Everything You Need to Know About Paper Cutter Machine Sourcing in 2025

Introduction: Navigating the Global Market for paper cutter machine

In the fast-paced world of business, sourcing the right paper cutter machine can pose significant challenges for international B2B buyers. From the diverse specifications of manual and automatic cutters to the varying applications in industries like printing and packaging, making an informed decision is crucial. This comprehensive guide aims to demystify the global market for paper cutter machines, offering insights into the different types available, their applications, and key considerations for supplier vetting.

Buyers from Africa, South America, the Middle East, and Europe—including regions like Germany and Saudi Arabia—will find actionable advice on navigating this complex landscape. With detailed sections dedicated to understanding cost structures, evaluating machine capabilities, and identifying reliable suppliers, this guide empowers businesses to make strategic purchasing decisions.

Understanding the nuances of paper cutter machines not only helps in selecting the right equipment but also enhances operational efficiency and reduces long-term costs. Whether you’re seeking high-volume production solutions or precision cutting for specialized tasks, this guide equips you with the knowledge needed to optimize your procurement process and align it with your business goals.

Understanding paper cutter machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Paper Cutters | Operated by hand; often compact; lower upfront cost | Small businesses, print shops, schools | Pros: Affordable, greater control. Cons: Slower, labor-intensive. |

| Automatic Paper Cutters | Motorized operation; programmable; higher throughput | Large print shops, commercial printing, publishing | Pros: Fast, reduces human error. Cons: Higher cost, requires training. |

| Stack Paper Cutters | Designed for cutting multiple sheets at once; robust build | High-volume printing, packaging, industrial use | Pros: Efficiency in bulk cutting. Cons: Larger footprint, higher maintenance. |

| Guillotine Cutters | Straight blade action; precise cuts; heavy-duty models | Professional graphic design, photography studios | Pros: Accuracy, versatility. Cons: Safety concerns, requires supervision. |

| Trimmers | Rotary or straight blade; often portable; used for finishing | Crafting, small-scale printing, schools | Pros: Versatile for various sizes, easy to use. Cons: Limited capacity for thick stacks. |

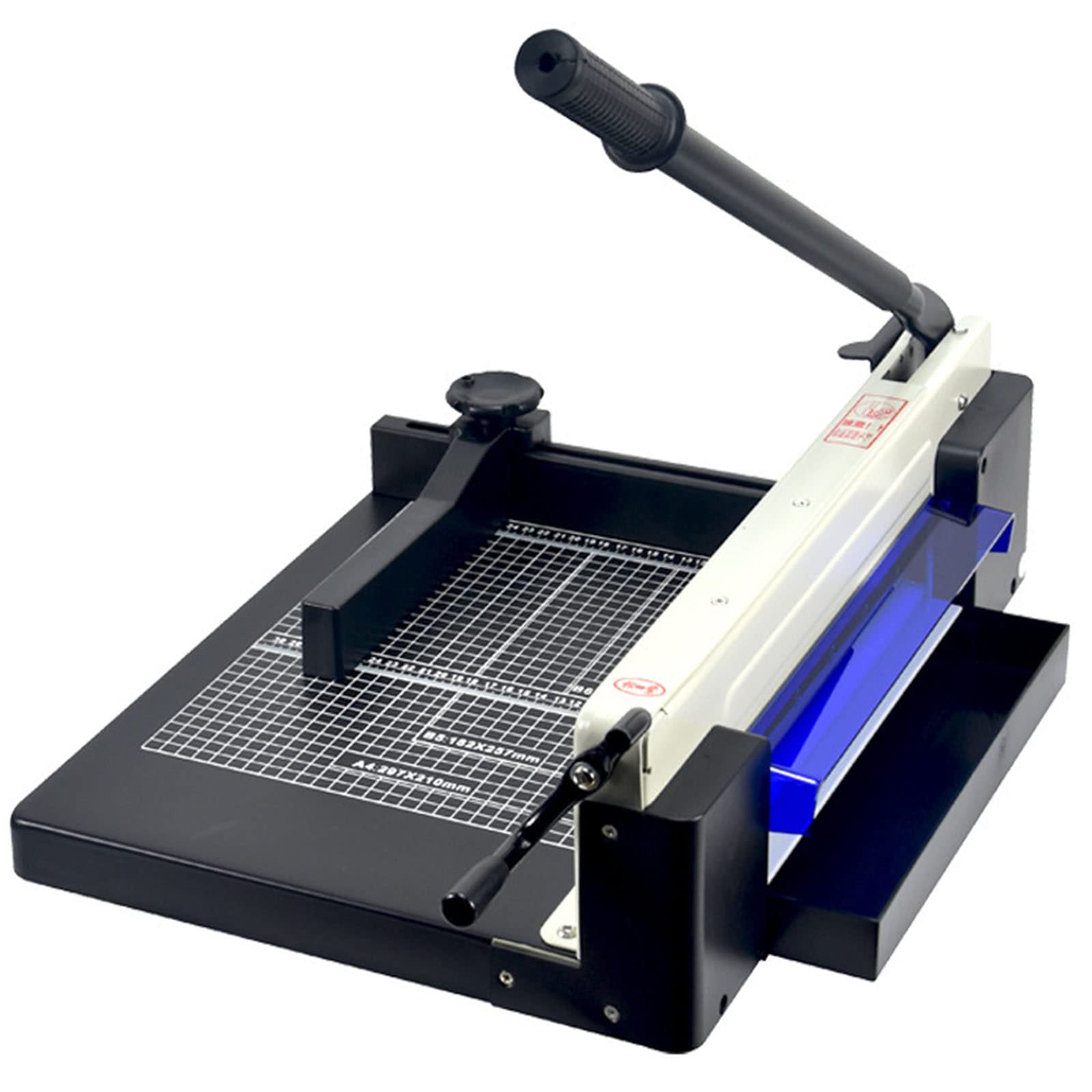

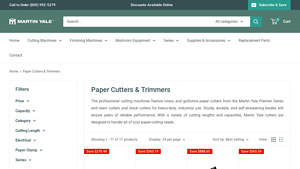

What Are the Characteristics of Manual Paper Cutters?

Manual paper cutters are typically operated by hand, making them a cost-effective solution for small-scale operations. These machines are often compact and easy to store, suitable for businesses with limited space. They are ideal for small print shops, schools, and offices that handle lower volumes of paper cutting. Buyers should consider their cutting needs, as manual cutters require more time and effort compared to automated options, making them less suitable for high-volume tasks.

Illustrative image related to paper cutter machine

How Do Automatic Paper Cutters Enhance Efficiency?

Automatic paper cutters feature motorized operation, allowing for faster cutting speeds and programmable settings that cater to various job requirements. They are perfect for large print shops and commercial printing businesses that need to manage high volumes efficiently. While they come with a higher initial investment, the reduction in labor costs and the minimization of human error can lead to significant long-term savings. Businesses must assess their production needs and budget to determine if the investment is justified.

Why Choose Stack Paper Cutters for High-Volume Needs?

Stack paper cutters are specifically designed for cutting multiple sheets simultaneously, making them a staple in high-volume environments like industrial printing and packaging. These machines boast a robust build and can handle large stacks, improving productivity. However, they require more space and can incur higher maintenance costs. Businesses looking to optimize their cutting processes should evaluate their volume requirements and available workspace before purchasing.

What Makes Guillotine Cutters a Preferred Choice for Precision?

Guillotine cutters operate with a straight blade action, offering exceptional precision for various paper sizes and types. They are commonly used in professional settings such as graphic design and photography studios, where accuracy is paramount. While they provide versatility and can handle thicker stacks, they also pose safety risks and often require supervision during operation. Buyers should weigh the benefits of precision against the necessary safety protocols when considering this type of cutter.

How Do Trimmers Fit into Smaller B2B Operations?

Trimmers, featuring either rotary or straight blades, are portable and versatile, making them ideal for crafting and small-scale printing tasks. They are often used in educational settings and by hobbyists, allowing for easy and precise cuts on various paper sizes. However, their capacity for cutting thicker stacks is limited, which may not meet the needs of larger operations. Businesses should assess their cutting volume and type to determine if a trimmer is the right fit for their requirements.

Key Industrial Applications of paper cutter machine

| Industry/Sector | Specific Application of paper cutter machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Printing and Publishing | Trimming printed materials to final sizes | Ensures precision and consistency in product output | Look for high-volume capacity and precision cutting blades |

| Education and Training | Cutting educational materials and handouts | Streamlines preparation of learning resources | Need for safety features and ease of use for staff |

| Packaging and Labeling | Cutting labels and packaging materials | Enhances efficiency in packaging processes | Consider automation options for higher throughput |

| Graphic Design and Advertising | Creating promotional materials and mock-ups | Facilitates creativity and professional presentation | Look for versatility in cutting sizes and types |

| Office Administration | Preparing documents, reports, and presentations | Improves organization and presentation quality | Ensure compatibility with various paper types and sizes |

How is a Paper Cutter Machine Used in the Printing and Publishing Industry?

In the printing and publishing sector, paper cutter machines are essential for trimming large stacks of printed materials to their final sizes. This process enhances the overall quality and consistency of the products, from books to brochures. For international buyers, especially in regions like Europe and South America, it’s critical to source machines that can handle high-volume workloads while maintaining precision cutting. Additionally, features such as programmable settings can minimize human error and increase efficiency.

What Role Does a Paper Cutter Machine Play in Education and Training?

In educational institutions, paper cutter machines are utilized to prepare handouts, worksheets, and other teaching materials. This application streamlines the process of creating organized and visually appealing resources for students and educators alike. Buyers from Africa and the Middle East should prioritize machines with user-friendly designs and enhanced safety features to ensure that staff can operate them without risk, especially in environments with limited training.

How Do Packaging and Labeling Industries Benefit from Paper Cutter Machines?

The packaging and labeling sector relies heavily on paper cutter machines for cutting labels, boxes, and other packaging materials to specified dimensions. This capability significantly boosts operational efficiency, allowing businesses to meet production deadlines and improve product presentation. When sourcing for this application, companies should consider automatic cutters that can handle diverse materials and offer quick changeovers to adapt to various packaging needs.

Why are Paper Cutter Machines Important for Graphic Design and Advertising?

In graphic design and advertising, precision is paramount when creating promotional materials, mock-ups, and client presentations. Paper cutter machines facilitate the accurate cutting of various paper types and sizes, ensuring that designs are presented professionally. For international buyers, especially in competitive markets like Germany and Saudi Arabia, investing in versatile machines that can accommodate different cutting styles and materials will enhance creative output and client satisfaction.

Illustrative image related to paper cutter machine

How Do Paper Cutter Machines Improve Office Administration Processes?

In office administration, paper cutter machines are employed to prepare documents, reports, and presentations, ensuring that materials are neatly trimmed and professionally presented. This not only improves the organization of paperwork but also enhances the overall quality of presentations. Buyers should focus on machines that can easily handle a variety of paper sizes and types, as well as those with safety features to protect employees in busy office environments.

3 Common User Pain Points for ‘paper cutter machine’ & Their Solutions

Scenario 1: Inconsistent Cutting Quality in High-Volume Production

The Problem: B2B buyers in the printing and publishing sectors often face the challenge of inconsistent cutting quality when using paper cutter machines. This inconsistency can lead to waste, increased operational costs, and dissatisfaction among clients who expect high precision. For instance, a company tasked with producing marketing materials for a major client may find that some printed pieces are unevenly cut, resulting in the need for reprints and missed deadlines.

The Solution: To ensure consistent cutting quality, businesses should invest in high-quality, heavy-duty paper cutter machines with precision engineering. When sourcing these machines, prioritize models with adjustable cutting guides and programmable settings that allow for precise control over the cutting depth and angle. Additionally, regular maintenance is crucial; ensure that blades are sharpened frequently and that the machine is calibrated correctly. Establish a routine check to evaluate the cutting performance and make adjustments as necessary. Training staff on the correct operation of the machine can also minimize human error, ensuring that each cut meets the required specifications.

Scenario 2: Safety Concerns with Manual Paper Cutters

The Problem: Safety is a paramount concern for B2B buyers, especially in environments where manual paper cutters are used. The risk of accidents, such as cuts or finger injuries, can deter employees from using the equipment effectively. A business may have invested in a manual cutter, but if employees are hesitant to use it due to safety fears, productivity can suffer.

The Solution: To address these safety concerns, businesses should consider upgrading to automatic or semi-automatic paper cutters that incorporate advanced safety features. Look for machines equipped with safety guards, automatic shut-off mechanisms, and user-friendly interfaces that require minimal manual input. Additionally, implementing comprehensive training programs that emphasize safety protocols can help build confidence among employees. Regular safety audits and encouraging open discussions about safety practices can further enhance a culture of safety in the workplace. Engaging employees in safety training not only minimizes the risk of accidents but also promotes efficient use of the machinery.

Scenario 3: Difficulty in Choosing Between Manual and Automatic Cutters

The Problem: B2B buyers often grapple with the decision of whether to invest in a manual or an automatic paper cutter. This dilemma can lead to indecision, delaying the purchasing process and potentially impacting operational efficiency. Companies may find themselves unsure about which type of cutter aligns best with their production needs, workload volume, and budget constraints.

The Solution: To make an informed decision, businesses should conduct a thorough assessment of their operational requirements. Start by analyzing the volume of paper cutting needed—if your business regularly handles large batches of paper, an automatic cutter may offer better efficiency and reduced labor costs. In contrast, if your operations are smaller or require intricate cuts, a manual cutter could provide the necessary control. Engage with suppliers to understand the specifications and features of different models, and don’t hesitate to request demonstrations or trial periods. Consider the total cost of ownership, including maintenance and replacement parts, when evaluating options. Ultimately, the right choice should balance operational efficiency, budget, and the specific cutting needs of your business.

Strategic Material Selection Guide for paper cutter machine

What Are the Key Materials Used in Paper Cutter Machines?

When selecting a paper cutter machine, the choice of materials can significantly impact performance, durability, and overall suitability for specific applications. Here, we analyze four common materials used in the construction of paper cutter machines: steel, aluminum, plastic, and composite materials. Each material has unique properties that cater to different operational needs and market preferences.

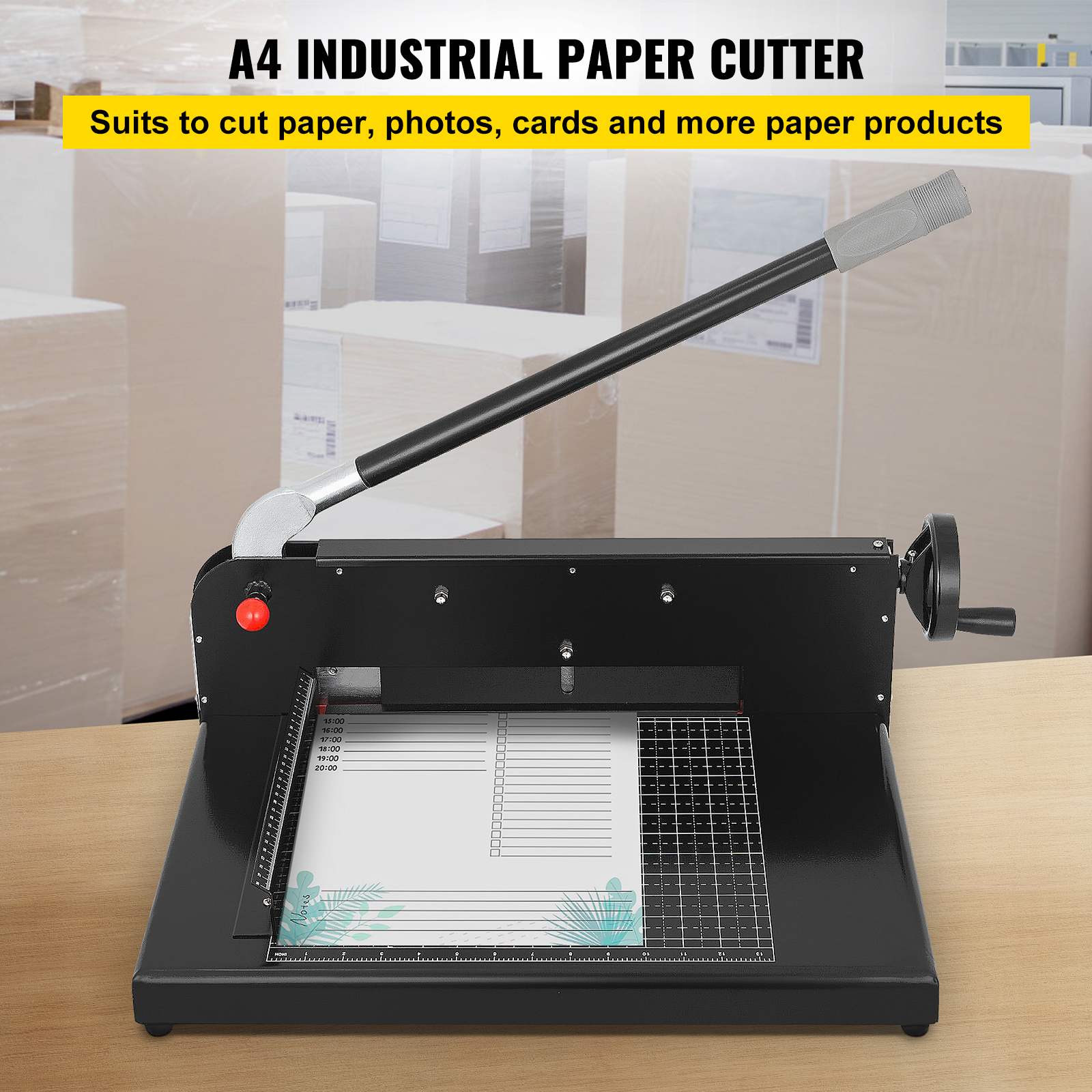

How Does Steel Enhance the Performance of Paper Cutter Machines?

Steel is a widely used material in paper cutter machines, particularly for blades and structural components. Its key properties include high tensile strength and excellent wear resistance, making it ideal for heavy-duty applications. Steel can withstand high pressure and temperature variations, ensuring consistent performance over time.

Pros: Steel offers exceptional durability and longevity, making it suitable for high-volume cutting tasks. Its robustness allows for precise cuts, which is crucial in commercial settings. However, the manufacturing complexity can lead to higher production costs.

Cons: While steel is durable, it is also susceptible to corrosion if not properly treated. This can be a concern in humid environments, which are common in regions like Africa and South America.

Impact on Application: Steel blades are compatible with a wide range of media, including thicker paper stocks, cardboard, and specialty materials.

Illustrative image related to paper cutter machine

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers in Europe, particularly Germany, often prefer machines that meet these standards for quality assurance.

What Role Does Aluminum Play in Paper Cutter Machines?

Aluminum is another popular material, especially for components that require a lightweight yet strong structure. Its key properties include corrosion resistance and a lower weight compared to steel, making it easier to handle and operate.

Pros: Aluminum is cost-effective and offers good thermal conductivity. Its lightweight nature allows for easier transportation and setup, which can be advantageous for businesses with limited space.

Cons: While aluminum is durable, it is not as strong as steel, making it less suitable for heavy-duty applications. It may also be prone to scratching, which can affect the aesthetic and functional quality of the machine.

Impact on Application: Aluminum components are well-suited for lighter media and smaller cutting tasks, such as business cards or brochures.

Considerations for International Buyers: Buyers should look for aluminum products that comply with local standards. In the Middle East, for instance, adherence to local regulations regarding material safety and environmental impact is critical.

How Do Plastics Contribute to Paper Cutter Machines?

Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, are used in certain components of paper cutter machines, such as guards and handles. Their key properties include lightweight, impact resistance, and flexibility.

Pros: Plastics are generally less expensive than metals and can be molded into complex shapes, allowing for innovative designs. They are also resistant to corrosion and can withstand various chemicals.

Cons: The durability of plastic can be a concern, especially in high-stress applications. Over time, plastics may become brittle and less effective, leading to potential safety issues.

Illustrative image related to paper cutter machine

Impact on Application: Plastic components are suitable for applications where weight is a concern, but they may not be ideal for heavy-duty cutting tasks.

Considerations for International Buyers: Buyers should ensure that the plastics used are compliant with safety standards in their region. In Europe, for example, REACH compliance is crucial for chemical safety.

What Advantages Do Composite Materials Offer in Paper Cutter Machines?

Composite materials, which combine various substances to enhance performance, are increasingly used in advanced paper cutter machines. Their key properties include high strength-to-weight ratios and resistance to environmental factors.

Illustrative image related to paper cutter machine

Pros: Composites can be engineered to provide specific benefits, such as enhanced durability and reduced weight. This makes them suitable for both manual and automatic cutters.

Cons: The manufacturing process for composites can be complex and costly, which may drive up the price of the final product.

Impact on Application: Composite materials are versatile and can be used in various applications, including high-volume cutting and specialized tasks.

Illustrative image related to paper cutter machine

Considerations for International Buyers: Buyers should verify that composite materials meet international safety and quality standards, as these can vary significantly between regions.

Summary Table of Material Selection for Paper Cutter Machines

| Material | Typical Use Case for paper cutter machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty cutting | Exceptional durability | Susceptible to corrosion | High |

| Aluminum | Lightweight applications | Cost-effective and easy to handle | Less strong than steel | Medium |

| Plastic | Guards and handles | Lightweight and corrosion-resistant | May become brittle over time | Low |

| Composite | Advanced cutting applications | High strength-to-weight ratio | Complex and costly manufacturing | High |

This strategic material selection guide provides insights that can help B2B buyers make informed decisions when sourcing paper cutter machines tailored to their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for paper cutter machine

What Are the Key Manufacturing Processes for Paper Cutter Machines?

The manufacturing process of paper cutter machines involves several critical stages, each designed to ensure the final product meets the required specifications for durability, precision, and safety. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Paper Cutter Production?

The initial stage of manufacturing begins with the selection and preparation of raw materials. High-quality steel is often the primary material used due to its strength and durability. Suppliers must ensure that the metal sheets are of the correct grade and thickness, which can withstand repeated cutting operations without warping or degrading.

Illustrative image related to paper cutter machine

Material preparation also involves cutting the raw steel into manageable sizes and shapes, followed by treatments such as annealing or surface hardening to enhance its properties. This step is crucial, as the quality of the materials directly affects the machine’s performance and longevity.

What Techniques Are Used in Forming Paper Cutter Components?

Forming techniques play a vital role in shaping the various components of the paper cutter. This may include processes such as stamping, laser cutting, and CNC machining. Each technique has its advantages:

- Stamping is used for producing high volumes of identical parts quickly and efficiently.

- Laser Cutting offers precision for intricate shapes and can handle complex designs without the need for extensive tooling.

- CNC Machining provides high accuracy and flexibility, allowing for the production of customized parts as required.

These methods help ensure that each component fits perfectly within the machine, which is critical for maintaining cutting precision and operational efficiency.

How Are Paper Cutter Machines Assembled?

The assembly stage involves bringing together all the manufactured components. This includes the cutting blades, frame, and any electronic parts for automated models. Each component must be carefully aligned and secured to ensure smooth operation.

Illustrative image related to paper cutter machine

During assembly, manufacturers often employ techniques such as torque testing and alignment checks to ensure that all parts are fitted correctly and securely. This step is essential for preventing mechanical failures during operation, which can lead to safety hazards and costly downtime.

What Quality Assurance Measures Are Essential for Paper Cutter Machines?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the machines meet both international and industry-specific standards.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with several international standards that guarantee product quality and safety. Key standards include:

Illustrative image related to paper cutter machine

- ISO 9001: This is a quality management standard that outlines the requirements for consistent quality in products and services. Adherence to ISO 9001 indicates a commitment to continuous improvement and customer satisfaction.

- CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards. This is particularly important for buyers in European markets.

- API Standards: For companies that require machines for specific industrial applications, compliance with American Petroleum Institute (API) standards may also be relevant.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integrated into the manufacturing process to ensure that each stage meets the required specifications. Common QC checkpoints include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet the specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any defects early on, allowing for immediate corrective actions.

- Final Quality Control (FQC): After assembly, the complete machine undergoes rigorous testing to ensure it functions correctly and meets all safety standards.

What Testing Methods Are Commonly Used for Paper Cutter Machines?

Various testing methods are employed to verify the performance and safety of paper cutter machines. These can include:

- Functional Testing: Ensuring that the machine operates correctly and meets performance specifications.

- Load Testing: Assessing the machine’s ability to handle its maximum load capacity without failure.

- Safety Testing: Evaluating the safety features of the machine, such as emergency stop mechanisms and blade guards, to prevent accidents during operation.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to ensure that their suppliers adhere to high-quality standards. Here are some effective strategies:

What Steps Can Buyers Take for Supplier Audits?

Conducting supplier audits is one of the most effective ways to verify compliance with quality standards. This can involve:

Illustrative image related to paper cutter machine

- Site Visits: Inspecting the manufacturing facility to assess the production process, equipment, and quality control measures in place.

- Document Reviews: Requesting and reviewing quality management system documentation, including ISO certifications, QC reports, and testing records.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control processes. These inspections can cover various aspects, including material quality, manufacturing practices, and final product testing.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Regulatory Compliance: Different countries have varying regulations regarding machinery safety and performance. It’s essential to ensure that the supplier’s products comply with local regulations in your region.

- Cultural Considerations: Understanding cultural differences in business practices can enhance communication and negotiation during the procurement process.

How Can Buyers Ensure Continuous Quality Improvement?

Buyers should encourage their suppliers to adopt a culture of continuous improvement in their manufacturing processes. This can include regular training for staff on quality standards, investment in advanced manufacturing technologies, and a commitment to addressing customer feedback.

By understanding the manufacturing processes and quality assurance measures that underpin paper cutter machines, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who deliver high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘paper cutter machine’

When sourcing a paper cutter machine, it is essential to follow a systematic approach to ensure you select the right equipment for your business needs. This checklist serves as a practical guide for B2B buyers, focusing on key considerations to streamline the procurement process.

Illustrative image related to paper cutter machine

Step 1: Define Your Technical Specifications

Start by identifying your specific cutting requirements. Consider factors such as the maximum paper size, thickness, and volume of cuts needed daily. Knowing these parameters will help you narrow down your options and ensure the machine can handle your workload efficiently.

- Cutting Capacity: Assess how many sheets you need to cut at once.

- Cutting Size: Determine the maximum dimensions of the paper you will work with.

Step 2: Research Available Types of Cutters

Understand the different types of paper cutters available in the market. There are manual, automatic, and hydraulic options, each with distinct advantages.

- Manual Cutters: Ideal for low-volume tasks and offer more control.

- Automatic Cutters: Best for high-volume operations, reducing the risk of human error and increasing efficiency.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers. Check their reputation, years in business, and customer reviews to ensure reliability.

Illustrative image related to paper cutter machine

- Request Documentation: Ask for company profiles, certifications, and case studies.

- Seek References: Reach out to other businesses in your region that have purchased similar equipment.

Step 4: Verify Compliance with Safety Standards

Ensure that the paper cutter complies with relevant safety regulations. This is crucial for protecting your employees and minimizing liability.

- Safety Features: Look for machines with automatic shut-off, blade guards, and emergency stop buttons.

- Certifications: Verify if the equipment meets international safety standards relevant to your region.

Step 5: Compare Pricing and Warranty Options

Gather quotes from multiple suppliers to compare pricing. However, don’t just focus on the initial cost; consider the total cost of ownership, including maintenance and parts replacement.

- Warranty Coverage: Check the warranty period and what it covers, as this can save you money in the long run.

- Maintenance Costs: Inquire about the cost of replacement parts and servicing.

Step 6: Assess After-Sales Support and Training

Look for suppliers who provide comprehensive after-sales support. This includes training for your staff on how to operate the machine safely and effectively.

Illustrative image related to paper cutter machine

- Training Programs: Ensure they offer training sessions or materials.

- Technical Support: Confirm the availability of technical assistance post-purchase.

Step 7: Finalize Your Purchase Agreement

Once you have selected a supplier, carefully review the purchase agreement. Ensure all terms, including delivery, installation, and payment, are clearly outlined.

- Delivery Timeline: Confirm how long it will take to receive the machine.

- Installation Services: Check if the supplier offers installation and setup services.

By following this checklist, you can make informed decisions and procure a paper cutter machine that meets your operational needs while ensuring safety and efficiency in your business processes.

Comprehensive Cost and Pricing Analysis for paper cutter machine Sourcing

What Are the Key Cost Components in Paper Cutter Machine Manufacturing?

When sourcing paper cutter machines, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

-

Materials: The quality of materials used directly influences the price. High-grade steel for cutting blades and durable plastics for housing can significantly increase costs but are essential for longevity and performance.

-

Labor: Skilled labor is necessary for the assembly and quality assurance of these machines. The labor cost varies significantly based on the region, with countries with higher wage standards affecting overall pricing.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and administrative expenses. Efficient production facilities can lower these costs, allowing for more competitive pricing.

-

Tooling: Initial setup costs for specialized equipment can be substantial. However, these costs are typically amortized over production runs, affecting the pricing structure for larger orders.

-

Quality Control (QC): Rigorous testing and quality assurance processes ensure that machines meet safety and performance standards, which can add to the overall cost but is necessary for compliance, especially in international markets.

-

Logistics: Shipping costs can vary widely based on distance, shipping method, and logistics provider. For international buyers, understanding Incoterms is essential to navigate these costs effectively.

-

Margin: Suppliers need to maintain a profit margin, which can range from 10% to 30% depending on market competition and product uniqueness.

How Do Price Influencers Affect Paper Cutter Machine Costs?

Several factors can influence the pricing of paper cutter machines, particularly for international B2B buyers.

-

Volume/MOQ (Minimum Order Quantity): Bulk orders typically lead to lower per-unit costs. Suppliers are often willing to negotiate prices based on the order size, so understanding your needs is essential.

-

Specifications and Customization: Customized machines tailored to specific requirements will generally cost more due to additional design and manufacturing processes. Buyers should weigh the benefits of customization against the cost.

-

Material Quality and Certifications: Machines made from higher-quality materials or those with certifications (such as ISO) will command a premium price. These certifications often assure buyers of the machine’s durability and performance.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality may charge higher prices, but they often provide better after-sales support and warranty terms.

-

Incoterms: Understanding the chosen Incoterm can significantly affect overall costs. FOB (Free on Board) or CIF (Cost, Insurance, and Freight) terms can lead to variations in pricing based on who bears the shipping costs.

What Are Effective Tips for Negotiating Paper Cutter Machine Prices?

International B2B buyers should adopt several strategies to ensure cost efficiency in their procurement processes:

-

Negotiate Terms: Engage suppliers in discussions about payment terms, lead times, and delivery schedules. Flexible terms can lead to better pricing or additional services.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, operational efficiency, and potential downtime costs. A higher upfront cost may lead to lower long-term expenses.

-

Research Market Prices: Familiarize yourself with market trends and competitor pricing to strengthen your negotiation position. Having comparative data can empower you during discussions.

-

Understand Pricing Nuances: Be aware that cultural differences can affect negotiation styles and expectations. Building rapport and understanding local business customs can facilitate smoother transactions.

-

Explore Financing Options: Look for suppliers that offer financing or leasing options, which can spread costs over time and alleviate cash flow constraints.

Disclaimer for Indicative Prices

Prices for paper cutter machines can vary widely based on specifications, supplier, and market conditions. It is advisable to obtain quotes from multiple suppliers and consider all cost components and potential additional expenses when making purchasing decisions.

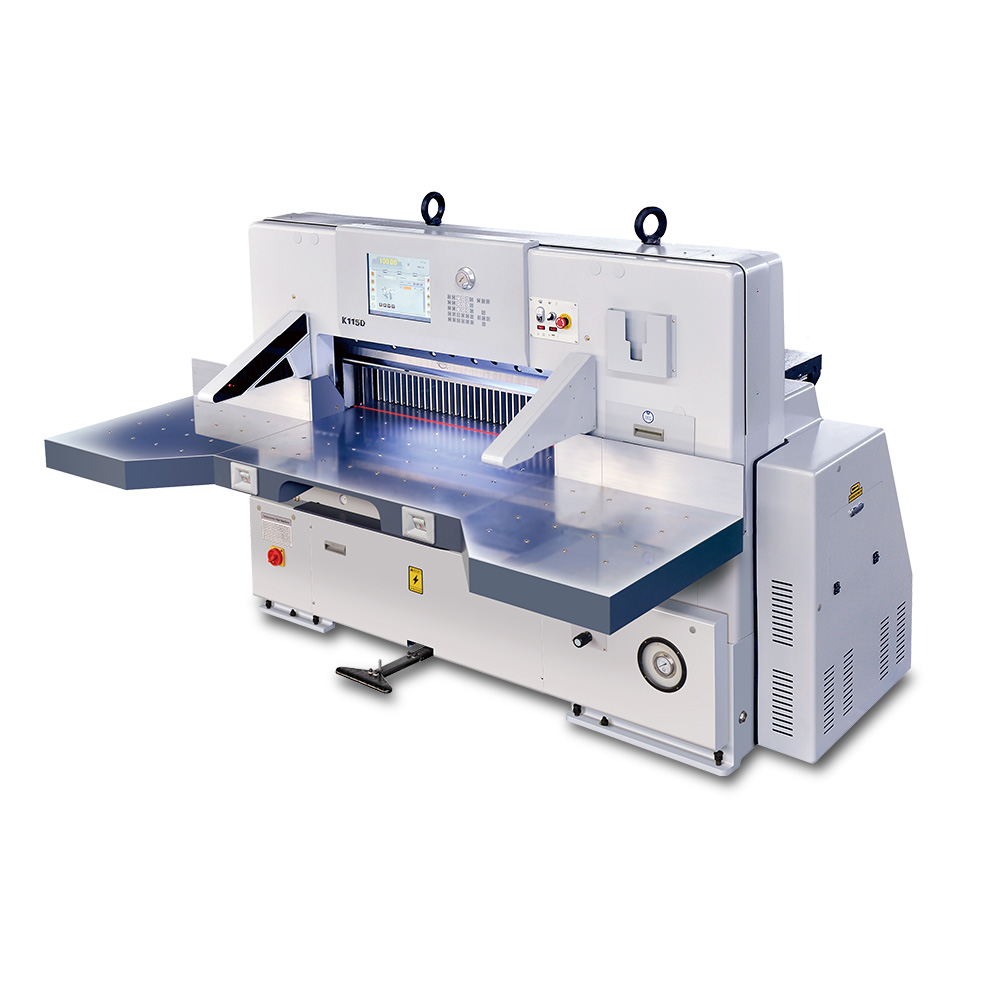

Alternatives Analysis: Comparing paper cutter machine With Other Solutions

When evaluating options for cutting paper in a business setting, it’s essential to consider various alternatives to the traditional paper cutter machine. Each solution presents unique benefits and limitations that can impact operational efficiency and cost-effectiveness. This analysis will compare the paper cutter machine with two viable alternatives: digital cutting software and manual cutting tools.

| Comparison Aspect | Paper Cutter Machine | Digital Cutting Software | Manual Cutting Tools |

|---|---|---|---|

| Performance | High precision, suitable for bulk cutting | Variable based on design complexity; requires skilled operators | Generally less precise; depends on user skill |

| Cost | Ranges from $900 to over $5,000 for automatic models | Initial software cost, plus ongoing licensing fees | Low initial cost, but may require multiple tools |

| Ease of Implementation | Requires physical space and setup | Software installation; requires training | Easy to use, no setup required; portable |

| Maintenance | Regular blade replacements; periodic servicing needed | Software updates; minimal maintenance | Manual tools require occasional sharpening and replacement |

| Best Use Case | High-volume cutting for businesses | Custom designs and patterns; prototyping | Low-volume jobs, crafts, or home use |

What Are the Advantages and Disadvantages of Digital Cutting Software?

Digital cutting software enables users to create intricate designs and cut patterns with high precision. This method is particularly beneficial for businesses that require customization, such as graphic design firms or print shops. However, the performance heavily relies on the operator’s skill level and understanding of the software. Additionally, while initial costs may be lower than purchasing a high-end machine, ongoing licensing fees can accumulate over time. This solution is best suited for companies that prioritize design flexibility and are willing to invest in training their staff.

How Do Manual Cutting Tools Compare in Practical Use?

Manual cutting tools, such as scissors or rotary cutters, are straightforward and portable, making them ideal for low-volume tasks. They have a minimal upfront cost and do not require extensive setup or maintenance. However, they lack the precision and efficiency of a paper cutter machine, particularly when handling larger stacks of paper. Manual tools are best for small businesses, schools, or crafts where high-volume cutting is not necessary, but the demand for precision remains important.

Illustrative image related to paper cutter machine

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right cutting solution hinges on understanding your specific operational needs, budget constraints, and volume of work. For high-volume environments, a paper cutter machine will typically offer the best balance of efficiency and precision. Conversely, if customization and design flexibility are paramount, digital cutting software may be more appropriate. For businesses with limited cutting needs, manual tools can suffice without the overhead associated with more advanced machinery. By analyzing these factors, B2B buyers can make informed decisions that enhance productivity and align with their strategic goals.

Essential Technical Properties and Trade Terminology for paper cutter machine

What Are the Essential Technical Properties of a Paper Cutter Machine?

When considering the purchase of a paper cutter machine, understanding its technical specifications is crucial for making an informed decision. Here are some key properties to evaluate:

-

Cutting Width

The cutting width refers to the maximum width of paper that the machine can cut in a single pass. This specification is vital for businesses that handle various paper sizes, from standard letter formats to larger sheets used in graphic design. A wider cutting width enables greater flexibility and efficiency in operations, particularly for high-volume tasks. -

Sheet Capacity

Sheet capacity indicates how many sheets the machine can cut at once. This property is essential for businesses that require high throughput. Machines with higher sheet capacities reduce the time spent on cutting and can significantly enhance productivity, making them ideal for print shops or packaging companies. -

Cutting Height Capacity

This specification defines the thickness of the stack of paper that the machine can handle. Understanding cutting height capacity is important for businesses that work with various paper types and thicknesses. Machines with higher cutting height capacities can accommodate thicker materials, which is beneficial for operations that deal with card stock or multiple sheets. -

Material Grade

The material grade of the cutter itself, including the construction of the cutting blades and frame, impacts durability and performance. High-grade materials often mean longer lifespan and better cutting precision. For B2B buyers, investing in machines made from robust materials can lead to lower maintenance costs and reduced downtime. -

Volume Throughput

Volume throughput measures the amount of paper processed by the cutter over a specified time. This property is crucial for businesses with tight deadlines and high demand. Understanding the throughput helps in selecting a machine that can meet production goals without bottlenecks. -

Safety Features

Safety features, such as blade guards and automatic shut-off mechanisms, are critical for protecting operators. A machine equipped with advanced safety features not only ensures compliance with industry standards but also minimizes the risk of workplace accidents, which can lead to costly liabilities.

What Are Common Trade Terms Related to Paper Cutter Machines?

Familiarity with trade terminology is just as important as understanding technical properties. Here are some common terms you should know:

Illustrative image related to paper cutter machine

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. When sourcing paper cutter machines, understanding OEM relationships can help in assessing product quality and warranty support. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers, as it can affect inventory management and cash flow. Knowing the MOQ helps businesses plan their purchases according to demand and budget. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. This term is essential in the procurement process, allowing businesses to compare prices and negotiate terms effectively. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC). They clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is critical for B2B buyers engaged in cross-border purchases, as they define who is responsible for shipping costs, insurance, and tariffs. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This term is vital for production planning, as longer lead times can impact workflow and delivery schedules. Knowing the lead time helps businesses manage expectations and optimize their operations. -

Warranty Period

The warranty period is the time frame during which a manufacturer guarantees the performance of their machine. This term is essential for B2B buyers, as it reflects the manufacturer’s confidence in the product and offers protection against defects, ensuring peace of mind in the investment.

By understanding these essential technical properties and industry terminology, B2B buyers can make informed decisions when purchasing paper cutter machines, ensuring they select the right equipment for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the paper cutter machine Sector

What Are the Current Trends Driving the Paper Cutter Machine Market?

The global paper cutter machine market is witnessing significant transformation driven by various factors. Increased demand for high-quality printing in commercial sectors, including publishing and advertising, is propelling the need for efficient cutting solutions. Additionally, the rise in digital printing technologies is pushing manufacturers to innovate their offerings, resulting in advanced features such as programmable settings and automated cutting processes. These developments cater to the growing preference for precision and efficiency among international B2B buyers, particularly in regions like Europe and the Middle East, where quality standards are exceptionally high.

Emerging technologies such as IoT and AI are also reshaping the landscape. Manufacturers are integrating smart features into paper cutters, allowing for real-time monitoring and optimization of cutting processes. This trend is especially appealing to B2B buyers looking to enhance productivity and reduce operational costs. Furthermore, the rise of e-commerce platforms has made sourcing more accessible, enabling buyers from Africa and South America to explore a wider range of options, including both manual and automatic machines tailored to their specific needs.

How Important Is Sustainability and Ethical Sourcing in the Paper Cutter Machine Industry?

Sustainability and ethical sourcing have become critical components of the purchasing decision for B2B buyers in the paper cutter machine sector. As environmental concerns grow, businesses are increasingly focused on the lifecycle impact of their machinery. This includes evaluating the materials used in manufacturing, energy consumption during operation, and the potential for recycling at the end of the machine’s life. Buyers are now prioritizing suppliers who demonstrate a commitment to reducing their environmental footprint, including the use of sustainable materials and processes.

Certifications such as ISO 14001 for environmental management and adherence to green manufacturing practices can significantly influence procurement decisions. Additionally, the use of eco-friendly lubricants and non-toxic materials in the production of cutting blades is gaining traction. By choosing suppliers with strong sustainability credentials, international B2B buyers can not only meet regulatory requirements but also enhance their brand reputation in increasingly eco-conscious markets.

What Is the Historical Context of Paper Cutter Machines in B2B Transactions?

The evolution of paper cutter machines reflects broader technological advancements in the printing and publishing sectors. Initially designed for manual use, early models of paper cutters required significant manual effort and skill. Over the decades, innovations led to the development of more automated solutions, dramatically increasing efficiency and precision. The introduction of hydraulic and electronic cutting machines in the late 20th century marked a significant turning point, enabling businesses to handle larger volumes with greater accuracy.

As the demand for customized printing solutions has grown, so too has the sophistication of paper cutter machines. Modern machines are equipped with features such as programmable cutting settings and advanced safety mechanisms, catering to the needs of diverse industries. This historical context underscores the importance of choosing the right equipment to stay competitive in an ever-evolving marketplace. International B2B buyers can leverage this knowledge to make informed decisions that align with their operational needs and growth strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of paper cutter machine

-

1. How do I choose the right paper cutter machine for my business needs?

Choosing the right paper cutter machine involves evaluating your specific requirements, including the volume of paper you handle, the types of cuts needed, and your budget. For high-volume tasks, consider automatic cutters that can handle larger stacks efficiently and reduce manual labor. If your needs are more modest or involve intricate cuts, a manual cutter may suffice. Additionally, assess features like cutting width, height, and safety mechanisms, ensuring the machine meets safety standards relevant to your region. -

2. What are the advantages of using automatic vs. manual paper cutters?

Automatic paper cutters offer speed and efficiency, making them ideal for businesses with high cutting volumes. They minimize human error and often come with programmable features for consistent results. Manual cutters, on the other hand, provide greater control for detailed tasks and are typically more cost-effective for smaller operations. Assess your operational scale and cutting precision requirements when choosing between the two. -

3. What customization options are available for paper cutter machines?

Many manufacturers offer customization options for paper cutter machines, allowing you to tailor features such as cutting size, blade type, and safety enhancements to meet your specific needs. Additionally, some suppliers provide options for branding the machines or integrating them with existing workflows. Discuss your requirements with potential suppliers to explore the available customization options and ensure they align with your operational needs. -

4. What is the typical minimum order quantity (MOQ) for paper cutter machines?

Minimum order quantities for paper cutter machines can vary significantly based on the manufacturer and the type of machine. Some suppliers may have an MOQ of one unit for smaller businesses, while others, especially for bulk purchases, may require larger quantities. It’s advisable to communicate directly with suppliers to understand their MOQ policies and negotiate terms that fit your purchasing strategy. -

5. How can I ensure the quality of the paper cutter machines I purchase?

To ensure quality, source machines from reputable manufacturers with a history of providing durable and reliable equipment. Request certifications, warranty details, and customer testimonials. Additionally, consider conducting a pre-purchase inspection or requesting samples if feasible. Engaging with suppliers who offer robust after-sales support can also enhance your confidence in the machine’s quality and performance. -

6. What payment terms should I expect when sourcing paper cutter machines internationally?

Payment terms for international orders can vary widely but typically include options such as full payment in advance, partial deposits, or net payment terms upon delivery. Common methods include wire transfers, letters of credit, or online payment platforms. Discuss payment terms upfront with suppliers to ensure they align with your cash flow and budgeting strategies, and be mindful of currency fluctuations that may affect the final cost. -

7. What logistics considerations should I keep in mind when importing paper cutter machines?

Logistics considerations include shipping methods, customs clearance, and delivery timelines. Choose a reliable shipping partner familiar with international trade regulations specific to your destination country. Understand the duties and taxes applicable to your purchase, and prepare necessary documentation for customs. Additionally, consider the machine’s weight and dimensions to determine the most cost-effective shipping options. -

8. How do I vet suppliers when sourcing paper cutter machines internationally?

Vetting suppliers involves researching their reputation, checking references, and evaluating their experience in the industry. Look for suppliers who have established relationships with businesses in your region and who provide transparent communication. Request samples or visit their manufacturing facility if possible. Additionally, review their compliance with international quality standards and their ability to provide after-sales support, ensuring a reliable partnership.

Top 6 Paper Cutter Machine Manufacturers & Suppliers List

1. Formax – CutTrue 13M

Domain: paperfolder.com

Registered: 2001 (24 years)

Introduction: Products: 1-12 of 12 Paper Cutters, Manual and Fully Automatic Paper Cutter Folding Machines, Shredders, Folder Inserters, Pressure Sealers, Cross Fold Machines. Manual Paper Cutters: Formax CutTrue 13M – 14.5″ Cutting Width, .75″ Cutting Height, Retail: $825.00, Price: $784.00; Martin Yale 7000E – 12″ Cutting Width, 1-1/2″ Cutting Height (up to 375 sheets), Retail: $2,075.00, Price: $1,199.00; Fo…

2. Whitaker Brothers – Commercial Paper Cutters

Domain: whitakerbrothers.com

Registered: 1996 (29 years)

Introduction: Commercial Paper Cutters | Automatic & Manual | Various Brands

3. Polar – Paper Cutters

Domain: papercutters.com

Registered: 1998 (27 years)

Introduction: Certified Used & Rebuilt Paper Cutters and Paper Handling Equipment. Types of machines include: Paper Cutters, Cutting Systems, Joggers, Loaders, Pile Turners, Stack Lifts, Unloaders, Three-Knife Trimmers, Sheeters. Brands include: Polar, PRISM, SABER, Challenge, Dexter, Lawson, Harris, Seybold, Perfecta, Wohlenberg, Baumann, Cauhe. Sizes range from 18″ to 144″. Machine conditions: As-Is, Certifie…

4. VEVOR – Electric Paper Cutter

Domain: vevor.com

Registered: 2009 (16 years)

Introduction: VEVOR Paper Cutter offers a range of cutting machines suitable for various needs. Key products include: 1. VEVOR Electric Paper Cutter – 1100W, 20.3 in cutting width, 3.1 in cutting thickness, features a 7 in touchscreen. Price: $2873.99. 2. VEVOR Electric Hydraulic Paper Cutter – 26 in cutting width, 3.14 in cutting thickness, 7 in touchscreen numerical control. Price: $4599.99. 3. VEVOR Electric…

5. Martin Yale – Professional Cutting Machines

Domain: martinyale-machines.com

Registered: 2007 (18 years)

Introduction: This company, Martin Yale – Professional Cutting Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Triumph – MBM Triumph 4305 Manual 16.8 Paper Cutter

Domain: triumphcutter.com

Registered: 2010 (15 years)

Introduction: [{‘name’: ‘MBM Triumph 4305 Manual 16.8″ Paper Cutter’, ‘price’: ‘$2,403’}, {‘name’: ‘MBM Triumph 5255 Automatic 20.4″ Paper Cutter’, ‘price’: ‘$15,077’}, {‘name’: ‘MBM Triumph 4315 Semi Automatic 16.8″ Paper Cutter’, ‘price’: ‘$5,721’}, {‘name’: ‘MBM Triumph 7260 Automatic 28″ Paper Cutter (VRCut Ready)’, ‘price’: ‘$32,654’}, {‘name’: ‘MBM Triumph 6655 Automatic 25.5″ Paper Cutter’, ‘price’: ‘$18…

Strategic Sourcing Conclusion and Outlook for paper cutter machine

As the demand for efficient and high-quality paper cutting solutions continues to rise across various industries, strategic sourcing of paper cutter machines has never been more critical. B2B buyers should prioritize selecting machines that align with their specific operational needs, whether that involves manual or automatic systems. Understanding key factors such as sheet capacity, cutting width, and durability will enable businesses to enhance productivity and minimize operational costs.

Investing in high-quality equipment not only ensures precision and safety but also fosters long-term partnerships with trusted suppliers, which is essential in today’s competitive market. Buyers from regions such as Africa, South America, the Middle East, and Europe—particularly Germany and Saudi Arabia—should leverage the expertise of established vendors to navigate their purchasing decisions effectively.

Looking ahead, as technology continues to evolve, the integration of automated solutions will likely become a standard requirement for businesses aiming to scale their operations. By engaging with reputable manufacturers and suppliers now, international buyers can position themselves advantageously for future growth and innovation in their paper processing capabilities. Take the next step towards optimizing your operations by exploring the latest offerings in paper cutter machines today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.