How to Source Automobile Stand Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for automobile stand

Navigating the complex landscape of sourcing automobile stands can be a significant challenge for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. With the automotive industry rapidly evolving, companies are often confronted with the need to identify the right stands that enhance workflow efficiency and ensure safety during repair and maintenance tasks. This guide offers a comprehensive overview of the various types of automobile stands available, their applications, and critical factors to consider when making purchasing decisions.

In the following sections, we will delve into the different categories of automobile stands—including mobile, adjustable, and stationary options—highlighting their specific use cases in automotive repair and body shops. Additionally, we will provide insights into effective supplier vetting processes, enabling buyers to discern between local and international suppliers, ensuring quality and reliability in their purchases. Cost analysis will also be a focal point, helping businesses budget effectively while maximizing value.

By equipping B2B buyers with the knowledge needed to navigate the global market, this guide aims to foster informed decision-making. Whether you are a purchasing manager in Nigeria looking for durable stands or a workshop owner in Brazil seeking versatile solutions, this resource will empower you to enhance your operational efficiency and ultimately drive your business success.

Understanding automobile stand Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Scissor Stands | Adjustable height, compact design, often mobile | Body shops, collision repair, painting | Pros: Versatile, space-saving; Cons: Limited load capacity compared to heavier stands. |

| Panel Stands | Specialized for holding panels, often with padded supports | Panel repair, painting, storage | Pros: Protects delicate surfaces; Cons: May require multiple units for efficiency. |

| Dolly Stands | Mobile, with wheels for easy transportation of parts | Moving large components like bumpers and doors | Pros: Enhances workflow efficiency; Cons: Potentially cumbersome if not designed well. |

| Work Platforms | Sturdy, often adjustable, designed for easy access to high areas | General repairs, maintenance tasks | Pros: Provides stable working height; Cons: May be overkill for smaller jobs. |

| Parts Carts | Equipped with storage for tools and parts, often mobile | Organization in workshops, transport of parts | Pros: Streamlines workflow; Cons: May take up floor space if not managed properly. |

What Are Scissor Stands and Their B2B Relevance?

Scissor stands are known for their height adjustability and compact design, making them ideal for body shops where space is limited. Their mobility allows technicians to easily reposition them as needed, enhancing workflow efficiency. When purchasing scissor stands, buyers should consider the load capacity, adjustability range, and material durability to ensure they meet the specific needs of their operations.

How Do Panel Stands Enhance Efficiency in Auto Body Repair?

Panel stands are specialized equipment designed to hold various automotive panels securely during repair and painting processes. They often feature padded supports to prevent damage to delicate surfaces. For B2B buyers, factors such as the stand’s adjustability and compatibility with different panel sizes are crucial. Investing in high-quality panel stands can significantly reduce the risk of damage during handling, leading to improved productivity and reduced costs.

Why Choose Dolly Stands for Moving Heavy Components?

Dolly stands facilitate the easy transportation of large automotive parts, such as bumpers and doors, across the shop floor. Their mobile design, often equipped with locking wheels, allows for safe and efficient movement. Buyers should evaluate the dolly’s weight capacity and ease of maneuverability when making a purchase decision. A well-designed dolly stand can drastically improve workflow by minimizing the physical strain on technicians.

What Benefits Do Work Platforms Offer in Automotive Repairs?

Work platforms provide a stable and elevated working surface, allowing technicians to access high areas of vehicles with ease. Their sturdy construction is designed to support significant weight, making them suitable for various maintenance tasks. When considering work platforms, B2B buyers should assess the platform’s height adjustability and load capacity. These features ensure that technicians can work comfortably and safely, which can lead to higher quality repairs.

How Do Parts Carts Improve Organization in Auto Workshops?

Parts carts are essential for maintaining organization within auto workshops, as they provide a mobile solution for storing and transporting tools and components. Their design often includes multiple shelves and compartments for efficient storage. B2B buyers should consider the size, wheel quality, and overall design of the cart to ensure it fits within their operational workflow. A well-organized workspace can lead to increased efficiency and reduced downtime in repair processes.

Key Industrial Applications of automobile stand

| Industry/Sector | Specific Application of automobile stand | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Support for bodywork and painting | Enhances workflow efficiency and minimizes damage risks | Look for stands with adjustable heights and robust mobility features. |

| Manufacturing Facilities | Parts handling and assembly | Streamlines production processes and reduces handling time | Consider weight capacity and durability of materials for heavy parts. |

| Automotive Customization | Display and storage of custom parts | Improves organization and accessibility of components | Ensure compatibility with various part sizes and shapes. |

| Vehicle Dealerships | Vehicle display and maintenance | Increases showroom appeal and facilitates servicing | Focus on aesthetic design and ease of use for customer engagement. |

| Collision Repair Services | Safe storage and movement of damaged panels | Prevents further damage and enhances repair efficiency | Evaluate stability and load capacity to handle large, fragile parts. |

How are Automobile Stands Used in Automotive Repair Shops?

In automotive repair shops, automobile stands serve as essential tools for bodywork and painting tasks. They provide a stable platform for holding panels, bumpers, and other components while technicians perform repairs or paint jobs. The ability to adjust the height and angle of the stands allows for improved ergonomics, reducing strain on workers and enhancing productivity. For international buyers, sourcing stands with high mobility and durable construction is crucial, especially in regions with limited access to replacement parts.

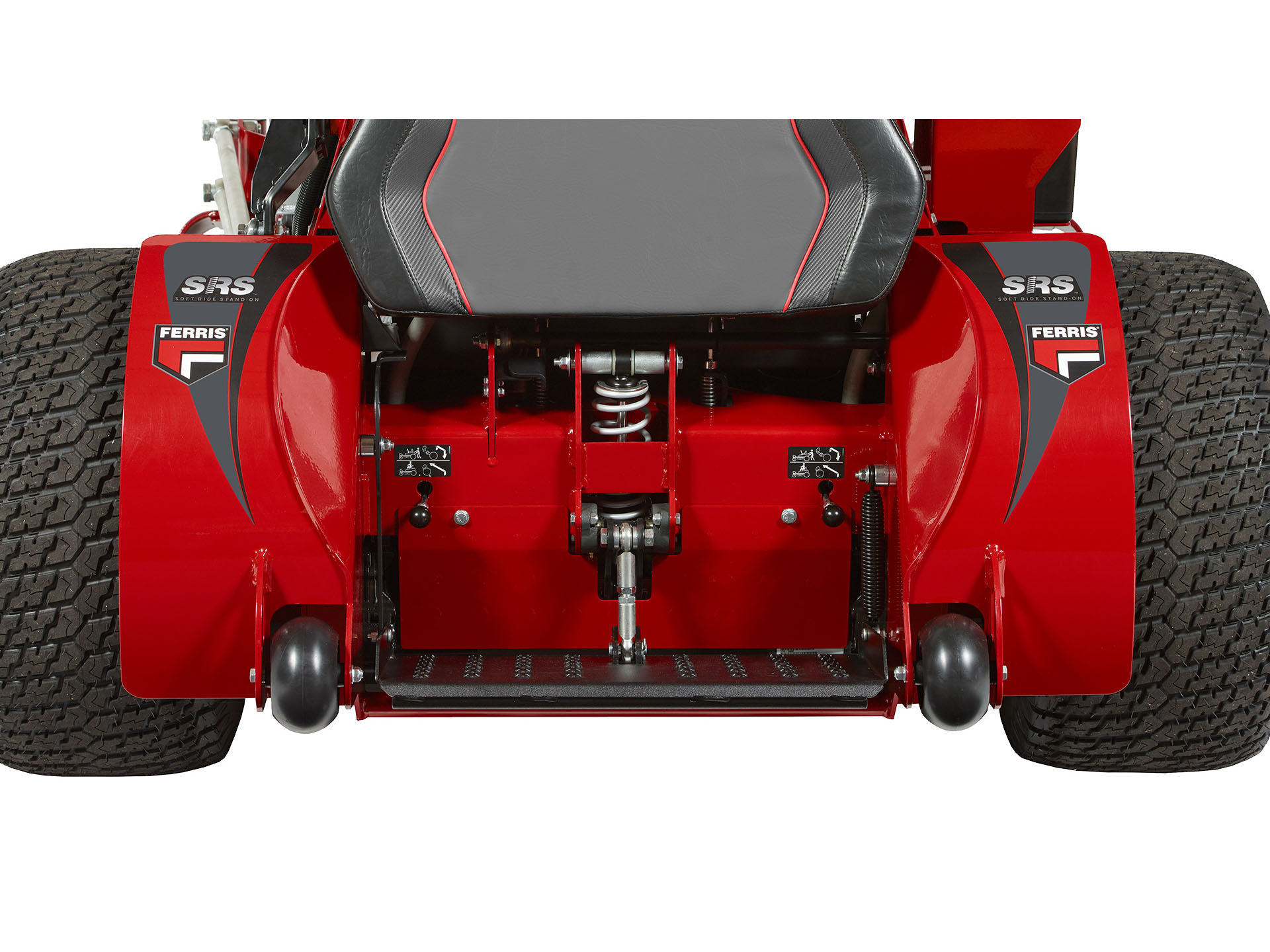

Illustrative image related to automobile stand

What Role Do Automobile Stands Play in Manufacturing Facilities?

Manufacturing facilities utilize automobile stands for parts handling and assembly, ensuring that components are easily accessible during production. By organizing parts on stands, businesses can streamline their workflow, minimize handling times, and reduce the risk of workplace accidents. Buyers in developing markets should prioritize stands that can support heavy loads and withstand rigorous use, as manufacturing demands often require robust solutions that can endure high-volume operations.

How Do Automobile Stands Benefit Automotive Customization?

In the automotive customization sector, stands are invaluable for displaying and storing custom parts. They help maintain an organized workspace, allowing technicians to quickly access the necessary components for modifications. This organization not only enhances efficiency but also improves the overall customer experience by ensuring that parts are readily available and well-maintained. Buyers should consider the versatility of stands to accommodate various part sizes and configurations, especially in regions where custom automotive work is increasingly popular.

What Advantages Do Automobile Stands Offer Vehicle Dealerships?

For vehicle dealerships, automobile stands are crucial for both display and maintenance purposes. They enhance showroom appeal by allowing vehicles to be presented attractively while also facilitating easier access for service technicians. This dual functionality can lead to improved customer satisfaction and increased sales. When sourcing stands, dealerships should focus on aesthetics and ease of use to create a welcoming environment that encourages customer interaction.

How Are Automobile Stands Used in Collision Repair Services?

In collision repair services, automobile stands are used for the safe storage and movement of damaged panels and components. They help prevent further damage during the repair process, ensuring that parts are securely held and easily accessible. The stability and load capacity of stands are critical considerations for international buyers, particularly in regions where high-quality materials may be limited. Investing in durable stands can enhance repair efficiency and reduce the likelihood of costly mistakes.

3 Common User Pain Points for ‘automobile stand’ & Their Solutions

Scenario 1: Limited Space in Body Shops

The Problem: In many automotive repair facilities, particularly in densely populated regions such as Nigeria or Brazil, space is at a premium. B2B buyers often face the challenge of efficiently utilizing every square meter of their workshop. Traditional automobile stands can be bulky and cumbersome, leading to clutter and inefficiencies when moving parts around. This not only affects workflow but can also pose safety risks to employees navigating through cramped spaces.

The Solution: To address this issue, B2B buyers should consider investing in compact and mobile automobile stands that are designed with space-saving features. Look for stands with a foldable design or those that can be stacked when not in use. Additionally, stands equipped with swivel casters allow for easy maneuverability, enabling technicians to transport parts effortlessly around the shop. When sourcing these stands, prioritize suppliers that offer customizable options, allowing you to adjust the height and configuration based on your specific needs. By selecting versatile stands, you can maximize your workspace while maintaining an organized and efficient environment.

Scenario 2: Inconsistent Quality of Auto Body Parts

The Problem: A significant concern for automotive repair businesses is the varying quality of auto body parts. B2B buyers often encounter difficulties with auto stands that do not adequately support the weight or dimensions of specific parts, leading to potential damage during repairs or painting. This inconsistency can result in costly rework, delays, and even dissatisfaction from end customers.

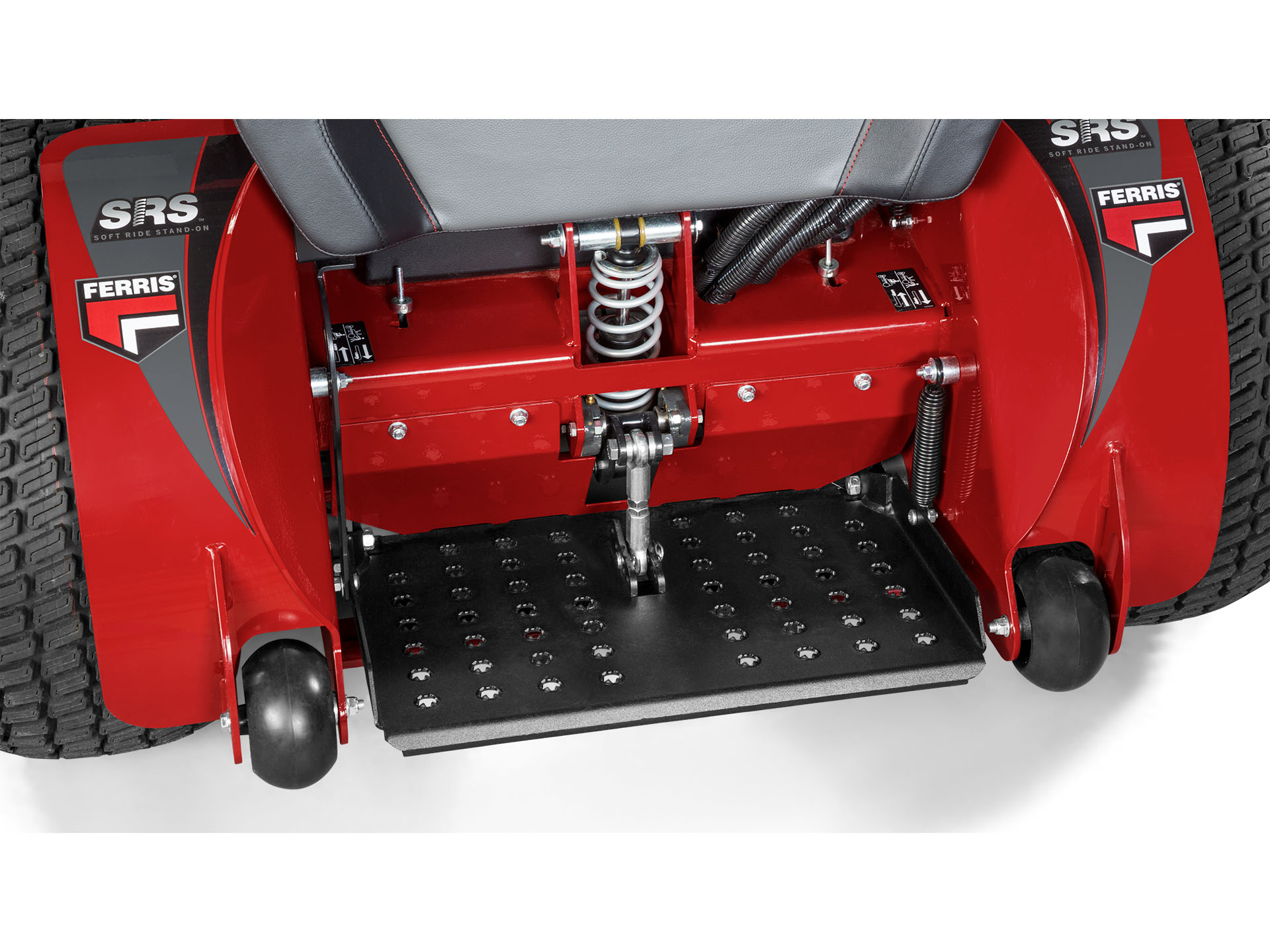

Illustrative image related to automobile stand

The Solution: To mitigate the risks associated with quality issues, it’s crucial to choose automobile stands specifically designed to accommodate a wide range of parts while ensuring stability. Opt for stands constructed from high-grade steel or aluminum, which offer superior strength and durability. Additionally, look for stands that feature adjustable arms or supports, allowing them to securely hold different shapes and sizes of parts. When purchasing, inquire about load capacities and seek recommendations from industry peers or reviews to ensure you are selecting reliable products. Establish relationships with reputable manufacturers known for their stringent quality control processes to consistently receive high-quality stands that meet your operational demands.

Scenario 3: Difficulty in Achieving Optimal Working Heights

The Problem: Technicians often face challenges when working on parts at awkward angles or heights, which can lead to strain and decreased productivity. B2B buyers need automobile stands that can easily adjust to various heights, accommodating technicians of different statures while maintaining ergonomic work conditions. Without proper height adjustment features, the risk of injury increases, and the quality of work may decline due to improper positioning.

The Solution: To resolve this issue, B2B buyers should prioritize adjustable automobile stands that offer a range of height settings. Innovative models, such as scissor stands, provide significant flexibility and can be tailored to individual technician preferences. When sourcing these stands, consider those with easy-to-use height adjustment mechanisms, allowing technicians to switch positions quickly during the repair process. Investing in ergonomic designs not only enhances comfort but also boosts productivity. Additionally, provide training on the proper usage of these stands to ensure that all technicians are aware of how to utilize the equipment effectively, which will lead to improved workflow and worker satisfaction.

Strategic Material Selection Guide for automobile stand

What Are the Key Properties of Steel for Automobile Stands?

Steel is a widely used material for automobile stands due to its exceptional strength and durability. It typically has a high tensile strength, allowing it to withstand significant loads without deforming. Steel stands can also be treated for corrosion resistance, which is particularly important in environments where moisture or chemicals are present. The main downside of steel is its weight, which can make mobility a challenge, especially in larger stands.

When considering steel for automobile stands, international buyers should be aware of compliance with standards such as ASTM A36 for structural steel, which is commonly used in manufacturing. Additionally, the cost of steel can fluctuate based on global market conditions, impacting overall project budgets.

Illustrative image related to automobile stand

How Does Aluminum Compare as a Material for Automobile Stands?

Aluminum is another popular choice for automobile stands, primarily due to its lightweight nature and resistance to corrosion. It is easier to maneuver than steel, making it ideal for mobile applications. Aluminum stands can also be anodized to enhance their resistance to wear and tear, which is beneficial in high-traffic environments.

However, aluminum generally has a lower load-bearing capacity compared to steel, which may limit its suitability for heavier applications. For international buyers, understanding the specific grades of aluminum, such as 6061 or 7075, is crucial, as these grades offer different mechanical properties. Compliance with standards like ISO 9001 can also be a consideration for quality assurance.

What Are the Benefits of Using Composite Materials in Automobile Stands?

Composite materials, often a blend of plastic and fiberglass, are increasingly being used for automobile stands due to their lightweight and corrosion-resistant properties. These materials can be engineered for specific applications, offering versatility in design. Composites are also less likely to scratch or damage vehicle surfaces, making them suitable for delicate tasks.

On the downside, composite materials may not provide the same level of structural integrity as metals, which can limit their use in high-load scenarios. For B2B buyers, it is essential to consider the specific application and any relevant industry standards, such as ASTM D638 for tensile properties of plastics, to ensure compliance and performance.

What Role Does Wood Play in the Manufacturing of Automobile Stands?

While less common, wood is sometimes used for specialized automobile stands, particularly in environments where aesthetics or sustainability are prioritized. Wood can offer sufficient strength for lighter applications and can be treated for weather resistance. However, wood is generally not recommended for high-stress applications due to its susceptibility to warping and degradation over time.

International buyers should consider the types of wood being sourced, as different species have varying properties. Compliance with environmental standards, such as those set by the Forest Stewardship Council (FSC), may also be a factor for companies focused on sustainability.

Summary Table of Material Selection for Automobile Stands

| Material | Typical Use Case for automobile stand | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty stands for workshops | High strength and durability | Heavy and less portable | Medium |

| Aluminum | Mobile stands for lighter applications | Lightweight and corrosion-resistant | Lower load-bearing capacity | High |

| Composite | Specialized stands for delicate tasks | Versatile design and surface protection | Limited structural integrity | Medium |

| Wood | Aesthetic or sustainable stands | Eco-friendly and visually appealing | Susceptible to warping and degradation | Low |

This guide provides a comprehensive overview of common materials used in the manufacture of automobile stands, highlighting key properties and considerations for B2B buyers in diverse global markets. Understanding these factors can aid in making informed decisions that align with operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for automobile stand

What Are the Key Stages in the Manufacturing Process of Automobile Stands?

The manufacturing process of automobile stands involves several critical stages, each crucial for ensuring the final product meets the required standards of quality and performance.

-

Material Preparation: The process begins with the selection of high-quality raw materials, typically steel or aluminum, known for their strength and durability. The materials are cut to specified dimensions using advanced machinery like laser cutters or plasma cutters, ensuring precision and reducing waste. Additionally, suppliers often treat the materials to enhance resistance to corrosion and wear, which is vital for the longevity of the automobile stands.

-

Forming: Once the materials are prepared, the forming stage begins. Techniques such as bending, welding, and stamping are employed to shape the components of the stands. For instance, steel tubing may be bent into specific angles to create the frame, while welding techniques ensure that joints are robust and can withstand significant loads. Automation plays a vital role in this stage, with CNC machines ensuring consistent quality and reducing the potential for human error.

-

Assembly: After forming, the components are assembled into the final product. This stage often includes the installation of wheels, casters, and any adjustable parts. Quality control measures are essential during assembly; components are checked for fit and finish to ensure they meet design specifications. Skilled technicians may perform manual inspections to identify any defects that could compromise the stand’s functionality.

-

Finishing: The final stage involves surface treatment processes like powder coating or painting, which not only enhance the aesthetic appeal but also provide additional protection against rust and scratches. The stands undergo curing in an oven to ensure that the finish adheres properly and provides a durable surface. This stage is critical, as a well-finished product is more likely to withstand the rigors of a busy workshop environment.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the automobile stands meet international and industry-specific standards.

-

International Standards: Compliance with standards such as ISO 9001 is essential for manufacturers aiming to operate in global markets. ISO 9001 focuses on maintaining a quality management system that emphasizes continuous improvement and customer satisfaction. For B2B buyers, this certification indicates that the manufacturer adheres to established quality benchmarks.

-

Industry-Specific Certifications: Depending on the target market, additional certifications like CE (Conformité Européenne) for Europe or API (American Petroleum Institute) for specific applications may be required. These certifications assure buyers that the products meet rigorous safety and performance criteria.

-

Quality Control Checkpoints: Various checkpoints throughout the manufacturing process are crucial for maintaining quality:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications before production begins.

– In-Process Quality Control (IPQC): During manufacturing, processes are monitored, and random samples may be taken to assess compliance with quality standards.

– Final Quality Control (FQC): After assembly, each automobile stand is subjected to rigorous testing to ensure it meets all functional and safety requirements. This may include load testing to confirm the stand can support specified weights without failure.

What Testing Methods Are Commonly Used in Quality Assurance for Automobile Stands?

Several testing methods are employed to verify the quality and safety of automobile stands:

-

Load Testing: This involves applying weight to the stand to ensure it can support the required loads without bending or breaking. It simulates real-world conditions that the stand will face in a workshop environment.

-

Stability Testing: Ensuring that the stand does not tip over during use is critical. Stability tests assess how the stand performs under various conditions, including uneven surfaces.

-

Corrosion Resistance Testing: For stands exposed to moisture and chemicals, corrosion resistance tests are essential. These tests simulate long-term exposure to harsh conditions to evaluate the durability of the finish.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, ensuring the quality of automobile stands is paramount. Here are actionable strategies for verifying supplier quality control processes:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. During an audit, buyers can assess compliance with international standards and the effectiveness of the supplier’s quality management system.

-

Quality Control Reports: Requesting detailed quality control reports from suppliers can help buyers understand the measures taken throughout the manufacturing process. This documentation should include results from various testing methods and any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control practices. These inspections can be scheduled at various stages of production, offering peace of mind regarding the final product’s quality.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers operating in international markets should be aware of several nuances related to quality control:

-

Understanding Regional Standards: Different regions may have varying regulatory requirements. For example, CE marking is essential for products sold in the European market, while other regions may have their standards. Buyers should familiarize themselves with these requirements to ensure compliance.

-

Cultural Considerations: Cultural differences can impact business practices and quality expectations. Understanding the local market’s expectations can help buyers communicate more effectively with suppliers and ensure that quality standards are met.

-

Logistical Challenges: Importing automobile stands can involve complex logistics, including customs regulations and shipping constraints. Buyers should consider these factors when evaluating supplier capabilities and the reliability of their quality assurance processes.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for automobile stands is essential for B2B buyers. By focusing on the key stages of production, relevant standards, testing methods, and effective verification strategies, buyers can make informed decisions that ensure they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automobile stand’

Introduction

This practical sourcing guide is designed to assist B2B buyers in effectively procuring automobile stands. As the demand for efficient and reliable equipment grows, selecting the right stand can significantly enhance workflow and productivity in automotive repair and maintenance settings. This checklist outlines critical steps to ensure you make an informed purchasing decision.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital before initiating the sourcing process. Consider the types of vehicles you’ll be servicing, the weight capacity required, and the specific tasks (e.g., painting, bodywork) the stand will facilitate.

- Weight Capacity: Ensure the stand can support the heaviest components you plan to work with.

- Adjustability: Look for features that allow for height and width adjustments to accommodate various vehicle parts.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers. Utilize online platforms, industry directories, and trade shows to identify manufacturers and distributors specializing in automobile stands.

- Industry Reputation: Check reviews and testimonials to gauge the reliability and quality of products.

- Geographic Reach: Consider suppliers who can ship to your region efficiently, particularly if you’re sourcing from international markets.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region to ensure their credibility.

- Certifications: Verify that suppliers adhere to international quality standards, such as ISO certifications, which can indicate product reliability.

- Customer Support: Assess the level of customer service offered, as this will be essential for addressing any post-purchase issues.

Step 4: Request Product Samples or Demonstrations

If possible, request samples or demonstrations of the automobile stands you are considering. This step allows you to physically assess the quality, functionality, and suitability for your specific needs.

- Hands-On Experience: Evaluate the ease of use, stability, and maneuverability of the stand.

- Material Quality: Inspect the materials used in construction to ensure durability and longevity.

Step 5: Compare Pricing and Terms of Sale

Once you have narrowed down your options, compare pricing structures and terms of sale among different suppliers. This step helps you find a balance between cost and quality.

- Bulk Discounts: Inquire about volume pricing if you intend to purchase multiple stands.

- Warranty and Return Policy: Understand the warranty terms and return policy to safeguard your investment.

Step 6: Finalize Your Purchase and Logistics

After selecting a supplier, finalize your order details and logistics. Confirm lead times, shipping costs, and delivery schedules to ensure timely receipt of your equipment.

Illustrative image related to automobile stand

- Payment Terms: Discuss payment options and terms to align with your budgetary constraints.

- Installation Support: If installation is required, check if the supplier offers assistance or guides to facilitate the setup.

Step 7: Plan for Future Maintenance and Upgrades

Consider the long-term maintenance and potential upgrades for your automobile stands. Establish a plan for regular inspections and servicing to prolong the equipment’s lifespan.

- Parts Availability: Ensure that replacement parts or service support are readily available from the supplier.

- Future Needs: Keep an eye on emerging technologies or improvements in automobile stands that could benefit your operations down the line.

Comprehensive Cost and Pricing Analysis for automobile stand Sourcing

Understanding the cost structure and pricing dynamics of automobile stands is essential for international B2B buyers. This analysis will delve into the critical components that influence costs, pricing strategies, and offer actionable insights tailored to buyers in regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Automobile Stand Manufacturing?

The cost structure for automobile stands encompasses several components:

-

Materials: The choice of materials significantly impacts cost. Common materials include steel and aluminum, with steel typically being more cost-effective but heavier, while aluminum offers portability at a higher price. Buyers should consider the balance between durability and weight based on their specific operational needs.

-

Labor: Labor costs vary by region. In regions with lower labor costs, such as certain parts of Africa and South America, manufacturers can offer competitive pricing. However, skilled labor for specialized manufacturing processes may demand higher wages, which can affect overall costs.

-

Manufacturing Overhead: This includes costs associated with facilities, equipment, and utilities. Efficient manufacturing processes can reduce overhead, thus lowering the final price for buyers.

-

Tooling and Setup Costs: Custom designs or specifications may require specialized tooling, which can escalate costs. Buyers should be aware that initial investments in tooling may be spread over larger production runs to reduce per-unit costs.

-

Quality Control (QC): Implementing rigorous QC processes ensures that stands meet safety and performance standards. While this may add to the cost, it can prevent costly returns and warranty claims.

-

Logistics: Transportation and warehousing costs are critical, especially for international shipments. Factors like shipping distance, mode of transport, and customs duties can significantly influence pricing.

-

Margin: Suppliers typically mark up prices to cover costs and ensure profitability. Understanding a supplier’s pricing strategy can provide insights into how much room there is for negotiation.

How Do Price Influencers Affect the Cost of Automobile Stands?

Several factors can influence the pricing of automobile stands:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes generally lead to lower per-unit costs. Buyers should negotiate for better pricing based on anticipated future orders.

-

Specifications and Customization: Custom features such as adjustable heights or added safety features can increase costs. Buyers should assess whether the benefits justify the additional expenditure.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO standards) can elevate costs but are essential for ensuring safety and longevity. Buyers should weigh the cost against the total cost of ownership, including maintenance and replacement.

-

Supplier Factors: Established suppliers with a track record of reliability may command higher prices. However, they often provide better service, warranties, and support.

-

Incoterms: Understanding shipping terms is vital. Incoterms dictate who is responsible for shipping, insurance, and tariffs, impacting the total landed cost of the stands.

What Are Effective Buyer Tips for Negotiating Prices on Automobile Stands?

International buyers should adopt strategic approaches to ensure cost-efficiency:

-

Conduct Market Research: Understanding local and international pricing trends can empower buyers during negotiations. Researching multiple suppliers can reveal competitive pricing and service offerings.

-

Negotiate Based on Total Cost of Ownership: Rather than focusing solely on the purchase price, consider the total cost of ownership, including maintenance and operational costs. This perspective may justify a higher initial investment for a more durable product.

-

Leverage Volume Discounts: If your operations require multiple stands, negotiating a bulk purchase can yield significant savings.

-

Assess Logistics and Shipping Costs: Factor in shipping and customs duties when evaluating supplier quotes. This understanding can help identify the most cost-effective options.

-

Be Mindful of Local Regulations: Compliance with local safety and quality regulations may necessitate specific certifications, which can influence costs. Ensure that suppliers can meet these requirements to avoid future complications.

Conclusion

Navigating the complexities of automobile stand sourcing requires a keen understanding of cost components and pricing influences. By employing strategic negotiation techniques and thoroughly assessing supplier options, international B2B buyers can optimize their purchasing decisions and achieve better value for their investments. Always remember that indicative prices may fluctuate based on market conditions, so staying informed and adaptable is crucial.

Alternatives Analysis: Comparing automobile stand With Other Solutions

Exploring Alternatives to Automobile Stands

In the automotive repair and maintenance industry, the efficiency and effectiveness of tools and equipment can significantly impact productivity and workflow. While automobile stands are essential for supporting parts during repairs and painting, it is crucial to consider alternative solutions that may offer similar or enhanced benefits. This analysis compares automobile stands with two viable alternatives: mobile work platforms and parts handling carts.

Comparison Table

| Comparison Aspect | Automobile Stand | Mobile Work Platform | Parts Handling Cart |

|---|---|---|---|

| Performance | High stability for part support | Versatile for various tasks | Excellent for transporting parts |

| Cost | Moderate ($200 – $600) | Variable ($100 – $1,000) | Low to moderate ($50 – $400) |

| Ease of Implementation | Simple assembly | Requires setup and adjustment | Ready to use, minimal setup needed |

| Maintenance | Low maintenance, durable materials | Moderate, depends on usage | Low maintenance, easy to clean |

| Best Use Case | Repairing and painting individual parts | General tasks, reaching heights | Transporting and organizing parts |

What Are the Advantages and Disadvantages of Mobile Work Platforms?

Mobile work platforms are height-adjustable structures that provide a stable surface for technicians to work on various tasks, from repairs to painting. They are particularly beneficial for accessing hard-to-reach areas of vehicles, like roofs or high panels.

Pros: Their versatility allows them to be used in multiple applications beyond automotive work, making them a valuable asset in various industries. Additionally, many models come with wheels for easy mobility.

Cons: However, they can be more expensive than automobile stands and may require more setup time. They also might not provide the same level of stability for holding specific parts, which could lead to safety concerns in a busy workshop environment.

How Do Parts Handling Carts Compare to Automobile Stands?

Parts handling carts are designed for transporting and organizing various automotive parts efficiently. These carts come equipped with wheels and multiple shelves or compartments, making it easy to move parts around the shop floor.

Pros: Their primary advantage is mobility and organization, allowing technicians to keep tools and parts readily accessible, thus improving workflow and minimizing downtime. They are generally less expensive than automobile stands.

Illustrative image related to automobile stand

Cons: However, they do not provide the same level of support for individual parts during repairs or painting. This limitation can lead to potential damage if delicate components are not secured properly while being transported.

Making the Right Choice for Your Automotive Needs

When selecting the right solution for automotive repair and maintenance, B2B buyers should consider the specific tasks and workflows in their operations. Automobile stands excel in providing stability and support for individual parts during repairs, making them ideal for collision repair shops focused on detailed work. Conversely, mobile work platforms are advantageous for workshops needing flexibility and access to various vehicle heights, while parts handling carts excel in organizing and transporting parts efficiently.

Ultimately, the choice depends on the unique needs of the business, including budget constraints, workspace layout, and the types of repairs most frequently performed. By evaluating these factors, buyers can make informed decisions that enhance productivity and ensure a smoother workflow in their operations.

Essential Technical Properties and Trade Terminology for automobile stand

When sourcing automobile stands, understanding their technical properties and industry terminology is crucial for making informed purchasing decisions. This guide will outline essential specifications and common trade terms that every B2B buyer should be aware of, especially when engaging with suppliers from diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Technical Properties of Automobile Stands?

-

Material Grade

Automobile stands are typically constructed from steel, aluminum, or a combination of both. Steel stands are favored for their strength and durability, making them suitable for heavy-duty applications. Aluminum, while lighter, offers excellent corrosion resistance. Understanding the material grade helps buyers assess the product’s longevity and suitability for specific tasks. -

Load Capacity

The load capacity of an automobile stand is a critical specification that indicates how much weight the stand can safely support. This figure is essential for ensuring safety and efficiency during operations. Buyers should evaluate their specific needs to select stands with appropriate load capacities for the parts they handle, ranging from lightweight panels to heavier components like bumpers. -

Adjustability

Many automobile stands feature adjustable heights and widths, which enhance usability for various tasks. Adjustable stands allow technicians to work ergonomically, reducing strain and increasing productivity. Buyers should consider the range of adjustability to ensure compatibility with different vehicle types and repair processes. -

Caster Type and Mobility

The presence of casters and their type (e.g., locking, swivel) significantly impacts the mobility of automobile stands. Heavy-duty casters facilitate easy movement across shop floors, while locking mechanisms prevent unwanted movement during repairs. Buyers should look for stands with robust casters that enhance workflow efficiency. -

Finish and Coating

The finish of an automobile stand, such as powder coating, plays a vital role in its durability and resistance to rust and corrosion. A quality finish not only prolongs the life of the stand but also reduces maintenance costs. Buyers should inquire about the type of finish to ensure it meets the operational conditions of their workshops. -

Assembly Requirements

Some automobile stands require assembly upon delivery, while others come pre-assembled. Understanding the assembly requirements can save time and labor costs during setup. Buyers should assess their technical capabilities and choose products that align with their operational readiness.

What Are Common Trade Terms in the Automobile Stand Industry?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications ensures that the stands purchased are compatible with original vehicle parts, which is crucial for quality repairs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchases effectively and avoid overstocking or understocking issues. It can also influence negotiations with suppliers. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers solicit price quotes from suppliers for specific products. Crafting a detailed RFQ can facilitate better pricing and terms, making it an essential step in sourcing automobile stands. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and protect their interests during cross-border transactions. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is vital for planning and inventory management. Buyers should factor in lead times when scheduling repairs or stocking up on automobile stands. -

Warranty

A warranty guarantees that a product will perform as specified for a certain period. Knowing the warranty terms can provide buyers with assurance regarding product quality and recourse options in case of defects.

In conclusion, recognizing the key specifications and industry terminology associated with automobile stands can significantly enhance purchasing decisions. By understanding these elements, B2B buyers can ensure they select the right products that meet their operational needs and drive efficiency in their workshops.

Illustrative image related to automobile stand

Navigating Market Dynamics and Sourcing Trends in the automobile stand Sector

What Are the Key Market Dynamics and Trends Shaping the Automobile Stand Sector?

The automobile stand sector is witnessing a significant transformation driven by global market dynamics and technological advancements. A surge in vehicle production and the increasing complexity of automotive designs are propelling demand for efficient and versatile body shop equipment. Emerging markets in Africa, South America, and the Middle East are particularly influential, as rising disposable incomes and urbanization lead to greater vehicle ownership. This trend is accompanied by a growing preference for advanced automotive repair solutions that enhance productivity and safety within workshops.

Technological innovations such as mobile applications for inventory management and IoT-enabled equipment are increasingly being adopted. These tools facilitate real-time monitoring of equipment usage and maintenance, thereby reducing downtime and operational costs. Additionally, the rise of electric and hybrid vehicles necessitates specialized stands that can accommodate unique designs and components, creating opportunities for suppliers to innovate.

International buyers are also focusing on the efficiency of their supply chains. The demand for just-in-time inventory practices is becoming more prevalent, which requires suppliers to be agile and responsive. As a result, B2B partnerships are shifting towards collaborative models that foster innovation and improve service delivery, essential for maintaining competitive advantage in this fast-paced market.

Illustrative image related to automobile stand

How Is Sustainability Influencing B2B Sourcing in the Automobile Stand Sector?

Sustainability has emerged as a critical consideration for B2B buyers in the automobile stand sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to seek suppliers who prioritize eco-friendly practices. This includes using sustainable materials, such as recycled steel and environmentally friendly coatings, in the production of automobile stands.

Moreover, ethical sourcing is gaining traction as businesses recognize the importance of transparent supply chains. Buyers are increasingly looking for suppliers who can demonstrate compliance with environmental regulations and who possess certifications such as ISO 14001 or other ‘green’ credentials. These certifications not only validate a company’s commitment to sustainability but also enhance its marketability in regions where consumers and businesses alike prioritize environmental responsibility.

Additionally, the emphasis on sustainability aligns with global initiatives aimed at reducing carbon footprints. For instance, manufacturers that adopt energy-efficient production methods can appeal to environmentally conscious buyers, thereby gaining a competitive edge. As the automobile stand sector evolves, integrating sustainability into sourcing strategies will be pivotal for companies looking to thrive in the global market.

How Has the Automobile Stand Sector Evolved Over Time?

The evolution of the automobile stand sector reflects broader changes in the automotive industry and technological advancements. Initially, automobile stands were rudimentary, primarily designed for basic support during repair and maintenance tasks. As vehicle designs became more complex, so too did the requirements for repair equipment.

The introduction of adjustable and mobile stands marked a significant turning point, allowing for greater flexibility and efficiency in body shops. With the rise of specialized vehicles, such as electric and hybrid models, the need for innovative solutions tailored to specific tasks has led to the development of advanced stands featuring enhanced safety mechanisms and ergonomic designs.

Today, the sector continues to innovate, focusing on integrating smart technologies that improve operational efficiencies and workflow management. This evolution not only demonstrates the adaptability of the industry but also highlights the ongoing need for suppliers to stay ahead of market demands and technological trends. As the automobile stand sector progresses, it remains crucial for B2B buyers to understand these dynamics to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of automobile stand

-

How do I choose the right automobile stand for my needs?

Choosing the right automobile stand involves assessing your specific requirements, such as the types of vehicles you work with and the tasks you’ll perform. Consider factors like weight capacity, adjustability, mobility (fixed vs. portable), and additional features like locking casters or padding for protection. It’s also wise to evaluate the construction material; heavy-duty steel stands are often preferable for durability. Reviewing supplier specifications and customer feedback can further guide your decision, ensuring you select a stand that enhances efficiency in your operations. -

What is the best stand for painting and repairing automobile parts?

The best stand for painting and repairing automobile parts is one that offers both stability and versatility. Look for adjustable scissor stands or mobile paint stands that accommodate various panel sizes and heights, allowing technicians to work comfortably. Stands with industrial-grade casters enhance mobility around the shop, while features like padded supports protect delicate surfaces. Popular models often include the Innovative X-Stand or similar options that provide secure support and ease of movement, making them ideal for collision repair and painting tasks. -

What are the typical minimum order quantities (MOQs) for automobile stands?

Minimum order quantities (MOQs) for automobile stands can vary significantly depending on the supplier and the type of stand. Generally, MOQs range from 5 to 50 units for bulk orders, with some suppliers offering lower MOQs for trial orders. It’s advisable to inquire directly with manufacturers or distributors to understand their specific requirements, especially if you’re looking to customize your order. Keep in mind that larger orders may also provide opportunities for discounts, making it beneficial to assess your needs carefully. -

What payment terms should I expect when sourcing automobile stands internationally?

Payment terms for international purchases of automobile stands can vary, but common practices include options like upfront payment, partial payment with balance upon delivery, or payment via letter of credit. Many suppliers prefer wire transfers or credit card payments for security. Always clarify payment terms in advance, and consider negotiating favorable conditions, especially for bulk orders. Additionally, be aware of any currency fluctuations and transaction fees that may apply, as these can impact the overall cost of your purchase. -

How can I vet suppliers when purchasing automobile stands from abroad?

Vetting suppliers is crucial to ensure reliability and quality. Start by researching potential suppliers through online marketplaces, trade shows, or industry directories. Check for reviews, testimonials, and ratings from previous buyers. Request samples to assess product quality firsthand. It’s also beneficial to verify their business licenses and certifications. Establishing direct communication can help gauge their responsiveness and professionalism. Lastly, consider leveraging third-party inspection services to conduct quality checks before shipment, ensuring you receive the expected standard. -

What logistics considerations should I keep in mind when importing automobile stands?

When importing automobile stands, logistics considerations are vital for ensuring timely delivery and minimizing costs. Evaluate shipping methods (air vs. sea freight) based on urgency and budget. Understand customs regulations and duties applicable in your country to avoid unexpected fees. Collaborate with a reputable freight forwarder to streamline the shipping process and manage documentation. Additionally, factor in warehousing needs upon arrival to efficiently handle inventory. Planning these logistics ahead of time can prevent delays and optimize your supply chain. -

What quality assurance practices should I expect from suppliers of automobile stands?

Reputable suppliers should implement stringent quality assurance (QA) practices to ensure their automobile stands meet industry standards. Expect them to conduct thorough inspections during production and before shipment, including load testing and material assessments. Many suppliers will provide certifications or compliance documentation to verify quality. It’s also advisable to discuss warranty terms and after-sales support, which can offer additional peace of mind regarding product reliability. Establishing a QA agreement with your supplier can further ensure that you receive consistent quality. -

Are there customization options available for automobile stands?

Yes, many suppliers offer customization options for automobile stands to meet specific needs. Customization can include alterations in dimensions, weight capacity, color finishes, or additional features like branding. Discuss your requirements with the supplier early in the negotiation process to understand the feasibility and associated costs. Be aware that customized orders may have longer lead times and higher MOQs, so planning is essential. This flexibility can significantly enhance the utility of the stands in your operations, making them tailored to your workflow.

Top 4 Automobile Stand Manufacturers & Suppliers List

1. Auto Body Tool Mart – $400 Delivery Free

Domain: autobodytoolmart.com

Registered: 1998 (27 years)

Introduction: This company, Auto Body Tool Mart – $400 Delivery Free, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Collision Services – Fast Delivery & Easy Returns

Domain: collisionservices.com

Registered: 1996 (29 years)

Introduction: This company, Collision Services – Fast Delivery & Easy Returns, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. My Lift Stand – Adjustable Car Lift Stands

Domain: myliftstand.com

Registered: 2010 (15 years)

Introduction: My Lift Stand offers unmatched lift height for DIY at-home car repair, allowing for easy access under vehicles. The stands can lift cars to either 8″ or 14″ under the tire, providing a safer alternative to traditional jack stands and ramps. They are designed to keep all tires at equal heights, ensuring stability and safety while working underneath. The product is patent-protected and manufactured …

4. eBay – Auto Body Stands

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Auto Body Stands available on eBay include various models such as Heavy Duty Portable Work Stand with a 500lb capacity, Automotive Painting Rack, Auto Body Bumper Stand, and Universal Auto Body Paint Stand. Prices range from $20.00 to $449.66, with many items offering free shipping and returns. Most products are new, with some used options available. Popular brands include ATD Tools, Cornwell, INO…

Strategic Sourcing Conclusion and Outlook for automobile stand

In navigating the evolving landscape of the automobile stand market, strategic sourcing emerges as a pivotal component for international B2B buyers. By prioritizing quality, versatility, and cost-efficiency, buyers can enhance operational workflows in their body shops. The insights gathered from diverse sourcing options—ranging from heavy-duty mobile stands to specialized paint and repair equipment—underscore the importance of selecting products that not only meet immediate needs but also align with long-term business goals.

Investing in high-quality automobile stands can significantly improve productivity and safety, allowing technicians to work more efficiently and effectively. Additionally, sourcing from reputable suppliers ensures access to innovative solutions tailored for specific market demands, particularly in regions such as Africa, South America, the Middle East, and Europe.

Illustrative image related to automobile stand

As the industry continues to advance, embracing new technologies and materials will be essential. We encourage international B2B buyers to explore partnerships that foster innovation and sustainability in their sourcing strategies. By doing so, they position themselves at the forefront of the automotive repair sector, ready to adapt to future challenges and opportunities. Make informed sourcing decisions today to drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to automobile stand