Choosing Your Blower Motor Parts: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for blower motor parts

In an increasingly competitive global market, sourcing high-quality blower motor parts presents a significant challenge for B2B buyers, especially those operating in diverse regions like Africa, South America, the Middle East, and Europe. The demand for reliable heating, ventilation, and air conditioning (HVAC) systems has never been higher, yet navigating the complexities of international supply chains can be daunting. This comprehensive guide aims to demystify the process of acquiring blower motor parts, providing insights into various types, applications, and the critical factors involved in supplier vetting.

By delving into the intricacies of blower motor components, including their functionality and compatibility, this resource empowers international buyers to make informed purchasing decisions. The guide also addresses cost considerations, helping businesses optimize their budgets while ensuring quality and reliability. Whether you are a seasoned procurement professional or a new entrant in the HVAC sector, understanding the nuances of blower motor parts will enable you to enhance operational efficiency and customer satisfaction.

With expert insights and actionable strategies tailored to the unique challenges faced by buyers in key markets like Germany and Brazil, this guide serves as an essential tool for successfully navigating the global landscape of blower motor parts. Equip yourself with the knowledge needed to forge strong supplier relationships and secure the best components for your HVAC needs.

Understanding blower motor parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Centrifugal Blower | High pressure, efficient air movement | HVAC systems, industrial ventilation | Pros: High efficiency; suitable for large volumes. Cons: Can be noisy; requires precise installation. |

| Axial Blower | Flat design, moves air parallel to the axis | Cooling systems, exhaust applications | Pros: Compact design; low energy consumption. Cons: Less effective in high-pressure situations. |

| Mixed Flow Blower | Combines features of centrifugal and axial blowers | Air conditioning, refrigeration | Pros: Versatile; efficient at various pressures. Cons: More complex design; potentially higher costs. |

| Inducer Motor | Moves flue gases, enhances combustion efficiency | Furnaces, boilers | Pros: Improves safety; prevents backdraft. Cons: Limited to specific applications; may require frequent maintenance. |

| EC Motor | Electronically commutated, variable speed capabilities | HVAC systems, energy-efficient setups | Pros: Energy-efficient; quiet operation. Cons: Higher initial investment; requires compatible controls. |

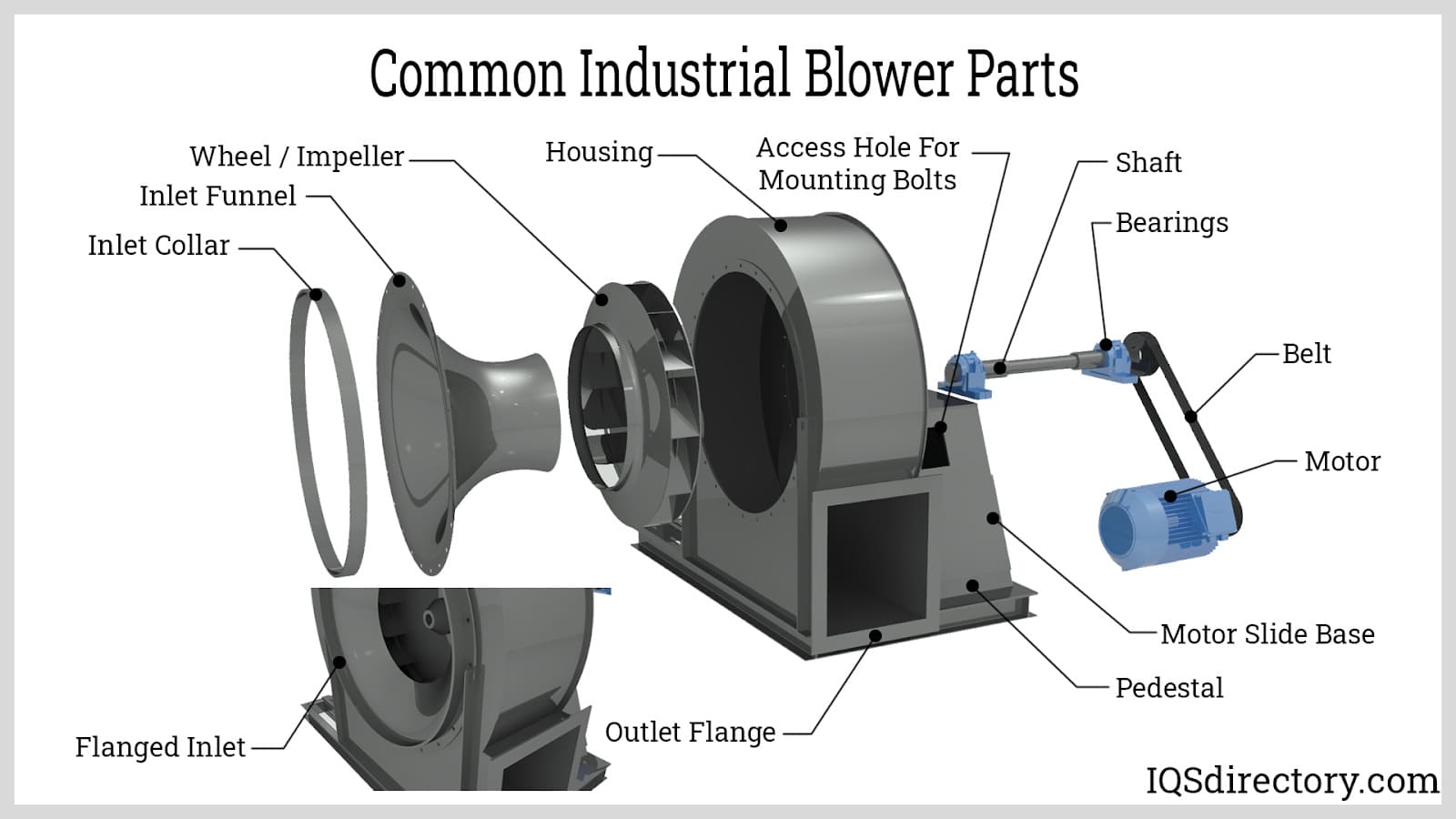

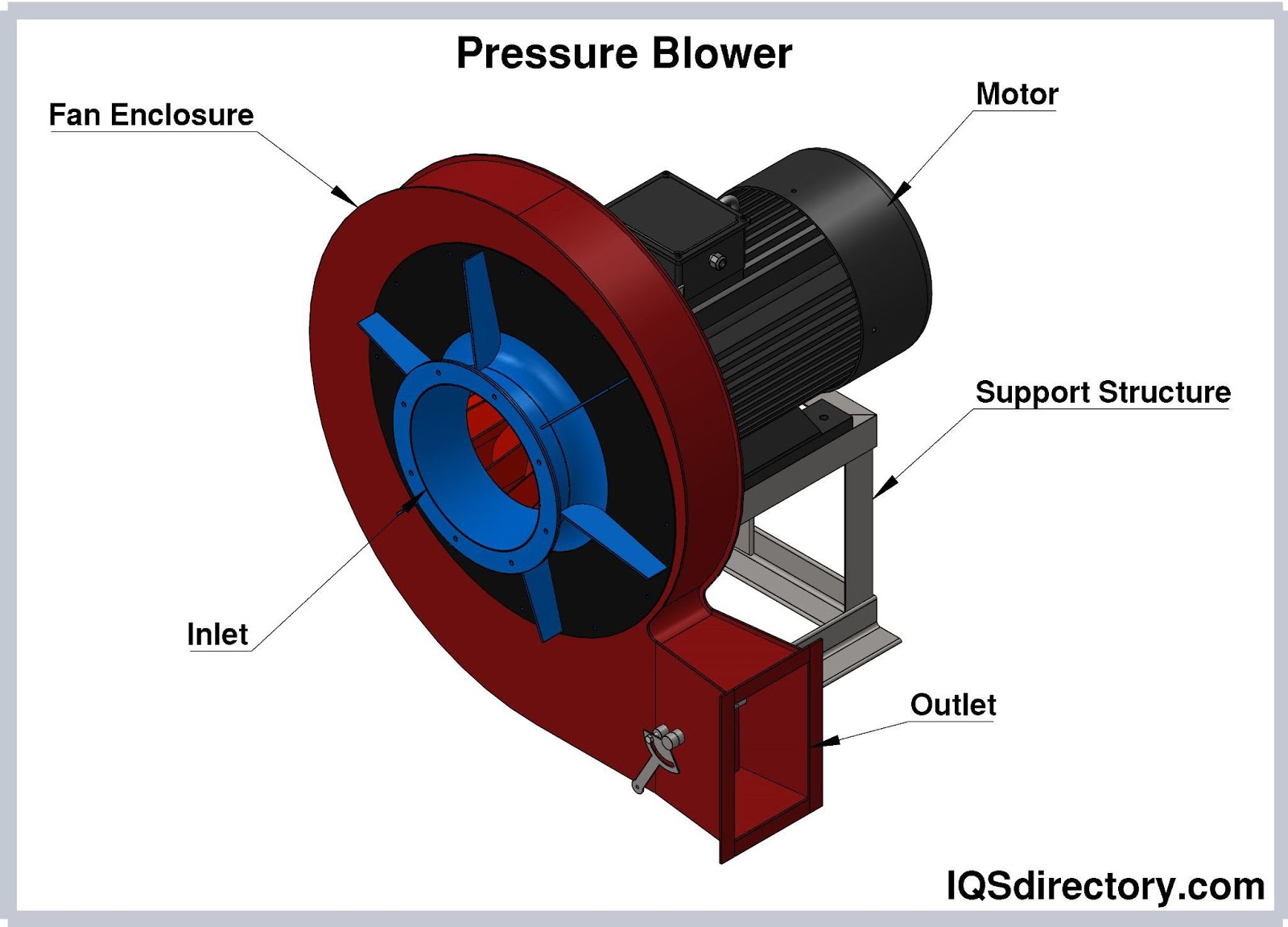

What Are the Characteristics of Centrifugal Blowers and Their Applications?

Centrifugal blowers are designed to generate high-pressure airflow, making them ideal for applications requiring significant air movement, such as HVAC systems and industrial ventilation. Their robust construction and efficiency enable them to handle large volumes of air effectively. B2B buyers should consider factors such as noise levels and installation requirements, as improper setup can lead to operational issues.

Illustrative image related to blower motor parts

How Do Axial Blowers Differ and Where Are They Used?

Axial blowers feature a flat design that facilitates the movement of air parallel to the axis of the fan. They are commonly used in cooling systems and exhaust applications due to their compact size and low energy consumption. Buyers should weigh the advantages of space-saving designs against their reduced effectiveness in high-pressure environments, which might limit their use in certain industrial settings.

What Makes Mixed Flow Blowers Versatile for B2B Applications?

Mixed flow blowers combine the features of both centrifugal and axial blowers, offering versatility for various applications, including air conditioning and refrigeration systems. They operate efficiently across a range of pressures, making them suitable for diverse environments. When purchasing, B2B buyers should consider the complexity of the design and potential costs associated with installation and maintenance.

Why Are Inducer Motors Important in HVAC Systems?

Inducer motors are crucial for moving flue gases in HVAC systems, enhancing combustion efficiency and ensuring safety by preventing backdrafts. They are commonly found in furnaces and boilers. Buyers should be aware of the specific applications of inducer motors and the need for regular maintenance to ensure optimal performance, as neglect can lead to safety hazards.

What Are the Benefits of EC Motors in Modern HVAC Systems?

Electronically commutated (EC) motors are becoming increasingly popular in HVAC applications due to their energy efficiency and variable speed capabilities. They provide quieter operation and can significantly reduce energy costs over time. However, B2B buyers must consider the higher initial investment and ensure compatibility with existing control systems to maximize the benefits of these advanced motors.

Key Industrial Applications of blower motor parts

| Industry/Sector | Specific Application of blower motor parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC and Climate Control | Air distribution in residential and commercial systems | Improved energy efficiency and air quality | OEM compatibility, energy ratings, and local regulatory compliance |

| Automotive | Cabin air circulation in vehicles | Enhanced passenger comfort and safety | Brand compatibility, performance specifications, and lead times |

| Food Processing | Ventilation in food storage and processing areas | Compliance with health standards and reduced spoilage | Hygiene standards, durability in harsh environments, and custom sizes |

| Industrial Manufacturing | Cooling and ventilation in production facilities | Increased operational efficiency and worker safety | Power requirements, noise levels, and maintenance support |

| Mining and Mineral Processing | Airflow management in underground operations | Enhanced safety and productivity in hazardous environments | Explosion-proof certifications, rugged designs, and reliability |

How Are Blower Motor Parts Utilized in HVAC and Climate Control Systems?

In HVAC applications, blower motor parts are critical for air distribution in both residential and commercial systems. They facilitate the movement of heated or cooled air through ductwork, ensuring consistent indoor temperatures. Efficient blower motors help reduce energy consumption, leading to lower operational costs. For international buyers, especially from regions like Africa and the Middle East, sourcing OEM parts that comply with local energy regulations is essential to avoid operational inefficiencies.

What Role Do Blower Motors Play in Automotive Applications?

In the automotive sector, blower motors are vital for cabin air circulation, providing comfort and safety for passengers. They control airflow for heating, ventilation, and air conditioning systems within vehicles. Problems such as poor airflow can lead to discomfort and reduced visibility. Buyers in South America and Europe must consider compatibility with specific vehicle models and performance specifications to ensure optimal functionality.

Why Are Blower Motors Important in Food Processing?

Blower motor parts are essential in food processing and storage facilities, where they are used for ventilation and air circulation. Proper airflow helps maintain temperature control and hygiene, significantly reducing the risk of spoilage and ensuring compliance with health regulations. Buyers in this sector should focus on sourcing motors that meet stringent hygiene standards and are durable enough for harsh processing environments.

How Do Blower Motors Contribute to Industrial Manufacturing?

In industrial manufacturing, blower motors are utilized for cooling and ventilation within production facilities. They play a crucial role in maintaining optimal working conditions, which enhances operational efficiency and worker safety. When sourcing blower motors, businesses must consider factors such as power requirements, noise levels, and the availability of maintenance support to minimize downtime and ensure continuous operation.

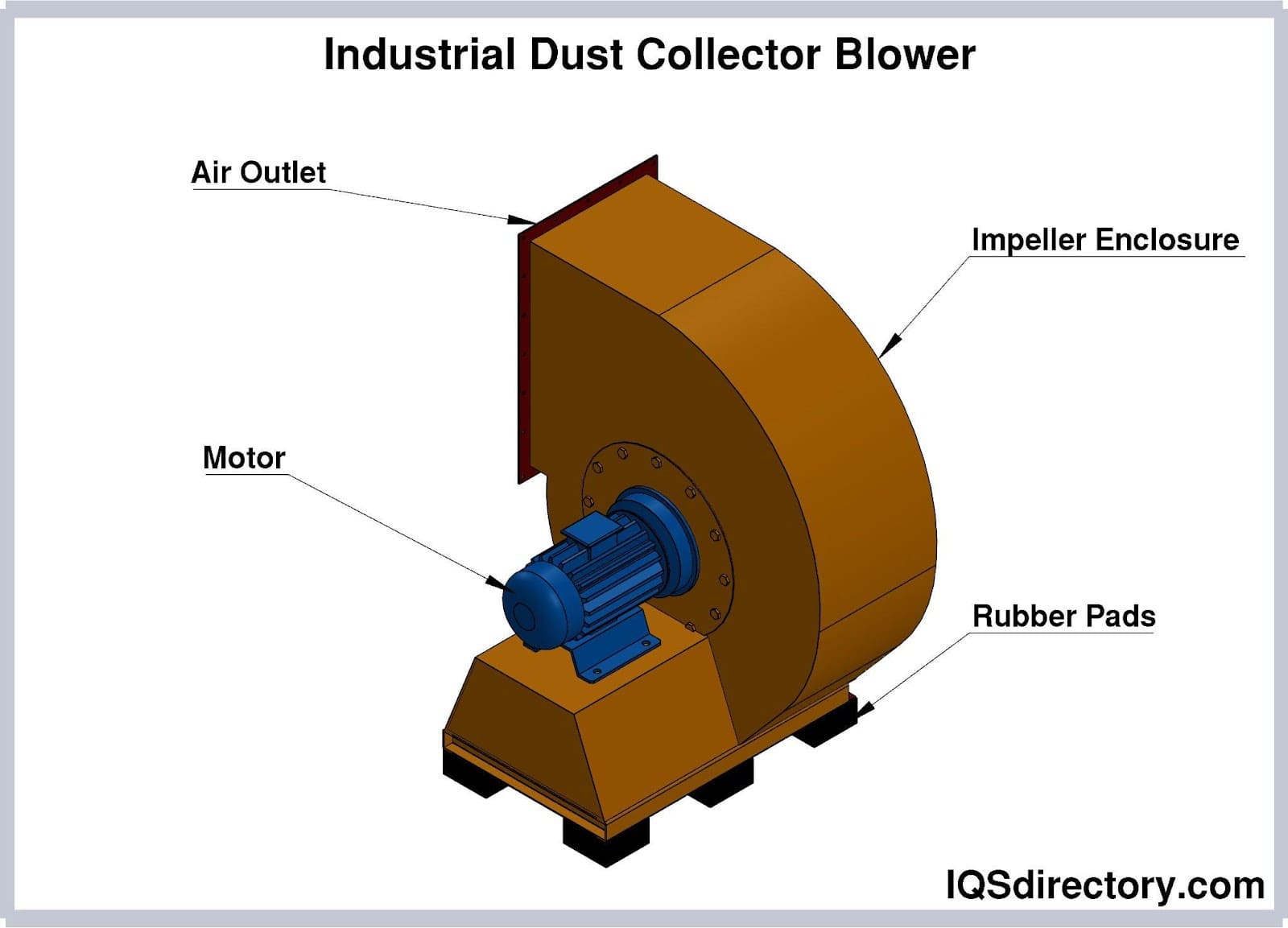

What Are the Applications of Blower Motors in Mining and Mineral Processing?

Blower motor parts are employed in mining and mineral processing for effective airflow management in underground operations. They help maintain air quality and temperature, which is critical for the safety and productivity of workers in hazardous environments. Buyers in this industry should prioritize sourcing explosion-proof certified motors that are designed for rugged conditions, ensuring reliability and safety in operations.

Illustrative image related to blower motor parts

3 Common User Pain Points for ‘blower motor parts’ & Their Solutions

Scenario 1: Difficulty Sourcing Quality Replacement Blower Motor Parts

The Problem: B2B buyers often struggle to find reliable suppliers for high-quality blower motor parts. With numerous vendors in the market, distinguishing between OEM (Original Equipment Manufacturer) parts and substandard alternatives can be challenging. This can lead to costly delays in repairs or installations and potential operational inefficiencies due to poor-quality components. In regions like Africa and South America, where logistics can be complex, sourcing the right parts becomes even more critical.

The Solution: To overcome this challenge, B2B buyers should prioritize establishing relationships with reputable suppliers who specialize in HVAC and blower motor components. Conduct thorough research to assess suppliers’ credibility—check for certifications, customer reviews, and warranty policies. It’s advisable to request samples or detailed specifications before making bulk purchases. Furthermore, buyers can leverage online platforms and marketplaces that focus on OEM parts to ensure they receive genuine components. Engaging with local distributors who understand the specific requirements of your region can also streamline the sourcing process, ensuring timely delivery and adherence to local standards.

Scenario 2: Understanding Technical Specifications and Compatibility

The Problem: Another common pain point for B2B buyers is navigating the technical specifications of blower motor parts. With various models and features, it can be overwhelming to ensure that the parts selected are compatible with existing HVAC systems. This confusion can lead to incorrect orders, resulting in delays and additional costs for returns or replacements.

The Solution: To address this issue, buyers should invest time in understanding the technical specifications of the blower motors they need, including dimensions, voltage, horsepower, and connection types. Utilizing manufacturer catalogs and technical datasheets can provide critical insights into compatibility. Additionally, engaging with technical support teams from suppliers can clarify any uncertainties regarding specifications. Buyers should also consider maintaining a database of existing equipment and their corresponding parts to simplify future orders. Leveraging digital tools such as part finders or compatibility checkers offered by some suppliers can further streamline this process, ensuring accurate selections.

Scenario 3: Ensuring Efficient Installation and Maintenance of Blower Motors

The Problem: Even after sourcing the correct blower motor parts, B2B buyers often face difficulties during installation and maintenance. Inadequate installation can lead to performance issues, while improper maintenance can shorten the lifespan of the equipment. This is particularly problematic in sectors like manufacturing or construction, where downtime can result in significant financial losses.

Illustrative image related to blower motor parts

The Solution: To ensure efficient installation and maintenance, buyers should prioritize comprehensive training for their technical staff. This can include workshops conducted by suppliers or manufacturers that cover installation best practices and maintenance protocols. Buyers should also ensure that they have access to detailed installation guides and service manuals, which can often be found on manufacturers’ websites. Additionally, implementing a proactive maintenance schedule can help in early detection of issues, ensuring that blower motors operate at peak efficiency. Utilizing diagnostic tools and monitoring systems can also assist in identifying potential problems before they escalate, thus minimizing unplanned downtime and repair costs.

Strategic Material Selection Guide for blower motor parts

What Are the Key Materials Used in Blower Motor Parts?

When selecting materials for blower motor parts, understanding the properties, advantages, and limitations of each material is crucial for ensuring optimal performance and longevity. Below are analyses of four common materials used in the manufacturing of blower motor components.

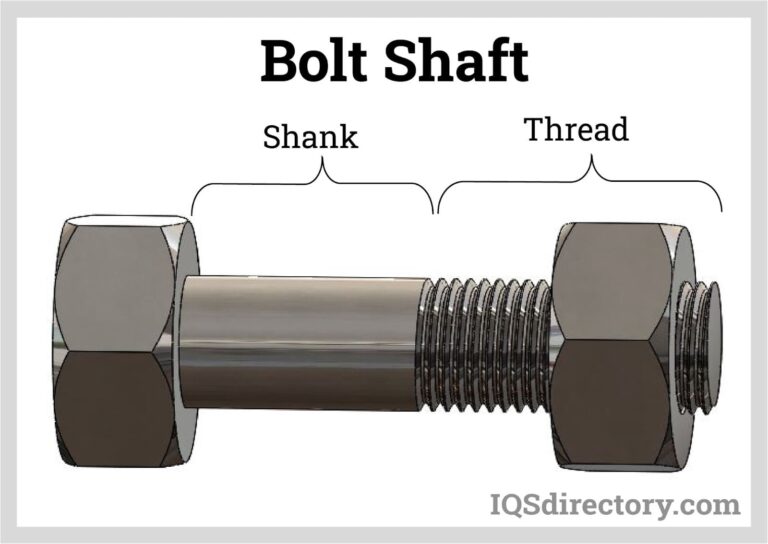

How Does Steel Perform in Blower Motor Applications?

Key Properties: Steel is known for its high tensile strength and durability, making it suitable for components subjected to mechanical stress. It typically has a temperature rating of up to 400°F (204°C) and offers good corrosion resistance when treated with coatings.

Pros & Cons: The primary advantage of steel is its strength and ability to withstand high pressures, which is essential for blower motors operating in demanding environments. However, its weight can be a disadvantage, increasing the overall mass of the motor, which may impact energy efficiency. Additionally, manufacturing complexity can rise due to the need for machining and finishing processes.

Illustrative image related to blower motor parts

Impact on Application: Steel is compatible with various media, including air and gas, making it a versatile choice for blower motors. However, its susceptibility to rust without proper treatment can limit its application in humid environments.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM A36 or DIN 10130 for structural steel. In South America, local regulations may also dictate specific grades of steel.

What Role Does Aluminum Play in Blower Motor Parts?

Key Properties: Aluminum is lightweight and exhibits excellent thermal conductivity, with a melting point around 1,220°F (660°C). It also has a natural corrosion resistance due to the formation of a protective oxide layer.

Pros & Cons: The lightweight nature of aluminum allows for more efficient blower motor designs, reducing energy consumption. However, it is less strong than steel, which may limit its use in high-stress applications. Additionally, aluminum can be more expensive to machine, leading to higher manufacturing costs.

Illustrative image related to blower motor parts

Impact on Application: Aluminum is particularly effective in applications where weight savings are critical, such as in automotive or portable HVAC systems. Its thermal properties make it suitable for heat exchangers and other components requiring efficient heat dissipation.

Considerations for International Buyers: Compliance with standards like ASTM B221 for aluminum extrusions is essential, especially for buyers in Germany and Brazil, where quality assurance is a priority.

Why Is Plastic a Viable Option for Blower Motor Components?

Key Properties: Plastics, particularly engineering-grade thermoplastics, offer good chemical resistance and can operate at temperatures up to 300°F (149°C). They are also lightweight and can be molded into complex shapes.

Pros & Cons: The primary advantage of plastics is their versatility and ease of manufacturing, allowing for cost-effective production of intricate parts. However, they may not withstand high temperatures or mechanical stress as well as metals, which can limit their application in certain blower motor components.

Impact on Application: Plastics are ideal for non-structural components such as housings or covers, where weight and corrosion resistance are more critical than strength. They are compatible with a wide range of media, making them suitable for diverse applications.

Illustrative image related to blower motor parts

Considerations for International Buyers: Buyers should ensure that the selected plastic meets relevant standards, such as ISO 9001 for quality management systems, particularly in markets like Europe and the Middle East.

How Do Copper Components Enhance Blower Motor Performance?

Key Properties: Copper is an excellent conductor of electricity and heat, with a melting point of approximately 1,984°F (1,085°C). It also has good corrosion resistance, particularly when alloyed with other metals.

Pros & Cons: The primary advantage of copper is its superior electrical conductivity, making it ideal for wiring and connections in blower motors. However, its high cost compared to other materials can be a significant drawback, especially in large-scale manufacturing.

Impact on Application: Copper components are crucial for electrical connections and motor windings, ensuring efficient operation of the blower motor. They are highly compatible with various electrical systems, enhancing overall performance.

Considerations for International Buyers: Compliance with standards such as ASTM B170 for copper wire is essential, particularly for buyers in regions with stringent electrical safety regulations, such as Germany.

Summary of Material Selection for Blower Motor Parts

| Material | Typical Use Case for blower motor parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components (housing, mounts) | High strength and durability | Heavy and complex to manufacture | Medium |

| Aluminum | Lightweight motor housings, heat sinks | Lightweight and excellent thermal conductivity | Less strength than steel, higher machining costs | Medium |

| Plastic | Non-structural parts (covers, housings) | Versatile and cost-effective | Limited temperature and stress resistance | Low |

| Copper | Electrical connections, windings | Superior electrical conductivity | High cost compared to alternatives | High |

This guide aims to provide B2B buyers with actionable insights into selecting the right materials for blower motor parts, considering performance, application, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for blower motor parts

What Are the Key Stages in the Manufacturing Process of Blower Motor Parts?

The manufacturing of blower motor parts involves several critical stages, each designed to ensure the final product meets stringent performance and durability standards. Understanding these stages can help B2B buyers assess the quality and reliability of the parts they are purchasing.

-

Material Preparation: The manufacturing process begins with the selection of high-quality raw materials, such as metals, plastics, and composites. These materials are sourced from reputable suppliers who adhere to international standards. Before production, materials undergo rigorous inspections to verify their properties, such as tensile strength and thermal conductivity, ensuring they are suitable for use in blower motors.

-

Forming: The forming stage involves shaping the raw materials into components. Techniques such as stamping, molding, and machining are commonly used. For instance, metal parts may be stamped into shape using high-precision dies, while plastic components could be produced through injection molding. This stage demands precision to ensure that all parts fit together seamlessly during assembly.

-

Assembly: In the assembly phase, individual components are brought together to create the final blower motor unit. This process can involve both manual labor and automated machinery, depending on the complexity of the design. Each component, such as the rotor, stator, fan blades, and motor housing, is assembled with precision to ensure optimal performance. Quality control measures are integrated at this stage to catch any defects early.

-

Finishing: The final stage of manufacturing involves finishing processes such as painting, coating, or polishing. These steps not only enhance the aesthetics of the blower motor but also improve its resistance to corrosion and wear. Protective coatings may be applied to critical components to extend their lifespan, particularly in harsh operating environments.

How Is Quality Assurance Integrated into the Manufacturing of Blower Motor Parts?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that each blower motor part meets specific standards before reaching the market. Various international and industry-specific standards guide these QA processes.

-

International Standards: Many manufacturers adhere to the ISO 9001 standard, which outlines requirements for a quality management system. Compliance with ISO 9001 indicates that a manufacturer has established processes for consistent quality and continual improvement. Other relevant certifications may include CE marking for products sold in Europe, indicating conformity with health, safety, and environmental protection standards.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components before they enter the production line. This step ensures that only materials that meet specified criteria are used in manufacturing.

– In-Process Quality Control (IPQC): During the manufacturing process, IPQC measures are implemented to monitor production. This may include periodic inspections of components as they are formed and assembled, ensuring that any deviations from quality standards are addressed promptly.

– Final Quality Control (FQC): Once the blower motors are fully assembled, they undergo a final inspection to verify that they meet all specifications and performance criteria. This can involve functional testing, where motors are run through various performance scenarios to ensure reliability and efficiency. -

Common Testing Methods: Manufacturers employ a variety of testing methods to validate the quality and performance of blower motor parts. These may include:

– Electrical Testing: Ensuring that motors operate within specified voltage and current ranges.

– Thermal Testing: Assessing how components perform under different temperature conditions.

– Vibration Testing: Evaluating the stability and noise levels of the motor during operation.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially those in Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is crucial. Here are several strategies to ensure that you are partnering with a reliable manufacturer.

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control systems. During an audit, buyers can assess the cleanliness of the facility, the expertise of the workforce, and adherence to quality standards.

-

Quality Reports and Certifications: Requesting quality reports and certifications from suppliers can help buyers verify compliance with international standards. Look for documentation that indicates the supplier’s adherence to ISO 9001 or other relevant certifications.

-

Third-Party Inspections: Engaging third-party inspection services can offer an independent assessment of the supplier’s quality control processes. These services can conduct inspections at various stages of production, providing detailed reports on compliance and quality assurance.

-

Understanding Regional Nuances: Different regions may have specific regulations and standards for manufacturing. For instance, European buyers may place a higher emphasis on CE certification, while buyers in the Middle East may focus on local compliance standards. Understanding these nuances can help buyers navigate supplier relationships more effectively.

What Are the Best Practices for Ensuring Quality in Blower Motor Parts?

For B2B buyers, ensuring quality in blower motor parts goes beyond simply selecting a supplier. Here are some best practices to consider:

Illustrative image related to blower motor parts

-

Establish Clear Specifications: Clearly define the technical specifications and performance requirements for blower motor parts. This will help suppliers understand your expectations and ensure they deliver products that meet your needs.

-

Regular Communication: Maintain ongoing communication with suppliers to discuss any quality issues or concerns. This proactive approach can help resolve problems before they escalate and foster a collaborative relationship.

-

Evaluate Supplier Performance: Regularly assess supplier performance based on quality metrics, delivery times, and responsiveness. This evaluation can inform future sourcing decisions and help identify suppliers that consistently meet or exceed expectations.

-

Invest in Training and Development: For companies involved in the manufacturing or assembly of blower motor parts, investing in employee training on quality control practices can enhance overall product quality. Well-trained staff are more likely to identify potential quality issues early in the process.

By understanding the manufacturing processes and quality assurance practices associated with blower motor parts, B2B buyers can make informed decisions that ensure they source reliable and high-quality components for their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘blower motor parts’

The procurement of blower motor parts is a critical undertaking for businesses involved in HVAC, automotive, and industrial applications. This guide provides a practical checklist designed to help international B2B buyers navigate the sourcing process efficiently and effectively.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is essential. Clearly outline the specifications for the blower motor parts you need, including dimensions, power ratings, and compatibility with existing systems. This clarity will enable you to communicate your needs effectively to suppliers and avoid costly mistakes.

- Key Considerations:

- Voltage and amperage ratings.

- Type of motor (e.g., single-speed vs. variable-speed).

- Specific industry standards or certifications required.

Step 2: Research and Identify Potential Suppliers

A thorough market analysis is key to finding reliable suppliers. Start by researching companies that specialize in blower motor parts. Look for suppliers with a strong reputation in your industry and positive customer reviews.

- Action Items:

- Utilize online marketplaces and industry directories.

- Attend trade shows or industry conferences to meet suppliers.

- Network with industry peers to gather recommendations.

Step 3: Evaluate Supplier Certifications and Compliance

Ensuring compliance with international standards is crucial. Verify that potential suppliers have the necessary certifications, such as ISO or CE, which indicate adherence to quality and safety standards.

- Checklist:

- Request copies of certifications.

- Confirm that products meet local and international regulations.

- Assess the supplier’s history of compliance issues.

Step 4: Request Samples for Quality Assessment

Testing samples is vital to ensure product quality. Before placing a bulk order, request samples of the blower motor parts to evaluate their performance and compatibility with your systems.

- What to Examine:

- Material quality and durability.

- Performance metrics, such as noise levels and energy efficiency.

- Installation ease and fit with existing components.

Step 5: Analyze Pricing and Payment Terms

Understanding pricing structures will help you negotiate better deals. Compare prices across different suppliers, but also consider the total cost of ownership, which includes shipping, taxes, and potential import duties.

- Negotiation Tips:

- Inquire about volume discounts for bulk orders.

- Discuss payment terms, including deposits and credit options.

- Be aware of currency fluctuations if sourcing internationally.

Step 6: Confirm Shipping and Delivery Logistics

Timely delivery is critical for maintaining operational efficiency. Clarify the shipping methods, lead times, and any potential delays that could affect your supply chain.

- Logistical Considerations:

- Choose reliable shipping partners with experience in international logistics.

- Understand customs requirements for your region.

- Plan for contingencies in case of shipping delays.

Step 7: Establish a Communication Plan

Ongoing communication with your supplier is essential for successful procurement. Develop a clear communication plan to address any issues that may arise during the sourcing process.

- Key Elements:

- Designate primary contacts for both parties.

- Set regular check-in points to monitor order status.

- Ensure transparency regarding any changes in specifications or delivery timelines.

By following this checklist, B2B buyers can streamline their sourcing process for blower motor parts, ensuring they procure high-quality components that meet their specific needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for blower motor parts Sourcing

In the competitive landscape of blower motor parts sourcing, understanding the comprehensive cost structure and pricing dynamics is crucial for B2B buyers. This analysis delves into the various cost components, price influencers, and offers actionable tips for navigating the procurement process, particularly for international buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Blower Motor Parts?

The cost structure of blower motor parts comprises several critical components:

-

Materials: The primary cost driver, materials such as high-grade metals and plastics are essential for durability and performance. Sourcing quality materials can significantly impact overall costs.

-

Labor: Labor costs vary by region and can affect manufacturing expenses. Skilled labor is often required for assembly and quality assurance, influencing the final pricing.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Initial tooling costs for molds and machinery can be substantial, especially for custom components. Buyers should consider these costs in the context of their total order volume.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and compliance with international standards, adding to the overall cost but enhancing value.

-

Logistics: Shipping and handling costs, particularly for international orders, can fluctuate based on the chosen Incoterms. Understanding these terms can help buyers anticipate additional expenses.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary significantly based on the supplier’s positioning and market conditions.

How Do Price Influencers Affect Blower Motor Parts Costs?

Several factors influence the pricing of blower motor parts, particularly in international markets:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs. Negotiating favorable MOQs can yield significant savings.

-

Specifications and Customization: Custom parts or specific performance requirements can increase costs. Buyers should clearly define their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: Parts that meet higher quality standards or come with certifications (such as ISO) may carry a premium price but often result in reduced Total Cost of Ownership (TCO) due to enhanced durability and efficiency.

-

Supplier Factors: The reputation and reliability of suppliers play a critical role in pricing. Established suppliers may charge more but offer better support and product assurance.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is essential for calculating total landed costs. These terms dictate responsibilities for shipping costs, insurance, and customs duties.

What Are Some Buyer Tips for Effective Blower Motor Parts Sourcing?

To maximize value and minimize costs, B2B buyers should consider the following strategies:

-

Negotiation: Always negotiate pricing and terms with suppliers. Leverage competitive offers and establish long-term relationships to secure better deals.

-

Cost-Efficiency: Evaluate the total cost of ownership, not just the upfront price. Consider aspects like maintenance, energy efficiency, and replacement frequency when assessing value.

-

International Pricing Nuances: Be aware of regional pricing differences and currency fluctuations. Establishing contracts in stable currencies can protect against exchange rate volatility.

-

Research and Benchmarking: Conduct thorough market research to understand industry standards and benchmark prices against competitors. This knowledge can empower buyers during negotiations.

-

Documentation and Compliance: Ensure that all parts meet necessary compliance standards for your region. Proper documentation can prevent costly delays and rejections at customs.

Conclusion

Navigating the cost structure and pricing dynamics of blower motor parts requires a strategic approach, especially for international B2B buyers. By understanding the key components of costs, recognizing the influencers on pricing, and employing effective sourcing strategies, buyers can optimize their procurement processes and achieve better financial outcomes. It is important to note that prices can vary widely based on market conditions and specific requirements, so always seek quotes from multiple suppliers to ensure competitive pricing.

Illustrative image related to blower motor parts

Alternatives Analysis: Comparing blower motor parts With Other Solutions

Exploring Alternatives to Blower Motor Parts for HVAC Solutions

In the HVAC industry, blower motor parts are essential for efficient air circulation and temperature control. However, businesses often seek alternatives that can provide similar functionalities. Understanding these alternatives is crucial for B2B buyers aiming to optimize their HVAC systems while considering cost, performance, and maintenance. Below, we compare blower motor parts with two viable alternatives: variable-speed fans and ductless mini-split systems.

| Comparison Aspect | Blower Motor Parts | Variable-Speed Fans | Ductless Mini-Split Systems |

|---|---|---|---|

| Performance | High airflow efficiency, adjustable speed | Variable airflow control, energy-efficient | Excellent temperature control, quiet operation |

| Cost | Moderate initial investment, ongoing maintenance costs | Lower upfront cost, minimal maintenance | Higher initial investment, lower long-term costs |

| Ease of Implementation | Requires skilled installation | Easy installation, often DIY-friendly | Requires professional installation |

| Maintenance | Regular maintenance needed for optimal performance | Low maintenance, occasional cleaning needed | Minimal maintenance, periodic filter changes |

| Best Use Case | Larger commercial spaces needing robust airflow | Residential and light commercial spaces | Ideal for zoned heating/cooling in diverse settings |

What are the Benefits and Drawbacks of Variable-Speed Fans?

Variable-speed fans offer an effective alternative to traditional blower motors, providing energy-efficient airflow control. These fans adjust their speed based on real-time heating and cooling needs, which can lead to significant energy savings. They are particularly advantageous for residential and light commercial applications where precise temperature control is desired.

However, the initial cost is generally lower than that of blower motors, and their installation can be straightforward, making them appealing for DIY projects. On the downside, variable-speed fans may not deliver the same robust airflow required for larger commercial spaces, limiting their applicability in high-demand environments.

How Do Ductless Mini-Split Systems Compare?

Ductless mini-split systems represent another innovative alternative to blower motors. These systems provide zoned heating and cooling, allowing users to control the temperature of individual rooms. Their performance is exceptional, offering quiet operation and rapid temperature adjustments, which enhances comfort in various settings.

The drawback, however, lies in the higher upfront installation costs, as professional installation is typically required. While they require less maintenance than traditional systems, regular filter changes are still necessary to maintain efficiency. Ductless systems are best suited for spaces where ductwork is impractical or where specific temperature zones are needed.

How Should B2B Buyers Choose the Right Solution?

Selecting the appropriate solution for HVAC needs requires careful consideration of several factors. Businesses should assess their specific requirements, including the size of the space, budget constraints, and maintenance capabilities. Blower motor parts are suitable for high-demand environments, while variable-speed fans can suffice for smaller spaces with fluctuating temperature needs. Ductless mini-split systems may be the best choice for businesses looking for flexibility and energy efficiency in temperature control.

Ultimately, the decision should align with both immediate and long-term operational goals, ensuring that investments lead to enhanced performance and cost savings in HVAC management.

Essential Technical Properties and Trade Terminology for blower motor parts

What Are the Key Technical Properties of Blower Motor Parts?

Understanding the essential technical specifications of blower motor parts is crucial for B2B buyers, particularly when making informed purchasing decisions. Here are several critical specifications to consider:

-

Material Grade

Blower motor components are typically made from materials such as aluminum, steel, and high-grade plastics. The material grade affects durability, performance, and resistance to corrosion. For instance, aluminum offers a lightweight solution with good thermal conductivity, while steel provides strength and longevity. Selecting the appropriate material grade ensures that the blower motor can withstand environmental conditions and operational stresses. -

Voltage Rating

The voltage rating indicates the electrical potential required for the blower motor to function optimally. Common ratings include 120V, 240V, and 480V. Understanding the voltage requirement is critical for compatibility with HVAC systems, ensuring efficient operation and preventing potential electrical failures. -

Airflow Capacity (CFM)

Airflow capacity, measured in cubic feet per minute (CFM), quantifies how much air a blower motor can move. This specification is vital for determining whether a blower motor can meet the heating or cooling demands of a specific application. Inadequate airflow can lead to inefficient system performance and increased energy costs. -

Speed (RPM)

The speed of a blower motor, measured in revolutions per minute (RPM), impacts its performance characteristics. Motors may operate at fixed or variable speeds, with variable-speed motors offering enhanced energy efficiency and comfort control. Understanding the speed requirements helps in selecting a motor that can adapt to varying operational needs. -

Torque Rating

Torque rating indicates the motor’s rotational force capability, which is essential for starting and maintaining airflow against resistance. Higher torque ratings allow motors to overcome initial inertia and maintain consistent airflow, particularly in systems with high static pressure. -

Tolerance

Tolerance refers to the permissible limits of variation in a physical dimension or measured value. For blower motors, tight tolerances are crucial for ensuring proper fit and function, minimizing vibrations, and maximizing efficiency. High-quality components with precise tolerances contribute to reliable operation and longevity.

What Are Common Trade Terms Used in the Blower Motor Industry?

Familiarity with industry terminology enhances communication and understanding among B2B buyers. Here are several common trade terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the equipment. Purchasing OEM parts ensures compatibility and reliability, as they are designed to meet the exact specifications of the original equipment. This is particularly important for maintaining warranties and ensuring optimal performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory costs effectively. It helps in planning purchases and ensuring that stock levels meet operational demands without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. This process is crucial for buyers to compare costs and negotiate better deals, ensuring they get the best value for their investment. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and delivery responsibilities, which can significantly impact the total cost of acquisition. -

Static Pressure

Static pressure measures the resistance to airflow in a duct system. It is a critical factor in selecting blower motors, as higher static pressure requires more powerful motors to maintain airflow. Understanding this term aids buyers in choosing appropriate motors for their specific applications. -

Lead Time

Lead time is the time it takes from placing an order to receiving the goods. Knowledge of lead times is essential for B2B buyers to plan their inventory and ensure timely project completion. It allows for better scheduling and resource management, minimizing disruptions in operations.

By understanding these technical properties and industry terms, B2B buyers can make informed decisions that enhance the efficiency and reliability of their HVAC systems.

Navigating Market Dynamics and Sourcing Trends in the blower motor parts Sector

What Are the Key Market Dynamics and Trends in the Blower Motor Parts Sector?

The global blower motor parts market is witnessing robust growth driven by several key factors. Increasing demand for HVAC systems across various sectors, including residential, commercial, and industrial, is a primary driver. As climate change concerns escalate, more businesses and consumers are investing in energy-efficient HVAC solutions, which in turn fuels the demand for high-performance blower motor parts. Additionally, advancements in technology, such as the rise of smart HVAC systems, are shaping the market landscape by introducing variable-speed motors and IoT-enabled components, enhancing energy efficiency and operational control.

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, are increasingly focusing on sourcing high-quality OEM parts to ensure system reliability and longevity. The trend towards online sourcing platforms has gained traction, allowing buyers to compare products, prices, and suppliers efficiently. Moreover, the recent emphasis on supply chain transparency is prompting buyers to seek suppliers who can provide detailed documentation and warranties, ensuring that all parts meet stringent quality standards.

How Is Sustainability Influencing B2B Sourcing of Blower Motor Parts?

Sustainability and ethical sourcing are becoming paramount in the blower motor parts sector. The environmental impact of manufacturing processes and materials used in these components is under scrutiny, pushing companies to adopt greener practices. Sustainable sourcing not only helps reduce carbon footprints but also aligns with the growing consumer demand for environmentally friendly products.

B2B buyers are increasingly prioritizing suppliers who adhere to sustainability certifications, such as ISO 14001 for environmental management and other green certifications that validate eco-friendly practices. Utilizing recyclable materials and energy-efficient manufacturing processes is becoming a standard expectation. Furthermore, suppliers are increasingly transparent about their supply chains, enabling buyers to make informed decisions that reflect their corporate social responsibility goals.

Illustrative image related to blower motor parts

As the global market moves towards a circular economy, companies that invest in sustainable practices are likely to gain a competitive edge, appealing to environmentally-conscious businesses and consumers alike.

What Has Been the Evolution of Blower Motor Parts in the B2B Context?

The evolution of blower motor parts can be traced back to the early days of HVAC systems, where basic mechanical fans were employed to circulate air. Over the decades, technological advancements have led to the development of electric blower motors, significantly enhancing efficiency and performance. The introduction of variable-speed motors has revolutionized the sector, allowing for better airflow control and energy savings.

With the rise of digital technology, the integration of smart features into blower motors has further transformed the landscape. Modern components now often come equipped with sensors and IoT capabilities, enabling real-time monitoring and adjustments based on environmental conditions. This evolution is not just a technological shift; it also reflects a broader trend towards energy efficiency and sustainability in HVAC systems, aligning with global efforts to combat climate change and promote sustainable practices in B2B sourcing.

In conclusion, understanding these market dynamics, sustainability considerations, and the historical context of blower motor parts will empower B2B buyers to make informed decisions, ensuring they are well-positioned to navigate the complexities of this evolving sector.

Illustrative image related to blower motor parts

Frequently Asked Questions (FAQs) for B2B Buyers of blower motor parts

-

1. How do I solve issues with insufficient airflow from my blower motor?

Insufficient airflow from your blower motor can stem from several factors, including a faulty motor, clogged filters, or ductwork obstructions. Start by inspecting the air filters; replacing them can often resolve airflow issues. If the problem persists, check for blockages in the ducts and ensure the blower motor is functioning properly. If you suspect motor failure, consider sourcing a replacement from a reputable supplier, ensuring compatibility with your HVAC system specifications. -

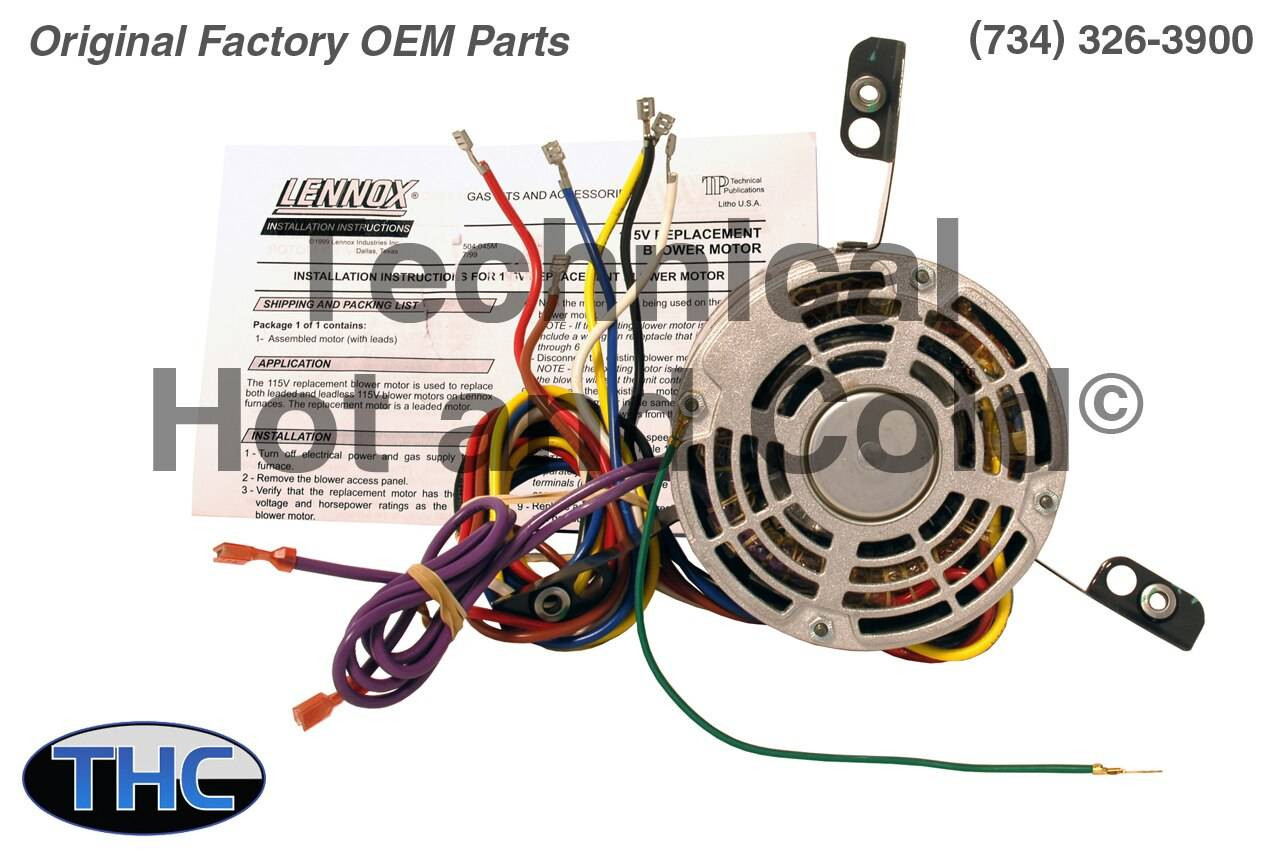

2. What is the best blower motor for HVAC systems in commercial applications?

The best blower motor for commercial HVAC systems typically features a variable-speed design, which allows for efficient airflow control and energy savings. Look for motors from established brands known for durability and reliability, such as Trane or Lennox. Ensure that the motor meets your system’s specific requirements, including voltage, horsepower, and mounting configuration. Consulting with a supplier can also help you identify the best options tailored to your unique application needs. -

3. How can I vet suppliers for blower motor parts effectively?

When vetting suppliers for blower motor parts, consider their industry reputation, experience, and product quality. Request references and reviews from previous clients to gauge reliability. Verify if they provide certifications for their products, such as ISO or OEM standards, which ensure quality control. Additionally, assess their customer service responsiveness and ability to handle international shipping, especially if you are sourcing from regions like Africa or South America. -

4. What are the typical minimum order quantities (MOQ) for blower motor parts?

Minimum order quantities (MOQ) for blower motor parts can vary significantly based on the supplier and the type of components. Generally, MOQs may range from 10 to 100 units, depending on the part’s cost and demand. It’s essential to discuss your purchasing needs with suppliers to negotiate MOQs that align with your business requirements. Some suppliers may offer flexibility for first-time orders or provide discounts for larger quantities. -

5. What payment terms should I expect when sourcing blower motor parts internationally?

Payment terms for international orders of blower motor parts typically include options such as upfront payment, partial payment upon order confirmation, or payment upon delivery. Common methods include wire transfers, letters of credit, and PayPal. It’s crucial to clarify payment terms upfront to avoid misunderstandings. Additionally, consider using escrow services for high-value transactions to ensure protection for both parties. -

6. How do I ensure quality assurance (QA) when purchasing blower motor parts?

To ensure quality assurance when purchasing blower motor parts, request detailed product specifications and certifications from the supplier. Ask for samples or trial orders to evaluate the parts’ performance before making a larger commitment. Additionally, inquire about the supplier’s QA processes, such as testing procedures and warranty policies. Establish clear communication regarding quality expectations to foster a reliable partnership. -

7. What logistics considerations should I keep in mind for international shipments of blower motor parts?

When sourcing blower motor parts internationally, consider logistics factors like shipping methods, lead times, and customs regulations. Choose reliable freight forwarders experienced in handling HVAC components to ensure timely delivery. Be aware of import duties and taxes that may apply, which can affect overall costs. Additionally, confirm that the supplier provides adequate packaging to protect the parts during transit. -

8. Can I customize blower motor parts for specific applications?

Yes, many suppliers offer customization options for blower motor parts to meet specific application requirements. Customization can include modifications in size, voltage, or mounting configurations. When discussing your needs with suppliers, provide detailed specifications and any unique performance criteria. This will help ensure that the customized parts function effectively within your system and meet industry standards.

Top 2 Blower Motor Parts Manufacturers & Suppliers List

1. HVAC Parts Shop – Quality OEM Parts

Domain: hvacpartsshop.com

Registered: 2006 (19 years)

Introduction: HVAC Repair Parts & Accessories including Furnace Parts, Air Conditioning Parts, and HVAC Controls. Key categories include Blower Motors, Flame Sensors, Gas Valves, Condenser Coils, and Electronic Air Filters. Offers fast shipping with same-day delivery, quality OEM parts, and expert support. Features thousands of HVAC parts from brands like Lennox, Goodman, Armstrong, Trane, and York. Provides ac…

2. Blower Motors – Quality Parts for Every Vehicle

Domain: carparts.com

Registered: 1999 (26 years)

Introduction: This company, Blower Motors – Quality Parts for Every Vehicle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for blower motor parts

In the rapidly evolving landscape of blower motor parts, strategic sourcing emerges as a cornerstone for businesses aiming to maintain operational efficiency and competitive advantage. By leveraging strong supplier relationships, international buyers can secure high-quality components that ensure optimal performance of HVAC systems, thereby enhancing customer satisfaction. This is particularly vital in regions like Africa, South America, the Middle East, and Europe, where market dynamics and regulatory requirements vary significantly.

Investing in a comprehensive understanding of the blower motor’s components—such as rotors, capacitors, and control boards—enables buyers to make informed decisions that minimize downtime and reduce maintenance costs. Moreover, aligning sourcing strategies with sustainable practices can lead to long-term cost savings and a stronger market position.

As the demand for energy-efficient solutions grows, international buyers are encouraged to explore innovative sourcing options that not only meet current needs but also anticipate future trends. Engaging with reputable suppliers who offer OEM parts, expert support, and valuable resources can significantly enhance operational reliability. By prioritizing strategic sourcing, businesses can confidently navigate the complexities of the blower motor parts market and position themselves for success in the years to come.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to blower motor parts