Tumbling Machine: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for tumbling machine

In the ever-evolving landscape of global manufacturing, sourcing a reliable tumbling machine can pose a significant challenge for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The right tumbling machine not only streamlines the finishing process but also enhances product quality, making it a critical investment for businesses aiming to maintain a competitive edge. This comprehensive guide will delve into the various types of tumbling machines, their applications across different industries, and essential criteria for vetting suppliers.

Understanding the nuances of these machines—from vibratory tumblers to barrel finishers—will empower international buyers to make informed decisions that align with their operational needs. Additionally, we will provide insights into cost considerations, ensuring that you can balance quality with budgetary constraints. By offering a detailed overview of market trends, technical specifications, and best practices, this guide serves as a vital resource for businesses looking to optimize their manufacturing processes. Whether you are in Germany, Vietnam, or beyond, navigating the complexities of the tumbling machine market becomes a more manageable task, paving the way for successful procurement and enhanced production capabilities.

Understanding tumbling machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vibratory Tumbler | High-speed operation, suitable for delicate and large parts | Metal and plastic parts deburring, polishing | Pros: Efficient, suitable for automation, minimal part stress. Cons: Initial investment can be high. |

| Barrel Finishing Machine | Rotational motion, typically for bulk processing | Mass finishing of small parts | Pros: Cost-effective for large batches. Cons: Less effective on intricate shapes. |

| Centrifugal Tumbler | High-speed centrifugal force, compact design | Precision deburring, polishing | Pros: Fast cycle times, effective for small parts. Cons: Limited capacity for larger items. |

| Dry Tumbling Machine | Utilizes dry media for finishing without moisture | Cleaning and polishing metal and plastic | Pros: Reduces drying time, ideal for moisture-sensitive materials. Cons: May not achieve as fine a finish as wet methods. |

| Aqueous Tumbling Machine | Uses liquid media for cleaning and finishing | Heavy-duty cleaning of industrial parts | Pros: Effective for removing tough contaminants, environmentally friendly. Cons: Requires more maintenance and water management. |

What Are the Key Characteristics of Vibratory Tumblers?

Vibratory tumblers are renowned for their high-speed operation and versatility, making them suitable for both delicate and larger parts. They utilize a unique shaking motion to create a rolling action that efficiently deburrs and polishes various materials. B2B buyers should consider their production needs, as vibratory tumblers can be automated for continuous operation, significantly reducing labor costs. However, the initial investment may be substantial, so assessing long-term benefits is crucial.

How Do Barrel Finishing Machines Differ from Other Types?

Barrel finishing machines operate on a rotational motion, allowing for the mass processing of small parts. This method is particularly effective for bulk finishing applications, where cost efficiency is paramount. While they are an economical choice for large batches, their effectiveness diminishes with intricate shapes or delicate components. Buyers should evaluate their specific finishing requirements against the machine’s capabilities to ensure optimal results.

What Makes Centrifugal Tumblers Unique?

Centrifugal tumblers leverage high-speed centrifugal force to achieve rapid deburring and polishing. Their compact design allows for efficient processing of small parts, making them ideal for precision applications. B2B buyers should consider cycle times and the machine’s capacity, as centrifugal tumblers may not accommodate larger items. The speed and effectiveness of these machines can significantly enhance productivity, but they may come with a higher price point.

When Should You Choose a Dry Tumbling Machine?

Dry tumbling machines utilize dry media for finishing, making them particularly suitable for moisture-sensitive materials. They excel in cleaning and polishing metal and plastic without the need for drying, thus reducing overall processing time. While they offer quick results, the finish may not be as refined as that achieved through wet methods. Buyers should weigh the advantages of time savings against the desired finish quality when selecting this type of machine.

Why Consider Aqueous Tumbling Machines for Heavy-Duty Cleaning?

Aqueous tumbling machines utilize liquid media, making them effective for cleaning and finishing tasks that require the removal of tough contaminants. Their environmentally friendly approach appeals to businesses focused on sustainability. However, they require more maintenance and careful water management. B2B buyers should assess their cleaning needs and environmental considerations when exploring aqueous tumbling options, as they can offer significant benefits for industrial applications.

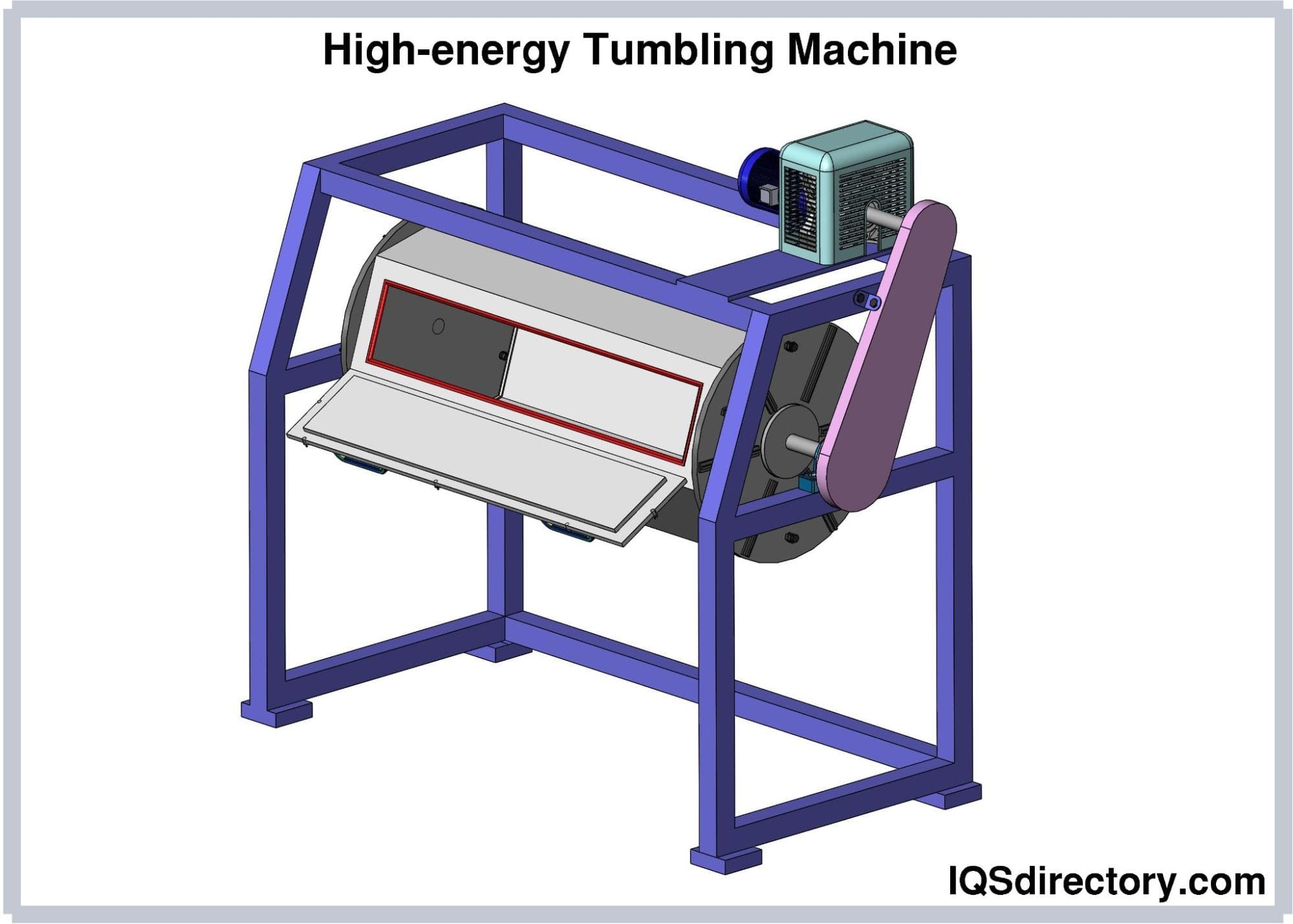

Illustrative image related to tumbling machine

Key Industrial Applications of tumbling machine

| Industry/Sector | Specific Application of Tumbling Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Deburring and polishing of aircraft components | Enhances safety and performance by ensuring precise finishes | Need for high tolerance and lightweight materials |

| Automotive | Surface finishing of metal and plastic parts | Reduces production time and improves part durability | Compatibility with various media types for different materials |

| Jewelry Manufacturing | Polishing and cleaning of intricate designs | Increases product appeal and customer satisfaction | Requirement for gentle processing to avoid damage |

| Electronics | Deburring of circuit boards and components | Improves reliability and functionality of electronic devices | Need for clean and precise finishes without contamination |

| Medical Devices | Finishing surgical instruments and implants | Ensures compliance with health standards and enhances safety | Strict adherence to regulatory standards and material safety |

How Are Tumbling Machines Utilized in the Aerospace Sector?

In the aerospace industry, tumbling machines are crucial for deburring and polishing components such as landing gear and turbine blades. These machines effectively remove sharp edges and unwanted burrs, enhancing the safety and performance of critical parts. Buyers in this sector must ensure that the tumbling machines can handle lightweight and high-tolerance materials, as precision is paramount in aerospace applications.

What Role Do Tumbling Machines Play in Automotive Manufacturing?

Tumbling machines are extensively used in the automotive sector for the surface finishing of both metal and plastic components, including gears and housings. By employing these machines, manufacturers can significantly reduce production times while improving the durability of parts. When sourcing tumbling machines, automotive buyers should prioritize compatibility with various media types to accommodate the different materials used in vehicle manufacturing.

How Are Tumbling Machines Beneficial in Jewelry Manufacturing?

In jewelry manufacturing, tumbling machines are employed for polishing and cleaning intricate designs, ensuring a high-quality finish that enhances product appeal. This process helps in removing oxidation and surface imperfections, leading to increased customer satisfaction. Buyers in this industry should seek machines that offer gentle processing capabilities to avoid damaging delicate pieces.

Why Are Tumbling Machines Important for Electronics?

Tumbling machines are essential in the electronics industry for deburring circuit boards and components, ensuring clean and precise finishes that enhance the reliability of electronic devices. The use of these machines minimizes the risk of contamination and improves overall functionality. Buyers should consider sourcing machines that can deliver consistent results without compromising the integrity of sensitive electronic components.

How Do Tumbling Machines Contribute to Medical Device Manufacturing?

In the medical device sector, tumbling machines are used for finishing surgical instruments and implants, ensuring compliance with stringent health standards. The smooth and polished surfaces achieved through tumbling reduce the risk of infection and enhance patient safety. Buyers must focus on sourcing machines that adhere to regulatory standards and utilize safe materials, as the stakes in this industry are particularly high.

3 Common User Pain Points for ‘tumbling machine’ & Their Solutions

Scenario 1: Inconsistent Finishing Quality Across Batches

The Problem: A manufacturer in the automotive parts industry faces challenges with inconsistent finishing quality in their vibratory tumbling operations. Due to varying load sizes and compositions, some batches emerge with a smooth finish, while others retain burrs or scratches. This inconsistency not only affects product quality but also leads to increased rework costs and potential customer dissatisfaction.

The Solution: To overcome this issue, it’s crucial to standardize the tumbling process by meticulously controlling several variables. Start by categorizing parts based on material, size, and finish requirements. Implement a systematic approach to adjust the tumbling media type, size, and shape according to each category. Regularly calibrate the machine settings, such as vibration frequency and cycle time, to ensure uniform results. Additionally, conducting periodic quality control checks on finished parts will help identify issues early. Investing in automation features, like load sensors and programmable controls, can enhance consistency by allowing for real-time adjustments based on the specific batch being processed.

Scenario 2: Equipment Downtime and Maintenance Challenges

The Problem: A metal fabrication company in Europe frequently experiences equipment downtime due to unexpected maintenance issues with their tumbling machines. These interruptions not only disrupt production schedules but also lead to increased operational costs and delayed deliveries, which can jeopardize client relationships.

The Solution: To mitigate downtime, establish a proactive maintenance schedule tailored to the specific requirements of your tumbling machines. Regularly inspect and maintain critical components, such as motors, bearings, and media separators, to prevent unexpected failures. Utilize a preventive maintenance management system that tracks machine usage and schedules maintenance based on operational hours or cycle counts. Additionally, consider training staff in basic troubleshooting to handle minor issues swiftly, reducing the need for external service calls. Partnering with a reliable equipment supplier who offers maintenance support can also ensure that you have access to expertise when needed, minimizing the risk of prolonged downtime.

Scenario 3: Difficulty in Selecting the Right Tumbling Media

The Problem: A supplier of precision components for the aerospace industry struggles with selecting the appropriate tumbling media for their diverse range of parts. Different materials and finishes require specific media types, and the wrong selection can lead to inadequate deburring or surface damage, impacting the integrity of critical components.

The Solution: To effectively choose the right tumbling media, start by conducting a comprehensive assessment of the parts to be processed. Consider factors such as material type, part geometry, and desired finish. Engage with media suppliers who can provide samples for testing to determine the best fit for your needs. It’s beneficial to experiment with different combinations of media types (ceramic, plastic, or steel) and sizes in small test runs before committing to larger batches. Document the outcomes to establish a reference for future operations. Furthermore, maintaining an open line of communication with your media supplier can provide insights into the latest advancements in media technology, ensuring you stay updated on options that might enhance your finishing processes.

Strategic Material Selection Guide for tumbling machine

What are the Key Materials Used in Tumbling Machines?

When selecting a tumbling machine, the choice of materials used in its construction and media is crucial for performance, durability, and cost-effectiveness. Here, we analyze four common materials: stainless steel, carbon steel, ceramic, and plastic. Each material has unique properties that can significantly impact the machine’s performance and suitability for specific applications.

How Does Stainless Steel Enhance Tumbling Machine Performance?

Stainless steel is a popular choice for both the construction of tumbling machines and the media used within them. Its key properties include excellent corrosion resistance, high strength, and the ability to withstand high temperatures. These characteristics make stainless steel particularly suitable for environments where moisture or chemical exposure is a concern.

Pros: Stainless steel is highly durable and maintains its integrity over time, even under rigorous use. It is also easy to clean, which is essential for maintaining hygiene in industries like food processing or pharmaceuticals.

Cons: The primary drawback of stainless steel is its cost, which can be significantly higher than other materials. Additionally, manufacturing processes can be more complex, leading to longer lead times.

Impact on Application: Stainless steel media is compatible with a wide range of materials, making it ideal for polishing metals and plastics without causing excessive wear.

Illustrative image related to tumbling machine

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN, especially in regions like Europe where regulations are stringent.

What Advantages Does Carbon Steel Offer for Tumbling Machines?

Carbon steel is another commonly used material, especially for tumbling media. It is known for its high tensile strength and durability, making it effective for heavy-duty applications.

Pros: Carbon steel is generally more affordable than stainless steel and offers excellent performance in abrasive applications. It is also readily available, which can shorten lead times.

Cons: However, carbon steel is susceptible to rust and corrosion if not properly maintained, which can limit its lifespan in humid or corrosive environments.

Impact on Application: Carbon steel media is particularly effective for deburring and polishing operations on ferrous materials but may not be suitable for non-ferrous applications due to the risk of contamination.

Considerations for International Buyers: Buyers from regions with high humidity, such as parts of Africa and South America, should consider the need for protective coatings or treatments to enhance corrosion resistance.

Why Choose Ceramic Media for Tumbling Machines?

Ceramic materials are widely used for tumbling media due to their hardness and ability to produce a superior finish.

Pros: Ceramic media is highly durable and effective for aggressive deburring and polishing. It can achieve finer finishes than many other media types, making it suitable for high-precision applications.

Cons: The primary limitation of ceramic media is its brittleness, which can lead to breakage if not handled properly. Additionally, it can be more expensive than other media options.

Impact on Application: Ceramic media is compatible with a variety of materials, including metals and plastics, and is often used in applications requiring a high degree of surface finish.

Considerations for International Buyers: Buyers should verify that the ceramic media meets local and international standards for manufacturing and safety, particularly in regulated markets.

What Role Does Plastic Play in Tumbling Machines?

Plastic media is increasingly used in tumbling applications, especially for delicate parts that require gentle treatment.

Pros: Plastic media is lightweight, non-abrasive, and less likely to damage fragile components. It is also resistant to moisture and chemicals, making it suitable for a variety of environments.

Cons: However, plastic media typically has a shorter lifespan compared to metal or ceramic options, which can lead to higher replacement costs over time.

Impact on Application: Plastic media is ideal for polishing and deburring softer materials, such as aluminum or plastic components, without causing damage.

Considerations for International Buyers: Buyers should ensure that the plastic media complies with relevant safety and environmental regulations in their regions.

Summary Table of Material Selection for Tumbling Machines

| Material | Typical Use Case for tumbling machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Polishing metals and plastics | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Carbon Steel | Heavy-duty deburring | Affordable and durable | Susceptible to rust and corrosion | Medium |

| Ceramic | Aggressive deburring and polishing | Produces superior finishes | Brittle and can break easily | High |

| Plastic | Gentle polishing of delicate parts | Non-abrasive and moisture-resistant | Shorter lifespan | Medium |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their tumbling machine choices based on specific applications and regional considerations.

Illustrative image related to tumbling machine

In-depth Look: Manufacturing Processes and Quality Assurance for tumbling machine

What Are the Main Stages in the Manufacturing Process of Tumbling Machines?

The manufacturing process of tumbling machines involves several critical stages that ensure the equipment meets industry standards and client specifications. Understanding these stages is essential for B2B buyers to make informed purchasing decisions.

1. Material Preparation

The first step in manufacturing tumbling machines is material preparation. High-quality raw materials, such as stainless steel or carbon steel, are sourced based on the machine’s intended application. Material selection is crucial, as it affects the durability and performance of the tumbling machine. Suppliers often conduct chemical composition tests to ensure the materials meet industry specifications.

2. Forming and Fabrication

Once the materials are prepared, the next stage involves forming and fabrication. This includes cutting, bending, and welding components to create the machine’s frame and structure. Advanced techniques like laser cutting and CNC machining are often employed to ensure precision and reduce waste. Each component, including the bowl, motor mounts, and drive systems, is fabricated to specific tolerances to facilitate efficient assembly later in the process.

3. Assembly Process

The assembly of tumbling machines is a critical phase that combines all fabricated components into a functional unit. This step often involves mechanical assembly, electrical wiring, and the installation of control systems. Skilled technicians carefully follow assembly protocols to ensure each machine operates correctly. During this stage, it’s common to integrate automation features that enhance efficiency and ease of use, especially for large-scale operations.

4. Finishing Techniques

Finishing processes are applied to enhance the machine’s aesthetic appeal and protect it from corrosion and wear. Techniques such as powder coating or anodizing are commonly used. These finishing methods not only improve the machine’s appearance but also extend its lifespan by providing a protective layer against environmental factors. Additionally, any necessary adjustments are made to ensure the machine operates at optimal efficiency.

How Is Quality Assurance Managed in Tumbling Machine Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of tumbling machines, ensuring that each product meets rigorous standards for performance and safety. B2B buyers should be aware of various QA processes and certifications that manufacturers adhere to.

Relevant International Standards for Quality Assurance

Manufacturers often comply with international quality standards such as ISO 9001, which outlines the requirements for a quality management system (QMS). This standard ensures that organizations consistently meet customer and regulatory requirements. For tumbling machines, other industry-specific certifications may include CE marking for compliance with European safety standards and API standards for equipment used in oil and gas industries.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically integrated throughout the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During the fabrication and assembly phases, regular inspections are conducted to identify any deviations from quality standards. This may include dimensional checks and functionality tests.

-

Final Quality Control (FQC): Once the machine is fully assembled, it undergoes a comprehensive final inspection, which includes operational testing to verify that all components function correctly and meet performance specifications.

What Common Testing Methods Are Used to Ensure Quality?

Various testing methods are employed to validate the quality and performance of tumbling machines. These include:

-

Functional Testing: Ensuring the machine operates as intended under load conditions.

-

Durability Testing: Assessing the machine’s performance over extended periods to identify any potential wear issues.

-

Vibration Analysis: Evaluating the machine’s stability and operational smoothness, which is crucial for maintaining consistent performance.

-

Noise Level Testing: Ensuring that the machine operates within acceptable noise limits, particularly for industrial environments.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control measures is essential to ensure they receive high-quality equipment. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits of the supplier’s manufacturing facility can help buyers assess compliance with quality standards and operational practices.

-

Request Quality Control Documentation: Buyers should request reports detailing the QC processes, including IQC, IPQC, and FQC results. This documentation provides insight into the reliability and consistency of the manufacturing process.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control practices. This is particularly important for international transactions where distance may complicate direct oversight.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control is crucial, especially when sourcing from different regions. Buyers should consider the following:

-

Regulatory Compliance: Different regions may have varying regulations regarding equipment safety and quality. Buyers should ensure that the machinery complies with local regulations in their respective countries.

-

Cultural Considerations: Understanding cultural differences in business practices can impact communication and expectations regarding quality. Establishing clear quality expectations and regular communication can mitigate potential misunderstandings.

-

Supply Chain Transparency: Buyers should seek suppliers who provide transparent supply chain information, including sourcing of materials and manufacturing practices, to ensure compliance with ethical and quality standards.

By comprehensively understanding the manufacturing processes and quality assurance practices associated with tumbling machines, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tumbling machine’

To ensure a successful procurement of tumbling machines, this guide provides a structured checklist for B2B buyers. By following these steps, buyers can make informed decisions that align with their operational requirements, budget, and quality standards.

Illustrative image related to tumbling machine

Step 1: Define Your Technical Specifications

Understanding your specific needs is paramount. Consider the size, weight, and type of parts you intend to process with the tumbling machine. Determine if you need a vibratory tumbler for delicate components or a barrel system for bulkier items. This clarity will streamline your sourcing process and help you identify the right machine.

Step 2: Assess Your Processing Requirements

Identify whether your applications require wet or dry processing. Each method has its benefits; for instance, wet processing can enhance cleaning and polishing, while dry processing is more suited for certain materials and quicker operations. Outline the cycle times, production volumes, and desired finishes to ensure that the tumbling machine meets your operational efficiency goals.

Step 3: Evaluate Potential Suppliers

Before making a purchase, thoroughly vet your potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. Verify their track record in providing reliable machinery and after-sales support, as this can significantly affect your long-term operational success.

- Check Certifications: Ensure that the suppliers comply with international quality standards, such as ISO certifications, which can be indicative of their manufacturing quality and reliability.

Step 4: Review Machine Features and Customization Options

Different tumbling machines come with various features that can enhance performance. Look for machines with adjustable speeds, multiple media options, and automation capabilities. Additionally, consider whether the supplier offers customization to tailor the machine to your specific needs, such as adapting to various part sizes or integrating with existing processes.

Step 5: Request Demonstrations and Trials

Whenever possible, request demonstrations or trials of the tumbling machines you are considering. This hands-on experience is invaluable in understanding the machine’s operation, efficiency, and the quality of the finish it produces. It’s also an opportunity to evaluate the supplier’s responsiveness and customer service during the process.

Illustrative image related to tumbling machine

Step 6: Compare Total Cost of Ownership (TCO)

Beyond the initial purchase price, evaluate the total cost of ownership, which includes maintenance, operational costs, and potential downtime. Consider energy consumption, wear and tear on components, and the availability of replacement parts. A more expensive machine may offer better durability and lower operational costs over time.

Step 7: Finalize Purchase Terms and Support Agreements

Once you have selected a supplier, clarify the purchase terms, including payment options, delivery timelines, and warranty conditions. Ensure that support agreements are in place for maintenance and troubleshooting. A solid support plan can minimize disruptions and extend the lifespan of your tumbling machine.

By following this checklist, B2B buyers can confidently navigate the procurement of tumbling machines, ensuring they select the right equipment for their needs while establishing a reliable partnership with their supplier.

Comprehensive Cost and Pricing Analysis for tumbling machine Sourcing

What Are the Key Cost Components in Tumbling Machine Sourcing?

When sourcing tumbling machines, understanding the cost structure is vital for effective budgeting and procurement. The primary components of cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the price. Common materials used in tumbling machines include steel for structural components and various types of media for the tumbling process. Higher-grade materials often result in increased durability and performance but come at a higher upfront cost.

-

Labor: Labor costs can vary widely based on the region and the complexity of the machine. Skilled labor is essential for assembly and quality assurance, particularly in regions with strict manufacturing standards.

-

Manufacturing Overhead: This includes indirect costs such as utilities, facility maintenance, and administrative expenses. Manufacturers with efficient operations can offer more competitive pricing.

-

Tooling: Custom tooling for specific tumbling machine designs can be a significant cost. Buyers should assess whether standard designs can meet their needs to minimize tooling expenses.

-

Quality Control (QC): Rigorous QC processes ensure that machines meet performance and safety standards. The costs associated with QC can vary based on certification requirements and testing protocols.

-

Logistics: Transportation costs, including shipping and handling, can substantially affect the final price. For international buyers, understanding Incoterms is crucial to determining who bears the cost and risk during transport.

-

Margin: Suppliers typically add a margin to cover their costs and profits. This margin can be influenced by market competition, demand for specific machines, and the supplier’s reputation.

How Do Price Influencers Affect Tumbling Machine Costs?

Several factors can influence the price of tumbling machines. Understanding these can help buyers negotiate better deals.

-

Volume and Minimum Order Quantity (MOQ): Purchasing larger quantities often leads to volume discounts. Buyers should consider their long-term needs to optimize their purchasing strategy.

-

Specifications and Customization: Custom machines tailored to specific requirements usually come with higher costs. Buyers should evaluate whether standard models can meet their needs to avoid unnecessary expenses.

-

Materials and Quality Certifications: Machines made from premium materials and those that comply with international quality certifications (e.g., ISO) may command higher prices. However, these machines often provide better performance and longevity, contributing to a lower Total Cost of Ownership (TCO).

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may offer premium products at higher prices but often provide better warranties and support.

-

Incoterms: Understanding Incoterms is essential for international buyers. These terms dictate the responsibilities of buyers and sellers in the shipping process, affecting overall costs and risk exposure.

What Are Effective Buyer Tips for Negotiating Tumbling Machine Prices?

-

Negotiation: Don’t hesitate to negotiate prices, especially for bulk orders. Suppliers often have flexibility in pricing, especially if they want to secure a long-term contract.

-

Cost-Efficiency: Look beyond the initial price. Calculate the TCO, including maintenance, energy consumption, and downtime, to ensure that you’re making a financially sound decision.

-

Research Market Prices: Familiarize yourself with current market prices and trends. This information can be invaluable during negotiations and can help you identify fair pricing.

-

Understand Pricing Nuances for International Purchases: Buyers from Africa, South America, the Middle East, and Europe should consider currency fluctuations, import duties, and taxes when calculating the final cost of machines sourced from abroad.

-

Request Multiple Quotes: Obtaining multiple quotes from different suppliers can provide a clearer picture of the market and help in negotiating better terms.

Disclaimer on Indicative Prices

Prices for tumbling machines can vary significantly based on specifications, supplier location, and market conditions. Always consult with suppliers for the most accurate and up-to-date pricing information tailored to your specific needs.

Alternatives Analysis: Comparing tumbling machine With Other Solutions

Exploring Alternatives to Tumbling Machines in Surface Finishing

In the realm of surface finishing, tumbling machines are a popular choice for deburring and polishing. However, several alternatives exist that may better suit specific operational needs or budget constraints. This analysis will compare tumbling machines with vibratory finishers and abrasive blasting systems, highlighting their unique advantages and limitations.

| Comparison Aspect | Tumbling Machine | Vibratory Finisher | Abrasive Blasting System |

|---|---|---|---|

| Performance | High efficiency for batch processing | Excellent for complex shapes and sizes | Superior for removing coatings and rust |

| Cost | Moderate initial investment | Generally lower than tumblers | Higher operational costs due to media and maintenance |

| Ease of Implementation | Requires setup and training | Easier to integrate into existing processes | Needs specialized training and safety measures |

| Maintenance | Moderate; periodic media replacement | Low; routine cleaning and media replacement | High; requires regular maintenance and safety checks |

| Best Use Case | High-volume production of uniform parts | Delicate or intricate part finishing | Heavy-duty cleaning and surface preparation |

What Are the Benefits and Drawbacks of Vibratory Finishers?

Vibratory finishers are an alternative to tumbling machines that utilize a shaking motion to polish and deburr parts. The primary advantage of vibratory systems is their ability to handle a wide variety of shapes and sizes, including delicate components. Additionally, they can be fully automated, enhancing efficiency in production lines. However, they may not achieve the same level of uniformity and efficiency in large batch processing as tumbling machines, potentially leading to longer cycle times for specific applications.

How Do Abrasive Blasting Systems Compare?

Abrasive blasting systems are well-suited for heavy-duty applications, particularly in cleaning rust, paint, and other surface contaminants from metal parts. The blasting process provides a thorough clean, which can be essential for surface preparation before coating or painting. However, abrasive blasting typically incurs higher operational costs due to the need for specialized media and safety equipment. It also requires significant training to ensure safe operation, which may not be practical for smaller operations.

How Should B2B Buyers Choose the Right Solution for Their Needs?

When selecting between tumbling machines and their alternatives, B2B buyers should consider several factors: the specific requirements of their production processes, the materials being finished, and budget constraints. For high-volume production of uniform parts, tumbling machines may provide the best efficiency. Conversely, if the application involves delicate or intricate components, vibratory finishers might be the better choice. For heavy-duty cleaning tasks, abrasive blasting systems can deliver superior results, albeit with increased operational complexities. Ultimately, aligning the choice with operational goals and production demands will ensure the most effective investment in finishing technology.

Essential Technical Properties and Trade Terminology for tumbling machine

What Are the Key Technical Properties of Tumbling Machines?

When considering a tumbling machine for industrial applications, understanding its technical properties is crucial for making informed purchasing decisions. Here are several essential specifications that can impact performance and efficiency:

-

Material Grade

The construction material of a tumbling machine significantly affects its durability and performance. Common materials include carbon steel, stainless steel, and composite materials. Stainless steel offers excellent corrosion resistance, making it ideal for wet applications, while carbon steel is often chosen for its strength and cost-effectiveness. Selecting the right material grade ensures longevity and minimizes maintenance costs, especially in high-volume operations. -

Tumbling Capacity

This specification refers to the maximum load that a tumbling machine can handle at one time, often measured in kilograms or liters. Understanding the tumbling capacity is vital for matching the machine to production needs. Overloading can lead to inefficient finishing and increased wear on the machine, while underutilization can result in higher operational costs. -

Cycle Time

Cycle time is the duration required to complete a tumbling process from start to finish. It is influenced by factors such as the type of media used, the size and shape of the parts being processed, and the machine’s design. Shorter cycle times can enhance productivity, enabling manufacturers to meet tight deadlines and improve throughput. -

Vibration Frequency and Amplitude

These parameters determine how effectively the tumbling machine can deburr and polish parts. Higher vibration frequencies and appropriate amplitudes lead to more efficient material removal. However, selecting the right balance is critical to avoid damaging delicate components. Understanding these settings can help buyers tailor the machine’s operation to specific applications. -

Media Type Compatibility

Different tumbling machines are designed to work with specific types of media, including ceramic, plastic, and steel. Each media type has its own properties that affect the finishing process. For instance, ceramic media is often used for heavy deburring, while plastic media is more suitable for delicate parts. Knowing the compatibility of the machine with various media types can enhance the finishing quality and efficiency. -

Automation Features

Automation capabilities, such as programmable controls and automatic media separation, can greatly enhance operational efficiency. Machines equipped with these features can reduce labor costs and improve consistency in finishing processes. For B2B buyers, investing in automation can lead to significant long-term savings and productivity gains.

What Are Common Trade Terms Related to Tumbling Machines?

Understanding industry-specific jargon is essential for effective communication and decision-making in B2B transactions involving tumbling machines. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce equipment or components that are marketed by another company. In the context of tumbling machines, buyers often seek OEMs for reliable and compatible parts, ensuring optimal performance and longevity. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for buyers to manage inventory and avoid over-commitment. It can also influence the negotiation process, especially for larger orders. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. When considering tumbling machines, submitting an RFQ can help buyers obtain competitive pricing and terms, allowing for better budget planning. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery obligations associated with tumbling machine purchases. -

Lead Time

Lead time is the period between placing an order and receiving the product. Knowing the lead time for tumbling machines can assist buyers in scheduling production and managing workflow effectively. -

Technical Specifications Sheet

This document provides detailed information about the machine’s features, capacities, and operational guidelines. Reviewing a technical specifications sheet is vital for buyers to ensure the machine meets their specific needs and expectations.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when investing in tumbling machines, ensuring that they select the right equipment for their operational requirements.

Navigating Market Dynamics and Sourcing Trends in the tumbling machine Sector

What Are the Key Market Dynamics and Trends Impacting the Tumbling Machine Sector?

The tumbling machine market is experiencing robust growth, driven by the increasing demand for efficient and effective surface finishing solutions across various industries, including automotive, aerospace, and manufacturing. As international buyers from regions like Africa, South America, the Middle East, and Europe look to enhance their production capabilities, they are gravitating towards advanced tumbling technologies that offer precision, speed, and automation. Current trends indicate a shift towards vibratory tumblers due to their versatility in handling both small and large parts while ensuring minimal damage during the finishing process. This adaptability makes them particularly appealing for manufacturers aiming to maintain high-quality standards in tight-tolerance applications.

Emerging technologies such as Industry 4.0 integration are also influencing sourcing decisions. Automated vibratory tumblers that can operate in a continuous flow-through manner are becoming increasingly popular, reducing labor costs and cycle times. Moreover, buyers are exploring options that allow for process customization, including the ability to switch between wet and dry processing, which enhances the overall efficiency of finishing operations. The emphasis on reducing operational downtime while maximizing output is reshaping purchasing strategies, with buyers seeking suppliers that provide robust support and maintenance services alongside their machinery.

How Is Sustainability Shaping the Sourcing of Tumbling Machines?

Sustainability is becoming a pivotal factor in sourcing decisions for tumbling machines. The environmental impact of manufacturing processes is under scrutiny, prompting buyers to prioritize equipment that minimizes waste and energy consumption. Companies are increasingly interested in suppliers who demonstrate a commitment to ethical sourcing and sustainable manufacturing practices, such as using recyclable materials and eco-friendly technologies.

Moreover, certifications like ISO 14001 (Environmental Management) and adherence to green manufacturing standards are becoming essential criteria for B2B buyers. These certifications not only affirm a supplier’s commitment to minimizing their environmental footprint but also enhance the buyer’s brand reputation in markets that are progressively valuing sustainability. The adoption of biodegradable tumbling media and energy-efficient systems is gaining traction, aligning with the global push towards greener industrial practices. Buyers are encouraged to engage with suppliers who provide transparent sourcing channels and demonstrate innovation in sustainable product offerings.

What Is the Evolution of Tumbling Machines and Its Importance for B2B Buyers?

The evolution of tumbling machines can be traced back to their origins in the early 20th century when manufacturers sought efficient ways to finish metal parts. Initially limited to simple barrel tumblers, advancements in technology led to the development of vibratory tumblers and other specialized systems that cater to diverse finishing needs. This transformation has allowed manufacturers to refine their processes, resulting in improved product quality and reduced labor costs.

For B2B buyers, understanding the history and technological advancements in tumbling machines is crucial. It provides insights into the capabilities and limitations of different systems, enabling informed purchasing decisions. As the industry continues to innovate with automation and sustainable practices, buyers can leverage this knowledge to align their sourcing strategies with future market demands and technological advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of tumbling machine

-

How do I solve issues with inconsistent finishes using a tumbling machine?

Inconsistent finishes often result from improper media selection or incorrect machine settings. To address this, ensure you are using the appropriate tumbling media that matches the material and desired finish of your parts. Adjust the machine’s speed and cycle time to optimize the tumbling process. Regular maintenance of the tumbling machine, including cleaning and checking for wear, is also crucial. If problems persist, consult with your supplier for tailored advice or consider testing different media combinations to achieve the desired finish. -

What is the best tumbling machine for large batch production?

For large batch production, a heavy-duty vibratory tumbler is typically the best choice. These machines are designed to handle high volumes of parts while ensuring consistent deburring and polishing. Look for models with adjustable settings for cycle times and media types to accommodate various materials. Additionally, automated systems can enhance efficiency by reducing manual handling. Brands like Kramer Industries offer robust options tailored for large-scale operations, making them ideal for industries such as automotive and aerospace. -

How can I ensure the quality of tumbling machines from international suppliers?

To ensure quality from international suppliers, start by verifying their certifications and compliance with industry standards, such as ISO 9001. Request samples or case studies showcasing their machinery in action, particularly in applications relevant to your needs. Additionally, consider conducting factory visits or audits if feasible, or using third-party inspection services to assess the machinery before shipment. Building a relationship with the supplier and maintaining open communication can also help address any quality concerns early in the process. -

What are the common payment terms when purchasing tumbling machines internationally?

Payment terms for international purchases can vary widely but typically include options such as letter of credit, advance payment, or payment upon delivery. Many suppliers may require a deposit (usually 30-50%) to initiate production, with the balance due before shipping. It’s essential to clarify payment terms in advance and ensure they are documented in the sales agreement. Discussing terms that align with your cash flow and risk management strategies will help facilitate a smoother transaction. -

What is the typical minimum order quantity (MOQ) for tumbling machines?

The minimum order quantity for tumbling machines can vary significantly based on the supplier and the type of machine. While some manufacturers may offer single units, others may have MOQs ranging from 2 to 5 machines, especially for custom or specialized models. It’s advisable to communicate your needs upfront and negotiate terms that fit your production requirements. Understanding the supplier’s production capabilities can also provide insights into potential flexibility regarding MOQs. -

How can I customize a tumbling machine to meet my specific production needs?

Customization options for tumbling machines may include adjustments to size, capacity, and features such as automation levels or integrated media separation systems. When approaching a supplier, clearly outline your production requirements and desired outcomes. Many manufacturers offer tailored solutions based on your specifications, including modifications for specific part geometries or materials. Engaging in discussions early in the procurement process will facilitate a better understanding of what can be achieved within your budget and timeframe. -

What logistics considerations should I keep in mind when importing tumbling machines?

Logistics considerations include shipping methods, customs regulations, and potential import duties that can affect the overall cost. Evaluate whether air freight or sea freight is more suitable based on your timeline and budget. Ensure that your supplier provides all necessary documentation, including invoices, packing lists, and certificates of origin, to facilitate smooth customs clearance. Engaging a freight forwarder experienced in handling industrial machinery can streamline the logistics process and mitigate potential delays. -

How do I maintain a tumbling machine for optimal performance?

Regular maintenance is essential for ensuring the optimal performance of tumbling machines. This includes routine cleaning of the machine and media, checking for wear and tear, and lubricating moving parts as specified by the manufacturer. Additionally, monitor the machine’s settings and performance regularly to identify any deviations that may indicate maintenance is required. Scheduling periodic professional inspections can help extend the machine’s lifespan and maintain consistent production quality.

Top 7 Tumbling Machine Manufacturers & Suppliers List

1. Kramer Industries – Vibratory Finishing System

Domain: kramerindustriesonline.com

Registered: 2001 (24 years)

Introduction: Vibratory Tumbler – Vibratory Finishing System:

– Ideal for batch and continuous parts deburring and vibratory polishing.

– Suitable for delicate parts with pockets, recesses, and bores.

– Available in bench model sizes for small parts and large tub and bowl style systems for bigger batches.

– Produces a cutting action by shaking the tub at high speed, allowing thorough and precise abrasions t…

2. IQS Directory – Tumbling Machines

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Tumbling machines are durable equipment designed for deburring and polishing metals, suitable for both large components and smaller parts. They operate by rotating parts inside a multi-faceted, urethane-coated barrel filled with processing media and a liquid compound. Key components include the machine structure (vibratory tub, motor, electric control panel, spring system), water for reducing fric…

3. Best Technology Inc – Centrifugal Barrel Finishing Machines

Domain: besttechnologyinc.com

Registered: 2001 (24 years)

Introduction: Centrifugal barrel finishing machines are designed for deburring and polishing large quantities of metal parts simultaneously. They utilize a cyclical sliding action to grind metal surfaces and are known for being fast and cost-effective. This type of mass finishing applies surface finishing to loose metal parts placed in a container, creating friction that results in cutting action on the metal s…

4. Contenti – Thumler’s Wet-or-Dry Rotary Tumbler Model B

Domain: contenti.com

Registered: 1997 (28 years)

Introduction: Vibratory & Tumbling products include a variety of vibratory finishing machines for deburring and polishing small parts, magnetic burnishing tumblers, abrasive tumbling media, and soaps. Key items include: 1. Thumler’s Wet-or-Dry Rotary Tumbler Model B – Starting at $12.65 2. VFM5 Vibratory Finishing Machine – Starting at $27.30 3. Raytech Adjusta-Vibe 40SS Vibratory Finisher – Starting at $1,546….

5. CM Topline – High Energy Centrifugal Barrel Tumblers

Domain: cmtopline.com

Registered: 2017 (8 years)

Introduction: {“products”:[{“name”:”CB-100 High Energy Centrifugal Barrel Tumbler”,”price”:”$42,300.00 USD”},{“name”:”CB-60 High Energy Centrifugal Barrel Tumbler”,”price”:”$33,500.00 USD”},{“name”:”CB-30 High Energy Centrifugal Barrel Tumbler”,”price”:”$24,400.00 USD”},{“name”:”Mr. Deburr DB600 (6.5 Cubic Foot)”,”price”:”$7,355.00 USD”},{“name”:”Mr. Deburr QDB3 (Portable, Quiet 3 Cubic Foot)”,”price”:”From $5,…

6. Deburring Machinery – Tumbling Machines

Domain: deburringmachinery.com

Registered: 2000 (25 years)

Introduction: Tumbling machines, also known as barrel tumblers, are essential tools for manufacturing processes used to smooth, polish, and deburr metal parts, plastics, and other materials. They have applications in various industries, including jewelry-making and metal fabrication. Key manufacturers include Otec USA Inc., ESMA, Inc., and Great Lakes Finishing Equipment, which offer a range of mass finishing e…

7. Giant Finishing – Surface Finishing Equipment

Domain: giantfinishing.com

Registered: 2000 (25 years)

Introduction: Giant Finishing, Inc. offers a range of surface finishing equipment and services, including:

1. **Machinery/Equipment**:

– Vibratory Tubs:

– Wedge Series

– GT Series

– Vibratory Bowls:

– GB Series

– GBB Series

– GO Series

– Vibratory Cob Dryers

– Continuous Flow FT Series

– High Energy Centrifugal Barrel

– GCB Series Slurry Blasters

– GSB Series Engin…

Strategic Sourcing Conclusion and Outlook for tumbling machine

In the rapidly evolving landscape of manufacturing, the strategic sourcing of tumbling machines is crucial for businesses aiming to enhance operational efficiency and product quality. Vibratory tumblers, known for their versatility in handling various part sizes and materials, provide significant advantages such as reduced labor costs and shorter cycle times. Their ability to automate processes not only streamlines production but also ensures consistent finishes across large batches, making them an invaluable asset in competitive markets.

International buyers from regions like Africa, South America, the Middle East, and Europe should prioritize sourcing high-quality tumbling machines that align with their specific operational needs. Understanding the diverse applications—from deburring to polishing—enables companies to select the right equipment that meets industry standards and enhances productivity.

Illustrative image related to tumbling machine

Looking ahead, the demand for advanced tumbling solutions is expected to grow as industries continue to emphasize efficiency and sustainability. Investing in state-of-the-art tumbling machines will not only improve product quality but also position businesses favorably in a global marketplace. Engage with trusted suppliers today to explore tailored solutions that will propel your operations into the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.