Top 5 General Steel Macon Ga Suppliers (And How to Choose)

Introduction: Navigating the Global Market for general steel macon ga

In today’s competitive landscape, sourcing general steel from Macon, GA, presents unique challenges for international B2B buyers. With fluctuating prices, varying quality standards, and complex logistics, making informed purchasing decisions can feel overwhelming. This guide aims to demystify the global market for general steel by providing a comprehensive overview of available materials, their applications across diverse industries, and insights into the best practices for supplier vetting.

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including countries like Brazil and Saudi Arabia—will benefit from detailed analyses of product specifications, cost considerations, and the essential certifications required for compliance in their respective markets. Understanding these factors not only helps in selecting the right products but also in negotiating favorable terms that align with your project needs.

By equipping you with actionable insights and a clear roadmap, this guide empowers you to navigate the complexities of sourcing general steel from Macon, GA, ensuring that your procurement process is efficient and effective. Whether you’re looking to support construction projects, industrial applications, or governmental contracts, this resource will serve as a vital tool in making strategic decisions that drive success in your business endeavors.

Understanding general steel macon ga Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Carbon Steel | High tensile strength, ductility, and affordability | Construction, manufacturing, automotive | Pros: Cost-effective, widely available. Cons: Prone to corrosion without treatment. |

| Stainless Steel | Corrosion-resistant, durable, and aesthetic appeal | Food processing, medical equipment, construction | Pros: Long-lasting, low maintenance. Cons: Higher cost than carbon steel. |

| Aluminum | Lightweight, non-corrosive, and malleable | Aerospace, automotive, packaging | Pros: Easy to fabricate, excellent strength-to-weight ratio. Cons: Lower strength compared to steel. |

| Rebar | Steel bars for reinforcing concrete | Construction of buildings and infrastructure | Pros: Increases concrete strength. Cons: Requires proper placement and handling. |

| Steel Plates | Flat pieces of steel available in various thicknesses | Manufacturing, shipbuilding, construction | Pros: Versatile, suitable for heavy-duty applications. Cons: Heavier and more difficult to handle. |

What Are the Characteristics and Suitability of Carbon Steel?

Carbon steel is characterized by its high tensile strength and ductility, making it a popular choice for various applications. Its affordability makes it particularly attractive for large-scale construction and manufacturing projects. B2B buyers should consider the need for corrosion protection, as untreated carbon steel can rust over time. Additionally, its availability in various grades allows for tailored solutions depending on project specifications.

How Does Stainless Steel Stand Out in B2B Applications?

Stainless steel is known for its exceptional corrosion resistance and durability, making it ideal for industries like food processing and healthcare, where hygiene is paramount. Its aesthetic appeal also makes it a preferred choice for architectural applications. While it comes at a higher price point, the long-term savings from reduced maintenance and replacement costs often justify the investment. B2B buyers must assess their specific requirements, including the environment in which the steel will be used.

Why is Aluminum a Preferred Choice for Certain Industries?

Aluminum is lightweight, non-corrosive, and highly malleable, which makes it suitable for industries such as aerospace and automotive. Its strength-to-weight ratio is excellent, allowing for innovative designs without compromising structural integrity. However, buyers should be aware that aluminum is generally less strong than steel, which may limit its application in heavy-duty scenarios. Understanding the balance between weight and strength is crucial for B2B purchasing decisions.

What Role Does Rebar Play in Construction Projects?

Rebar, or reinforcing bar, is essential in construction for enhancing the tensile strength of concrete structures. Its integration into concrete is vital for the longevity and durability of buildings and infrastructure. While the benefits of using rebar are clear, buyers must ensure proper placement and handling during construction to maximize its effectiveness. The choice of rebar grade and diameter can significantly impact project outcomes, making it crucial for B2B buyers to consult with structural engineers.

How Are Steel Plates Utilized Across Various Industries?

Steel plates are flat steel products that are available in various thicknesses and are utilized in diverse industries, including manufacturing and shipbuilding. Their versatility allows them to be used in heavy-duty applications, providing structural support and durability. However, the weight of steel plates can pose handling challenges, and buyers should consider logistics in their purchasing decisions. Understanding the specific requirements of the application will aid in selecting the appropriate thickness and grade.

Key Industrial Applications of general steel macon ga

| Industry/Sector | Specific Application of general steel macon ga | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural Steel for Building Frameworks | Provides strength and durability for long-lasting structures | Compliance with local building codes and standards |

| Transportation | Steel for Noise Barriers | Enhances public safety and comfort by reducing noise pollution | Availability of specific grades and processing capabilities |

| Energy | Steel Components for Renewable Energy Projects | Supports sustainable energy initiatives and reduces carbon footprint | Expertise in custom fabrication and project timelines |

| Manufacturing | Steel for Machinery and Equipment | Increases efficiency and productivity in production processes | Need for high-quality materials and precision engineering |

| Oil & Gas | Steel Pipes and Tubing | Essential for safe and efficient transportation of resources | Consideration of corrosion resistance and pressure ratings |

How is General Steel Macon GA Used in Construction Projects?

In the construction industry, General Steel in Macon, GA, supplies high-quality structural steel utilized in building frameworks. These materials provide the necessary strength and durability to support various structures, from commercial buildings to residential homes. For international buyers, particularly in developing regions, understanding local building codes and standards is crucial to ensure compliance and avoid project delays. The availability of a diverse range of steel products, including beams, columns, and plates, allows for tailored solutions that meet specific project requirements.

What Role Does General Steel Macon GA Play in Transportation?

General Steel is a key supplier of steel used in noise barriers along highways and railways, significantly enhancing public safety and comfort. These barriers are essential in urban areas where noise pollution can impact the quality of life. For B2B buyers, sourcing steel for noise barriers involves considerations such as the specific grades of steel required for durability and compliance with environmental regulations. Understanding local market demands and regulations in regions like Brazil or Saudi Arabia can facilitate smoother procurement processes.

How is General Steel Macon GA Supporting Renewable Energy Initiatives?

In the energy sector, General Steel provides components for renewable energy projects, such as wind and solar installations. The use of steel in these applications supports sustainable energy initiatives, helping companies reduce their carbon footprint. International buyers should focus on sourcing steel that meets specific durability and performance standards to withstand environmental conditions. Additionally, expertise in custom fabrication can streamline the integration of these components into large-scale projects.

What is the Importance of General Steel Macon GA in Manufacturing?

In manufacturing, General Steel supplies steel for machinery and equipment, which is critical for enhancing operational efficiency. The strength and reliability of steel components directly impact production processes, making it essential for manufacturers to source high-quality materials. Buyers should consider precision engineering capabilities and the ability to meet specific production timelines when selecting suppliers. This is particularly important for international businesses aiming to maintain competitive advantage in their local markets.

How Does General Steel Macon GA Serve the Oil & Gas Industry?

The oil and gas sector relies heavily on steel pipes and tubing supplied by General Steel for the transportation of resources. These products must meet stringent standards for corrosion resistance and pressure ratings to ensure safety and efficiency. International buyers, especially those in regions with harsh environmental conditions, should prioritize sourcing from suppliers that offer high-quality steel products tailored to their specific operational needs. Understanding the material specifications and compliance requirements is vital for successful sourcing in this industry.

Illustrative image related to general steel macon ga

3 Common User Pain Points for ‘general steel macon ga’ & Their Solutions

Scenario 1: Supply Chain Delays Affecting Project Timelines

The Problem: One of the most pressing challenges B2B buyers face when sourcing general steel in Macon, GA, is supply chain delays. International buyers, especially from regions like Africa and South America, may experience longer lead times due to shipping logistics, customs clearance, or unexpected demand spikes. These delays can jeopardize project timelines, causing financial strain and loss of client trust. The urgency to deliver materials on time is compounded by the need for compliance with local regulations and standards, which further complicates procurement.

The Solution: To mitigate supply chain issues, buyers should establish strong relationships with local suppliers such as Triple-S Steel® of Georgia. Engaging in proactive communication about timelines and inventory levels can help anticipate potential delays. Additionally, consider placing bulk orders or scheduling deliveries well in advance of project milestones. This approach allows suppliers to allocate resources effectively and reduces the likelihood of last-minute shortages. Utilize tracking tools and platforms to monitor the status of shipments and be ready to pivot to alternative suppliers if necessary. By doing so, you can ensure a steady flow of materials and maintain project integrity.

Scenario 2: Difficulty in Understanding Product Specifications

The Problem: Many B2B buyers struggle with the technical specifications of general steel products, which can lead to misordering or the selection of inappropriate materials for specific applications. For instance, a buyer from the Middle East may not be fully aware of the distinctions between various grades of carbon steel, stainless steel, and aluminum, resulting in costly mistakes that affect project quality and safety. This knowledge gap can be particularly pronounced for companies venturing into new industries or markets.

The Solution: To overcome this challenge, buyers should invest time in understanding the specific properties and applications of different steel products. A practical step is to consult with experts at local suppliers like General Steel in Macon, GA, who can provide detailed guidance on material choices tailored to project requirements. Additionally, creating a checklist of project specifications—such as load-bearing capacity, corrosion resistance, and environmental conditions—can facilitate informed decision-making. Consider requesting samples or conducting small-scale trials to evaluate material performance before making bulk purchases. This proactive approach not only enhances buyer confidence but also ensures compliance with industry standards.

Scenario 3: Compliance with Local Regulations and Standards

The Problem: Navigating the complex landscape of local regulations and industry standards can be a significant hurdle for international B2B buyers sourcing general steel in Macon, GA. Each region has its own set of compliance requirements, which can vary widely based on project type—be it construction, manufacturing, or infrastructure. Buyers may find themselves unprepared for audits or inspections, leading to project delays and potential fines.

The Solution: To effectively manage compliance issues, it is crucial to familiarize yourself with the local regulations governing steel procurement and usage in the U.S. Collaborate closely with suppliers who have a deep understanding of these regulations, such as Triple-S Steel®, which has extensive experience dealing with local government agencies and compliance standards. Consider engaging a local compliance consultant or legal advisor to help interpret regulations and ensure that your procurement processes align with industry standards. Additionally, keeping abreast of changes in legislation or standards through industry publications and trade associations can provide a competitive edge. By prioritizing compliance, you can mitigate risks and ensure smooth project execution.

Strategic Material Selection Guide for general steel macon ga

What Are the Key Materials for General Steel in Macon, GA?

When selecting materials for steel applications in Macon, GA, international B2B buyers should consider several common materials that are widely used in the industry. Each material has distinct properties, advantages, and limitations that can significantly impact project outcomes.

How Does Carbon Steel Perform in Various Applications?

Carbon steel is one of the most prevalent materials in the steel industry, known for its strength and versatility. Key properties include high tensile strength and good weldability, making it suitable for structural applications. However, it has limited corrosion resistance, which can be a concern in humid or corrosive environments.

Pros: Carbon steel is relatively inexpensive and widely available, making it a cost-effective choice for many projects. Its durability and ability to withstand high pressures make it ideal for construction and manufacturing.

Cons: Its susceptibility to rust and corrosion can lead to increased maintenance costs over time. Additionally, carbon steel may not perform well in applications involving extreme temperatures without proper treatment.

Impact on Application: Carbon steel is compatible with a wide range of media, including water and various chemicals, but care must be taken in corrosive environments.

Considerations for International Buyers: Compliance with standards such as ASTM A36 or EN 10025 is crucial. Buyers from regions like Africa and South America should also consider local climate conditions and potential corrosion factors when selecting carbon steel.

Illustrative image related to general steel macon ga

What Are the Advantages of Stainless Steel for B2B Applications?

Stainless steel is renowned for its corrosion resistance, making it suitable for applications in environments where exposure to moisture and chemicals is a concern. Key properties include a high chromium content, which provides excellent corrosion resistance and durability.

Pros: Its aesthetic appeal and resistance to staining make stainless steel a preferred choice for architectural applications. It also requires less maintenance compared to carbon steel, which can lead to lower long-term costs.

Cons: The primary drawback is its higher cost compared to carbon steel. Additionally, stainless steel can be more challenging to fabricate due to its toughness, which can increase manufacturing complexity.

Impact on Application: Stainless steel is compatible with a variety of media, including food and pharmaceuticals, making it ideal for industries requiring stringent hygiene standards.

Considerations for International Buyers: Compliance with standards such as ASTM A240 or EN 10088 is essential. Buyers should also be aware of the specific grades required for their applications, as preferences may vary by region.

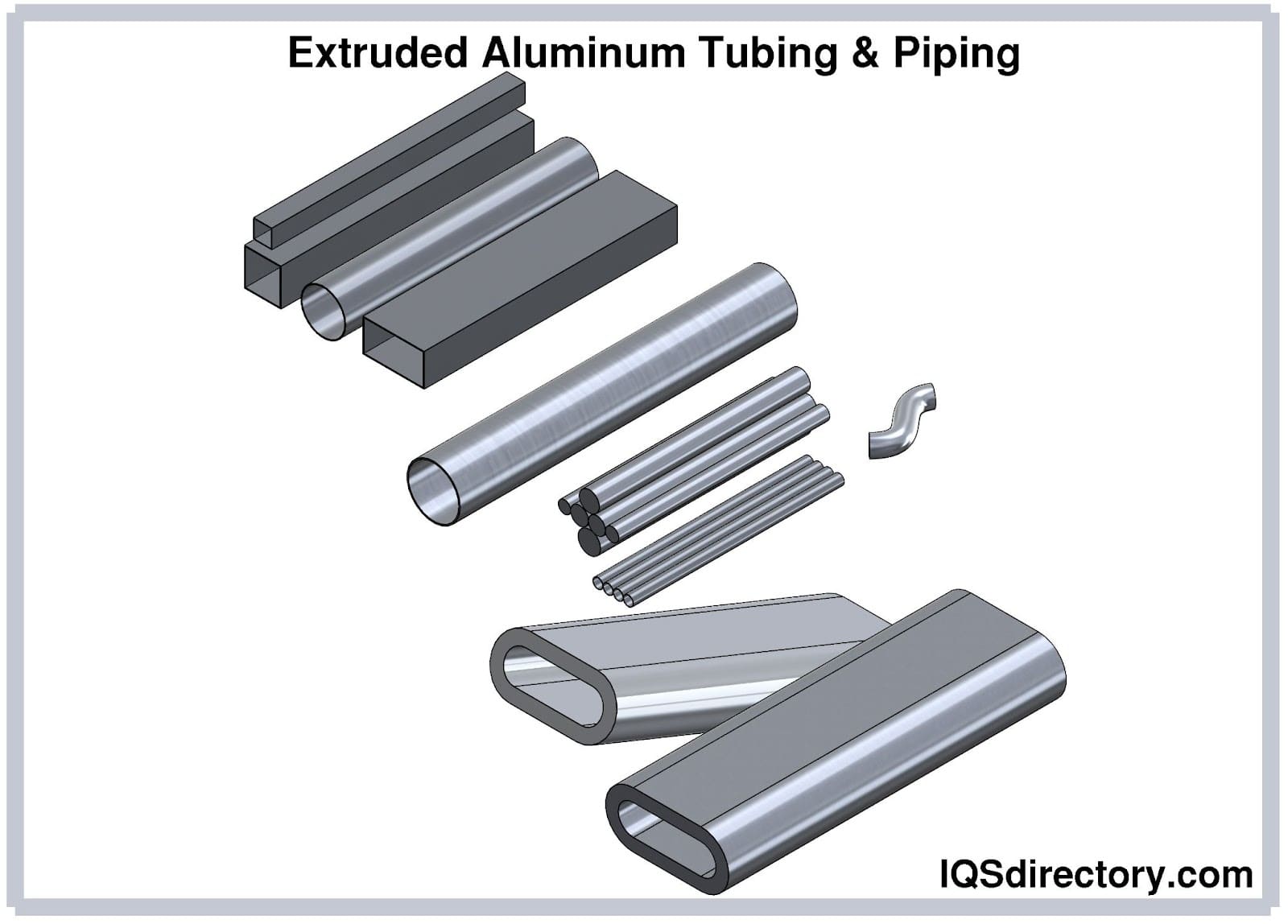

How Does Aluminum Compare as a Material Choice?

Aluminum is increasingly used in construction and manufacturing due to its lightweight and corrosion-resistant properties. Key properties include a low density and excellent malleability, making it easy to work with.

Pros: Aluminum is highly resistant to corrosion and is lightweight, which can reduce shipping costs and ease handling. Its versatility allows it to be used in various applications, from structural components to decorative elements.

Cons: The primary limitation is its lower strength compared to steel, which may not be suitable for all structural applications. Additionally, aluminum can be more expensive than carbon steel.

Impact on Application: Aluminum is compatible with a wide range of media, including water and some chemicals, but care should be taken with highly alkaline or acidic substances.

Considerations for International Buyers: Compliance with standards such as ASTM B221 or EN 573 is important. Buyers should also consider local availability and the potential for higher costs in regions where aluminum is less commonly used.

What Role Does Alloy Steel Play in Specialized Applications?

Alloy steel is designed with specific alloying elements to enhance certain properties, such as strength, toughness, and wear resistance. Key properties include improved mechanical properties and the ability to withstand extreme conditions.

Pros: Alloy steel offers superior performance in demanding applications, making it ideal for industries such as aerospace and automotive. Its enhanced properties can lead to longer service life and reduced maintenance.

Cons: The complexity of manufacturing alloy steel can lead to higher costs. Additionally, specific grades may not be as readily available as carbon or stainless steel.

Illustrative image related to general steel macon ga

Impact on Application: Alloy steel is suitable for high-stress applications and can be used with various media, but compatibility should be assessed based on the specific alloy composition.

Considerations for International Buyers: Compliance with standards such as ASTM A335 or EN 10083 is critical. Buyers should also be aware of the specific properties required for their applications, as these can vary significantly.

Summary Table of Strategic Material Selection

| Material | Typical Use Case for general steel macon ga | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural beams, manufacturing components | Cost-effective and durable | Susceptible to corrosion | Low |

| Stainless Steel | Food processing, architectural applications | Excellent corrosion resistance | Higher cost and fabrication complexity | High |

| Aluminum | Lightweight structures, decorative elements | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Alloy Steel | High-stress applications, automotive parts | Superior mechanical properties | Higher manufacturing costs | High |

This guide should assist international B2B buyers in making informed decisions regarding material selection for projects involving General Steel in Macon, GA, ensuring compliance with relevant standards and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for general steel macon ga

What Are the Key Stages in the Manufacturing Process of Steel Products in Macon, GA?

The manufacturing process for steel products at General Steel in Macon, GA, typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is designed to ensure high-quality outcomes, catering to a diverse range of B2B clients.

Material Preparation

Material preparation is the foundational step in steel manufacturing. It begins with sourcing high-grade raw materials, such as hot-rolled and cold-rolled carbon steel, stainless steel, and aluminum. The quality of these materials is paramount, as it affects the overall integrity of the final product. In Macon, suppliers typically conduct rigorous inspections and testing of incoming materials to ensure they meet industry standards.

Once the materials are sourced, they undergo processing, which may include cutting, shearing, or machining to create manageable sizes and shapes suitable for further processing. This stage is crucial for minimizing waste and optimizing the efficiency of subsequent manufacturing steps.

How Is Steel Formed in the Manufacturing Process?

The forming stage involves shaping the prepared materials into the desired configurations. Techniques employed can include:

- Hot and Cold Rolling: These methods alter the material’s shape and thickness while enhancing its mechanical properties. Hot rolling is typically used for structural applications, while cold rolling is preferred for products requiring tighter tolerances.

- Welding and Fabrication: These processes join different steel components to create assemblies. Techniques like MIG and TIG welding are common, ensuring robust connections that meet specific engineering requirements.

- Casting: In some cases, steel may be cast into specific shapes. This method allows for intricate designs and complex geometries that are otherwise difficult to achieve through traditional forming techniques.

What Is Involved in the Assembly of Steel Products?

Assembly involves combining various formed components into a complete product. This stage may require additional processing steps, such as drilling, tapping, or threading, to prepare the parts for assembly.

Quality control is vital during this phase. Manufacturers often implement assembly jigs and fixtures to ensure that components fit together precisely. This reduces the likelihood of errors and improves the efficiency of the assembly process.

What Finishing Techniques Are Commonly Used for Steel Products?

Finishing processes enhance the performance and aesthetics of steel products. Common techniques include:

- Galvanizing: A protective zinc coating is applied to steel to prevent corrosion. This is particularly important for products exposed to harsh environmental conditions.

- Painting and Coating: Various paints and coatings can be applied to improve appearance and durability. This is especially relevant for products used in architectural applications.

- Heat Treatment: Processes such as annealing and quenching can be applied to improve the hardness and toughness of steel components, which is essential for high-stress applications.

How Are Quality Control Measures Implemented in Steel Manufacturing?

Quality assurance is integral to steel manufacturing, especially for B2B buyers who require reliable products. General Steel adheres to international standards, including ISO 9001, which outlines a framework for a quality management system. This certification assures clients that the manufacturing processes meet international quality benchmarks.

Illustrative image related to general steel macon ga

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are strategically placed throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Any materials that do not pass this checkpoint are rejected or returned to the supplier.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during manufacturing to identify and rectify any deviations from quality standards. This can involve regular inspections and testing of semi-finished products.

- Final Quality Control (FQC): Once products are completed, a thorough inspection is conducted to verify compliance with specifications. This may include dimensional checks, surface finish inspections, and functional testing.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to validate the quality of steel products. These include:

- Mechanical Testing: Assessing properties such as tensile strength, hardness, and ductility to ensure the material can withstand the intended application.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing, magnetic particle inspection, and radiographic testing help identify internal defects without damaging the product.

- Chemical Analysis: Ensuring that the steel composition meets required specifications is critical, particularly for specialized applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers from international markets, including Africa, South America, the Middle East, and Europe, should take proactive steps to verify supplier quality control practices:

- Conduct Audits: Regular audits of manufacturing facilities can help buyers assess compliance with quality standards. This includes reviewing documentation and observing processes firsthand.

- Request Quality Reports: Suppliers should provide detailed quality reports that outline testing results, compliance with standards, and any corrective actions taken for non-conformities.

- Engage Third-Party Inspectors: Hiring independent inspectors can provide an unbiased assessment of the supplier’s quality control measures. This is particularly beneficial for international buyers who may not be able to visit facilities regularly.

What Are the Quality Certification Nuances for International B2B Buyers?

When dealing with international suppliers, B2B buyers must be aware of specific quality certification nuances. Different regions may have varying standards and certifications. For instance, CE marking is essential for products sold within the European Union, while API certification may be required for products intended for the oil and gas sector.

Buyers should ensure that their suppliers hold relevant certifications that are recognized in their target markets. This not only guarantees product quality but also facilitates smoother trade and compliance with local regulations.

Conclusion

Understanding the manufacturing processes and quality assurance protocols at General Steel in Macon, GA, equips B2B buyers with the insights needed to make informed purchasing decisions. By focusing on each stage of production and implementing robust quality control measures, suppliers can ensure that their products meet the high standards expected by international clients. As global competition intensifies, these practices will be critical in establishing trust and reliability in the steel supply chain.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘general steel macon ga’

This guide aims to provide international B2B buyers with a comprehensive checklist for sourcing general steel from Macon, Georgia. As a region with a rich history in steel production, Macon is home to suppliers that offer a diverse range of steel products and processing capabilities. By following this step-by-step checklist, buyers can ensure they make informed decisions that align with their project requirements and business goals.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your project’s technical requirements. This includes the type of steel needed (e.g., carbon steel, stainless steel, aluminum), dimensions, and any specific standards or certifications that must be met. Having a detailed specification helps you communicate your needs effectively to potential suppliers and ensures you receive accurate quotes.

Step 2: Research Reputable Suppliers

Conduct thorough research to identify reputable steel suppliers in Macon, GA. Look for companies with a strong presence in the industry, such as Triple-S Steel, which has a comprehensive inventory and processing capabilities. Utilize online resources, industry directories, and trade associations to compile a list of potential suppliers.

- Tip: Check for customer reviews and testimonials to gauge supplier reliability and service quality.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications, such as ISO 9001 or membership in industry associations like the North American Steel Alliance (NASA). These certifications indicate a commitment to quality and adherence to industry standards, which is critical for ensuring product reliability and safety.

Illustrative image related to general steel macon ga

- Note: Inquire about their compliance with local and international regulations, especially if you’re sourcing for projects in different regions.

Step 4: Request Quotes and Compare Pricing

Once you have identified suitable suppliers, request detailed quotes based on your specifications. Ensure that the quotes include all costs, such as materials, processing, shipping, and any additional fees. Comparing quotes will help you understand the market pricing and identify the best value for your investment.

- Caution: Be wary of significantly lower quotes, as they may indicate subpar quality or hidden costs.

Step 5: Assess Processing Capabilities

Evaluate the processing capabilities of your shortlisted suppliers. Suppliers like General Steel in Macon offer a range of services, including rebar fabrication, precision sawing, and galvanizing. Ensure that the supplier can meet your specific processing needs, as this can significantly impact your project timeline and budget.

Step 6: Request Samples

Before making a final decision, request material samples from your top suppliers. This allows you to assess the quality of the steel products firsthand. Inspect the samples for compliance with your specifications, and consider conducting any necessary tests to verify their performance.

- Recommendation: Discuss any concerns about the samples directly with the supplier to gauge their responsiveness and willingness to address issues.

Step 7: Establish Clear Communication

Once you select a supplier, establish clear lines of communication. Discuss timelines, delivery schedules, and any potential challenges that may arise during the procurement process. Maintaining open communication ensures that both parties are aligned and can address any issues promptly.

By following this checklist, B2B buyers can navigate the sourcing process more effectively, ensuring they procure high-quality steel products from reputable suppliers in Macon, GA, while fostering strong business relationships.

Comprehensive Cost and Pricing Analysis for general steel macon ga Sourcing

What Are the Key Cost Components in Sourcing General Steel from Macon, GA?

When evaluating the cost structure for sourcing general steel from Macon, GA, several critical components must be considered. These include:

-

Materials: The base cost of steel fluctuates based on market conditions, global supply chains, and raw material availability. Buyers should monitor commodity prices to anticipate changes in their procurement costs.

-

Labor: Labor costs in the U.S. are influenced by regional wage standards and labor availability. In Macon, the local workforce’s skill level can impact the overall labor costs associated with steel processing and fabrication.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, rent, and administrative expenses. Efficient management of these overheads can significantly affect pricing.

-

Tooling: Investment in specialized tools for steel fabrication can be substantial. Custom tooling may lead to higher upfront costs but can enhance production efficiency.

-

Quality Control (QC): Ensuring that steel products meet industry standards and specifications incurs costs. Effective QC processes can reduce returns and rework, ultimately impacting the total cost.

-

Logistics: Transportation costs from Macon to the final destination can vary widely based on distance, mode of transport, and current fuel prices. Consideration of local shipping options can provide cost advantages.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure sustainability. Understanding a supplier’s margin structure can aid in negotiations.

How Do Price Influencers Affect General Steel Pricing in Macon, GA?

Several factors can influence the pricing of general steel sourced from Macon, GA:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically yield lower per-unit costs due to economies of scale. Buyers should assess their needs against suppliers’ MOQs to optimize costs.

-

Specifications and Customization: Custom specifications may increase costs due to the need for specialized processes or materials. Clear communication of requirements can help mitigate unexpected expenses.

-

Materials Quality and Certifications: Higher quality materials or certifications (e.g., ISO, ASTM) can command premium pricing. Buyers should weigh the benefits of certified products against their project requirements.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may offer better service but at a higher price point.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is crucial for international transactions, as they dictate who bears shipping costs and risks. This can significantly influence the total landed cost.

What Tips Can Help International B2B Buyers Optimize Costs in Steel Sourcing?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiation: Engage in discussions with suppliers to negotiate better pricing, especially for larger orders or long-term contracts. Highlighting a commitment to ongoing business can incentivize favorable terms.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the complete cost of acquiring and using the steel, including maintenance, logistics, and potential rework costs. This broader view can lead to better purchasing decisions.

-

Understand Pricing Nuances: Awareness of regional pricing trends and fluctuations can help buyers time their purchases effectively. Additionally, understanding local market conditions in Macon can provide leverage in negotiations.

-

Leverage Local Knowledge: Partnering with local sourcing agents or consultants can provide insights into the Macon market and help navigate logistical challenges, ensuring a smoother procurement process.

Disclaimer on Indicative Prices

Prices for general steel can vary widely based on market conditions, specifications, and supplier negotiations. The information provided here is indicative and should be used as a guide rather than a definitive cost structure. Buyers are encouraged to conduct their own market research and consult with suppliers for accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing general steel macon ga With Other Solutions

Introduction to Alternative Solutions for Steel Supply

In the competitive landscape of steel supply, B2B buyers are often faced with various options that can meet their specific needs. Understanding these alternatives is crucial for making informed decisions that align with project requirements and budget constraints. This analysis will compare General Steel in Macon, GA, with two viable alternatives: local steel suppliers and international steel manufacturers. Each option has distinct advantages and disadvantages that can influence your choice based on factors like performance, cost, and ease of implementation.

Illustrative image related to general steel macon ga

Comparison Table

| Comparison Aspect | General Steel Macon GA | Local Steel Suppliers | International Steel Manufacturers |

|---|---|---|---|

| Performance | High-quality structural and processing capabilities | Varies; often limited to standard products | Wide range of innovative and specialized products |

| Cost | Competitive pricing, good for local projects | Generally lower due to reduced shipping costs | Higher due to import tariffs and shipping |

| Ease of Implementation | Streamlined processes and local support | Quick turnaround times, local delivery | Longer lead times; potential customs delays |

| Maintenance | Comprehensive support and service options | Varies; may lack extensive support | Limited local support; relies on distributors |

| Best Use Case | Large-scale construction and public projects | Smaller projects and local construction | Specialized industrial applications requiring unique materials |

Detailed Breakdown of Alternatives

Local Steel Suppliers

Local steel suppliers can be an excellent alternative for businesses that prioritize cost-effectiveness and quick service. These suppliers often provide a range of standard steel products that can meet the immediate needs of smaller projects. The main advantages include reduced shipping costs and faster delivery times, which can be critical for timely project completion. However, the downside is that local suppliers may not offer the same breadth of products or specialized services as General Steel, limiting options for more complex projects.

International Steel Manufacturers

International steel manufacturers present a unique alternative, particularly for projects requiring specialized steel products or innovative solutions. These manufacturers often have extensive inventories and advanced technology that can cater to a wide array of industrial applications. While they might offer high-quality materials, the costs can be significantly higher due to shipping fees, import tariffs, and longer lead times. Additionally, the lack of localized support can be a drawback for businesses needing immediate assistance or maintenance services.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating which steel supply option is best for your business, consider your specific project requirements, budget constraints, and timeline. General Steel in Macon, GA, stands out for its high-quality products and comprehensive support, making it ideal for large-scale projects. Local suppliers may be best for smaller, cost-sensitive projects requiring quick delivery, while international manufacturers are suited for specialized needs. Ultimately, the right choice will depend on balancing performance, cost, and the level of service required to ensure project success.

Essential Technical Properties and Trade Terminology for general steel macon ga

What Are the Key Technical Properties of General Steel in Macon, GA?

Understanding the essential technical properties of steel is crucial for international B2B buyers, especially when sourcing materials for construction and manufacturing projects. Here are some critical specifications to consider:

-

Material Grade

Steel is categorized into various grades, such as ASTM A36, A992, and A572, which indicate the steel’s chemical composition and mechanical properties. Material grades are vital for ensuring that the steel meets specific strength, ductility, and weldability requirements for different applications. Choosing the correct grade affects the overall safety and durability of the final product. -

Yield Strength

This property measures the maximum stress that a material can withstand while maintaining its shape. For example, A36 steel has a yield strength of around 36,000 psi. In a B2B context, selecting steel with the appropriate yield strength is critical for structural integrity, particularly in load-bearing applications. -

Tensile Strength

Tensile strength refers to the maximum amount of tensile (stretching) stress that a material can endure before failure. For instance, structural steel commonly used in construction typically has a tensile strength range of 58,000 to 80,000 psi. Understanding tensile strength helps buyers assess the material’s performance under various loads, ensuring that it meets the demands of specific projects. -

Thickness Tolerance

This specification indicates the allowable deviation from nominal thickness in steel plates or sheets. Tolerances are crucial for ensuring that components fit together correctly during assembly. In B2B transactions, adhering to specified tolerances minimizes waste and reduces the risk of project delays. -

Corrosion Resistance

Steel’s ability to resist corrosion is increasingly important, especially in harsh environments. Stainless steel grades like 304 and 316 provide excellent corrosion resistance, making them ideal for outdoor or marine applications. Buyers must consider corrosion resistance to ensure longevity and reduce maintenance costs over time. -

Weldability

This property indicates how easily steel can be welded without compromising its integrity. Factors affecting weldability include carbon content and the presence of alloying elements. Understanding weldability is essential for manufacturers who require seamless assembly of components.

What Are Common Trade Terms in the Steel Industry?

Familiarity with industry jargon can enhance communication and negotiation in B2B transactions. Here are several important trade terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, working with OEMs often guarantees quality and compatibility, as these companies typically adhere to strict manufacturing standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is crucial for buyers to manage inventory effectively and to ensure they are purchasing sufficient quantities to meet project demands without incurring excessive costs. -

RFQ (Request for Quotation)

An RFQ is a formal request for price quotes from suppliers. B2B buyers use RFQs to compare prices and terms from different suppliers, ensuring they secure the best deal for their procurement needs. -

Incoterms (International Commercial Terms)

These are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for buyers to clarify shipping, delivery, and risk management, which can significantly impact overall costs. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. For B2B buyers, understanding lead times is essential for project planning and ensuring timely delivery of materials to avoid delays in construction or manufacturing processes. -

Fabrication

This term encompasses the processes involved in cutting, shaping, and assembling steel components. Buyers should be aware of the fabrication capabilities of suppliers to ensure they can meet specific project requirements efficiently.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing steel from Macon, GA, ensuring the success of their projects across diverse markets.

Navigating Market Dynamics and Sourcing Trends in the general steel macon ga Sector

What Are the Key Market Dynamics and Trends Influencing the General Steel Sector in Macon, GA?

The general steel sector in Macon, GA, is significantly influenced by global market dynamics and emerging trends that shape international trade. A primary driver is the increasing demand for infrastructure development across various regions, particularly in Africa, South America, the Middle East, and Europe. Countries like Brazil and Saudi Arabia are investing heavily in construction projects, creating a robust market for steel products. Additionally, the rise of Industry 4.0 is transforming the steel sourcing landscape, with digital platforms enhancing supply chain transparency and efficiency. These platforms allow international buyers to access a wider range of suppliers and streamline procurement processes.

Moreover, sustainability is becoming a critical consideration for B2B buyers. As the world shifts towards greener practices, steel manufacturers are adopting more sustainable production methods. This includes using recycled materials and reducing carbon footprints, which resonate with buyers seeking ethical sourcing options. The ongoing global supply chain disruptions, exacerbated by geopolitical tensions and the COVID-19 pandemic, have also prompted buyers to seek more localized suppliers to mitigate risks and ensure supply chain resilience.

How Is Sustainability and Ethical Sourcing Shaping the Steel Industry in Macon, GA?

Sustainability and ethical sourcing are increasingly important in the B2B steel market, particularly for international buyers. The environmental impact of steel production is substantial, prompting manufacturers in Macon, GA, to adopt greener practices. For instance, many suppliers are focusing on reducing emissions through innovative technologies and utilizing electric arc furnaces, which can significantly lower carbon outputs compared to traditional methods.

Moreover, ethical supply chains are gaining traction as companies prioritize transparency and social responsibility. Buyers are now looking for suppliers that can provide certifications for sustainable practices, such as LEED or ISO 14001, which denote adherence to environmental management standards. Additionally, sourcing from manufacturers that use recycled steel not only reduces waste but also appeals to environmentally conscious buyers.

In Macon, GA, suppliers are responding to these trends by integrating sustainability into their business models. This includes offering a range of green materials and ensuring compliance with international environmental regulations, making them more attractive to buyers who value ethical sourcing.

What Is the Historical Context of the Steel Sector in Macon, GA?

The steel sector in Macon, GA, has a rich history dating back to the mid-20th century. Established in 1956, General Steel has evolved from a local supplier to a significant player in the national market. Its acquisition by Triple-S Steel in 2013 marked a pivotal moment, enhancing its capabilities and expanding its inventory to include a diverse range of steel products, including structural steel, plates, and specialized materials.

Over the decades, the industry in Macon has adapted to changing market demands and technological advancements, transitioning from traditional manufacturing methods to more innovative practices. This evolution has positioned Macon as a key hub for steel supply in the southeastern United States, catering to a diverse clientele that includes construction firms, manufacturers, and government agencies. As the market continues to grow, the legacy of quality and service established in the past remains a cornerstone of the sector’s ongoing success.

Frequently Asked Questions (FAQs) for B2B Buyers of general steel macon ga

-

How do I ensure the quality of steel products from suppliers in Macon, GA?

To ensure the quality of steel products, request certifications and compliance documents from the supplier. Look for adherence to industry standards such as ASTM and ISO certifications. It’s advisable to conduct a factory audit or quality assurance check, especially for international shipments. Engaging third-party inspection services can also provide an unbiased evaluation of the steel products before shipping. Establishing a clear communication channel with the supplier can facilitate immediate resolution of any quality concerns. -

What is the best type of steel for construction projects?

The best type of steel for construction projects typically includes carbon steel, stainless steel, and structural steel. Carbon steel is widely used due to its strength and versatility, making it ideal for various structural applications. Stainless steel offers corrosion resistance, making it suitable for environments exposed to moisture or chemicals. Structural steel, with its high strength-to-weight ratio, is essential for beams, columns, and frames. The choice largely depends on specific project requirements, including load-bearing capacity and environmental conditions. -

What are the minimum order quantities (MOQs) for steel products from suppliers in Macon?

Minimum order quantities (MOQs) can vary based on the type of steel product and the supplier’s policies. For standard items like structural steel beams or plates, MOQs may range from a few tons to several dozen, while custom orders might have higher MOQs. It’s essential to discuss your project needs with the supplier to understand their MOQ policies and negotiate if necessary. Suppliers may also accommodate smaller orders based on availability or ongoing stock. -

What payment terms should I expect when sourcing steel internationally?

Payment terms can vary significantly among suppliers and depend on the buyer’s relationship with them. Common terms include advance payment, letter of credit, or payment upon delivery. For international transactions, consider using secure payment methods such as escrow services to mitigate risk. It’s also wise to clarify currency exchange rates and fees associated with international payments. Establishing a clear agreement on payment terms before placing an order helps avoid misunderstandings later. -

How can I customize my steel orders to meet specific project requirements?

Customization options often include specific dimensions, grades, and finishes tailored to your project specifications. Most suppliers in Macon, GA, offer processing services such as cutting, drilling, and galvanizing. When placing an order, provide detailed drawings and specifications to the supplier. Discuss lead times for custom orders, as they may differ from standard products. Engaging in early communication about your requirements allows suppliers to offer solutions that meet your unique needs. -

What are the logistics considerations for importing steel from Macon, GA?

Logistics for importing steel include selecting the right shipping method (air or sea), understanding customs regulations, and ensuring compliance with import duties. Consider working with a freight forwarder experienced in steel transportation to streamline the process. Packaging and securing the steel for transport is crucial to prevent damage during transit. Additionally, be aware of lead times and coordinate with suppliers to align production schedules with shipping arrangements. -

How can I vet suppliers of steel products in Macon, GA?

To vet suppliers, start by researching their market reputation through customer reviews and industry ratings. Request references from previous clients to gauge their reliability and service quality. Check for relevant certifications and memberships in industry associations, such as the North American Steel Alliance. A visit to the supplier’s facility can provide valuable insights into their operational standards and capabilities. Engaging in initial small transactions can also help assess their performance before committing to larger orders. -

What after-sales support should I expect from steel suppliers?

After-sales support can include assistance with product installation, warranty claims, and troubleshooting issues. Reputable suppliers often provide technical support and guidance on product use and maintenance. It’s beneficial to clarify the extent of after-sales service during the initial negotiation phase. Additionally, inquire about return policies and how they handle product defects or discrepancies. A strong after-sales support system reflects a supplier’s commitment to customer satisfaction and can enhance the overall purchasing experience.

Top 5 General Steel Macon Ga Manufacturers & Suppliers List

1. Triple S Steel – Structural Steel Solutions

Domain: triple-s-steel.com

Registered: 2024 (1 years)

Introduction: Steel Angle Bar, Bar Grating, Beam, Jumbo Beam, Standard I-Beam, Wide Flange Beam, Channel, Hot-Rolled Steel Bar Channel, MC Channel (Car, Ship, & Jr.), Stair-Stringer Channel, Structural Steel Channel, Rebar, Decking, Composite Deck, Roof Deck, Steel Joists, Expanded Metal Standard (Raised), Expanded Metal Flattened, Expanded Metal Grating, Floor Plate, Metal Building Components, Pipe, Steel Plat…

2. Triple-S Steel® – Diverse Steel Products

Domain: sss-steel.com

Registered: 1997 (28 years)

Introduction: Triple-S Steel® offers a diverse range of steel products and processing services, including:

– **Materials:**

– Carbon Steel

– Alloy Steel

– Stainless & Aluminum

– Copper, Brass, Copper Nickel

– **Shapes:**

– Angle

– Bar

– Beam

– Channel

– Pipe

– Plate

– Sheet

– Tube

– **Steel Decking:**

– Composite Deck

– Roof Deck

– **Expanded Metal & Grating:** …

3. Yelp – Business Insights

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Yelp – Business Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Macon Iron – Family-Owned Success

Domain: indeed.com

Registered: 1998 (27 years)

Introduction: This company, Macon Iron – Family-Owned Success, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. General Steel – Metal Building Kits

Domain: gensteel.com

Registered: 1998 (27 years)

Introduction: General Steel offers a variety of metal building kits suitable for different purposes including commercial, agricultural, industrial, and personal use. Key product categories include:

– Business: Auto Shops, Breweries, Car Washes, Casinos, Commercial Fitness Centers, Golf Cart Storage, Horse Stables, Industrial Manufacturing, Medical Offices, Mini Storage, Offices, Retail, RV Storage, Strip Malls,…

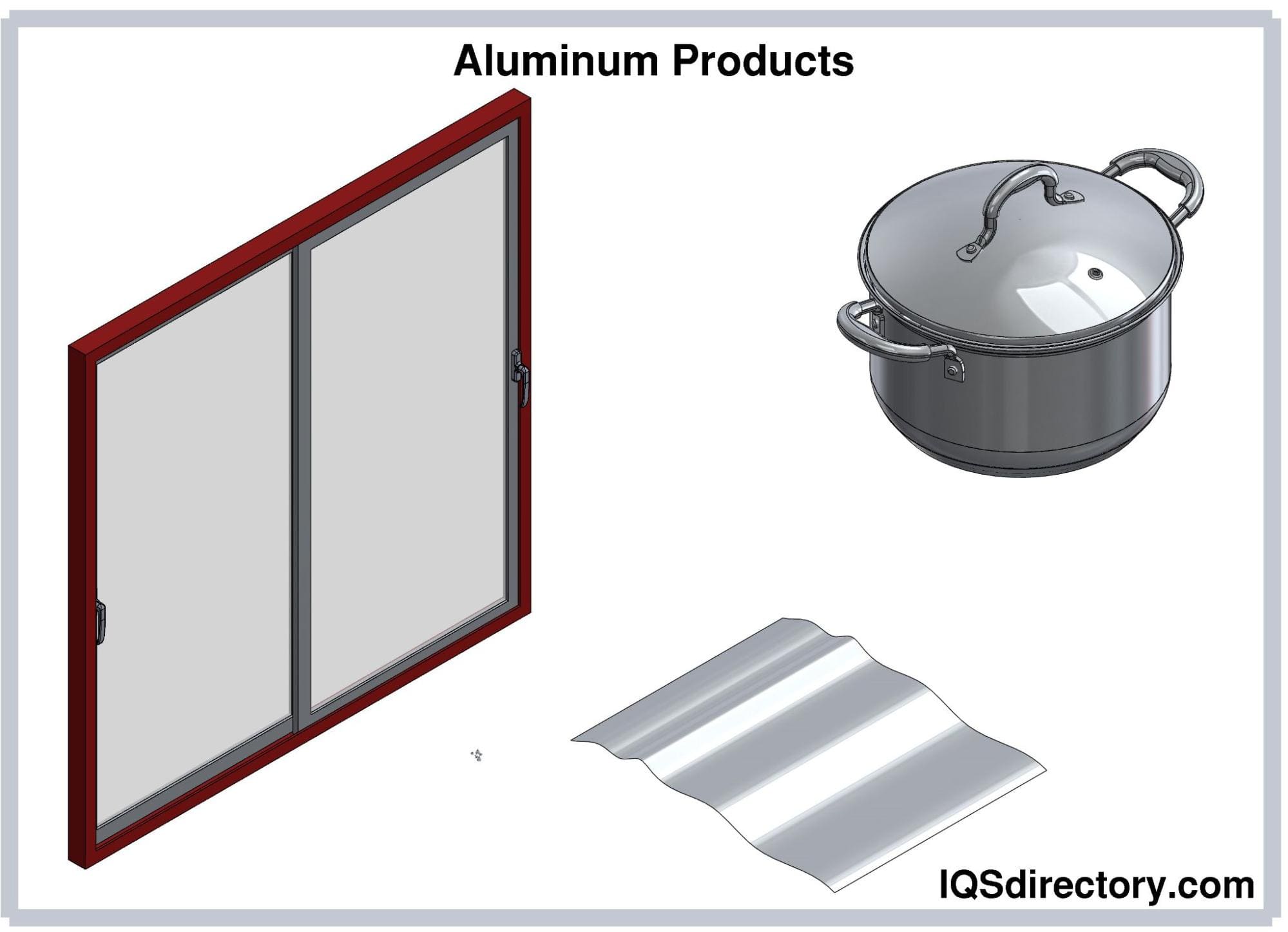

Strategic Sourcing Conclusion and Outlook for general steel macon ga

In the realm of strategic sourcing, the General Steel facility in Macon, GA, stands out as a pivotal player for international B2B buyers. With its extensive inventory of carbon steel products and an array of processing capabilities, the facility caters to diverse industries, including construction and energy. Buyers can leverage the competitive pricing and superior quality offered by General Steel to enhance their operational efficiency and project outcomes.

The strategic sourcing model emphasizes the importance of building strong partnerships with reliable suppliers like General Steel. This not only ensures consistent product availability but also fosters innovation and adaptability in meeting market demands. As international markets continue to evolve, particularly in regions such as Africa, South America, the Middle East, and Europe, the ability to source high-quality steel solutions becomes increasingly vital for sustained growth.

Illustrative image related to general steel macon ga

Looking ahead, B2B buyers are encouraged to explore the benefits of collaboration with General Steel. By aligning with a trusted supplier, businesses can position themselves strategically to capitalize on emerging opportunities and navigate the complexities of global supply chains. Embrace the future of steel sourcing—partner with General Steel in Macon, GA, to drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.