Slider Bed Conveyor: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for slider bed conveyor

In today’s fast-paced global market, sourcing reliable slider bed conveyors is a critical challenge for businesses aiming to optimize their material handling processes. As industries across Africa, South America, the Middle East, and Europe seek efficient solutions for assembly, sorting, and packaging, understanding the nuances of slider bed conveyor systems becomes essential. This guide provides a comprehensive overview of the various types of slider bed conveyors available, their specific applications, and the factors to consider when selecting a supplier.

International B2B buyers will find valuable insights into the key attributes of slider bed conveyors, including customization options, material compatibility, and operational efficiencies. The guide delves into essential aspects such as supplier vetting criteria, cost considerations, and maintenance tips, ensuring that buyers can make informed decisions tailored to their unique operational needs.

By equipping decision-makers with the knowledge to navigate the complexities of slider bed conveyor sourcing, this guide empowers businesses to enhance productivity and streamline operations. Whether you are in Vietnam exploring innovative handling solutions or in Germany seeking robust equipment for heavy-duty applications, this resource will serve as your essential companion in the quest for optimal material handling solutions.

Understanding slider bed conveyor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Model 102 “Mini-Pro” | Low profile frame, lightweight, customizable belt types | Small parts removal, scrap handling | Pros: Compact design, easy to install. Cons: Limited load capacity compared to heavier models. |

| Model 104 | General duty, versatile, various accessories available | Moderate applications in assembly and sorting | Pros: Flexible configurations, robust. Cons: May require additional accessories for specific needs. |

| Model 108 | Heavy-duty construction, larger diameter drive pulleys | Bulk material handling, longer distance transport | Pros: High load capacity, durable. Cons: Higher cost, may be overbuilt for light applications. |

| Model SB | Channel frame design, reversible center drive | Long runs, integration with roller bed conveyors | Pros: Easy to connect multiple units, customizable. Cons: Requires careful planning for layout. |

| V-Guide Slider Bed | V-guide belt support for vertical applications | Side loading/unloading, tight spaces | Pros: Stability in challenging environments, versatile. Cons: More complex installation and maintenance. |

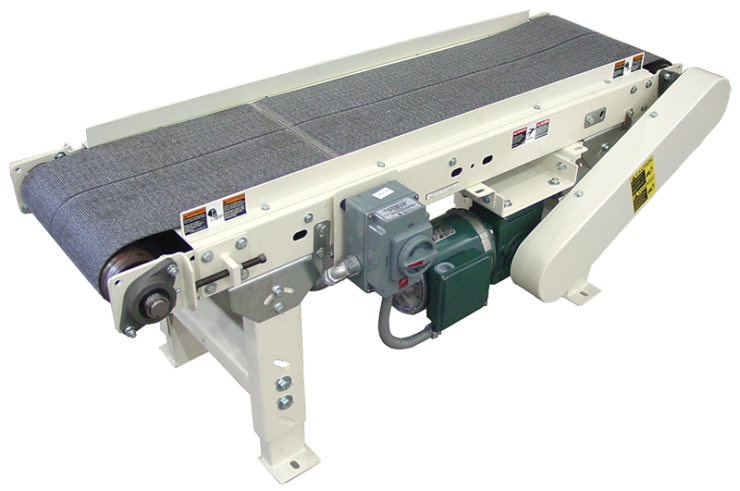

What Are the Characteristics of the Model 102 “Mini-Pro” Slider Bed Conveyor?

The Model 102 “Mini-Pro” is designed for low-profile applications, making it ideal for environments where space is limited. Its lightweight frame allows for easy maneuverability, and it can be customized with various belt materials to suit specific needs. This model excels in small parts removal and scrap handling, making it suitable for manufacturing operations. Buyers should consider its compact design but note that its load capacity is limited compared to heavier-duty models.

How Does the Model 104 Serve General Duty Applications?

The Model 104 slider bed conveyor is a versatile option for general duty applications, featuring a robust design that can handle moderate loads. This model is equipped with various accessories, allowing buyers to customize it for specific tasks such as assembly and sorting. Its flexibility in configuration makes it a popular choice among businesses looking for adaptability. However, buyers should be aware that additional accessories may be necessary to fully meet unique operational requirements.

What Makes the Model 108 Ideal for Heavy-Duty Use?

The Model 108 is characterized by its heavy-duty construction and larger diameter drive pulleys, enabling it to handle substantial loads over longer distances. This model is particularly suited for bulk material handling, making it a preferred choice in industries such as manufacturing and logistics. While its durability is a significant advantage, potential buyers should consider the higher cost and assess whether its capabilities align with their specific operational needs.

Why Choose the Model SB for Long Runs?

The Model SB slider bed conveyor features a channel frame design that allows for easy integration with roller bed conveyors. Its reversible center drive enables bi-directional operation, making it ideal for creating longer runs of conveyor systems. This model is particularly beneficial for businesses looking to streamline their material handling processes. However, careful planning is necessary to ensure optimal layout and functionality, which may require additional time and resources.

What Are the Advantages of the V-Guide Slider Bed Conveyor?

The V-Guide slider bed conveyor is designed with a unique belt support system that provides stability in vertical applications. This model is particularly effective for side loading and unloading tasks in tight spaces, offering versatility in various operational environments. While its design enhances stability, buyers should be prepared for a more complex installation and maintenance process, which may involve additional training or resources.

Key Industrial Applications of slider bed conveyor

| Industry/Sector | Specific Application of Slider Bed Conveyor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Assembly Line Operations | Increases efficiency and reduces labor costs | Customization options for size and load capacity |

| Food Processing | Transporting Packaged Goods | Ensures hygiene and minimizes product damage | Materials suitable for food safety regulations |

| Automotive | Parts Sorting and Inspection | Streamlines production and enhances quality control | Durability and ability to handle heavy loads |

| Warehousing and Logistics | Sorting and Packing of Goods | Optimizes space and improves order fulfillment | Flexibility in configuration and integration with other systems |

| Recycling and Waste Management | Moving Recyclable Materials | Increases recycling rates and reduces waste | Robust design to handle various material types |

How Are Slider Bed Conveyors Used in Manufacturing?

In manufacturing, slider bed conveyors are frequently employed in assembly line operations, where they facilitate the smooth movement of components from one workstation to another. By enhancing operational efficiency, these conveyors help minimize manual handling, thus reducing labor costs and the potential for workplace injuries. Buyers in this sector should consider customization options, such as varying belt widths and load capacities, to meet specific production requirements.

What Role Do Slider Bed Conveyors Play in Food Processing?

In the food processing industry, slider bed conveyors are essential for transporting packaged goods through various stages, including sorting, packing, and inspection. These conveyors are designed to meet stringent hygiene standards, ensuring that food products remain uncontaminated during transit. International buyers must prioritize sourcing materials that comply with food safety regulations and consider features such as easy cleaning and maintenance.

How Are Slider Bed Conveyors Used in the Automotive Sector?

The automotive industry utilizes slider bed conveyors for sorting and inspecting parts as they move through production lines. These conveyors enhance quality control by allowing for easy access to components for inspection and testing. Buyers should focus on the durability and load capacity of the conveyors to accommodate the heavier components typically found in automotive manufacturing, ensuring that they can withstand rigorous operational demands.

What Benefits Do Slider Bed Conveyors Provide in Warehousing and Logistics?

In warehousing and logistics, slider bed conveyors are vital for sorting and packing goods, improving the overall efficiency of order fulfillment processes. By optimizing space and facilitating the quick movement of products, these conveyors help businesses reduce delivery times and enhance customer satisfaction. When sourcing these conveyors, buyers should consider flexibility in configuration to integrate seamlessly with existing systems and the ability to customize for varying product sizes.

How Are Slider Bed Conveyors Used in Recycling and Waste Management?

In the recycling and waste management sector, slider bed conveyors are used to transport recyclable materials efficiently, helping to streamline sorting processes. These conveyors can handle a diverse range of materials, from plastics to metals, which increases recycling rates and reduces landfill waste. Buyers in this sector should look for robust designs that can withstand the wear and tear of heavy-duty applications, ensuring long-term operational efficiency.

3 Common User Pain Points for ‘slider bed conveyor’ & Their Solutions

Scenario 1: Inconsistent Material Flow Disruptions

The Problem: Many B2B buyers experience challenges with inconsistent material flow when using slider bed conveyors. This often occurs in high-volume operations where the conveyor is tasked with handling varying weights and sizes of materials. Buyers frequently encounter issues such as jams or slippage, which can lead to production delays, increased labor costs, and even damage to the materials being transported. Such disruptions not only affect operational efficiency but can also compromise the integrity of the entire assembly line, resulting in costly downtime.

Illustrative image related to slider bed conveyor

The Solution: To mitigate these disruptions, it’s crucial to carefully assess the specific requirements of the materials being handled. Buyers should consider investing in custom slider bed conveyors that can be tailored to accommodate various material sizes and weights. For instance, selecting a model with adjustable speed settings can help maintain a consistent flow, while wider belt options can prevent slippage and ensure stability. Regular maintenance and monitoring of the conveyor system are essential to identify and resolve potential issues before they escalate. Additionally, integrating sensors to monitor material flow can provide real-time feedback and facilitate timely adjustments, ensuring smooth operations.

Scenario 2: Difficulty in Integration with Existing Systems

The Problem: Another common pain point for buyers is the difficulty in integrating slider bed conveyors into existing material handling systems. Many organizations operate with a combination of conveyor types, and the inability to seamlessly connect new slider bed models with roller bed systems or other conveyor types can create operational bottlenecks. This integration challenge can lead to additional costs for modifications or even necessitate a complete overhaul of the existing infrastructure.

The Solution: To overcome integration issues, buyers should prioritize selecting slider bed conveyors designed with compatibility in mind. Models that feature built-in transition rollers or adjustable frames can facilitate easier connections with different conveyor types, minimizing the need for extensive modifications. Before making a purchase, it’s advisable to engage with the supplier to understand the specific compatibility features of the conveyors. Conducting a thorough assessment of the existing system and identifying any potential gaps or mismatches will also help in selecting the right components. Furthermore, investing in modular conveyor systems can offer greater flexibility for future expansions or adjustments.

Scenario 3: High Maintenance Costs and Downtime

The Problem: Buyers often face high maintenance costs and unplanned downtime due to wear and tear on slider bed conveyors. Frequent repairs not only strain budgets but can also disrupt production schedules, leading to significant losses. The challenge is often compounded by a lack of clarity on when maintenance is needed, as well as the absence of predictive maintenance strategies that can help anticipate issues before they arise.

The Solution: Implementing a proactive maintenance strategy can significantly reduce costs and downtime associated with slider bed conveyors. Buyers should consider establishing a routine inspection and maintenance schedule based on the manufacturer’s recommendations and the operational environment. Utilizing condition monitoring technologies, such as vibration analysis and thermal imaging, can provide valuable insights into the health of the conveyor system, allowing for early detection of potential failures. Additionally, sourcing high-quality components, including durable belts and robust frames, can extend the lifespan of the conveyor and reduce the frequency of repairs. Training operational staff on basic maintenance procedures can also empower them to identify minor issues before they escalate into major problems, fostering a more efficient and cost-effective operation.

Strategic Material Selection Guide for slider bed conveyor

What Are the Key Properties of Common Materials for Slider Bed Conveyors?

When selecting materials for slider bed conveyors, it is essential to consider their properties, advantages, and limitations. This analysis will focus on four common materials: steel, aluminum, plastic, and rubber, providing insights that are particularly relevant for international B2B buyers.

How Does Steel Perform in Slider Bed Conveyor Applications?

Steel is a widely used material in slider bed conveyors due to its strength and durability. Key properties include high tensile strength, excellent wear resistance, and the ability to withstand high temperatures and pressures. However, steel is susceptible to corrosion, which can be mitigated through coatings or galvanization.

Pros: Steel offers significant durability and load-bearing capacity, making it suitable for heavy-duty applications. Its availability and relatively low cost make it a popular choice.

Cons: The primary drawback is its weight, which can complicate installation and maintenance. Additionally, corrosion can be a concern, especially in humid or corrosive environments.

Illustrative image related to slider bed conveyor

For international buyers, compliance with standards such as ASTM or DIN is crucial, especially in regions like Europe where regulations are stringent.

What Advantages Does Aluminum Offer for Slider Bed Conveyors?

Aluminum is another common material for slider bed conveyors, known for its lightweight nature and resistance to corrosion. It has a lower tensile strength compared to steel but compensates with ease of handling and installation.

Pros: Aluminum is lightweight, making it easier to transport and install. Its corrosion resistance is beneficial in environments where moisture is prevalent.

Illustrative image related to slider bed conveyor

Cons: The lower strength means aluminum may not be suitable for very heavy loads. Additionally, it tends to be more expensive than steel, which can impact budget considerations.

International buyers should be aware of the specific alloy grades and their compliance with standards like JIS in Japan or EN in Europe, which can affect material selection.

How Do Plastic Materials Perform in Slider Bed Conveyor Systems?

Plastic materials, such as high-density polyethylene (HDPE) and polypropylene, are increasingly used in slider bed conveyors, especially in food and packaging industries. They offer excellent chemical resistance and are lightweight.

Illustrative image related to slider bed conveyor

Pros: Plastics are resistant to corrosion and chemicals, making them ideal for specific applications. They are also quieter in operation and require less maintenance.

Cons: The primary limitation is their lower load-bearing capacity compared to metals. They may also be more susceptible to wear and tear over time.

For B2B buyers, understanding the specific chemical compatibility and compliance with food safety regulations is essential, particularly in regions with strict health standards.

What Role Does Rubber Play in Slider Bed Conveyor Applications?

Rubber is often used for conveyor belts in slider bed systems due to its flexibility and grip. It can handle a variety of materials and is effective in reducing noise and vibration.

Illustrative image related to slider bed conveyor

Pros: Rubber provides excellent traction and is ideal for handling bulk materials. Its flexibility allows it to conform to different shapes and sizes.

Cons: Rubber can degrade over time, particularly in extreme temperatures or exposure to certain chemicals. It may also require more frequent replacement compared to metal options.

International buyers should consider the specific rubber grades and their compliance with relevant standards, especially in industries like automotive or food processing where safety is paramount.

Summary Table of Material Properties

| Material | Typical Use Case for slider bed conveyor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications requiring high strength | Excellent durability and load capacity | Susceptible to corrosion; heavier | Low |

| Aluminum | Lightweight applications; food processing | Corrosion resistance; lightweight | Lower strength; higher cost | Med |

| Plastic | Chemical handling; food packaging | Corrosion resistant; quieter operation | Lower load capacity; wear over time | Med |

| Rubber | Bulk material handling; noise reduction | Excellent traction; flexible | Degrades over time; requires frequent replacement | Med |

This strategic material selection guide provides valuable insights for B2B buyers, enabling them to make informed decisions based on the specific needs of their applications and compliance with international standards.

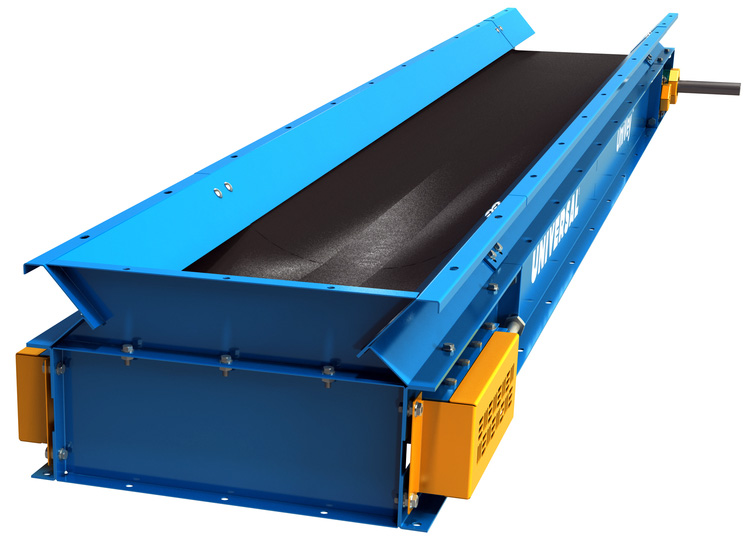

In-depth Look: Manufacturing Processes and Quality Assurance for slider bed conveyor

What Are the Main Stages in the Manufacturing Process of Slider Bed Conveyors?

The manufacturing process of slider bed conveyors involves several critical stages, each designed to ensure high-quality output that meets the diverse needs of various industries.

Illustrative image related to slider bed conveyor

Material Preparation

The first step in manufacturing slider bed conveyors is material preparation. This includes sourcing high-grade materials such as steel for the frame, rubber for the belt, and other components. Suppliers often adhere to strict specifications to guarantee durability and performance. For instance, 12-gauge formed steel is commonly used for the frames to provide strength while maintaining a lightweight profile. Quality checks on raw materials are essential to avoid defects that could compromise the final product.

Forming Processes

Once the materials are prepared, the next stage is forming. This involves cutting, bending, and welding the steel components into the desired shapes. Techniques such as laser cutting and CNC machining are frequently employed to achieve precision. The forming process also includes creating the slider bed and pulleys, which are crucial for the conveyor’s functionality. The use of advanced machinery ensures that the components fit together perfectly, reducing assembly time and enhancing reliability.

Assembly Techniques

After forming, the individual components are assembled into a complete slider bed conveyor system. This stage often involves using automated assembly lines that improve efficiency and reduce human error. Key components such as motors, belts, and drives are integrated during assembly. Manufacturers may also offer customization options, allowing clients to specify features like belt width and drive type to suit their operational needs.

Illustrative image related to slider bed conveyor

Finishing Processes

The final stage of manufacturing is finishing, which includes painting, coating, and quality inspections. A powder coating finish is commonly applied to enhance corrosion resistance and improve aesthetics. This step is vital for ensuring that the conveyor can withstand harsh environments, particularly in industries like food processing and manufacturing.

How Is Quality Assurance Implemented in Slider Bed Conveyor Manufacturing?

Quality assurance (QA) is crucial in the manufacturing of slider bed conveyors to ensure that products meet both international standards and customer expectations.

What International Standards Are Relevant for Slider Bed Conveyors?

International standards such as ISO 9001 play a significant role in the quality assurance processes for slider bed conveyors. ISO 9001 focuses on quality management systems and emphasizes continuous improvement and customer satisfaction. Additionally, industry-specific certifications like CE mark (for compliance with European safety standards) and API (American Petroleum Institute) certifications for conveyors used in oil and gas applications are also important. These standards ensure that the conveyors are safe, reliable, and efficient.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process. Common practices include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specifications.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, inspections are conducted to monitor the quality of the components being formed and assembled. This helps identify issues early on, reducing waste and rework.

- Final Quality Control (FQC): Once the conveyor system is fully assembled, a comprehensive inspection is performed. This includes functional testing of motors, drive systems, and overall performance to ensure they operate as intended.

What Common Testing Methods Are Used for Quality Assurance?

Manufacturers employ various testing methods to validate the performance and safety of slider bed conveyors. These can include:

- Load Testing: Assessing the conveyor’s ability to handle specified loads without failure.

- Operational Testing: Running the conveyor under real-world conditions to ensure it meets performance criteria.

- Durability Testing: Simulating long-term usage to evaluate wear and tear on components.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital to ensure product reliability and compliance.

What Are Effective Ways to Conduct Supplier Audits?

Conducting supplier audits can provide insight into a manufacturer’s quality control practices. Buyers should consider:

- On-Site Audits: Visiting the manufacturing facility allows buyers to observe processes, equipment, and the overall environment. It also enables discussions with quality assurance personnel.

- Review of Documentation: Requesting access to quality management system documentation, including certifications, inspection reports, and testing results, can provide additional assurance of the supplier’s commitment to quality.

How Can Buyers Utilize Third-Party Inspections?

Engaging third-party inspection services can further enhance buyer confidence. Independent inspectors can provide unbiased assessments of the manufacturing processes and final products, ensuring compliance with international standards.

Illustrative image related to slider bed conveyor

What Nuances Should International Buyers Be Aware Of in Quality Control?

International B2B buyers must be aware of certain nuances in quality control that may vary by region.

- Cultural Differences: Understanding how different cultures approach quality assurance can impact supplier relationships. For instance, some regions may prioritize speed over quality, which can lead to discrepancies in product standards.

- Regulatory Compliance: Buyers should familiarize themselves with local regulations that may affect manufacturing practices. This is especially important in industries like food and pharmaceuticals, where compliance with safety standards is critical.

By understanding the manufacturing processes and quality assurance measures associated with slider bed conveyors, international buyers can make informed decisions that align with their operational needs and standards, ultimately ensuring successful supply chain management.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘slider bed conveyor’

To effectively procure a slider bed conveyor, it is essential to follow a structured approach that ensures you meet your operational requirements while maximizing value. This guide provides a clear checklist to help B2B buyers navigate the complexities of sourcing slider bed conveyors.

Illustrative image related to slider bed conveyor

Step 1: Define Your Technical Specifications

Begin by clearly defining your operational needs, including the types of materials to be handled, load capacities, and conveyor lengths. Understanding these specifications will help you determine the appropriate model and features required for your application. Consider factors like belt width, speed, and the environment in which the conveyor will operate (e.g., temperature, humidity).

Step 2: Research Different Models and Features

Explore various slider bed conveyor models to understand the range of options available. Different models, such as lightweight, general duty, or heavy-duty conveyors, offer unique benefits suited to specific applications. Pay attention to customizable features such as belt materials, drive configurations, and additional accessories like side rails or adjustable supports.

Step 3: Evaluate Potential Suppliers

Before making a purchase, it’s crucial to thoroughly vet potential suppliers. Request company profiles, product catalogs, and case studies to gauge their experience and reliability. Look for suppliers who have a proven track record in your industry and can provide references from previous clients, particularly in regions similar to your own.

Step 4: Check for Compliance and Certifications

Ensure that the conveyor systems comply with relevant industry standards and safety regulations. Certifications such as ISO or CE indicate adherence to quality and safety protocols, which can mitigate risks in operation. Inquire about the supplier’s manufacturing processes and quality assurance measures to ensure you are sourcing a reliable product.

Step 5: Request Quotes and Compare Pricing

Gather quotes from multiple suppliers to compare pricing structures. When evaluating costs, consider not only the initial purchase price but also factors such as shipping, installation, and maintenance services. A detailed breakdown of costs can help you identify the best overall value rather than just the lowest price.

Step 6: Review Warranty and Support Options

Before finalizing your purchase, carefully review the warranty terms and after-sales support offered by the supplier. A strong warranty can provide peace of mind regarding the durability and performance of the conveyor. Also, consider the availability of technical support and spare parts, which can be critical in minimizing downtime.

Illustrative image related to slider bed conveyor

Step 7: Plan for Installation and Training

Finally, consider how the installation process will be managed and whether training is required for your staff. Some suppliers offer installation services, while others may provide training sessions to ensure your team can operate the conveyor efficiently. Proper setup and training can significantly enhance the performance and longevity of your new equipment.

By following these steps, B2B buyers can make informed decisions when sourcing slider bed conveyors, ensuring that they select the best solutions for their material handling needs.

Comprehensive Cost and Pricing Analysis for slider bed conveyor Sourcing

What Are the Key Cost Components in Slider Bed Conveyor Sourcing?

When sourcing slider bed conveyors, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The type of materials used in manufacturing, such as steel for the frame and rubber for the belt, significantly impact the overall cost. High-quality materials may increase initial costs but can lead to lower maintenance expenses over time.

-

Labor: The cost of skilled labor for assembly and manufacturing varies by region. In countries with higher labor costs, such as Germany, the total cost might be elevated compared to regions with lower wage rates, such as Vietnam.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, facility costs, and administrative expenses. Suppliers often factor these costs into their pricing models.

-

Tooling: Specialized tools required for manufacturing custom conveyor systems can add to upfront costs. If you need unique specifications or modifications, be prepared for higher tooling expenses.

-

Quality Control (QC): Ensuring that the conveyors meet industry standards often requires investment in quality control measures. While this adds to the cost, it is essential for long-term reliability and performance.

-

Logistics: Transportation and shipping costs vary significantly based on the distance, mode of transport, and Incoterms. Import duties and customs fees can also add to the overall cost for international buyers.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market dynamics can help you evaluate whether a quoted price is competitive.

What Influences Pricing for Slider Bed Conveyors?

Several factors can influence the pricing of slider bed conveyors, particularly for international buyers:

Illustrative image related to slider bed conveyor

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract discounts, making it more cost-effective per unit. Always inquire about pricing tiers based on order volume.

-

Specifications and Customization: Customized conveyors tailored to specific operational needs can significantly increase costs. Standard models are usually more affordable, so weigh the necessity of customization against potential budget constraints.

-

Materials and Quality Certifications: High-quality materials and certifications (e.g., ISO, CE) can enhance the price but are often justified by improved durability and performance. Ensure that the suppliers you consider meet the necessary industry standards.

-

Supplier Factors: Reputation, reliability, and experience of the supplier can influence pricing. Established suppliers may charge a premium, but they often provide better customer service and support.

-

Incoterms: Understanding Incoterms is critical for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of the conveyors.

What Are Effective Buyer Tips for Cost-Efficient Sourcing?

-

Negotiate Strategically: Leverage your purchasing power, especially if ordering in bulk. Don’t hesitate to negotiate terms that can lower costs, such as payment terms or delivery schedules.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also the long-term costs associated with maintenance, energy consumption, and potential downtime. Selecting a reliable conveyor may incur a higher initial expense but save costs in the long run.

-

Research Pricing Nuances for International Purchases: Different regions may have varying pricing strategies. For instance, suppliers in Africa or South America may offer competitive prices due to lower labor costs, but consider the trade-offs in quality and service.

-

Request Multiple Quotes: Always obtain quotes from several suppliers to ensure you are getting a fair price. This practice not only provides options but also allows you to compare features and services offered.

-

Stay Informed About Market Trends: Regularly review market trends and pricing fluctuations to better understand the factors affecting costs. This knowledge can empower you during negotiations and help you make timely purchasing decisions.

In summary, understanding the cost structure, pricing influencers, and effective negotiation strategies is essential for international B2B buyers of slider bed conveyors. By being informed and strategic, you can optimize your sourcing decisions for better value and performance.

Alternatives Analysis: Comparing slider bed conveyor With Other Solutions

When evaluating material handling solutions, it is essential to consider various conveyor systems that can meet specific operational needs. Slider bed conveyors are widely recognized for their versatility and efficiency in transporting materials. However, alternative conveyor solutions may offer distinct advantages depending on the application, budget, and operational environment. Here, we compare slider bed conveyors with two viable alternatives: belt over roller conveyors and modular plastic belt conveyors.

| Comparison Aspect | Slider Bed Conveyor | Belt Over Roller Conveyor | Modular Plastic Belt Conveyor |

|---|---|---|---|

| Performance | High friction, suitable for diverse materials | Lower friction, efficient for lighter loads | Flexible configurations for various products |

| Cost | Moderate initial investment | Generally higher due to roller components | Variable, often cost-effective for specific applications |

| Ease of Implementation | Moderate, requires proper setup | Typically straightforward installation | Easy to configure and adapt on-site |

| Maintenance | Regular checks, lower wear components | Requires more frequent maintenance due to rollers | Low maintenance; components are easy to replace |

| Best Use Case | Heavy materials, assembly lines, packing | Light to moderate loads, packaging, sorting | Food processing, small parts assembly |

What are the advantages and disadvantages of a belt over roller conveyor compared to a slider bed conveyor?

Belt over roller conveyors utilize a belt that rides over a series of rollers. This design reduces friction, making it ideal for transporting lighter materials over longer distances. They are particularly beneficial in environments where speed is crucial, such as packaging and sorting operations. However, the initial cost may be higher due to the complexity of the roller system, and maintenance can be more frequent as the rollers may wear down over time. For B2B buyers, this system is excellent for applications involving less heavy-duty handling.

How does a modular plastic belt conveyor stack up against a slider bed conveyor?

Modular plastic belt conveyors consist of interlocking plastic segments that can be configured to meet specific operational needs. This flexibility allows for easy adjustments in width and length, accommodating varying product sizes. They are particularly advantageous in food processing and industries requiring sanitary conditions, as they are easy to clean and resistant to corrosion. However, the upfront costs can vary, and while they generally require less maintenance than other systems, the specific application may dictate the need for more frequent replacements of modular sections.

How should B2B buyers select the right conveyor solution for their operations?

Choosing the right conveyor system hinges on understanding operational requirements, including the types of materials being transported, the environment in which the conveyor will operate, and budget constraints. Buyers should assess the performance needs—whether high friction or low friction is required—and consider the ease of maintenance and implementation. By aligning these factors with the specific application demands—such as the need for flexibility, speed, or sanitation—B2B buyers can make informed decisions that enhance productivity and efficiency in their operations.

In summary, while slider bed conveyors are an excellent choice for various material handling tasks, exploring alternatives like belt over roller and modular plastic belt conveyors can provide tailored solutions that better fit specific operational requirements.

Essential Technical Properties and Trade Terminology for slider bed conveyor

What Are the Key Technical Properties of Slider Bed Conveyors?

Understanding the essential technical properties of slider bed conveyors is crucial for B2B buyers looking to optimize their material handling processes. Here are some critical specifications to consider:

-

Material Grade

The construction material significantly influences the conveyor’s durability and performance. Common materials include steel (often powder-coated for corrosion resistance) and high-strength aluminum. Steel provides robustness, making it ideal for heavy-duty applications, while aluminum is lightweight and suitable for less demanding tasks. Selecting the right material ensures longevity and minimizes maintenance costs. -

Belt Width and Length

The width and length of the conveyor belt determine its capacity and compatibility with various products. Standard widths range from 2 inches to over 72 inches, with lengths customizable to fit specific operational needs. B2B buyers must assess the dimensions based on the size of the items being transported to ensure efficient handling and prevent bottlenecks in production lines. -

Drive Type

Slider bed conveyors can feature different drive types, such as center drives or end drives. Center drives provide a reversible direction without additional costs, which can be advantageous in dynamic environments. Understanding the drive mechanism helps in selecting a conveyor that aligns with the specific flow and handling requirements of the operation. -

Pulleys and Tensioning System

The type and size of pulleys affect the conveyor’s load capacity and operational efficiency. Larger pulleys can handle heavier loads and longer distances. Additionally, a robust tensioning system is essential for maintaining optimal belt performance. Buyers should evaluate these aspects to ensure smooth and reliable operation in their material handling systems. -

Speed and Load Capacity

The travel speed, often measured in feet per minute, and the load capacity are critical for assessing the conveyor’s efficiency. Typical speeds range from 50 to 100 feet per minute, depending on the application. Understanding these metrics allows businesses to match conveyor performance with production requirements, ultimately enhancing productivity. -

Customization Options

Many suppliers offer customization options, including adjustable heights, guard rails, and specialized belt materials. Customization allows B2B buyers to tailor the conveyor to their unique operational needs, ensuring seamless integration into existing systems and processes.

What Are Common Trade Terms Associated with Slider Bed Conveyors?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are several key terms:

Illustrative image related to slider bed conveyor

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of slider bed conveyors, understanding OEM relationships can help buyers source high-quality components that meet their specifications. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is vital for budget-conscious buyers who need to plan their purchases effectively while ensuring they meet the supplier’s requirements for cost efficiency. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products or services. Crafting a comprehensive RFQ can help buyers obtain competitive pricing and clarify technical specifications, ultimately aiding in decision-making. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), helps businesses understand shipping costs and risks associated with their purchases. -

Lead Time

Lead time refers to the amount of time from placing an order to receiving it. Understanding lead times is crucial for planning operations and ensuring that production schedules remain on track. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and performance of the conveyor. Understanding warranty terms is essential for buyers to protect their investment and ensure they have recourse in case of defects or failures.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, streamline their procurement processes, and enhance their operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the slider bed conveyor Sector

What are the Current Market Dynamics and Sourcing Trends in the Slider Bed Conveyor Sector?

The global slider bed conveyor market is witnessing significant growth driven by the increasing demand for automation in material handling processes. Industries such as manufacturing, packaging, and logistics are increasingly adopting conveyor systems to enhance efficiency and reduce operational costs. Emerging technologies, such as IoT-enabled conveyors and AI-driven predictive maintenance, are transforming traditional conveyor systems, making them smarter and more efficient. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding these technological advancements is crucial for making informed purchasing decisions.

Additionally, the trend towards customization is becoming prominent. Many manufacturers are now offering bespoke solutions tailored to specific industry needs, which is particularly advantageous for buyers in diverse sectors like food and beverage, automotive, and pharmaceuticals. The demand for modular and expandable systems also reflects a shift towards flexible manufacturing processes, allowing companies to adapt their operations in response to changing market conditions.

Moreover, sustainability is increasingly influencing purchasing behavior. Buyers are seeking suppliers that adhere to eco-friendly practices, which is shaping sourcing strategies across the globe. Understanding the regional market dynamics, such as differing regulatory environments and economic conditions in countries like Vietnam and Germany, is essential for successful procurement.

How are Sustainability and Ethical Sourcing Impacting the Slider Bed Conveyor Sector?

Sustainability is becoming a non-negotiable aspect of sourcing strategies in the slider bed conveyor sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Companies are increasingly prioritizing suppliers who demonstrate commitment to reducing their carbon footprint. This trend is particularly relevant for international buyers, as they are often required to comply with stringent environmental regulations and standards in their respective markets.

Illustrative image related to slider bed conveyor

Ethical sourcing is equally important, with a growing emphasis on transparency and accountability within supply chains. Buyers are encouraged to inquire about the sourcing of materials used in conveyor systems, such as steel and belt materials, and to seek certifications that confirm compliance with environmental and labor standards. Certifications like ISO 14001 for environmental management and other “green” labels can guide buyers in selecting suppliers who prioritize sustainability.

Additionally, advancements in materials science have led to the development of more sustainable options for conveyor belts, such as those made from recycled materials or biodegradable components. These innovations not only address environmental concerns but also enhance the durability and performance of conveyor systems.

What is the Historical Context of Slider Bed Conveyors in the B2B Market?

The slider bed conveyor has its origins in the early 20th century, evolving from simpler belt systems designed for material transport in factories. Initially used in assembly lines, these conveyors quickly gained popularity due to their versatility and efficiency in handling various materials. As industries grew, so did the complexity of conveyor systems, leading to innovations such as the slider bed design, which allows for smoother operation and better load distribution.

Over the decades, slider bed conveyors have adapted to meet the demands of changing markets and technologies. The integration of automation and control systems has transformed these conveyors into essential components of modern manufacturing and logistics operations. Today, they are not only critical for enhancing productivity but also for supporting sustainable practices within supply chains, reflecting the ongoing evolution of industrial processes in a rapidly changing global economy.

Frequently Asked Questions (FAQs) for B2B Buyers of slider bed conveyor

-

How do I solve material handling challenges in my facility with a slider bed conveyor?

Slider bed conveyors are versatile solutions for various material handling challenges, such as transporting heavy loads, sorting, and packing. To address specific issues, assess your operational requirements, such as load capacity, belt width, and the types of materials being handled. Consider implementing custom configurations, including different belt materials or additional accessories, to enhance functionality. Collaborating with suppliers who specialize in slider bed conveyors can provide tailored solutions that align with your workflow and productivity goals. -

What is the best slider bed conveyor model for heavy-duty applications?

For heavy-duty applications, the Model 108 slider bed conveyor is often recommended. It features an 8-inch diameter drive pulley, allowing it to handle heavier loads over longer distances. This model is designed for durability and can be customized in length to fit specific needs. When selecting a model, evaluate your load requirements, the materials being transported, and any space constraints to ensure optimal performance and efficiency. -

How can I customize a slider bed conveyor to meet my specific needs?

Customization options for slider bed conveyors are extensive and can include variations in belt material, frame design, and additional features like side rails or adjustable supports. When working with suppliers, clearly communicate your operational needs and challenges. Many manufacturers offer bespoke solutions, so consider discussing your requirements for width, length, and load capacity to ensure the conveyor system fits seamlessly into your workflow. -

What are typical minimum order quantities (MOQ) for slider bed conveyors?

Minimum order quantities for slider bed conveyors can vary significantly based on the manufacturer and the complexity of the customization required. Generally, suppliers may set MOQs to ensure cost-effectiveness in production. For standard models, the MOQ could be as low as one unit, while customized conveyors might require larger orders. It’s advisable to communicate directly with suppliers to negotiate terms that align with your purchasing strategy. -

What payment terms should I expect when sourcing slider bed conveyors internationally?

Payment terms for international B2B transactions can vary widely. Common practices include upfront payments, partial payments upon order confirmation, and balance payments before shipment. Some suppliers may offer flexible financing options or credit terms based on your business relationship and order size. Always clarify payment methods, currency, and any associated fees or tariffs with your supplier to avoid unexpected costs. -

How do I ensure quality assurance (QA) when sourcing slider bed conveyors?

To ensure quality assurance when sourcing slider bed conveyors, conduct thorough supplier vetting, including checking for certifications and industry standards. Request samples or visit manufacturing facilities if possible to assess quality firsthand. Establish clear QA protocols, including inspection criteria and testing requirements, in your purchase agreement. Additionally, consider suppliers with strong reputations and positive customer reviews to mitigate risks. -

What logistics considerations should I keep in mind when importing slider bed conveyors?

Logistics plays a critical role in importing slider bed conveyors. Factors to consider include shipping methods, delivery timelines, and costs associated with customs clearance. Partner with a reliable freight forwarder familiar with international trade regulations to navigate the complexities of cross-border shipping. Ensure that your supplier provides accurate documentation to facilitate a smooth customs process, and plan for potential delays by allowing ample time for delivery. -

How can I assess the reliability of a supplier for slider bed conveyors?

To assess the reliability of a supplier, start by researching their industry experience and customer testimonials. Request references from previous clients and evaluate their responsiveness to inquiries and issues. Analyze their manufacturing capabilities and quality control measures. It’s also beneficial to verify any certifications or compliance with international standards, which can indicate a commitment to quality and reliability in their products.

Top 5 Slider Bed Conveyor Manufacturers & Suppliers List

1. Flexco – Slider Beds

Domain: flexco.com

Registered: 1993 (32 years)

Introduction: Slider Beds are designed to provide a smooth surface for material handling and to protect the conveyor belt from impact. They feature a low-friction design that allows for easy movement of materials, reducing wear and tear on the belt. The beds are constructed from durable materials to withstand harsh environments and are available in various sizes to fit different conveyor systems. Slider Beds ar…

2. Bastian Solutions – Slider Bed Belt Conveyor

3. Superior Industries – Slider Bed

Domain: superior-ind.com

Registered: 1996 (29 years)

Introduction: Slider Bed is designed to maintain a tight, consistent seal between the conveyor belt and hopper skirting, preventing material spillage in load zones. It eliminates belt sagging and can be upgraded with impact rolls for enhanced impact absorption. The product fits CEMA C or D idler frames and accommodates belt widths ranging from 24″ to 72″ (600mm to 1,800mm). Key advantages include a continuous s…

4. Russell Conveyor – Slider Beds

Domain: russellconveyor.com

Registered: 2015 (10 years)

Introduction: Slider Beds: Flat surface conveyors with belts supported by a metal sheet that slides on steel bars. Advantages include reduced friction, versatility for various materials, and cost-effectiveness. Ideal for handling delicate or oddly shaped items in industries like electronics and pharmaceuticals. Weaknesses include limitations on load capacity and suitability for fragile or lightweight materials….

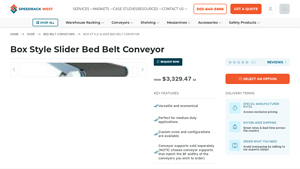

5. Speedrack West – Box Style Slider Bed Conveyor Belt System

Domain: speedrackwest.com

Registered: 1999 (26 years)

Introduction: {‘product_name’: ‘Box Style Slider Bed Conveyor Belt System’, ‘key_features’: [‘Versatile and economical’, ‘Perfect for medium duty applications’, ‘Custom sizes and configurations available’, ‘Conveyor supports sold separately’], ‘available_options’: [{‘belt_width’: ’18″‘, ‘BF’: ’19″‘, ‘OAW’: ’22″‘, ‘length’: “10′”, ‘price’: ‘$3,329.47’}, {‘belt_width’: ’24″‘, ‘BF’: ’25″‘, ‘OAW’: ’28″‘, ‘length’: …

Strategic Sourcing Conclusion and Outlook for slider bed conveyor

In the competitive landscape of material handling, slider bed conveyors emerge as a versatile solution, addressing a wide range of applications from assembly lines to packing operations. Their adaptability in configuration, coupled with options for custom specifications, makes them a prime choice for businesses looking to optimize efficiency and reduce operational costs. Strategic sourcing of these conveyors not only ensures you acquire the best technology suited for your needs but also fosters relationships with reputable suppliers who can provide ongoing support and innovation.

As you consider the procurement of slider bed conveyors, emphasize the importance of understanding your operational requirements and the unique challenges of your industry. This approach will empower you to make informed decisions that enhance productivity while aligning with sustainability goals.

Looking ahead, the demand for efficient material handling solutions will continue to grow across regions, including Africa, South America, the Middle East, and Europe. Now is the time to engage with trusted suppliers and explore tailored conveyor systems that meet your specific operational needs. By investing in the right slider bed conveyors today, you position your business for success in an evolving market landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to slider bed conveyor