The Definitive Guide to Box Locks And Latches: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for box locks and latches

In today’s rapidly evolving global market, sourcing reliable box locks and latches presents a significant challenge for international B2B buyers. With the increasing demand for security solutions across various sectors—ranging from manufacturing to retail—understanding the nuances of different lock and latch types is crucial. This comprehensive guide aims to equip you with essential insights into the diverse applications, materials, and mechanisms of box locks and latches, ensuring that you can make informed purchasing decisions tailored to your specific business needs.

As you navigate through this guide, you will discover valuable information on the various types of locks and latches available, their appropriate applications, and critical factors to consider when vetting suppliers. Furthermore, we will delve into pricing structures, helping you assess the cost-effectiveness of your options without compromising on quality. Whether you are based in Africa, South America, the Middle East, or Europe—regions with distinct market dynamics—this guide empowers you to confidently select the best products that align with your operational requirements.

By understanding the intricacies of box locks and latches, you can enhance the security of your operations while also improving efficiency. Our goal is to provide you with the knowledge necessary to navigate this complex landscape, ensuring that your procurement strategy is both effective and economically sound.

Understanding box locks and latches Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cam Locks | Simple mechanism with a rotating cam | Cabinets, lockers, storage units | Pros: Cost-effective, easy to install. Cons: Limited security for high-value items. |

| Mortise Locks | Installed within the door, offering robust security | Commercial doors, high-security applications | Pros: High security, durable. Cons: More complex installation, higher cost. |

| Hasp Locks | Flexible metal loop with a padlock | Toolboxes, sheds, gates | Pros: Versatile, allows for various padlock types. Cons: Can be vulnerable to bolt cutters. |

| Slide Bolt Latches | Simple sliding mechanism for easy operation | Gates, cabinets, doors | Pros: Easy to use, cost-effective. Cons: Limited security, can be disengaged easily. |

| Hook Latches | Hook design that secures doors or lids | Storage boxes, furniture | Pros: Strong hold, quick access. Cons: May require additional locking mechanism for security. |

What are Cam Locks and Their B2B Relevance?

Cam locks are commonly used in various applications, particularly where ease of access and cost-effectiveness are essential. They feature a simple mechanism that rotates a cam to lock or unlock. Ideal for cabinets, lockers, and storage units, cam locks are an excellent choice for businesses needing affordable and straightforward locking solutions. However, they may not provide adequate security for high-value items, making it essential for buyers to assess the level of security required for their specific applications.

Why Choose Mortise Locks for High-Security Needs?

Mortise locks are embedded within the door, providing enhanced security compared to surface-mounted options. They are often used in commercial settings where durability and safety are paramount, such as in office buildings or retail environments. The installation process is more complex, often requiring professional assistance, and they come at a higher price point. Buyers looking for robust security solutions should consider mortise locks, particularly for doors that require frequent access.

How Do Hasp Locks Offer Versatility in Various Applications?

Hasp locks consist of a metal loop that secures a padlock, making them versatile for various applications, including toolboxes, sheds, and gates. Their flexibility allows businesses to choose padlocks that fit their security needs. While they are cost-effective and easy to install, buyers should be aware that hasp locks can be vulnerable to bolt cutters, which may not suit high-security environments. Assessing the security requirements of the application is crucial for B2B buyers.

What Benefits Do Slide Bolt Latches Provide for Everyday Use?

Slide bolt latches are characterized by their straightforward sliding mechanism, making them easy to operate. They are commonly used for gates, cabinets, and doors. Their simplicity and cost-effectiveness make them appealing for businesses requiring functional locking solutions without extensive security needs. However, buyers should note that slide bolt latches offer limited security and can be easily disengaged, which may necessitate supplementary locking mechanisms for sensitive applications.

Why Are Hook Latches a Popular Choice for Storage Solutions?

Hook latches feature a design that secures doors or lids with a hook mechanism, providing a strong hold while allowing for quick access. They are frequently used in storage boxes and furniture. While hook latches are robust and user-friendly, buyers should consider the potential need for additional locking mechanisms to enhance security, especially for items of higher value. Understanding the specific security requirements of the application will guide B2B buyers in making informed decisions.

Illustrative image related to box locks and latches

Key Industrial Applications of box locks and latches

| Industry/Sector | Specific Application of box locks and latches | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Securing cargo boxes on trucks and trailers | Enhanced security reduces theft and loss of valuable goods | Durability under harsh conditions, ease of installation |

| Construction & Manufacturing | Locking toolboxes and storage units | Protects tools and materials, ensuring operational efficiency | Compliance with safety standards, resistance to corrosion |

| Retail & E-commerce | Securing display cases and storage cabinets | Prevents theft, maintains product integrity | Aesthetic appeal, compatibility with existing fixtures |

| Electronics & Technology | Enclosures for sensitive equipment | Ensures equipment security while allowing access for maintenance | Customization options, tamper-proof designs |

| Furniture & Cabinetry | Locking mechanisms for cabinets and drawers | Enhances privacy and security for residential and commercial use | Variety in sizes and finishes, ease of integration |

How Are Box Locks and Latches Used in Transportation and Logistics?

In the transportation and logistics sector, box locks and latches are essential for securing cargo boxes on trucks and trailers. They provide a robust barrier against theft and unauthorized access, which is crucial for safeguarding high-value goods during transit. For international B2B buyers, particularly in regions with high theft rates, sourcing durable and tamper-resistant locking mechanisms can significantly reduce losses. Buyers must consider the environmental conditions in which these locks will be used, ensuring they can withstand exposure to weather and rough handling.

What Role Do Box Locks and Latches Play in Construction and Manufacturing?

Box locks and latches are commonly used to secure toolboxes and storage units on construction sites and manufacturing floors. They protect valuable tools and materials, thus enhancing operational efficiency by preventing loss and ensuring that equipment is readily available. For businesses in these sectors, it is vital to select locks that comply with safety standards and are resistant to corrosion, especially in outdoor or industrial environments. Buyers should also assess the ease of installation and maintenance of these locking systems to minimize downtime.

How Do Retail and E-commerce Benefit from Box Locks and Latches?

In retail and e-commerce, box locks and latches are employed to secure display cases and storage cabinets, protecting products from theft while maintaining their integrity. This is particularly important in high-footfall areas where merchandise is on constant display. For B2B buyers in this sector, sourcing aesthetically pleasing locks that align with the store’s design can enhance the customer experience. Additionally, compatibility with existing fixtures and ease of use for staff are key considerations in the procurement process.

Why Are Box Locks and Latches Critical in Electronics and Technology?

In the electronics and technology industry, box locks and latches are vital for securing enclosures that house sensitive equipment. These locks prevent unauthorized access while allowing for maintenance and servicing when needed. B2B buyers in this field should prioritize sourcing locks that offer customization options and tamper-proof designs to enhance security. Furthermore, ensuring that the locks are compatible with various enclosure materials and designs is essential for seamless integration.

How Are Box Locks and Latches Used in Furniture and Cabinetry?

Box locks and latches are integral to locking mechanisms for cabinets and drawers in both residential and commercial furniture. They enhance privacy and security, making them a popular choice for office environments and home settings alike. For international buyers, it is crucial to consider the variety in sizes, finishes, and styles available to match diverse design aesthetics. Additionally, ease of integration into existing furniture designs can significantly influence purchasing decisions, making it essential to source versatile locking solutions.

3 Common User Pain Points for ‘box locks and latches’ & Their Solutions

Scenario 1: Inconsistent Security Standards for Box Locks

The Problem: B2B buyers often face challenges ensuring that the box locks and latches they purchase meet industry security standards. In regions with varying regulations, such as Africa and the Middle East, a buyer may find that the locks they’ve sourced do not comply with local laws or industry best practices. This inconsistency can lead to security vulnerabilities, increased theft risk, and ultimately, financial loss. The frustration is compounded when buyers must navigate multiple suppliers to find compliant products, leading to delays in project timelines.

The Solution: To effectively address this issue, B2B buyers should establish clear security specifications before initiating the sourcing process. This involves researching the applicable regulations in their target markets, including any specific certifications required for box locks and latches. Collaborating with reputable suppliers who understand these standards is crucial. Buyers should request detailed product information, including compliance documentation and testing results. Additionally, consider engaging with local regulatory bodies or industry associations to stay informed about evolving standards. By prioritizing compliance in the procurement process, buyers can ensure that their security measures are robust and reliable.

Scenario 2: High Failure Rates in Heavy-Duty Applications

The Problem: Many B2B buyers in sectors like logistics or construction find that standard box locks and latches fail to withstand the rigors of heavy-duty applications. For example, a buyer sourcing locks for truck boxes may encounter frequent mechanical failures, leading to compromised security and costly replacements. This not only affects operational efficiency but also damages the buyer’s reputation, as clients depend on secure storage solutions.

The Solution: To mitigate this pain point, buyers should conduct a thorough assessment of their operational needs and select locks specifically designed for heavy-duty use. Look for products that offer enhanced durability, such as those made from high-grade materials like stainless steel or brass with corrosion resistance. Additionally, consider locks with features like reinforced mechanisms or weatherproofing for outdoor applications. Engaging in discussions with manufacturers about the specific conditions under which the locks will be used can yield valuable insights. Requesting samples for testing in real-world conditions before making bulk purchases can also help ensure that the selected locks will perform reliably over time.

Scenario 3: Difficulty in Installation and Maintenance of Locks

The Problem: B2B buyers often encounter issues with the installation and maintenance of box locks and latches, which can lead to inefficiencies and increased labor costs. For instance, a buyer may find that their team struggles with complex installation processes or that the locks require frequent adjustments or replacements due to poor design. This can disrupt workflows and lead to frustration among employees who rely on these security solutions.

The Solution: To alleviate installation and maintenance challenges, buyers should prioritize products that are designed with user-friendliness in mind. When sourcing locks, look for options that include comprehensive installation guides, clear diagrams, and customer support from the manufacturer. Additionally, consider investing in training for staff on proper installation techniques and routine maintenance practices. Implementing a regular maintenance schedule can help identify potential issues before they escalate, ensuring locks remain functional and secure. Moreover, selecting modular or adjustable locks can simplify future replacements or upgrades, making the overall management of security hardware more efficient. By focusing on ease of installation and long-term maintenance, buyers can reduce operational disruptions and enhance the effectiveness of their security measures.

Strategic Material Selection Guide for box locks and latches

What Are the Key Properties of Common Materials Used in Box Locks and Latches?

When selecting materials for box locks and latches, several factors come into play, including performance properties, manufacturing complexity, and regional compliance standards. The following analysis explores four common materials used in the production of box locks and latches: steel, stainless steel, aluminum, and plastic.

How Does Steel Perform in Box Locks and Latches?

Steel is a widely used material for box locks and latches due to its strength and durability. It typically has a high tensile strength, making it suitable for high-pressure applications. However, it is prone to corrosion if not properly treated or coated.

Pros: Steel offers excellent durability and can withstand significant wear and tear. It is also relatively inexpensive, making it a cost-effective choice for many applications.

Illustrative image related to box locks and latches

Cons: The primary drawback is its susceptibility to rust and corrosion, especially in humid or coastal environments. Additionally, steel components can be heavier than alternatives, which may not be suitable for all applications.

Impact on Application: Steel locks are ideal for heavy-duty applications but may not be suitable for environments with high moisture unless adequately coated.

Considerations for International Buyers: Buyers in regions like the Middle East and Africa should ensure that the steel used complies with local corrosion resistance standards, such as ASTM A123 for zinc coatings.

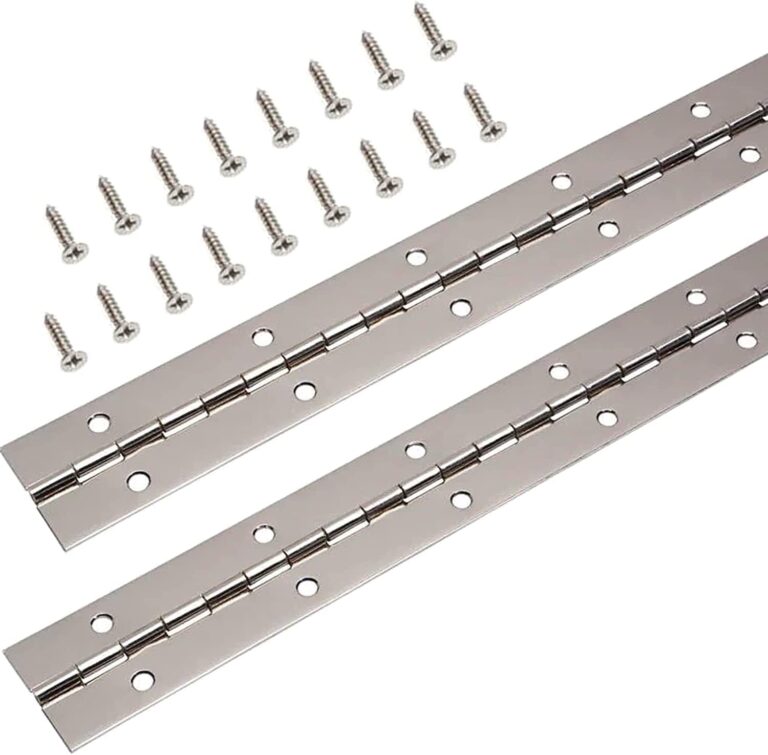

What Advantages Does Stainless Steel Offer for Box Locks and Latches?

Stainless steel is known for its excellent corrosion resistance and aesthetic appeal, making it a popular choice for box locks and latches exposed to the elements. It is particularly advantageous in coastal regions where saltwater can accelerate corrosion.

Pros: The primary advantage of stainless steel is its ability to resist rust, making it suitable for outdoor applications. It also provides a sleek appearance, which can be a selling point for consumer-facing products.

Cons: Stainless steel is generally more expensive than regular steel and can be more complex to manufacture due to its hardness.

Impact on Application: This material is ideal for applications requiring longevity and aesthetic appeal, such as in marine or outdoor environments.

Considerations for International Buyers: Buyers must ensure that the stainless steel grade used (e.g., 304 or 316) meets the specific environmental conditions of their region, complying with standards like JIS G4303.

Why Choose Aluminum for Box Locks and Latches?

Aluminum is lightweight and resistant to corrosion, making it an excellent choice for applications where weight is a concern. It also has good thermal and electrical conductivity.

Pros: The primary advantage of aluminum is its lightweight nature, which can reduce shipping costs and ease installation. It is also resistant to corrosion, making it suitable for various environments.

Cons: Aluminum is generally less durable than steel and may not withstand high-impact applications as effectively.

Impact on Application: Aluminum locks are well-suited for lightweight applications, such as portable boxes or equipment that requires frequent transport.

Considerations for International Buyers: Buyers should verify that aluminum components meet local standards for strength and corrosion resistance, such as ASTM B221.

What Role Does Plastic Play in Box Locks and Latches?

Plastic is often used in applications where weight reduction and cost savings are critical. It is available in various forms, including high-density polyethylene (HDPE) and polycarbonate.

Pros: Plastic is lightweight, resistant to corrosion, and can be manufactured at a lower cost compared to metals. It also allows for versatile design options.

Cons: The main limitation is its lower durability compared to metal options, which may not be suitable for high-security applications.

Impact on Application: Plastic locks are ideal for lightweight, low-security applications, such as toolboxes or storage containers.

Considerations for International Buyers: Buyers should ensure that the plastic used meets fire safety and durability standards relevant to their market, such as ISO 9001.

Summary Table of Material Selection for Box Locks and Latches

| Material | Typical Use Case for box locks and latches | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications | High durability | Prone to corrosion | Low |

| Stainless Steel | Outdoor and marine applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Lightweight and portable applications | Lightweight and corrosion-resistant | Less durable than steel | Medium |

| Plastic | Low-security applications | Cost-effective and versatile | Lower durability | Low |

This guide provides a comprehensive overview of material selection for box locks and latches, allowing international B2B buyers to make informed decisions based on their specific application needs and regional standards.

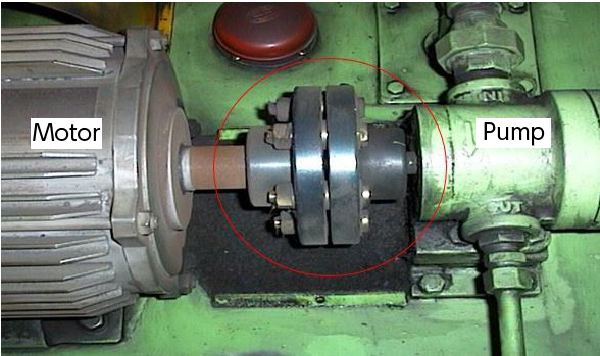

In-depth Look: Manufacturing Processes and Quality Assurance for box locks and latches

What Are the Key Stages in the Manufacturing Process of Box Locks and Latches?

The manufacturing process for box locks and latches involves several critical stages that ensure the final product meets the required specifications and quality standards. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of appropriate materials, typically metals such as stainless steel, brass, or zinc alloys, chosen for their durability and resistance to corrosion. The raw materials undergo cutting and shaping into initial components, which may involve processes like laser cutting, stamping, or machining.

-

Forming Techniques: Once the materials are prepared, they are formed into the desired shapes. Techniques such as die casting, extrusion, or forging are commonly used. These methods allow manufacturers to create intricate designs and ensure precise dimensions, which are crucial for the functionality of locks and latches.

-

Assembly Process: After forming, the components are assembled. This stage may involve welding, riveting, or using screws and fasteners. Automated assembly lines are increasingly used to enhance efficiency and reduce labor costs. Each component must fit perfectly to ensure the locking mechanism operates smoothly.

-

Finishing Touches: The final stage involves surface treatment and finishing. This can include processes like electroplating, powder coating, or anodizing, which improve aesthetic appeal and provide additional protection against wear and environmental factors. Quality finishing is essential for enhancing the longevity of locks and latches, especially in harsh climates.

How Is Quality Assurance Implemented in Box Lock and Latch Manufacturing?

Quality assurance (QA) is vital in the manufacturing of box locks and latches to ensure that products meet safety and performance standards. Various international and industry-specific standards guide these processes.

-

International Standards: Many manufacturers comply with ISO 9001, which outlines requirements for a quality management system. This standard emphasizes a process-based approach and continual improvement, ensuring that the products consistently meet customer and regulatory requirements.

-

Industry-Specific Certifications: In addition to ISO standards, manufacturers may seek certifications such as CE marking for products sold in Europe, indicating conformity with health, safety, and environmental protection standards. For specialized applications, such as in the oil and gas industry, certifications from organizations like the American Petroleum Institute (API) may be relevant.

-

Quality Control Checkpoints: Effective quality control (QC) involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Inspecting raw materials before production starts to ensure they meet specifications.

– In-Process Quality Control (IPQC): Monitoring the manufacturing process to catch defects early. This can include regular inspections and testing of components as they are produced.

– Final Quality Control (FQC): Conducting thorough inspections and tests on the finished product before shipment. This may include functionality tests, dimensional checks, and stress testing.

What Testing Methods Are Commonly Used in Quality Assurance for Box Locks and Latches?

To maintain high standards of quality, various testing methods are employed throughout the manufacturing process. These methods ensure that the locks and latches perform reliably under different conditions.

-

Mechanical Testing: This includes tensile strength tests, shear tests, and fatigue tests to evaluate the durability of the materials used. These tests simulate real-world conditions to ensure that the locks can withstand repeated use without failure.

-

Functional Testing: Each lock and latch is tested for functionality. This involves testing the locking mechanism to ensure it engages and disengages smoothly and securely. Manufacturers may also conduct tests to assess resistance to tampering and unauthorized access.

-

Environmental Testing: Products are subjected to environmental tests to simulate conditions such as extreme temperatures, humidity, and exposure to corrosive elements. This helps verify that the finishes and materials will endure the conditions they will face in real-world applications.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is crucial. Here are some practical steps to ensure that suppliers meet stringent quality standards:

-

Supplier Audits: Conducting on-site audits can provide insight into the manufacturing processes and quality control systems in place. This allows buyers to assess the factory’s capabilities, equipment, and adherence to quality standards.

-

Requesting Quality Reports: Buyers should ask for detailed quality reports that outline the results of testing and inspections conducted throughout the manufacturing process. This documentation can help verify that products meet the required specifications.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality control processes and product quality. These inspections can be scheduled at various stages of production, providing an added layer of assurance.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must be aware of specific nuances related to quality control when sourcing box locks and latches from suppliers in different regions. Understanding these nuances can enhance procurement strategies and mitigate risks.

Illustrative image related to box locks and latches

-

Cultural and Regulatory Differences: Quality standards and expectations can vary significantly across regions. Buyers should familiarize themselves with local regulations and standards to ensure compliance.

-

Supply Chain Transparency: Ensuring transparency in the supply chain is crucial. Buyers should establish clear communication with suppliers regarding quality control measures and any certifications they hold. This transparency helps build trust and ensures accountability.

-

Logistics and Shipping Considerations: Quality control does not end with manufacturing. Buyers should consider how products will be stored and transported. Proper handling during shipping is essential to prevent damage, which can compromise the integrity of locks and latches.

Conclusion

Understanding the manufacturing processes and quality assurance measures in the production of box locks and latches is vital for B2B buyers seeking reliable suppliers. By focusing on material preparation, forming techniques, and stringent quality control practices, businesses can ensure they are sourcing high-quality products that meet international standards. With the right verification processes in place, buyers can confidently navigate the complexities of global procurement, ensuring that their security needs are met with excellence.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘box locks and latches’

Introduction

In the evolving landscape of security hardware, sourcing box locks and latches requires careful consideration to ensure that products meet both technical specifications and market demands. This guide serves as a practical checklist for B2B buyers, helping you navigate the procurement process effectively. From defining your needs to evaluating suppliers, each step is designed to optimize your sourcing strategy.

Step 1: Define Your Technical Specifications

Before you begin sourcing, clearly outline the technical specifications required for your box locks and latches. Consider factors such as material, size, locking mechanism, and compatibility with your existing systems.

– Material: Choose durable materials like stainless steel or brass for longevity and security.

– Size and Fit: Ensure the locks and latches are compatible with the dimensions of your boxes.

Illustrative image related to box locks and latches

Step 2: Research Market Trends and Regulations

Understanding current market trends and regulatory requirements is crucial for compliance and competitiveness. Investigate the latest innovations in locking technology and any industry-specific standards.

– Certifications: Look for products that comply with international standards, such as ANSI or ISO certifications, which assure quality and security.

– Market Demand: Analyze regional preferences for lock types, as these can vary significantly between markets like Africa and Europe.

Step 3: Identify and Shortlist Suppliers

Create a list of potential suppliers based on your research. Look for manufacturers and distributors with a strong reputation in the industry.

– Experience: Prioritize suppliers with a proven track record in producing box locks and latches.

– Geographical Reach: Consider suppliers who can efficiently ship to your region, ensuring timely delivery.

Step 4: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request detailed company profiles, case studies, and references from previous clients in similar industries.

– Quality Assurance: Inquire about their quality control processes to ensure that products meet your specifications.

– Customer Support: Assess the level of customer service provided, as effective communication can ease the procurement process.

Step 5: Request Samples for Testing

Always request samples before placing a bulk order. Testing samples allows you to evaluate the quality and functionality of the locks and latches.

– Performance Testing: Check how well the locks operate under various conditions to ensure reliability.

– Durability Assessment: Examine the materials for wear resistance and overall strength.

Step 6: Negotiate Terms and Pricing

Once you have selected a supplier, engage in negotiations to finalize pricing and terms. Ensure that you understand all aspects of the deal, including payment terms, lead times, and return policies.

– Bulk Discounts: Inquire about pricing flexibility for larger orders, which can lead to significant savings.

– Warranty and Support: Clarify warranty terms and after-sales support to safeguard your investment.

Step 7: Finalize the Order and Monitor Delivery

After agreeing on terms, place your order and monitor the delivery process closely. Establish a communication line with the supplier for updates on shipping and potential delays.

– Tracking: Use tracking systems to stay informed about shipment progress.

– Quality Checks: Plan for an inspection upon arrival to confirm that products meet your specifications.

By following these steps, B2B buyers can streamline the procurement process for box locks and latches, ensuring that they source high-quality products that meet their operational needs and regional market demands.

Comprehensive Cost and Pricing Analysis for box locks and latches Sourcing

What Are the Key Cost Components in Box Locks and Latches Sourcing?

When sourcing box locks and latches, understanding the comprehensive cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials such as steel, brass, and zinc alloy vary in price based on market conditions. Additionally, the use of corrosion-resistant finishes or specialty coatings can further increase material costs.

-

Labor: Labor costs encompass the expenses related to manufacturing, assembly, and quality control. Regions with lower labor costs can offer competitive pricing, but this may come at the expense of quality.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and administrative costs associated with the production process. Efficient manufacturing processes can help reduce overhead, translating to lower prices for buyers.

-

Tooling: Initial setup costs for molds and fixtures can be substantial, particularly for custom designs. These costs are amortized over production volume, which means higher minimum order quantities (MOQs) can lead to lower per-unit costs.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to the overall cost. Certifications such as ISO or specific industry standards can also influence pricing.

-

Logistics: Shipping and handling costs vary based on the distance, mode of transport, and freight terms. International buyers should consider these logistics costs, especially when sourcing from regions like Asia or Europe.

-

Margin: Supplier profit margins are influenced by competition and market demand. Understanding the market landscape can help buyers negotiate better pricing.

How Do Price Influencers Affect Box Locks and Latches Pricing?

Several factors play a crucial role in determining the pricing of box locks and latches:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk purchases. Buyers should assess their needs carefully to optimize order sizes that maximize cost savings.

-

Specifications and Customization: Custom designs or specific functional requirements can increase costs. Clear communication of specifications upfront can help avoid unexpected expenses.

-

Material Choices: Higher quality materials or unique finishes may lead to increased pricing. Buyers should balance cost with quality to ensure durability and performance.

-

Quality and Certifications: Products that meet specific quality standards or certifications tend to command higher prices. Buyers in regulated markets may need to prioritize these factors.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their assurance of quality and service.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can significantly affect total landed costs. Understanding these terms helps buyers anticipate additional costs associated with shipping, insurance, and customs clearance.

What Are the Best Buyer Tips for Cost-Efficiency in Box Locks and Latches?

To maximize cost-efficiency when sourcing box locks and latches, buyers should consider the following tips:

-

Negotiate Effectively: Leverage volume purchases and long-term relationships to negotiate better prices. Building rapport with suppliers can lead to favorable terms.

-

Assess Total Cost of Ownership (TCO): Look beyond initial purchase prices. Consider maintenance, replacement, and operational costs associated with the product over its lifecycle.

-

Understand Pricing Nuances for International Transactions: For buyers in regions like Africa, South America, the Middle East, and Europe, it’s vital to understand local market conditions and currency fluctuations that may impact pricing.

-

Request Samples: Before committing to large orders, request samples to evaluate quality and performance. This helps in making informed decisions and avoiding costly mistakes.

-

Stay Informed: Keep abreast of market trends, material costs, and technological advancements that may affect pricing. Being knowledgeable can empower buyers during negotiations.

Conclusion

Sourcing box locks and latches involves a complex interplay of various cost components and pricing influencers. By understanding these elements and applying strategic purchasing practices, international B2B buyers can optimize their sourcing decisions and achieve better value. While prices can vary widely based on numerous factors, diligent research and negotiation can lead to significant savings. Always remember to check with suppliers for indicative prices, as market conditions can fluctuate.

Illustrative image related to box locks and latches

Alternatives Analysis: Comparing box locks and latches With Other Solutions

Understanding the Alternatives to Box Locks and Latches

In the realm of securing boxes and enclosures, box locks and latches are traditional solutions that have stood the test of time. However, as technology advances and security needs evolve, several alternative solutions have emerged. These alternatives not only vary in their mechanisms but also in their effectiveness, cost, and implementation requirements. This analysis will compare box locks and latches with two viable alternatives: electronic locks and padlocks.

Comparison Table

| Comparison Aspect | Box Locks And Latches | Electronic Locks | Padlocks |

|---|---|---|---|

| Performance | Reliable for light to moderate security | High security; often customizable | Good for portable use; varies in security |

| Cost | Moderate initial investment | Higher initial cost; potential ongoing fees | Low to moderate cost |

| Ease of Implementation | Straightforward installation | Requires wiring or setup; may need professionals | Simple installation; no tools required |

| Maintenance | Low; occasional lubrication needed | Moderate; battery changes and software updates | Low; minimal upkeep needed |

| Best Use Case | Storage units, toolboxes | High-security environments, smart homes | Temporary or portable security |

Exploring Electronic Locks as an Alternative

Electronic locks represent a modern alternative to traditional box locks and latches, offering enhanced security features like keyless entry and remote access. These locks often integrate with smart home systems, allowing users to control access via smartphones or keypads. However, they come with a higher initial investment and may require professional installation, especially in retrofitting scenarios. Maintenance can also be a concern, as electronic locks depend on battery life and software updates, which can lead to downtime if not managed properly.

Evaluating Padlocks as a Portable Solution

Padlocks are another alternative to box locks and latches, especially for situations requiring portability and ease of use. They are available in various sizes and security levels, making them suitable for a wide range of applications, from securing gates to locking luggage. The primary advantages of padlocks include their low cost and straightforward implementation—users can secure items quickly without specialized tools. However, padlocks may not provide the same level of security as box locks for permanent installations, particularly against determined intruders.

Conclusion: Choosing the Right Security Solution

When selecting the appropriate security solution for your needs, consider factors such as the intended application, budget constraints, and the level of security required. Box locks and latches are ideal for fixed installations where reliability is paramount, while electronic locks offer advanced features for high-security environments. In contrast, padlocks serve well in temporary or portable scenarios. By assessing these aspects, B2B buyers can make informed decisions that align with their operational requirements and security objectives.

Essential Technical Properties and Trade Terminology for box locks and latches

What Are the Key Technical Properties of Box Locks and Latches?

When sourcing box locks and latches, understanding their essential technical properties is crucial for ensuring product reliability and security. Here are several critical specifications that buyers should consider:

1. Material Grade

The material used in box locks and latches significantly impacts their durability and resistance to corrosion. Common materials include stainless steel, brass, and zinc alloys. Stainless steel offers high corrosion resistance, making it ideal for outdoor applications, while brass provides aesthetic appeal and moderate corrosion resistance. Buyers should assess the material grade to ensure it meets the specific environmental conditions and intended use of the product.

2. Locking Mechanism

The locking mechanism defines how secure the latch or lock is. Common types include deadbolts, cam locks, and padlocks. Deadbolts provide higher security as they require a key or combination to unlock, while cam locks are easier to operate but offer less security. Understanding the locking mechanism helps buyers select the right level of security for their applications.

3. Tolerance Levels

Tolerance refers to the allowable variation in dimensions during manufacturing. For box locks and latches, tight tolerances ensure proper fit and function. A tolerance of ±0.01 inches, for example, is typical in precision-engineered components. Ensuring that manufacturers adhere to specific tolerance levels can prevent installation issues and enhance product performance.

4. Finish and Coating

The finish or coating applied to box locks and latches affects their appearance and resistance to wear and corrosion. Options include powder coating, anodizing, and plating. A powder-coated finish can enhance durability and aesthetic appeal, while anodizing improves corrosion resistance. Buyers should select finishes that align with both functional and aesthetic requirements.

5. Load Rating

Load rating indicates the maximum weight or force a latch or lock can withstand before failure. This property is particularly important for applications involving heavy boxes or containers. Buyers should ensure that the load rating meets or exceeds the demands of their specific use case to prevent premature failure.

What Are Common Trade Terms in the Box Lock and Latch Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of box locks and latches, buyers often deal directly with OEMs to procure custom solutions that fit their specific needs, ensuring quality and compatibility.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it affects inventory management and cost. Suppliers may set MOQs based on production costs and material availability, influencing purchasing decisions.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. When dealing with box locks and latches, issuing an RFQ can help buyers compare offers and select the best supplier based on price, lead time, and quality.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms helps buyers clarify shipping, insurance, and delivery responsibilities, reducing the risk of misunderstandings in cross-border transactions.

5. Lead Time

Lead time is the period between placing an order and receiving the goods. In the box lock and latch industry, lead times can vary based on manufacturing processes and supply chain logistics. Buyers should factor in lead times when planning inventory to avoid disruptions.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing box locks and latches, ensuring they meet their operational needs while maximizing efficiency and security.

Navigating Market Dynamics and Sourcing Trends in the box locks and latches Sector

What Are the Key Market Trends Influencing the Box Locks and Latches Sector?

The box locks and latches market is experiencing significant transformation driven by globalization, technological advancements, and evolving consumer preferences. Key drivers include the increasing demand for security solutions in various sectors such as logistics, automotive, and residential applications. As international trade expands, especially in regions like Africa, South America, and the Middle East, the need for reliable and innovative locking mechanisms is paramount. Emerging technologies, such as smart locks and integrated security systems, are reshaping the landscape, offering advanced features such as remote access and enhanced security.

Illustrative image related to box locks and latches

Moreover, B2B buyers are increasingly prioritizing customization and flexibility in sourcing, looking for suppliers that can accommodate specific needs and provide quick turnaround times. The rise of e-commerce has also influenced sourcing trends, with businesses gravitating towards suppliers that offer seamless online ordering and supply chain transparency. This shift is particularly evident in regions such as Saudi Arabia and Vietnam, where digital transformation is rapidly changing traditional procurement processes.

How Is Sustainability Shaping the Sourcing of Box Locks and Latches?

Sustainability has become a crucial consideration in the sourcing of box locks and latches. As environmental concerns grow, B2B buyers are seeking suppliers that prioritize eco-friendly practices and materials. The use of recycled metals and sustainable manufacturing processes is gaining traction, aligning with the global push for reduced carbon footprints.

Ethical sourcing plays a vital role in this context, as businesses increasingly demand transparency within their supply chains. Suppliers who can demonstrate compliance with environmental regulations and sustainability certifications are more likely to gain trust and secure partnerships. Certifications such as ISO 14001 for environmental management systems or the use of green materials can provide a competitive edge in the market. For buyers in regions like Europe, where regulations around sustainability are stringent, sourcing from compliant suppliers is not just preferred but often mandatory.

What Is the Historical Context of Box Locks and Latches in B2B Markets?

The evolution of box locks and latches dates back centuries, with their origins rooted in ancient civilizations that prioritized security for valuable possessions. Over time, the design and functionality of locking mechanisms have evolved significantly. The introduction of standardized manufacturing processes in the 19th century allowed for mass production, making locks more accessible to the general public.

In the modern context, the box locks and latches sector has witnessed a shift from purely mechanical designs to sophisticated electronic systems. This evolution reflects the broader trends in technology and security, emphasizing the importance of reliable locking mechanisms across various applications. As markets continue to globalize, the historical context of these products informs current practices, highlighting the ongoing need for innovation while ensuring the fundamental purpose of security remains paramount.

In conclusion, understanding the market dynamics, sustainability imperatives, and historical context surrounding box locks and latches provides B2B buyers with the insights necessary to make informed sourcing decisions in an increasingly competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of box locks and latches

-

How do I select the right box lock or latch for my application?

Choosing the appropriate box lock or latch requires understanding the specific requirements of your application. Consider factors such as the material of the box, the level of security needed, environmental conditions (e.g., moisture, temperature), and the frequency of use. For example, heavy-duty steel locks are ideal for high-security needs, while lighter materials may suffice for low-security applications. Additionally, assess the ease of installation and whether the latch mechanism aligns with your operational workflow. -

What are the best practices for sourcing box locks and latches internationally?

When sourcing box locks and latches internationally, conduct thorough market research to identify reputable suppliers. Utilize platforms such as Alibaba, Global Sources, and industry-specific trade shows. Verify supplier credentials through references and customer reviews, and ensure they comply with international quality standards. It’s also wise to request samples to assess product quality and functionality before committing to larger orders. -

What customization options are available for box locks and latches?

Many manufacturers offer customization options for box locks and latches to meet specific business needs. Customization may include variations in size, material, color, and branding. Some suppliers can also tailor the locking mechanism to enhance security features or fit unique box designs. Discuss your requirements with potential suppliers to explore available options and ensure the product meets your specifications. -

What is the minimum order quantity (MOQ) for box locks and latches?

Minimum order quantities (MOQ) for box locks and latches vary by supplier and product type. Typically, MOQs can range from as low as 50 units to several thousand, depending on the manufacturer and customization options. When negotiating with suppliers, consider your budget and inventory needs, and inquire about the flexibility of MOQs, especially if you are testing new products or entering a new market. -

What payment terms should I expect when purchasing box locks and latches?

Payment terms can vary significantly among suppliers. Common options include upfront payment, 30% deposit with the balance due upon shipment, or net terms after delivery. It’s crucial to discuss payment methods accepted (e.g., bank transfer, credit card, or PayPal) and any applicable transaction fees. Establishing clear payment terms in the contract can prevent misunderstandings and ensure smoother transactions. -

How can I ensure the quality of box locks and latches I purchase?

To ensure product quality, request detailed specifications and certifications from suppliers. Look for quality assurance processes they have in place, such as ISO certification or compliance with relevant industry standards. Conducting third-party inspections or requesting samples for testing can also help verify the product’s durability and functionality before placing larger orders. Establishing a reliable quality control system is essential for maintaining product standards. -

What logistics considerations should I keep in mind when importing box locks and latches?

When importing box locks and latches, consider shipping methods, lead times, and customs regulations. Air freight is faster but more expensive, while sea freight is cost-effective for bulk orders. Understand the tariffs and duties applicable to your products in your destination country, and ensure all documentation is complete to avoid delays. Partnering with a freight forwarder can streamline the logistics process and ensure compliance with international shipping regulations. -

What are common challenges faced when sourcing box locks and latches internationally?

Common challenges include language barriers, cultural differences, and varying quality standards. Additionally, navigating international trade regulations and customs can be complex. To mitigate these issues, establish clear communication with suppliers and consider hiring local experts or consultants who understand the market. Building strong relationships with suppliers can also help address challenges more effectively and create a smoother sourcing experience.

Top 4 Box Locks And Latches Manufacturers & Suppliers List

1. nVent Hoffman – Keylock Handle

Domain: graybar.com

Registered: 1995 (30 years)

Introduction: Keylock Handle, SKU: 94027161, Manufacturer: nVent Hoffman, Replacement Keys for SOHO Net Series PC Cabinet, SKU: 25084929, Manufacturer: nVent Hoffman, T-Handle Lock Steel, SKU: 93173723, Manufacturer: B-Line (Eaton).

2. McMaster – Electrical Box Locks

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Electrical Box Locks, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Spring Creek Products – Lockable Spring Loaded Latch

Domain: springcreekproducts.com

Registered: 2008 (17 years)

Introduction: This company, Spring Creek Products – Lockable Spring Loaded Latch, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Tool Box Lock Latch – Essential Storage Solution

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Tool Box Lock Latch

– Categories: Tool Boxes, Door Hardware, Cabinet Hardware, Home Storage Boxes, Tool Storage

– Sizes: 24in, 25in, 30in, 34in, 38in, 58in, 66in, 69in

– Materials: Stainless Steel, Aluminum, Steel, Plastic

– Types: Trailer Tongue Tool Box, Underbody Tool Box, Side Mount Tool Box, Flush Mount Tool Box, 5th Wheel Tool Box, Top Mount Tool Box

– Colors: Silver, Black, Gray, Multi-Colo…

Strategic Sourcing Conclusion and Outlook for box locks and latches

In the evolving landscape of box locks and latches, strategic sourcing emerges as a pivotal factor for international B2B buyers. By prioritizing quality and security, businesses can enhance their operational efficiency and safeguard their assets. As explored throughout this guide, the diverse range of products—from truck box latches to cabinet locks—demonstrates the necessity of selecting reliable suppliers who can meet specific regional demands, particularly in Africa, South America, the Middle East, and Europe.

For buyers in these markets, understanding the regional preferences and compliance requirements is crucial. Engaging with manufacturers and distributors who offer customizable solutions can significantly enhance your product offerings and customer satisfaction. It’s essential to leverage technology and data analytics to streamline procurement processes and ensure timely delivery.

Looking ahead, the demand for innovative and secure locking mechanisms is set to grow. As businesses expand globally, investing in strategic sourcing will not only mitigate risks but also foster long-term partnerships. Take the initiative now—assess your current suppliers, explore new opportunities, and adapt to the changing market dynamics to stay ahead in the competitive landscape of box locks and latches.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.