3 Prong Charger Cord: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for 3 prong charger cord

As businesses expand globally, sourcing the right components becomes crucial, especially when it comes to essential items like a 3 prong charger cord. International B2B buyers often face challenges in identifying reliable suppliers, ensuring compliance with varying regional standards, and navigating fluctuating pricing structures. This guide addresses these challenges head-on, providing a comprehensive overview of the 3 prong charger cord market.

Within these pages, you’ll explore various types of charger cords tailored for different applications, from home appliances to industrial equipment. We will also delve into supplier vetting processes, offering insights on how to select trustworthy manufacturers and distributors. Furthermore, understanding the cost implications, including shipping and import duties, is essential for effective budgeting and maximizing profitability.

This guide is designed specifically for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia. By leveraging the knowledge contained herein, you will be empowered to make informed purchasing decisions that align with your business needs and objectives. From technical specifications to market trends, our insights will help you navigate the complexities of sourcing 3 prong charger cords with confidence and efficiency.

Understanding 3 prong charger cord Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| NEMA 5-15P to IEC C13 Power Cord | Commonly used in North America; 3-prong male NEMA 5-15P to C13 female connector. | Computers, printers, and monitors. | Pros: Widely compatible, cost-effective. Cons: Limited to specific regions. |

| C5 Power Cord | Features a 3-prong connector shaped like a triangle; often used for laptops. | Laptops and portable devices. | Pros: Compact design, portable. Cons: Less robust for heavy-duty applications. |

| C13 Power Cord | Standardized for many appliances; connects to devices requiring a C13 socket. | Servers, network equipment, and UPS. | Pros: High compatibility, reliable power delivery. Cons: May require adapters for some devices. |

| Extension Power Cord | Longer length; allows for flexible placement of devices. | Industrial equipment and home appliances. | Pros: Versatile, flexible usage. Cons: Can be bulky, potential for wear and tear. |

| Appliance Power Cord | Designed for specific appliances; often features a unique connector. | Home appliances like refrigerators. | Pros: Tailored for specific uses, ensures compatibility. Cons: Limited versatility for other devices. |

What are the Characteristics of NEMA 5-15P to IEC C13 Power Cords?

The NEMA 5-15P to IEC C13 power cord is a staple in the North American market, characterized by its 3-prong male NEMA connector on one end and a C13 female connector on the other. This type is ideal for powering computers, printers, and monitors, making it a popular choice among B2B buyers in the IT and office equipment sectors. When purchasing, consider the cord length, gauge, and compliance with safety standards, as these factors can influence performance and reliability in commercial settings.

How Does the C5 Power Cord Suit Laptops and Portable Devices?

The C5 power cord, often referred to as a “cloverleaf” connector, is specifically designed for laptops and portable devices. Its unique shape allows for a secure connection while remaining compact, making it ideal for travel and mobile work environments. B2B buyers should assess compatibility with their specific laptop models, as well as the cord’s length and durability, to ensure it meets the demands of their workforce.

Why Choose a C13 Power Cord for Servers and Network Equipment?

C13 power cords are widely used in server rooms and data centers due to their standardized design. They connect seamlessly to devices that require a C13 socket, such as servers, network switches, and uninterruptible power supplies (UPS). When sourcing these cords, businesses should prioritize cords with robust insulation and high-quality materials to ensure longevity and safety in high-demand environments.

What Advantages Do Extension Power Cords Offer for Industrial Applications?

Extension power cords are invaluable in industrial settings, providing the flexibility to place equipment where needed without being constrained by outlet locations. These cords come in various lengths and are often designed for heavy-duty use. B2B buyers should consider the cord’s amperage rating and insulation type to match the specific requirements of their equipment and to minimize the risk of electrical hazards.

How Do Appliance Power Cords Ensure Compatibility with Specific Devices?

Appliance power cords are tailored for specific devices, such as refrigerators and washing machines, featuring connectors designed for those particular appliances. This specificity ensures optimal performance and safety. When purchasing, B2B buyers should verify that the cord meets the manufacturer’s specifications for their appliances to avoid issues related to compatibility and functionality.

Key Industrial Applications of 3 prong charger cord

| Industry/Sector | Specific Application of 3 prong charger cord | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics Manufacturing | Power supply for assembly line machinery | Ensures reliable operation of critical production equipment | Compliance with safety standards and voltage ratings |

| IT and Data Centers | Power connections for servers and networking equipment | Provides stable power, reducing downtime and data loss | Length, gauge, and connector type for compatibility |

| Healthcare | Powering medical devices and equipment | Supports critical operations, enhancing patient care | Durability, safety certifications, and voltage requirements |

| Retail | Charging stations for consumer electronics | Enhances customer experience by providing charging options | Aesthetic design and cable length for visibility |

| Construction | Temporary power supply for tools and equipment | Facilitates efficient work on-site, reducing delays | Weather resistance and length for site adaptability |

How Are 3 Prong Charger Cords Utilized in Electronics Manufacturing?

In the electronics manufacturing sector, 3 prong charger cords are essential for powering assembly line machinery. These cords ensure that equipment operates reliably, which is critical for maintaining production schedules. Manufacturers must consider safety standards and voltage ratings when sourcing these cords to prevent downtime due to electrical issues. Additionally, compatibility with various machinery types is vital, making it essential for buyers to verify specifications before procurement.

What Role Do 3 Prong Charger Cords Play in IT and Data Centers?

In IT and data centers, 3 prong charger cords are crucial for connecting servers and networking equipment to power sources. They provide a stable power supply, which is vital for minimizing downtime and protecting sensitive data. When sourcing these cords, businesses must focus on the length, gauge, and connector type to ensure compatibility with existing infrastructure. Furthermore, considering the environmental conditions of data centers, durability and flexibility of the cords are also important factors.

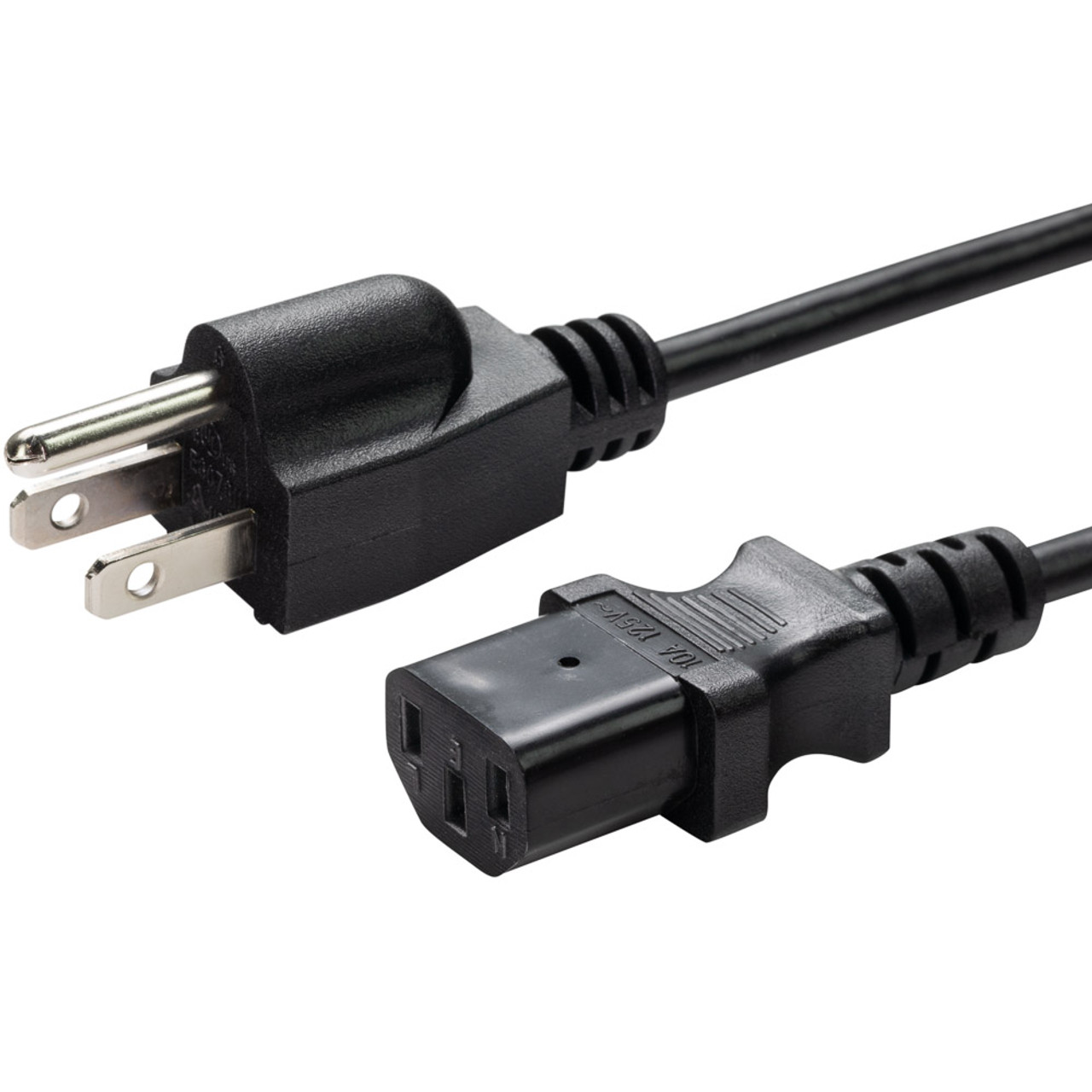

Illustrative image related to 3 prong charger cord

Why Are 3 Prong Charger Cords Important in Healthcare?

In the healthcare industry, 3 prong charger cords are used to power various medical devices and equipment, ensuring they operate effectively during critical procedures. The reliability of these power cords directly impacts patient care and safety. Buyers in this sector should prioritize sourcing cords that meet strict durability and safety certifications, as well as specific voltage requirements to guarantee that medical devices function without interruption.

How Do Retailers Benefit from 3 Prong Charger Cords?

Retail environments often utilize 3 prong charger cords to create charging stations for consumer electronics. These charging solutions enhance the customer experience by allowing shoppers to recharge their devices while browsing. When sourcing these cords, retailers should consider aesthetic designs that complement their store layout, as well as the length of the cords to ensure they are visible and accessible to customers. Additionally, the durability of the cords is crucial to withstand frequent usage.

What Are the Applications of 3 Prong Charger Cords in Construction?

In the construction industry, 3 prong charger cords are essential for providing temporary power supplies to tools and equipment on job sites. They facilitate efficient work and help prevent delays caused by power shortages. Buyers must consider sourcing cords that are weather-resistant and of adequate length to adapt to various site conditions. Ensuring that these cords can withstand outdoor environments is vital for maintaining productivity and safety on construction projects.

Illustrative image related to 3 prong charger cord

3 Common User Pain Points for ‘3 prong charger cord’ & Their Solutions

Scenario 1: Compatibility Issues with Devices

The Problem: B2B buyers often face challenges when sourcing 3 prong charger cords that are compatible with various devices. This is especially true in industries like manufacturing and IT, where equipment may vary significantly in terms of voltage and connector types. A mismatch can lead to operational downtime, increased costs, and potential safety hazards if devices are improperly powered.

The Solution: To mitigate compatibility issues, buyers should conduct thorough research on the specifications of the devices they intend to power. When sourcing 3 prong charger cords, ensure that the cords meet the necessary voltage and amperage requirements as specified by the device manufacturers. It’s beneficial to consult with suppliers who can provide detailed product specifications and compatibility charts. Additionally, consider investing in cords that feature universal connectors or those that comply with international standards, which can enhance flexibility and reduce the likelihood of future compatibility problems.

Scenario 2: Durability and Quality Concerns

The Problem: Another common pain point for B2B buyers is the durability and overall quality of 3 prong charger cords. In environments where cords are frequently plugged and unplugged, or subject to environmental stressors (like moisture or extreme temperatures), low-quality cords can lead to failures, posing risks to both equipment and personnel.

Illustrative image related to 3 prong charger cord

The Solution: Buyers should prioritize sourcing high-quality 3 prong charger cords that are designed for heavy-duty use. Look for cords that feature reinforced connectors, durable sheathing, and are rated for the specific environmental conditions they will encounter. Requesting samples from suppliers to test under real-world conditions can provide insights into their longevity. Additionally, consider implementing a regular maintenance schedule to inspect cords for wear and tear, and establish a replacement policy to ensure that faulty cords are promptly replaced to maintain safety and efficiency.

Scenario 3: Sourcing and Procurement Challenges

The Problem: B2B buyers often struggle with sourcing 3 prong charger cords in bulk at competitive prices, especially when dealing with international suppliers. Fluctuating prices, shipping delays, and varying quality standards can complicate the procurement process, leading to supply chain disruptions and increased operational costs.

The Solution: To streamline the sourcing process, buyers should establish relationships with reliable suppliers who have a proven track record in providing high-quality 3 prong charger cords. It is advisable to use a combination of local and international suppliers to balance cost and reliability. Additionally, consider leveraging bulk purchasing agreements that can offer discounts while ensuring a consistent supply. Implementing a vendor management system can help track supplier performance, quality, and delivery times, allowing for more strategic procurement decisions. Regularly reviewing and negotiating contracts can also help in securing better pricing and terms, reducing the overall cost of ownership for charger cords.

Strategic Material Selection Guide for 3 prong charger cord

What Are the Key Materials Used in 3 Prong Charger Cords?

When selecting materials for 3 prong charger cords, various factors such as electrical performance, durability, and cost must be taken into account. Here we analyze four common materials used in the construction of these cords.

What Are the Key Properties of PVC in 3 Prong Charger Cords?

Polyvinyl Chloride (PVC) is a widely used material for insulation and jacketing in power cords. It has a temperature rating typically up to 70°C and exhibits good resistance to abrasion and chemicals. PVC is also non-flammable, making it a safe choice for electrical applications.

Pros: PVC is cost-effective, easy to manufacture, and offers decent flexibility. It is suitable for a wide range of applications, including indoor use and environments where moisture is not a major concern.

Cons: The main limitations of PVC include its lower temperature resistance compared to other materials and potential environmental concerns regarding its production and disposal.

Impact on Application: PVC is compatible with standard electrical devices and is often used in consumer electronics, making it a popular choice for international buyers.

Considerations for International Buyers: Compliance with standards such as ASTM D3032 and IEC 60332 is crucial. Buyers from regions like Europe may prefer PVC that meets RoHS and REACH regulations.

How Does Thermoplastic Elastomer (TPE) Compare for Charger Cords?

Thermoplastic Elastomer (TPE) is gaining traction in the production of charger cords due to its excellent flexibility and resilience. TPE can withstand temperatures ranging from -40°C to 105°C and has good resistance to UV light, oils, and chemicals.

Pros: TPE offers superior durability and flexibility compared to PVC, making it ideal for environments where cords are frequently bent or twisted. It is also recyclable, appealing to environmentally conscious buyers.

Cons: TPE is generally more expensive than PVC and may require more complex manufacturing processes.

Impact on Application: TPE is suitable for outdoor applications and devices that may be exposed to harsh conditions, making it a preferred choice for industrial applications.

Considerations for International Buyers: TPE should comply with international standards such as ISO 9001 for quality management. Buyers in regions like Germany may prioritize TPE that meets stringent environmental regulations.

What Advantages Does Silicone Offer for Charger Cords?

Silicone is another material option for 3 prong charger cords, known for its exceptional temperature resistance, ranging from -60°C to 200°C. It is also highly resistant to aging and environmental factors.

Pros: Silicone’s flexibility and durability make it ideal for high-performance applications, including those requiring frequent movement or exposure to extreme conditions.

Illustrative image related to 3 prong charger cord

Cons: The primary drawback of silicone is its higher cost compared to PVC and TPE, which may deter budget-sensitive buyers.

Impact on Application: Silicone is particularly suitable for medical devices and high-end electronics, where safety and reliability are paramount.

Considerations for International Buyers: Buyers should ensure compliance with medical-grade standards, such as ISO 10993 for biocompatibility, especially in regions with strict health regulations.

How Does Rubber Stack Up as a Material for Charger Cords?

Rubber, particularly natural rubber or synthetic variants, is used in some charger cord applications due to its excellent electrical insulation properties and flexibility. It can handle temperatures from -40°C to 90°C.

Pros: Rubber provides excellent durability and resistance to wear and tear, making it suitable for heavy-duty applications.

Cons: The main disadvantage is that rubber can be more expensive and may not be as environmentally friendly as other materials.

Impact on Application: Rubber is often used in industrial settings where cords are subject to high stress and environmental exposure.

Considerations for International Buyers: Compliance with safety standards such as UL and IEC is essential, particularly for buyers from regions with rigorous electrical safety regulations.

Summary Table of Material Selection for 3 Prong Charger Cords

| Material | Typical Use Case for 3 prong charger cord | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Consumer electronics | Cost-effective and flexible | Lower temperature resistance | Low |

| Thermoplastic Elastomer (TPE) | Outdoor and industrial applications | Superior durability and flexibility | Higher cost and manufacturing complexity | Med |

| Silicone | Medical devices and high-performance electronics | Excellent temperature resistance | Higher cost | High |

| Rubber | Heavy-duty industrial applications | Excellent durability | More expensive and less eco-friendly | Med |

This guide provides a comprehensive overview of material options for 3 prong charger cords, helping international B2B buyers make informed decisions based on their specific requirements and regional standards.

Illustrative image related to 3 prong charger cord

In-depth Look: Manufacturing Processes and Quality Assurance for 3 prong charger cord

What Are the Main Stages of Manufacturing a 3-Prong Charger Cord?

The manufacturing process of a 3-prong charger cord involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the quality and reliability of the final product.

Material Preparation

The first step is sourcing high-quality materials. Typically, this includes copper for the conductors, which is chosen for its excellent conductivity, and PVC or thermoplastic elastomer (TPE) for the insulation. Suppliers often conduct preliminary quality checks to ensure that materials meet specific standards before they are used in production. This stage also involves cutting the materials to the required lengths for the cords.

Forming

In the forming stage, the copper conductors are shaped into the appropriate configurations. This includes drawing the wire to the desired gauge (commonly 18 AWG) and adding insulation. The insulation process often involves extrusion, where the insulating material is heated and forced over the wire, ensuring a tight fit that adheres to safety standards.

Assembly

Once the materials are prepared and formed, they are assembled. This involves attaching the connectors to each end of the cord. The connectors typically include a NEMA 5-15P male plug on one end and an IEC 60320 C13 female connector on the other. During assembly, workers or automated machines ensure that connections are secure, and any strain relief mechanisms are added to prevent wear and tear.

Finishing

The final stage, finishing, involves quality checks and packaging. Cords are often tested for continuity and insulation resistance to ensure they meet safety standards. After passing quality checks, they are packaged for shipment. Proper labeling is crucial, especially for international shipping, to comply with various regulations.

What Quality Control Measures Are Essential for 3-Prong Charger Cords?

Quality control (QC) is a vital component of the manufacturing process, ensuring that each 3-prong charger cord meets both safety and performance standards. Various international standards, such as ISO 9001, CE, and UL certification, guide these QC measures.

International Standards and Certifications

ISO 9001 outlines requirements for a quality management system, emphasizing continuous improvement and customer satisfaction. The CE mark indicates conformity with health and safety standards within the European Economic Area, while UL certification ensures that products meet stringent safety standards. B2B buyers should prioritize suppliers that hold these certifications, as they reflect a commitment to quality.

Illustrative image related to 3 prong charger cord

Quality Control Checkpoints

QC typically involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): Materials are inspected upon arrival to verify their compliance with specifications. This includes checking the electrical properties of copper and the integrity of insulation materials.

-

In-Process Quality Control (IPQC): During the forming and assembly stages, random samples are tested for defects. This can include checking the dimensions of the connectors and ensuring that the insulation is free from gaps or defects.

-

Final Quality Control (FQC): Before packaging, the finished cords undergo rigorous testing. This includes electrical testing for continuity, insulation resistance, and stress testing to ensure durability.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is crucial for ensuring product reliability.

Audits and Reports

Conducting regular audits of suppliers can provide insight into their manufacturing and QC processes. Buyers should request documentation that demonstrates adherence to international standards, such as quality reports, inspection records, and testing results.

Illustrative image related to 3 prong charger cord

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s manufacturing practices. These services can conduct random checks during the production process, as well as verify compliance with safety standards before shipment.

Understanding QC/Certification Nuances

Different regions have varying regulations and standards. For example, while CE certification is critical for products sold in Europe, UL certification may be more relevant for the North American market. Buyers should familiarize themselves with the specific requirements of their target markets and ensure that suppliers can provide appropriate certifications.

What Common Testing Methods Are Used in Quality Assurance for Charger Cords?

To ensure the safety and effectiveness of 3-prong charger cords, manufacturers employ several common testing methods:

-

Electrical Testing: This includes tests for continuity, insulation resistance, and dielectric strength. These tests help confirm that cords can handle the expected electrical load without risk of failure.

-

Mechanical Testing: Cords are subjected to mechanical stress tests, such as bending and pulling, to assess durability and resistance to wear.

-

Environmental Testing: Cords may also undergo environmental tests to determine their performance under various conditions, including temperature fluctuations and humidity. These tests are crucial for ensuring that products can withstand diverse climates, particularly for buyers in regions like Africa and South America.

How Does Understanding Manufacturing and Quality Assurance Benefit B2B Buyers?

A thorough understanding of manufacturing processes and quality assurance measures enables B2B buyers to make informed decisions when sourcing 3-prong charger cords. By prioritizing suppliers with robust QC practices and relevant certifications, buyers can mitigate risks associated with product failures and enhance their supply chain reliability.

Investing time in supplier evaluations, understanding testing methods, and recognizing international standards can lead to stronger partnerships and ultimately result in higher customer satisfaction. As the global market continues to evolve, staying informed about manufacturing and quality assurance practices will empower B2B buyers to navigate challenges and seize opportunities effectively.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 prong charger cord’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure 3-prong charger cords. Whether you are supplying electronic devices or looking to enhance your product offerings, understanding the nuances of sourcing these essential components is critical for ensuring quality and compliance with international standards.

Step 1: Define Your Technical Specifications

Before initiating your sourcing process, clearly outline the technical specifications required for your 3-prong charger cords. This includes parameters such as gauge, length, and compatibility with devices.

– Gauge: Ensure you specify the appropriate wire gauge (e.g., 18 AWG) to support the current requirements of your devices.

– Length: Determine the length that meets your operational needs, whether for home use or commercial applications.

Step 2: Research Regulatory Standards

Understanding the regulatory landscape is vital for compliance and safety. Different regions have specific standards for electrical components.

– Certifications: Look for cords that meet certifications such as UL, CE, or RoHS, which indicate adherence to safety and environmental regulations.

– Local Regulations: Consider any additional requirements specific to the countries where you plan to distribute your products.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your quality and reliability standards.

– Supplier Profiles: Request detailed company profiles, including their manufacturing capabilities and experience in your industry.

– References: Ask for case studies or references from other businesses that have sourced similar products, preferably in your target market.

Step 4: Request Samples for Testing

Before making bulk purchases, always request samples to evaluate the product quality.

– Performance Testing: Check the cords for durability, flexibility, and performance under load conditions.

– Compatibility Testing: Ensure the samples work seamlessly with the devices they are intended for, verifying that there are no issues during operation.

Step 5: Negotiate Pricing and Terms

Once you’ve identified suitable suppliers, engage in negotiations to secure favorable pricing and terms.

– Volume Discounts: Discuss potential discounts based on order volume, which can significantly affect your overall procurement costs.

– Payment Terms: Establish clear payment terms that align with your cash flow and operational timelines.

Step 6: Plan for Logistics and Delivery

Effective logistics planning is essential for timely delivery and cost management.

– Shipping Options: Evaluate different shipping methods to find the most efficient and cost-effective options, considering factors like delivery time and customs clearance.

– Inventory Management: Coordinate with suppliers to align delivery schedules with your inventory needs to avoid stockouts or overstock situations.

Illustrative image related to 3 prong charger cord

Step 7: Establish Quality Control Measures

Implementing quality control measures post-delivery ensures that the products meet your standards before they reach customers.

– Inspection Protocols: Develop inspection protocols to assess the quality and compliance of the cords upon arrival.

– Return Policies: Clarify return and warranty policies with suppliers to manage any defective products efficiently.

By following this checklist, B2B buyers can streamline their sourcing process for 3-prong charger cords, ensuring they select the right products that meet technical requirements and compliance standards while optimizing costs and supplier relationships.

Comprehensive Cost and Pricing Analysis for 3 prong charger cord Sourcing

What Are the Key Cost Components for Sourcing 3 Prong Charger Cords?

Understanding the cost structure of 3 prong charger cords is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

-

Materials: The most significant component is the raw materials, which typically include copper for the wires and PVC or thermoplastic rubber for insulation. The quality of materials can vary widely, affecting both durability and price.

-

Labor: Labor costs can fluctuate based on geographic location and local wage standards. Regions with lower labor costs may offer more competitive pricing but could also lead to questions regarding product quality.

-

Manufacturing Overhead: This encompasses costs related to utilities, rent, and administrative expenses. Efficient factories with optimized processes can reduce these costs, allowing suppliers to offer better pricing.

-

Tooling: Initial tooling costs for custom designs or specifications can be substantial. Buyers should consider this when evaluating suppliers, especially if they require unique cable lengths or connectors.

-

Quality Control (QC): Ensuring compliance with international safety standards (e.g., UL, CE) often necessitates additional QC measures. Buyers should factor these costs into their overall budget, as they can impact both the price and reliability of the product.

-

Logistics: Shipping costs, which are influenced by distance, weight, and shipping methods, play a crucial role in the total cost. Incoterms will also dictate who bears these costs, impacting the final price.

-

Margin: Suppliers will typically add a profit margin to their cost base. This margin can vary significantly based on competition, brand reputation, and market demand.

How Do Price Influencers Affect 3 Prong Charger Cord Pricing?

Several factors influence the pricing of 3 prong charger cords, particularly for international buyers:

Illustrative image related to 3 prong charger cord

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide tiered pricing based on order volume. Higher quantities can lead to substantial discounts, making it essential for buyers to assess their needs carefully.

-

Specifications and Customization: Custom specifications or certifications can increase costs. Buyers should weigh the benefits of customization against the additional expenses.

-

Materials and Quality Certifications: Higher-quality materials and compliance with safety certifications typically command higher prices. International buyers should prioritize suppliers who offer certifications relevant to their markets.

-

Supplier Factors: The supplier’s reputation, reliability, and historical performance can influence pricing. Established suppliers may charge more due to their perceived value and reliability.

-

Incoterms: Understanding the implications of Incoterms is vital. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) affect who pays for shipping and insurance, thereby impacting the total cost.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing?

B2B buyers should consider several strategies to enhance cost-efficiency in sourcing 3 prong charger cords:

-

Negotiation: Effective negotiation can lead to better pricing, especially for large orders. Establishing a good relationship with suppliers can also facilitate more favorable terms over time.

-

Total Cost of Ownership (TCO): Assessing TCO, which includes initial purchase price, shipping, maintenance, and potential replacement costs, can provide a clearer picture of the true expense of sourcing.

-

Pricing Nuances for International Buyers: Understanding local market conditions, tariffs, and currency fluctuations can help buyers make informed decisions. It is crucial to factor in potential import duties or taxes that may affect the final cost.

-

Research and Due Diligence: Conducting thorough research on potential suppliers and comparing quotes can reveal hidden costs and better options. Buyers should request samples to assess quality before committing to larger orders.

Disclaimer

The prices referenced in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable for buyers to conduct their own market research to obtain the most accurate and current pricing information.

Alternatives Analysis: Comparing 3 prong charger cord With Other Solutions

Exploring Alternative Solutions to the 3 Prong Charger Cord

When considering power solutions for various devices, it’s essential to evaluate alternatives to the traditional 3 prong charger cord. Various options can cater to different use cases, performance needs, and cost efficiencies. This analysis will compare the 3 prong charger cord against two viable alternatives: the 2-prong charger cord and the smart power strip. Each solution has its unique advantages and disadvantages, making it crucial for B2B buyers to understand which product aligns best with their operational requirements.

Comparison Table

| Comparison Aspect | 3 Prong Charger Cord | 2-Prong Charger Cord | Smart Power Strip |

|---|---|---|---|

| Performance | Provides grounding; safe for high-power devices | Generally less safe; suitable for low-power devices | Multiple outlets; surge protection available |

| Cost | Moderate price point | Lower cost than 3-prong cords | Higher initial investment, but cost-effective for multiple devices |

| Ease of Implementation | Plug-and-play installation | Simple installation; fewer safety features | Requires setup; may need configuration for smart features |

| Maintenance | Low maintenance required | Low maintenance required | Moderate maintenance; firmware updates may be needed |

| Best Use Case | High-power appliances; industrial use | Lightweight electronics; basic applications | Home/office setups with multiple devices needing protection |

Detailed Breakdown of Alternatives

2-Prong Charger Cord

The 2-prong charger cord is a lighter, more economical option primarily designed for low-power devices such as lamps and small electronics. Its simplicity makes it easy to use, but it lacks the grounding feature that the 3 prong charger cord offers, potentially leading to safety issues in high-power applications. While the lower cost is attractive, businesses must consider whether the lack of grounding poses a risk to their equipment or safety.

Smart Power Strip

Smart power strips provide a modern approach to power management, allowing users to connect multiple devices while offering features like surge protection and energy monitoring. While the initial cost is higher, the long-term benefits of energy savings and device safety can offset this investment. These strips are ideal for environments where multiple devices require power, particularly in office settings. However, they may require more maintenance and initial setup time, especially if advanced features are utilized.

Conclusion: How to Choose the Right Power Solution for Your Business Needs

Selecting the appropriate power solution hinges on understanding your specific operational requirements. If you are working with high-power devices, the 3 prong charger cord remains the safest and most reliable choice. For lower power applications, the 2-prong charger cord may suffice, providing a cost-effective solution without unnecessary features. Conversely, a smart power strip is ideal for dynamic environments with multiple devices, offering protection and efficiency. By carefully evaluating the performance, cost, and specific use cases of each alternative, B2B buyers can make informed decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for 3 prong charger cord

What Are the Key Technical Properties of a 3 Prong Charger Cord?

When sourcing 3 prong charger cords, understanding their technical specifications is essential for ensuring compatibility, safety, and performance. Below are some critical technical properties to consider:

Illustrative image related to 3 prong charger cord

1. Material Grade

The material used for the cord’s insulation and conductors significantly impacts durability and electrical performance. Common materials include PVC (Polyvinyl Chloride) and TPE (Thermoplastic Elastomer). PVC is widely used for its cost-effectiveness and resistance to abrasion, while TPE offers better flexibility and temperature resistance. Buyers should prioritize high-grade materials to minimize failures in demanding environments.

2. Wire Gauge

The wire gauge, typically measured in AWG (American Wire Gauge), indicates the thickness of the wire and affects the cord’s current-carrying capacity. For instance, an 18 AWG wire can handle up to 10 amps at 125 volts, making it suitable for most consumer electronics. Understanding wire gauge is crucial for ensuring that the cord can handle the power requirements of connected devices without overheating.

3. Voltage and Current Rating

Each charger cord has specific voltage and current ratings, typically expressed in volts (V) and amperes (A). For example, a standard 3 prong charger may be rated for 125V and 10A. These ratings are vital for compliance with safety standards and ensuring that the cord can safely deliver the required power without risk of failure or fire hazards.

4. Length

The length of the charger cord affects its usability in different settings. Standard lengths range from 3 to 15 feet, but custom lengths may be available for specific applications. When selecting a length, consider the installation environment and the distance between power sources and devices to avoid excessive strain on the cord.

5. Connector Type

The connectors at each end of the cord must be compatible with the devices they are intended to power. Common connector types include NEMA 5-15P (standard 3-prong plug) and IEC 60320 C13 (often used for computers and monitors). Ensuring the right connectors are used is vital for operational efficiency and safety.

What Are Common Trade Terms Used in the 3 Prong Charger Cord Industry?

Familiarity with industry jargon can streamline communications and negotiations between suppliers and buyers. Here are several important terms:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand name. In the context of 3 prong charger cords, OEMs often produce the cords to specifications provided by the branding company, ensuring quality and compatibility with branded devices.

2. MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it impacts inventory management and cost-effectiveness. Suppliers often set MOQs to ensure profitability and minimize manufacturing costs.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and availability for specific products. Including detailed specifications, such as wire gauge and material type, in an RFQ can facilitate accurate and competitive quotations.

4. Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms can help in negotiating shipping costs and responsibilities, ensuring smoother cross-border transactions.

5. UL Listing

A UL Listing indicates that a product has been tested and meets safety standards set by Underwriters Laboratories (UL). For charger cords, this certification ensures compliance with safety regulations, providing peace of mind to buyers regarding product safety and reliability.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 3 prong charger cords, ensuring they meet both operational requirements and compliance standards.

Navigating Market Dynamics and Sourcing Trends in the 3 prong charger cord Sector

What Are the Key Market Drivers and Trends in the 3 Prong Charger Cord Sector?

The global market for 3 prong charger cords is experiencing significant growth, driven by the surge in electronic device usage and the increasing demand for reliable power solutions. Key markets in Africa, South America, the Middle East, and Europe, particularly in countries like Germany and Saudi Arabia, are witnessing a shift toward higher quality and more durable charging solutions. This trend is fueled by the proliferation of technology in various sectors, including automotive, consumer electronics, and industrial applications, necessitating robust power supply systems.

Emerging B2B tech trends include the integration of smart technology into power cords, enabling features such as energy monitoring and safety alerts. Additionally, the demand for customized solutions tailored to specific industrial needs is rising. B2B buyers are increasingly seeking suppliers that can provide not just standard products but also specialized options that cater to unique applications, such as medical devices or high-performance computing systems.

Furthermore, supply chain dynamics are evolving, with an emphasis on regional sourcing to mitigate risks associated with global supply disruptions. B2B buyers are encouraged to establish relationships with local manufacturers who can ensure timely delivery and compliance with regional electrical standards. This localized approach not only enhances reliability but also reduces lead times, a critical factor in maintaining competitive advantage in fast-paced markets.

How Is Sustainability Influencing B2B Sourcing of 3 Prong Charger Cords?

Sustainability is becoming a core consideration for B2B buyers in the 3 prong charger cord sector. The environmental impact of electrical components, including plastic waste and energy consumption during production, is driving the demand for eco-friendly materials and practices. Suppliers that prioritize sustainable sourcing and manufacturing processes are becoming increasingly attractive to international buyers.

Ethical supply chains are critical, with businesses now expected to ensure that their suppliers adhere to environmental regulations and fair labor practices. Certifications such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) are vital for products aimed at environmentally conscious markets. Buyers should seek suppliers that can provide documentation for these certifications, as they not only ensure compliance but also reflect a commitment to sustainability.

The use of recyclable materials in the production of 3 prong charger cords is gaining traction. Suppliers are exploring alternatives such as biodegradable plastics and recycled materials, which can reduce the overall carbon footprint of their products. B2B buyers are encouraged to engage with manufacturers who are pioneering these materials, as this can enhance their own sustainability credentials while meeting the growing consumer demand for greener products.

What Historical Context Is Relevant for the B2B 3 Prong Charger Cord Market?

The evolution of the 3 prong charger cord can be traced back to the increasing standardization of electrical systems in the late 20th century. Initially designed for household appliances, these cords have transitioned into a vital component for various electronic devices, including computers, home entertainment systems, and industrial machinery.

Illustrative image related to 3 prong charger cord

In the early 2000s, the introduction of international safety standards significantly influenced the design and manufacturing processes, leading to improved safety features and reliability. As technology advanced, the shift towards universal compatibility became paramount, prompting manufacturers to innovate continuously. The rise of the internet and e-commerce has also transformed the way these products are marketed and distributed, allowing B2B buyers to access a broader range of suppliers and solutions than ever before.

Understanding this historical context is essential for B2B buyers, as it highlights the importance of compliance with evolving standards and the need for adaptability in a fast-changing market landscape. As the industry continues to grow and evolve, staying informed about these trends will be critical for making informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of 3 prong charger cord

-

How do I choose the right 3 prong charger cord for my devices?

Selecting the appropriate 3 prong charger cord involves understanding your devices’ power requirements. Check the voltage and amperage ratings specified by the manufacturer. Ensure compatibility with the plug type, which can vary by region—NEMA 5-15P is common in North America, while IEC 60320 C13 is often used in Europe. Additionally, consider the cord length needed for your setup and whether you require features like heavy-duty insulation for industrial applications. -

What is the best way to ensure the quality of a 3 prong charger cord?

To guarantee quality, source cords from reputable manufacturers or suppliers with established track records. Look for certifications such as UL, CE, or RoHS, which indicate compliance with safety and environmental standards. Request product samples for testing, and consider third-party quality assurance checks to evaluate durability and performance. Establishing clear quality criteria in your purchase agreement can further safeguard against subpar products. -

What are the common customization options available for 3 prong charger cords?

Many suppliers offer customization options, including length, color, gauge of wire, and specific connector types. You can also request modifications for unique applications, such as enhanced insulation for outdoor use or specialized connectors for specific devices. Discuss your requirements with potential suppliers early in the negotiation process to understand their capabilities and any associated costs. -

What should I consider regarding minimum order quantities (MOQ) when sourcing 3 prong charger cords?

MOQs can vary significantly between suppliers, influenced by factors such as production capabilities and material availability. When sourcing, clarify the MOQ and assess how it aligns with your purchasing needs. If your demand is low, consider negotiating a smaller order or exploring suppliers who cater to smaller businesses. Be mindful that higher MOQs often lead to better pricing per unit. -

What payment terms should I expect when buying 3 prong charger cords internationally?

Payment terms can differ based on the supplier’s policies and the country of origin. Common terms include advance payments, letters of credit, or payment upon delivery. Establishing trust with your supplier can lead to more favorable terms. Always ensure that payment methods are secure and consider using an escrow service for large transactions to mitigate risks. -

How can I vet suppliers for 3 prong charger cords effectively?

Effective supplier vetting involves multiple steps. Start by researching their reputation through reviews and testimonials from previous clients. Request references and verify their business licenses and certifications. Conduct a site visit if feasible, or utilize third-party inspection services to evaluate their production capabilities. Additionally, assess their communication responsiveness and willingness to accommodate your needs. -

What logistics considerations should I keep in mind when importing 3 prong charger cords?

Logistics plays a crucial role in the timely delivery of your order. Consider factors such as shipping methods, customs regulations, and potential tariffs based on the origin of the goods. Collaborate with a reliable freight forwarder who understands international shipping complexities. Ensure that your supplier provides proper documentation to facilitate smooth customs clearance. -

What are the common safety standards applicable to 3 prong charger cords?

Safety standards for 3 prong charger cords vary by region. In the U.S., look for UL certification, while in Europe, CE marking is essential. These certifications ensure that the cords meet specific safety and performance criteria. Familiarize yourself with the standards relevant to your market to ensure compliance and protect against potential liability issues.

Top 3 3 Prong Charger Cord Manufacturers & Suppliers List

1. Reddit – USB-C Charger with Triple Prong Stability

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: USB-C charger with three prongs for stability when plugged into the wall.

2. Apple – MacBook Air (15-inch, M2, 2023) Charging Solutions

Domain: discussions.apple.com

Registered: 1987 (38 years)

Introduction: MacBook Air (15-inch, M2, 2023) requires a three-prong charger to prevent vibrations while charging. The standard charger available is a 2m USB-C to MagSafe 3 cable. Users are seeking a three-prong charging option specifically for this model.

3. Winford – Power Adapter Cord

Domain: winford.com

Registered: 2002 (23 years)

Introduction: Power Adapter Cord: IEC Male to AC 3-Prong Female\n- Available Lengths: 1 ft and 6 ft\n- Wire Gauge: 18 AWG\n- Description: Allows utilization of power outlets on the back of PCs and other equipment. Features an IEC Male connector on one end and a standard 3-Prong AC Female socket on the other.\n- Pricing: \n – PWRADP1 (1Ft): $2.75 (1+), $2.50 (10+), $2.35 (50+), $2.35 (100+)\n – PWRADP1-6 (6Ft)…

Strategic Sourcing Conclusion and Outlook for 3 prong charger cord

As the demand for 3 prong charger cords continues to surge globally, strategic sourcing emerges as a critical component for B2B buyers looking to optimize procurement processes. Understanding the diverse applications and specifications of these cords—from consumer electronics to industrial equipment—enables buyers to make informed decisions that enhance operational efficiency. Key factors such as compatibility, durability, and safety standards should be prioritized when selecting suppliers, particularly in regions like Africa, South America, the Middle East, and Europe.

In this dynamic market, leveraging strategic partnerships with reliable manufacturers can lead to cost-effective solutions that meet diverse regional needs. Buyers are encouraged to explore local and international suppliers to ensure competitive pricing and timely delivery, which are essential for maintaining a robust supply chain.

Looking ahead, the emphasis on sustainability and technological advancements will shape the future of the 3 prong charger cord market. B2B buyers should remain proactive in seeking innovative solutions that align with evolving market demands and regulatory standards. By embracing strategic sourcing practices, you can secure the best products for your operations while positioning your business for future growth. Engage with trusted partners today to capitalize on these opportunities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.