly effective in applications requiring precise torque transmission, such as in gearboxes, motors, and conveyor systems. Their ability to accommodate misalignments makes them ideal for dynamic environments. Additionally, they are often found in heavy machinery where durability and reliability are critical for operational efficiency. -

What customization options are available for spline couplings?

Many suppliers offer customization options for spline couplings, including variations in size, material, and design features. You can specify the dimensions, spline type, and additional features such as clamping mechanisms or specific coatings for corrosion resistance. When requesting customization, provide detailed specifications and consider the intended operating conditions to ensure the coupling meets your performance needs. Collaborating closely with the manufacturer can lead to tailored solutions that enhance your system’s efficiency. -

What is the typical minimum order quantity (MOQ) for spline couplings?

The minimum order quantity for spline couplings can vary significantly by supplier and the complexity of the customization requested. Standard products may have lower MOQs, often starting from 10 to 50 units, while custom designs might require higher quantities. Discussing your needs directly with suppliers can help determine the best options for your project, and some may be willing to accommodate smaller orders, especially for repeat customers or long-term partnerships. -

What payment terms should I expect when sourcing spline couplings internationally?

Payment terms for international orders of spline couplings often include options like wire transfers, letters of credit, or payment upon delivery, depending on the supplier’s policies. Some suppliers may offer discounts for upfront payments or larger orders. It’s essential to clarify payment terms before finalizing your order to avoid misunderstandings. Additionally, consider factors like currency exchange rates and transaction fees that may impact the overall cost. -

How can I vet suppliers for spline couplings effectively?

To effectively vet suppliers, start by researching their industry reputation, customer reviews, and certifications (like ISO standards). Request samples to evaluate product quality and assess their technical support capabilities. Check their manufacturing processes and lead times to ensure they can meet your delivery requirements. Establishing communication with their customer service team can also provide insights into their responsiveness and reliability. -

What quality assurance measures should I expect for spline couplings?

Reputable suppliers implement strict quality assurance measures to ensure the performance and reliability of spline couplings. This may include testing for dimensional accuracy, material strength, and fatigue resistance. Inquire about their testing protocols and certifications, such as ISO 9001, which indicate adherence to quality management standards. Understanding their quality control process can help you ensure the couplings you receive meet your specifications and industry requirements. -

What logistical considerations should I keep in mind when importing spline couplings?

When importing spline couplings, consider shipping methods, delivery times, and customs regulations that may impact your order. Partnering with a logistics provider experienced in international trade can help streamline the process. Ensure you have the necessary documentation ready, such as invoices and certificates of origin, to avoid delays at customs. Additionally, factor in potential tariffs and duties when budgeting for your purchase to avoid unexpected costs.

Top 5 Spline Coupling Manufacturers & Suppliers List

1. Concentric – 1/2 Shaft Coupler

Domain: surpluscenter.com

Registered: 1996 (29 years)

Introduction: Keyed, Splined & Hex 1 Piece Solid Couplers; Categories: Shaft Couplers, Power Transmission; Brands: Concentric, G & G Mfg; Price Range: $0 to $100; Available Items: 27; Example Products: 1/2″ Shaft Coupler – $7.30, 5/8″ 9T Splined Coupling – $12.20, 3/4″ Shaft Coupler – $11.40, 1″ Shaft Coupler – $15.40; Stock Availability: Various quantities in stock for each item.

2. OneHydraulics – Hydraulic and Pneumatic Equipment

Domain: onehydraulics.com

Registered: 2016 (9 years)

Introduction: This company, OneHydraulics – Hydraulic and Pneumatic Equipment, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Regal Rexnord – Hub City® Involute Splined Couplings

Domain: regalrexnord.com

Registered: 2021 (4 years)

Introduction: Hub City® Involute Splined Couplings are designed for mechanical power transmission applications. They are part of the Non-PTO products category under Farm Solutions. These couplings provide a reliable connection between shafts, allowing for efficient power transfer while accommodating misalignment and reducing wear. The couplings are engineered for durability and performance in demanding environm…

4. Tingue – Spline Coupling

5. YNF Machinery – Spline Couplings

Domain: ynfmachinery.com

Registered: 2014 (11 years)

Introduction: Spline coupling is a mechanical component used to connect two rotary shafts, ensuring proper transfer of power and torque. It consists of an inner spline and an outer spline, with ridges or teeth that mesh together for accurate power transfer. Types of spline couplings include: 1. Parallel Spline Coupling – features straight teeth for high torque transmission. 2. Involute Spline Coupling – has cur…

Strategic Sourcing Conclusion and Outlook for spline coupling

In summary, strategic sourcing of spline couplings is critical for ensuring optimal performance in various mechanical applications across industries. By understanding the different types of spline couplings, such as parallel and involute designs, buyers can make informed decisions that enhance power transmission efficiency while accommodating alignment variations. Investing in high-quality couplings not only improves the lifespan of machinery but also reduces maintenance costs and downtime.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, the emphasis on strategic sourcing becomes even more pronounced. The right partnerships with reliable suppliers can lead to significant cost savings and enhanced operational capabilities. Buyers should prioritize suppliers who offer robust support, customization options, and competitive pricing to meet their specific needs.

Looking ahead, the demand for innovative and efficient spline coupling solutions is expected to grow. As industries evolve, staying ahead of technological advancements and sourcing trends will be vital. Engage with suppliers who are committed to quality and innovation, and take proactive steps to secure the best products for your operational requirements. Your strategic sourcing decisions today will shape the efficiency and success of your operations tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.