Polyurethane Moulding: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for polyurethane moulding

In today’s competitive landscape, sourcing high-quality polyurethane moulding presents a significant challenge for international B2B buyers. As industries evolve, the demand for versatile, durable, and cost-effective moulding solutions has surged. This guide aims to navigate the complexities of the global market for polyurethane moulding, addressing critical factors such as product types, applications, supplier vetting, and pricing structures.

Buyers from regions like Africa, South America, the Middle East, and Europe—including key markets such as Saudi Arabia and Brazil—will find invaluable insights tailored to their unique purchasing needs. By understanding the various applications of polyurethane moulding—from architectural elements to functional components—businesses can make informed decisions that enhance their project outcomes.

This comprehensive resource empowers buyers to identify reliable suppliers, assess product quality, and negotiate favorable terms, ultimately streamlining their procurement process. With actionable insights and expert analysis, this guide will serve as an essential tool for those looking to capitalize on the benefits of polyurethane moulding, ensuring they stay ahead in a rapidly changing market.

Understanding polyurethane moulding Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Crown Moulding | Decorative, often used at ceiling junctions | Residential and commercial spaces | Pros: Aesthetic appeal, lightweight, easy installation. Cons: May require precise cutting for corners. |

| Baseboard Moulding | Installed along the bottom of walls | Retail, hospitality, residential | Pros: Protects walls, enhances décor. Cons: Can be prone to scuffing in high-traffic areas. |

| Chair Rail Moulding | Installed horizontally to protect walls | Restaurants, offices, homes | Pros: Adds visual interest, protects walls. Cons: Limited application in modern designs. |

| Flexible Moulding | Can bend to fit curved surfaces | Custom installations, unique designs | Pros: Versatile, adaptable to any shape. Cons: May be more expensive than rigid options. |

| Panel Moulding | Used to create a raised panel effect | Commercial interiors, cabinetry | Pros: Creates depth, customizable. Cons: Installation can be complex, requiring skilled labor. |

What Are the Key Characteristics of Crown Moulding in Polyurethane?

Crown moulding is a popular choice for adding elegance to both residential and commercial spaces. Its distinctive design enhances the junction between walls and ceilings, creating a polished look. Made from lightweight polyurethane, it is easy to install and can be painted or finished to match various interior styles. For B2B buyers, the aesthetics of crown moulding can significantly influence customer perceptions, making it a valuable addition to high-end residential projects or upscale commercial environments.

How Does Baseboard Moulding Enhance Spaces?

Baseboard moulding serves both functional and decorative purposes by covering the joint between the wall and the floor. It protects walls from damage while providing a finished look. Polyurethane baseboards are moisture-resistant, making them suitable for a range of environments including retail and hospitality settings. B2B buyers should consider the durability and ease of installation, as these factors can affect labor costs and overall project timelines.

Why Choose Chair Rail Moulding for Commercial Applications?

Chair rail moulding is installed horizontally around a room to protect walls from damage and to create visual interest. It is particularly popular in restaurants and office settings, where it can delineate spaces and add character. While it enhances the aesthetic appeal, its application may be limited in contemporary designs. B2B buyers should weigh the benefits of increased wall protection against the potential for limited versatility in modern projects.

What Advantages Do Flexible Mouldings Offer for Custom Installations?

Flexible moulding is designed to bend and conform to curves, making it ideal for unique architectural features or custom installations. It is especially useful in spaces where traditional moulding would not fit. While flexible options can be more costly, their adaptability provides significant value for projects requiring creativity and customization. B2B buyers should consider the specific needs of their projects when opting for flexible moulding, as it can enhance design possibilities.

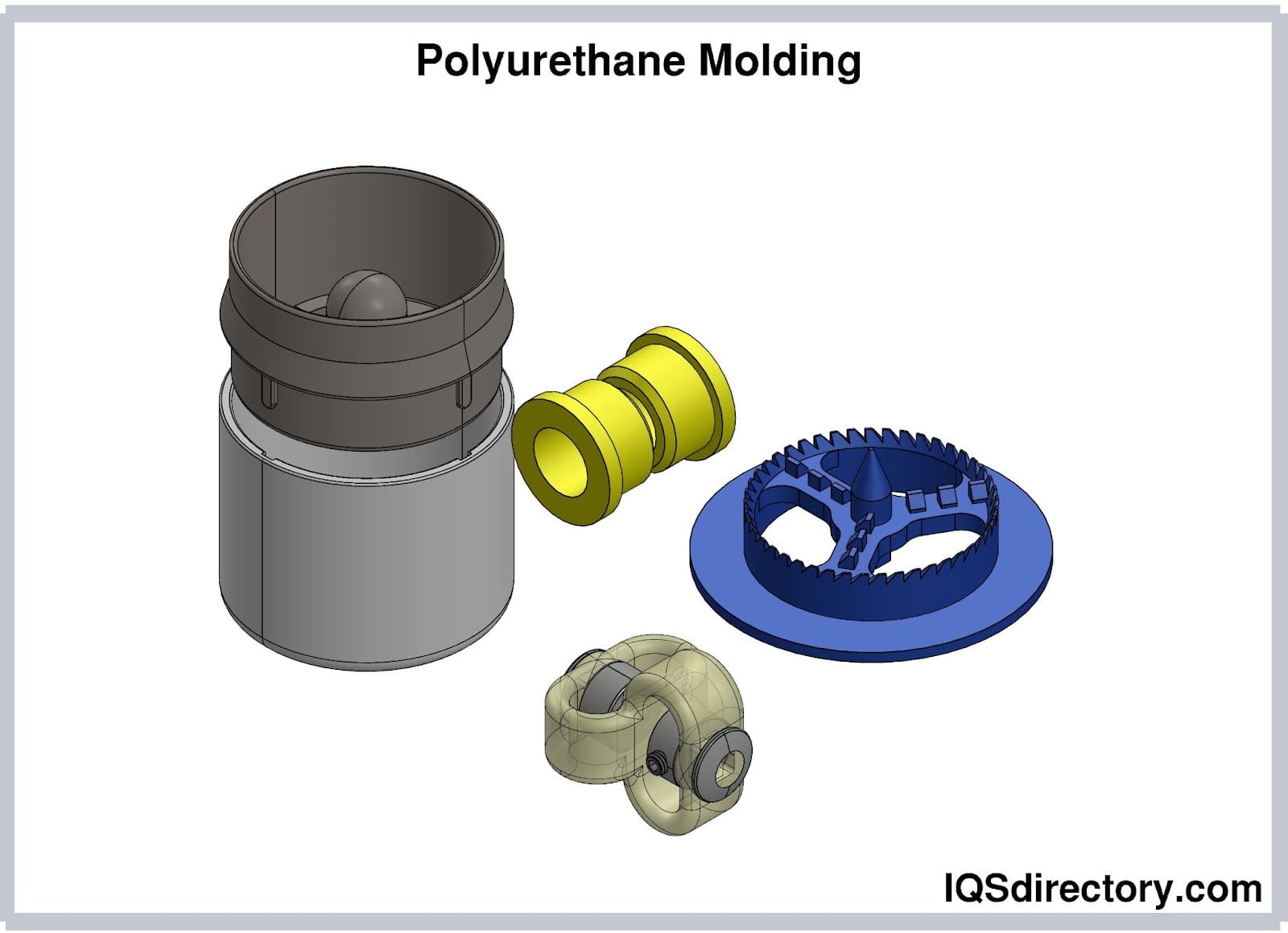

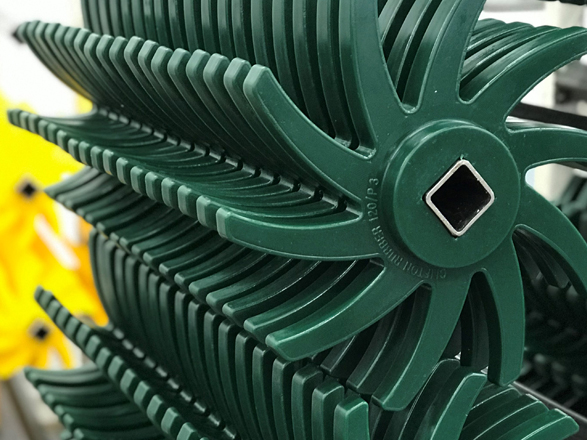

Illustrative image related to polyurethane moulding

How Does Panel Moulding Create Depth in Designs?

Panel moulding is used to create a raised panel effect, adding depth and dimension to walls. This type of moulding is commonly found in commercial interiors and cabinetry, where it can elevate the overall design aesthetic. While it allows for extensive customization, installation can be complex and may require skilled labor. B2B buyers should evaluate the skill set of their installation team when considering panel moulding, as this can impact project costs and timelines.

Key Industrial Applications of polyurethane moulding

| Industry/Sector | Specific Application of polyurethane moulding | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Decorative mouldings for interiors and exteriors | Enhances aesthetic appeal while being cost-effective | Look for lightweight, moisture-resistant options; ensure compatibility with local building codes. |

| Automotive | Interior trim and components | Durable and lightweight, improving vehicle efficiency | Seek suppliers that offer custom designs and high durability for varied climates. |

| Furniture Manufacturing | Custom furniture accents and mouldings | Adds unique design elements, enhancing marketability | Consider sourcing from manufacturers with a variety of profiles and finishes. |

| Marine Industry | Boat interior and exterior finishing | Water-resistant properties increase longevity | Ensure compliance with marine safety standards; focus on UV resistance for longevity. |

| HVAC & Construction Equipment | Insulation and protective casings | Improves energy efficiency and reduces operational costs | Prioritize thermal insulation properties and ease of installation for various applications. |

How is Polyurethane Moulding Used in Construction & Architecture?

In the construction and architecture sectors, polyurethane moulding is extensively used for decorative applications both indoors and outdoors. It serves as crown moulding, baseboards, and architectural accents, enhancing the overall aesthetic of buildings. The lightweight nature of polyurethane allows for easy installation, reducing labor costs. Buyers in Africa and the Middle East should ensure that the moulding is moisture-resistant to withstand local climates, while European buyers may prioritize compliance with stringent building regulations.

What are the Applications of Polyurethane Moulding in the Automotive Sector?

In the automotive industry, polyurethane moulding is utilized for creating interior trim pieces, dashboard components, and even exterior accents. Its durability and lightweight characteristics contribute to improved fuel efficiency and vehicle performance. International buyers, particularly from South America and Europe, should look for suppliers who can provide custom designs that meet specific vehicle requirements, ensuring quality and longevity in diverse environmental conditions.

Illustrative image related to polyurethane moulding

How is Polyurethane Moulding Beneficial in Furniture Manufacturing?

Furniture manufacturers leverage polyurethane moulding for crafting custom accents, such as chair rails and decorative elements that enhance the visual appeal of their products. This material allows for intricate designs at a fraction of the cost of traditional materials. Buyers should consider sourcing from manufacturers that offer a variety of profiles and finishes to cater to different market preferences, ensuring that the products stand out in a competitive marketplace.

In What Ways is Polyurethane Moulding Used in the Marine Industry?

The marine industry employs polyurethane moulding for both interior and exterior finishes on boats, taking advantage of its water-resistant properties. This application not only enhances the aesthetic quality of the vessels but also prolongs their lifespan against harsh marine conditions. Buyers need to ensure that the moulding complies with marine safety standards, and focus on UV-resistant options to maintain appearance and structural integrity over time.

How Does Polyurethane Moulding Improve HVAC and Construction Equipment?

Polyurethane moulding finds application in the HVAC sector for insulation and protective casings, providing superior thermal insulation that enhances energy efficiency. This is particularly beneficial for construction equipment, where reduced weight can lead to lower operational costs. Buyers should prioritize sourcing options that offer high thermal performance and ease of installation, ensuring that they meet the specific needs of their projects while optimizing overall efficiency.

3 Common User Pain Points for ‘polyurethane moulding’ & Their Solutions

Scenario 1: The Challenge of Durability in Varied Environments

The Problem: B2B buyers in regions with extreme weather conditions—such as the hot, humid climates of parts of Africa and South America—often struggle with the durability of building materials. Polyurethane moulding, while generally known for its moisture resistance, can still face challenges if not properly specified or installed. Buyers may find that subpar products warp, crack, or degrade over time, leading to costly repairs and project delays. This issue can be especially frustrating when they have invested in what they believed to be high-quality materials.

Illustrative image related to polyurethane moulding

The Solution: To ensure that the polyurethane moulding selected can withstand extreme conditions, buyers should prioritize sourcing products specifically designed for durability. Look for moulding that is labeled as “high-performance” and check if it includes additional features like UV resistance or enhanced moisture barriers. Collaborating with reputable suppliers who provide comprehensive technical specifications can also help in making informed choices. Furthermore, proper installation is crucial—consider hiring experienced professionals who can ensure that the moulding is fitted correctly and sealed to prevent moisture infiltration. Regular maintenance checks can also extend the lifespan of the moulding, providing ongoing assurance against environmental stressors.

Scenario 2: Complexity in Customization

The Problem: Many B2B buyers require customized solutions for their projects, especially in architectural applications where unique designs are pivotal. However, standard polyurethane moulding may not meet specific aesthetic or functional requirements. This can lead to frustration when trying to source materials that align with a client’s vision while still maintaining structural integrity and affordability. The complexity involved in customization often results in longer lead times and increased costs, which can jeopardize project timelines.

The Solution: Engaging with suppliers who offer tailored solutions can alleviate these concerns. Buyers should seek out manufacturers that specialize in custom polyurethane moulding and can work collaboratively to create designs that meet specific project requirements. It’s beneficial to provide detailed drawings or 3D models to ensure that the final product matches the intended design. Additionally, consider utilizing CAD software to visualize the moulding in context before production begins, which can help in identifying potential issues early in the process. Establishing a clear communication channel with suppliers will also enhance collaboration and streamline the customization process, ultimately saving time and costs.

Scenario 3: Cost Management and Budget Constraints

The Problem: Budget constraints are a common concern for B2B buyers, particularly in regions where economic conditions may fluctuate. While polyurethane moulding is often seen as a cost-effective alternative to traditional materials like wood, buyers may still encounter unexpected expenses related to sourcing, shipping, or installation. The fear of overspending can lead to hesitation in making purchasing decisions, which can stall projects and hinder business growth.

The Solution: To manage costs effectively, buyers should conduct a thorough cost-benefit analysis before committing to a purchase. Start by comparing the total cost of ownership for different materials, including initial purchase price, installation costs, and long-term maintenance expenses. Additionally, consider bulk purchasing options or negotiating long-term contracts with suppliers to secure lower rates. It’s also advantageous to explore local suppliers who can reduce shipping costs and times. Investing in quality products upfront can lead to lower overall costs due to reduced maintenance and replacement needs. Finally, leveraging technology, such as project management software, can help track expenses and budget adherence, ensuring that projects remain financially viable.

Strategic Material Selection Guide for polyurethane moulding

What Are the Key Properties of Polyurethane Moulding Materials?

When selecting materials for polyurethane moulding, it is essential to consider various properties that directly impact product performance. The most common materials used in polyurethane moulding include polyurethane itself, PVC, wood, and polystyrene. Each material has unique characteristics that influence its suitability for different applications.

How Does Polyurethane Compare as a Moulding Material?

Polyurethane is a versatile material known for its excellent durability and flexibility. It can withstand a wide range of temperatures and is resistant to moisture, making it suitable for both interior and exterior applications. Polyurethane moulding is lightweight, which simplifies transportation and installation. However, it can be more expensive than other options, and its manufacturing process may require specialized equipment.

For international buyers, particularly in regions like Africa and the Middle East, compliance with local building codes and standards such as ASTM or DIN is crucial. Buyers should also consider the environmental impact of polyurethane, as regulations around VOC emissions may vary by country.

What Are the Benefits and Limitations of PVC in Moulding?

PVC (polyvinyl chloride) is another popular choice for moulding due to its cost-effectiveness and resistance to moisture and chemicals. PVC moulding is often used in areas prone to humidity, such as bathrooms and kitchens. It is also easy to clean and maintain, which is a significant advantage for commercial applications.

However, PVC is less durable than polyurethane and may become brittle over time, especially when exposed to extreme temperatures. International buyers should be aware of the varying regulations regarding PVC usage in construction, as some regions have restrictions due to environmental concerns.

How Does Wood Perform in Polyurethane Moulding Applications?

Wood remains a traditional choice for moulding, prized for its aesthetic appeal and structural integrity. It offers excellent performance in terms of strength and can be easily customized to fit specific design requirements. However, wood is susceptible to moisture, insects, and rot, which can limit its application in humid environments.

From a B2B perspective, sourcing quality wood can be challenging, especially in regions where deforestation regulations are strict. Buyers in Europe and South America should ensure compliance with local sustainability standards and consider the impact of transportation on overall costs.

What Role Does Polystyrene Play in Moulding Choices?

Polystyrene is a lightweight and cost-effective option for moulding, often used in decorative applications. It is easy to shape and paint, making it suitable for various design styles. However, polystyrene lacks the durability of polyurethane and wood, making it less suitable for high-stress applications.

For international buyers, polystyrene can be an attractive option due to its affordability. However, they should consider the material’s lower resistance to heat and moisture, which may limit its use in certain climates, particularly in hotter regions like Saudi Arabia and Brazil.

Illustrative image related to polyurethane moulding

Summary Table of Material Selection for Polyurethane Moulding

| Material | Typical Use Case for polyurethane moulding | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane | Decorative and structural moulding | Excellent durability and flexibility | Higher cost and manufacturing complexity | High |

| PVC | Moisture-prone areas (bathrooms, kitchens) | Cost-effective and easy to maintain | Less durable, can become brittle | Medium |

| Wood | Traditional moulding applications | Aesthetic appeal and strength | Susceptible to moisture and insects | Medium |

| Polystyrene | Decorative moulding | Lightweight and easy to shape | Lower durability and heat resistance | Low |

This guide provides a comprehensive overview of the strategic considerations for selecting materials for polyurethane moulding. By understanding the properties, advantages, and limitations of each material, international B2B buyers can make informed decisions that align with their specific application needs and regulatory requirements.

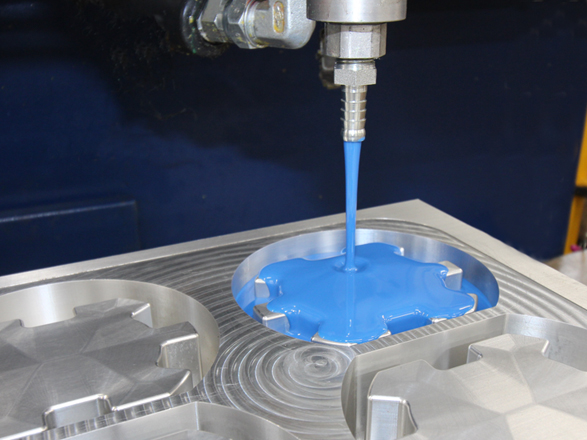

In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane moulding

Polyurethane moulding has become a staple in various industries due to its versatility, durability, and aesthetic appeal. Understanding the manufacturing processes and quality assurance protocols is crucial for B2B buyers seeking reliable suppliers. This section outlines the key stages of manufacturing polyurethane moulding, essential quality control measures, and how international buyers can navigate these processes effectively.

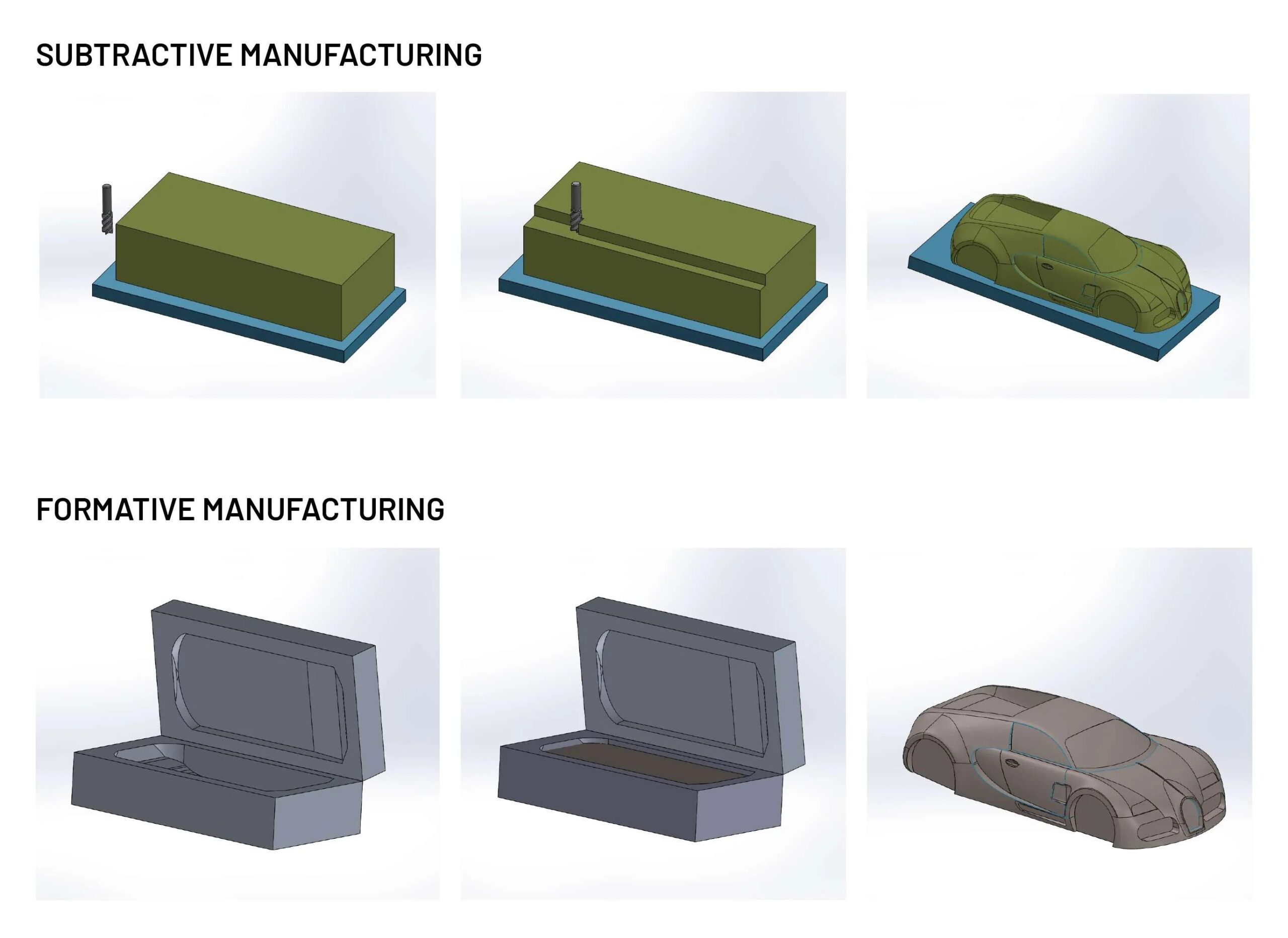

What Are the Main Stages of Polyurethane Moulding Manufacturing?

The manufacturing of polyurethane moulding typically involves several critical stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Polyurethane Moulding?

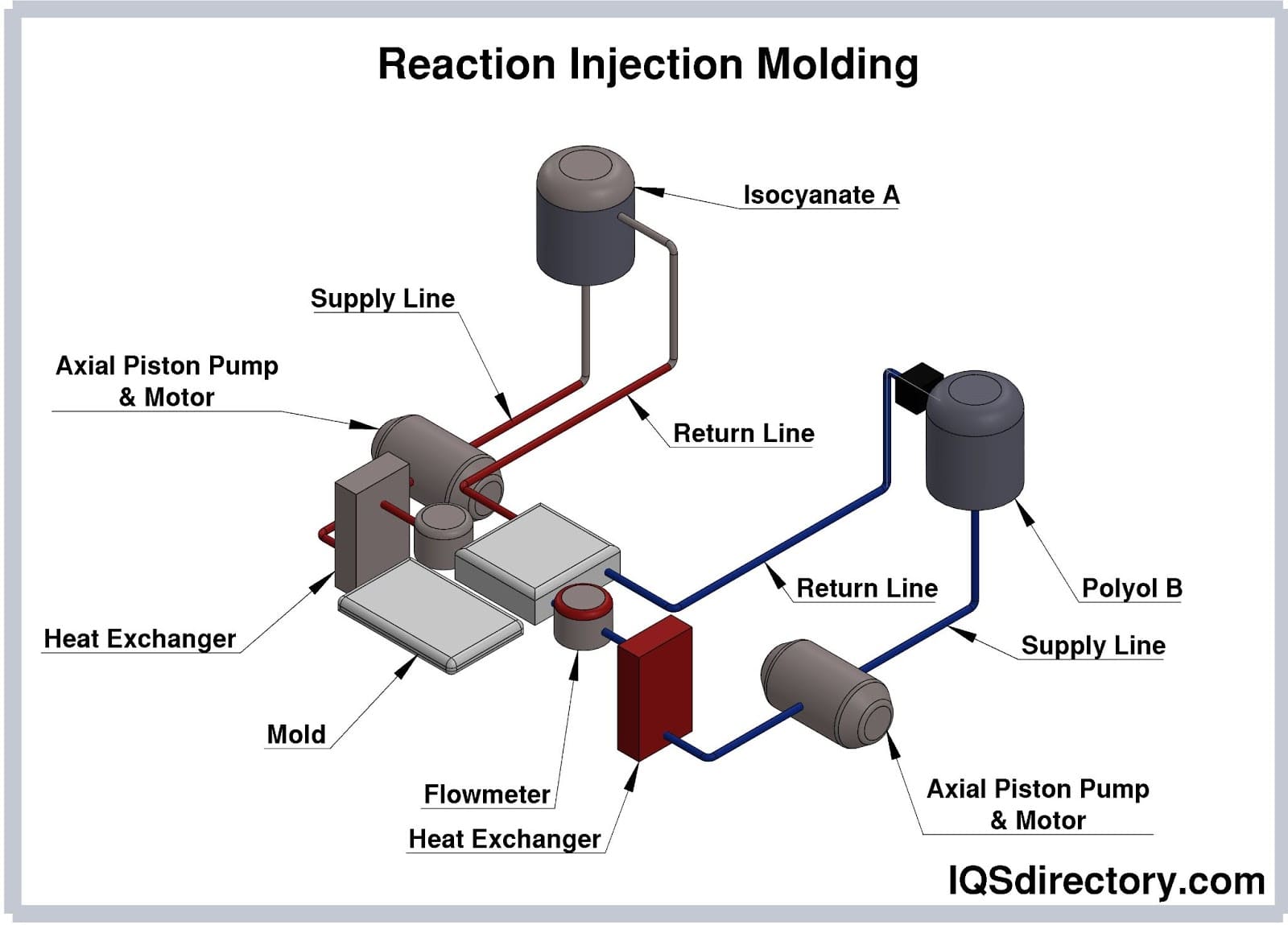

Material preparation is the foundational stage, where raw polyurethane materials are sourced and processed. Manufacturers often use a blend of polyols and isocyanates, which are mixed in precise ratios to achieve the desired properties of the final product. Quality suppliers ensure that these raw materials meet industry standards and are free from contaminants.

Before the mixing process, suppliers may conduct Incoming Quality Control (IQC) checks to verify the integrity and composition of the materials. This step is essential for maintaining consistency and quality throughout the production cycle.

What Techniques Are Used in the Forming Stage of Polyurethane Moulding?

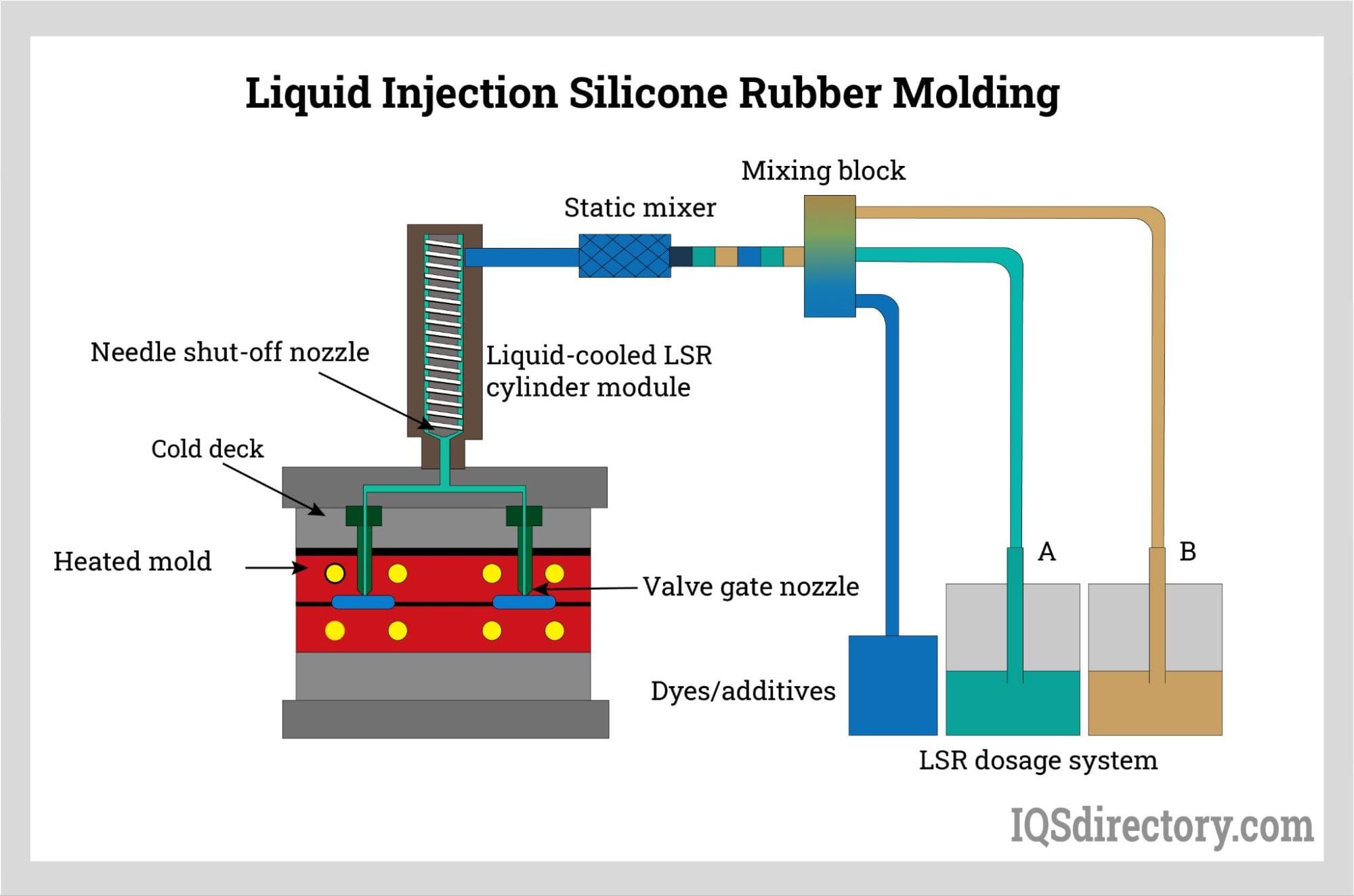

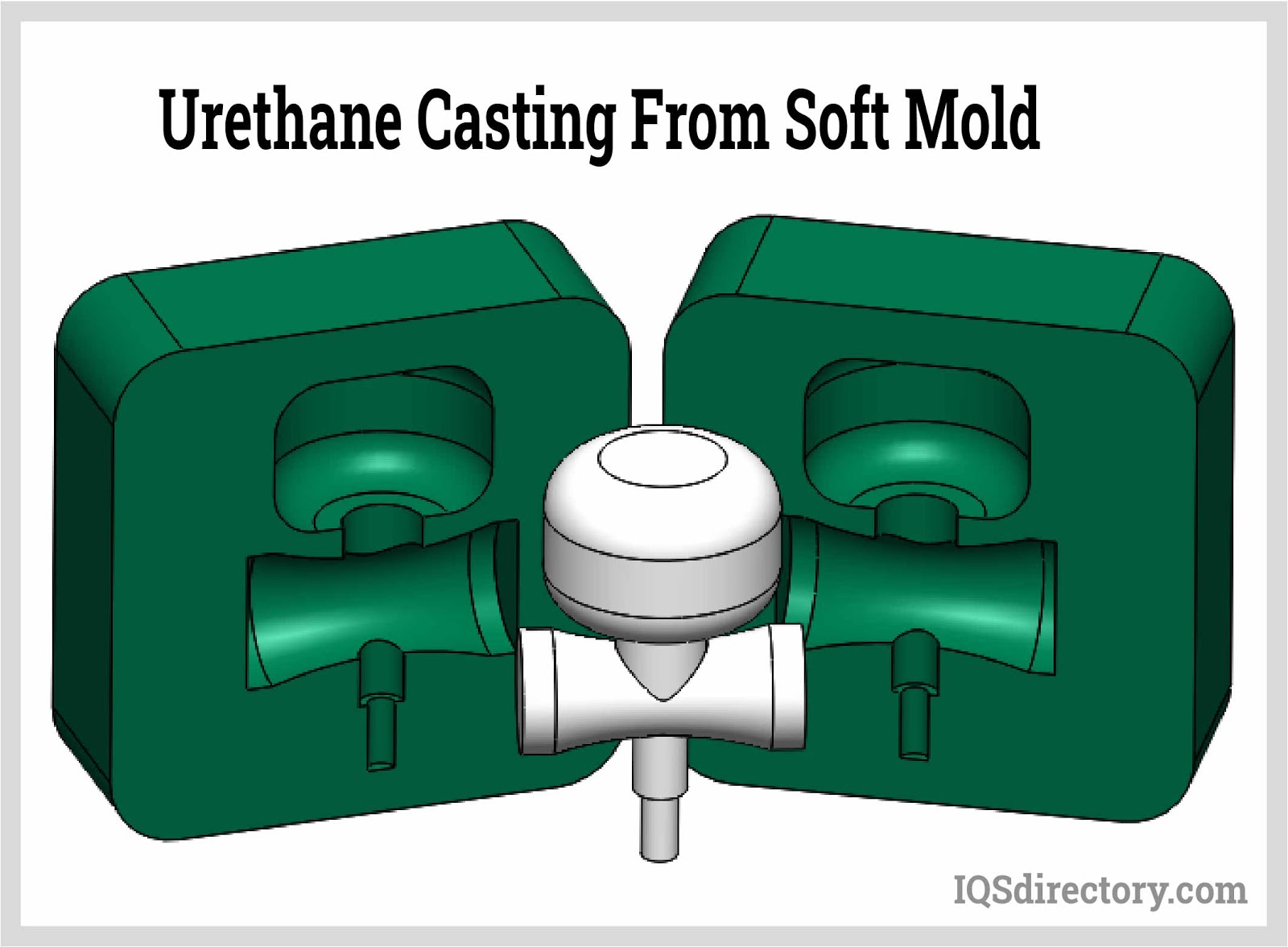

The forming stage involves creating the moulds that will shape the polyurethane. This can be achieved through various techniques, including:

-

Injection Moulding: A common method where the mixed polyurethane is injected into a pre-designed mould. This technique allows for high precision and detail in the final product.

-

Compression Moulding: In this process, a pre-measured amount of polyurethane is placed in a heated mould, where it is compressed and cured. This method is often used for larger, simpler shapes.

-

Extrusion: For continuous profiles, extrusion is employed, where the polyurethane is forced through a die to create long sections of moulding.

Each technique has its advantages, depending on the complexity and volume of production required.

How Is Assembly and Finishing Conducted in Polyurethane Moulding?

After forming, the moulded pieces may require assembly. This can involve joining multiple components or adding features such as decorative elements. The finishing stage includes processes like sanding, priming, and painting to enhance the aesthetic appeal and ensure the product meets customer specifications.

Quality suppliers often conduct In-Process Quality Control (IPQC) during these stages to monitor the manufacturing process and ensure that products meet predetermined standards.

Illustrative image related to polyurethane moulding

What Quality Control Standards Are Relevant for Polyurethane Moulding?

Quality assurance is paramount in the manufacturing of polyurethane moulding. Several international and industry-specific standards guide these processes, including:

-

ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent quality in manufacturing processes.

-

CE Marking: Relevant for products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

-

API Standards: For applications in the oil and gas sector, adherence to American Petroleum Institute (API) standards is crucial.

What Are the Key Quality Control Checkpoints in Polyurethane Moulding?

Quality control in the manufacturing process typically involves several checkpoints:

-

Incoming Quality Control (IQC): Assessment of raw materials upon arrival to ensure they meet specifications.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch defects early.

-

Final Quality Control (FQC): A thorough inspection of the finished products to ensure they meet all design and quality specifications.

Common testing methods during these checkpoints include dimensional inspections, tensile strength tests, and visual inspections for surface defects.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should implement a robust verification strategy to ensure that their suppliers maintain high-quality standards. Here are some actionable steps:

-

Request Audits and Certifications: Buyers can ask for copies of certifications such as ISO 9001 and CE markings. These documents serve as proof of compliance with international quality standards.

-

Review Quality Control Reports: Suppliers should provide detailed reports from their quality control processes. This transparency helps buyers understand how products are monitored and tested.

-

Engage Third-Party Inspectors: For added assurance, buyers can hire third-party inspection services to evaluate the supplier’s facilities and processes. This independent verification can uncover potential issues that may not be apparent through documentation alone.

What Nuances Should International B2B Buyers Consider for Quality Control?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of certain nuances in quality control:

-

Cultural and Regulatory Differences: Different regions have varying regulations and expectations regarding quality. Buyers should familiarize themselves with local compliance requirements to avoid issues during importation.

-

Logistics and Supply Chain Considerations: The supply chain can impact quality. Buyers should assess how suppliers manage logistics to ensure that products are delivered without damage and remain compliant with quality standards.

-

Communication Barriers: Language and cultural differences can lead to misunderstandings regarding quality expectations. Establishing clear communication channels and expectations upfront can mitigate these risks.

In conclusion, understanding the manufacturing processes and quality assurance measures for polyurethane moulding is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing, as well as implementing rigorous quality control practices, buyers can ensure they are sourcing high-quality products that meet their specific needs. Moreover, being proactive in verifying supplier practices and understanding international nuances can lead to successful partnerships and high-quality outcomes in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyurethane moulding’

To effectively procure polyurethane moulding, B2B buyers must navigate a series of critical steps. This guide outlines a structured approach to ensure that your sourcing process is efficient and successful.

Step 1: Define Your Technical Specifications

Clearly outline the specific requirements for the polyurethane moulding you need. This includes dimensions, design features, and material characteristics. Consider factors such as moisture resistance, flexibility, and whether the moulding will be used for interior or exterior applications. A well-defined specification helps streamline communication with suppliers and reduces the likelihood of errors.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Look for companies that specialize in polyurethane moulding and have a strong track record in your target market. Utilize industry directories, trade shows, and online reviews to gauge supplier reliability. Pay attention to their experience in serving regions similar to yours, such as Africa, South America, or Europe.

Illustrative image related to polyurethane moulding

Step 3: Evaluate Supplier Certifications

Before moving forward, verify that potential suppliers hold relevant certifications and comply with industry standards. Certifications can indicate adherence to quality and safety regulations, which is particularly important in construction materials. Look for certifications such as ISO 9001 for quality management and any local certifications that may apply.

Step 4: Request Samples

Always request samples of the polyurethane moulding before placing a bulk order. This allows you to assess the quality, finish, and durability of the product firsthand. Evaluate the samples against your technical specifications to ensure they meet your requirements. This step can prevent costly mistakes and ensure that the final product aligns with your expectations.

Step 5: Assess Pricing and Terms

Once you have shortlisted potential suppliers, compare pricing structures and payment terms. Be aware of additional costs such as shipping, taxes, and tariffs that may apply, especially for international transactions. Evaluate whether the pricing aligns with your budget while considering the quality of the moulding being offered.

Step 6: Review Delivery and Lead Times

Inquire about the delivery timelines and lead times associated with your order. Understanding the supplier’s production capacity and logistical capabilities is crucial, especially if your project is time-sensitive. Make sure to confirm that the supplier can meet your deadlines without compromising quality.

Step 7: Negotiate and Finalize the Contract

Once you have selected a supplier, engage in negotiations to finalize terms that are favorable for both parties. Clearly outline payment terms, delivery schedules, and any warranties or guarantees. A well-structured contract can protect your interests and set clear expectations for the partnership.

By following these steps, B2B buyers can navigate the complexities of sourcing polyurethane moulding effectively, ensuring a successful procurement process that meets both quality and budgetary needs.

Comprehensive Cost and Pricing Analysis for polyurethane moulding Sourcing

What Are the Key Cost Components for Polyurethane Moulding?

When sourcing polyurethane moulding, understanding the cost structure is essential for effective budgeting and supplier negotiations. The main components of cost include:

-

Materials: The primary material, polyurethane, is generally more cost-effective than traditional wood or plaster. However, fluctuations in raw material prices can impact the overall cost significantly. Sourcing from regions with lower raw material costs may provide additional savings.

-

Labor: Labor costs can vary widely based on geographic location. In countries with lower labor costs, such as some regions in South America and Africa, buyers may find competitive pricing. However, skilled labor is necessary for quality moulding production, which can affect costs.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, equipment maintenance, and facility costs. Buyers should inquire about a supplier’s operational efficiency, as this can influence pricing.

-

Tooling: Custom moulds and tooling can represent a significant upfront investment, especially for unique designs. Buyers should consider the amortization of these costs over larger production runs to better understand the pricing implications.

-

Quality Control (QC): Ensuring product quality can incur additional costs. Suppliers with rigorous QC processes may charge more, but this investment is crucial for minimizing defects and returns.

-

Logistics: Transportation costs can vary significantly based on the shipping method and distance. Buyers should consider the total landed cost, which includes shipping, customs duties, and insurance.

-

Margin: Suppliers will add a profit margin, which can vary based on market conditions and competition. Understanding the typical margins in the polyurethane moulding market can help buyers gauge pricing fairness.

What Influences Pricing in Polyurethane Moulding?

Several factors can influence the pricing of polyurethane moulding, particularly in international B2B transactions:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to lower per-unit costs. Buyers should assess their needs and negotiate for better pricing on bulk orders.

-

Specifications and Customization: Custom designs and specifications often come with additional costs. Buyers should clearly communicate their needs and understand how customization will impact pricing.

-

Materials and Quality Certifications: Higher quality or specialized materials may increase costs. Ensure suppliers provide certifications that meet your region’s standards, as compliance may affect your purchasing decisions.

-

Supplier Factors: Supplier reliability, reputation, and experience can affect pricing. Established suppliers may charge more but often provide better quality assurance and service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is critical for determining responsibilities in shipping, insurance, and customs clearance. These terms can significantly impact the overall cost of goods.

What Tips Should Buyers Consider for Negotiating Polyurethane Moulding Prices?

When negotiating prices for polyurethane moulding, buyers should keep the following strategies in mind:

-

Leverage Volume Discounts: Consolidating orders or committing to long-term contracts can provide leverage for negotiating better pricing.

-

Assess Total Cost of Ownership (TCO): Consider not just the upfront costs but also ongoing expenses, including maintenance and replacement costs. A cheaper initial price may lead to higher long-term expenses if quality is compromised.

-

Negotiate with Multiple Suppliers: Engaging multiple suppliers can create competition, potentially leading to better pricing. However, ensure that quality is not sacrificed for cost.

-

Understand Local Market Conditions: Prices may vary significantly based on local economic factors. Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing trends and how they impact negotiations.

-

Be Aware of Pricing Nuances: International buyers should consider currency fluctuations, trade tariffs, and shipping delays, which can all influence the final price.

Conclusion

In summary, sourcing polyurethane moulding requires a thorough understanding of the cost structure and pricing influencers. By focusing on these aspects, international B2B buyers can make informed decisions that align with their budgetary constraints and quality requirements. Always remember that prices can vary widely, so continuous market research and supplier evaluation are key to achieving the best value.

Illustrative image related to polyurethane moulding

Alternatives Analysis: Comparing polyurethane moulding With Other Solutions

Exploring Alternatives to Polyurethane Moulding for B2B Buyers

In the realm of construction and design, selecting the right moulding material can significantly impact both aesthetic and functional outcomes. Polyurethane moulding has gained popularity due to its versatility and durability, but other alternatives also exist. Understanding these options can help B2B buyers make informed decisions that align with their project needs and budget.

| Comparison Aspect | Polyurethane Moulding | Wood Moulding | PVC Moulding |

|---|---|---|---|

| Performance | High durability, moisture-resistant, can mimic wood | Strong and durable, but can warp or split | Excellent moisture resistance, less durable than wood |

| Cost | Generally affordable | Higher cost, especially for premium woods | Typically lower cost than wood and polyurethane |

| Ease of Implementation | Lightweight, easy to install, can be cut and shaped easily | Requires skilled labor for installation | Easy to install, often lighter than wood |

| Maintenance | Low maintenance, paintable | Requires regular painting/staining | Minimal maintenance, resistant to fading |

| Best Use Case | Ideal for high-moisture areas (bathrooms, kitchens) | Best for traditional aesthetics and high-end projects | Suitable for outdoor applications due to weather resistance |

What Are the Advantages and Disadvantages of Wood Moulding?

Wood moulding has long been considered the traditional choice for interior design. Its natural beauty and structural integrity make it appealing for high-end projects. However, wood is susceptible to warping, splitting, and moisture damage, especially in humid climates. While it can be more expensive than polyurethane, its aesthetic value often justifies the cost for luxury applications. Additionally, wood requires ongoing maintenance, including painting or staining, to preserve its appearance and structural integrity.

How Does PVC Moulding Compare to Polyurethane Moulding?

PVC moulding is a synthetic alternative that offers excellent moisture resistance, making it suitable for outdoor applications or areas prone to humidity. It is generally more affordable than both wood and polyurethane options. PVC is lightweight and easy to install, which can reduce labor costs. However, it lacks the aesthetic appeal and structural strength of wood and polyurethane, often appearing less natural. It is a great choice for budget-conscious projects where durability is essential, but it may not suit high-end designs.

Conclusion: How Should B2B Buyers Choose the Right Moulding Solution?

When selecting a moulding material, B2B buyers should consider various factors such as project requirements, budget constraints, and aesthetic goals. Polyurethane moulding stands out for its durability and moisture resistance, making it a versatile option for diverse applications. However, for projects emphasizing traditional aesthetics, wood may be preferred despite its higher maintenance needs. Alternatively, PVC moulding offers a cost-effective solution for less demanding environments. Ultimately, understanding the specific context of each project will guide buyers toward the most suitable moulding solution that meets their operational and design objectives.

Essential Technical Properties and Trade Terminology for polyurethane moulding

What Are the Key Technical Properties of Polyurethane Moulding?

Understanding the technical properties of polyurethane moulding is essential for B2B buyers to make informed decisions. Here are several critical specifications to consider:

1. Material Composition

Polyurethane moulding is primarily composed of a polymer that combines flexibility and strength. This material is lightweight yet durable, making it ideal for various applications, including architectural details and interior design. Its moisture-resistant properties enhance its usability in areas prone to humidity, such as kitchens and bathrooms.

2. Density

The density of polyurethane moulding affects its weight and durability. A higher density typically indicates a sturdier product that can withstand impact and wear, essential for long-term applications. For B2B buyers, understanding density helps in selecting the right moulding for specific projects, ensuring that the product meets the required structural integrity.

3. Finish Type

Polyurethane moulding can come in various finishes, including primed, painted, or unfinished. A primed finish allows for immediate painting, facilitating quicker project completion. For buyers, choosing the appropriate finish can reduce labor costs and time, as well as enhance aesthetic appeal.

Illustrative image related to polyurethane moulding

4. Flexibility

One of the standout features of polyurethane moulding is its flexibility, allowing it to be used in curved or irregular spaces. This property is particularly beneficial in custom applications where standard moulding may not fit. Understanding flexibility can help buyers determine the suitability of a product for intricate designs.

5. Thermal Resistance

Polyurethane moulding can withstand a range of temperatures, making it suitable for both indoor and outdoor applications. Thermal resistance is crucial for projects in regions with extreme weather conditions, ensuring that the moulding retains its shape and integrity over time.

6. Environmental Impact

Many polyurethane moulding products are designed to be eco-friendly, often made with recyclable materials. This is becoming increasingly important for companies looking to enhance their sustainability credentials. B2B buyers should consider the environmental impact of the products they choose, as this can influence brand reputation and compliance with regulations.

What Are Common Trade Terms in Polyurethane Moulding?

Familiarity with industry terminology is crucial for effective communication and negotiation in the polyurethane moulding sector. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of polyurethane moulding, understanding OEM relationships can help buyers identify reliable sources for custom or branded products.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to manage inventory effectively and ensure that purchasing aligns with project demands without incurring excess costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products. This term is vital for buyers looking to compare costs and negotiate better pricing terms, particularly in competitive markets.

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding these terms is crucial for B2B buyers involved in cross-border transactions to ensure clarity in logistics and cost management.

5. Lead Time

Lead time is the period between the initiation of an order and the delivery of the product. Awareness of lead times helps buyers plan their projects effectively, ensuring that materials arrive when needed to avoid delays.

6. Customization

Customization refers to the ability to tailor products to meet specific requirements. For polyurethane moulding, this can include unique designs or sizes, allowing businesses to differentiate their offerings and better serve their clients’ needs.

Understanding these properties and terms can significantly enhance decision-making processes for B2B buyers in the polyurethane moulding market, ensuring they select the right products for their projects while navigating industry complexities with confidence.

Navigating Market Dynamics and Sourcing Trends in the polyurethane moulding Sector

What Are the Key Drivers and Trends Shaping the Polyurethane Moulding Market?

The polyurethane moulding sector is witnessing significant growth fueled by various global drivers. One of the primary factors is the increasing demand for lightweight and durable construction materials across diverse industries, including architecture, automotive, and consumer goods. With the rise of urbanization and infrastructure development, particularly in regions such as Africa, South America, and the Middle East, the need for innovative building solutions is paramount.

Illustrative image related to polyurethane moulding

Emerging technologies are also transforming sourcing strategies within the industry. Digital platforms and e-commerce solutions are streamlining procurement processes, making it easier for international buyers to access a variety of suppliers. Additionally, automation in manufacturing is enhancing production efficiency while reducing costs. Companies are increasingly adopting just-in-time inventory management to minimize storage expenses and respond swiftly to market demands.

In regions like Europe, sustainability is becoming a critical consideration. Buyers are seeking suppliers who can provide eco-friendly polyurethane moulding options, driven by stricter regulations and consumer preference for green building materials. This creates opportunities for suppliers to differentiate themselves by offering sustainable products that meet ethical sourcing standards.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in Polyurethane Moulding?

Sustainability is a crucial concern for B2B buyers in the polyurethane moulding sector. The environmental impact of sourcing and manufacturing practices can significantly affect a company’s reputation and marketability. Buyers should prioritize suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials and reducing waste in production.

Additionally, ethical supply chains are becoming increasingly important. Transparency in sourcing can help buyers mitigate risks associated with labor practices and environmental degradation. Certifications such as LEED (Leadership in Energy and Environmental Design) and ISO 14001 (Environmental Management) are valuable indicators of a supplier’s commitment to sustainable practices.

As the demand for environmentally friendly materials rises, polyurethane moulding options that are water-resistant, lightweight, and versatile will become increasingly sought after. Buyers should also consider the lifecycle impact of products, from production to disposal, ensuring they align with their sustainability goals.

What Is the Historical Context of Polyurethane Moulding in the B2B Landscape?

The evolution of polyurethane moulding can be traced back to the development of polyurethane itself in the mid-20th century. Initially used for insulation and cushioning, the material’s versatility led to its adoption in various applications, including decorative moulding. Over time, advances in manufacturing techniques, such as injection moulding and CNC machining, have enabled the production of intricate designs that rival traditional materials like wood and plaster.

As industries continue to innovate and adapt to changing market demands, polyurethane moulding has positioned itself as a leading choice for builders and designers. Its lightweight nature, durability, and resistance to moisture make it an attractive option for modern construction, while ongoing research and development are likely to enhance its applications even further.

Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane moulding

-

How do I choose the right polyurethane moulding for my project?

Selecting the appropriate polyurethane moulding requires understanding the specific requirements of your project. Consider factors such as the application area (interior or exterior), design aesthetics, and the environmental conditions (moisture, temperature). Lightweight options are excellent for DIY projects, while moisture-resistant moulding is ideal for areas like bathrooms and kitchens. Additionally, reviewing samples and consulting with suppliers can help ensure you make an informed choice that meets both functional and aesthetic needs. -

What are the advantages of using polyurethane moulding over traditional materials?

Polyurethane moulding offers several benefits compared to traditional materials like wood or plaster. It is lightweight, making installation easier and more cost-effective. Polyurethane is also resistant to moisture, rot, and termites, enhancing durability and longevity. Furthermore, it can be intricately designed using molds, allowing for detailed finishes that are often more affordable than custom woodwork. These properties make polyurethane an excellent choice for both residential and commercial projects. -

What is the minimum order quantity (MOQ) for polyurethane moulding?

Minimum order quantities for polyurethane moulding can vary significantly among suppliers. Typically, MOQs may range from a few pieces to several hundred linear feet, depending on the manufacturer and the specific product line. It’s advisable to communicate directly with suppliers to understand their MOQs and whether they offer flexibility for small orders, especially if you are testing a new product or service. -

How can I vet suppliers of polyurethane moulding for international trade?

To vet suppliers effectively, start by researching their reputation in the industry. Look for reviews, testimonials, and case studies from previous clients. Verify their certifications and compliance with international standards, as well as their experience in exporting to your region. Engaging in direct communication and requesting product samples can also provide insights into their quality and service. Additionally, consider visiting their manufacturing facilities if feasible. -

What payment terms should I expect when sourcing polyurethane moulding internationally?

Payment terms can vary widely based on the supplier’s policies and the nature of the transaction. Common options include upfront payments, partial payments with a deposit, or payment upon delivery. International buyers often use letters of credit or escrow services to ensure secure transactions. It’s crucial to clarify payment terms in advance and ensure they are documented in the contract to avoid misunderstandings. -

How do I ensure quality assurance for my polyurethane moulding orders?

To ensure quality assurance, establish clear specifications and standards with your supplier before placing an order. Request samples to assess material quality, finish, and durability. Many suppliers offer quality control measures, including third-party inspections and certifications. Additionally, consider implementing a quality assurance plan that includes random inspections during production and before shipment to verify that products meet your standards. -

What logistics considerations should I keep in mind when importing polyurethane moulding?

Logistics plays a crucial role in the successful importation of polyurethane moulding. Consider shipping methods (air vs. sea), estimated delivery times, and customs clearance processes. Collaborate with a logistics partner experienced in handling international shipments to navigate tariffs and import regulations specific to your country. Additionally, ensure that the supplier provides proper packaging to protect the moulding during transit. -

Can I customize polyurethane moulding designs to fit my project needs?

Yes, many suppliers offer customization options for polyurethane moulding. You can request specific dimensions, designs, and finishes to align with your project’s requirements. It’s advisable to provide detailed specifications and any design files to facilitate the customization process. Keep in mind that custom orders may have longer lead times and different pricing structures, so it’s essential to discuss these factors with your supplier upfront.

Top 3 Polyurethane Moulding Manufacturers & Suppliers List

1. White River – Urethane Mouldings

Domain: mouldings.com

Registered: 1995 (30 years)

Introduction: This company, White River – Urethane Mouldings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Melton Classics – Architectural Mouldings

Domain: meltonclassics.com

Registered: 1996 (29 years)

Introduction: Architectural Urethane & Polyurethane Mouldings, including Columns, Balustrade, Fiberglass Cornice, Shutters, Pergolas & Arbors, Cast Stone Elements, Millwork & Mouldings, Column Capitals & Bases. Features include: low maintenance, rot-resistant, and durable materials; hundreds of individual mouldings available; custom profiles offered; multi-profile cornice mouldings to reduce installation costs;…

3. Outwater Industries – Resin Artisan Crown Mouldings

Domain: outwater.com

Registered: 1995 (30 years)

Introduction: This company, Outwater Industries – Resin Artisan Crown Mouldings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for polyurethane moulding

In today’s competitive landscape, strategic sourcing of polyurethane moulding presents a unique opportunity for international B2B buyers. The advantages of this material, such as its lightweight nature, moisture resistance, and cost-effectiveness, make it an ideal choice for various applications, from interior design to industrial use. By focusing on suppliers that prioritize sustainability and quality, businesses can ensure they are not only meeting their immediate needs but also contributing to a more environmentally responsible industry.

Buyers from regions like Africa, South America, the Middle East, and Europe should leverage the growing market for polyurethane moulding to enhance their product offerings and streamline their supply chains. Establishing relationships with reliable manufacturers can lead to better pricing, improved product availability, and innovative design solutions tailored to specific market demands.

Illustrative image related to polyurethane moulding

Looking ahead, the polyurethane moulding sector is poised for significant growth as demand increases for versatile and sustainable building materials. Now is the time for B2B buyers to engage with suppliers and explore how polyurethane moulding can elevate their projects and drive profitability. Embrace this opportunity to differentiate your business and secure a competitive edge in the marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.