A B2B Buyer’s Guide to Cleated Conveyor Belt: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for cleated conveyor belt

In the fast-paced world of manufacturing and logistics, sourcing the right cleated conveyor belt can be a daunting challenge. These specialized belts are essential for effectively moving products, especially in applications that require secure handling on inclines and declines. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe (including Brazil and Germany) seek to optimize their operations, understanding the intricacies of cleated conveyor belts becomes crucial for informed decision-making.

This comprehensive guide delves into the diverse types of cleated conveyor belts available in the market, exploring their various applications across industries such as food processing, automotive, and pharmaceuticals. We will also cover critical aspects such as supplier vetting, ensuring that you partner with reliable manufacturers who adhere to quality standards and safety regulations. Additionally, we provide insights into cost considerations, enabling you to make budget-conscious choices without compromising on quality.

By equipping you with in-depth knowledge and actionable insights, this guide empowers B2B buyers to navigate the complexities of the cleated conveyor belt market confidently. Whether you’re looking to enhance production efficiency, minimize product loss, or comply with stringent safety requirements, our resource will serve as your trusted companion in making strategic purchasing decisions that align with your operational goals.

Understanding cleated conveyor belt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| T-Cleat | Standard design, uniform height, versatile applications | General manufacturing, food processing | Pros: Easy to install; Cons: Limited height options. |

| Scoop Cleat | Angled design for improved capacity on inclines | Bulk handling, packaging, and assembly lines | Pros: Enhanced grip; Cons: May require more space. |

| Beefy Cleat | Extra thick for heavy loads, robust construction | Heavy-duty applications, mining, and recycling | Pros: High durability; Cons: Heavier and more expensive. |

| Gusset Cleat | Reinforced backing for added strength | Industries handling large or heavy items | Pros: Enhanced load stability; Cons: May complicate installation. |

| Baseless HF Cleat | High-frequency welded, no base for a sleek profile | Food industry, cleanroom applications | Pros: Seamless bond reduces contamination risk; Cons: Specialized manufacturing process. |

What are T-Cleats and When Should You Use Them?

T-Cleats are the most commonly utilized type of cleat in conveyor systems. Their standard design allows for uniform height across the belt, making them suitable for a variety of applications, including general manufacturing and food processing. B2B buyers should consider T-Cleats for their ease of installation and adaptability, although they may find limitations in height options for specific needs.

How Do Scoop Cleats Improve Efficiency on Inclines?

Scoop Cleats feature an angled design that enhances their capacity to hold products securely when moving up or down inclines. This makes them ideal for bulk handling, packaging, and assembly lines where product stability is critical. Buyers should weigh the benefits of improved grip against the requirement for additional space that these cleats may demand, especially in tight operational environments.

What Makes Beefy Cleats Suitable for Heavy-Duty Applications?

Beefy Cleats are designed with extra thickness to handle heavy loads, making them particularly beneficial in sectors like mining and recycling. Their robust construction offers high durability, ensuring they can withstand the rigors of heavy-duty applications. However, B2B buyers should consider the increased weight and cost associated with these cleats when evaluating their suitability for specific tasks.

Why Choose Gusset Cleats for Stability?

Gusset Cleats are characterized by their reinforced backing, providing additional strength to accommodate large or heavy items. They are commonly used in industries where load stability is paramount. While they offer enhanced durability, buyers should be aware that the installation of Gusset Cleats may be more complex, potentially requiring specialized skills or tools.

What are the Benefits of Baseless HF Cleats in Food Applications?

Baseless HF Cleats are high-frequency welded cleats that eliminate the need for a base, resulting in a sleek profile ideal for food processing and cleanroom applications. Their seamless bond minimizes the risk of contamination, making them a preferred choice for food safety. However, the specialized manufacturing process may pose challenges in sourcing, and B2B buyers should ensure compatibility with their existing systems.

Key Industrial Applications of cleated conveyor belt

| Industry/Sector | Specific Application of cleated conveyor belt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Transporting packaged goods on inclines | Enhances efficiency and minimizes spillage | Food-safe materials, custom cleat heights |

| Automotive Manufacturing | Moving heavy parts across assembly lines | Improves safety and reduces downtime | Load capacity, durability under heavy use |

| Mining and Bulk Handling | Conveying bulk materials like sand and gravel | Streamlines operations and reduces labor costs | Resistance to wear, cleat profile options |

| Pharmaceutical | Handling products in cleanroom environments | Ensures compliance with hygiene standards | FDA-approved materials, seamless cleat bonding |

| Distribution Centers | Sorting packages on inclines | Increases throughput and reduces handling time | Custom spacing and height for various package sizes |

How Are Cleated Conveyor Belts Used in Food Processing?

In the food processing industry, cleated conveyor belts are essential for transporting packaged goods, especially on inclines. They prevent items from slipping or falling, ensuring safe and efficient movement through production lines. Buyers must prioritize food-safe materials that meet regulatory standards, as well as the ability to customize cleat heights to accommodate various product sizes. The seamless bond created during the manufacturing process minimizes contamination risks, which is critical for maintaining hygiene in food handling.

What Role Do Cleated Conveyor Belts Play in Automotive Manufacturing?

In automotive manufacturing, cleated conveyor belts are utilized to move heavy parts along assembly lines. These belts enhance safety by securely transporting components, thus reducing the risk of accidents caused by falling items. When sourcing, businesses should consider the load capacity and durability of the belts, as they must withstand rigorous operational demands. Additionally, custom cleat designs may be necessary to fit specific parts, ensuring efficient handling and assembly processes.

How Do Cleated Conveyor Belts Improve Mining and Bulk Handling Operations?

For the mining and bulk handling sectors, cleated conveyor belts are critical for efficiently conveying bulk materials like sand and gravel. The cleats help maintain the integrity of the load, reducing spillage and loss during transport. Buyers should focus on sourcing belts that are resistant to wear and tear, as the harsh environments of mining operations can lead to rapid deterioration. Selecting the right cleat profile is also important for optimizing material flow and enhancing operational efficiency.

Why Are Cleated Conveyor Belts Important in the Pharmaceutical Industry?

In the pharmaceutical industry, cleated conveyor belts facilitate the handling of products in cleanroom environments. These belts are designed to meet stringent hygiene standards, ensuring that no contaminants affect the integrity of pharmaceutical products. Buyers should look for FDA-approved materials and seamless cleat bonding to prevent any potential sources of contamination. Customization options for cleat sizes and spacing are also crucial to accommodate various product shapes and sizes.

How Do Cleated Conveyor Belts Enhance Efficiency in Distribution Centers?

In distribution centers, cleated conveyor belts are used to sort packages on inclines, significantly increasing throughput and reducing handling time. The cleats maintain package stability, preventing items from sliding off during transit. Businesses should consider the need for custom cleat designs to match varying package sizes and weights. Additionally, sourcing belts that allow for quick installation and maintenance can further enhance operational efficiency, making them a valuable investment for companies in this sector.

3 Common User Pain Points for ‘cleated conveyor belt’ & Their Solutions

Scenario 1: Inefficient Product Spacing on Inclines

The Problem: B2B buyers often face the challenge of maintaining consistent product spacing while transporting items on inclined conveyor systems. In industries such as food processing or packaging, products can shift or tumble if not properly spaced, leading to increased waste, product damage, and inefficiencies in production. This not only disrupts operations but also affects the overall product quality, resulting in potential financial losses.

The Solution: To address this issue, it is crucial to select the right cleat design and height for the specific products being transported. For instance, opting for scoop cleats can significantly improve product stability on inclines. These cleats are angled and bent, which helps to cradle the products securely, preventing them from sliding backward. When sourcing cleated conveyor belts, buyers should communicate their specific needs regarding product size, weight, and incline angle to manufacturers. This will enable suppliers to recommend the most suitable cleat configurations, ensuring that products are moved efficiently without risk of falling or jamming.

Scenario 2: Difficulty in Customizing Conveyor Solutions

The Problem: Many businesses encounter limitations with standard conveyor solutions that do not accommodate their unique operational requirements. This often leads to the frustration of having to compromise on efficiency or invest in costly modifications. For companies in specialized sectors, such as pharmaceuticals or automotive parts, using a one-size-fits-all conveyor belt can hinder productivity and affect compliance with industry regulations.

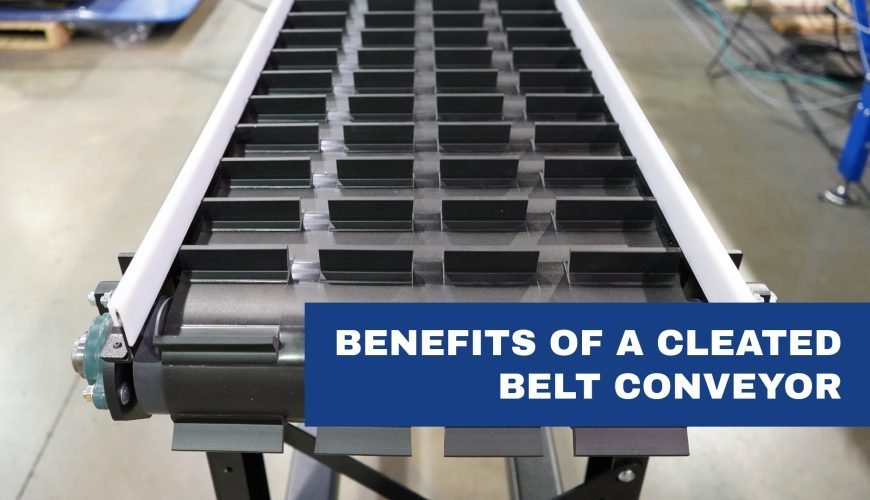

Illustrative image related to cleated conveyor belt

The Solution: Buyers should seek suppliers who offer customizable cleated conveyor belt solutions. Engaging with manufacturers that provide in-house cleating services is advantageous, as they can tailor cleat height, spacing, and material to fit specific applications. For example, a manufacturer like Dorner allows for custom cleat designs to be integrated seamlessly into the conveyor system, ensuring optimal performance. Before finalizing a purchase, it’s advisable for buyers to consult with engineers or technical experts from the supplier. This collaboration can yield a conveyor system that meets all operational requirements while maximizing productivity and compliance.

Scenario 3: Maintenance Challenges Leading to Downtime

The Problem: Regular maintenance of conveyor systems is essential, but many B2B buyers find that their cleated conveyor belts require frequent repairs or replacements, leading to unexpected downtime. This is particularly problematic in high-throughput environments, where even minimal delays can have significant financial implications. Issues such as wear and tear on cleats, improper installation, or low-quality materials can exacerbate these challenges.

The Solution: To mitigate maintenance challenges, it is vital to invest in high-quality cleated conveyor belts that are designed for durability. Buyers should look for products made from robust materials such as urethane or reinforced rubber, which are less prone to damage and wear. Furthermore, implementing a routine inspection and maintenance schedule can help identify potential issues before they lead to failures. Establishing a partnership with a supplier that offers ongoing support and replacement parts can also enhance reliability. Training staff on proper usage and maintenance practices will empower them to identify early signs of wear, thereby reducing downtime and prolonging the life of the conveyor system.

Illustrative image related to cleated conveyor belt

Strategic Material Selection Guide for cleated conveyor belt

What are the Key Materials for Cleated Conveyor Belts?

When selecting materials for cleated conveyor belts, it is essential to consider various factors such as durability, cost, and specific application requirements. Below are analyses of four common materials used in cleated conveyor belts, highlighting their properties, advantages, disadvantages, and considerations for international buyers.

1. Rubber

Key Properties: Rubber is known for its excellent flexibility and high friction coefficient, which enhances grip on inclines. It typically withstands temperatures up to 120°C (248°F) and offers good abrasion resistance.

Pros & Cons: Rubber cleats provide durability and resistance to wear, making them suitable for heavy-duty applications. However, they can be prone to degradation from UV exposure and certain chemicals, which may limit their use in specific environments. The manufacturing process can also be complex, impacting lead times.

Impact on Application: Rubber cleats are ideal for applications involving heavy materials, such as bulk handling in mining or agriculture. However, they may not be suitable for food-grade applications unless specifically designed for such use.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards for rubber products, such as ASTM or DIN. In Europe, buyers may prefer rubber that meets specific EU regulations regarding environmental impact.

2. Urethane

Key Properties: Urethane cleats exhibit excellent abrasion resistance and can operate effectively in a temperature range of -30°C to 80°C (-22°F to 176°F). They also offer good chemical resistance, particularly against oils and solvents.

Pros & Cons: The main advantage of urethane is its versatility and ability to maintain performance in various environments. However, urethane can be more expensive than rubber, and its production may require specialized manufacturing techniques.

Impact on Application: Urethane cleats are often used in food processing and packaging due to their non-toxic nature. They are also suitable for applications requiring high precision and cleanliness, such as pharmaceuticals.

Considerations for International Buyers: Buyers should verify that urethane materials comply with food safety standards, such as FDA regulations in the U.S. and EU food contact regulations in Europe. This is particularly important for buyers in the Middle East and Europe, where food safety compliance is strictly monitored.

Illustrative image related to cleated conveyor belt

3. Plastic (Engineered Plastics)

Key Properties: Engineered plastics, such as polyethylene and polypropylene, offer lightweight options with good chemical resistance and durability. They can withstand temperatures ranging from -40°C to 90°C (-40°F to 194°F).

Pros & Cons: The lightweight nature of plastic cleats makes them easy to handle and install, reducing overall system weight. However, they may not provide the same level of grip as rubber or urethane, which can limit their effectiveness in steep incline applications.

Impact on Application: Plastic cleats are well-suited for light to medium-duty applications, including packaging and assembly lines. Their resistance to moisture makes them ideal for environments where water exposure is common.

Considerations for International Buyers: Buyers should ensure that the plastics used are compliant with local regulations regarding recyclability and environmental impact. In Europe, for instance, adherence to REACH regulations is crucial for compliance.

Illustrative image related to cleated conveyor belt

4. Metal (Steel or Aluminum)

Key Properties: Metal cleats, typically made from steel or aluminum, offer high strength and durability, making them suitable for heavy-duty applications. They can withstand high temperatures and have excellent wear resistance.

Pros & Cons: The primary advantage of metal cleats is their robustness, allowing them to handle heavy loads and harsh environments. However, they can be heavier and more expensive than other materials, and they may require more complex installation processes.

Impact on Application: Metal cleats are ideal for bulk handling applications in industries such as mining and construction. They are also used in high-temperature environments where other materials may fail.

Considerations for International Buyers: Buyers should be aware of corrosion resistance, especially in humid or coastal regions. Compliance with international standards for metal products, such as ISO or ASTM, is also essential for ensuring quality and safety.

Summary Table of Material Selection for Cleated Conveyor Belts

| Material | Typical Use Case for cleated conveyor belt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Heavy-duty applications (mining, agriculture) | High durability and grip | Prone to UV degradation | Medium |

| Urethane | Food processing and packaging | Excellent abrasion and chemical resistance | Higher cost and complex manufacturing | High |

| Plastic | Light to medium-duty applications (packaging) | Lightweight and easy to handle | Limited grip on steep inclines | Low |

| Metal | Heavy-duty bulk handling (construction) | High strength and durability | Heavier and more expensive | High |

This guide provides a comprehensive overview of the materials available for cleated conveyor belts, helping B2B buyers make informed decisions tailored to their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cleated conveyor belt

What Are the Main Stages in the Manufacturing Process of Cleated Conveyor Belts?

The manufacturing of cleated conveyor belts involves several critical stages, each designed to ensure the final product meets industry standards and customer specifications. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Cleated Conveyor Belts?

Material preparation is the initial step in the manufacturing process. This phase involves selecting high-quality raw materials, such as rubber, urethane, or engineered plastics, which are essential for the durability and performance of the conveyor belts. Suppliers often perform rigorous material testing to ensure that the materials comply with international standards, such as ISO 9001.

Once the materials are sourced, they undergo pre-processing, which may include cutting, mixing, and conditioning to achieve the desired properties. For example, rubber compounds may be mixed with additives to enhance their strength and flexibility. This preparation is crucial for ensuring that the cleats adhere properly during the forming stage.

What Techniques Are Used in Forming Cleated Conveyor Belts?

The forming stage is where the raw materials are transformed into cleated conveyor belts. Several techniques can be employed during this phase, including extrusion and molding.

-

Extrusion: This technique is commonly used for producing the base of the conveyor belt. The prepared materials are fed into an extruder, where they are heated and forced through a die to create a continuous sheet. This method allows for precise control over the thickness and width of the belt.

-

Molding: For the cleats, molding techniques such as injection molding or compression molding are often utilized. In injection molding, the cleat material is injected into a mold to form the desired shape. Compression molding, on the other hand, involves placing the material in a heated mold and applying pressure to shape it. Both methods ensure that the cleats are uniform and meet the specific height and design requirements.

How Are Cleated Conveyor Belts Assembled and Finished?

After forming, the next step is assembly. This process involves attaching the cleats to the base belt. Depending on the manufacturer, this can be done through various methods, including high-frequency welding, adhesive bonding, or mechanical fastening. High-frequency welding is particularly advantageous for food-grade applications, as it creates a seamless bond that minimizes contamination risks.

The finishing stage involves several quality checks and surface treatments. The belts may be coated with protective layers to enhance durability and resistance to wear and chemicals. Furthermore, the belts are often tested for dimensional accuracy and overall quality before they are packaged and shipped.

What Quality Assurance Standards Are Relevant for Cleated Conveyor Belts?

Quality assurance is critical in the manufacturing of cleated conveyor belts, particularly for international B2B buyers who demand reliability and consistency. Compliance with internationally recognized standards such as ISO 9001 is essential, as it ensures that manufacturers follow established quality management principles.

Illustrative image related to cleated conveyor belt

In addition to ISO certifications, industry-specific standards may also apply. For instance, the CE mark indicates compliance with European safety standards, while the American Petroleum Institute (API) standards are relevant for applications in the oil and gas sector. Manufacturers must be knowledgeable about the standards applicable to their specific market to ensure compliance.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is integrated into various stages of the manufacturing process. The primary QC checkpoints include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): This checkpoint occurs at the beginning of the manufacturing process. Incoming materials are inspected for quality and compliance with specifications. Any defective materials are rejected to prevent downstream issues.

-

In-Process Quality Control (IPQC): During the manufacturing stages, quality checks are conducted to monitor processes and identify any deviations from established parameters. This includes verifying the dimensions of the cleats and the bond strength between the cleats and the base belt.

-

Final Quality Control (FQC): Before shipment, the finished conveyor belts undergo a final inspection. This includes testing for durability, flexibility, and performance under load. Manufacturers may also conduct stress tests to ensure that the belts can withstand operational demands.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers have several options for verifying the quality control processes of potential suppliers.

-

Audits: Conducting supplier audits is an effective way to assess the manufacturing capabilities and QC practices of a supplier. Buyers can evaluate the entire production process, from material sourcing to final testing, to ensure compliance with quality standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC procedures and past performance. These reports should include information on testing methods, results, and any corrective actions taken for non-conformities.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing process and product quality. These inspections can be particularly valuable for international buyers who may not have the resources to conduct on-site audits.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Factors such as import regulations, trade agreements, and local standards can significantly impact procurement decisions.

For instance, buyers should ensure that the products they import comply with both international standards and any local regulations in their respective countries. This may require additional documentation or certifications, such as conformity assessment certificates or import permits.

Moreover, understanding the supply chain dynamics in different regions can influence quality assurance efforts. Buyers should consider the reliability of logistics providers and the potential for delays or damages during transport, which may affect the overall quality of the delivered products.

By prioritizing these aspects, B2B buyers can make informed decisions when selecting suppliers for cleated conveyor belts, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cleated conveyor belt’

Introduction

This sourcing guide provides B2B buyers with a comprehensive checklist for procuring cleated conveyor belts. Understanding the specific requirements and evaluating potential suppliers can significantly enhance your operational efficiency. This guide will help you navigate the procurement process with confidence and ensure you select the right product for your needs.

Step 1: Define Your Technical Specifications

Before initiating your search for a cleated conveyor belt, clearly outline your technical requirements. Consider factors such as the dimensions of the belt, the type of materials to be conveyed, and the operational environment (e.g., temperature, humidity).

– Product Size and Weight: Identify the average size and weight of the products you will be transporting to determine the necessary cleat height and spacing.

– Incline/Decline Requirements: Specify whether the conveyor will operate on inclines or declines, as this impacts the cleat design needed for stability.

Illustrative image related to cleated conveyor belt

Step 2: Research Available Cleat Options

Explore the different types of cleats available, as they are crucial for optimizing the conveyor’s performance. Cleats come in various designs, such as T-cleats, scoop cleats, and gusset cleats, each suited for specific applications.

– Material Considerations: Common materials include rubber, urethane, and engineered plastics, which offer varying levels of durability and grip.

– Customizations: Determine if custom cleats are necessary for your specific application, as many suppliers offer tailored solutions.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers to ensure they can meet your needs effectively. Look for companies with proven expertise in manufacturing cleated conveyor belts.

– Request Documentation: Ask for product specifications, certifications, and case studies from past clients in similar industries.

– Assess Reliability: Check online reviews and testimonials to gauge the supplier’s reliability and customer service track record.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers have the necessary certifications to meet industry standards. This is particularly important in sectors like food processing, where hygiene and safety are paramount.

– Quality Assurance Standards: Look for ISO certifications or other relevant quality management certifications.

– Compliance with Regulations: Verify that the materials used in the conveyor belts comply with local regulations, particularly if they will come into contact with food products.

Step 5: Request Samples for Testing

Before making a bulk purchase, request samples of the cleated conveyor belts to test their performance in your specific environment. This step is essential to ensure that the product meets your operational needs.

– Operational Testing: Evaluate how the cleat design holds up under the weight and movement of your products.

– Compatibility Checks: Confirm that the cleats work well with your existing equipment and operational workflow.

Step 6: Discuss Warranty and Support Options

Inquire about the warranty and support services offered by the supplier. A robust warranty can protect your investment and provide peace of mind.

– Warranty Length: Understand the duration of the warranty and what it covers, including defects or performance issues.

– After-Sales Support: Ensure that the supplier offers adequate support for installation, maintenance, and troubleshooting.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier and confirmed all specifications, finalize the purchase agreement. Ensure that all terms, including delivery timelines, payment terms, and service agreements, are clearly outlined.

– Clear Communication: Maintain open lines of communication with the supplier throughout this process to address any concerns promptly.

– Documentation: Keep a detailed record of all agreements and communications for future reference.

By following this checklist, you can streamline your procurement process and ensure that you select the right cleated conveyor belt for your operations.

Comprehensive Cost and Pricing Analysis for cleated conveyor belt Sourcing

What Are the Key Cost Components for Cleated Conveyor Belts?

The cost structure for cleated conveyor belts encompasses several key components, each contributing to the overall pricing strategy.

-

Materials: The choice of materials significantly affects the cost. Common options include rubber, urethane, and engineered plastics. High-quality materials that offer durability and resistance to wear typically come at a higher price but can lead to lower maintenance costs over time.

-

Labor: Labor costs include the workforce required for manufacturing, assembly, and installation. Skilled labor may command higher wages, particularly for custom cleating solutions, which require specialized knowledge.

-

Manufacturing Overhead: This category includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce these overheads, allowing suppliers to offer competitive pricing.

-

Tooling: Custom tooling for cleat designs or specific belt dimensions can be a significant upfront cost. However, if multiple orders utilize the same tooling, this cost can be amortized over a larger production volume.

-

Quality Control (QC): Implementing strict QC processes is essential, especially in industries like food processing where contamination risks are higher. QC costs can influence pricing but are necessary for ensuring product reliability and safety.

-

Logistics: The logistics of transporting cleated conveyor belts can vary greatly depending on distance, mode of transport, and the complexity of delivery. International shipments may incur additional costs related to customs and tariffs.

-

Margin: Suppliers will include a margin on top of their costs to ensure profitability. This margin can vary widely based on market competition and supplier reputation.

What Influences Pricing for Cleated Conveyor Belts?

Several factors can influence the pricing of cleated conveyor belts, making it essential for buyers to understand these nuances.

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes typically lead to lower unit prices. Suppliers may offer discounts for bulk orders, making it beneficial for companies with consistent or large-scale needs.

-

Specifications and Customization: Custom cleat designs, sizes, and materials can significantly impact pricing. Complex specifications often incur higher costs due to the additional labor and materials required.

-

Quality and Certifications: Products that meet specific industry standards or certifications, particularly in food safety, may command a premium. Buyers should consider whether the added cost aligns with their operational needs.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can affect pricing. Established suppliers with a track record of quality may charge more but can provide peace of mind regarding reliability.

-

Incoterms: Understanding the agreed-upon Incoterms (International Commercial Terms) is crucial, as they define responsibilities for shipping, insurance, and tariffs. Different terms can lead to significant cost variations.

How Can Buyers Negotiate Better Prices for Cleated Conveyor Belts?

Effective negotiation strategies can help B2B buyers secure favorable pricing for cleated conveyor belts.

-

Research and Benchmarking: Before negotiations, conduct market research to understand standard pricing and competitor offerings. This information can provide leverage during discussions.

-

Emphasize Long-Term Relationships: Suppliers may be more willing to offer discounts or favorable terms to buyers who commit to long-term partnerships or larger order volumes.

-

Discuss Total Cost of Ownership (TCO): Highlight the benefits of investing in higher-quality belts that may cost more upfront but result in lower maintenance and replacement costs over time.

-

Be Flexible with Specifications: If possible, be open to alternative specifications or materials that may lower costs without compromising the functionality required for your operations.

-

Consider Local Suppliers: For international buyers, sourcing from local suppliers can reduce logistics costs and lead times, which may result in overall cost savings.

Conclusion: Understanding Pricing Nuances for International Buyers

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of the specific challenges and opportunities in sourcing cleated conveyor belts. Currency fluctuations, import duties, and local market conditions can all influence pricing. It’s essential to factor these elements into the total cost of ownership and to engage in thorough negotiations to achieve the best value. Always keep in mind that indicative prices may vary based on changing market conditions, so obtaining multiple quotes and assessing supplier reliability is crucial.

Alternatives Analysis: Comparing cleated conveyor belt With Other Solutions

Exploring Alternatives to Cleated Conveyor Belts

When considering conveyor solutions, businesses must evaluate various options to determine which best meets their operational needs. Cleated conveyor belts are designed to efficiently transport items, especially on inclines, but there are other technologies available that may offer distinct advantages depending on specific applications. This section compares cleated conveyor belts with two viable alternatives: modular conveyor systems and belt-less conveyors.

Comparison Table

| Comparison Aspect | Cleated Conveyor Belt | Modular Conveyor System | Belt-less Conveyor |

|---|---|---|---|

| Performance | Excellent for incline transport and spacing of items. | Highly versatile; can adapt to various layouts and product types. | Ideal for moving small items and packages without a traditional belt. |

| Cost | Generally moderate to high depending on customization. | Costs vary significantly based on configuration and components. | Typically lower upfront costs, but may require additional components for specific uses. |

| Ease of Implementation | Requires precise installation and setup. | Modular design allows for easier assembly and reconfiguration. | Simple installation; requires minimal setup time. |

| Maintenance | Regular maintenance needed to check cleat integrity and belt wear. | Low maintenance; easy to replace sections as needed. | Minimal maintenance, but can have wear issues if not managed properly. |

| Best Use Case | Ideal for food processing, packaging, and heavy materials on inclines. | Suitable for diverse applications including assembly lines and product sorting. | Best for lightweight items, small packages, and spaces where traditional belts cannot fit. |

Detailed Breakdown of Alternatives

Modular Conveyor Systems

Modular conveyor systems are flexible and can be easily customized to fit different production layouts. They consist of interlocking parts, allowing for quick assembly and reconfiguration. The adaptability of modular systems makes them ideal for industries that require frequent changes in production processes or layouts. However, the initial investment can vary widely based on the complexity of the system, and while maintenance is generally low, replacing specific sections can still incur costs.

Belt-less Conveyors

Belt-less conveyors, such as roller or chain-based systems, utilize moving components to transport items without a traditional conveyor belt. This design can significantly reduce maintenance needs and installation time, making it appealing for businesses looking for quick solutions. However, they are typically best suited for smaller, lighter items, as they may struggle with larger or heavier loads. Additionally, the lack of a belt means that items may not be as secure during transport, which could be a concern for certain industries.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers evaluating conveyor solutions, the choice between a cleated conveyor belt and its alternatives hinges on specific operational requirements. Factors such as the type of products being handled, the layout of the production area, and budget constraints should all play a role in the decision-making process. Cleated conveyor belts are excellent for secure transport of items on inclines, while modular and belt-less systems offer flexibility and lower maintenance. Ultimately, a thorough analysis of these aspects will guide buyers toward the most effective solution for their unique applications.

Illustrative image related to cleated conveyor belt

Essential Technical Properties and Trade Terminology for cleated conveyor belt

When considering cleated conveyor belts for your operations, understanding the essential technical properties and industry terminology is crucial for making informed purchasing decisions. Below are key specifications and terms that will help you navigate the complexities of this equipment.

What Are the Critical Technical Specifications for Cleated Conveyor Belts?

-

Material Grade

The material used in the construction of cleated conveyor belts significantly impacts their durability and performance. Common materials include rubber, urethane, and engineered plastics. Each material offers distinct advantages, such as resistance to abrasion or chemical exposure, making it essential to select the right grade based on your specific application. -

Cleat Height and Spacing

Cleat height typically ranges from a few millimeters to several inches, depending on the products being transported. The spacing between cleats is equally important, as it determines the grip on items and prevents slipping. Understanding these dimensions helps optimize the conveyor for inclines or declines and ensures products are securely transported. -

Load Capacity

This specification indicates the maximum weight the conveyor belt can handle safely. Load capacity is critical for operations that involve heavy or bulky items. Selecting a belt with an adequate load capacity ensures reliable performance and minimizes the risk of belt failure or damage during operation. -

Belt Tension and Tolerance

Proper tension is vital for the efficient operation of cleated conveyor belts. It affects the belt’s ability to move products smoothly and can lead to wear or slippage if not maintained correctly. Tolerance refers to the permissible variation in dimensions; understanding this ensures that the belt fits correctly within your system. -

Surface Texture

The texture of the belt surface can influence grip and material handling efficiency. A textured surface can enhance friction, helping to secure products during transport. Different textures are suitable for various applications, from food processing to bulk handling. -

Temperature Resistance

Different materials have varying degrees of temperature resistance. For applications involving extreme heat or cold, selecting a belt that can withstand these conditions is crucial to avoid premature wear or failure.

What Are the Common Trade Terms Associated with Cleated Conveyor Belts?

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help in sourcing high-quality components and ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is vital for B2B buyers as it affects inventory management and cost efficiency. Knowing the MOQ helps in planning purchases according to operational needs. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products. Utilizing RFQs enables businesses to compare multiple suppliers effectively, ensuring they secure the best possible deal. -

Incoterms (International Commercial Terms)

These are internationally recognized standard trade terms that define the responsibilities of buyers and sellers in global transactions. Familiarity with Incoterms helps in understanding shipping costs, insurance, and delivery responsibilities, which are crucial for international procurement. -

Lead Time

This term refers to the time it takes from placing an order to receiving the product. Understanding lead time is essential for planning and inventory management, particularly in industries with tight production schedules. -

Cleat Profile

The cleat profile describes the shape and design of the cleats on the belt. Different profiles are suited for various applications, affecting grip and the ability to handle different materials. Selecting the right cleat profile is crucial for optimal performance in specific environments.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing cleated conveyor belts, ensuring they select products that meet their operational needs efficiently.

Navigating Market Dynamics and Sourcing Trends in the cleated conveyor belt Sector

What Are the Current Market Dynamics and Key Trends in the Cleated Conveyor Belt Sector?

The global market for cleated conveyor belts is witnessing significant growth, driven by several factors including increased automation in manufacturing processes, the rising demand for efficient material handling solutions, and advancements in conveyor technology. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for solutions that enhance operational efficiency while minimizing downtime. The cleated conveyor belt’s ability to facilitate the movement of goods on inclines and declines without loss or damage is a crucial advantage that many industries, including food processing, packaging, and mining, are leveraging.

Illustrative image related to cleated conveyor belt

Emerging technologies such as IoT (Internet of Things) are transforming how cleated conveyor systems operate, allowing for real-time monitoring and predictive maintenance. This trend is particularly beneficial for B2B buyers seeking to optimize their operations. Additionally, there is a noticeable shift towards customization in cleated conveyor solutions, with manufacturers offering tailored cleat designs and materials to meet specific application requirements. This adaptability enhances product stability and efficiency, further driving demand.

Moreover, the rise of e-commerce has led to increased investment in logistics and distribution centers, amplifying the need for sophisticated conveyor systems. Buyers in regions like Brazil and Germany are particularly focused on scalability and flexibility in their conveyor solutions, reflecting a broader trend towards modularity in manufacturing and logistics.

How Is Sustainability Impacting the Cleated Conveyor Belt Sector and What Are the Ethical Sourcing Considerations?

Sustainability is becoming a pivotal consideration for international B2B buyers in the cleated conveyor belt sector. As businesses increasingly recognize their environmental impact, there is a growing demand for ethically sourced materials and sustainable manufacturing practices. Buyers are looking for suppliers who can demonstrate a commitment to reducing carbon footprints through energy-efficient processes and the use of recyclable materials.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers for compliance with environmental standards and certifications, such as ISO 14001, which focuses on effective environmental management systems. Additionally, green materials—such as those made from recycled plastics or sustainably sourced rubber—are gaining traction in the market. Manufacturers that prioritize these materials not only appeal to environmentally conscious buyers but also gain a competitive edge.

Illustrative image related to cleated conveyor belt

Incorporating sustainability into sourcing strategies can also lead to long-term cost savings. For instance, investing in durable, high-quality cleated conveyor belts can reduce replacement frequency and maintenance costs, aligning with both economic and environmental goals. As a result, B2B buyers are encouraged to engage with suppliers that prioritize sustainability, ensuring that their procurement decisions contribute positively to both their operations and the planet.

What Is the Brief Evolution of the Cleated Conveyor Belt Industry?

The cleated conveyor belt industry has evolved significantly over the past few decades. Originally designed for basic material handling, early cleated belts were primarily constructed from rubber and lacked the advanced features available today. The introduction of synthetic materials in the late 20th century marked a turning point, as these materials offered enhanced durability and resistance to wear and tear.

In recent years, technological advancements have propelled the industry forward. Innovations such as high-frequency welding for cleat attachment and the development of custom cleat designs have transformed the functionality and versatility of cleated conveyor systems. These advancements not only improve performance but also cater to the specific needs of various industries, including food and pharmaceuticals, where hygiene and safety are paramount.

Illustrative image related to cleated conveyor belt

Today, the cleated conveyor belt sector stands at the intersection of technology and sustainability, providing B2B buyers with efficient solutions that meet the demands of modern manufacturing and logistics while also addressing environmental concerns. As the industry continues to innovate, buyers can expect even more customized, efficient, and sustainable solutions in the years to come.

Frequently Asked Questions (FAQs) for B2B Buyers of cleated conveyor belt

-

How do I solve issues with product slippage on inclined surfaces using cleated conveyor belts?

To address product slippage on inclined surfaces, opt for cleated conveyor belts with appropriately sized and designed cleats. Cleats should be tailored to the specific product dimensions and incline angle to ensure maximum grip. Additionally, consider the material of the cleats—rubber or urethane can provide better traction. Regular maintenance and inspection of the conveyor system will also help to identify and resolve potential issues before they affect production. -

What is the best type of cleated conveyor belt for transporting bulk materials?

The ideal cleated conveyor belt for transporting bulk materials is typically the beefy cleat design. These cleats are thicker and more robust, allowing for the safe movement of heavy loads without risk of damage or slippage. Additionally, the material of the belt—often rubber or heavy-duty fabric—should be chosen based on the specific bulk material being transported to ensure durability and efficiency. -

How can I customize a cleated conveyor belt to suit my operational needs?

Customization options for cleated conveyor belts include selecting cleat height, spacing, and material based on your specific application. Most suppliers offer in-house fabrication, allowing for tailored cleat designs that accommodate various product sizes and weights. Discuss your requirements with the supplier’s engineering team to ensure that the customizations will enhance operational efficiency and meet safety standards. -

What are the minimum order quantities (MOQ) for cleated conveyor belts when sourcing internationally?

Minimum order quantities for cleated conveyor belts can vary significantly among suppliers. Typically, MOQs can range from a few units for standard products to larger quantities for custom designs. For international buyers, it’s advisable to communicate directly with suppliers to negotiate MOQs that align with your operational needs, especially if you are looking to test the market with smaller initial orders. -

What payment terms should I expect when sourcing cleated conveyor belts internationally?

Payment terms can differ based on the supplier and the nature of the transaction. Common terms include payment in advance, letter of credit, or net 30/60 days after shipment. For international transactions, it’s crucial to clarify these terms upfront to avoid misunderstandings. Always ensure that payment methods are secure and that you have a clear invoice detailing the costs involved. -

How do I vet suppliers for cleated conveyor belts to ensure quality and reliability?

Vetting suppliers involves checking their industry reputation, certifications, and customer reviews. Look for suppliers who have a proven track record in your specific industry and can provide references. Additionally, request samples of their products to assess quality firsthand. Engaging in direct communication and asking about their manufacturing processes and quality assurance measures can also provide insights into their reliability. -

What logistics considerations should I keep in mind when importing cleated conveyor belts?

When importing cleated conveyor belts, consider shipping costs, lead times, and customs regulations in your country. Ensure that your supplier is familiar with international shipping practices and can provide necessary documentation for customs clearance. Additionally, factor in potential tariffs and taxes that may apply to your shipments. Working with a logistics partner experienced in international trade can streamline this process. -

What quality assurance measures should be in place for cleated conveyor belts?

Quality assurance for cleated conveyor belts should include rigorous testing of materials and construction methods. Ensure that the supplier conducts inspections at various stages of production and provides certifications for compliance with industry standards. Request documentation related to material properties, durability tests, and any relevant safety certifications. Regular audits of the supplier’s processes can also ensure ongoing quality control.

Top 6 Cleated Conveyor Belt Manufacturers & Suppliers List

1. McMaster – Cleated Conveyor Belts

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Cleated Conveyor Belts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Accurate Industrial – Conveyor Belt Cleats

Domain: accurateindustrial.com

Registered: 1999 (26 years)

Introduction: Conveyor Belt Cleats: Various types including T-cleat, Baseless HF cleat, Scoop cleat, Beefy cleat, Gusset cleat, Fabric reinforced cleat, and Bolt on cleat (Tatch-A-Cleat®). Cleats are used for moving items through inclines/declines and providing consistent spacing between products. Options available for different load capacities and applications. Dimensions include height, width, cleat indent, c…

3. Big River Rubber – Cleated Heavy Duty Rubber Belt

Domain: bigriverrubber.com

Registered: 1996 (29 years)

Introduction: Cleated Heavy Duty Rubber Belt, Reference Number: 781, suitable for industrial, agricultural, packaging, and warehouse applications. Custom fabrication available, including cutting, lacing, and vulcanizing. Same-day shipping possible. Located in Owensboro, KY. Customer service available Monday to Friday 7:00 a.m. – 5:00 p.m. CST and Saturday 8:00 a.m. – 12:00 p.m. CST. Contact via phone at 800-626…

4. Apache Inc – Cleated Belting Solutions

Domain: apache-inc.com

Registered: 2012 (13 years)

Introduction: Cleated Belting: Cleats are used to convey materials up an incline and prevent product rollback. Other names include flights, lugs, and profiles. Variety of cleat styles and patterns available. Types include: T-Cleat (for most incline needs), Scoop cleats (for steeper angles), Thin line cleats (for smaller pulley diameters and lower tonnages). Available in many sizes, styles, and colors. General c…

5. Mill Creek – Cleated Conveyor Belt 88

Domain: parts.millcreekmfg.com

Registered: 1999 (26 years)

Introduction: {‘product_name’: ‘Cleated Conveyor Belt 88″‘, ‘product_id’: ‘215236’, ‘price’: ‘$1,120.00’, ‘quantity’: ‘1’, ‘product_line’: ‘Row Mulchers’, ‘product_group’: ‘Conveyor Belt’, ‘compatible_models’: [‘Model 406’, ‘Model 506’, ‘Model 606’, ‘Model 706’], ‘contact_number’: ‘800.311.1323’, ‘manufacturer’: ‘Millcreek Manufacturing’, ‘address’: ‘525 Reservoir Road Honey Brook, PA 19344’}

6. First Foods – Cleated Belt Conveyor Top

Domain: firstfoodseg.com

Registered: 2024 (1 years)

Introduction: Cleated belt conveyor top, Price: $49.99 (originally $99.98), Payment plan: $0 today, followed by 3 monthly payments of $16.66, interest-free. Available in one size. Delivery options include Express Delivery ($11.99), Standard Delivery ($6.99), and Store Delivery ($6.99). International delivery available. Returns accepted within 28 days of delivery, with an extended Christmas returns policy from O…

Strategic Sourcing Conclusion and Outlook for cleated conveyor belt

As the demand for efficient material handling solutions continues to grow globally, strategic sourcing of cleated conveyor belts emerges as a vital consideration for businesses across various industries. By investing in high-quality cleated belts, organizations can enhance operational efficiency, reduce downtime, and improve product safety—especially critical in sectors like food processing and manufacturing.

Key takeaways for B2B buyers include the importance of selecting the right cleat type and material to match specific application needs, as well as the advantages of working with suppliers that offer in-house customization and rigorous quality controls. This attention to detail not only maximizes the utility of conveyor systems but also ensures compliance with industry standards.

Looking forward, international buyers from regions such as Africa, South America, the Middle East, and Europe should seize the opportunity to optimize their supply chains through strategic partnerships with reliable conveyor belt manufacturers. By doing so, they can not only enhance their operational capabilities but also position themselves for long-term success in an increasingly competitive marketplace. Take the next step—evaluate your current conveyor systems and explore innovative cleated solutions to future-proof your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to cleated conveyor belt

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.