Choosing Your 14 Gauge Hardware Cloth: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for 14 gauge hardware cloth

Navigating the complex landscape of sourcing 14 gauge hardware cloth presents a unique challenge for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. With diverse applications ranging from agricultural fencing to construction reinforcement, understanding the specifications, quality, and pricing of this essential material is crucial. This guide will delve into the intricacies of 14 gauge hardware cloth, highlighting its various types, applications, and the critical factors to consider when vetting suppliers.

As global markets evolve, the need for a reliable, durable, and cost-effective solution becomes paramount. This guide is designed to empower buyers with the knowledge necessary to make informed purchasing decisions, ensuring they select the right hardware cloth that meets their specific needs. We will explore the importance of galvanization processes, mesh sizes, and the implications of different wire gauges, all while providing insights on pricing strategies and shipping considerations.

Whether you’re a buyer in Vietnam looking for agricultural solutions or a procurement manager in Nigeria seeking reliable materials for construction, this comprehensive resource aims to demystify the purchasing process. By equipping you with actionable insights and best practices, we aim to enhance your sourcing efficiency and ensure that you secure the best value for your investment in 14 gauge hardware cloth.

Understanding 14 gauge hardware cloth Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Galvanized After Welding (GAW) | Smooth surface, corrosion-resistant, strong | Agricultural fencing, garden enclosures | Pros: Durable, rust-resistant. Cons: Higher cost than uncoated options. |

| Vinyl Coated | Additional PVC coating for enhanced weather resistance | Landscaping, pet enclosures | Pros: Aesthetic appeal, extra protection. Cons: Higher price, potential for coating wear. |

| Welded Wire Mesh | Uniformly welded joints, high tensile strength | Construction, industrial applications | Pros: Robust structure, versatile. Cons: Can be heavier and more expensive. |

| Hardware Cloth with Varying Mesh Sizes | Customizable mesh openings (e.g., 1/2″ x 1″, 1″ x 1″) | Pest control, animal housing | Pros: Versatile for different applications. Cons: Requires careful selection for specific needs. |

| Heavy Duty Variants | Thicker wire, increased gauge (e.g., 12 gauge) | Security fencing, commercial uses | Pros: Superior strength, long-lasting. Cons: More expensive, heavier to handle. |

What are the Characteristics of Galvanized After Welding (GAW) Hardware Cloth?

Galvanized After Welding (GAW) hardware cloth features a smooth surface created through a process where the wire is galvanized after it has been welded. This type is particularly valued for its corrosion resistance, making it ideal for outdoor applications such as agricultural fencing and garden enclosures. B2B buyers should consider the higher initial cost as a trade-off for its longevity and durability, especially in regions with harsh weather conditions.

How Does Vinyl Coated Hardware Cloth Enhance Durability?

Vinyl-coated hardware cloth adds a layer of PVC protection over the galvanized wire, offering enhanced weather resistance and aesthetic appeal. This type is commonly used in landscaping projects and for pet enclosures, where visual appeal is important. While the vinyl coating provides excellent protection against rust and corrosion, buyers must be aware of the potential for wear over time, which could expose the underlying wire.

What Makes Welded Wire Mesh a Preferred Choice in Industrial Applications?

Welded wire mesh is known for its uniformly welded joints and high tensile strength, making it suitable for heavy-duty applications such as construction and industrial settings. Its robust structure allows it to withstand significant stress and strain, making it a reliable choice for B2B buyers looking for long-lasting solutions. However, the increased weight and cost compared to other types may require careful consideration in budgeting and logistics.

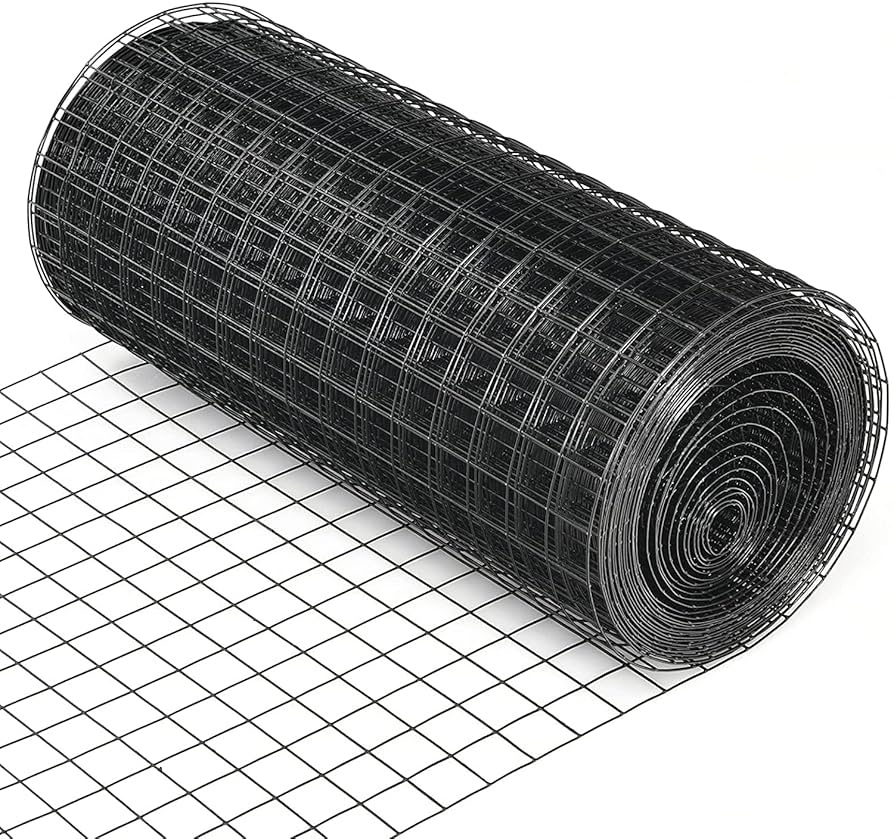

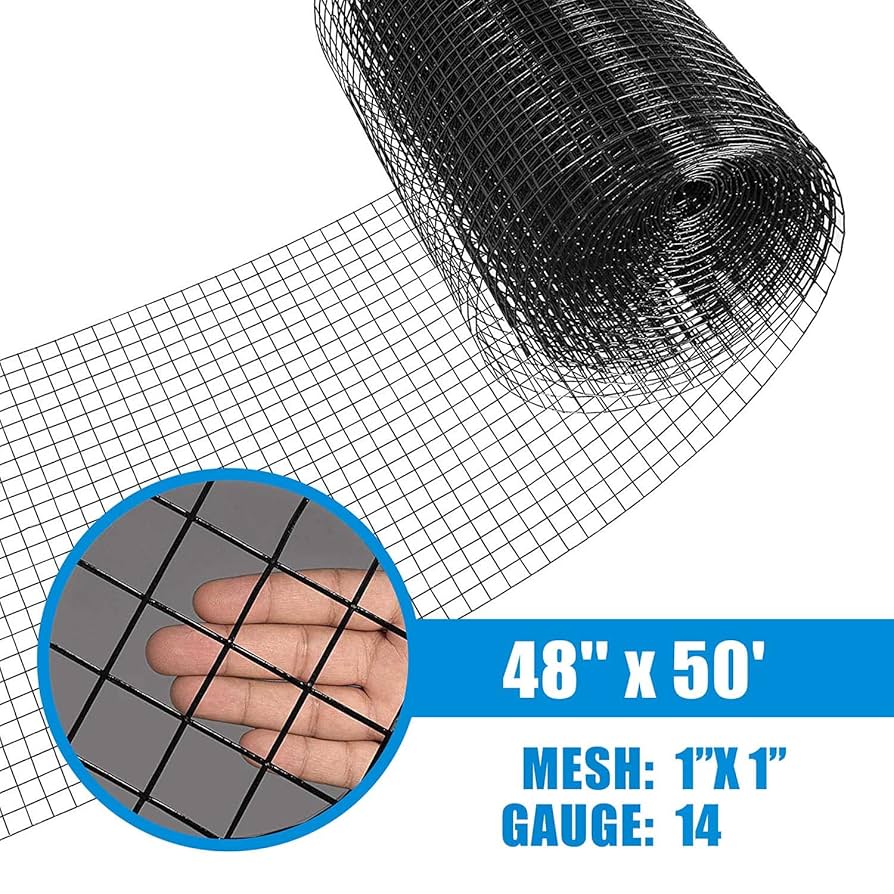

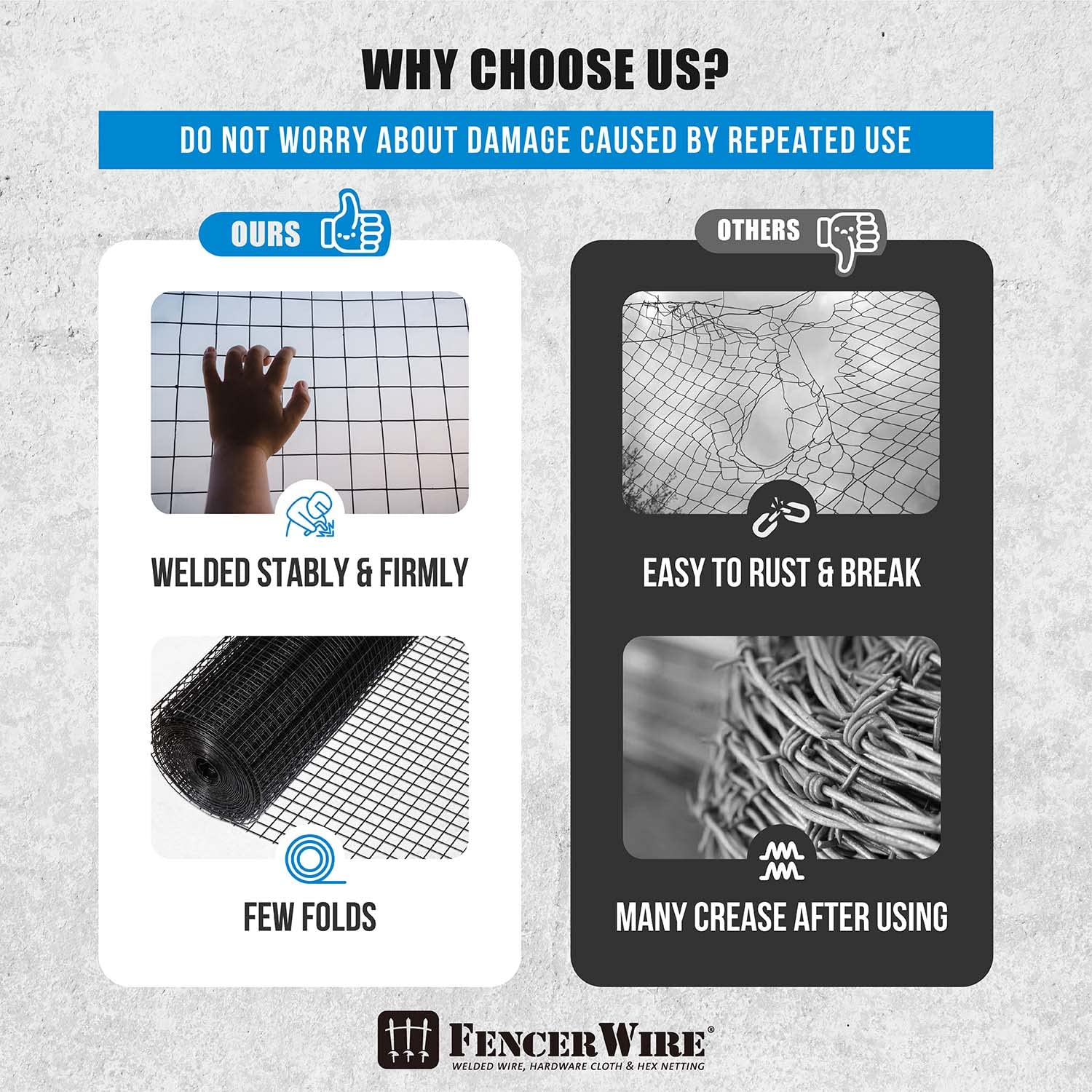

Illustrative image related to 14 gauge hardware cloth

Why Choose Hardware Cloth with Varying Mesh Sizes?

Hardware cloth with varying mesh sizes offers customization for specific needs, such as pest control or animal housing. Buyers can select from different mesh openings, like 1/2″ x 1″ or 1″ x 1″, to suit their particular application. This flexibility is beneficial for businesses that require tailored solutions. However, careful selection is crucial, as the wrong mesh size could lead to ineffective pest control or inadequate security.

What are the Benefits of Heavy Duty Variants of Hardware Cloth?

Heavy-duty variants of hardware cloth, such as those made from thicker wire or lower gauge numbers (e.g., 12 gauge), provide superior strength and durability. These are often used for security fencing and commercial applications where robustness is essential. While they offer long-lasting performance, the trade-off includes a higher price point and increased weight, which can complicate handling and installation processes for B2B buyers.

Key Industrial Applications of 14 gauge hardware cloth

| Industry/Sector | Specific Application of 14 gauge hardware cloth | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Livestock enclosures and protection against predators | Ensures the safety and health of livestock, reducing losses from predation | Consider local climate conditions and rust resistance needs. |

| Construction | Reinforcement in concrete and masonry applications | Increases structural integrity and longevity of buildings | Verify compliance with local building codes and standards. |

| Landscaping & Gardening | Garden fencing and plant protection | Protects crops from pests and animals, enhancing yield | Assess mesh size for specific plant types and local fauna. |

| Industrial Manufacturing | Safety barriers and equipment guarding | Reduces workplace accidents and enhances safety compliance | Ensure high-quality galvanization to withstand industrial wear. |

| Mining and Quarrying | Sifting and separating materials | Improves efficiency in material handling and processing | Evaluate mesh size and gauge for specific material types. |

How is 14 Gauge Hardware Cloth Used in Agriculture?

In the agricultural sector, 14 gauge hardware cloth is extensively used for constructing livestock enclosures. This robust material provides a secure barrier against predators, ensuring the safety of animals such as chickens, goats, and sheep. By preventing losses from predation, farmers can protect their investments and maintain healthy livestock populations. When sourcing, international buyers should consider factors such as local climate conditions and the need for rust-resistant materials, especially in humid or wet environments prevalent in regions like West Africa or Southeast Asia.

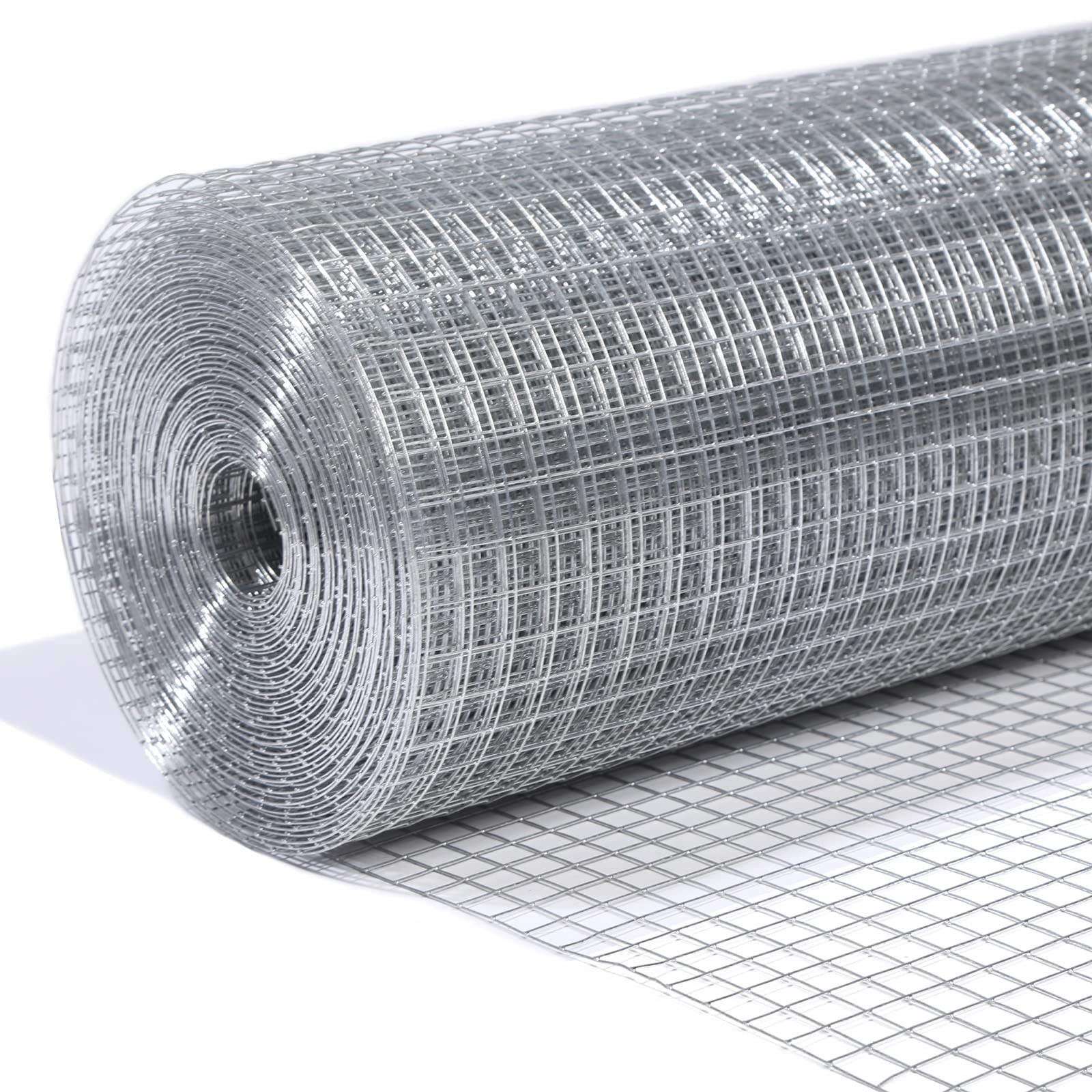

Illustrative image related to 14 gauge hardware cloth

What Role Does 14 Gauge Hardware Cloth Play in Construction?

Within the construction industry, 14 gauge hardware cloth is often employed as reinforcement in concrete and masonry applications. Its strength enhances the structural integrity of buildings, making it a vital component in various construction projects. The use of this material can lead to longer-lasting structures, reducing maintenance costs over time. Buyers should ensure that their sourcing aligns with local building codes and standards, particularly in regions with stringent regulations, such as Europe and the Middle East.

How is 14 Gauge Hardware Cloth Beneficial in Landscaping and Gardening?

In landscaping and gardening, 14 gauge hardware cloth serves as an effective solution for garden fencing and plant protection. It safeguards crops from pests and animals, which can significantly enhance yield and reduce the need for chemical deterrents. By allowing air and water to pass through while blocking unwanted intruders, it creates a healthy growing environment. Buyers must assess the mesh size to ensure it is suitable for the specific plant types they are cultivating, particularly in diverse ecosystems found in regions like South America.

What Safety Advantages Does 14 Gauge Hardware Cloth Provide in Industrial Manufacturing?

In industrial manufacturing, 14 gauge hardware cloth is crucial for creating safety barriers and equipment guarding. This application helps to reduce workplace accidents, ensuring compliance with safety regulations and protecting employees. The durability of the material means it can withstand harsh industrial environments, contributing to long-term safety solutions. When sourcing for this application, businesses should prioritize high-quality galvanization to ensure the material can endure wear and tear, particularly in demanding sectors like mining or heavy machinery.

How is 14 Gauge Hardware Cloth Utilized in Mining and Quarrying?

In the mining and quarrying sectors, 14 gauge hardware cloth is used for sifting and separating materials. Its sturdy construction allows for efficient handling and processing of various minerals and aggregates, improving operational efficiency. This material is particularly valuable in regions rich in natural resources, such as parts of Africa and South America. Buyers should evaluate the mesh size and gauge to ensure compatibility with the specific types of materials being processed, maximizing productivity and safety in their operations.

3 Common User Pain Points for ’14 gauge hardware cloth’ & Their Solutions

Scenario 1: Challenges with Sourcing Quality 14 Gauge Hardware Cloth

The Problem: B2B buyers often struggle with sourcing high-quality 14 gauge hardware cloth that meets their specific project requirements. In regions like Africa and South America, where supply chains can be inconsistent, buyers may encounter products that do not adhere to the expected standards of durability and rust resistance. This can lead to delays in project timelines, increased costs due to returns or replacements, and ultimately dissatisfaction from end clients who rely on the integrity of the materials used.

Illustrative image related to 14 gauge hardware cloth

The Solution: To mitigate these sourcing challenges, B2B buyers should prioritize suppliers who provide detailed product specifications and quality certifications. When evaluating potential suppliers, look for those that offer galvanized after welding (GAW) products, as this process enhances corrosion resistance and longevity. It’s advisable to request samples before committing to larger orders, allowing you to assess the quality firsthand. Additionally, consider building relationships with multiple suppliers to diversify your sourcing options, thereby reducing the risk of stock shortages or quality discrepancies.

Scenario 2: Misunderstanding Mesh Size and Its Applications

The Problem: A common issue for buyers is the confusion surrounding mesh sizes and their appropriate applications. For instance, a buyer may mistakenly select a mesh size that is too large for their intended use, such as preventing small animals from entering a garden or construction site. This oversight can lead to costly mistakes, such as damage to crops or infrastructure, as well as safety concerns, particularly in environments where small animals could pose a threat.

The Solution: To prevent these misunderstandings, buyers should invest time in understanding the specific needs of their projects. For 14 gauge hardware cloth, a common mesh size is 1/2″ x 1″, which is ideal for applications requiring moderate security and animal containment. Buyers should analyze the requirements of their specific application—whether it’s for fencing, reinforcement, or pest control—and choose the mesh size accordingly. Additionally, consulting with suppliers about the best practices for installation and usage can provide valuable insights, ensuring that the selected hardware cloth effectively meets project goals.

Scenario 3: Installation Challenges Leading to Inefficiencies

The Problem: Installation of 14 gauge hardware cloth can pose significant challenges, particularly for buyers who lack experience in handling metal mesh products. Improper installation can lead to sagging, tearing, or ineffective barriers, resulting in wasted materials and time. In regions with skilled labor shortages, such inefficiencies can exacerbate project delays and inflate costs, affecting overall project profitability.

Illustrative image related to 14 gauge hardware cloth

The Solution: To address installation challenges, B2B buyers should ensure that their teams are well-trained in the proper techniques for handling and installing hardware cloth. This includes using the right tools, such as wire cutters and fastening hardware, and understanding the necessary tension and support needed to maintain the integrity of the installation. It may also be beneficial to develop a standardized installation guide that includes best practices and troubleshooting tips tailored to specific applications. Collaborating with suppliers who offer training resources or installation support can further enhance the installation process, ensuring a more efficient and successful outcome.

Strategic Material Selection Guide for 14 gauge hardware cloth

What Are the Key Materials for 14 Gauge Hardware Cloth?

When selecting 14 gauge hardware cloth for various applications, understanding the materials used is crucial for ensuring performance, durability, and compliance with international standards. Below, we analyze four common materials used in the production of 14 gauge hardware cloth: galvanized steel, vinyl-coated wire, stainless steel, and aluminum. Each material has unique properties, advantages, and limitations that can significantly impact application suitability.

How Does Galvanized Steel Perform in 14 Gauge Hardware Cloth?

Galvanized steel is a popular choice for 14 gauge hardware cloth due to its excellent corrosion resistance and strength. The galvanization process involves coating the steel with zinc, which protects it from rust and extends its lifespan, especially in outdoor applications. This material can withstand various environmental conditions, making it suitable for agricultural, construction, and fencing applications.

Illustrative image related to 14 gauge hardware cloth

Pros:

– High durability and strength.

– Excellent corrosion resistance.

– Cost-effective compared to other materials.

Cons:

– Limited high-temperature tolerance.

– Can be prone to scratches that may expose the underlying steel.

For international buyers, galvanized steel complies with various standards such as ASTM A653 and EN 10244, ensuring quality and reliability.

What Advantages Does Vinyl-Coated Wire Offer for 14 Gauge Hardware Cloth?

Vinyl-coated wire adds an additional layer of protection to galvanized steel, enhancing its resistance to corrosion and providing a more aesthetically pleasing finish. This coating is particularly beneficial in applications where visual appeal is important, such as garden fencing or decorative enclosures.

Pros:

– Enhanced corrosion resistance due to the vinyl coating.

– Aesthetic appeal with various color options.

– Reduces the risk of cuts or injuries from sharp edges.

Illustrative image related to 14 gauge hardware cloth

Cons:

– Higher cost compared to standard galvanized wire.

– The coating may wear off over time, especially in high-traffic areas.

International buyers should consider compliance with local environmental regulations regarding plastic coatings, as some regions may have specific requirements.

How Does Stainless Steel Compare for 14 Gauge Hardware Cloth?

Stainless steel is renowned for its exceptional corrosion resistance and strength, making it ideal for harsh environments, including coastal areas and industrial applications. Its durability ensures a long service life, even when exposed to moisture and chemicals.

Pros:

– Superior corrosion resistance.

– High strength-to-weight ratio.

– Low maintenance requirements.

Cons:

– Higher upfront cost.

– More complex manufacturing process, which may lead to longer lead times.

For B2B buyers in regions with stringent quality standards, stainless steel hardware cloth often meets ASTM A240 and EN 10088 standards, ensuring compliance and reliability.

What Are the Benefits of Using Aluminum for 14 Gauge Hardware Cloth?

Aluminum is lightweight yet strong, making it an excellent choice for applications requiring easy handling and installation. It is also resistant to corrosion, particularly in non-saltwater environments, which can be advantageous for agricultural and residential uses.

Pros:

– Lightweight, making it easy to handle and install.

– Good corrosion resistance, especially in freshwater environments.

– Cost-effective for large-scale applications.

Illustrative image related to 14 gauge hardware cloth

Cons:

– Lower strength compared to steel options.

– Can be more susceptible to deformation under heavy loads.

International buyers should consider the specific application environment when choosing aluminum, as its performance can vary significantly based on exposure to different elements.

Summary Table of Material Selection for 14 Gauge Hardware Cloth

| Material | Typical Use Case for 14 gauge hardware cloth | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Fencing, agricultural applications | High durability and strength | Limited high-temperature tolerance | Low |

| Vinyl-Coated Wire | Garden fencing, decorative enclosures | Enhanced corrosion resistance | Higher cost, coating wear over time | Medium |

| Stainless Steel | Industrial applications, coastal environments | Superior corrosion resistance | Higher upfront cost, complex manufacturing | High |

| Aluminum | Residential uses, lightweight applications | Lightweight, easy to install | Lower strength, deformation risk | Medium |

This strategic material selection guide provides insights into the properties and considerations of various materials used in 14 gauge hardware cloth, helping international B2B buyers make informed decisions tailored to their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 14 gauge hardware cloth

What Are the Main Stages in the Manufacturing Process of 14 Gauge Hardware Cloth?

The manufacturing process of 14 gauge hardware cloth involves several critical stages, ensuring that the final product meets the stringent requirements of durability, strength, and corrosion resistance. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The process begins with the selection of high-quality steel wire, typically galvanized to enhance corrosion resistance. The wire is drawn to the desired gauge (14 gauge in this case), ensuring uniformity in diameter. Precise control during wire drawing is essential to maintain consistency, which is crucial for both strength and handling. -

Forming

Once the wire is prepared, it undergoes a forming process where it is cut to specific lengths and configured into a mesh pattern. The mesh openings, commonly 1/2 x 1 inch for 14 gauge hardware cloth, are created using automated machinery that ensures precise spacing and alignment. This stage may involve welding the wires at the intersections to create a robust structure, which enhances the overall strength of the mesh. -

Assembly

After forming, the mesh is assembled into rolls or sheets, depending on customer specifications. This may include cutting the mesh into smaller sections for easier handling and shipping. The assembly process is often automated, but manual checks are also employed to ensure accuracy and quality. -

Finishing

The final stage involves additional treatments, such as galvanization after welding (GAW), which provides a protective coating to prevent rust and corrosion. This process often involves dipping the finished product in molten zinc, ensuring that every part of the wire is covered. Some manufacturers may also apply a PVC coating for additional protection and aesthetic appeal.

How Is Quality Assurance Implemented in Manufacturing 14 Gauge Hardware Cloth?

Quality assurance (QA) is vital in the production of hardware cloth, particularly when catering to international markets. Manufacturers typically adhere to various international standards, such as ISO 9001, to ensure consistent quality throughout the production process.

-

What International Standards Should B2B Buyers Consider?

– ISO 9001: This standard focuses on quality management systems and is essential for ensuring that manufacturers consistently meet customer and regulatory requirements.

– CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

– API Standards: If the hardware cloth is used in specific industrial applications, adherence to American Petroleum Institute (API) standards may be required. -

What Are the Key Quality Control Checkpoints?

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): This involves ongoing checks during the manufacturing process to catch any defects early. Techniques such as visual inspections and measurements are commonly employed.

– Final Quality Control (FQC): Once the product is finished, a thorough inspection is conducted to verify that it meets all specifications and standards. This may include strength testing, corrosion resistance tests, and dimensional checks.

Which Common Testing Methods Are Used to Ensure Quality?

To ensure the durability and functionality of 14 gauge hardware cloth, several testing methods are commonly employed:

- Tensile Strength Testing: This measures the force required to pull the wire apart, ensuring it meets strength specifications.

- Corrosion Resistance Testing: Samples may undergo salt spray tests to evaluate their resistance to rust and corrosion over time.

- Mesh Opening Verification: Automated systems often measure the mesh openings to ensure they conform to specified dimensions, which is critical for their intended use.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, can take several steps to verify the quality control processes of potential suppliers:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. Buyers should request audit reports that detail compliance with international standards.

-

Request Certification Documentation: Suppliers should provide documentation of their compliance with relevant standards, such as ISO certifications, CE markings, and any industry-specific certifications.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures. This is particularly beneficial for buyers who may not have the resources to conduct on-site inspections themselves.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must be aware of specific nuances that can affect the quality of 14 gauge hardware cloth:

- Cultural Differences: Understanding local manufacturing practices and quality expectations is crucial. Buyers should be prepared to communicate their standards clearly and ensure that suppliers can meet them.

- Logistics and Transport Issues: The journey from the manufacturing facility to the buyer can affect product integrity. Buyers should discuss packaging and transport methods with suppliers to minimize damage during transit.

- Regulatory Compliance: Different regions may have varying regulations regarding materials used in construction or industrial applications. Buyers should verify that suppliers are aware of and compliant with these regulations.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their specific needs for 14 gauge hardware cloth.

Practical Sourcing Guide: A Step-by-Step Checklist for ’14 gauge hardware cloth’

Introduction

When sourcing 14 gauge hardware cloth, a systematic approach is essential for ensuring that you procure a product that meets your specific requirements while also aligning with your budget and timelines. This guide provides a step-by-step checklist to facilitate your purchasing process, helping you make informed decisions and minimize risks.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications required for your project. Consider factors such as:

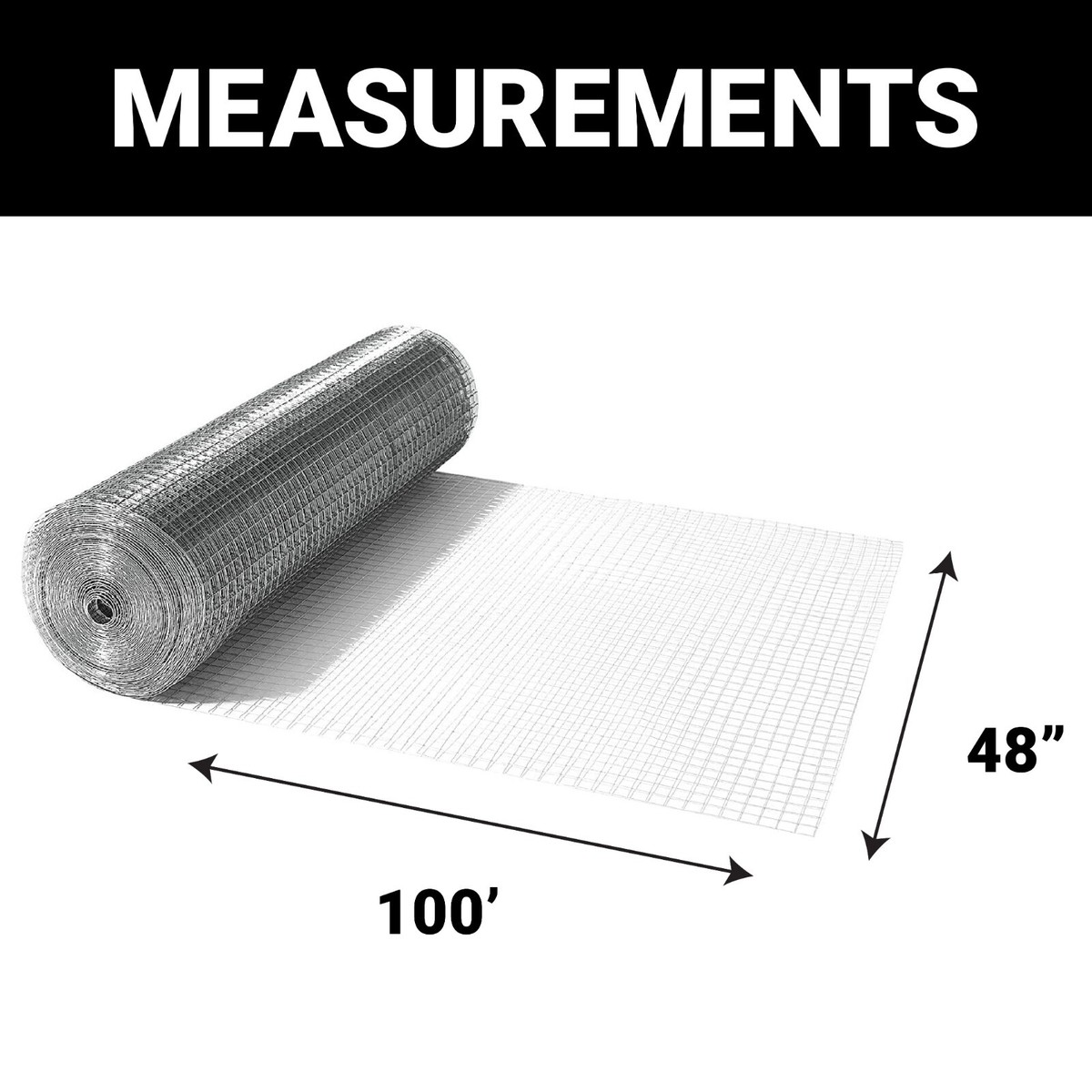

– Mesh Size: Common options include 1/2″ x 1″ or 1/4″ x 1/4″. Specify your needs based on intended applications like fencing, gardening, or construction.

– Material Type: Most hardware cloth is galvanized, but some options may have additional coatings for enhanced durability. Determine if you need a standard galvanized finish or a more specialized coating.

Step 2: Determine Your Quantity and Budget

Establishing the quantity required and your budget constraints is crucial to streamline the sourcing process. Keep in mind:

– Purchase Volume Discounts: Many suppliers offer tiered pricing; for example, buying in bulk can significantly reduce costs. Aim for quantities that allow you to take advantage of these savings.

– Shipping Costs: Factor in logistics, especially if ordering from international suppliers. Understand shipping terms and potential freight charges to avoid unexpected expenses.

Illustrative image related to 14 gauge hardware cloth

Step 3: Research Potential Suppliers

Thoroughly vet suppliers to ensure they can meet your requirements and maintain quality standards. Consider:

– Supplier Reputation: Look for reviews, testimonials, and case studies from other businesses in your region or industry. This insight can help gauge reliability.

– Certifications and Standards: Verify that suppliers comply with relevant industry standards and certifications, ensuring the quality and safety of the products.

Step 4: Request Samples

Before placing a large order, request samples of the hardware cloth to evaluate quality firsthand. This step is critical because:

– Material Assessment: Inspect the thickness, mesh size, and finish to ensure they meet your specifications. This can prevent costly mistakes later.

– Durability Testing: If possible, conduct tests to assess the material’s strength and resistance to corrosion, especially if it will be exposed to harsh environmental conditions.

Step 5: Negotiate Terms and Conditions

Once you identify a suitable supplier, discuss and negotiate the terms of your purchase. Key points to address include:

– Payment Terms: Understand the payment options available, including upfront payments, installments, or credit terms.

– Lead Times: Confirm production and shipping timelines to ensure they align with your project schedule. Ask about potential delays and how they handle them.

Step 6: Finalize the Order and Confirm Shipping Details

After reaching an agreement, finalize your order and confirm all shipping details. Pay attention to:

– Order Confirmation: Ensure that all specifications, quantities, and prices are accurately reflected in the order confirmation.

– Tracking Information: Request tracking details once the order is shipped to monitor the delivery process and address any issues promptly.

Illustrative image related to 14 gauge hardware cloth

Step 7: Evaluate Post-Purchase Performance

After receiving your order, evaluate the hardware cloth’s performance against your expectations. This review will help inform future sourcing decisions and supplier relationships. Consider:

– Quality Check: Inspect the product for any defects or discrepancies from your order.

– Supplier Feedback: Provide feedback to the supplier based on your experience, which can foster a stronger business relationship and improve future transactions.

By following these steps, you can confidently source 14 gauge hardware cloth that meets your project needs while ensuring quality and cost-effectiveness.

Comprehensive Cost and Pricing Analysis for 14 gauge hardware cloth Sourcing

What Are the Key Cost Components in 14 Gauge Hardware Cloth Sourcing?

When sourcing 14 gauge hardware cloth, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

- Materials: The cost of raw materials, such as galvanized steel wire, significantly influences the final price. The quality of the steel and the galvanization process (e.g., Galvanized After Welding or GAW) affects durability and, consequently, pricing.

- Labor: Labor costs encompass wages for production staff, as well as overhead for training and skilled labor, especially for quality control measures.

- Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment depreciation, and maintenance. Efficient manufacturing processes can reduce overhead costs.

- Tooling: The initial investment in machinery and tools for producing hardware cloth can be significant. Tooling costs may be amortized over larger production runs, impacting unit costs.

- Quality Control: Rigorous QC processes ensure that the finished product meets specifications, which can add to costs. Certifications for quality assurance may also be necessary for certain markets.

- Logistics: Shipping costs are influenced by the weight and volume of the order, as well as the distance to the destination. Bulk orders can often lead to reduced shipping rates.

- Margin: Suppliers typically add a margin to cover their operational costs and profit, which can vary based on market conditions and competition.

How Do Price Influencers Affect the Cost of 14 Gauge Hardware Cloth?

Several factors can influence the pricing of 14 gauge hardware cloth, particularly for B2B buyers operating internationally.

- Volume and Minimum Order Quantity (MOQ): Larger orders generally lead to lower per-unit prices due to economies of scale. Suppliers often provide tiered pricing; for instance, a buyer might receive a significant discount when purchasing 100 feet or more.

- Specifications and Customization: Customized mesh sizes or coatings can increase costs. Buyers should specify their requirements clearly to avoid unexpected charges.

- Material Quality and Certifications: Higher-quality materials or specific certifications (e.g., ISO or ASTM compliance) can command a premium price, reflecting their reliability and performance.

- Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a track record of quality may charge more but offer better service and assurance.

- Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting overall costs.

What Are Some Effective Buyer Tips for Sourcing 14 Gauge Hardware Cloth?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

- Negotiate with Suppliers: Leverage volume purchases to negotiate better pricing. Building long-term relationships can lead to favorable terms and discounts.

- Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs associated with maintenance, durability, and potential replacements. A higher initial investment in quality may lead to lower TCO.

- Be Aware of Pricing Nuances: Fluctuations in raw material prices or shipping costs can affect pricing. Stay informed about market trends to time purchases strategically.

- Request Multiple Quotes: Obtaining quotes from various suppliers can provide a clearer picture of the market rate and help identify the best deal.

- Understand Shipping and Customs Fees: Factor in all logistics costs, including customs duties and taxes, which can significantly impact the final price.

Conclusion

Sourcing 14 gauge hardware cloth requires a nuanced understanding of cost components and pricing influencers. By considering these factors and employing effective negotiation strategies, international B2B buyers can achieve optimal pricing while ensuring quality and compliance with their specific needs. Always approach sourcing with a clear understanding of the total cost implications and market dynamics to maximize value.

Alternatives Analysis: Comparing 14 gauge hardware cloth With Other Solutions

In today’s competitive marketplace, B2B buyers often seek alternatives to traditional solutions to meet their operational needs. When considering 14 gauge hardware cloth, it’s crucial to evaluate other viable options that may provide similar benefits or address specific requirements more effectively. This section will compare 14 gauge hardware cloth with two alternative solutions: 16 gauge vinyl-coated welded wire mesh and stainless steel wire mesh.

| Comparison Aspect | 14 Gauge Hardware Cloth | 16 Gauge Vinyl-Coated Welded Wire Mesh | Stainless Steel Wire Mesh |

|---|---|---|---|

| Performance | High tensile strength; effective for various applications including fencing and gardening | Durable with a double coating for enhanced rust resistance; suitable for decorative and functional uses | Exceptional durability and corrosion resistance; ideal for harsh environments |

| Cost | Generally economical, around $4.06 per foot for bulk purchases | Higher cost, ranging from $62.69 to $455.99 depending on size | More expensive due to material quality; price varies widely based on specifications |

| Ease of Implementation | Easy to cut and shape; requires minimal tools for installation | Simple installation; pre-coated for quick use | Requires specialized tools for cutting and installation; heavier material |

| Maintenance | Low maintenance; galvanized coating protects against rust | Low maintenance; vinyl coating provides added protection | Minimal maintenance; highly resistant to corrosion but may require cleaning |

| Best Use Case | Versatile; ideal for garden fencing, animal enclosures, and DIY projects | Best for decorative applications, garden fencing, and areas needing aesthetic appeal | Suitable for industrial applications, outdoor furniture, and environments with high corrosion risk |

What Are the Advantages and Disadvantages of 16 Gauge Vinyl-Coated Welded Wire Mesh?

16 gauge vinyl-coated welded wire mesh offers a robust alternative to 14 gauge hardware cloth. Its double coating provides enhanced rust resistance, making it an excellent choice for outdoor applications where aesthetics matter. However, this solution tends to be more expensive, which may deter budget-conscious buyers. While installation is straightforward, the vinyl coating can limit certain applications where high heat exposure is expected.

Illustrative image related to 14 gauge hardware cloth

How Does Stainless Steel Wire Mesh Compare to 14 Gauge Hardware Cloth?

Stainless steel wire mesh is recognized for its unparalleled durability and corrosion resistance, making it ideal for harsh environments such as coastal areas or industrial settings. Its strength ensures longevity, but the cost can be significantly higher compared to 14 gauge hardware cloth. Additionally, installation may require specialized tools and expertise, which could increase overall project costs. However, for buyers prioritizing long-term investment and minimal maintenance, stainless steel is often the preferred choice.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right material depends on various factors, including the specific application, budget constraints, and environmental conditions. For those looking for a cost-effective and versatile solution, 14 gauge hardware cloth is an excellent option. However, if aesthetics and additional rust protection are paramount, 16 gauge vinyl-coated welded wire mesh may be more appropriate. Conversely, for environments requiring maximum durability and resistance to corrosion, stainless steel wire mesh is likely the best choice. Ultimately, buyers should assess their unique needs and consider the trade-offs of each solution before making a decision.

Essential Technical Properties and Trade Terminology for 14 gauge hardware cloth

What are the Key Technical Properties of 14 Gauge Hardware Cloth?

When selecting 14 gauge hardware cloth, understanding its technical specifications is crucial for ensuring suitability for your intended application. Here are some essential properties to consider:

-

Material Grade

Most 14 gauge hardware cloth is made from galvanized steel, which provides excellent resistance to corrosion and rust. The galvanization process often occurs after welding (GAW), enhancing the cloth’s durability. For B2B buyers, selecting a high-grade material ensures longevity and reduces maintenance costs, particularly in outdoor or industrial environments. -

Wire Gauge

The gauge of the wire (14 in this case) indicates its thickness. A lower gauge number signifies a thicker wire, which typically translates to higher strength and durability. For applications requiring structural integrity, such as fencing or reinforcement, opting for 14 gauge is advantageous. It balances strength with weight, making it easier to handle and install. -

Mesh Size

The mesh size, often expressed in inches (e.g., 1/2″ x 1″), defines the openings between the wires. This specification is vital for determining the cloth’s suitability for various uses—whether for pest control, security, or containment. For example, smaller mesh sizes can prevent small animals from passing through, making it ideal for gardening or poultry enclosures. -

Width and Height

Common widths for hardware cloth can vary, with 24 inches being a standard size. The height impacts the application area, especially in fencing or barriers. Knowing the dimensions helps B2B buyers calculate the material required for specific projects, ensuring they order the correct amount without excess or shortage. -

Finish Type

The finish type, whether galvanized, vinyl-coated, or plain, affects both appearance and functionality. A vinyl coating can enhance resistance to environmental factors while providing aesthetic appeal. B2B buyers should consider the finish based on the end-use environment, as it can impact both performance and longevity. -

Tensile Strength

This property measures the material’s ability to withstand tension without breaking. For applications involving loads or stress, understanding the tensile strength helps ensure that the hardware cloth will perform adequately under operational conditions, thus safeguarding investments.

What Are Common Trade Terms Related to 14 Gauge Hardware Cloth?

Familiarity with industry jargon is essential for effective communication in B2B transactions. Here are key terms you should know:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable sources for their hardware cloth needs. -

MOQ (Minimum Order Quantity)

MOQ defines the minimum number of units a supplier is willing to sell. For B2B buyers, knowing the MOQ helps in planning inventory and managing costs effectively. Suppliers may have varying MOQs based on production capabilities and market demand. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific quantities of products. For buyers, submitting an RFQ is an effective way to compare prices and negotiate terms, ensuring they receive competitive offers. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international contracts to clarify the responsibilities of buyers and sellers. Understanding Incoterms helps buyers manage logistics, shipping costs, and risks associated with international transactions. -

Lead Time

This refers to the time taken from placing an order to the delivery of goods. For B2B buyers, knowing the lead time is crucial for project planning and inventory management, ensuring that operations run smoothly without delays. -

Certification Standards

Many hardware cloth products may need to meet specific industry standards or certifications (e.g., ASTM). Familiarity with these standards ensures that the products meet safety and quality expectations, which is particularly important in regulated industries.

By understanding these properties and terms, B2B buyers can make informed decisions when sourcing 14 gauge hardware cloth, ensuring they select the right products for their applications.

Navigating Market Dynamics and Sourcing Trends in the 14 gauge hardware cloth Sector

What Are the Current Market Dynamics Influencing 14 Gauge Hardware Cloth?

The global market for 14 gauge hardware cloth is experiencing significant growth, driven by increasing demand across various sectors, including construction, agriculture, and industrial applications. In regions such as Africa, South America, the Middle East, and Europe, buyers are increasingly looking for versatile and durable materials that can withstand harsh environmental conditions. The trend toward urbanization in developing nations is propelling the construction industry, leading to a heightened need for protective materials like hardware cloth.

Emerging technologies in manufacturing, such as automated welding and advanced galvanization processes, are improving the quality and durability of hardware cloth. These innovations allow suppliers to offer products that meet high standards while also reducing production costs. Furthermore, the rise of e-commerce platforms has streamlined the procurement process, enabling international buyers to easily compare prices and specifications, facilitating smarter purchasing decisions.

Additionally, the impact of geopolitical factors, such as trade agreements and tariffs, can significantly influence sourcing strategies. For instance, buyers should stay informed about the regulatory environment affecting imports and exports in their respective regions, as these can alter supply chain dynamics and pricing structures.

How Is Sustainability Influencing Sourcing Decisions for 14 Gauge Hardware Cloth?

Sustainability has become a critical focus for international B2B buyers, particularly as environmental concerns rise globally. The production of 14 gauge hardware cloth can have substantial environmental impacts, particularly when sourced from regions with lax regulations. As a result, businesses are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, including responsible sourcing of raw materials and eco-friendly manufacturing processes.

Ethical supply chains are gaining traction, with buyers favoring manufacturers who can provide transparency regarding their sourcing practices. Certifications such as ISO 14001 for environmental management systems or those indicating the use of recycled materials can serve as indicators of a supplier’s commitment to sustainability. Moreover, the demand for green-certified materials is influencing product offerings, prompting manufacturers to explore alternative materials and coatings that minimize environmental impact.

Investing in sustainable hardware cloth not only aligns with corporate social responsibility goals but also enhances brand reputation among environmentally conscious consumers. Therefore, B2B buyers are encouraged to conduct thorough assessments of potential suppliers’ sustainability credentials before making purchasing decisions.

What Is the Historical Context of 14 Gauge Hardware Cloth in B2B Markets?

The use of hardware cloth dates back several decades, originally emerging as a practical solution for various agricultural and construction needs. Initially, it was primarily manufactured from mild steel and used in applications such as animal enclosures and garden fencing. Over time, advancements in galvanization techniques have led to the development of more durable and rust-resistant products, such as those made from 14 gauge wire.

In the past few years, the market has seen a shift towards more specialized applications, including the use of hardware cloth in landscaping, architectural designs, and even as decorative elements in modern construction. This evolution reflects the increasing versatility of hardware cloth and its ability to meet the changing demands of international B2B buyers. As the market continues to grow, understanding this historical context can aid buyers in recognizing the value and potential applications of 14 gauge hardware cloth in contemporary projects.

Frequently Asked Questions (FAQs) for B2B Buyers of 14 gauge hardware cloth

-

How do I determine the appropriate gauge of hardware cloth for my project?

To choose the right gauge of hardware cloth, consider the specific requirements of your application. A 14 gauge wire is robust and suitable for heavy-duty tasks such as fencing, animal enclosures, and construction reinforcement. Evaluate factors like the types of animals or materials you need to contain, environmental conditions, and the expected load. Consulting with suppliers about your project’s specifics can also provide valuable insights into the best gauge to use. -

What factors should I consider when sourcing 14 gauge hardware cloth internationally?

When sourcing internationally, consider the supplier’s reputation, product quality, and compliance with international standards. Look for certifications that ensure the material meets your country’s regulations. Additionally, assess logistics capabilities, including shipping times and costs, as well as customs duties that may apply. Building relationships with reliable suppliers can also enhance communication and streamline the procurement process. -

What customization options are available for 14 gauge hardware cloth?

Many suppliers offer customization options for 14 gauge hardware cloth, including variations in mesh size, roll length, and coating types (e.g., galvanized or vinyl-coated). Customization can enhance the material’s suitability for specific applications, such as enhancing rust resistance or aesthetic appeal. When inquiring, provide detailed specifications of your needs to ensure the supplier can meet your requirements effectively. -

What are the minimum order quantities (MOQ) for purchasing 14 gauge hardware cloth?

Minimum order quantities can vary significantly among suppliers. Typically, MOQs for 14 gauge hardware cloth may range from a few rolls to several hundred square feet, depending on the manufacturer. It’s advisable to confirm with potential suppliers about their MOQ policies. Some suppliers may offer flexibility for smaller orders, especially if you are a first-time buyer or establishing a long-term partnership. -

What payment terms should I expect when ordering 14 gauge hardware cloth?

Payment terms can vary by supplier and may include options such as upfront payments, net 30/60 terms, or letters of credit, especially for international transactions. Discussing payment methods like wire transfers, credit cards, or trade financing options is essential. Ensure that you understand any currency conversion fees or transaction charges that may apply, particularly when dealing with suppliers in different countries. -

How can I ensure the quality of the 14 gauge hardware cloth I am purchasing?

To ensure quality, request product samples before placing a large order. Look for certifications or compliance with international standards, such as ASTM or ISO, which indicate the material’s reliability. Additionally, inquire about the supplier’s quality control processes and testing methods. Reviews and testimonials from other buyers can also provide insights into the quality of the products offered. -

What shipping options are available for international orders of 14 gauge hardware cloth?

Shipping options for international orders typically include air freight and sea freight, with sea freight being more cost-effective for large quantities. Discuss with your supplier about their logistics partners and shipping methods, as well as estimated delivery times. Consider the total shipping costs, including insurance and customs duties, which can impact your overall budget. -

Are there any specific regulations I need to be aware of when importing 14 gauge hardware cloth?

Yes, importing hardware cloth may be subject to specific regulations, including safety standards and tariffs imposed by your country. Familiarize yourself with local import regulations, including potential restrictions or certifications required for construction materials. It may also be beneficial to consult with a customs broker to navigate the import process smoothly and avoid delays.

Top 3 14 Gauge Hardware Cloth Manufacturers & Suppliers List

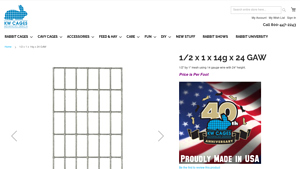

1. KWCages – Galvanized Wire Mesh Roll

Domain: kwcages.com

Registered: 1998 (27 years)

Introduction: {“SKU”:”1552″,”Price_Per_Foot”:”$6.93″,”Bulk_Pricing”:”Buy 10 for $5.39 each and save 22%, Buy 100 for $4.06 each and save 41%”,”Mesh_Size”:”1/2 x 1 inches”,”Gauge”:”14″,”Height”:”24 inches”,”Material”:”Galvanized After Welding (GAW)”,”Weight”:”1.000000 lbs”,”Description”:”Super smooth, flat roll out. Premium galvanized after weld, ultra high quality control standards. Full rolls can be cut in hal…

2. McNICHOLS® – Metal Wire Mesh

Domain: mcnichols.com

Registered: 1996 (29 years)

Introduction: This company, McNICHOLS® – Metal Wire Mesh, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Louis Page – Galvanized Before Welded Wire Mesh

Domain: louispage.com

Registered: 1999 (26 years)

Introduction: Product: Galvanized Before Welded Wire Mesh, 14 gauge

Serving Regions: USA & Canada

Current Pricing Valid Through: October 1, 2024

Contact: 978-486-3116

Product Types: GBW (Galvanized Before Welded) available in various gauges (16, 14, 12 1/2)

Mesh Sizes Available: 1″ x 1″, 1″ x 2″, 2″ x 4″

Cage Quality: Smooth finish, consistent mesh openings

Weight and SKU Information:

– 1″ x 1″ mesh:

– 18″ x …

Strategic Sourcing Conclusion and Outlook for 14 gauge hardware cloth

In summary, strategic sourcing for 14 gauge hardware cloth presents a valuable opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. The versatility and durability of 14 gauge hardware cloth make it an essential material for various applications, from agricultural needs to construction projects. By leveraging bulk purchasing strategies, buyers can significantly reduce costs while ensuring high-quality materials that meet stringent industry standards.

Investing in a reliable supplier with a strong track record in quality control and logistics can enhance supply chain efficiency. The availability of galvanized options further ensures longevity and resistance to harsh environmental conditions, which is particularly beneficial for projects in regions with varying climates.

As the demand for construction and agricultural infrastructure continues to rise globally, now is the ideal time to engage with suppliers who can meet your needs with competitive pricing and flexible shipping options. Embrace the potential of 14 gauge hardware cloth in your upcoming projects and establish partnerships that will drive growth and innovation in your business.

Illustrative image related to 14 gauge hardware cloth

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.