The Definitive Guide to Waterjet Cutting Machine Psi 120000: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for waterjet cutting machine psi 120000

In the fast-evolving landscape of industrial manufacturing, sourcing a waterjet cutting machine capable of operating at 120,000 psi presents a significant challenge for B2B buyers across the globe. As industries seek precision and versatility in their cutting processes, understanding the nuances of high-pressure waterjet technology becomes crucial. This guide serves as an essential resource for international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Brazil.

Within this comprehensive guide, we delve into various types of waterjet cutting machines, their applications across diverse sectors—from aerospace to food processing—and critical factors for supplier vetting. Additionally, we explore cost considerations and the long-term value these machines can bring to your operations. By equipping yourself with this knowledge, you will be empowered to make informed purchasing decisions, ensuring that your investment meets your specific manufacturing needs.

As you navigate the global market for waterjet cutting machines, this guide will provide the insights necessary to enhance operational efficiency and drive innovation within your organization, positioning you ahead of the competition.

Understanding waterjet cutting machine psi 120000 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Abrasive Waterjet Cutting | Utilizes abrasive materials mixed with water for cutting hard materials | Aerospace, automotive, industrial equipment | Pros: Handles tough materials, precise cuts. Cons: Higher operational costs due to abrasives. |

| Pure Waterjet Cutting | Uses high-pressure water only for softer materials | Food processing, textiles, foam cutting | Pros: Clean cuts, no contamination. Cons: Limited to softer materials. |

| Micro Waterjet Cutting | Employs ultra-fine jets for precision in small-scale applications | Electronics, jewelry, medical devices | Pros: Exceptional detail, minimal material waste. Cons: Slower processing time. |

| Dynamic Waterjet Cutting | Features advanced nozzle technology for zero taper cuts | Art & design, architectural elements | Pros: High accuracy, excellent edge quality. Cons: Higher initial investment. |

| Robotic Waterjet Cutting | Integrates robotics for automated cutting processes | High-volume manufacturing, custom components | Pros: Increased efficiency, repeatability. Cons: Requires significant programming and setup time. |

What Are the Key Characteristics of Abrasive Waterjet Cutting Machines?

Abrasive waterjet cutting machines are designed to handle a wide variety of hard materials such as metals and composites. By mixing abrasives like garnet with high-pressure water, these machines can achieve precise cuts with minimal thermal distortion. This technology is particularly suitable for industries such as aerospace and automotive, where precision and material integrity are paramount. When considering a purchase, buyers should evaluate the cost of abrasives and the machine’s maintenance requirements, as these can significantly impact operational expenses.

How Do Pure Waterjet Cutting Machines Differ from Other Types?

Pure waterjet cutting machines utilize high-pressure water jets alone, making them ideal for softer materials such as rubber, foam, and food products. This method ensures clean cuts without the risk of contamination, which is crucial for food processing applications. B2B buyers should consider the types of materials they need to cut, as pure waterjet systems are limited in their capability compared to abrasive systems. Additionally, the lower operational costs associated with pure waterjet cutting can be a significant advantage for businesses focused on softer substrates.

What Advantages Does Micro Waterjet Cutting Offer for Precision Applications?

Micro waterjet cutting technology is tailored for applications requiring extreme precision, such as electronics and jewelry manufacturing. These systems employ ultra-fine jets that minimize kerf and material waste, making them suitable for intricate designs. B2B buyers should assess their production needs, as micro waterjet cutting can be slower than traditional methods but offers unparalleled detail. The investment in such technology is justified for businesses that prioritize high-quality, detailed components over speed.

Why Choose Dynamic Waterjet Cutting Machines for High-Quality Results?

Dynamic waterjet cutting machines are equipped with advanced nozzle technology that allows for zero taper cuts, resulting in superior edge quality. This makes them particularly valuable in artistic and architectural applications where aesthetics are crucial. When purchasing, buyers should consider the initial investment and the potential for enhanced precision and quality in their finished products. The ability to achieve complex shapes with high accuracy can justify the higher costs associated with these systems.

How Can Robotic Waterjet Cutting Enhance Manufacturing Efficiency?

Robotic waterjet cutting systems combine the precision of waterjet technology with the automation capabilities of robotics, making them ideal for high-volume manufacturing. These machines can operate continuously, providing consistent quality and reducing labor costs. B2B buyers should evaluate the programming and setup time required, as well as the potential return on investment from increased efficiency. For businesses that require customization and scalability, robotic waterjet cutting presents a compelling solution.

Key Industrial Applications of waterjet cutting machine psi 120000

| Industry/Sector | Specific Application of waterjet cutting machine psi 120000 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision cutting of turbine blades and aircraft components | Ensures high precision and reduces thermal distortion | Supplier reliability, certification for aerospace standards |

| Automotive | Shaping of body panels and engine components | Enhances design flexibility and reduces waste | Material compatibility, turnaround time |

| Industrial Equipment Fabrication | Production of machine frames and enclosures | Increases durability and structural integrity | Customization capabilities, after-sales support |

| Electronics & Communications | Routing of circuit boards and cutting specialty enclosures | Facilitates complex designs while maintaining precision | Technology integration, lead times |

| Food Processing | Hygienic slicing of food products and packaging components | Meets safety standards and minimizes contamination risk | Compliance with food safety regulations, material sourcing |

How is Waterjet Cutting Used in Aerospace Applications?

In the aerospace sector, a waterjet cutting machine operating at 120,000 psi is essential for the precision cutting of turbine blades, aircraft panels, and other critical components. The process eliminates thermal distortion, which can compromise the integrity of high-performance materials. International buyers, especially from regions like the Middle East and Europe, must ensure that suppliers adhere to stringent aerospace quality standards and certifications, while also considering the reliability and maintenance support of the equipment.

What Role Does Waterjet Cutting Play in Automotive Manufacturing?

Waterjet cutting machines at 120,000 psi are utilized in the automotive industry for shaping body panels and creating complex engine components. This method allows manufacturers to achieve intricate designs while minimizing material waste during production. B2B buyers from South America and Africa should evaluate the compatibility of their materials with waterjet technology and consider suppliers that can provide quick turnaround times to meet fast-paced automotive production schedules.

Why is Waterjet Cutting Important for Industrial Equipment Fabrication?

In industrial equipment fabrication, waterjet cutting machines are employed to produce durable machine frames, enclosures, and various wear-resistant parts. The ability to create precise cuts enhances the structural integrity of the final products, which is crucial for demanding industrial applications. Buyers in Africa and South America should prioritize suppliers who offer customization options to meet specific equipment requirements and ensure robust after-sales support for maintenance and troubleshooting.

How is Waterjet Cutting Applied in Electronics & Communications?

Waterjet cutting technology is vital in the electronics and communications sectors for routing circuit boards and cutting specialty enclosures. The high precision of waterjet cutting allows for the creation of complex designs that are essential for modern electronic devices. International buyers, particularly from Europe and the Middle East, should focus on sourcing equipment that integrates well with their existing production technologies and offers reliable delivery schedules to maintain production efficiency.

What Benefits Does Waterjet Cutting Provide in Food Processing?

In food processing, a waterjet cutting machine operating at 120,000 psi is used for hygienic slicing of food products and packaging materials. This method ensures that food safety standards are met, significantly reducing the risk of contamination. B2B buyers in regions like Brazil and Saudi Arabia must consider suppliers that comply with local food safety regulations and can provide materials that are suitable for food contact, ensuring both safety and quality in their operations.

3 Common User Pain Points for ‘waterjet cutting machine psi 120000’ & Their Solutions

Scenario 1: Inconsistent Cutting Quality Across Materials

The Problem: Many B2B buyers find that their waterjet cutting machine, particularly those operating at psi 120000, struggles to maintain consistent cutting quality across different materials. This inconsistency can lead to variations in thickness, edge quality, and even structural integrity of the final product. For industries like aerospace or automotive, where precision is critical, these discrepancies can result in costly rework or scrapped materials, ultimately affecting production timelines and profitability.

The Solution: To achieve consistent cutting quality, it’s essential to calibrate the waterjet cutting machine correctly for each material type. Buyers should consult the machine’s operational manual to understand the optimal pressure settings and cutting speeds for various materials. For instance, while metals like aluminum may require higher pressure, softer materials such as rubber can be effectively cut at lower psi. Additionally, investing in advanced software that integrates with the waterjet machine can help operators simulate cuts before actual processing, allowing for adjustments that ensure uniform quality. Regular maintenance checks and nozzle replacements are also critical to ensure that the cutting head is functioning at peak efficiency, minimizing variations in the cutting process.

Scenario 2: High Operational Costs and Resource Waste

The Problem: As buyers of waterjet cutting machines at psi 120000 scale their operations, they often encounter unexpectedly high operational costs. Factors such as water consumption, abrasive material usage, and energy costs can add up quickly, making the cutting process less economical. This is particularly challenging for businesses operating in competitive markets where cost efficiency is crucial for maintaining margins.

The Solution: To mitigate high operational costs, buyers should explore options for optimizing their waterjet cutting processes. Implementing a closed-loop water recycling system can significantly reduce water waste, enabling businesses to minimize their water consumption and lower costs. Additionally, assessing the type and quality of abrasives used can yield savings; using higher-quality abrasives may result in longer-lasting performance and reduced frequency of replacement. Buyers should also evaluate their cutting schedules and consider batch processing to maximize machine utilization and minimize downtime. Furthermore, conducting a comprehensive cost-benefit analysis on different cutting parameters can help identify the most economical settings for specific applications, ensuring that the operation remains competitive.

Scenario 3: Difficulty in Training Operators on Advanced Features

The Problem: As technology advances, many waterjet cutting machines at psi 120000 come equipped with complex features and capabilities that can be challenging for operators to master. This steep learning curve can lead to decreased productivity, increased error rates, and an overall lack of confidence among staff, particularly in regions where skilled labor may be scarce.

The Solution: To address training challenges, businesses should invest in comprehensive training programs that cover both the operational and technical aspects of the waterjet cutting machine. This can include hands-on workshops led by experienced technicians or manufacturers, as well as digital resources such as video tutorials and detailed manuals. Additionally, establishing a mentorship program where seasoned operators can guide newer staff can foster a culture of continuous learning. Companies should also consider collaborating with educational institutions or technical training centers to create specialized courses tailored to their operational needs. By empowering operators with the knowledge and skills necessary to effectively utilize advanced features, businesses can enhance productivity and reduce operational errors, ultimately leading to better outcomes in their cutting processes.

Strategic Material Selection Guide for waterjet cutting machine psi 120000

When selecting materials for a waterjet cutting machine operating at 120,000 psi, it is essential to consider the specific properties, advantages, and limitations of each material. This selection process not only impacts the efficiency of the cutting operation but also the quality and applicability of the final products. Here, we analyze four common materials used in waterjet cutting, focusing on their properties, pros and cons, and relevant considerations for international B2B buyers.

What are the Key Properties of Metals for Waterjet Cutting?

Metals (e.g., Steel, Aluminum, Titanium)

Metals are among the most commonly processed materials in waterjet cutting due to their structural integrity and versatility. Key properties include high tensile strength, excellent durability, and varying levels of corrosion resistance depending on the alloy. For instance, stainless steel offers superior corrosion resistance, while aluminum is lightweight and easier to cut.

Pros & Cons

The advantages of cutting metals with waterjet technology include the ability to achieve tight tolerances and intricate designs without thermal distortion, which is crucial for maintaining the integrity of the material. However, the cost of high-quality metals can be significant, and the manufacturing complexity increases with the thickness and type of metal being cut.

Impact on Application

Metals are widely used in industries such as aerospace, automotive, and construction. The choice of metal affects the application; for example, titanium is preferred in aerospace for its strength-to-weight ratio, while aluminum is often used in automotive applications for its lightweight properties.

Considerations for International Buyers

Buyers from regions like Africa and the Middle East should be aware of local standards (e.g., ASTM, DIN) that may dictate the quality and specifications of metals. Additionally, sourcing high-quality materials may present challenges in areas with less developed supply chains.

How Do Composites Perform in Waterjet Cutting?

Composites (e.g., Carbon Fiber, Fiberglass)

Composites are engineered materials made from two or more constituent materials that provide enhanced properties. They are lightweight and have high strength-to-weight ratios, making them ideal for applications in aerospace and automotive industries.

Pros & Cons

The primary advantage of using composites is their ability to withstand harsh environmental conditions and their resistance to corrosion. However, they can be more expensive than traditional materials and may require specialized cutting techniques to prevent delamination during the waterjet process.

Impact on Application

Composites are often utilized in high-performance applications where weight savings are critical, such as in aircraft and high-end automotive parts. The choice of composite material can significantly influence the performance and longevity of the final product.

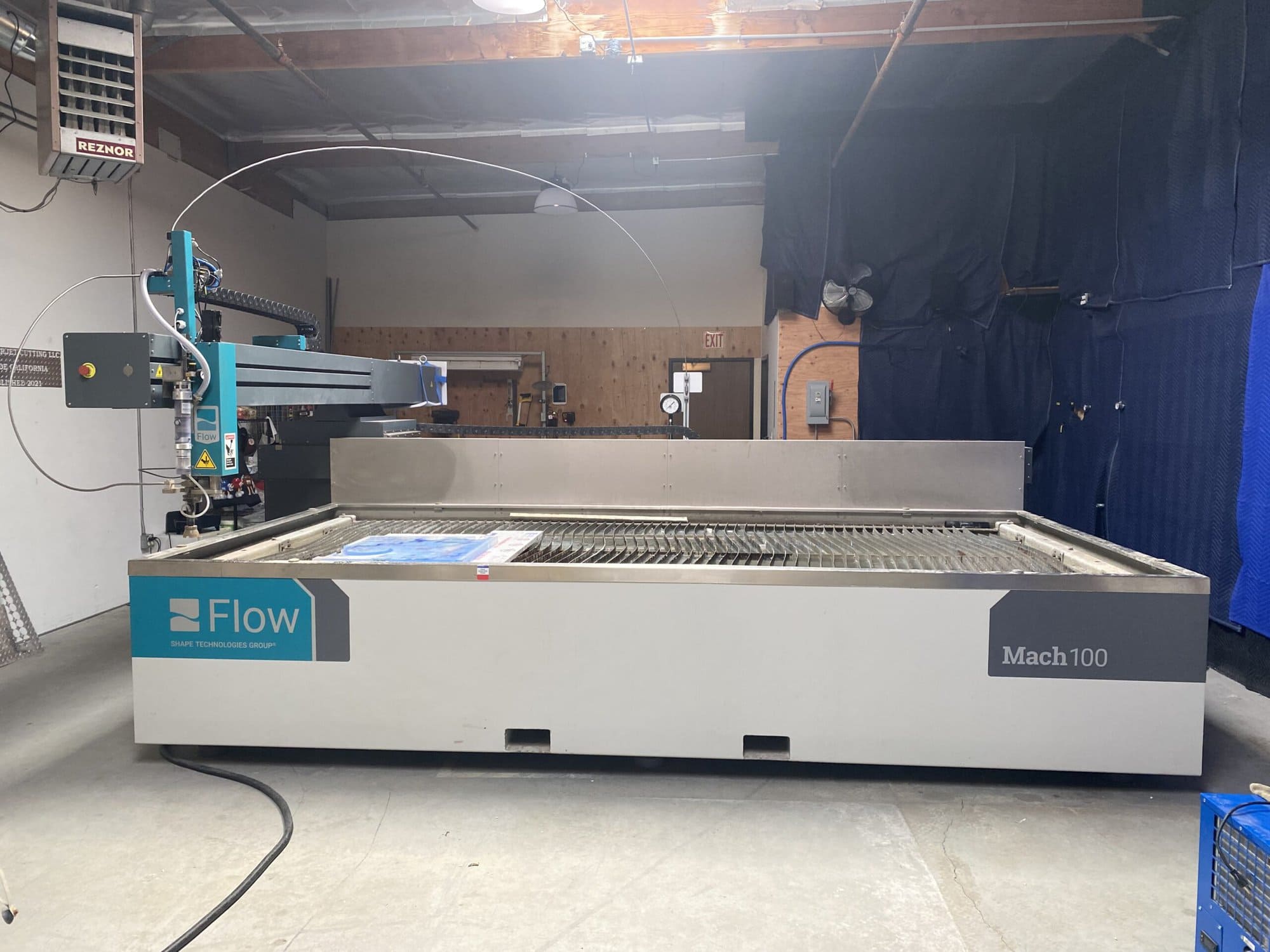

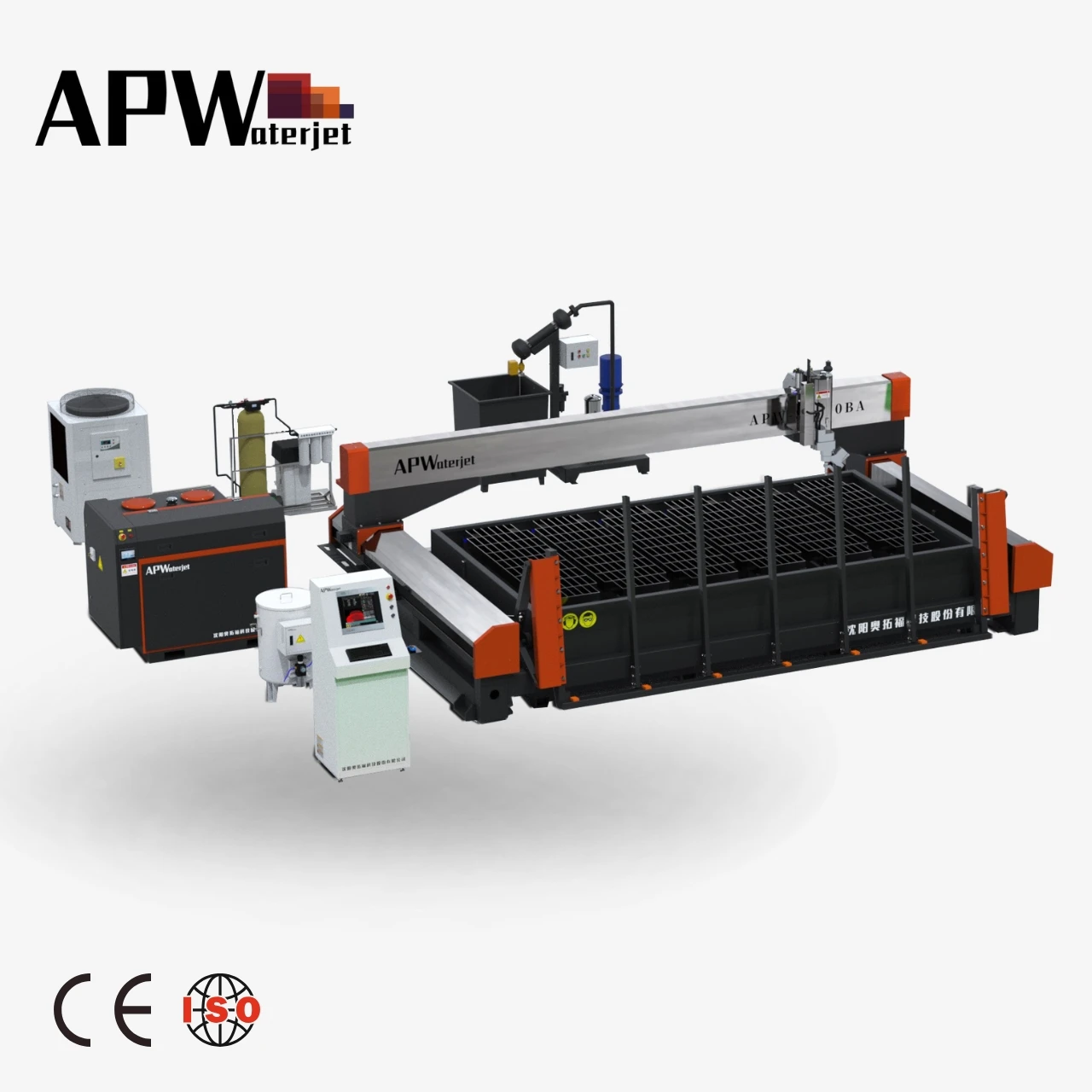

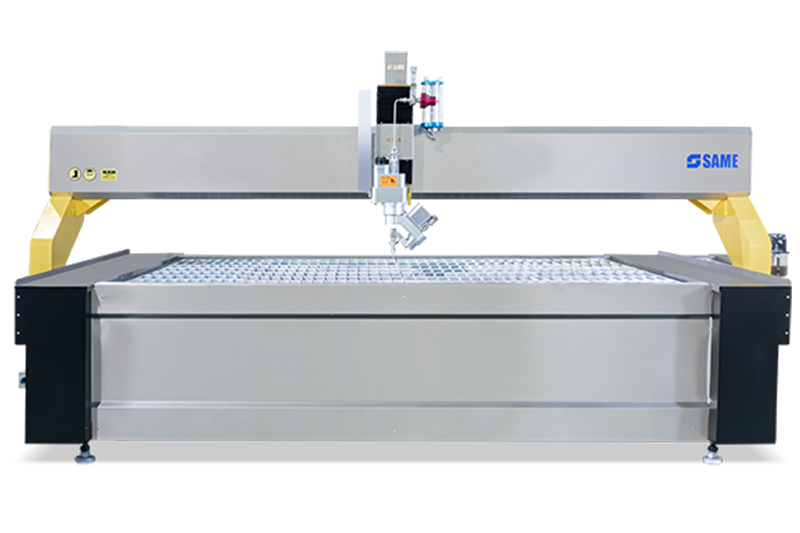

Illustrative image related to waterjet cutting machine psi 120000

Considerations for International Buyers

Buyers should ensure compliance with international standards for composite materials, particularly in industries such as aerospace where safety is paramount. Understanding local regulations regarding composite use is also essential.

What Are the Benefits and Limitations of Cutting Stone Materials?

Stone (e.g., Granite, Marble)

Stone materials are popular in construction and artistic applications due to their durability and aesthetic appeal. Waterjet cutting offers a way to achieve precise shapes and finishes without the risk of chipping or cracking.

Pros & Cons

The advantages of cutting stone include the ability to create intricate designs and the material’s inherent durability. However, stone can be heavy and may require specialized handling equipment, increasing operational costs.

Impact on Application

Stone is commonly used for countertops, flooring, and decorative elements in architecture. The choice of stone can affect both the visual appeal and the structural performance of the finished product.

Considerations for International Buyers

B2B buyers should be aware of the availability of specific stone types in their regions and the associated costs of transportation. Compliance with local building codes and standards is also crucial when using stone in construction projects.

How Do Plastics Fare in Waterjet Cutting Applications?

Plastics (e.g., Acrylic, Polycarbonate)

Plastics are versatile materials used in a wide range of applications from signage to packaging. They are lightweight and can be easily cut into complex shapes using waterjet technology.

Pros & Cons

The main advantage of cutting plastics is the ability to produce clean edges without the need for secondary finishing processes. However, certain plastics can be sensitive to heat, which may limit the cutting speed and increase the risk of deformation.

Impact on Application

Plastics are widely used in the electronics, automotive, and consumer goods industries. The choice of plastic material can significantly impact the durability and functionality of the end product.

Considerations for International Buyers

International buyers should consider the specific regulations regarding plastic materials in their regions, especially in terms of environmental compliance and recyclability standards.

Illustrative image related to waterjet cutting machine psi 120000

Summary Table

| Material | Typical Use Case for waterjet cutting machine psi 120000 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Metals (Steel, Aluminum, Titanium) | Aerospace components, automotive parts | High strength and durability | Higher cost and manufacturing complexity | High |

| Composites (Carbon Fiber, Fiberglass) | Aerospace and automotive applications | Lightweight and corrosion-resistant | Higher material costs and specialized cutting | High |

| Stone (Granite, Marble) | Countertops, flooring, decorative elements | Precise cuts without chipping | Heavy and requires specialized handling | Medium |

| Plastics (Acrylic, Polycarbonate) | Signage, packaging, consumer goods | Clean edges and complex shapes | Heat sensitivity may cause deformation | Low to Medium |

This strategic material selection guide provides essential insights for B2B buyers considering waterjet cutting machines operating at 120,000 psi. Understanding the properties and implications of each material can lead to more informed purchasing decisions and optimized production outcomes.

In-depth Look: Manufacturing Processes and Quality Assurance for waterjet cutting machine psi 120000

What Are the Key Stages in the Manufacturing Process of a Waterjet Cutting Machine with 120,000 PSI?

The manufacturing process of a waterjet cutting machine capable of operating at 120,000 PSI involves several critical stages: material preparation, forming, assembly, and finishing. Each stage requires meticulous attention to detail to ensure the machine’s performance, durability, and precision.

Material Preparation: Ensuring Quality from the Start

Material selection is vital, as the components of the waterjet cutting machine must withstand high pressures and abrasive materials. Commonly used materials include high-strength steel, aluminum alloys, and specialized composites. The initial stage involves sourcing high-quality raw materials that meet industry standards.

Illustrative image related to waterjet cutting machine psi 120000

Once materials are procured, they undergo rigorous testing to confirm their properties. This includes tensile strength testing, hardness testing, and chemical composition analysis. Suppliers may need to provide certification that their materials comply with relevant international standards, such as ASTM or ISO.

How Is the Forming Process Carried Out for Waterjet Cutting Machines?

The forming stage typically employs advanced machining techniques, such as CNC (Computer Numerical Control) machining, to achieve precise dimensions and geometries. High-pressure tubes, nozzles, and components are formed through processes like laser cutting, waterjet cutting, and milling.

For components that require high durability, such as the pressure intensifier, specialized techniques like heat treatment and surface hardening may be applied to enhance their performance. The forming stage concludes with quality checks to ensure each component meets specified tolerances.

What Is Involved in the Assembly Stage of Waterjet Cutting Machines?

Assembly is a crucial phase where all manufactured parts are meticulously put together. Skilled technicians follow detailed assembly guides, ensuring each component is installed correctly. This includes the integration of electronic systems, hydraulic components, and safety features.

During assembly, various checks are performed, including torque testing of bolts, alignment checks, and pressure tests on the hydraulic systems. The assembly process may also involve the use of software to calibrate the machine, ensuring that it operates within specified parameters.

Illustrative image related to waterjet cutting machine psi 120000

How Is the Finishing Process Conducted to Enhance Performance?

The finishing stage includes surface treatments and coatings to enhance wear resistance and improve aesthetic appeal. Components may undergo processes such as anodizing, powder coating, or painting. These treatments not only improve the machine’s longevity but also contribute to its overall efficiency.

Quality assurance during this phase involves visual inspections and tests for surface imperfections, ensuring that the machine meets both functional and aesthetic standards.

What Quality Assurance Standards Are Relevant for Waterjet Cutting Machines?

Quality assurance is paramount in the manufacturing of waterjet cutting machines, particularly those designed for high-pressure applications. International standards such as ISO 9001 provide a framework for maintaining quality management systems. Compliance with these standards is essential for manufacturers aiming to compete in global markets.

In addition to ISO 9001, industry-specific certifications such as CE marking (for compliance with European health and safety standards) and API (American Petroleum Institute) certifications for components used in the oil and gas industry are crucial. These certifications assure B2B buyers of the machine’s safety and reliability.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integral to ensuring that every stage of the manufacturing process adheres to established quality standards. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint evaluates the quality of raw materials and components upon arrival. Suppliers must provide documentation to verify compliance with quality standards.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC involves continuous monitoring of production processes. This includes verifying tolerances, dimensions, and material properties at various stages.

-

Final Quality Control (FQC): The final checkpoint occurs after assembly and finishing, where the entire machine undergoes comprehensive testing. This includes performance tests, safety tests, and compliance checks with international standards.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers must be proactive in verifying the quality control measures employed by suppliers. Here are some actionable steps:

-

Conduct Audits: Regular audits of the manufacturing facility can provide insight into the supplier’s adherence to quality standards. Buyers should request access to quality management system documentation and audit reports.

-

Request Quality Control Reports: Suppliers should be able to provide detailed QC reports, including results from IQC, IPQC, and FQC. These documents should clearly outline any deviations and corrective actions taken.

-

Engage Third-Party Inspectors: Employing third-party inspection services can offer an unbiased assessment of the manufacturing process. These inspectors can conduct thorough evaluations of the equipment and processes, ensuring compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Understanding Regional Standards: Different regions may have varying standards and regulations. Buyers should ensure that suppliers comply with local regulations in their respective markets.

-

Language and Documentation: Clear communication is essential. Buyers should confirm that all quality assurance documentation is available in a language they understand, ensuring they can accurately interpret compliance reports.

-

Cultural Considerations: Building relationships with suppliers in different regions may require understanding cultural practices. Engaging in open dialogue about quality expectations can foster better cooperation and trust.

In conclusion, the manufacturing processes and quality assurance protocols for waterjet cutting machines operating at 120,000 PSI are complex yet essential for ensuring reliability and performance. By understanding these processes and implementing robust verification strategies, B2B buyers can make informed purchasing decisions that align with their operational needs and quality expectations.

Illustrative image related to waterjet cutting machine psi 120000

Practical Sourcing Guide: A Step-by-Step Checklist for ‘waterjet cutting machine psi 120000’

This guide aims to assist international B2B buyers in the strategic procurement of a waterjet cutting machine with a pressure rating of 120,000 psi. By following this step-by-step checklist, you can ensure that you make an informed decision that meets your operational needs and aligns with your business goals.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical requirements for your waterjet cutting machine. Consider factors such as the types of materials you will be cutting, the desired precision, and the machine’s operational capacity. This clarity will help you narrow down options and focus on suppliers that can meet your specific needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in high-pressure waterjet cutting machines. Utilize industry directories, trade shows, and online platforms to compile a list of potential vendors. Pay attention to their experience, market presence, and customer reviews to gauge their reliability and product quality.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for evidence of successful installations and satisfied customers to ensure that the supplier has a solid track record.

Illustrative image related to waterjet cutting machine psi 120000

- Check for industry certifications: Look for certifications such as ISO 9001 or other relevant quality management standards to ensure that the supplier adheres to recognized quality practices.

Step 4: Request Quotes and Compare Pricing

Reach out to your shortlisted suppliers to request detailed quotes. Ensure that each quote includes not only the base price but also additional costs such as shipping, installation, and warranty services. Comparing these aspects will give you a clearer picture of the total investment required.

Step 5: Assess After-Sales Support and Warranty Options

Evaluate the after-sales support and warranty terms provided by each supplier. A robust support system is essential for minimizing downtime and ensuring the longevity of your equipment. Check the length of the warranty and what it covers, as well as the availability of spare parts and technical assistance.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, enter into negotiations to finalize terms and conditions. Be clear about delivery timelines, payment terms, and any additional services such as training for your staff. Effective negotiation can lead to better pricing and terms that align with your budget and operational needs.

Step 7: Finalize Purchase Agreement

After all terms are agreed upon, ensure that you have a written purchase agreement that outlines all details clearly. This document should include specifications, pricing, warranty, and support commitments. A well-documented agreement protects both parties and serves as a reference for future interactions.

By following this checklist, you can navigate the complex landscape of sourcing a waterjet cutting machine with 120,000 psi effectively, ensuring you make a choice that enhances your manufacturing capabilities while optimizing cost efficiency.

Comprehensive Cost and Pricing Analysis for waterjet cutting machine psi 120000 Sourcing

What Are the Key Cost Components for Waterjet Cutting Machines at 120,000 PSI?

When sourcing a waterjet cutting machine operating at 120,000 PSI, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The cost of raw materials for manufacturing waterjet cutting machines typically represents a significant portion of the overall price. High-quality stainless steel, specialized alloys, and components that can withstand high pressures are necessary, which can drive up material costs.

-

Labor: Skilled labor is crucial for both the manufacturing and assembly processes. Costs associated with labor can vary based on geographic location and the complexity of the machine. Workers need to be trained in advanced manufacturing techniques, which can add to the overall labor expenses.

-

Manufacturing Overhead: This encompasses utilities, facility costs, and equipment maintenance. Overhead costs can fluctuate based on production volume and operational efficiency. For manufacturers in regions like Europe or North America, these costs may be higher due to stricter labor regulations and higher utility prices.

-

Tooling: Specialized tools and dies required for manufacturing waterjet cutting machines can be a notable expense. These costs may vary depending on the complexity and customization of the machine.

-

Quality Control (QC): Ensuring that each machine meets stringent quality standards requires rigorous testing and inspection processes. This not only adds to the cost but is essential for maintaining reliability and safety.

-

Logistics: Shipping costs, particularly for international buyers, can significantly impact the final price. Factors such as distance, shipping method, and customs fees should be considered when calculating total logistics costs.

-

Margin: Manufacturers typically add a profit margin to cover their costs and ensure business sustainability. This margin can vary based on market demand and competition.

How Do Price Influencers Impact the Cost of Waterjet Cutting Machines?

Several factors influence the pricing of waterjet cutting machines, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger quantities often allows buyers to negotiate better pricing. Manufacturers may offer discounts for bulk orders, which can significantly affect overall costs.

-

Specifications and Customization: Customized machines tailored to specific industry needs can incur higher costs. Buyers should assess the necessity of custom features against their budget.

-

Material Quality and Certifications: Machines built with higher-grade materials and those that meet international certifications (like ISO or CE) may command higher prices. These factors, however, can influence the machine’s longevity and performance, justifying the cost.

-

Supplier Factors: Supplier reputation, experience, and after-sales support can also affect pricing. Established suppliers with proven track records may charge a premium for their expertise.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can affect the total landed cost. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for international buyers to avoid unexpected costs.

What Negotiation Tips Can Help Buyers Optimize Costs?

To maximize value and minimize costs, B2B buyers should consider the following strategies:

-

Research and Comparison: Conduct thorough market research to compare prices and features across different suppliers. This knowledge empowers buyers during negotiations.

-

Highlight Long-Term Relationships: Emphasizing the potential for future orders can incentivize suppliers to offer better pricing or terms.

-

Total Cost of Ownership (TCO): Consider not just the upfront cost but also maintenance, operational costs, and potential downtime. A lower initial purchase price may lead to higher TCO if the machine is less reliable.

-

Leverage Local Partnerships: For buyers in regions like Africa or South America, partnering with local distributors can help navigate logistics and reduce costs associated with customs and shipping.

-

Stay Informed on Pricing Trends: Keeping abreast of industry trends and material costs can provide leverage in negotiations, enabling buyers to challenge inflated prices.

Disclaimer on Indicative Prices

Pricing for waterjet cutting machines can vary widely based on numerous factors, including specifications, supplier location, and market conditions. It is advisable for buyers to request detailed quotes and conduct due diligence to ensure they receive competitive pricing tailored to their needs.

Alternatives Analysis: Comparing waterjet cutting machine psi 120000 With Other Solutions

Exploring Alternatives to Waterjet Cutting Machine Psi 120000

In the landscape of industrial cutting technologies, selecting the right equipment can significantly impact operational efficiency, cost-effectiveness, and overall output quality. While the waterjet cutting machine operating at 120,000 psi offers remarkable precision and versatility, it is essential to evaluate alternative cutting methods that might better suit specific applications or budgets.

Illustrative image related to waterjet cutting machine psi 120000

| Comparison Aspect | Waterjet Cutting Machine Psi 120000 | Plasma Cutting | Laser Cutting |

|---|---|---|---|

| Performance | Exceptional precision; can cut a wide range of materials, including metals and composites. | Fast cutting speed but less precision; limited to conductive materials. | High precision with smooth edges; ideal for thin materials. |

| Cost | High initial investment; operating costs vary based on material and abrasive use. | Lower initial cost; reduced operational costs due to speed. | Moderate initial investment; higher operational costs for maintenance and consumables. |

| Ease of Implementation | Requires specialized training and setup; versatile but complex. | Easier to set up and operate; less training needed. | Requires skilled operators; setup can be complex depending on material. |

| Maintenance | Regular maintenance needed for high-pressure systems; abrasive wear can be significant. | Lower maintenance due to fewer moving parts; consumables require replacement. | Moderate maintenance; optics and mirrors need regular cleaning and replacement. |

| Best Use Case | Ideal for intricate designs and multi-material applications; excellent for aerospace and automotive sectors. | Best for thick metals and applications needing speed; used in construction and fabrication. | Suitable for thin materials and high-volume production; common in electronics and signage. |

What Are the Pros and Cons of Plasma Cutting?

Plasma cutting is a process that uses a high-velocity jet of ionized gas to cut through electrically conductive materials. One of its primary advantages is speed, making it a cost-effective solution for high-volume applications. However, plasma cutting is limited in material versatility and precision compared to waterjet cutting. It works best with thicker metals but may struggle with intricate designs or non-metal materials.

How Does Laser Cutting Compare to Waterjet Cutting?

Laser cutting utilizes focused light to melt or vaporize materials, providing high precision and clean cuts. This method is particularly effective for thin materials like plastics and metals, making it an excellent choice for industries such as electronics and signage. However, laser cutting can be more expensive to operate due to higher energy consumption and the need for regular maintenance of optical components. Additionally, it is less effective with thicker materials compared to waterjet cutting.

Conclusion: How Can B2B Buyers Choose the Right Cutting Solution?

When considering cutting solutions, B2B buyers must assess their specific requirements, including the types of materials to be processed, production volumes, and budget constraints. The waterjet cutting machine at 120,000 psi stands out for its versatility and precision, especially for complex designs and multi-material applications. However, alternatives like plasma and laser cutting offer distinct advantages in speed and cost-effectiveness for specific use cases. A careful evaluation of these factors will enable buyers to make informed decisions that align with their operational goals and financial parameters.

Essential Technical Properties and Trade Terminology for waterjet cutting machine psi 120000

What Are the Critical Technical Specifications of a Waterjet Cutting Machine Operating at 120,000 PSI?

When evaluating a waterjet cutting machine operating at 120,000 psi, understanding the key technical specifications is crucial for B2B buyers. These specifications not only impact the machine’s performance but also its suitability for specific applications.

1. Pressure Rating

The pressure rating, expressed in psi (pounds per square inch), is the maximum pressure the machine can deliver. A machine rated at 120,000 psi is capable of cutting through a wider range of materials, including hard metals and composites. For buyers, selecting a machine with an appropriate pressure rating ensures optimal cutting efficiency and reduces the risk of material damage.

2. Cutting Tolerance

Cutting tolerance refers to the permissible limit of variation in the dimensions of the cut part. A waterjet machine can achieve tolerances as tight as ±0.001 inches, making it suitable for precision applications in industries like aerospace and electronics. For B2B buyers, understanding the tolerance capabilities is vital for ensuring that the final product meets stringent specifications.

3. Material Compatibility

Waterjet cutting machines can process a diverse range of materials, including metals, plastics, stone, and glass. The ability to cut various materials expands the machine’s application across multiple industries, from automotive to art. Buyers should assess the specific materials they intend to cut to ensure compatibility with the machine’s capabilities.

4. Abrasive Material Type

For machines using abrasive waterjet cutting, the type of abrasive material (commonly garnet) affects the cutting speed and quality. Different grades of abrasives can enhance cutting efficiency and edge quality, making it essential for buyers to understand their options. Selecting the right abrasive material can lead to significant cost savings in both time and material waste.

5. Nozzle Design

The design of the cutting nozzle influences the waterjet’s focus and precision. Advanced nozzle designs can create a more concentrated jet, leading to cleaner cuts and reduced kerf width. For B2B buyers, investing in machines with superior nozzle technology can yield better outcomes in complex cutting tasks.

Which Trade Terms Should B2B Buyers Know When Purchasing Waterjet Cutting Machines?

Understanding trade terminology is essential for navigating the procurement process of waterjet cutting machines. Here are some common terms that B2B buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of waterjet cutting machines, knowing the OEM can help buyers assess the quality and reliability of the machine, as well as any potential warranty support.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers, especially when considering bulk purchases or spare parts for waterjet machines. It helps in budget planning and inventory management.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer submits to suppliers to request pricing and other details for specific products or services. Crafting a detailed RFQ can lead to better pricing and options, making it a valuable tool in the purchasing process for waterjet machines.

Illustrative image related to waterjet cutting machine psi 120000

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to clarify shipping costs and responsibilities, which can significantly affect the total cost of ownership for waterjet cutting machines.

5. Lead Time

Lead time is the period from placing an order to the delivery of the product. Understanding lead times can help buyers plan their production schedules effectively. For industries with tight deadlines, knowing the lead time for a waterjet cutting machine is critical for maintaining workflow.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the waterjet cutting machine psi 120000 Sector

What Are the Key Drivers and Trends in the Waterjet Cutting Machine PSI 120000 Market?

The waterjet cutting machine market, particularly for systems operating at 120,000 psi, is experiencing significant growth driven by several global factors. First, industries are increasingly focused on precision and versatility in manufacturing processes, making waterjet cutting an attractive option for cutting a wide variety of materials, including metals, plastics, and ceramics. This is particularly relevant for B2B buyers in regions like Africa, South America, the Middle East, and Europe, where diverse manufacturing needs require adaptable and efficient solutions.

Emerging technologies, such as CNC integration and advancements in high-pressure systems, are reshaping the landscape. These innovations enhance cutting accuracy and reduce operational costs, appealing to manufacturers aiming for high productivity and minimal waste. Additionally, the rise of Industry 4.0 is fostering greater automation and connectivity in manufacturing, allowing for real-time monitoring and data-driven decision-making, which can be crucial for maintaining competitive advantage.

Illustrative image related to waterjet cutting machine psi 120000

International buyers are also increasingly looking for suppliers that can offer rapid prototyping and customization capabilities. As supply chains become more globalized, the ability to quickly adapt to local market needs and provide just-in-time solutions is a key differentiator. In regions like Saudi Arabia and Brazil, where infrastructure projects and industrialization are on the rise, the demand for high-performance waterjet cutting machines is expected to grow steadily.

How Important Is Sustainability and Ethical Sourcing in the Waterjet Cutting Sector?

Sustainability is becoming a critical concern for B2B buyers, influencing their sourcing decisions in the waterjet cutting machine sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Waterjet cutting is inherently more environmentally friendly compared to traditional cutting methods, as it produces minimal waste and often requires less energy. However, companies must also consider the entire lifecycle of their equipment and materials.

Ethical sourcing is gaining traction, with an increasing number of manufacturers seeking suppliers that adhere to sustainable practices. This includes using eco-friendly materials and obtaining certifications that demonstrate commitment to sustainability. For instance, sourcing from companies that use recycled materials or that have a clear waste management strategy can enhance a buyer’s reputation while minimizing their carbon footprint.

Illustrative image related to waterjet cutting machine psi 120000

Buyers should look for suppliers that offer ‘green’ certifications, such as ISO 14001, which indicates an organization’s commitment to environmental management. Additionally, transparency in the supply chain is essential; businesses need assurance that their suppliers are not only compliant with environmental regulations but also committed to ethical labor practices. This focus on sustainability and ethics can lead to stronger partnerships and a more resilient supply chain.

What Is the Historical Context of Waterjet Cutting Technology Relevant to B2B Buyers?

The evolution of waterjet cutting technology has significantly influenced its adoption in various industries. Beginning in the 1930s, early applications focused on cutting soft materials, but advancements in the 1950s and 1960s allowed for the processing of harder substances, including metals. The introduction of abrasive waterjet cutting in the 1980s marked a pivotal moment, enabling manufacturers to achieve precise cuts in a broader range of materials.

The integration of computer numerical control (CNC) technology in the 1990s transformed waterjet cutting into a highly accurate and efficient method for producing complex geometries. Modern systems, capable of operating at pressures around 120,000 psi, have further enhanced the precision and capabilities of waterjet machines. For B2B buyers, understanding this historical context underscores the technology’s reliability and evolution, positioning it as a critical component in modern manufacturing processes across diverse sectors.

Illustrative image related to waterjet cutting machine psi 120000

By recognizing the advancements in waterjet cutting technology, international buyers can make informed decisions when sourcing equipment that meets their specific operational needs while also aligning with industry trends toward efficiency and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of waterjet cutting machine psi 120000

-

How do I choose the right waterjet cutting machine psi 120000 for my business needs?

When selecting a waterjet cutting machine, consider factors such as the materials you will be cutting, the thickness of those materials, and the precision required for your projects. Evaluate your production volume and whether you need a machine that can handle rapid job changes. Additionally, assess the machine’s compatibility with various abrasives and its ability to integrate with existing manufacturing processes. Consulting with suppliers who specialize in waterjet technology can provide tailored recommendations based on your specific requirements. -

What materials can be effectively cut with a waterjet cutting machine psi 120000?

Waterjet cutting machines operating at 120,000 psi can handle a diverse range of materials, including metals (like steel, aluminum, and titanium), plastics, glass, stone, and even composites. This versatility makes them suitable for industries such as aerospace, automotive, and construction. However, while most materials can be processed, it’s essential to verify the machine’s capabilities regarding specific thicknesses and types of materials, especially for more fragile or ultra-hard substances. -

What are the common applications for waterjet cutting machines in international markets?

Waterjet cutting machines are used globally across various sectors, including aerospace for precision components, automotive for prototyping and body parts, and manufacturing for intricate designs. They are also utilized in the food industry for hygienic slicing and in art for creating complex sculptures. The adaptability of waterjet technology allows it to meet the unique demands of different industries, making it a valuable asset for manufacturers in Africa, South America, the Middle East, and Europe. -

What customization options are available when sourcing a waterjet cutting machine?

Many manufacturers offer customization options for waterjet cutting machines, including modifications to cutting heads, tank sizes, and software integration for specific applications. You can also request features like automated loading systems or enhanced safety measures. Discussing your particular needs with suppliers can lead to tailored solutions that optimize performance and efficiency in your production environment. -

What are the minimum order quantities (MOQs) for purchasing waterjet cutting machines?

Minimum order quantities can vary widely between manufacturers and depend on the specific machine model and configuration. Some suppliers may offer single-unit sales, while others may have MOQs that require bulk purchases, especially for customized machines. It’s advisable to inquire directly with potential suppliers about their MOQs and explore options for financing or leasing if you’re concerned about large upfront investments. -

What payment terms should I expect when purchasing a waterjet cutting machine internationally?

Payment terms for international purchases typically include options such as upfront payment, letter of credit, or payment upon delivery. Many suppliers may offer flexible financing options or installment plans, especially for larger equipment purchases. It’s important to clarify these terms in advance and ensure that they align with your financial capabilities and cash flow considerations. -

How can I ensure quality assurance (QA) when sourcing a waterjet cutting machine?

To ensure quality assurance, request detailed documentation from manufacturers, including certifications, performance testing results, and user testimonials. Consider visiting the supplier’s facility for firsthand observation of their production processes and quality controls. Additionally, inquire about warranty terms and after-sales support to ensure that you have reliable service and maintenance options post-purchase. -

What logistics considerations should I keep in mind for importing a waterjet cutting machine?

When importing a waterjet cutting machine, consider factors such as shipping methods, customs regulations, and potential tariffs. Ensure that the supplier provides necessary documentation for customs clearance. Additionally, assess the logistics of installation and setup, including whether the supplier offers on-site assistance. Planning for transportation and installation can help minimize downtime and ensure a smooth integration into your manufacturing operations.

Top 4 Waterjet Cutting Machine Psi 120000 Manufacturers & Suppliers List

1. Waterjet Cutting – High-Precision Material Cutting Solutions

Domain: waterjet-cutting.com

Registered: 2002 (23 years)

Introduction: Waterjet cutting, also known as hydro cutting, is an industrial process that utilizes a high-pressure stream of water or water mixed with an abrasive substance to cut materials. Key features include:

– Capable of cutting a variety of materials such as plastic, rubber, copper, aluminum, titanium, metals, glass, ceramics, and more.

– High precision with tolerances as tight as ±0.001″.

– Versatile ap…

2. IQS Directory – Water Jet Cutters

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Water jet cutters use high-pressure and high-velocity streams of water to cut through materials with extreme precision. They can cut various materials including metals, glass, and some ceramics. Typical water jet cutter capacities range from 30,000 to 90,000 PSI, with some designs reaching up to 120,000 PSI. The process is managed by computer numerical control (CNC) systems, ensuring high accuracy…

3. TrueForm Design – Waterjet Cutting Solutions

Domain: trueformdesign.com

Registered: 2012 (13 years)

Introduction: Waterjet cutting is an effective method for cutting shapes in metal. Key details include: 1) Water is the vehicle for cutting media, with abrasive garnet mixed with high-pressure water. 2) Machines generate pressure ranging from 30,000 psi to 120,000 psi. 3) Any thickness can be cut, but cutting speed decreases with thickness; parts thicker than 1.5″ may be more cost-effective to flame cut. 4) Mat…

4. Water Jet Technology – Key Pressure Insights

Domain: engineering.stackexchange.com

Registered: 2009 (16 years)

Introduction: Maximum water jet pressure: 100,000 psi (4,100 bar) commonly used; theoretical maximum pressure: 150,000 psi with titanium; concerns about metal fatigue at pressures above 60,000 psi; need for increased flow rate for faster cutting; potential methods include increasing orifice diameter; challenges with material strength for pump construction; importance of balancing pressure and flow rate for cutt…

Strategic Sourcing Conclusion and Outlook for waterjet cutting machine psi 120000

As global industries continue to evolve, the demand for high-precision cutting solutions like the waterjet cutting machine operating at 120,000 psi becomes increasingly critical. This advanced technology offers unparalleled versatility, enabling manufacturers to process a diverse range of materials, from metals to composites, with exceptional accuracy and minimal waste. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, strategic sourcing of waterjet cutting machines is essential for enhancing operational efficiency and meeting the stringent quality standards demanded by today’s competitive landscape.

Investing in state-of-the-art waterjet technology not only boosts production capabilities but also supports sustainable practices by minimizing resource consumption and waste generation. By forming partnerships with reputable suppliers and leveraging local expertise, businesses can ensure they are equipped with the best tools to meet their unique challenges.

Looking ahead, the future of waterjet cutting technology promises further innovations that will expand its applications and efficiency. International buyers are encouraged to engage with suppliers and explore the potential of this cutting-edge technology to drive their businesses forward. Embrace the opportunity to enhance your manufacturing processes and stay ahead in an increasingly competitive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.