How to Source Rig Laet Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for rig laet

In today’s complex global market, sourcing reliable and efficient rig laet solutions presents a significant challenge for B2B buyers, especially those operating in high-stakes industries across Africa, South America, the Middle East, and Europe. The need for durable, energy-efficient lighting designed for hazardous environments is critical to ensuring safety and operational efficiency. This guide is tailored to help you navigate the multifaceted landscape of rig laet, offering insights into various types of lighting solutions, their applications, and how to effectively vet suppliers.

We will explore essential factors such as compliance with international safety standards, retrofitting capabilities, and cost considerations, enabling you to make informed decisions that align with your operational needs and budget constraints. Additionally, this comprehensive resource will highlight the importance of selecting products that not only enhance workplace safety but also contribute to sustainability goals by reducing energy consumption and maintenance costs.

By empowering international B2B buyers with actionable knowledge, this guide serves as a vital tool for optimizing your procurement process. Whether you’re from Vietnam, Brazil, or elsewhere, you’ll find the insights necessary to identify high-quality rig laet solutions that meet the rigorous demands of your industry while promoting long-term efficiency and safety.

Understanding rig laet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Class 1 Division 1 Lighting | Explosion-proof, designed for areas with constant flammable gases. | Oil & gas drilling, chemical processing. | Pros: High safety standards, reliable performance. Cons: Higher initial costs. |

| Class 1 Division 2 Lighting | Provides safety where flammable gases are unlikely but possible. | Refining, petrochemical plants. | Pros: Cost-effective, versatile. Cons: Less protection than Division 1. |

| Class 2 Division 1 Lighting | Prevents ignition of combustible dust in hazardous conditions. | Food processing, pharmaceutical manufacturing. | Pros: Enhanced safety in dusty environments. Cons: Limited to dust hazards. |

| EX-Series Lighting | Globally certified for hazardous environments with versatile designs. | Offshore rigs, wastewater treatment. | Pros: International compliance, durable. Cons: May require specialized installation. |

| High Bay Lighting | Designed for high ceilings, offers broad illumination. | Warehouses, manufacturing plants. | Pros: Efficient for large spaces, energy-saving. Cons: Not suitable for low-clearance areas. |

What Are the Key Characteristics of Class 1 Division 1 Lighting?

Class 1 Division 1 lighting is engineered for environments where flammable gases are consistently present, such as oil and gas drilling sites and chemical processing plants. Its explosion-proof design ensures that ignition sources are contained, promoting safety in high-risk areas. For B2B buyers, investing in this type of lighting often involves a higher upfront cost, but the long-term safety benefits and compliance with stringent regulations can justify the expense.

How Does Class 1 Division 2 Lighting Differ from Division 1?

Class 1 Division 2 lighting is suitable for areas where flammable gases are only occasionally present. It is ideal for applications in refining and petrochemical plants where safety is still a concern, but the risk of ignition is lower. This type of lighting is generally more cost-effective than Division 1, making it appealing for businesses looking to maintain safety without incurring excessive costs. Buyers should consider the balance between safety needs and budget constraints when selecting this option.

Why Choose Class 2 Division 1 Lighting for Dusty Environments?

Class 2 Division 1 lighting is specifically designed to prevent ignition in environments with combustible dust, such as food processing and pharmaceutical manufacturing. The robust construction of these fixtures ensures they can withstand the harsh conditions typical of these industries. For B2B buyers, the main advantage lies in enhanced safety, while the limitation is that it is only effective against dust hazards, which may require additional safety measures for other risks.

What Advantages Do EX-Series Lighting Solutions Offer?

EX-Series lighting provides globally certified protection for hazardous environments, making it a versatile choice for offshore rigs and wastewater treatment facilities. Its designs accommodate various installation needs while ensuring compliance with international safety standards. B2B buyers benefit from its durability and reliability; however, the installation may necessitate expertise, which could add to overall project costs.

When Is High Bay Lighting the Best Option?

High Bay lighting is ideal for large indoor spaces with high ceilings, such as warehouses and manufacturing plants. These fixtures provide broad illumination, enhancing visibility and safety in expansive areas. The energy efficiency of high bay lighting is a significant advantage for B2B buyers looking to reduce operational costs. However, they are not suitable for low-clearance areas, which could limit their application in some facilities.

Key Industrial Applications of rig laet

| Industry/Sector | Specific Application of rig laet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Offshore drilling platforms | Enhanced safety and operational efficiency in hazardous environments | Compliance with international safety standards and certifications |

| Petrochemical | Chemical processing plants | Reliable illumination that minimizes downtime and maintenance costs | Durability under extreme conditions and chemical exposure |

| Food Processing | NSF-rated lighting for food production facilities | Ensures compliance with health regulations and enhances worker safety | Certification standards and ease of cleaning |

| Water Treatment | Lighting for wastewater treatment facilities | Promotes safety and operational efficiency in challenging environments | Resistance to corrosion and water exposure |

| Marine | Corrosion-resistant lighting for ships and docks | Increased safety and visibility in harsh maritime environments | Compliance with maritime safety regulations and certifications |

How is rig laet Used in the Oil and Gas Industry?

In the oil and gas sector, rig laet lighting solutions are critical for offshore drilling platforms where safety is paramount. These environments often contain flammable gases and vapors, necessitating explosion-proof lighting to prevent ignition. RIG-A-LITE’s products meet stringent international safety standards, ensuring reliable performance even in the harshest conditions. International buyers from regions like Africa and the Middle East must prioritize compliance with local regulations and certifications when sourcing these lighting solutions to mitigate risks associated with hazardous locations.

What Role Does rig laet Play in Petrochemical Applications?

Petrochemical processing plants require robust lighting solutions to ensure safety and efficiency during operations. RIG-A-LITE’s hazardous location lighting is designed to withstand exposure to corrosive chemicals and extreme temperatures, reducing maintenance needs and operational downtime. For B2B buyers, the focus should be on sourcing lighting that not only meets durability requirements but also aligns with energy efficiency goals, as this can lead to significant cost savings over time.

Why is rig laet Essential for Food Processing Facilities?

In food processing, compliance with health and safety regulations is non-negotiable. RIG-A-LITE’s NSF-rated lighting solutions ensure that facilities maintain high hygiene standards while providing adequate illumination for workers. The benefits extend beyond compliance, as effective lighting can improve worker productivity and safety. Buyers in this sector must consider the ease of cleaning and maintenance of the lighting fixtures to ensure ongoing compliance and operational efficiency.

How Does rig laet Improve Water Treatment Operations?

Lighting in wastewater treatment facilities must be reliable and resilient to harsh environmental conditions. RIG-A-LITE provides specialized lighting solutions that enhance visibility and safety in these challenging settings. International buyers need to ensure that the products sourced are resistant to corrosion and water exposure, as this will prolong the lifespan of the lighting and minimize maintenance costs. Adopting these advanced lighting solutions can lead to improved operational efficiency and safety.

What Benefits Does rig laet Offer to Marine Applications?

Marine environments pose unique challenges due to exposure to saltwater and extreme weather conditions. RIG-A-LITE’s corrosion-resistant lighting is specifically designed for ships and docks, enhancing safety and visibility. For B2B buyers in the maritime industry, it is essential to source lighting solutions that comply with maritime safety regulations, ensuring both worker safety and operational reliability. The right lighting can significantly reduce accidents and improve navigation in these demanding environments.

3 Common User Pain Points for ‘rig laet’ & Their Solutions

Scenario 1: Safety Concerns in Hazardous Locations

The Problem: B2B buyers in industries such as oil and gas or chemical processing often face significant safety challenges when operating in hazardous environments. The risk of explosions due to flammable gases or dust is a constant concern, making the selection of appropriate lighting solutions critical. A misstep in choosing non-compliant or inadequate lighting can not only endanger workers’ safety but also lead to costly operational disruptions and legal liabilities.

The Solution: To address these safety concerns, buyers should prioritize sourcing explosion-proof lighting solutions specifically designed for hazardous locations. RIG-A-LITE offers a range of lighting products that meet rigorous safety standards, such as Class 1 Division 1 and Division 2 ratings. When specifying lighting solutions, ensure they are certified for the specific hazardous conditions present in your facility. Conduct a thorough site assessment to identify the classifications required, and select RIG-A-LITE products that comply with these standards. Additionally, consider investing in lighting with field-replaceable components to extend the lifespan and maintain compliance without frequent full unit replacements, thus ensuring ongoing safety and operational efficiency.

Scenario 2: High Maintenance Costs and Downtime

The Problem: Many companies operating in demanding environments experience high maintenance costs associated with traditional lighting solutions. Frequent bulb replacements, the need for specialized maintenance personnel, and the risk of unexpected downtime can significantly impact productivity and profit margins. This is particularly problematic in sectors such as manufacturing and energy, where every hour of downtime translates to substantial revenue loss.

The Solution: Upgrading to RIG-A-LITE’s LED lighting solutions can drastically reduce maintenance costs and downtime. These products not only have a longer operational lifespan compared to incandescent or halogen lights but also consume significantly less energy—up to 40% savings. When transitioning, consider a retrofit approach that allows for the installation of LED luminaires without the need for extensive infrastructure changes. RIG-A-LITE’s retrofit capabilities mean that you can replace outdated lighting systems with modern, efficient options while minimizing costs. Furthermore, implementing a proactive maintenance schedule that includes regular inspections can help identify potential issues before they result in downtime, ensuring that operations remain seamless.

Scenario 3: Compliance with International Standards

The Problem: International B2B buyers, especially in Africa, South America, the Middle East, and Europe, often grapple with the complexities of complying with varying regulations and standards for hazardous location lighting. Each region may have different requirements, and failure to comply can lead to not only safety risks but also legal penalties and loss of business opportunities.

The Solution: To navigate this challenge, it’s vital to choose a lighting partner like RIG-A-LITE that understands and complies with international standards, such as IEC 60079 for hazardous areas. Buyers should conduct thorough research on the specific compliance requirements in their regions and industries. When procuring lighting, ensure that the products are certified for the applicable standards in your operational regions. RIG-A-LITE’s commitment to compliance, including adherence to the Buy American Act (BAA) and Build America, Buy America Act (BABA), ensures that buyers can rely on their products for safety and regulatory adherence. Additionally, engaging with a knowledgeable distributor or representative can provide insights into the latest regulations and help streamline the procurement process, ensuring compliance while optimizing the purchasing decision.

Strategic Material Selection Guide for rig laet

What Are the Key Materials Used in RIG-A-LITE Products?

When selecting materials for RIG-A-LITE hazardous location lighting, it is crucial to consider properties that ensure optimal performance in demanding environments. Below, we analyze four common materials used in the manufacturing of RIG-A-LITE products, focusing on their properties, advantages, disadvantages, and implications for international buyers.

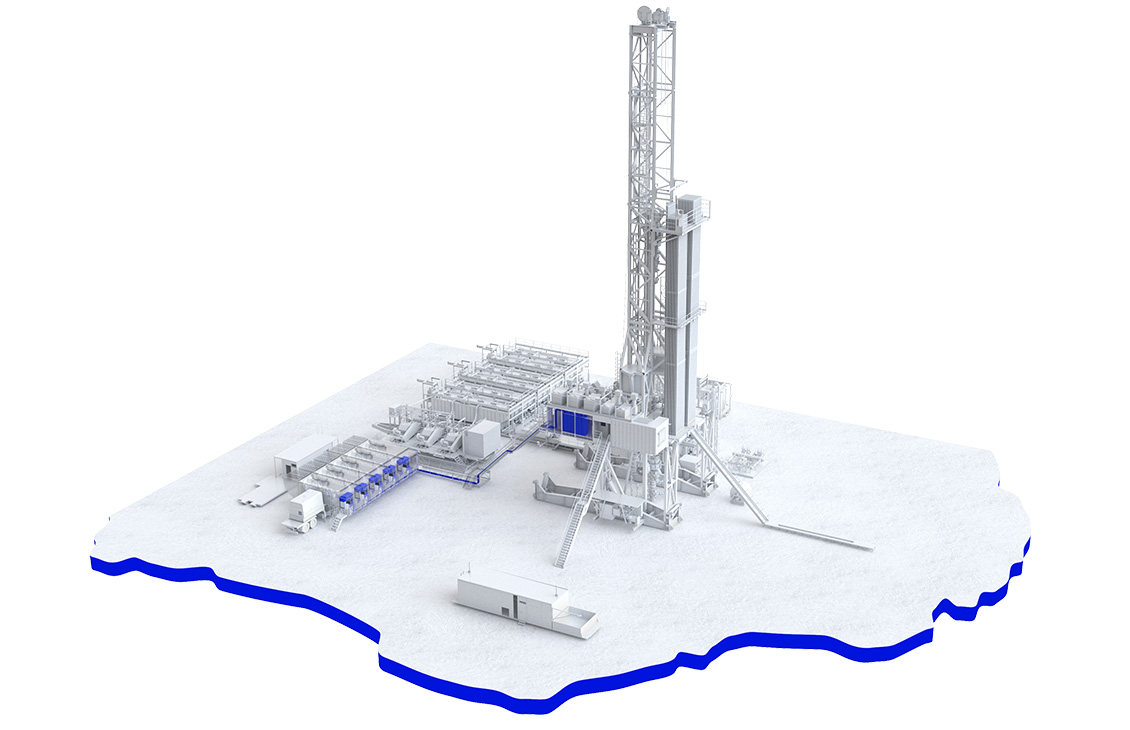

Illustrative image related to rig laet

How Does Aluminum Perform in Hazardous Lighting Applications?

Aluminum is a widely used material in hazardous lighting due to its lightweight and corrosion-resistant properties. It typically has a temperature rating up to 150°C, making it suitable for various industrial applications.

Pros: Aluminum is highly durable and resistant to corrosion, which is essential in environments exposed to harsh chemicals and moisture. Its lightweight nature simplifies installation and reduces shipping costs.

Cons: While aluminum is cost-effective, it may not withstand extreme temperatures as well as other materials, such as stainless steel. Additionally, it can be prone to scratches and dents, which may affect its aesthetic appeal over time.

Impact on Application: Aluminum’s compatibility with various media makes it ideal for environments like oil and gas facilities, where exposure to corrosive substances is common.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM for material quality, while considering the availability of aluminum in their markets.

What Role Does Stainless Steel Play in RIG-A-LITE Products?

Stainless steel is another popular choice for hazardous lighting applications, particularly in environments where durability and corrosion resistance are paramount. It can withstand temperatures up to 300°C, making it suitable for high-heat applications.

Pros: Stainless steel offers exceptional strength and resistance to corrosion and oxidation, ensuring longevity in harsh environments. Its robust nature makes it ideal for offshore and industrial applications.

Cons: The primary drawback of stainless steel is its higher cost compared to aluminum. Additionally, its weight can complicate installation and increase shipping expenses.

Impact on Application: Stainless steel is particularly effective in environments where exposure to saltwater or corrosive chemicals is a concern, such as marine and petrochemical applications.

Considerations for International Buyers: Buyers in Europe and the Middle East should verify compliance with standards like DIN and IEC, which govern safety and performance in hazardous environments.

How Does Polycarbonate Enhance Lighting Solutions?

Polycarbonate is often used for lenses and protective covers in RIG-A-LITE products due to its excellent impact resistance and transparency. It can withstand temperatures ranging from -40°C to 120°C.

Pros: Polycarbonate is lightweight and shatter-resistant, making it ideal for environments where physical impacts are a concern. Its transparency allows for maximum light transmission, enhancing visibility.

Cons: While polycarbonate is resistant to impact, it can be susceptible to certain chemicals, which may cause degradation over time. Additionally, it may not provide the same level of UV resistance as glass.

Impact on Application: Polycarbonate is suitable for applications in food processing and wastewater treatment, where safety and visibility are critical.

Considerations for International Buyers: Buyers should be aware of chemical compatibility and ensure that polycarbonate meets local safety standards, particularly in regions with stringent regulations.

Why Is Glass Still Relevant in Hazardous Lighting?

Glass is a traditional material used in hazardous lighting applications, particularly for its ability to withstand high temperatures and its excellent optical clarity. It can typically handle temperatures up to 300°C.

Pros: Glass offers superior resistance to UV radiation and is less prone to scratching compared to polycarbonate. Its durability makes it suitable for high-temperature applications.

Cons: The primary limitation of glass is its weight and fragility, which can complicate installation and increase the risk of breakage.

Impact on Application: Glass is often used in environments where high levels of UV exposure are present, such as outdoor applications in sunny climates.

Considerations for International Buyers: Buyers must ensure that glass products comply with international safety standards, particularly in regions with specific regulations regarding hazardous materials.

Summary Table of Material Selection for RIG-A-LITE

| Material | Typical Use Case for rig laet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Oil and gas facilities | Lightweight and corrosion-resistant | Limited high-temperature performance | Medium |

| Stainless Steel | Offshore and industrial applications | Exceptional strength and corrosion resistance | Higher cost and weight | High |

| Polycarbonate | Food processing and wastewater treatment | Shatter-resistant and lightweight | Chemical susceptibility | Medium |

| Glass | High-temperature outdoor applications | Superior UV resistance and optical clarity | Heavy and fragile | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on the specific demands of their applications in hazardous environments.

In-depth Look: Manufacturing Processes and Quality Assurance for rig laet

What Are the Main Stages in the Manufacturing Process of Rig Laet Products?

The manufacturing process for rig laet products, particularly hazardous location lighting, involves several critical stages that ensure both quality and performance in demanding environments. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing process is material preparation, where raw materials are selected based on their properties and suitability for hazardous environments. Common materials include robust metals and specialized plastics that can withstand extreme temperatures, corrosive chemicals, and mechanical stress. Suppliers must adhere to rigorous standards to ensure that these materials meet industry-specific requirements, such as those set by the American National Standards Institute (ANSI) and the International Electrotechnical Commission (IEC).

What Techniques Are Used in Forming and Assembly?

Once the materials are prepared, the next stage is forming. This typically involves processes such as stamping, machining, and molding to create the various components of the lighting systems. Advanced techniques like computer numerical control (CNC) machining are often employed to achieve precise specifications, which is crucial for ensuring product safety and performance.

Following forming, the assembly stage takes place. This involves integrating various components, such as LED modules, circuit boards, and housing units. Automated assembly lines may be used to enhance efficiency, but manual assembly is also critical for quality assurance, particularly for complex installations. Field-replaceable circuit boards and drivers are designed to simplify maintenance and prolong product life, a significant advantage for B2B buyers seeking long-term solutions.

How Is Quality Assurance Implemented During Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that each product meets established safety and performance standards. Rig laet products often adhere to international standards such as ISO 9001:2015, which outlines criteria for a quality management system. This certification indicates that the manufacturing processes are continuously monitored and improved.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are critical in the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications before they enter the production line.

- In-Process Quality Control (IPQC): Regular inspections are conducted throughout the manufacturing process to detect any deviations from the standards early on.

- Final Quality Control (FQC): Once products are assembled, they undergo rigorous testing to ensure they function correctly and comply with safety regulations.

What International Standards and Certifications Should Buyers Look For?

For B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the relevant certifications is crucial for verifying product safety and compliance. Common international standards include:

- ISO 9001: This certification ensures that a company maintains a quality management system that meets customer and regulatory requirements.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: The American Petroleum Institute provides specifications for equipment used in the oil and gas industry, ensuring that products meet the necessary safety and performance benchmarks.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers can take several proactive steps to verify the quality control processes of potential suppliers:

Illustrative image related to rig laet

-

Supplier Audits: Conducting regular audits of suppliers allows buyers to assess their quality management systems, manufacturing processes, and compliance with international standards.

-

Requesting Quality Reports: Buyers should request documentation that outlines the supplier’s quality assurance processes, including IQC, IPQC, and FQC results. This transparency is vital for building trust.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures and product reliability. These inspections often include material testing, functional assessments, and compliance checks against relevant standards.

What Are the Challenges and Nuances for International Buyers?

International B2B buyers must navigate various challenges and nuances related to quality assurance and certification. For instance, different regions may have varying standards and compliance requirements. Buyers should be aware of local regulations in their markets, as well as any potential barriers to product importation.

Furthermore, language barriers and cultural differences can complicate communication with suppliers. It is essential for buyers to engage with suppliers who can provide clear documentation and support throughout the procurement process. Establishing strong relationships with suppliers through regular communication and visits can also help mitigate potential misunderstandings and ensure a smooth purchasing experience.

Conclusion

The manufacturing processes and quality assurance measures for rig laet products are crucial for ensuring their safety and reliability in hazardous environments. By understanding the various stages of manufacturing, key quality control checkpoints, and relevant certifications, B2B buyers can make informed decisions when selecting suppliers. Verifying supplier quality control processes through audits, reports, and third-party inspections can further enhance buyer confidence, ensuring that they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rig laet’

When sourcing RIG-A-LITE lighting solutions, particularly for hazardous locations, it’s essential to follow a systematic approach to ensure you meet both operational needs and regulatory compliance. This guide provides a step-by-step checklist to assist international B2B buyers in navigating the procurement process effectively.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the lighting solutions you require. Consider factors such as the environment where the lights will be installed, the required brightness (lumens), and energy efficiency ratings. This step is crucial as it ensures that the selected products will perform optimally under specific conditions, minimizing operational disruptions.

- Environmental Considerations: Identify whether the lighting will be used in areas classified as Class 1 or Class 2, which involve flammable gases or combustible dust.

- Energy Requirements: Evaluate energy consumption to align with your sustainability goals and cost-saving measures.

Step 2: Conduct Market Research

Investigate the market to identify potential suppliers of RIG-A-LITE products. This includes reviewing their product offerings, market reputation, and compliance with international standards. A thorough understanding of the market landscape enables you to make informed decisions based on quality and reliability.

- Competitive Analysis: Compare different suppliers’ product ranges and pricing to find the best fit for your needs.

- Reputation Check: Look for reviews, testimonials, and case studies from other businesses that have purchased similar products.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct a comprehensive evaluation. Request company profiles, product specifications, and references from existing customers, especially those within your industry or region.

- Certification Verification: Ensure that the supplier holds necessary certifications, such as ISO 9001:2015, which indicates adherence to quality management standards.

- Experience Assessment: Consider how long the supplier has been in business and their expertise in hazardous location lighting.

Step 4: Request Product Samples

Before finalizing your order, request samples of the RIG-A-LITE products. This allows you to assess the quality and suitability of the lighting solutions firsthand. Testing the products in your operational environment can provide insights into their performance under real-world conditions.

- Performance Evaluation: Check for brightness, durability, and ease of installation.

- Compatibility Check: Ensure the samples fit well with your existing infrastructure and meet your specific requirements.

Step 5: Review Warranty and Support Options

Understand the warranty terms and customer support services offered by the supplier. A robust warranty and responsive customer service can save you time and costs in the long run, especially when dealing with hazardous location lighting.

Illustrative image related to rig laet

- Warranty Coverage: Look for comprehensive warranty coverage that protects against manufacturing defects and performance issues.

- Support Services: Confirm the availability of technical support and maintenance services, which can be critical in ensuring continuous operation.

Step 6: Finalize Pricing and Terms

Once you have evaluated suppliers and products, negotiate pricing and payment terms. Ensure that the final agreement includes all costs, such as shipping, installation, and any potential tariffs, especially when sourcing internationally.

- Cost Breakdown: Request a detailed cost breakdown to avoid unexpected expenses.

- Payment Flexibility: Discuss payment terms that align with your budget and cash flow considerations.

Step 7: Place Your Order

After confirming all details, proceed to place your order with the chosen supplier. Make sure to document all agreements and maintain clear communication regarding delivery timelines and expectations.

- Order Confirmation: Ensure you receive a confirmation of your order that outlines all agreed terms.

- Tracking and Follow-Up: Keep track of the order status and establish a follow-up plan to ensure timely delivery and installation.

By following these steps, you will be better equipped to source RIG-A-LITE products that meet your operational needs while ensuring compliance and performance in hazardous environments.

Comprehensive Cost and Pricing Analysis for rig laet Sourcing

What Are the Key Cost Components in Sourcing RIG-A-LITE Products?

Understanding the cost structure for sourcing RIG-A-LITE hazardous location lighting is crucial for international B2B buyers. The primary cost components include:

Illustrative image related to rig laet

-

Materials: High-quality materials are essential for ensuring durability and performance in harsh environments. The use of corrosion-resistant metals and robust lenses can significantly impact the material costs.

-

Labor: Skilled labor is required for manufacturing and assembly, particularly in specialized production processes for hazardous-rated lighting. Labor costs can vary significantly depending on the region and workforce availability.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize overhead costs, but it’s essential to ensure that quality is not compromised.

-

Tooling: Investment in specialized tooling for production can be a significant upfront cost, especially for custom designs. However, efficient tooling can reduce long-term production costs.

-

Quality Control (QC): Rigorous quality assurance processes are critical, particularly for products used in hazardous environments. The costs associated with testing and certifications can influence overall pricing.

-

Logistics: Shipping and transportation costs can vary widely based on distance, mode of transport, and the complexity of the supply chain. International buyers should account for these costs to avoid surprises.

-

Margin: Suppliers typically add a profit margin to cover their expenses and risk. Understanding the margin expectations of suppliers can aid in negotiation.

How Do Price Influencers Affect Sourcing Decisions?

Several factors influence the pricing of RIG-A-LITE products, and understanding these can help buyers make informed decisions:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing often leads to lower per-unit costs. Buyers should evaluate their needs to determine if they can meet MOQ requirements for better pricing.

-

Specifications and Customization: Custom solutions may incur additional costs. Buyers should clearly define their requirements and assess whether standard products could meet their needs to control costs.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as IEC 60079 for hazardous environments) can elevate costs. However, investing in quality can reduce long-term maintenance and replacement expenses.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a track record of quality may charge higher prices but offer better long-term value.

-

Incoterms: Understanding Incoterms is essential for determining liability and costs associated with shipping. This knowledge can help buyers negotiate better terms and avoid unexpected expenses.

What Buyer Tips Can Enhance Cost Efficiency in Sourcing?

International buyers can leverage several strategies to enhance cost efficiency when sourcing RIG-A-LITE products:

-

Negotiation: Building a relationship with suppliers can provide leverage during negotiations. Understanding the supplier’s cost structure can help buyers negotiate more favorable terms.

-

Total Cost of Ownership (TCO): Evaluating the TCO, including installation, maintenance, and energy consumption, can provide a clearer picture of value beyond initial purchase price. RIG-A-LITE’s energy-efficient solutions can lead to significant savings over time.

-

Pricing Nuances for International Markets: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, tariffs, and import duties that can affect pricing. Conducting thorough market research can help in anticipating these costs.

-

Leverage Local Partnerships: Collaborating with local distributors or agents can help navigate regional regulations and logistics challenges, potentially leading to cost savings.

-

Stay Informed: Keeping abreast of industry trends and technological advancements can help buyers identify opportunities for cost savings, such as switching to energy-efficient LED solutions.

Disclaimer for Indicative Prices

Prices can vary widely based on market conditions, supplier relationships, and specific buyer requirements. It is advisable to obtain quotes from multiple suppliers to ensure competitive pricing and to factor in all associated costs for a comprehensive analysis.

Alternatives Analysis: Comparing rig laet With Other Solutions

Understanding Alternatives for Hazardous Location Lighting Solutions

In the quest for optimal hazardous location lighting, it’s crucial for B2B buyers to explore various alternatives to RIG-A-LITE. Evaluating different solutions allows businesses to select the most effective lighting systems that align with their operational needs, budget constraints, and environmental requirements. This section compares RIG-A-LITE against two viable alternatives: traditional High-Intensity Discharge (HID) lighting and advanced smart lighting systems.

Comparison Table

| Comparison Aspect | ‘Rig Laet’ | Traditional HID Lighting | Smart Lighting Systems |

|---|---|---|---|

| Performance | High durability, energy-efficient LEDs; optimal for harsh environments | Good brightness but less efficient; shorter lifespan | Adaptive lighting with sensors; can adjust brightness based on needs |

| Cost | Higher initial cost, lower total cost of ownership due to energy savings | Lower initial cost, higher long-term energy and maintenance costs | Higher upfront investment; potential long-term savings through efficiency |

| Ease of Implementation | Simple retrofit options; minimal disruption | Straightforward installation; often requires complete fixture replacement | May require significant system integration and training |

| Maintenance | Low maintenance with field-replaceable components | Regular maintenance needed; frequent bulb replacements | Generally low maintenance but requires software updates and monitoring |

| Best Use Case | Ideal for industrial applications in extreme environments | Suitable for general outdoor lighting; less optimal for hazardous areas | Best for smart buildings and environments where adaptability is key |

Detailed Breakdown of Alternatives

Traditional High-Intensity Discharge (HID) Lighting

HID lighting has long been a staple in industrial and outdoor applications due to its ability to produce bright light at a relatively low initial cost. While HID lights are effective for general illumination, they fall short in hazardous environments where durability and safety are paramount. The lifespan of HID bulbs is shorter compared to LED solutions, leading to higher maintenance costs over time. Additionally, their energy consumption is significantly higher, contributing to increased operational costs and carbon emissions.

Illustrative image related to rig laet

Smart Lighting Systems

Smart lighting systems represent the forefront of technological advancements in lighting, offering adaptive solutions that can respond to environmental changes. These systems utilize sensors to adjust brightness based on occupancy and ambient light conditions, resulting in energy efficiency. However, the initial investment for smart systems can be substantial, and their implementation often involves complex integration with existing infrastructure. While they offer long-term savings, the need for regular software updates and potential training for personnel can complicate maintenance.

Conclusion: How to Choose the Right Hazardous Location Lighting Solution

When selecting a lighting solution for hazardous environments, B2B buyers should consider their specific operational needs, budget, and long-term goals. RIG-A-LITE stands out for its durability, energy efficiency, and low maintenance, making it an excellent choice for industries facing extreme conditions. However, for businesses looking to minimize upfront costs, traditional HID lighting may be suitable, albeit with higher long-term expenses. Alternatively, smart lighting systems offer innovative features that can enhance energy savings but require a more significant investment and integration effort. Ultimately, the best choice will depend on a careful assessment of the trade-offs between initial costs, performance, and maintenance needs.

Essential Technical Properties and Trade Terminology for rig laet

What Are the Key Technical Properties of Rig Laet Lighting Solutions?

1. Material Grade

The material grade used in rig laet lighting solutions typically includes high-grade aluminum or stainless steel, which provide resistance to corrosion and harsh environmental conditions. This is crucial for longevity and reliability, especially in offshore or industrial settings where exposure to chemicals and moisture is common. B2B buyers must prioritize materials that not only meet safety standards but also ensure durability and performance over time, reducing the need for frequent replacements.

2. Luminaire Efficacy

Luminaire efficacy refers to the amount of light produced per watt of energy consumed, usually expressed in lumens per watt (lm/W). High efficacy ratings indicate energy-efficient lighting solutions that can significantly reduce operational costs. For businesses, investing in high-efficacy lighting can lead to substantial savings on energy bills while also contributing to sustainability goals by lowering carbon footprints.

3. Ingress Protection Rating (IP Rating)

The IP rating defines the level of protection provided by the lighting fixture against dust and moisture. A higher IP rating indicates better resistance to environmental factors. For example, an IP66 rating signifies that the light is completely dust-tight and protected against powerful water jets. B2B buyers should ensure that the lighting solutions they choose have appropriate IP ratings for their specific application environments to guarantee safety and compliance with industry standards.

4. Hazardous Location Classification

Rig laet lighting solutions often come with classifications such as Class 1 Division 1 or Class 2 Division 2, which denote their suitability for use in hazardous environments. These classifications are critical for industries dealing with flammable gases, vapors, or dust. Understanding these classifications helps B2B buyers ensure that they are selecting the right lighting solutions that comply with safety regulations, thereby protecting workers and minimizing risks.

5. Field-Replaceable Components

Many modern rig laet lighting solutions feature field-replaceable components, such as drivers and circuit boards. This design allows for easier maintenance and can significantly extend the product’s lifespan. For businesses, the ability to replace parts without needing to replace the entire unit not only reduces downtime but also lowers the overall cost of ownership, making these products more appealing.

What Are Common Trade Terms Relevant to Rig Laet Lighting Solutions?

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of rig laet lighting, understanding OEM relationships is essential for B2B buyers to ensure they are purchasing high-quality components that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. This term is significant for B2B buyers as it impacts inventory costs and cash flow. Understanding MOQs helps buyers plan their purchases effectively and negotiate better terms with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a formal process through which businesses request pricing information from suppliers for specific products or services. Utilizing an RFQ allows B2B buyers to compare prices and terms effectively, facilitating informed decision-making when sourcing rig laet lighting solutions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is vital for B2B buyers to understand shipping costs, risk management, and delivery responsibilities when importing rig laet lighting solutions from different regions.

5. Lead Time

Lead time is the period between placing an order and receiving the goods. Knowing the lead time is crucial for B2B buyers to manage project timelines and inventory levels effectively. It helps in planning and ensures that businesses can meet operational demands without interruption.

By understanding these critical technical properties and trade terms, B2B buyers can make informed decisions, enhance operational efficiency, and ensure compliance with industry standards when selecting rig laet lighting solutions.

Illustrative image related to rig laet

Navigating Market Dynamics and Sourcing Trends in the rig laet Sector

What Are the Key Market Trends Influencing the Rig Laet Sector?

The rig laet sector is experiencing significant transformation driven by technological advancements, regulatory changes, and evolving buyer expectations. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking innovative solutions that enhance operational efficiency and safety in hazardous environments. Key trends include the adoption of LED lighting technology, which offers superior energy efficiency and reduced maintenance costs, thus appealing to businesses focused on long-term savings.

Moreover, the shift towards automation and smart technologies is reshaping sourcing strategies. Companies are now looking for integrated solutions that not only meet stringent safety standards but also incorporate smart features for monitoring and control. This dynamic is especially relevant in regions like Brazil and Vietnam, where industrial expansion is met with a growing emphasis on safety and compliance. Buyers are advised to remain agile, adapting to these shifts by partnering with suppliers that offer comprehensive, compliant solutions tailored to local market needs.

Additionally, global supply chain disruptions have prompted B2B buyers to reassess their sourcing strategies, favoring suppliers with robust logistics and quick delivery capabilities. This is particularly critical for hazardous location lighting, where downtime can lead to significant operational risks. As such, establishing relationships with suppliers who can ensure reliability and responsiveness is paramount.

Illustrative image related to rig laet

How Does Sustainability Influence Sourcing Decisions in the Rig Laet Sector?

Sustainability has become a cornerstone of sourcing strategies in the rig laet sector, driven by both regulatory requirements and growing environmental consciousness among consumers and businesses alike. The environmental impact of lighting solutions, particularly in hazardous locations, necessitates a focus on energy-efficient products that minimize carbon footprints. Companies that prioritize sustainability can not only comply with regulations but also enhance their brand reputation and appeal to environmentally conscious clients.

Ethical sourcing practices are equally vital, as buyers increasingly prefer suppliers who demonstrate a commitment to social responsibility. This includes ensuring fair labor practices throughout the supply chain and sourcing materials from environmentally responsible sources. Certifications such as Energy Star or ISO 14001 can guide buyers in identifying products that align with their sustainability goals.

The transition to LED lighting solutions exemplifies this trend, as these products typically offer energy savings of over 40% compared to traditional lighting options. Furthermore, manufacturers that provide transparent information about their sourcing practices and the lifecycle impact of their products can gain a competitive edge in the marketplace. B2B buyers should prioritize partnerships with suppliers who are proactive in sustainability initiatives, as this not only aids in compliance but also fosters long-term operational resilience.

What Is the Historical Context of the Rig Laet Sector’s Development?

The rig laet sector has evolved significantly since its inception, initially focused on basic lighting solutions for the drilling industry. Established in 1938, RIG-A-LITE quickly gained recognition for its commitment to quality and reliability in hazardous environments. Over the decades, advancements in technology have driven the development of more sophisticated lighting solutions, particularly in response to the demands of offshore and industrial applications.

As industries expanded globally, the need for compliant and durable lighting solutions became increasingly apparent. The introduction of stringent safety regulations and standards further shaped the sector, pushing manufacturers to innovate continuously. The current emphasis on energy efficiency and sustainability reflects the sector’s evolution from traditional practices to a more modern, technology-driven approach. This historical context is essential for B2B buyers, as it highlights the importance of partnering with established suppliers who understand the complexities and demands of the rig laet market.

Frequently Asked Questions (FAQs) for B2B Buyers of rig laet

-

How do I solve lighting compliance issues in hazardous locations?

To resolve lighting compliance issues in hazardous locations, first ensure that the lighting products meet local and international safety standards, such as IEC 60079 for explosive atmospheres. Partner with suppliers who specialize in hazardous location lighting and can provide certifications for their products. Conduct a thorough site assessment to identify specific risks and choose appropriate lighting classifications, such as Class 1 Division 1 or Division 2. Regularly review and update your compliance practices to align with industry regulations and advancements in technology. -

What is the best lighting solution for offshore oil rigs?

The best lighting solution for offshore oil rigs includes explosion-proof and corrosion-resistant LED fixtures designed for harsh marine environments. Look for products with high durability ratings and compliance with relevant safety standards. RIG-A-LITE’s E-Series and EX-Series lighting offer excellent energy efficiency and longevity, making them ideal for offshore applications. Additionally, consider options with field-replaceable components to minimize downtime and maintenance costs, ensuring continuous operation in critical conditions. -

How can I evaluate suppliers for hazardous location lighting?

When evaluating suppliers for hazardous location lighting, check their industry experience, certifications, and product quality. Request case studies or references from similar projects to gauge their reliability. Ensure they provide comprehensive technical support and warranty policies. Additionally, assess their capacity for customization and whether they can meet your specific project requirements, including compliance with local regulations and timely delivery schedules. -

What are the minimum order quantities (MOQ) for rig laet products?

Minimum order quantities (MOQ) for rig laet products can vary significantly by supplier and product type. Many manufacturers offer flexible MOQs, especially for bulk orders or long-term partnerships. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms. Smaller orders may incur higher unit costs, so consider combining orders with other products or planning for future needs to optimize costs and streamline logistics. -

What payment terms are typically offered for international B2B transactions?

Payment terms for international B2B transactions often include options such as letter of credit, wire transfers, or payment upon delivery. Suppliers may require a deposit upfront, typically ranging from 20% to 50%, with the balance due before shipment or upon delivery. Discussing terms upfront can help avoid misunderstandings and ensure smooth transactions. Additionally, consider the implications of currency fluctuations and payment processing fees when negotiating terms. -

How do I ensure quality assurance for rig laet products?

To ensure quality assurance for rig laet products, establish clear specifications and standards before placing orders. Request samples for evaluation and conduct factory inspections if possible. Choose suppliers with ISO certifications, such as ISO 9001:2015, which indicates adherence to quality management systems. Regular communication throughout the production process can help address any issues promptly, and consider implementing a third-party quality control service for additional assurance. -

What logistics considerations should I keep in mind when sourcing rig laet?

When sourcing rig laet products, logistics considerations include shipping methods, lead times, and customs regulations. Select suppliers who offer reliable shipping options and can provide estimated delivery times. Be aware of import duties, taxes, and compliance documentation required for your region. Collaborating with logistics partners experienced in international trade can help navigate these complexities and ensure timely delivery of your lighting solutions. -

Can rig laet products be customized for specific applications?

Yes, many rig laet products can be customized to meet specific application needs. This may include modifications in size, light output, color temperature, or mounting options. When discussing customization with suppliers, clearly outline your requirements and any relevant industry standards. Engaging in early-stage design discussions can facilitate a smoother production process and ensure that the final products align with your operational needs and safety regulations.

Top 5 Rig Laet Manufacturers & Suppliers List

1. RIG-A-LITE – Hazardous Location Lighting Solutions

Domain: availinfra.com

Registered: 2022 (3 years)

Introduction: RIG-A-LITE provides hazardous location lighting solutions designed for optimal performance in industrial applications. Key features include:

– Compliance with Build America, Buy America Act (BABA) and Buy American Act (BAA)

– Classifications: Class 1 Division 1, Class 1 Division 2, Class 2 Division 1, Class 2 Division 2, Class 3, and IEC 60079 Zone Classification

– Luminaire Types: Area Lights,…

2. Ulanzi – Ring Light

Domain: ulanzi.com

Registered: 2016 (9 years)

Introduction: This company, Ulanzi – Ring Light, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Larson Electronics – Fast Delivery & Easy Returns

Domain: larsonelectronics.com

Registered: 2001 (24 years)

Introduction: This company, Larson Electronics – Fast Delivery & Easy Returns, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. GPX – GPX 8 Ring Light Vlogging Kit

Domain: gpx.com

Registered: 1997 (28 years)

Introduction: {“Product Name”: “GPX 8″ Ring Light Vlogging Kit (TPDL801B)”, “Features”: [“8-inch ring light”, “Adjustable brightness levels”, “Tripod included”, “Phone holder”, “USB powered”], “Usage”: “Ideal for vlogging, photography, and video conferencing”, “Dimensions”: “8 inches in diameter”, “Weight”: “Lightweight and portable”, “Power Source”: “USB powered for convenience”}

5. Smartphone Video Rig – Handheld LED Ring Light

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“item_name”:”Smartphone Video Rig Handheld LED Ring Light Selfie Light Phone Video U200″,”price”:”$121.50″,”condition”:”New”,”quantity_available”:1,”item_number”:”116722313057″,”shipping_estimate”:”Mon, Sep 15 – Sat, Sep 20″,”shipping_origin”:”Miami, Florida, United States”,”returns”:”Seller does not accept returns”,”seller_username”:”buyandgrowrich”,”seller_feedback”:”742 positive feedback”,”sel…

Strategic Sourcing Conclusion and Outlook for rig laet

How Can Strategic Sourcing Enhance Your Operations with RIG-A-LITE?

In today’s competitive landscape, strategic sourcing is not merely a procurement tactic; it is a critical component for operational efficiency, particularly for industries that require hazardous location lighting. By opting for RIG-A-LITE solutions, businesses can significantly reduce energy costs and maintenance overheads while ensuring compliance with stringent safety standards. The advanced design features, such as field-replaceable components, extend product life and enhance reliability, making RIG-A-LITE a smart investment for B2B buyers across various sectors, from oil and gas to food processing.

What Does the Future Hold for Your Business with RIG-A-LITE?

Looking ahead, the demand for energy-efficient and durable lighting solutions in hazardous environments will only grow. International B2B buyers from Africa, South America, the Middle East, and Europe should seize the opportunity to partner with RIG-A-LITE. By integrating these innovative lighting solutions into your operations, you can not only elevate safety standards but also contribute to sustainability goals. Now is the time to act—explore the comprehensive range of RIG-A-LITE products and secure your competitive edge in the marketplace. Engage with us to discover how we can support your specific needs and enhance your operational efficiency.

Illustrative image related to rig laet

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to rig laet