Top 6 Coaster Wheel Suppliers (And How to Choose)

Introduction: Navigating the Global Market for coaster wheel

Navigating the complexities of sourcing coaster wheels can be a daunting challenge for international B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. The need for reliable, high-quality coaster wheels that suit specific applications—ranging from industrial manufacturing to healthcare equipment—is paramount. This guide serves as a comprehensive resource, addressing critical aspects such as types of coaster wheels, their various applications, supplier vetting processes, and cost considerations.

In today’s global marketplace, where product quality and supplier reliability can significantly impact operational efficiency, having the right information is essential for informed purchasing decisions. This guide empowers B2B buyers by offering actionable insights into the selection process, enabling them to navigate the nuances of sourcing coaster wheels tailored to their unique requirements. Whether you are in Vietnam seeking durable solutions for automotive applications or in Brazil looking for specialized wheels for healthcare equipment, this guide will provide the necessary tools and knowledge to make confident purchasing choices. By understanding the landscape of coaster wheels, buyers can ensure they meet their operational needs while also optimizing their supply chain for quality and efficiency.

Understanding coaster wheel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Coaster Wheels | Simple design, typically made from rubber or polyurethane, with a hub for brake integration. | General use in bicycles, light-duty carts, and furniture. | Pros: Cost-effective, versatile. Cons: Limited load capacity. |

| Heavy-Duty Coaster Wheels | Enhanced durability, larger diameter, and reinforced materials for increased weight capacity. | Industrial carts, warehouse equipment, and heavy machinery. | Pros: High load capacity, long-lasting. Cons: Higher cost. |

| Coaster Brake Wheels | Integrated braking mechanism, often used in bicycles, offering better control. | Cycling, recreational vehicles, and specialized carts. | Pros: Improved safety, control. Cons: More complex assembly. |

| Swivel Coaster Wheels | Ability to pivot, allowing for greater maneuverability in tight spaces. | Medical equipment, office furniture, and retail displays. | Pros: Enhanced mobility, ease of use. Cons: Potential for instability under heavy loads. |

| Specialty Coaster Wheels | Customizable features such as color, material, and size for niche markets. | Vintage restoration, custom builds, and specialized applications. | Pros: Tailored solutions, aesthetic appeal. Cons: Longer lead times, potentially higher prices. |

What Are Standard Coaster Wheels and Where Are They Used?

Standard coaster wheels are characterized by their straightforward design, typically featuring a rubber or polyurethane composition that offers a good balance of grip and durability. These wheels are commonly found in bicycles, light-duty carts, and furniture applications. When purchasing, buyers should consider the wheel diameter and load capacity to ensure they meet their operational needs. Their cost-effectiveness makes them an attractive option for businesses looking for versatile solutions without a hefty investment.

How Do Heavy-Duty Coaster Wheels Differ from Standard Options?

Heavy-duty coaster wheels are designed for more demanding applications, featuring larger diameters and reinforced materials that allow them to handle increased weight capacities. They are primarily used in industrial carts, warehouse equipment, and heavy machinery. Buyers should focus on load ratings and material specifications to ensure these wheels can withstand their specific operational environments. While they come at a higher price point, their durability often justifies the investment over time.

Why Choose Coaster Brake Wheels for Enhanced Control?

Coaster brake wheels incorporate an integrated braking mechanism that provides better control, making them popular in bicycles and recreational vehicles. These wheels allow for smoother stopping and enhanced safety, which is crucial in high-traffic environments. When considering these wheels, businesses should evaluate the compatibility with existing equipment and the complexity of installation. While they may require more assembly effort, the safety benefits can significantly outweigh these considerations.

What Are the Advantages of Swivel Coaster Wheels in Business?

Swivel coaster wheels are designed to pivot, offering enhanced maneuverability, especially in tight spaces. They are ideal for applications such as medical equipment, office furniture, and retail displays. Buyers should assess the wheel’s swivel mechanism and locking capabilities to ensure stability under load. While these wheels provide superior mobility, they may introduce some instability when heavily loaded, so careful selection is essential.

How Do Specialty Coaster Wheels Cater to Niche Markets?

Specialty coaster wheels offer customizable features such as color, material, and size, making them suitable for niche markets like vintage restoration and custom builds. These wheels allow businesses to create tailored solutions that meet specific aesthetic or functional requirements. However, buyers should be aware of longer lead times and potentially higher prices associated with custom orders. These factors should be weighed against the unique value that specialty wheels can bring to their projects.

Key Industrial Applications of coaster wheel

| Industry/Sector | Specific Application of Coaster Wheel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Assembly line carts for part transportation | Increases efficiency and reduces manual handling risks | Durability, load capacity, and compatibility with existing systems |

| Healthcare/Medical | Mobile medical equipment and carts | Enhances mobility and ensures quick access to equipment | Hygiene standards, wheel material, and locking mechanisms |

| Industrial Manufacturing | Material handling trolleys and equipment | Streamlines operations and improves safety | Weight tolerance, wheel size, and environmental resistance |

| Logistics and Warehousing | Shipping and storage carts for inventory management | Optimizes space and improves workflow efficiency | Maneuverability, wheel type (swivel or rigid), and load capacity |

| Retail and Hospitality | Shopping carts and service carts in stores and hotels | Improves customer experience and operational efficiency | Aesthetic options, wheel noise levels, and ease of maintenance |

How Are Coaster Wheels Used in Automotive Manufacturing?

In automotive manufacturing, coaster wheels are pivotal for assembly line carts that transport parts and tools. These wheels enhance mobility, allowing for smooth movement along the production floor, which minimizes downtime and increases productivity. Buyers in this sector must consider durability and load capacity, ensuring that the wheels can withstand heavy components while maintaining optimal performance. Additionally, compatibility with existing systems is crucial for seamless integration into current workflows.

What Role Do Coaster Wheels Play in Healthcare Settings?

In healthcare and medical environments, coaster wheels are essential for mobile medical equipment, such as carts and trolleys used for transporting supplies and patients. Their design facilitates easy maneuvering in tight spaces, which is vital in emergency situations. The value lies in improved access to equipment and a reduction in the risk of injuries associated with manual handling. Buyers should prioritize hygiene standards, selecting materials that can withstand frequent cleaning, as well as reliable locking mechanisms to prevent unintended movement.

How Are Coaster Wheels Beneficial in Industrial Manufacturing?

In the industrial manufacturing sector, coaster wheels are commonly used in material handling trolleys and equipment. They help streamline operations by enabling the easy movement of heavy materials across the factory floor, thus enhancing safety and operational efficiency. When sourcing these wheels, businesses must focus on weight tolerance and wheel size to match specific applications, as well as environmental resistance to withstand harsh working conditions.

Why Are Coaster Wheels Important in Logistics and Warehousing?

Coaster wheels play a critical role in logistics and warehousing by facilitating the use of shipping and storage carts for inventory management. This application helps optimize space and improve workflow efficiency, allowing for quicker access to products. Buyers should pay attention to maneuverability, opting for swivel or rigid wheels based on the layout of their facilities, and ensure that the load capacity meets their operational requirements.

How Do Coaster Wheels Enhance Retail and Hospitality Experiences?

In the retail and hospitality sectors, coaster wheels are used in shopping carts and service carts, enhancing customer experience by improving the ease of transporting goods. These wheels contribute to operational efficiency by allowing staff to move items quickly and quietly. When sourcing, businesses should consider aesthetic options that align with their branding, as well as the noise levels produced by the wheels during use, ensuring a pleasant environment for customers.

3 Common User Pain Points for ‘coaster wheel’ & Their Solutions

Scenario 1: Navigating Wheel Compatibility Issues

The Problem: One of the most common challenges B2B buyers face with coaster wheels is ensuring compatibility with existing equipment. With various specifications such as hub spacing, axle diameter, and weight capacities, buyers often find themselves confused about which wheels will seamlessly integrate into their systems. This lack of clarity can lead to costly errors, wasted time, and operational downtime if the wrong wheel is ordered.

The Solution: To avoid compatibility issues, it’s essential to conduct a thorough assessment of the existing equipment before making a purchase. Buyers should gather detailed specifications such as hub spacing, axle dimensions, and load requirements. Once this information is compiled, consult with manufacturers or suppliers who specialize in coaster wheels to confirm compatibility. Many suppliers offer customized solutions or alternative products that meet specific needs. Additionally, buyers should consider opting for suppliers that provide a comprehensive range of options and can offer expert advice on selecting the right wheel for their applications. Implementing a checklist during the ordering process can also help ensure that all specifications are met, reducing the risk of errors.

Scenario 2: Dealing with Durability Concerns in Harsh Environments

The Problem: In industries such as manufacturing or healthcare, coaster wheels are often subjected to harsh conditions, including heavy loads, dirt, and fluctuating temperatures. Buyers frequently express concerns regarding the durability of wheels, as subpar products can lead to frequent replacements and increased operational costs. This is particularly critical in environments where equipment reliability is paramount.

The Solution: To enhance durability, buyers should prioritize wheels made from high-quality materials designed for specific environmental challenges. For instance, polyurethane wheels are known for their resistance to wear and tear, making them suitable for heavy-duty applications. When sourcing coaster wheels, inquire about the material properties, weight ratings, and load capacity. Additionally, consider investing in wheels that feature sealed bearings to prevent dust and debris from causing damage. Establishing a routine maintenance schedule, including cleaning and inspecting wheels regularly, can extend their lifespan significantly. Buyers should also seek recommendations from suppliers who understand the specific demands of their industry and can suggest products tailored to withstand harsh conditions.

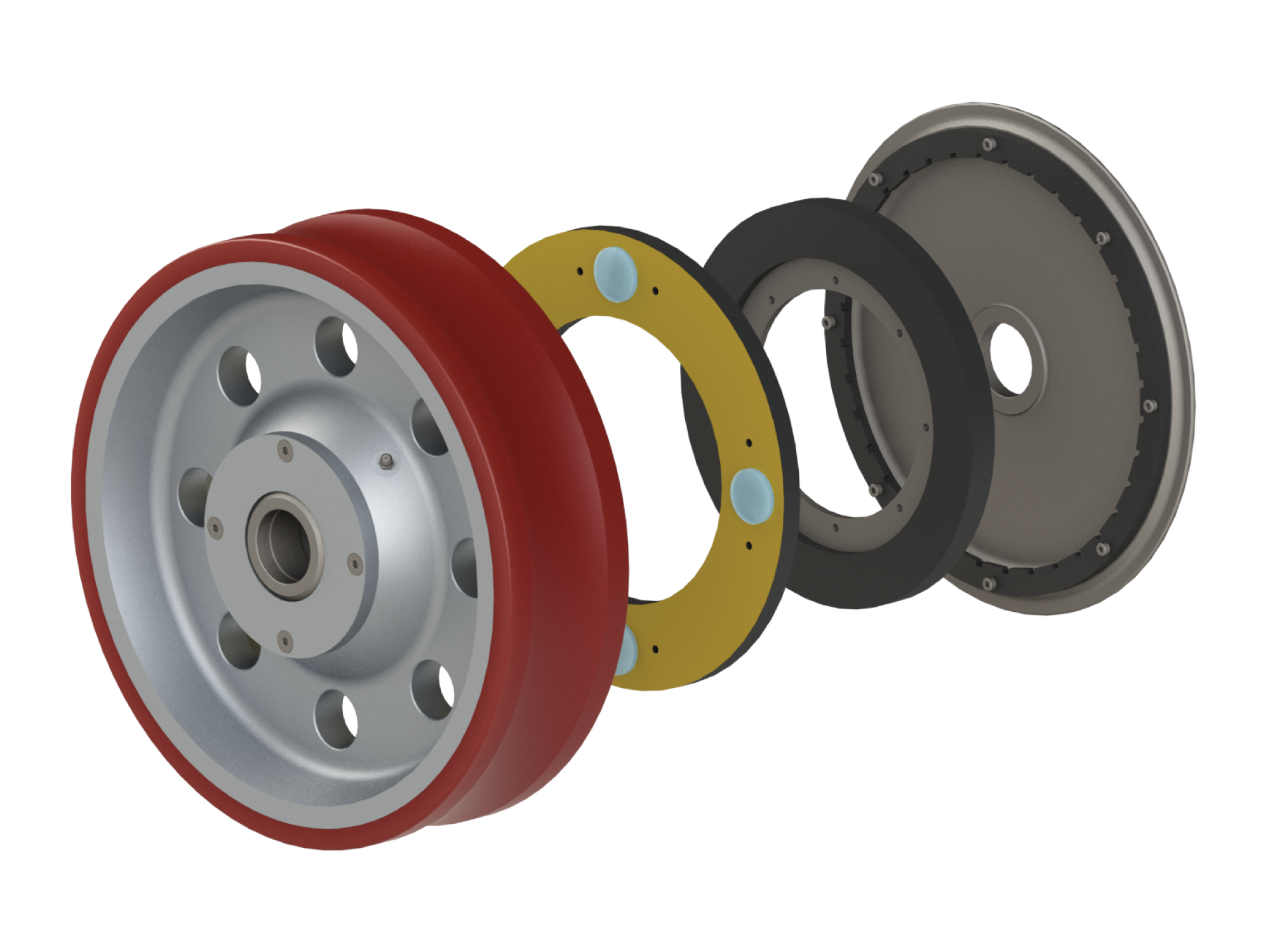

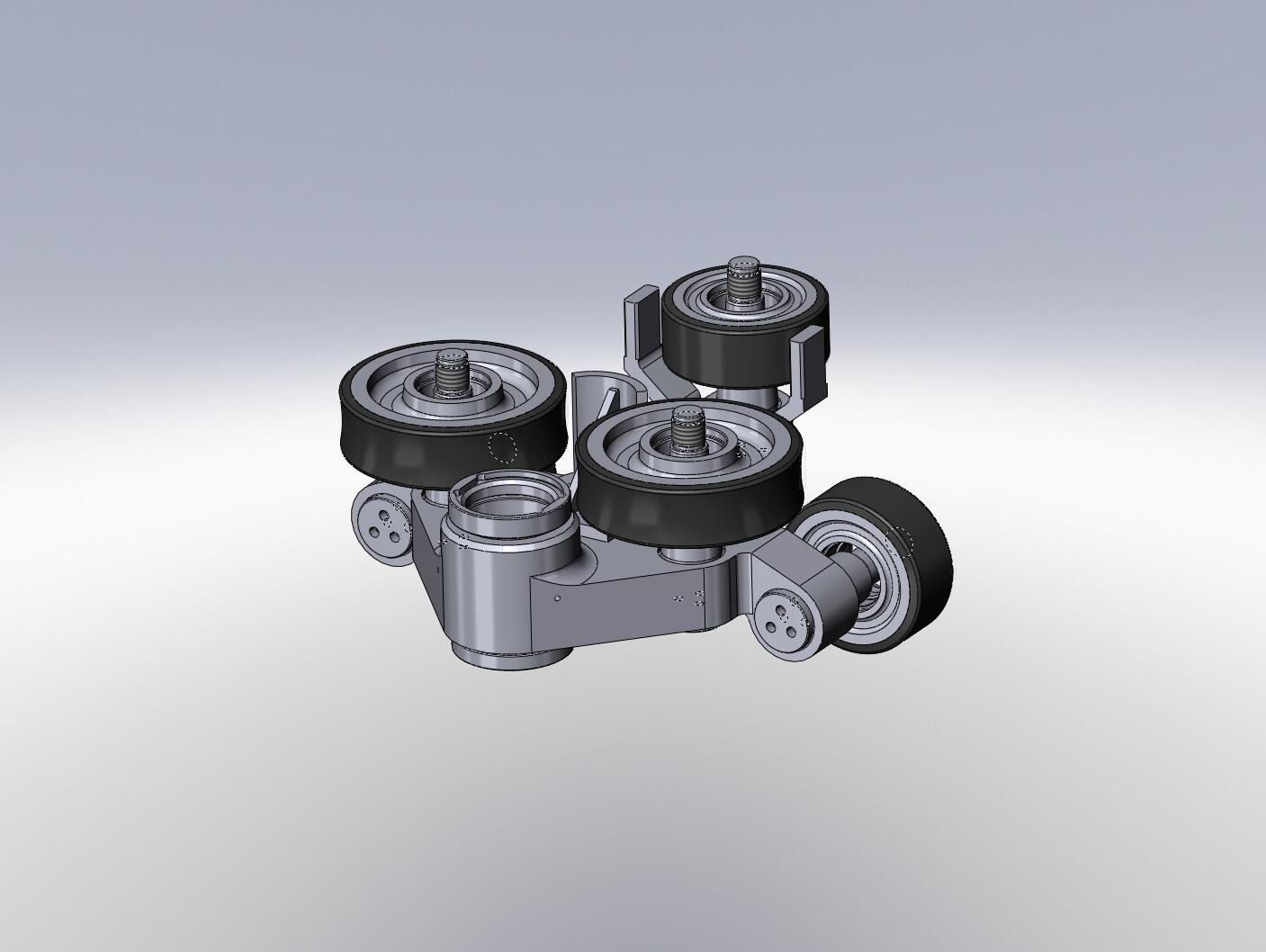

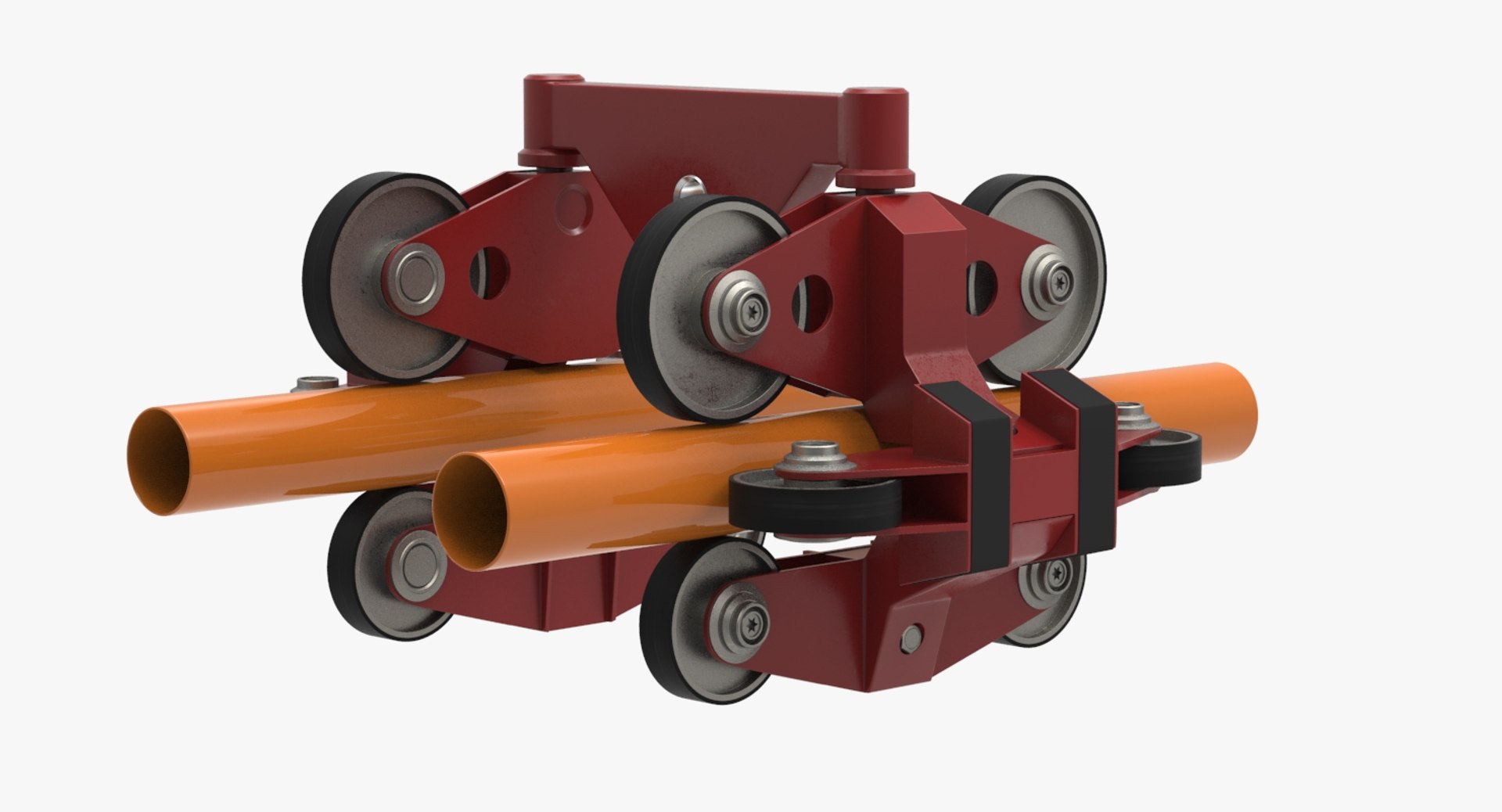

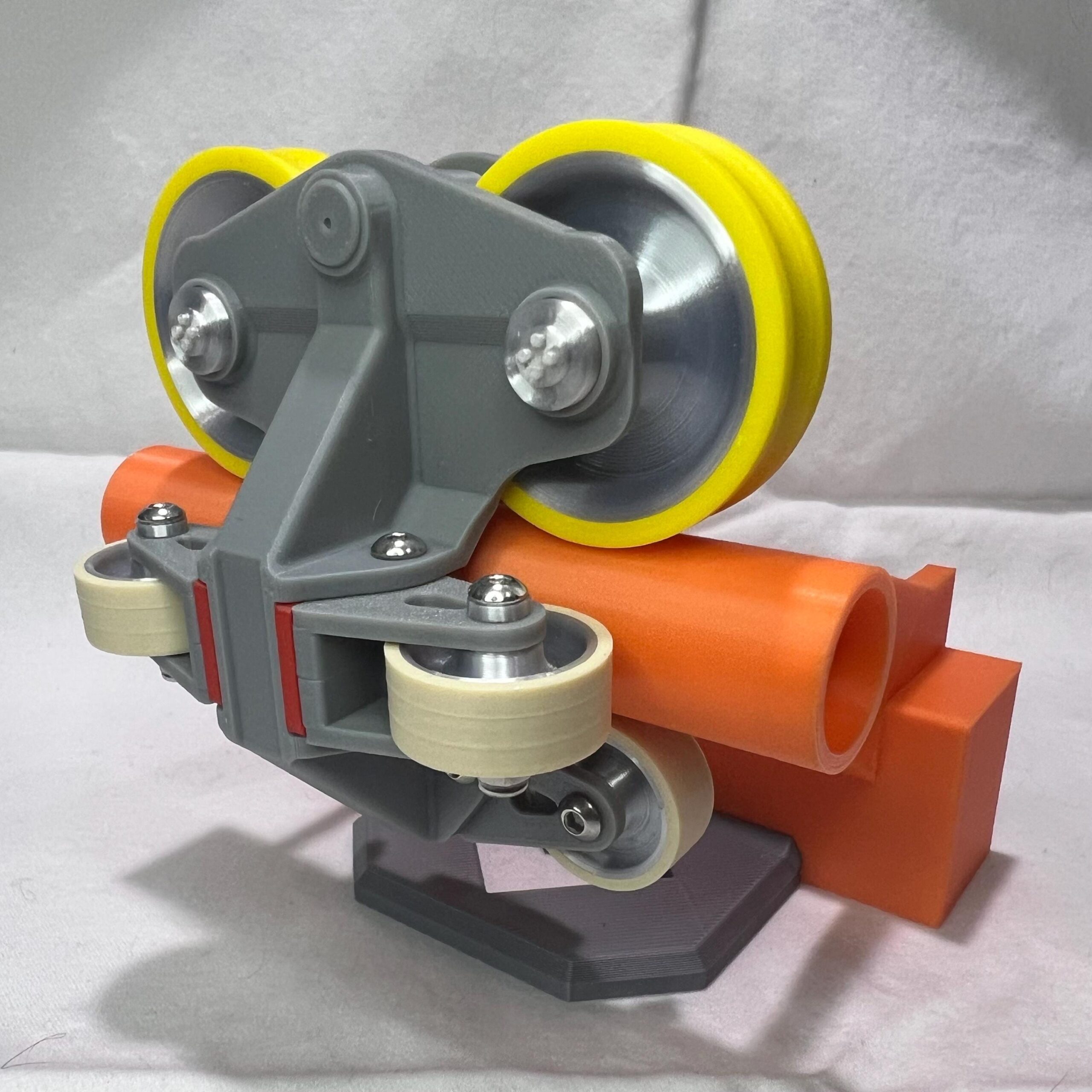

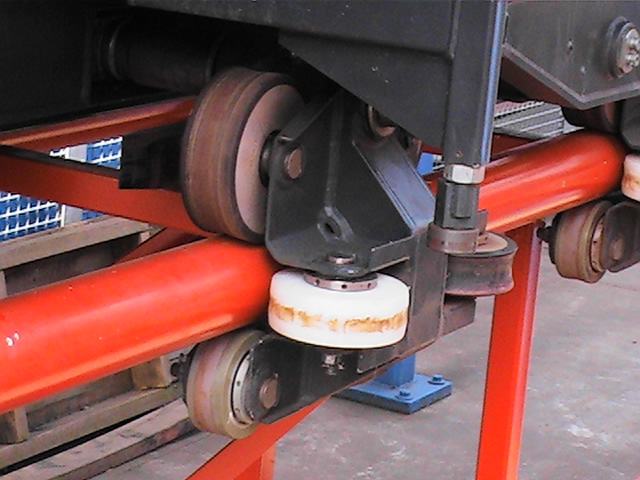

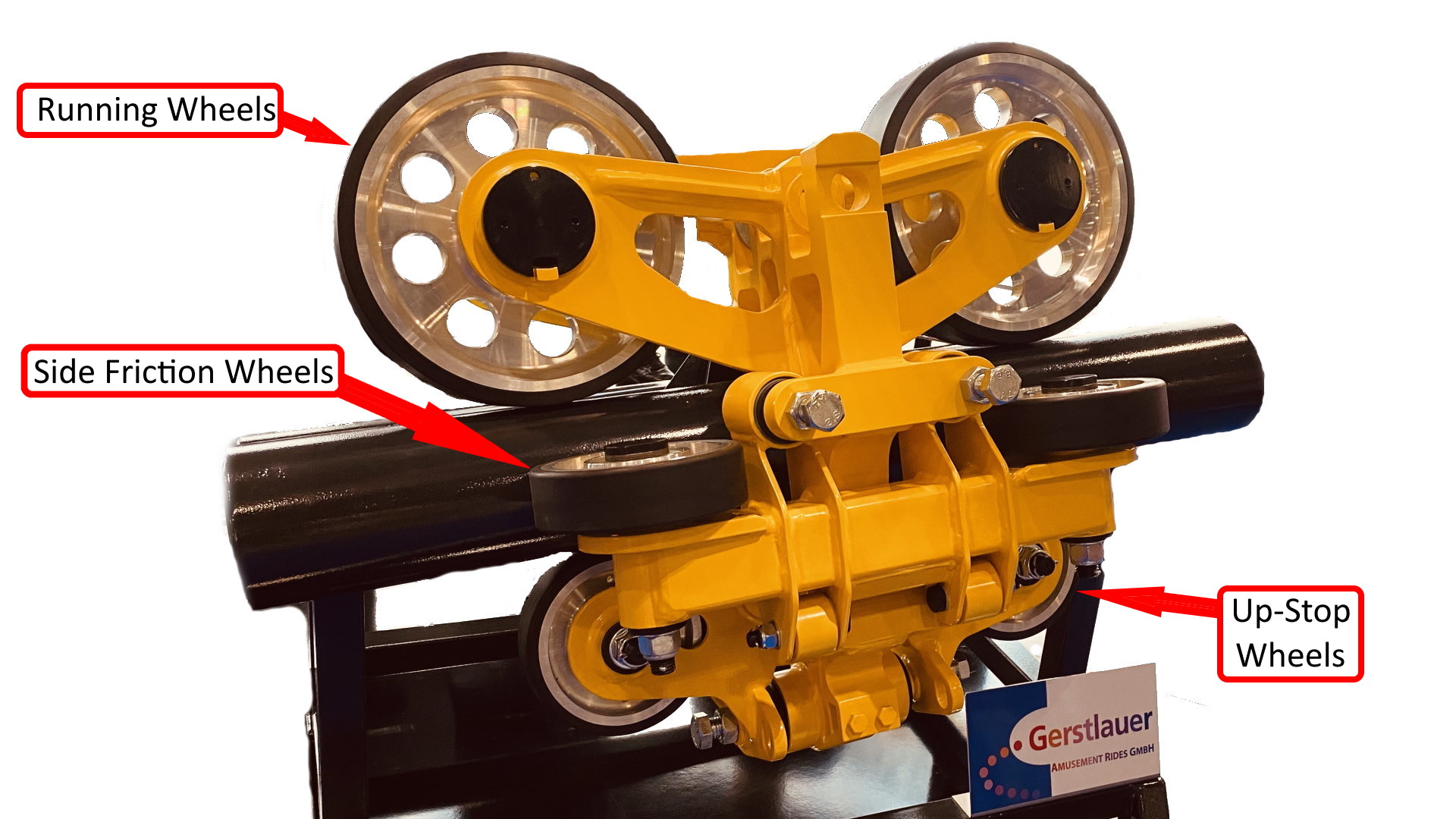

Illustrative image related to coaster wheel

Scenario 3: Managing Cost Without Compromising Quality

The Problem: Cost management is a significant concern for B2B buyers, especially when sourcing coaster wheels in bulk. While it may be tempting to opt for the cheapest options, this approach often leads to poor performance and increased maintenance costs, ultimately affecting the bottom line. Buyers are frequently caught in a dilemma between finding economical solutions and ensuring quality.

The Solution: To strike the right balance between cost and quality, buyers should adopt a strategic sourcing approach. Begin by identifying the total cost of ownership (TCO), which includes not just the purchase price but also maintenance, replacement, and operational costs over time. Engage with multiple suppliers to obtain quotes and compare the long-term benefits of higher-quality wheels against cheaper alternatives. Look for suppliers that offer volume discounts or loyalty programs to reduce costs while maintaining quality. Additionally, consider collaborating with manufacturers that allow for customization, which can lead to cost savings by tailoring products to specific needs, thereby avoiding over-specification. Regularly reviewing supplier performance and maintaining strong relationships can also yield better pricing and product options in the long run.

Strategic Material Selection Guide for coaster wheel

What Are the Key Materials Used in Coaster Wheel Manufacturing?

Coaster wheels are essential components in various applications, from bicycles to industrial carts. Selecting the right material for these wheels can significantly impact performance, durability, and overall cost. Below, we analyze four common materials used in coaster wheel manufacturing, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Polyurethane Impact Coaster Wheel Performance?

Polyurethane is a popular material for coaster wheels due to its excellent balance of durability and performance. It boasts high abrasion resistance, making it suitable for heavy-duty applications. Polyurethane wheels can handle a wide range of temperatures and provide good shock absorption, which is beneficial in reducing vibrations during operation.

Pros: Polyurethane wheels are highly durable, resistant to wear and tear, and provide a smooth ride. They also have a lower rolling resistance compared to rubber wheels, enhancing efficiency.

Cons: The primary drawback is cost; polyurethane wheels tend to be more expensive than rubber alternatives. Additionally, they can degrade when exposed to harsh chemicals or extreme temperatures.

Application Impact: Polyurethane wheels are ideal for environments where noise reduction and shock absorption are critical, such as in healthcare or high-end retail settings.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM or DIN, especially when dealing with heavy loads or specific environmental conditions.

Illustrative image related to coaster wheel

What Are the Benefits and Limitations of Rubber in Coaster Wheels?

Rubber is one of the most common materials used in coaster wheel production. It offers excellent traction and is relatively inexpensive compared to other materials. Rubber wheels are typically softer, providing good shock absorption and noise reduction.

Pros: Rubber wheels are cost-effective and provide good grip on various surfaces, making them suitable for indoor applications. They are also resistant to impact and can handle moderate loads.

Cons: However, rubber wheels can wear out faster than polyurethane wheels, especially in high-load or abrasive environments. They may also deform under heavy loads over time.

Application Impact: Rubber wheels are ideal for applications requiring good traction, such as in warehouses or on uneven surfaces.

Considerations for International Buyers: Buyers should consider the specific load requirements and environmental conditions, ensuring that the rubber used meets local standards for durability and performance.

Illustrative image related to coaster wheel

How Does Metal Influence the Durability of Coaster Wheels?

Metal wheels, often made from steel or aluminum, are known for their strength and durability. They are typically used in heavy-duty applications where high load capacities are required.

Pros: Metal wheels can withstand significant weight and are resistant to deformation. They also have a long lifespan and are suitable for outdoor use, as they are less affected by environmental conditions.

Cons: The primary disadvantage is that metal wheels can be noisy and may damage floors if not properly equipped with protective coatings or rubber tires. They are also heavier, which can affect maneuverability.

Application Impact: Metal wheels are commonly used in industrial settings, such as factories and warehouses, where heavy loads are frequent.

Considerations for International Buyers: Buyers should verify that metal wheels comply with international standards for safety and load-bearing capacity, particularly in regions with stringent regulations.

What Role Does Plastic Play in Coaster Wheel Applications?

Plastic wheels, often made from materials like nylon or polypropylene, are lightweight and resistant to corrosion. They are commonly used in applications where weight savings are crucial.

Pros: Plastic wheels are lightweight, resistant to chemicals, and do not rust, making them suitable for various environments. They are also cost-effective, which can benefit budget-conscious buyers.

Cons: However, plastic wheels may not be suitable for heavy loads, as they can deform under pressure. They also provide less shock absorption than rubber or polyurethane wheels.

Application Impact: Plastic wheels are ideal for light-duty applications, such as office furniture or lightweight carts.

Illustrative image related to coaster wheel

Considerations for International Buyers: Buyers should assess the load requirements and environmental factors, ensuring that the plastic material meets local compliance standards for performance and durability.

Summary Table of Material Selection for Coaster Wheels

| Material | Typical Use Case for coaster wheel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane | Healthcare equipment, retail carts | High durability and abrasion resistance | Higher cost, chemical sensitivity | High |

| Rubber | Warehouse carts, indoor applications | Cost-effective, good traction | Faster wear in heavy use | Low |

| Metal | Industrial settings, heavy-duty carts | Excellent load capacity | Noisy, potential floor damage | Medium |

| Plastic | Office furniture, lightweight carts | Lightweight, corrosion-resistant | Limited load capacity | Low |

This strategic material selection guide provides valuable insights for B2B buyers, facilitating informed decisions based on application needs and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for coaster wheel

What Are the Key Stages in the Manufacturing Process for Coaster Wheels?

The manufacturing process for coaster wheels involves several critical stages, each designed to ensure the final product meets the required performance and safety standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with selecting high-quality materials suitable for the intended application of the coaster wheel. Common materials include high-strength aluminum, steel, and various polymers for the wheel and hub. These materials undergo rigorous testing to ensure they meet mechanical and thermal properties. Additionally, suppliers may utilize recycled materials to promote sustainability, which is increasingly important to international buyers.

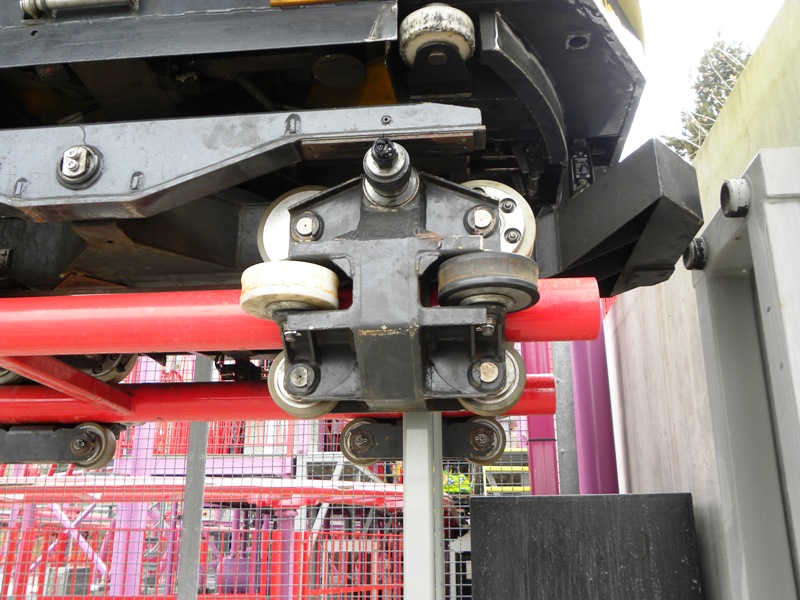

Illustrative image related to coaster wheel

Forming Techniques

Once the materials are prepared, they are subjected to forming processes. For metal components, techniques such as casting, forging, and machining are employed to create the wheel’s shape and dimensions. For polymer wheels, injection molding is commonly used. Precision is paramount; therefore, Computer Numerical Control (CNC) machines are often utilized to ensure accurate tolerances. This precision is essential for ensuring compatibility with various axle sizes and types, which is critical for B2B applications.

Assembly

In the assembly stage, the formed components are brought together. This may involve fitting the wheel to its hub, adding bearings, and securing any necessary locking mechanisms. Automated assembly lines can enhance efficiency and reduce labor costs, but manual assembly may still be employed for specialized custom orders. This stage also often includes an initial inspection to identify any defects that could affect performance.

Finishing Processes

The final stage involves finishing treatments, which can include surface coatings, painting, or anodizing. These processes enhance durability, corrosion resistance, and aesthetic appeal. Quality assurance checks are integrated into this stage to confirm that the finishing meets the specified standards.

How Is Quality Assurance Implemented in Coaster Wheel Manufacturing?

Quality assurance (QA) is integral to the manufacturing of coaster wheels to ensure that products meet international standards and customer expectations. Various standards and methodologies guide these processes.

International and Industry-Specific Standards

Most manufacturers adhere to ISO 9001 standards, which provide a framework for quality management systems. Additionally, industry-specific certifications such as CE marking (for products sold in Europe) and API (American Petroleum Institute) standards may apply, depending on the application of the coaster wheels. Compliance with these standards is crucial for B2B buyers, particularly when sourcing from different regions, as it often reflects the manufacturer’s commitment to quality and safety.

Illustrative image related to coaster wheel

Quality Control Checkpoints

To maintain high-quality standards, manufacturers typically implement several quality control checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival to ensure they meet specified requirements.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic inspections are conducted to monitor compliance with specifications. This includes checking dimensions, tolerances, and mechanical properties.

-

Final Quality Control (FQC): At the end of the manufacturing process, a comprehensive evaluation of the finished product takes place. This often includes functional testing, load testing, and visual inspections to identify any defects.

What Testing Methods Are Commonly Used for Coaster Wheels?

Various testing methods are employed to verify the performance and durability of coaster wheels. These tests are critical for assuring B2B buyers of the product’s quality.

Common Testing Methods

1. Static Load Testing: This test evaluates the wheel’s ability to withstand weight without deforming, ensuring it can support the intended load.

Illustrative image related to coaster wheel

-

Dynamic Load Testing: Similar to static testing, dynamic load testing assesses the wheel’s performance under movement and real-world conditions, simulating operational stresses.

-

Durability Testing: This involves subjecting the wheels to repeated cycles of load and movement to simulate long-term use, ensuring they can withstand wear and tear.

-

Environmental Testing: For wheels intended for outdoor or harsh environments, manufacturers may conduct tests for corrosion resistance, UV exposure, and temperature extremes.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential to mitigate risks associated with product quality. Here are several strategies:

Supplier Audits

Conducting audits is one of the most effective ways to assess a supplier’s quality control processes. These audits can be performed by the buyer’s internal team or by third-party inspection agencies. An audit typically includes an examination of the supplier’s manufacturing processes, quality management systems, and compliance with international standards.

Quality Assurance Reports

Requesting detailed quality assurance reports from suppliers can provide insights into their testing methodologies and results. These reports should outline the types of tests conducted, standards met, and any corrective actions taken in response to previous quality issues.

Third-Party Inspections

Engaging third-party inspection services can add an extra layer of verification. These independent entities can conduct inspections at various stages of the manufacturing process, ensuring compliance with agreed-upon specifications and standards.

Illustrative image related to coaster wheel

What Are the Quality Control and Certification Nuances for International Buyers?

When sourcing coaster wheels from different regions, international buyers must be aware of specific quality control and certification nuances.

Regional Compliance Standards

Different regions may have varying compliance requirements. For example, European buyers must ensure that products meet CE marking requirements, while buyers in the United States may need to consider ASTM standards. Understanding these nuances is crucial for compliance and market entry.

Cultural Considerations

Cultural factors can influence quality control practices. For instance, certain regions may prioritize different aspects of quality assurance, and communication can vary. It’s essential for buyers to establish clear expectations and ensure that suppliers understand their specific requirements.

Documentation and Traceability

Finally, proper documentation is vital for quality control. Buyers should request documentation that outlines the manufacturing process, materials used, and quality tests conducted. This traceability can be invaluable in case of disputes or quality issues.

In conclusion, understanding the manufacturing processes and quality assurance measures for coaster wheels is essential for B2B buyers. By focusing on these areas, buyers can make informed decisions and foster successful partnerships with suppliers.

Illustrative image related to coaster wheel

Practical Sourcing Guide: A Step-by-Step Checklist for ‘coaster wheel’

In the competitive landscape of B2B procurement, sourcing coaster wheels requires a strategic approach to ensure quality and suitability for your specific applications. This guide provides a practical checklist to help international buyers navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before reaching out to suppliers. Consider factors such as the wheel size, load capacity, material (e.g., rubber, polyurethane), and any specific design features like locking mechanisms. A detailed specification helps eliminate unsuitable options early and ensures that you get a product that meets your operational needs.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers who specialize in coaster wheels. Utilize online marketplaces, industry directories, and trade shows to compile a list of potential vendors. Pay attention to their market presence and customer reviews, as these can provide insights into their reliability and product quality.

Step 3: Evaluate Supplier Certifications and Compliance

Before finalizing a supplier, verify their certifications and compliance with industry standards. Look for certifications such as ISO 9001 for quality management systems and any relevant safety or environmental standards. This step is vital as it reassures you of the supplier’s commitment to quality and ethical practices.

Illustrative image related to coaster wheel

Step 4: Request Product Samples

Always request samples of the coaster wheels you are considering. Testing samples allows you to assess their performance under real-world conditions and ensures they meet your specifications. This step can prevent costly mistakes in large orders and helps establish a relationship of trust with the supplier.

Step 5: Assess Pricing and Payment Terms

Engage in discussions about pricing and payment terms with shortlisted suppliers. Compare quotes while considering factors such as shipping costs, bulk discounts, and payment flexibility. Understanding these terms upfront can help you manage your budget more effectively and avoid unexpected costs later.

Step 6: Inquire About Lead Times and Delivery Options

Discuss lead times and delivery options with your potential suppliers to ensure they align with your project timelines. Ask about their production capacity and shipping methods, especially if sourcing from international suppliers. Timely delivery is crucial in maintaining your operational schedule, so clarity on this aspect is essential.

Step 7: Establish a Communication Plan

Develop a communication plan that outlines how you will interact with the supplier throughout the procurement process. Clear communication channels help resolve issues quickly and keep all parties informed. Regular updates and feedback can foster a better working relationship and ensure that any modifications or concerns are addressed promptly.

Following this checklist can enhance your sourcing process for coaster wheels, ensuring you select the right products from reliable suppliers while maintaining quality and efficiency in your operations.

Illustrative image related to coaster wheel

Comprehensive Cost and Pricing Analysis for coaster wheel Sourcing

What Are the Key Cost Components in Coaster Wheel Sourcing?

When sourcing coaster wheels, B2B buyers must understand the various cost components that contribute to the overall pricing structure. The primary cost factors include:

-

Materials: The choice of materials significantly affects pricing. For instance, high-quality rubber or polyurethane wheels will generally command higher prices than plastic alternatives due to durability and performance benefits.

-

Labor: Labor costs can vary depending on the manufacturing location. Regions with higher wage standards may lead to increased costs, while manufacturers in areas with lower labor costs can offer competitive pricing.

-

Manufacturing Overhead: This includes costs associated with facilities, equipment maintenance, and utilities. Efficient manufacturing processes can help minimize overhead, affecting the final price.

-

Tooling: Custom tooling for specialized wheel designs or sizes can add to initial costs. However, for high-volume orders, these costs can be amortized over time, potentially lowering per-unit pricing.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability but may increase costs. Certifications like ISO can also add to expenses but may be necessary for certain markets.

-

Logistics: Shipping costs, which are influenced by distance, weight, and shipping method, are critical. International buyers should consider Incoterms that dictate who bears the shipping costs and risks.

-

Margin: Supplier margins will vary based on market competition and perceived value. Understanding the supplier’s margin can provide insight into pricing flexibility during negotiations.

How Do Price Influencers Impact Coaster Wheel Costs?

Several factors influence the pricing of coaster wheels, particularly for international B2B buyers:

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Larger orders often yield discounts, making it essential for buyers to balance inventory needs with cost-effectiveness.

-

Specifications and Customization: Custom specifications can increase costs due to additional design and manufacturing requirements. Buyers should assess the necessity of custom features against the associated price increases.

-

Material Quality and Certifications: High-quality materials and industry certifications can justify higher prices. Buyers should evaluate whether the benefits align with their operational requirements.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: Understanding Incoterms is crucial for managing logistics costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the total landed cost of the wheels.

What Are Effective Buyer Tips for Negotiating Coaster Wheel Prices?

B2B buyers can adopt several strategies to optimize costs when sourcing coaster wheels:

-

Negotiate on Volume: Leverage larger order quantities to negotiate better pricing. Suppliers are often more willing to offer discounts for bulk purchases.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but the total cost of ownership, including maintenance, durability, and replacement frequency. Sometimes, a higher upfront cost can lead to long-term savings.

-

Research Pricing Nuances for International Markets: Understand regional pricing differences and currency fluctuations. For buyers in Africa, South America, the Middle East, and Europe, local market conditions can greatly influence cost.

-

Seek Multiple Quotes: Obtain quotes from multiple suppliers to compare prices and terms. This can provide leverage during negotiations and help identify the best value.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing and service over time. Suppliers may offer exclusive deals or prioritize your orders based on a solid partnership.

Disclaimer on Pricing

Prices for coaster wheels can vary significantly based on the aforementioned factors. It is advisable for buyers to conduct thorough market research and obtain detailed quotes from suppliers to understand the specific pricing landscape.

Alternatives Analysis: Comparing coaster wheel With Other Solutions

Understanding Alternative Solutions to Coaster Wheels

When evaluating options for wheel solutions in various applications, it is essential to consider alternatives to the coaster wheel. While coaster wheels are popular for their unique braking capabilities and robustness, other technologies may offer advantages in specific contexts. This analysis compares coaster wheels with two viable alternatives: traditional ball bearing wheels and pneumatic wheels, enabling B2B buyers to make informed decisions.

| Comparison Aspect | Coaster Wheel | Traditional Ball Bearing Wheel | Pneumatic Wheel |

|---|---|---|---|

| Performance | Reliable braking, moderate speed | High speed, smooth movement | Soft ride, shock absorption |

| Cost | Moderate to high ($300+) | Generally lower ($50-$150) | Moderate ($100-$250) |

| Ease of Implementation | Requires specific mounting | Easy to install and replace | Moderate; requires proper inflation |

| Maintenance | Low; durable but needs occasional checks | Low; generally long-lasting | Moderate; needs regular inflation checks |

| Best Use Case | Cycling, heavy-duty carts | Industrial equipment, furniture | Transportation over uneven terrain |

What are the Advantages and Disadvantages of Traditional Ball Bearing Wheels?

Traditional ball bearing wheels are a well-established choice for a variety of applications. Their primary advantage lies in their performance; they provide smooth and fast movement, making them ideal for industrial equipment and furniture. The cost of these wheels is generally lower than that of coaster wheels, making them a budget-friendly option for businesses. However, they do not offer the same braking capabilities as coaster wheels, which can be a significant drawback in applications requiring controlled stopping.

How Do Pneumatic Wheels Compare to Coaster Wheels?

Pneumatic wheels are designed with air-filled tires that provide excellent shock absorption, making them suitable for uneven surfaces and outdoor applications. The soft ride they offer can enhance comfort when transporting goods. However, they come with the downside of needing regular maintenance, particularly in ensuring proper inflation. Pneumatic wheels are typically more expensive than traditional ball bearing wheels but can be less costly than high-end coaster wheels. They are less effective in terms of braking precision compared to coaster wheels, which may limit their use in certain scenarios.

Conclusion: How to Choose the Right Wheel Solution for Your Business Needs

Selecting the appropriate wheel solution requires a thorough understanding of your specific needs and application context. Coaster wheels excel in environments where reliable braking is crucial, such as in cycling or heavy-duty carts. Traditional ball bearing wheels are ideal for fast-paced environments, offering a lower-cost alternative with easy maintenance. Pneumatic wheels shine in applications requiring shock absorption and comfort over rough terrain. By carefully considering performance requirements, budget constraints, and maintenance capabilities, B2B buyers can choose the most suitable solution for their operational needs, ensuring optimal efficiency and effectiveness in their operations.

Essential Technical Properties and Trade Terminology for coaster wheel

What Are the Key Technical Properties of a Coaster Wheel?

Understanding the critical specifications of coaster wheels is essential for B2B buyers to ensure that the products meet their operational needs. Here are some key technical properties:

-

Material Composition

Coaster wheels are typically made from various materials such as rubber, polyurethane, or plastic. Each material offers different benefits: rubber provides excellent grip and shock absorption, while polyurethane is known for its durability and resistance to wear. Selecting the right material can significantly impact performance, especially in environments that require high load-bearing capabilities. -

Wheel Diameter

The diameter of a coaster wheel can range from small (around 2 inches) to larger sizes (up to 10 inches or more). The diameter affects maneuverability, load capacity, and speed. Larger wheels generally roll over obstacles more easily, making them suitable for uneven surfaces, while smaller wheels can offer better precision in confined spaces. -

Load Capacity

Each coaster wheel has a specified load capacity, which indicates the maximum weight it can safely support. This specification is crucial for B2B buyers, as exceeding this limit can lead to wheel failure or equipment damage. Understanding the load requirements for specific applications ensures that the correct wheel is chosen for the job. -

Tolerance Levels

Tolerance levels refer to the permissible limits of variation in the dimensions of the wheel and its components. High tolerance levels are essential in precision applications where small deviations can affect performance. Buyers should ensure that the manufacturer can meet their required tolerance specifications to avoid operational issues. -

Brake Mechanism

Many coaster wheels come equipped with brake systems that enhance safety and control. Understanding the type of brake mechanism, whether it’s a locking brake or a directional lock, is vital. This feature allows users to secure the equipment in place and prevent unintended movement, which is especially important in industrial settings. -

Hub Spacing and Axle Size

Hub spacing and axle size are critical for compatibility with various equipment. Buyers must ensure that the coaster wheels they purchase will fit their existing setups. This specification includes measurements for the axle diameter and spacing, which can vary widely depending on the application.

What Are Common Trade Terms Related to Coaster Wheels?

Familiarity with industry jargon can help streamline communication and negotiations. Here are some common trade terms relevant to coaster wheels:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is vital for buyers looking for replacement parts or custom solutions. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers, as it can affect inventory management and cost-efficiency. Knowing the MOQ helps in planning purchases and managing budgets effectively. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. It’s essential for B2B transactions, allowing buyers to compare offers and select the best supplier based on quality, price, and delivery terms. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers involved in cross-border purchases, as they clarify shipping responsibilities, risk transfer, and cost allocation. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. This term is critical for B2B buyers who need to synchronize their supply chain and production schedules. Knowing the lead time helps in planning and ensuring that operational needs are met without delays. -

Customization

This term refers to the ability to modify a product to meet specific requirements. In the context of coaster wheels, customization could involve different materials, sizes, or features tailored to unique applications. Being aware of customization options allows buyers to optimize their purchases for better performance in their specific environments.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions regarding coaster wheels, ensuring that their operational requirements are met efficiently and effectively.

Navigating Market Dynamics and Sourcing Trends in the coaster wheel Sector

What Are the Key Trends Influencing the Coaster Wheel Market?

The coaster wheel sector is experiencing a transformative phase driven by several global trends. First, the increasing demand for mobility solutions across various industries, including healthcare, logistics, and manufacturing, is propelling growth. As businesses strive for enhanced efficiency, the need for high-performance coaster wheels that provide durability and maneuverability is paramount. In regions like Africa and South America, urbanization and the expansion of transportation networks further drive this demand.

Illustrative image related to coaster wheel

Moreover, technological advancements are reshaping sourcing trends. The integration of smart technologies, such as IoT-enabled wheels that monitor wear and performance, is becoming more prevalent. This shift towards smart sourcing allows businesses to optimize inventory management and reduce downtime. Additionally, e-commerce growth is influencing buyer behavior, with B2B customers increasingly seeking online platforms for sourcing parts.

International buyers, particularly from Europe and the Middle East, are also focused on customization. Manufacturers are responding by offering tailored solutions that meet specific regional needs, such as climate resilience in tropical areas or compatibility with local machinery standards. This adaptability is crucial for maintaining competitiveness in diverse markets.

How Is Sustainability Shaping the Coaster Wheel Industry?

Sustainability has emerged as a critical factor in the coaster wheel sector, affecting sourcing decisions and supply chain strategies. The environmental impact of manufacturing processes is under scrutiny, prompting businesses to seek eco-friendly materials and production methods. For instance, manufacturers are increasingly using recycled plastics and sustainable rubber compounds, which not only reduce waste but also appeal to environmentally conscious buyers.

Illustrative image related to coaster wheel

Ethical sourcing practices are becoming non-negotiable for many international B2B buyers. Ensuring that suppliers adhere to fair labor practices and environmental regulations is essential for maintaining brand integrity. Certifications such as ISO 14001 for environmental management and Fair Trade can enhance a company’s reputation and build trust with customers.

Furthermore, the demand for transparency in supply chains is growing. Buyers are now more inclined to work with suppliers who can provide detailed information about their sourcing processes and material origins. This trend is particularly pronounced in regions like Europe, where regulatory frameworks often require compliance with stringent environmental standards.

What Is the Historical Context of Coaster Wheel Development?

The evolution of coaster wheels dates back to the early 20th century when the need for efficient mobility solutions became apparent in manufacturing and logistics. Initially made from wood and metal, coaster wheels have undergone significant advancements in materials and design. The introduction of synthetic materials in the mid-20th century revolutionized the industry, allowing for lighter, more durable options that enhanced performance.

Illustrative image related to coaster wheel

Over the decades, coaster wheels have adapted to meet the needs of various sectors, including healthcare, where specialized wheels for hospital beds and equipment became critical. Today, the focus is on innovation, with manufacturers exploring smart technologies and sustainable materials to cater to an increasingly discerning market. This historical context underscores the importance of continuous adaptation in the coaster wheel sector, ensuring that businesses remain competitive in a rapidly changing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of coaster wheel

-

How do I select the right coaster wheel for my application?

Selecting the right coaster wheel involves considering several factors such as load capacity, wheel material, and the surface it will be used on. For heavy-duty applications, polyurethane wheels are ideal due to their durability and resistance to wear. If your application requires mobility over uneven surfaces, opt for larger diameters. Additionally, assess the environment—wheels with brakes might be necessary for stability in certain settings. Always consult with suppliers to ensure the chosen wheel meets specific operational needs. -

What are the common specifications for coaster wheels?

Coaster wheels vary widely in specifications, including diameter, load capacity, and hub type. Typically, wheel diameters range from 2 to 10 inches, with load capacities from a few hundred to several thousand pounds. The hub type can be fixed or swivel, influencing maneuverability. Always ensure that the specifications align with your equipment’s requirements. Request samples or detailed catalogs from suppliers to compare and choose the best fit for your operational needs. -

What customization options are available for coaster wheels?

Many suppliers offer customization options for coaster wheels, including specific sizes, materials, colors, and tread patterns. You can also request modifications such as enhanced load-bearing capabilities or specific braking systems. Customization can cater to unique operational environments or aesthetic requirements. It’s advisable to discuss your needs with potential suppliers early in the procurement process to understand their capabilities and lead times for custom orders. -

What is the minimum order quantity (MOQ) for coaster wheels?

Minimum order quantities for coaster wheels can vary significantly among suppliers. Some may require a MOQ of 50 units, while others might allow smaller orders depending on the product line and customization options. Always clarify the MOQ with the supplier upfront, as this will help you plan your inventory and budgeting. If your needs are lower than the MOQ, inquire about potential alternatives, such as group purchases or stock options. -

What payment terms should I expect when sourcing coaster wheels?

Payment terms can differ widely depending on the supplier’s policies and the scale of the order. Common practices include a deposit upon order confirmation, with the balance due before shipping or upon delivery. Some suppliers may offer net terms (e.g., 30 or 60 days) for established businesses. Always negotiate terms that align with your cash flow needs and ensure that payment methods are secure, especially for international transactions. -

How can I ensure quality assurance when purchasing coaster wheels?

To ensure quality assurance, request certifications and quality control processes from suppliers. Look for compliance with international standards such as ISO or ANSI, which can indicate reliability and safety. Additionally, consider conducting a factory audit or requesting samples for testing. Establishing a clear communication channel for addressing quality issues is crucial, as this helps maintain standards throughout the production process. -

What logistics considerations should I keep in mind when importing coaster wheels?

When importing coaster wheels, logistics considerations include shipping methods, lead times, and customs regulations. Determine whether air freight or sea freight is more suitable for your order size and urgency. Factor in potential delays at customs, which may require additional documentation. Engage with a logistics partner experienced in international shipping to navigate these complexities, ensuring timely delivery and compliance with local regulations. -

How do I vet suppliers for coaster wheels in international markets?

Vetting suppliers involves researching their reputation, production capabilities, and customer reviews. Utilize platforms such as Alibaba or TradeKey to find verified suppliers and read feedback from previous buyers. Request references and conduct background checks to ensure credibility. If possible, visit the supplier’s facility or engage a local representative to assess their operations and quality control measures, providing you with confidence in their ability to meet your needs.

Top 6 Coaster Wheel Manufacturers & Suppliers List

1. Caster Connection – Versatile Wheels for Every Load Capacity

Domain: casterconnection.com

Registered: 1999 (26 years)

Introduction: Wheels available in various load capacities: Light Duty (Under 500 LBs), Medium Duty (500 – 2000 LBs), Heavy Duty (Over 2000 LBs). Wheel diameters range from 2″ to 12″ and larger. Wheel materials include Polyurethane, Rubber, Pneumatic, Cast Iron, Steel, Nylon, Phenolic, and Polyolefin. Applications include ergonomic performance, safety, pallet jacks, shopping carts, automotive manufacturing, heal…

2. Santafixie – Coaster Brake Wheelsets

Domain: santafixie.com

Registered: 2011 (14 years)

Introduction: Coaster Brake Wheels available in various options including:

– Santafixie 30mm Coaster Brake Wheelset + Inner Tubes + Tires – Black: $204.88

– Santafixie 30mm Coaster Brake Wheelset – Black: $175.61

– Santafixie 30mm Coaster Brake Rear Wheel – Black: $93.63

– Santafixie 30mm Coaster Brake Wheelset – White: $175.61

– Santafixie 30mm Coaster Brake Rear Wheel – White: $93.63

– Origin8 Coaster Brake 7…

3. Profileracing – Z Coaster® Hub 20 Wheel

4. Shimano – CB-110 Coaster Hub

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Coaster hub options include Shimano CB-110 with 36 holes; compatibility with rim hole count is important (Weinmann rim likely has 32 holes). Most coaster hubs have 110mm spacing, may require axle adjustment for 135mm frames. Consider purchasing a complete coaster brake wheel for simplicity. Wheelmaster steel wheels are noted as overpriced. Suggestion to look for used coaster brake bikes for cost e…

5. Weinmann – Coaster Brake 700c Track Rear Wheel

Domain: velomine.com

Registered: 2009 (16 years)

Introduction: {“product_name”: “Weinmann Coaster Brake 700c Track Single Speed Rear Wheel Only”, “price”: “$129.00 USD”, “availability”: “In stock”, “category”: “Coaster Brake Wheelsets & Wheels”}

6. Hamilton Caster – Industrial Casters and Wheels

Domain: hamiltoncaster.com

Registered: 1996 (29 years)

Introduction: Hamilton Caster manufactures industrial casters and wheels, including UltraGlide™ casters designed for heavy manufacturing, aerospace, automotive, ergonomic applications, automatic guided vehicles, high heat environments, and wash down conditions. They offer custom solutions, heavy-duty casters, shock-absorbing casters, and stainless steel casters. Their wheels include polyurethane wheels, flanged…

Strategic Sourcing Conclusion and Outlook for coaster wheel

In the evolving landscape of coaster wheel procurement, strategic sourcing emerges as a cornerstone for enhancing operational efficiency and cost-effectiveness. International buyers, particularly those from Africa, South America, the Middle East, and Europe, should prioritize partnerships with suppliers who offer a diverse range of products tailored to specific industry needs, from automotive to healthcare. Understanding the nuances of wheel specifications—such as load capacity, material composition, and design—can significantly impact the performance and longevity of equipment.

Moreover, leveraging technology in sourcing processes, such as utilizing online platforms for comparison shopping and supplier evaluation, can streamline decision-making and reduce lead times. As the demand for high-quality, customized solutions grows, staying informed about market trends and innovations in coaster wheel technology will be crucial.

Looking ahead, B2B buyers are encouraged to engage with suppliers who prioritize sustainable practices and innovative designs. This proactive approach not only ensures competitive pricing but also aligns with global standards and customer expectations. Embrace the opportunity to enhance your operations through strategic sourcing, and connect with reliable partners to drive your business forward in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to coaster wheel

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.