Choosing Your Push Button Switch Diagram: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for push button switch diagram

In today’s competitive landscape, sourcing the right push button switch diagram can be a pivotal challenge for B2B buyers looking to enhance operational efficiency and safety in their electrical systems. As these switches play a crucial role in controlling the flow of current in various applications—from industrial machinery to home appliances—understanding their functionalities is vital. This comprehensive guide delves into the nuances of push button switches, covering the different types, operational mechanisms, and diverse applications tailored to meet the needs of international markets, particularly in regions like Africa, South America, the Middle East, and Europe.

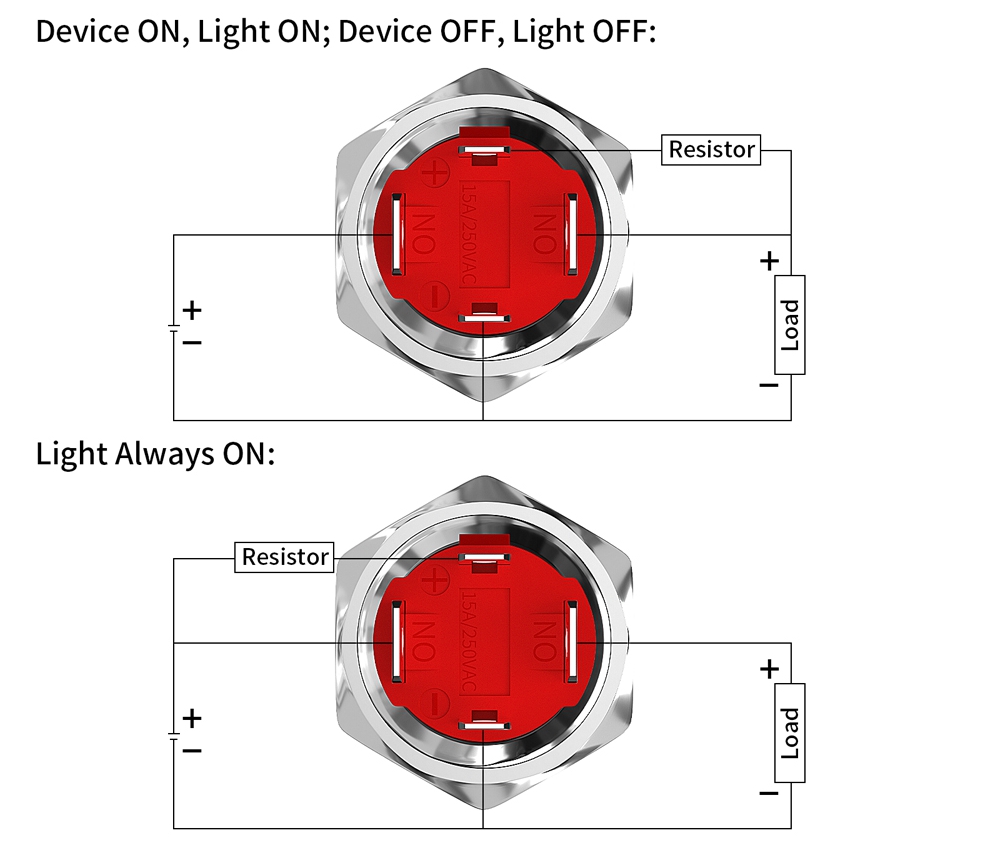

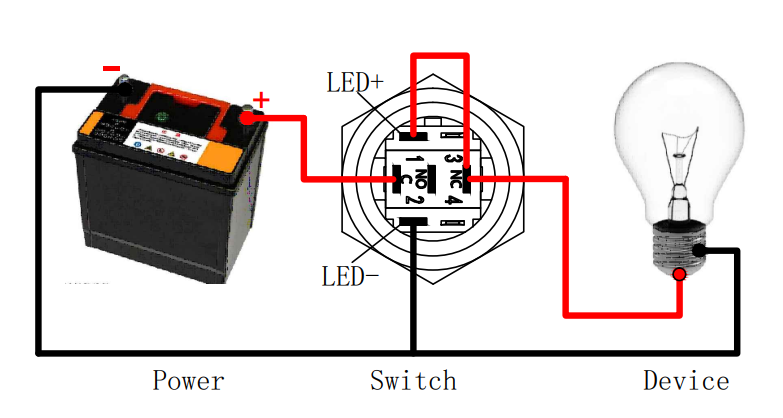

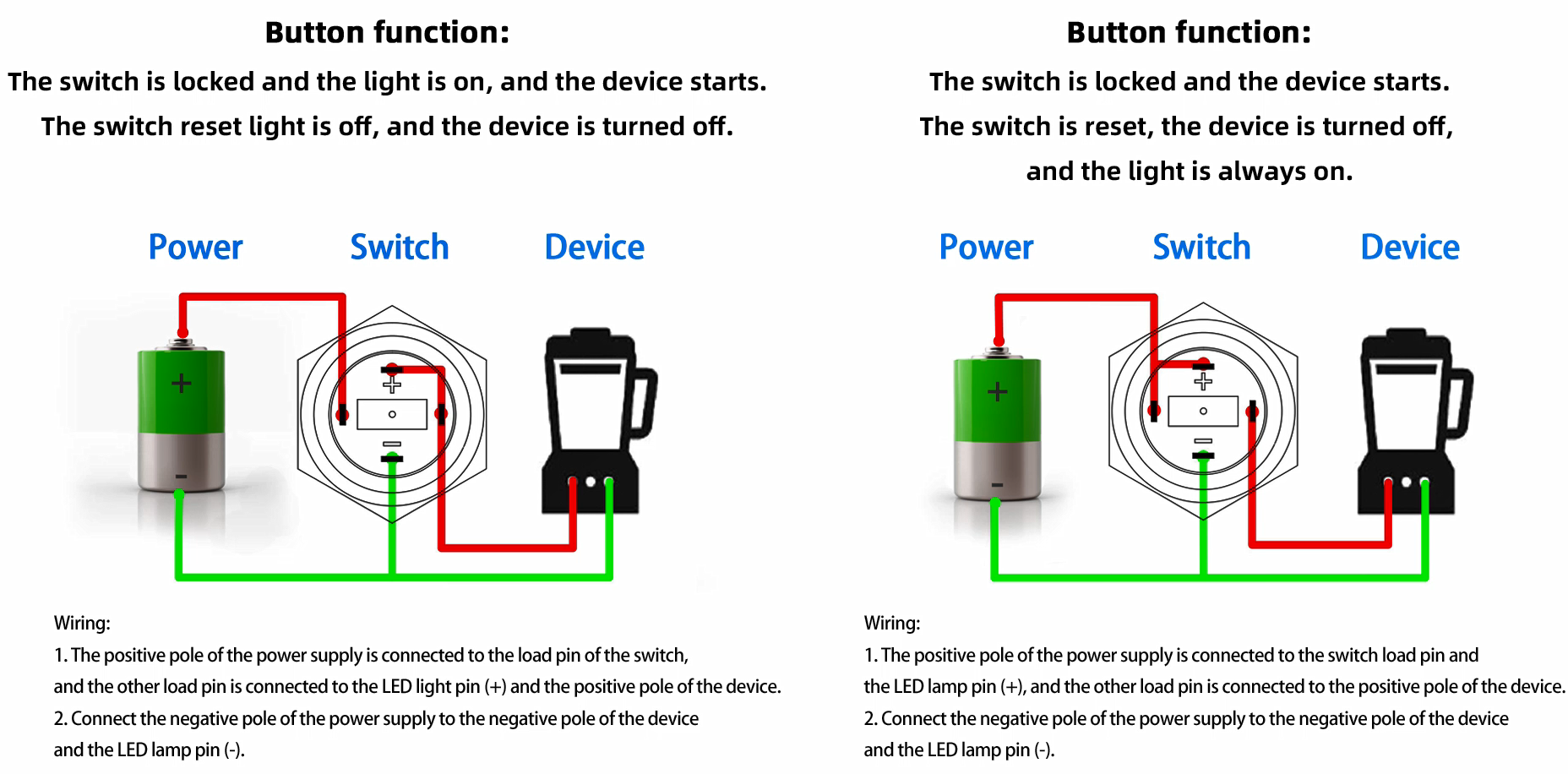

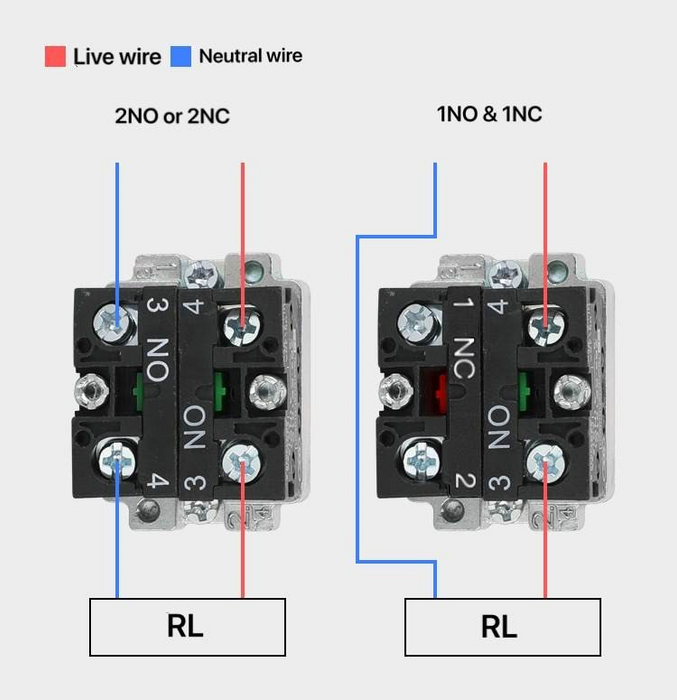

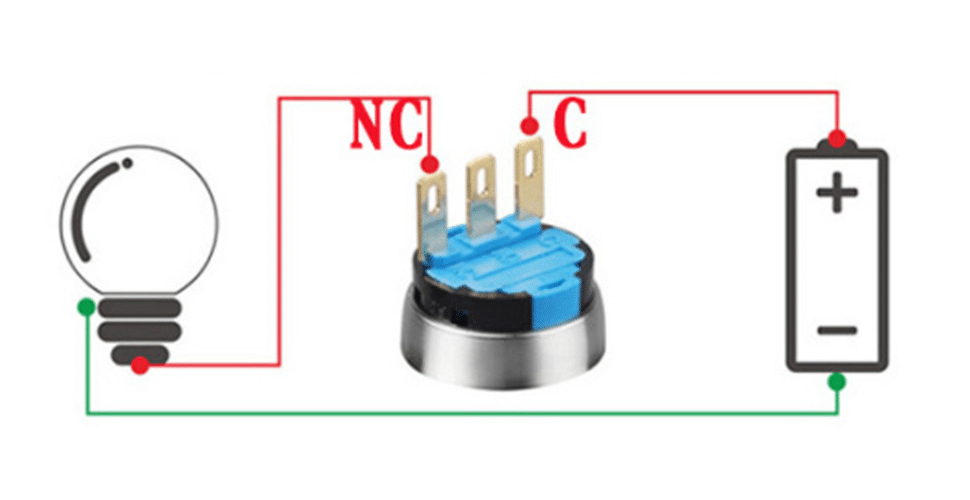

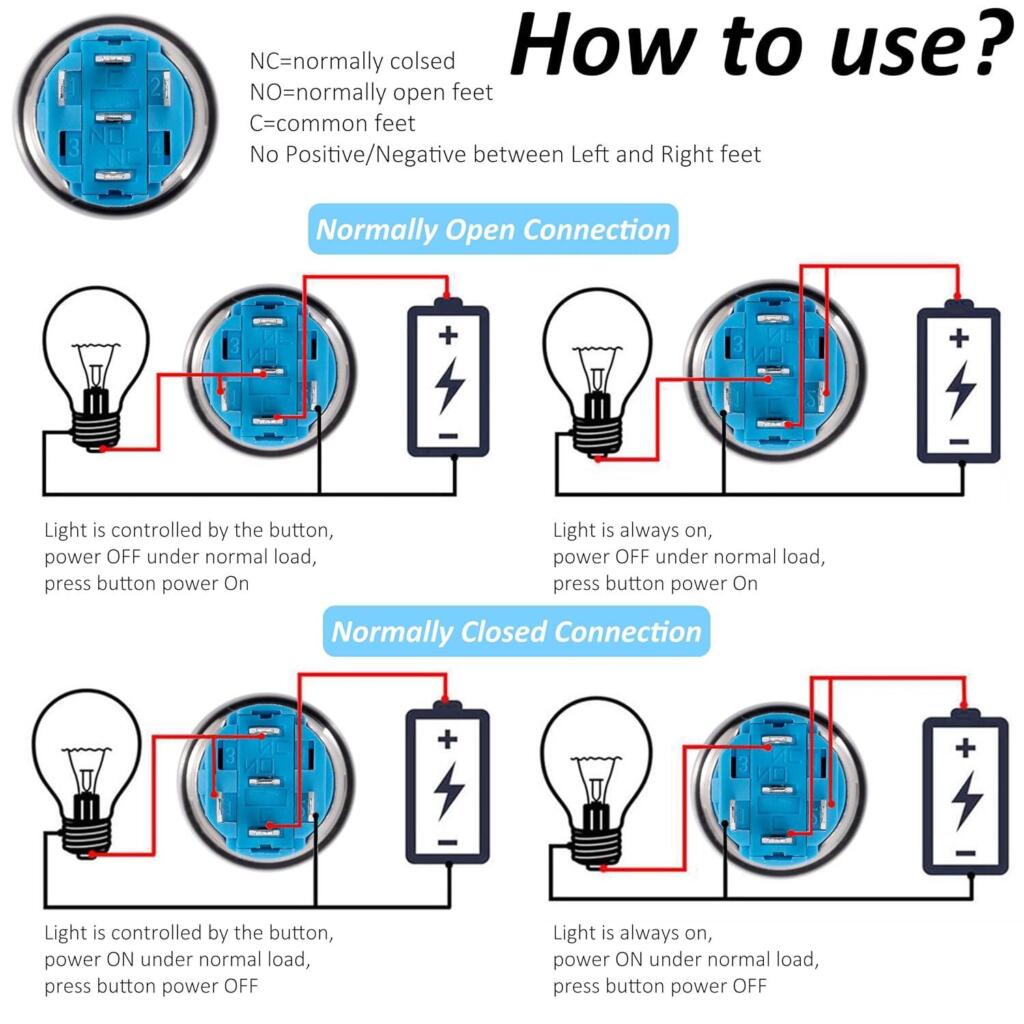

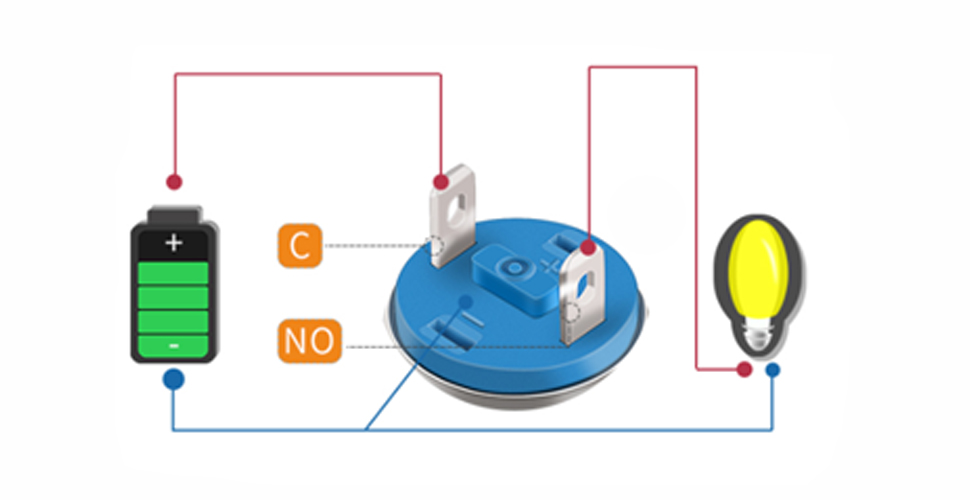

As you navigate this essential resource, you will gain insights into the distinctions between normally open (N/O) and normally closed (N/C) contacts, explore the advantages of momentary versus maintained push buttons, and learn about the critical factors influencing supplier selection and cost considerations. Furthermore, we will provide actionable diagrams and examples to facilitate informed decision-making in your procurement process. By equipping yourself with this knowledge, you can confidently choose the most suitable push button switches for your specific applications, ensuring both performance and compliance in your operations. This guide empowers you to make strategic purchasing decisions that align with your business objectives, enhancing both productivity and safety in your projects.

Understanding push button switch diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Momentary Push Button Switch | Requires continuous pressure to maintain circuit | Doorbells, intercoms, industrial machinery | Pros: Ideal for temporary actions; easy to use. Cons: Not suitable for applications needing a constant state. |

| Maintained Push Button Switch | Stays in the set state until pressed again | Start/stop machinery, lighting control | Pros: Simple operation for continuous control. Cons: Can lead to accidental activation if not designed properly. |

| Locking Push Button Switch | Mechanical lock mechanism prevents accidental release | Heavy machinery, safety systems | Pros: Enhanced safety; prevents unintentional operation. Cons: More complex and potentially higher cost. |

| Dual Push Button Switch | Separate buttons for connection and disconnection | Control panels, automation systems | Pros: Clear status indication with color coding. Cons: Requires more space for installation. |

| Tactile Push Button Switch | Compact design with audible feedback | Consumer electronics, keyboards | Pros: Space-efficient; provides clear user feedback. Cons: May not be durable in harsh environments. |

What Are the Characteristics of Momentary Push Button Switches?

Momentary push button switches are designed to perform an action only while the button is pressed. This type is commonly used in applications such as doorbells and intercoms, where temporary activation is required. For B2B buyers, it’s essential to consider the switch’s durability and responsiveness, especially in high-frequency usage environments. Momentary switches are typically easier to install and are available in various shapes and sizes, making them versatile for numerous applications.

How Do Maintained Push Button Switches Function?

Maintained push button switches, or latching switches, remain in their last activated state until pressed again. This feature makes them ideal for applications like machinery control and lighting systems, where a continuous on/off state is necessary. Buyers should evaluate the switch’s mechanical design to ensure it meets the operational demands of their specific application. While they offer simplicity in operation, there is a risk of accidental activation if not properly secured.

What Are the Benefits of Locking Push Button Switches?

Locking push button switches incorporate a mechanical locking feature that requires an additional press to release, ensuring that the device remains in a set state until intentionally changed. These switches are crucial in environments where safety is paramount, such as heavy machinery and emergency systems. B2B buyers should consider the switch’s locking mechanism and ensure it aligns with safety standards. While they provide significant safety benefits, they can be more complex and costly compared to standard switches.

How Do Dual Push Button Switches Enhance Control?

Dual push button switches consist of two separate buttons for turning a device on and off, often color-coded for clarity (e.g., green for on, red for off). This design is particularly useful in control panels and automated systems where clear status indication is vital. Buyers should consider the physical space required for installation and the switch’s compatibility with existing systems. The dual functionality enhances user experience but may require more complex wiring.

What Makes Tactile Push Button Switches Suitable for Electronics?

Tactile push button switches are compact and designed for low-force activation, often used in consumer electronics and keyboards. They provide audible feedback, indicating successful activation, which is beneficial for user interaction. B2B buyers should assess their durability and environmental resistance, especially for applications subject to wear and tear. While they are space-efficient, they may not be the best choice for harsh industrial environments where robustness is critical.

Key Industrial Applications of push button switch diagram

| Industry/Sector | Specific Application of push button switch diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Control panels for machinery and assembly lines | Enhanced operational efficiency and safety | IP ratings, durability, and compatibility with existing systems |

| Automotive | Ignition systems and dashboard controls | Improved reliability and user experience | Temperature resistance, compact design, and regulatory compliance |

| Energy & Utilities | Emergency shut-off systems in power plants | Increased safety and risk management | Certification standards, response time, and maintenance requirements |

| Building Automation | Lighting control and HVAC systems | Energy efficiency and user comfort | Integration with smart systems and ease of installation |

| Medical Equipment | Patient monitoring systems and emergency alarms | Critical for patient safety and operational reliability | Compliance with health regulations and ease of cleaning |

How is the push button switch diagram utilized in manufacturing applications?

In the manufacturing sector, push button switches are integral to control panels that manage machinery and assembly lines. The push button switch diagram outlines how these switches control various functions, such as starting or stopping machines, adjusting settings, or resetting systems. This application enhances operational efficiency by allowing quick, intuitive control of complex machinery. For international buyers, particularly in regions like Africa and South America, sourcing switches with high durability and appropriate ingress protection ratings is vital to withstand harsh industrial environments.

What role do push button switches play in automotive applications?

In the automotive industry, push button switches are commonly used for ignition systems and dashboard controls. The push button switch diagram illustrates how these switches interact with various vehicle systems, providing essential functions such as starting the engine or controlling lights. This enhances reliability and user experience, crucial for automotive manufacturers. Buyers in the Middle East and Europe must consider temperature resistance and compliance with automotive regulations when sourcing these components, ensuring they meet the necessary safety standards.

How are push button switches critical in energy and utilities sectors?

Push button switches serve a vital role in emergency shut-off systems within power plants and utilities. The corresponding switch diagram helps visualize the circuit layout, ensuring that operators can quickly and effectively manage emergency situations. This capability is essential for risk management and safety, particularly in high-stakes environments. Buyers in these sectors should prioritize sourcing switches that meet certification standards and have quick response times, as these features are critical in emergency scenarios.

In what ways do push button switches enhance building automation?

In building automation, push button switches are utilized for controlling lighting and HVAC systems. The push button switch diagram provides a clear representation of how these switches integrate into larger control systems, enhancing energy efficiency and user comfort. For international buyers, especially in Europe, sourcing switches that can seamlessly integrate with smart building technologies is crucial. Additionally, ease of installation and compatibility with existing systems are key factors to consider.

Why are push button switches essential in medical equipment?

Push button switches are critical components in medical equipment, used in patient monitoring systems and emergency alarms. The switch diagram illustrates the connections and functionalities that ensure immediate response in critical situations, which is vital for patient safety. Buyers in this sector must ensure that sourced switches comply with health regulations and are easy to clean, as hygiene is paramount in medical environments. This focus on compliance and usability enhances operational reliability, benefiting healthcare providers.

3 Common User Pain Points for ‘push button switch diagram’ & Their Solutions

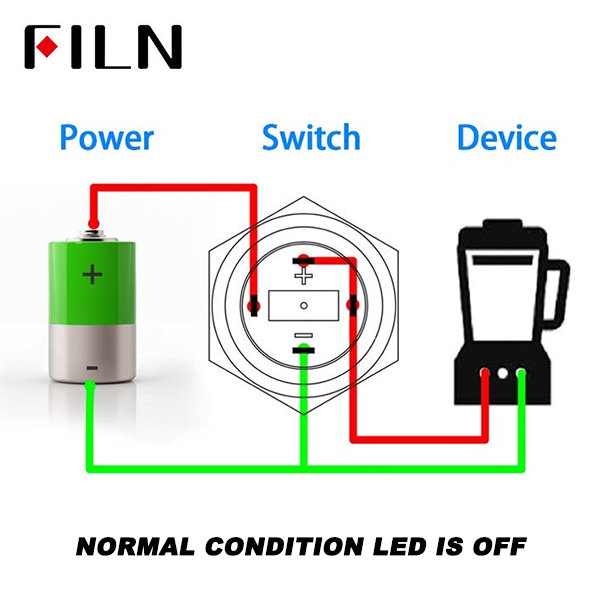

Scenario 1: Confusion Over Circuit Diagrams for Push Button Switches

The Problem: Many B2B buyers struggle to interpret complex circuit diagrams associated with push button switches, particularly when integrating them into existing systems. This confusion can lead to incorrect installations, resulting in operational downtime and increased costs. For example, a manufacturer in Nigeria may receive a shipment of push button switches with accompanying diagrams that use technical jargon and symbols unfamiliar to their local technicians, creating frustration and potential errors in implementation.

Illustrative image related to push button switch diagram

The Solution: To mitigate these challenges, buyers should prioritize sourcing push button switches from suppliers that provide clear, simplified diagrams and comprehensive installation guides. When reviewing product specifications, look for manufacturers that offer multilingual support or visual aids that break down the installation process step-by-step. Additionally, consider investing in training sessions or workshops for your team, focusing on reading and understanding circuit diagrams. This proactive approach not only enhances your team’s skills but also fosters confidence in executing installations accurately.

Scenario 2: Variability in Push Button Switch Types and Applications

The Problem: Buyers often encounter difficulty in selecting the right type of push button switch for their specific applications. With a plethora of options available—from momentary to maintained switches, and varying IP ratings—deciding which switch best meets the operational requirements can be overwhelming. For instance, a company in Saudi Arabia might need a push button switch for an outdoor application but may inadvertently select a model that lacks adequate weatherproofing, leading to premature failure.

The Solution: To effectively navigate the diverse push button switch landscape, buyers should conduct a thorough needs assessment before making a purchase. Begin by defining the specific environmental conditions and functional requirements of the application—such as exposure to moisture, frequency of use, and required voltage ratings. Utilize product comparison charts provided by manufacturers to streamline the selection process. Furthermore, engaging with industry experts or technical support teams can provide invaluable insights into choosing the appropriate switch type. Documenting these requirements in a checklist can serve as a reference for future purchases, ensuring consistency and reliability.

Scenario 3: Maintenance and Troubleshooting of Push Button Switches

The Problem: Once installed, push button switches may develop issues that are difficult to diagnose, leading to operational disruptions. Buyers often find themselves unable to identify whether the problem lies with the switch itself, the electrical circuit, or external factors like environmental conditions. For example, a factory in Brazil could experience intermittent failures with push button switches in a high-vibration environment, but without a clear troubleshooting framework, they may waste time and resources on ineffective solutions.

The Solution: Establishing a robust maintenance and troubleshooting protocol is essential for addressing operational challenges related to push button switches. Start by creating a detailed log of switch performance, including installation dates, usage frequency, and any issues encountered. Incorporate regular inspection schedules to check for signs of wear or damage, particularly in high-stress environments. When problems arise, refer to manufacturer guidelines for troubleshooting steps that can help isolate the issue. Additionally, consider implementing a feedback loop where technicians can share insights and solutions based on their experiences, fostering a culture of continuous improvement. This proactive maintenance strategy not only enhances the longevity of the switches but also minimizes costly downtime.

Strategic Material Selection Guide for push button switch diagram

What Are the Key Materials Used in Push Button Switches?

When selecting materials for push button switches, understanding the properties and performance implications of each material is crucial for ensuring product reliability and longevity. Here, we analyze four common materials used in push button switch manufacturing, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Do Different Plastics Perform in Push Button Switches?

Polycarbonate (PC) is widely used for push button switch housings due to its excellent impact resistance and clarity. It can withstand high temperatures (up to 135°C) and offers good electrical insulation. However, it can be susceptible to UV degradation if not treated, which may limit its outdoor applications. For buyers in regions with high UV exposure, such as parts of Africa and the Middle East, UV-stabilized grades of polycarbonate should be considered.

Illustrative image related to push button switch diagram

Pros: High durability, good thermal stability, and excellent electrical insulation.

Cons: Higher cost than standard plastics, potential UV degradation without treatment.

Impact on Application: Suitable for environments requiring high mechanical strength and electrical insulation, but may need additional coatings for outdoor use.

What Role Does Metal Play in Push Button Switch Design?

Stainless Steel is another common material, especially for industrial push buttons. It provides exceptional corrosion resistance and can withstand harsh environments, making it ideal for applications in sectors like food processing and chemical manufacturing. Stainless steel buttons can also endure high temperatures and pressures.

Pros: Superior durability, excellent corrosion resistance, and high-temperature tolerance.

Cons: Higher manufacturing costs and weight compared to plastic alternatives.

Impact on Application: Ideal for environments with exposure to moisture or corrosive substances, commonly preferred in industries across Europe and the Middle East.

Why Is Rubber Important for Push Button Switches?

Silicone Rubber is often used for the actuators of push button switches due to its flexibility and resilience. It can operate effectively in a wide temperature range (from -60°C to +200°C) and offers good chemical resistance. However, silicone rubber can wear out faster than harder materials, especially in high-use applications.

Pros: Excellent flexibility, high-temperature resistance, and good chemical compatibility.

Cons: Potential for wear under heavy use and lower structural integrity compared to metals.

Impact on Application: Suitable for consumer electronics and applications requiring a soft touch, but may not be ideal for heavy-duty industrial applications.

What Are the Benefits of Using Thermoplastic Elastomers (TPE)?

Thermoplastic Elastomers (TPE) combine the properties of rubber and plastic, offering flexibility and durability. TPEs are resistant to UV light, ozone, and various chemicals, making them versatile for different applications. They can be molded into complex shapes, allowing for ergonomic designs.

Pros: Good flexibility, resistance to environmental factors, and ease of manufacturing.

Cons: May not provide the same level of durability as metals in extreme conditions.

Impact on Application: Well-suited for consumer products and environments where aesthetics and tactile feedback are important, particularly in markets like South America and Africa.

Summary Table of Material Selection for Push Button Switches

| Material | Typical Use Case for push button switch diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | Electrical panels, consumer electronics | High durability and insulation | Susceptible to UV degradation | Medium |

| Stainless Steel | Industrial machinery, food processing | Excellent corrosion resistance | Higher cost and weight | High |

| Silicone Rubber | Consumer electronics, medical devices | Flexibility and chemical resistance | Potential for wear under heavy use | Medium |

| Thermoplastic Elastomers | Automotive controls, consumer products | Good flexibility and UV resistance | Lower durability than metals | Medium |

This guide provides a comprehensive overview of material selection for push button switches, helping international B2B buyers make informed decisions based on specific application needs and environmental conditions. Understanding these materials will ensure that the selected push button switches meet performance expectations and regulatory standards in various regions.

In-depth Look: Manufacturing Processes and Quality Assurance for push button switch diagram

What Are the Key Stages in the Manufacturing Process of Push Button Switches?

The manufacturing of push button switches involves several critical stages, each designed to ensure the final product meets rigorous performance and quality standards. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation: What Materials Are Used and How Are They Processed?

The first stage in manufacturing push button switches is material preparation. Common materials include high-grade plastics, metals such as stainless steel or aluminum, and electronic components like copper and silicon. Suppliers typically source these materials from certified vendors to ensure compliance with international standards.

Once the materials are procured, they undergo processing, which may involve cutting, molding, or machining. For instance, plastic components are often produced using injection molding, where heated plastic is injected into a mold to create the desired shape. This process is crucial as it defines the switch’s functionality, durability, and aesthetic appeal.

2. Forming: How Are Components Shaped and Assembled?

In the forming stage, individual components such as the switch housing, button, and internal contacts are shaped. Techniques like stamping and die-cutting are used for metal parts, while injection molding is common for plastic components. Precision is vital at this stage to ensure that all parts fit together seamlessly.

Illustrative image related to push button switch diagram

Once the components are formed, they are assembled. This can involve manual assembly or automated processes, depending on the complexity and scale of production. Automated assembly lines often utilize robotic arms to enhance efficiency and reduce human error, ensuring a consistent quality of the product.

3. Finishing: What Processes Ensure Quality and Aesthetic Appeal?

The finishing stage focuses on enhancing the product’s durability and appearance. This may involve surface treatments such as painting, powder coating, or anodizing, which not only improve aesthetics but also provide resistance against corrosion and wear. Additionally, quality checks are integrated into the finishing process to catch any defects early.

For illuminated push buttons, this stage includes the installation of LED lights, which requires precise handling to ensure functionality. The final product is then packaged for distribution, with careful attention to prevent damage during transit.

What Quality Assurance Measures Are Essential for Push Button Switches?

Quality assurance (QA) is a critical aspect of the manufacturing process, especially for components used in various applications, from industrial machinery to consumer electronics. Adhering to international standards and implementing rigorous QA protocols can greatly enhance product reliability.

Illustrative image related to push button switch diagram

1. What International Standards Should Buyers Be Aware Of?

For push button switches, compliance with international standards such as ISO 9001 is fundamental. This standard outlines a framework for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE mark (indicating conformity with health, safety, and environmental protection standards) and API standards for certain applications may also apply.

Understanding these standards can aid B2B buyers in assessing the credibility of suppliers. Suppliers with ISO certifications are often more reliable as they have demonstrated a commitment to quality.

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process. These include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Suppliers check for compliance with specifications and reject materials that do not meet quality standards.

-

In-Process Quality Control (IPQC): During production, continuous monitoring is conducted to ensure that the manufacturing process adheres to established standards. This may include random sampling and testing of components at various stages.

-

Final Quality Control (FQC): Before packaging and shipment, the finished products undergo final inspections. This stage includes functional tests to ensure that each switch operates as intended.

3. What Common Testing Methods Are Employed?

Testing methods for push button switches vary based on their intended application but generally include:

-

Electrical Testing: Ensures that the switch operates correctly under specified voltage and current conditions.

-

Environmental Testing: Assesses the product’s performance under various environmental conditions, such as temperature and humidity.

-

Durability Testing: Evaluates the switch’s lifespan by simulating prolonged use, including the number of presses it can withstand.

-

Ingress Protection Testing: For switches with specific IP ratings, tests are conducted to verify protection against dust and water ingress.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing push button switches, B2B buyers must verify the quality control practices of potential suppliers to ensure they meet the necessary standards.

1. What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting audits is one of the most effective ways to assess a supplier’s quality control processes. Buyers can request audits from third-party organizations or conduct their own assessments. Key areas to focus on include:

-

Manufacturing Facilities: Examine the production environment for cleanliness, organization, and adherence to safety standards.

-

Documentation and Processes: Review the supplier’s quality management documentation, including their procedures for IQC, IPQC, and FQC.

-

Test Reports and Certificates: Request test reports and certifications to verify compliance with international standards.

2. How Do Quality Control Reports Influence Supplier Selection?

Quality control reports provide insights into a supplier’s performance over time. Buyers should analyze these reports for trends in defect rates, compliance issues, and corrective actions taken. Consistent quality performance can indicate a reliable supplier, while frequent issues may warrant further investigation.

3. What Nuances Should International Buyers Consider?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider additional nuances in supplier QC practices. This includes understanding local regulations, potential language barriers in communication, and the logistics of shipping and compliance with customs standards.

Furthermore, buyers should be aware of cultural differences that may impact quality expectations and practices. Establishing clear communication channels and setting explicit quality requirements can mitigate misunderstandings and enhance the overall purchasing experience.

In summary, understanding the manufacturing processes and quality assurance measures for push button switches is vital for B2B buyers. By focusing on these aspects, buyers can ensure they select reliable suppliers capable of delivering high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘push button switch diagram’

In the rapidly evolving landscape of industrial applications, sourcing the right push button switch can significantly influence operational efficiency and safety. This practical checklist serves as a guide for B2B buyers looking to procure push button switches and their corresponding diagrams, ensuring informed and strategic purchasing decisions.

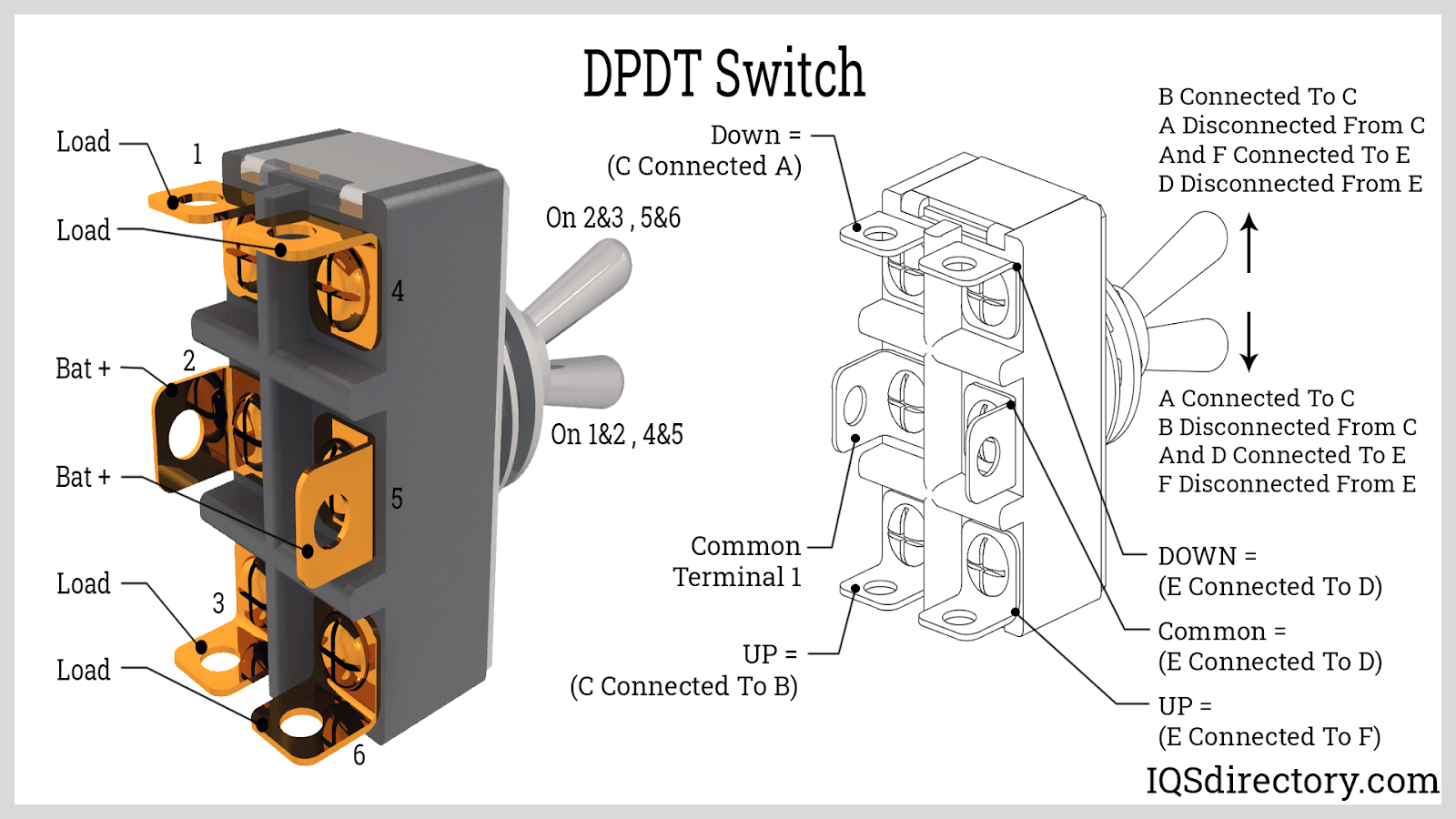

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for identifying the right push button switch for your application. Consider factors such as the type of action (momentary vs. maintained), contact configuration (N/O vs. N/C), and environmental conditions (e.g., water resistance and temperature range). This foundational step helps streamline the selection process and ensures that the chosen switch meets operational needs.

Step 2: Understand Application Requirements

Different applications require specific types of push button switches. For instance, industrial machinery may necessitate switches with high ingress protection ratings, while consumer electronics might prioritize tactile feedback. Assess your application’s unique requirements to ensure compatibility and functionality, which can prevent costly errors and downtime.

Step 3: Research Regulatory Compliance

Verify that the push button switches comply with relevant international standards and regulations, such as IEC or UL certifications. Compliance ensures that the switches are safe for use and meet quality benchmarks. Suppliers should provide documentation to demonstrate adherence to these standards, which is vital for maintaining safety and reliability in your operations.

Step 4: Evaluate Supplier Capabilities

Conduct thorough evaluations of potential suppliers to gauge their reliability and quality. Request product samples and technical datasheets to assess the performance characteristics of their push button switches. Look for suppliers with a proven track record in your industry, as this often correlates with better service and support.

Step 5: Request Detailed Diagrams and Technical Documentation

Obtain detailed diagrams and technical documentation for the push button switches you are considering. This information should include wiring diagrams, installation guides, and maintenance instructions. Comprehensive documentation aids in the installation process and ensures that your team can operate and troubleshoot effectively.

Step 6: Assess Pricing and Total Cost of Ownership

While price is a significant factor, evaluate the total cost of ownership, which includes installation, maintenance, and potential downtime costs associated with inferior products. Request quotes from multiple suppliers and compare not only the upfront costs but also the long-term value provided by the switches. This comprehensive financial assessment is essential for budget-conscious B2B buyers.

Step 7: Establish a Communication Plan with Suppliers

Effective communication with suppliers is essential throughout the procurement process. Establish clear lines of communication for discussing technical questions, delivery timelines, and post-purchase support. A proactive approach to supplier relationships can lead to better service and responsiveness, ultimately enhancing your supply chain efficiency.

Illustrative image related to push button switch diagram

By following this checklist, B2B buyers can navigate the complexities of sourcing push button switches with confidence, ensuring that they make informed decisions that align with their operational goals.

Comprehensive Cost and Pricing Analysis for push button switch diagram Sourcing

What Are the Key Cost Components for Sourcing Push Button Switch Diagrams?

When sourcing push button switches, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Common materials like plastic and metal are used for the button casing, while internal components may require specialized materials to ensure durability and performance. For instance, switches designed for high ingress protection (IP ratings) may utilize more expensive materials to withstand environmental challenges.

-

Labor: Labor costs vary by region and manufacturing complexity. In countries with lower labor costs, such as those in certain parts of Africa and South America, the overall pricing may be reduced. However, skilled labor may command higher wages, especially for intricate designs or custom specifications.

-

Manufacturing Overhead: This includes costs associated with the production process, such as utilities, rent, and equipment maintenance. Factories that specialize in high-volume production might have lower overhead per unit due to economies of scale.

-

Tooling: Tooling costs can be significant, particularly for custom designs. Initial investments in molds and dies for production can be high, but these costs can be amortized over larger production runs, making them more manageable for bulk orders.

-

Quality Control (QC): Ensuring product quality is crucial, especially in industries where safety and reliability are paramount. QC processes add to overall costs but are essential to prevent defects and ensure compliance with standards.

-

Logistics: Shipping and handling can vary widely based on the destination and the chosen Incoterms. Factors such as freight costs, customs duties, and local taxes can significantly influence the final price.

-

Margin: Suppliers will add a margin to cover their risks and operational costs, which varies based on market conditions and competition.

How Do Price Influencers Affect the Cost of Push Button Switch Diagrams?

Several factors influence the pricing of push button switch diagrams:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to better pricing. Suppliers often provide discounts for bulk purchases, making it crucial for buyers to assess their needs against minimum order requirements.

-

Specifications and Customization: Custom switches tailored to specific applications will generally be more expensive than standard models. Buyers should consider whether customization is necessary for their applications to avoid unnecessary costs.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., CE, UL) can increase costs but ensure safety and reliability. Buyers should weigh the benefits of higher quality against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms can significantly impact logistics costs. Understanding whether the price includes shipping, insurance, and duties is essential for calculating the total landed cost.

What Are Effective Buyer Tips for Negotiating Prices on Push Button Switches?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation and cost management strategies can lead to significant savings:

-

Negotiate with Multiple Suppliers: Engaging with various suppliers can provide leverage in negotiations. Request quotes from multiple sources to identify competitive pricing.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but the long-term costs associated with maintenance, reliability, and energy efficiency. A higher upfront cost may be justified by lower operational costs over time.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, tariffs, and local market conditions can affect pricing. Staying informed about these factors can help buyers negotiate better terms.

-

Establish Strong Relationships: Building long-term relationships with suppliers can lead to better pricing and service. Suppliers are often more willing to negotiate with reliable, repeat customers.

-

Explore Local Suppliers: For buyers in Africa and South America, sourcing from local manufacturers may reduce shipping costs and lead times, enhancing overall cost-effectiveness.

Disclaimer

Prices for push button switches can vary widely based on market conditions, supplier pricing strategies, and specific buyer requirements. The information provided here is indicative and should be verified with suppliers for accurate and current pricing.

Alternatives Analysis: Comparing push button switch diagram With Other Solutions

Exploring Alternatives to Push Button Switch Diagrams

In the landscape of electrical control systems, push button switches play a pivotal role in managing the flow of current. However, several alternative solutions exist that can serve similar functions in various applications. Understanding these alternatives can help B2B buyers make informed decisions tailored to their specific operational needs.

| Comparison Aspect | Push Button Switch Diagram | Touchscreen Interface | Rotary Switch |

|---|---|---|---|

| Performance | Reliable for simple tasks | Highly versatile, can handle complex functions | Good for multi-position control |

| Cost | Generally low | Higher initial investment due to technology | Moderate, depending on complexity |

| Ease of Implementation | Straightforward, minimal training required | Requires training for users to navigate | Simple installation, intuitive use |

| Maintenance | Low, durable components | Moderate, software updates may be needed | Low, mechanical wear over time |

| Best Use Case | Simple ON/OFF functions | Complex control panels, modern interfaces | Equipment needing variable settings |

What are the Advantages and Disadvantages of a Touchscreen Interface?

Touchscreen interfaces have emerged as a modern alternative to traditional push button switches. They offer an array of functionalities, allowing users to control multiple functions with a single interface. The primary advantage lies in their versatility; they can easily be programmed to handle complex tasks and provide real-time feedback. However, the higher initial investment and the need for user training can be a barrier for some businesses, particularly in regions with limited access to advanced technology.

How Does a Rotary Switch Compare?

Rotary switches are another alternative, commonly used in applications requiring multi-position control. They allow users to select from various settings by turning a knob, making them intuitive for users familiar with traditional controls. The primary advantages include their durability and the ease of use in environments where precision is critical. However, they may not be suitable for applications needing quick ON/OFF functionality, and their mechanical nature can lead to wear over time, necessitating periodic maintenance.

How Can B2B Buyers Choose the Right Solution?

When selecting the appropriate solution for electrical control needs, B2B buyers should carefully assess the specific requirements of their applications. Factors such as the complexity of tasks, budget constraints, and user training capabilities should guide their decision. For simple ON/OFF functions, push button switch diagrams may suffice. However, for more intricate control systems that require feedback and adaptability, investing in a touchscreen interface could yield long-term benefits. Conversely, for applications requiring multi-position control, rotary switches may be the most efficient choice. By aligning the operational needs with the strengths of each alternative, businesses can optimize their electrical systems for improved efficiency and user satisfaction.

Essential Technical Properties and Trade Terminology for push button switch diagram

What Are the Key Technical Properties of Push Button Switches?

Understanding the essential technical properties of push button switches is crucial for B2B buyers to ensure they select the right components for their applications. Here are some critical specifications to consider:

1. Material Grade

The materials used in push button switches often include plastics (like polycarbonate) and metals (like stainless steel). The choice of material affects durability, resistance to environmental factors, and overall lifespan. For example, stainless steel provides superior resistance to corrosion, making it ideal for harsh environments, while high-grade plastics can offer lightweight options for portable devices. Selecting the right material is vital for ensuring longevity and reliability, which ultimately impacts operational costs.

2. Contact Rating

Contact rating refers to the maximum voltage and current that a switch can handle without failure. This specification is essential for ensuring that the switch can operate safely within the parameters of the intended application. For instance, a switch rated for 10A at 250V AC is suitable for light industrial use, while higher ratings may be necessary for heavy machinery. Understanding contact ratings helps prevent circuit failures and increases the safety of electrical systems.

3. Ingress Protection (IP) Rating

The IP rating indicates the level of protection a switch has against dust and moisture. For example, an IP67 rating means the switch is dust-tight and can withstand immersion in water up to 1 meter for 30 minutes. This property is particularly important for outdoor applications or in environments where exposure to liquids is a concern. Buyers should assess the environmental conditions to choose a switch that meets the necessary IP standards, enhancing the longevity and reliability of the component.

Illustrative image related to push button switch diagram

4. Actuation Type

Push button switches can be momentary or maintained. Momentary switches require continuous pressure to remain in an active state, while maintained switches stay in their last position until actuated again. Understanding the actuation type is crucial for the intended functionality, such as emergency stops or machine controls. This choice directly affects user interaction and operational efficiency.

5. Electrical Life Cycle

This specification refers to the number of cycles a switch can endure before failing electrically. A switch with a higher electrical life cycle is more cost-effective in the long run, especially for high-usage applications. Knowing the expected life cycle helps B2B buyers plan maintenance schedules and budget for replacements, reducing unexpected downtime.

What Are Common Trade Terms Related to Push Button Switches?

Navigating the purchasing process involves understanding certain industry jargon. Here are some common terms that B2B buyers should be familiar with:

Illustrative image related to push button switch diagram

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For push button switches, OEMs provide the essential components that integrate into larger systems or devices. Understanding this term is vital for buyers looking to source high-quality components that ensure compatibility and reliability.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is essential for budgeting and inventory management, as larger orders may be required to secure lower prices. Buyers should consider their demand and storage capabilities when negotiating MOQs to optimize costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It is a critical step in the procurement process, enabling buyers to compare prices and terms from multiple suppliers. A well-structured RFQ can lead to better pricing and improved supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade, outlining the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and risks during the shipping process, ensuring smoother transactions.

5. Lead Time

Lead time refers to the time taken from placing an order until it is received. This metric is crucial for planning and inventory management, particularly for businesses with tight production schedules. Understanding lead times can help buyers make informed decisions about when to place orders to avoid production delays.

Illustrative image related to push button switch diagram

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when selecting push button switches, ensuring optimal performance and reliability for their applications.

Navigating Market Dynamics and Sourcing Trends in the push button switch diagram Sector

What Are the Current Market Dynamics in the Push Button Switch Diagram Sector?

The push button switch sector is witnessing significant growth driven by several global trends. The increasing automation across various industries, particularly in manufacturing and consumer electronics, is a key driver. As businesses aim to enhance operational efficiency, the demand for user-friendly interfaces like push button switches has surged. Emerging technologies such as IoT and smart home systems are further propelling this demand, enabling more sophisticated applications ranging from industrial machinery to consumer appliances.

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific sourcing trends. The push towards digitalization has led to a greater emphasis on integrating push button switches with advanced technologies, making them essential components in smart devices. Additionally, the rise of e-commerce platforms has made it easier for buyers to access a wider variety of push button switches and their configurations. This shift not only broadens options but also fosters competitive pricing, which is crucial for cost-sensitive markets.

Moreover, the growing importance of customization in industrial applications means that suppliers must offer tailored solutions. Buyers should prioritize suppliers who can provide detailed technical specifications and diagrams to ensure compatibility with their unique systems. Understanding regional preferences and compliance requirements, especially in markets like Nigeria and Saudi Arabia, is also essential for successful procurement.

How Is Sustainability Influencing Sourcing Decisions in the Push Button Switch Diagram Market?

Sustainability is becoming increasingly important in the sourcing of push button switches. As environmental concerns rise globally, B2B buyers are prioritizing suppliers who adopt sustainable practices. This includes the use of eco-friendly materials and processes in manufacturing. Buyers should look for products that are certified by recognized green standards, which indicate that they meet specific environmental criteria.

The environmental impact of push button switches extends beyond their production; it includes considerations for their entire lifecycle. B2B buyers are encouraged to assess the recyclability and energy efficiency of the products they source. For instance, switches designed with longer lifespans reduce waste and contribute to a circular economy. Additionally, sourcing from suppliers with transparent supply chains ensures ethical practices, such as fair labor conditions and reduced carbon footprints.

Illustrative image related to push button switch diagram

In regions like Africa and South America, where environmental regulations are evolving, aligning sourcing strategies with sustainability goals can enhance brand reputation and customer loyalty. By prioritizing suppliers who adhere to sustainability standards, international B2B buyers can not only meet regulatory demands but also appeal to environmentally conscious consumers.

What Are the Historical Developments in the Push Button Switch Diagram Sector?

The evolution of push button switches dates back to the early 20th century, initially serving basic electrical functions. As technology advanced, these switches became integral components in various applications, from industrial machinery to consumer electronics. The introduction of illuminated and multifunctional switches marked a significant milestone, enhancing user interface design and safety.

In recent decades, the shift towards automation and digitalization has transformed the push button switch sector. The integration of smart technologies has led to the development of sophisticated switches capable of communicating with other devices. This evolution has not only expanded the functionality of push button switches but has also increased their relevance in modern applications.

For international B2B buyers, understanding this historical context provides insight into the ongoing innovations and market dynamics. Recognizing the trajectory of push button switch technology can inform strategic sourcing decisions and enhance partnerships with manufacturers who are at the forefront of this evolution.

Frequently Asked Questions (FAQs) for B2B Buyers of push button switch diagram

-

1. How do I solve issues with push button switch functionality?

To troubleshoot push button switch functionality, first inspect the wiring for any loose connections or shorts. Ensure that the switch type matches your application—momentary switches require continuous pressure, while maintained switches do not. Check for mechanical damage or wear that could affect performance. If issues persist, consult the manufacturer’s specifications or seek support from your supplier to ensure proper installation and operation. -

2. What is the best push button switch for industrial applications?

For industrial applications, look for push button switches with high ingress protection (IP) ratings, such as IP65 or higher, to ensure durability against dust and moisture. Consider using maintained action switches for functions like emergency stops or machinery controls. Additionally, illuminated buttons can enhance visibility in low-light conditions. Evaluate the electrical rating, actuator style, and compatibility with your existing systems to find the most suitable option. -

3. How can I customize push button switches for my specific needs?

Customization options for push button switches may include altering the button shape, color, and labeling, as well as modifying the electrical specifications. Many manufacturers offer tailored solutions to meet specific operational requirements, such as different voltage ratings or actuator styles. To initiate customization, contact your supplier with detailed specifications, and inquire about their design capabilities and lead times for delivery. -

4. What are the minimum order quantities (MOQ) for push button switches?

Minimum order quantities (MOQ) for push button switches can vary significantly depending on the supplier and the complexity of the switch design. Standard models may have lower MOQs, while customized options typically require larger orders. It’s essential to discuss your requirements with potential suppliers to understand their MOQ policies and explore bulk purchasing options that could benefit your business financially. -

5. What payment terms should I expect when sourcing push button switches internationally?

Payment terms for international orders of push button switches generally include options like wire transfer, letters of credit, or payment upon delivery. Some suppliers may offer net 30 or 60-day terms for established buyers. Always clarify payment conditions before placing an order, and consider negotiating terms that align with your cash flow needs while ensuring the supplier’s confidence in the transaction. -

6. How can I vet suppliers for push button switches in international markets?

To vet suppliers effectively, start by researching their reputation through online reviews and industry references. Request samples to evaluate product quality and compliance with your specifications. Additionally, verify their manufacturing capabilities, certifications, and adherence to international standards. Engaging in direct communication and visiting their facilities, if feasible, can also provide valuable insights into their operations and reliability. -

7. What logistics considerations should I be aware of when importing push button switches?

When importing push button switches, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Assess the total landed cost, including freight and duties, to ensure accurate budgeting. Establish a clear timeline for delivery and ensure that your supplier can meet your deadlines. Collaborating with a freight forwarder experienced in handling electrical components can help streamline the shipping process and avoid delays. -

8. How do I ensure quality assurance (QA) for push button switches?

To ensure quality assurance for push button switches, request detailed technical specifications and certifications from your supplier. Implement a quality control process that includes pre-shipment inspections to verify product conformity to your requirements. Establish clear return policies and warranty agreements to protect your investment. Maintaining open lines of communication with your supplier can also help address any quality concerns promptly.

Top 4 Push Button Switch Diagram Manufacturers & Suppliers List

1. Chinadaier – Push Button Switches

Domain: chinadaier.com

Registered: 2003 (22 years)

Introduction: Push Button Switches: Types include Momentary, Latching, Illuminated, and Safety switches. Key terminals: C (Common), NO (Normally Open), NC (Normally Closed), + (LED Positive), – (LED Negative). Safety tips for wiring: Disconnect power before connecting, double-check connections, seek expert advice if uncertain.

2. RS Components – Push Button Switches

Domain: uk.rs-online.com

Registered: 2001 (24 years)

Introduction: A push button switch controls an action in a machine or process, commonly used in homes and workplaces. They are made from durable materials like plastic or metal and come in various shapes, including flat, round, and customized ergonomic designs. Push button switches can be momentary (requiring continuous pressure) or maintained (staying in the set state until pressure is reapplied). They feature…

3. Reddit – 12V 20A Latching Switch

4. YIYUAN – YTSPS-22E58LM

Domain: forum.arduino.cc

Registered: 2005 (20 years)

Introduction: YTSPS-22E58LM YIYUAN | C2941005 – LCSC Electronics

Strategic Sourcing Conclusion and Outlook for push button switch diagram

As the global demand for push button switches continues to rise, strategic sourcing becomes paramount for businesses aiming to enhance operational efficiency and product reliability. Understanding the intricacies of push button switch types, their applications, and the technical specifications can empower international buyers from regions like Africa, South America, the Middle East, and Europe to make informed decisions.

By aligning sourcing strategies with supplier capabilities, organizations can not only ensure compliance with regional standards but also leverage innovations in design and technology. This is particularly important in rapidly evolving markets where the integration of advanced features, such as illuminated buttons and high ingress protection ratings, can significantly enhance product functionality and user experience.

Looking ahead, the push button switch market presents numerous opportunities for growth and differentiation. International buyers should prioritize collaborations with reputable manufacturers who can deliver quality products tailored to specific market needs. As you navigate your sourcing journey, consider the long-term benefits of building partnerships that emphasize quality, reliability, and innovation. Embrace the future of push button switches—your strategic choices today will shape the success of your projects tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.