A B2B Buyer’s Guide to C&M Wire And Rope: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for c&m wire and rope

In an increasingly interconnected world, sourcing high-quality C&M wire and rope products presents a formidable challenge for B2B buyers, especially in emerging markets across Africa, South America, the Middle East, and Europe. With diverse applications ranging from construction and mining to marine and transportation, the need for reliable wire rope solutions is paramount. This guide serves as a comprehensive resource to navigate the complexities of the global wire and rope market, providing insights into various types of products, their applications, and the nuances of supplier vetting.

International buyers often face hurdles such as fluctuating costs, varying quality standards, and the necessity for customized solutions to meet specific operational demands. By equipping you with essential knowledge regarding product specifications, supplier capabilities, and industry best practices, this guide empowers informed purchasing decisions. It delves into critical aspects such as cost analysis, supplier evaluation methods, and sustainable practices within the wire and rope sector.

Whether you are a buyer in Vietnam seeking durable wire solutions or a procurement manager in Nigeria looking for reliable suppliers, this guide offers actionable insights tailored to your unique market conditions. Embrace the opportunity to enhance your procurement strategy and ensure that your projects are supported by the best wire and rope solutions available globally.

Understanding c&m wire and rope Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Wire Rope | High tensile strength, corrosion resistance, various diameters | Construction, mining, oil and gas | Pros: Excellent load capacity, durability. Cons: Heavier than alternatives, potential for rust without proper maintenance. |

| Stainless Steel Wire Rope | Corrosion-resistant, aesthetic finish, non-magnetic | Marine applications, food processing | Pros: Superior corrosion resistance, longevity. Cons: Higher cost compared to regular steel. |

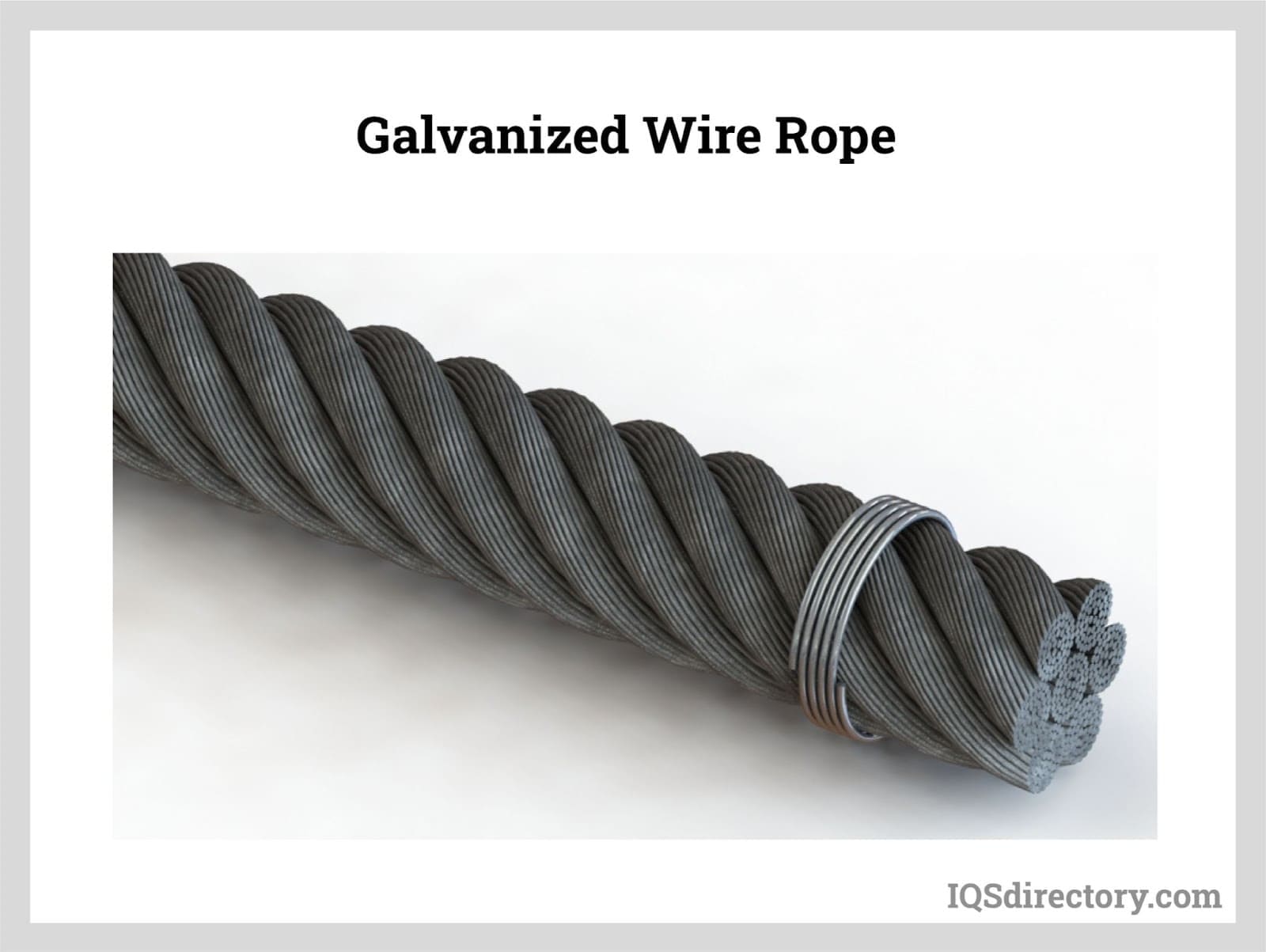

| Galvanized Wire Rope | Coated with zinc for enhanced corrosion protection | Outdoor construction, scaffolding | Pros: Cost-effective, good protection against rust. Cons: Coating may wear over time, leading to potential corrosion. |

| Non-Rotating Wire Rope | Designed to maintain orientation, reduces torque | Cranes, hoists, and rigging applications | Pros: Improved safety, easier handling. Cons: More complex to manufacture, potentially higher cost. |

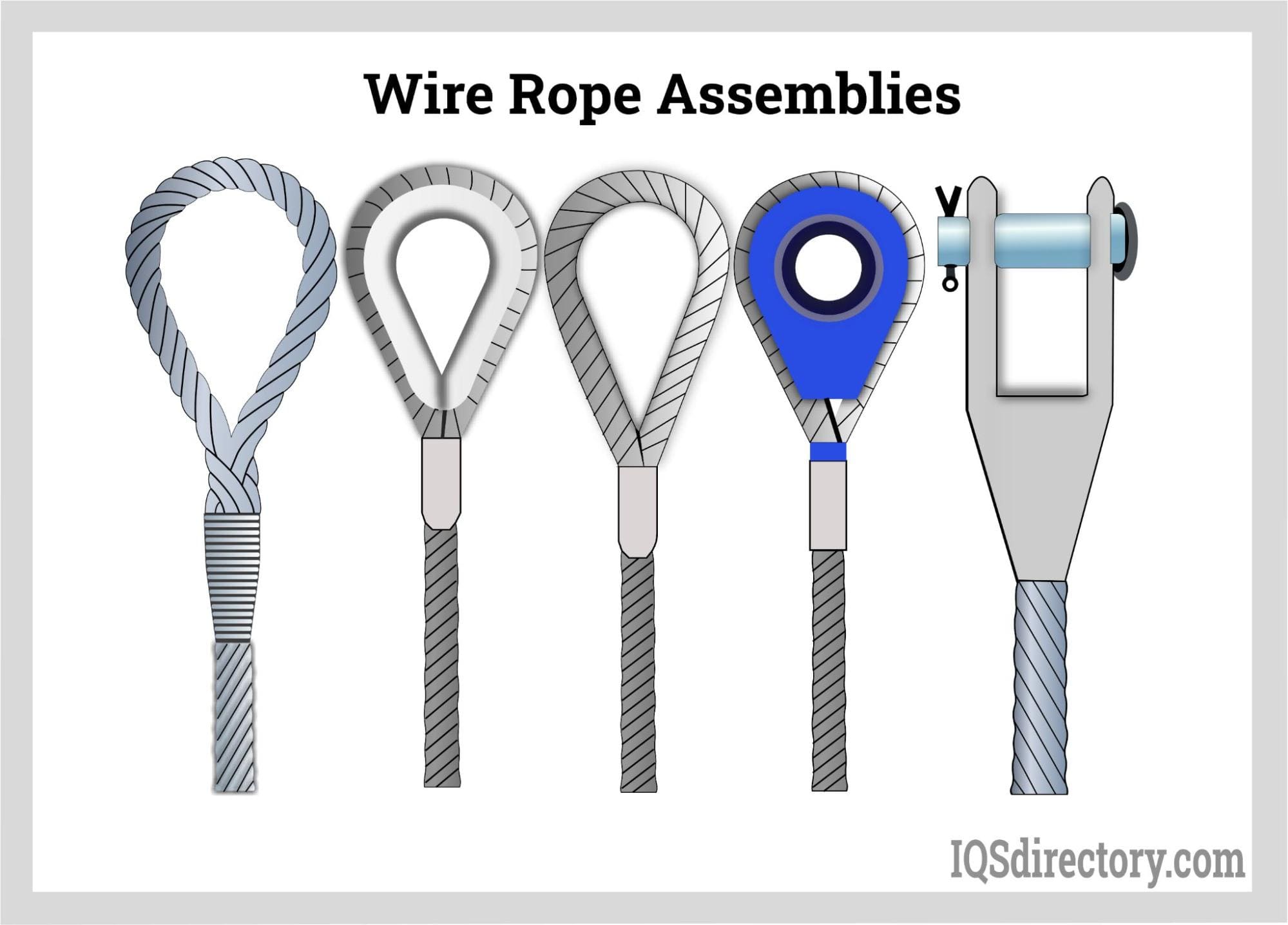

| Wire Rope Assemblies | Includes wire rope with end fittings for specific uses | Lifting and hoisting operations | Pros: Customizable for specific applications, ready-to-use. Cons: Requires accurate specifications to avoid mismatches. |

What are the Key Characteristics of Steel Wire Rope?

Steel wire rope is renowned for its high tensile strength and versatility. It is made from multiple strands of steel wires twisted together, providing exceptional load-bearing capabilities. This type of wire rope is widely used in industries such as construction, mining, and oil and gas, where heavy lifting is common. When purchasing steel wire rope, buyers should consider factors such as diameter, construction type, and the specific load requirements of their applications. Regular maintenance is essential to prevent rust and ensure longevity.

How Does Stainless Steel Wire Rope Differ from Other Types?

Stainless steel wire rope is distinct for its resistance to corrosion and aesthetic appeal. It is often used in marine applications and environments where exposure to moisture is prevalent, such as food processing facilities. The longevity and durability of stainless steel wire rope make it a popular choice despite its higher price point compared to carbon steel options. Buyers should evaluate the cost against the expected lifespan and maintenance needs to determine if it fits their project requirements.

Why Choose Galvanized Wire Rope for Outdoor Applications?

Galvanized wire rope is coated with zinc to enhance its resistance to corrosion, making it ideal for outdoor construction and scaffolding projects. This type offers a balance between performance and cost, as it is generally more affordable than stainless steel while still providing adequate protection against rust. However, buyers should be aware that the zinc coating can wear over time, necessitating periodic inspections to ensure the rope’s integrity remains intact.

Illustrative image related to c&m wire and rope

What Advantages Does Non-Rotating Wire Rope Offer?

Non-rotating wire rope is specifically engineered to reduce torque, which is crucial in applications involving cranes and hoists. This feature enhances safety and ease of handling, making it a preferred choice in environments where precise control is necessary. While it may be more complex to manufacture and potentially more costly than standard wire ropes, the benefits in operational efficiency and safety can justify the investment for many businesses.

How Do Wire Rope Assemblies Enhance Operational Efficiency?

Wire rope assemblies integrate wire rope with end fittings tailored for specific lifting and hoisting tasks. These ready-to-use solutions streamline operations by eliminating the need for separate component purchases and assembly. Buyers should ensure accurate specifications to avoid mismatches that could lead to safety hazards or operational inefficiencies. The customization options available for wire rope assemblies make them a versatile choice for a wide range of industrial applications.

Key Industrial Applications of c&m wire and rope

| Industry/Sector | Specific Application of c&m wire and rope | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Hoisting and lifting heavy materials | Enhances efficiency and safety in construction projects | Ensure compliance with local safety standards and load ratings |

| Mining | Cable support for drilling and extraction | Increases operational reliability and reduces downtime | Look for corrosion-resistant materials for harsh environments |

| Marine | Mooring and towing operations | Provides secure anchoring and towing capabilities | Consider saltwater corrosion resistance and breaking strength |

| Oil and Gas | Rigging and lifting equipment for offshore rigs | Improves safety and efficiency in oil extraction | Verify certifications and testing standards for high-stress applications |

| Transportation | Load securing for freight and cargo | Minimizes damage during transit and ensures safety | Assess compatibility with various cargo types and weights |

How is C&M Wire and Rope Utilized in Construction Projects?

In the construction industry, C&M wire and rope are critical for hoisting and lifting heavy materials such as steel beams and concrete blocks. These products enhance operational efficiency and safety, allowing construction teams to manage heavy loads effectively. Buyers in this sector should prioritize sourcing wire ropes that comply with local safety standards and load ratings to avoid accidents and ensure project timelines are met.

What Role Does C&M Wire and Rope Play in Mining Operations?

Mining operations heavily rely on C&M wire and rope for cable support in drilling and extraction processes. These wire ropes are designed to withstand extreme tension and harsh conditions, thus increasing operational reliability and minimizing downtime. For international buyers, particularly from regions with challenging mining environments, it is essential to select corrosion-resistant materials that can endure exposure to various chemicals and weather conditions.

Illustrative image related to c&m wire and rope

How is C&M Wire and Rope Essential for Marine Applications?

In the marine sector, C&M wire and rope are used for mooring and towing operations, providing secure anchoring and towing capabilities for vessels. This application is crucial for maintaining safety and stability in maritime operations. Buyers should consider the saltwater corrosion resistance of the wire ropes, as well as their breaking strength, to ensure they can handle the demanding marine environment.

Why is C&M Wire and Rope Important in Oil and Gas Industries?

For the oil and gas industry, C&M wire and rope are integral for rigging and lifting equipment on offshore rigs. These wire ropes must meet stringent safety and performance standards to ensure safe operations in high-stress conditions. Buyers should verify that the products sourced have the necessary certifications and testing standards, particularly for applications involving heavy lifting and dynamic loads.

How Does C&M Wire and Rope Contribute to Transportation Logistics?

In transportation, C&M wire and rope are utilized for securing loads during freight and cargo transit. This application minimizes the risk of damage to goods and enhances safety during transport. Buyers should assess the compatibility of wire ropes with various cargo types and weights, ensuring that the selected products are suitable for the specific transportation methods employed, whether by land, sea, or air.

Illustrative image related to c&m wire and rope

3 Common User Pain Points for ‘c&m wire and rope’ & Their Solutions

Scenario 1: Inadequate Load Capacity for Heavy Applications

The Problem: B2B buyers in industries such as construction, mining, or oil and gas often face the challenge of selecting wire rope products that can withstand heavy loads. Many buyers may choose products based solely on price, overlooking critical specifications like load capacity and safety factors. This oversight can lead to catastrophic failures, risking not just equipment but also worker safety and project timelines.

The Solution: To ensure that you select wire rope with adequate load capacity, start by conducting a thorough assessment of the loads your operations require. Consult with manufacturers like C&M Wire Rope & Supply to understand the specifications of their various wire rope products, including tensile strength and diameter. It’s crucial to consider not just the maximum load, but also the conditions of use, such as dynamic loading scenarios or exposure to corrosive environments. Additionally, engage with experienced engineers to tailor a wire rope solution that meets your specific operational demands, ensuring compliance with industry safety standards.

Scenario 2: Difficulty in Customizing Wire Rope for Unique Applications

The Problem: Many B2B buyers encounter challenges when trying to customize wire rope products for specialized applications, such as marine environments or unique machinery. Off-the-shelf solutions often do not meet specific requirements for length, diameter, or type of coating, leading to inefficiencies and increased operational risks.

The Solution: When seeking customized wire rope solutions, work closely with manufacturers like C&M Wire Rope & Supply, which specializes in tailoring products to meet unique specifications. Clearly communicate your operational needs, including environmental conditions and specific load requirements. Consider requesting prototypes or samples before committing to a bulk order, allowing you to test the wire rope in real-world conditions. Furthermore, inquire about additional services such as splicing and swaging, which can provide further customization and ensure that the wire rope assembly is optimized for your application.

Scenario 3: Lack of Maintenance and Inspection Protocols

The Problem: Another common pain point for B2B buyers is the lack of a structured maintenance and inspection protocol for wire rope products. Over time, wear and tear can compromise the integrity of wire ropes, leading to unexpected failures that can halt operations and result in costly downtime.

The Solution: Establishing a robust maintenance and inspection protocol is essential for extending the life of your wire rope products. Collaborate with suppliers like C&M Wire Rope & Supply to create a maintenance schedule that includes regular inspections and testing. Implement a checklist that covers visual inspections for signs of fraying, corrosion, or deformation, and ensure that trained personnel conduct these assessments. Additionally, consider investing in training programs for your team, focusing on best practices for wire rope handling and maintenance. Regularly updating your inventory with certified products and adhering to inspection protocols can significantly mitigate risks and enhance operational efficiency.

Strategic Material Selection Guide for c&m wire and rope

What Are the Key Materials Used in C&M Wire and Rope?

When selecting materials for c&m wire and rope, understanding the properties, advantages, and limitations of each option is crucial for ensuring optimal performance in various applications. Here, we analyze four common materials: steel, stainless steel, galvanized steel, and synthetic fibers.

How Does Steel Perform in C&M Wire and Rope Applications?

Steel is the most commonly used material for wire ropes due to its high tensile strength and durability. It typically withstands extreme temperatures and pressures, making it suitable for heavy-duty applications in construction, mining, and marine environments. However, while steel wire ropes are robust, they are susceptible to corrosion if not properly treated.

Illustrative image related to c&m wire and rope

Pros: High strength, excellent load-bearing capacity, and versatility in various applications.

Cons: Prone to rusting without protective coatings, heavier than alternatives, and can be less flexible.

Impact on Application: Steel wire ropes are ideal for lifting and hoisting applications but may require additional coatings or treatments for environments with high moisture or corrosive elements.

International Considerations: Buyers should ensure compliance with standards such as ASTM A1023/A1023M for wire ropes and consider local regulations regarding material specifications.

What Advantages Does Stainless Steel Offer for C&M Wire and Rope?

Stainless steel wire ropes are renowned for their corrosion resistance, making them suitable for marine and chemical applications. They maintain their strength and integrity even in harsh environments, which is a significant advantage for industries operating in coastal or chemically aggressive settings.

Pros: Exceptional corrosion resistance, aesthetic appeal, and good tensile strength.

Cons: Higher cost compared to carbon steel, and may not have the same load capacity as standard steel ropes.

Impact on Application: Ideal for applications requiring exposure to saltwater or chemicals, such as in the oil and gas sector.

International Considerations: Buyers should verify compliance with international standards such as ISO 10425 for stainless steel wire ropes, which may vary by region.

Why Choose Galvanized Steel for C&M Wire and Rope?

Galvanized steel wire ropes are coated with a layer of zinc to enhance their corrosion resistance. This makes them a cost-effective alternative to stainless steel, especially in environments where exposure to moisture is a concern. They provide a good balance between performance and price.

Pros: Cost-effective, good corrosion resistance, and retains strength similar to carbon steel.

Cons: The zinc coating can wear off over time, leading to potential corrosion issues, and they can be heavier than synthetic alternatives.

Impact on Application: Suitable for outdoor applications and industries like construction and agriculture, where exposure to moisture is common.

International Considerations: Ensure adherence to standards such as ASTM A475 for galvanized wire ropes, which is critical for international buyers.

What Role Do Synthetic Fibers Play in C&M Wire and Rope?

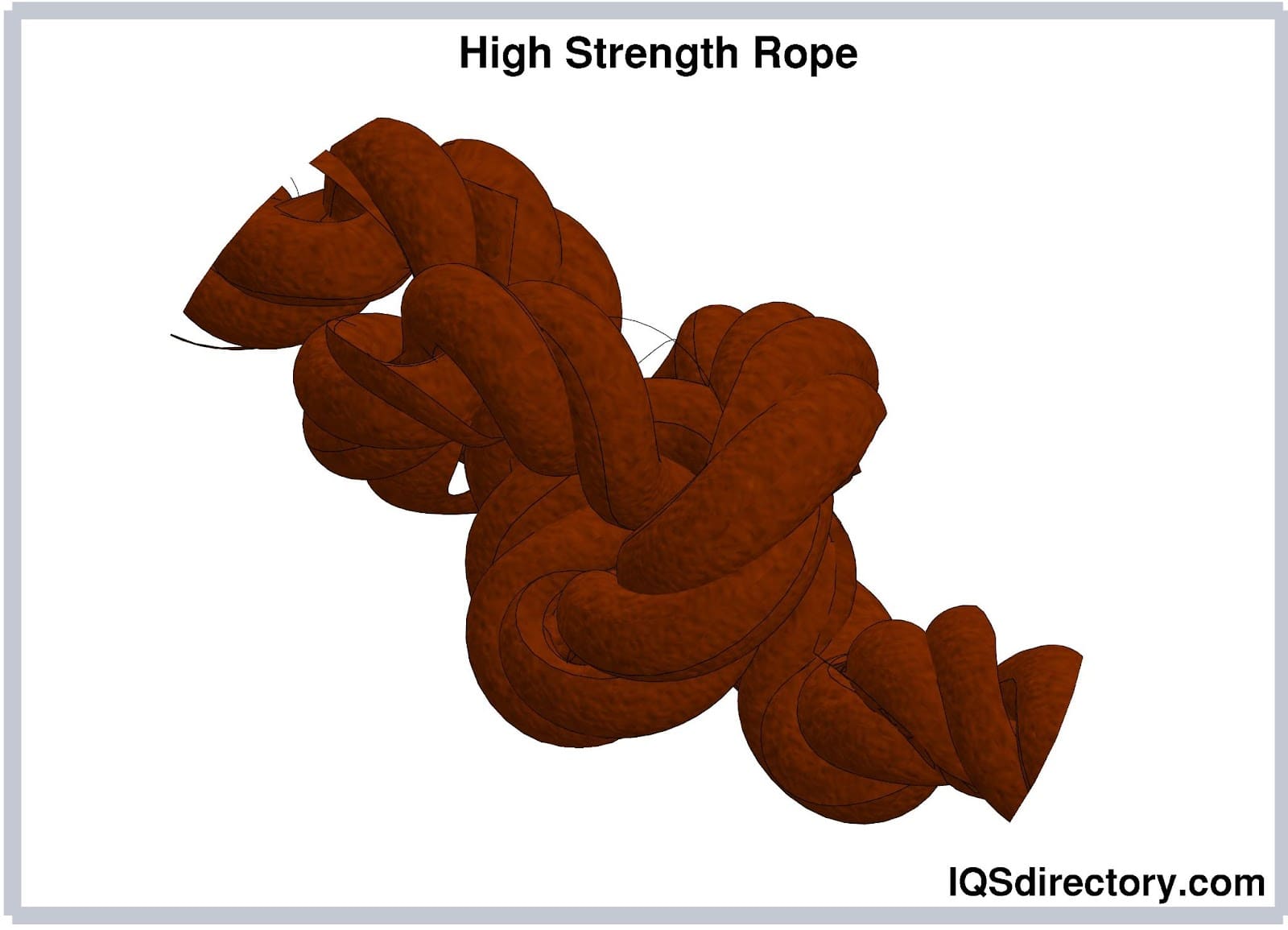

Synthetic fibers, such as nylon and polyester, have gained popularity due to their lightweight and high flexibility. They are often used in applications where weight is a critical factor, such as in aerial lifts or climbing gear. Synthetic ropes are also resistant to UV rays and moisture.

Pros: Lightweight, flexible, and resistant to UV and chemical degradation.

Cons: Lower tensile strength compared to steel options, and can be more susceptible to abrasion.

Impact on Application: Ideal for applications requiring high flexibility and low weight, such as in recreational or rescue operations.

International Considerations: Buyers should check for compliance with standards like EN 1891 for ropes used in climbing and rescue operations, ensuring safety and reliability.

Summary Table of Material Selection for C&M Wire and Rope

| Material | Typical Use Case for c&m wire and rope | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty lifting and hoisting | High strength and durability | Prone to corrosion | Medium |

| Stainless Steel | Marine and chemical applications | Exceptional corrosion resistance | Higher cost | High |

| Galvanized Steel | Outdoor construction and agriculture | Cost-effective corrosion resistance | Zinc coating may wear off | Medium |

| Synthetic Fibers | Aerial lifts and recreational gear | Lightweight and flexible | Lower tensile strength | Low |

This guide provides a comprehensive overview of material options for c&m wire and rope, enabling international B2B buyers to make informed decisions tailored to their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for c&m wire and rope

What Are the Key Stages in the Manufacturing Process of C&M Wire and Rope?

The manufacturing process of C&M wire and rope involves several critical stages, each designed to ensure the final product meets the rigorous demands of various industries such as construction, mining, and marine applications.

1. Material Preparation

The first step is material preparation, where high-quality steel or stainless steel wire is sourced. This wire must meet specific tensile strength and ductility requirements to ensure it can withstand heavy loads and harsh conditions. Suppliers often conduct thorough inspections of the raw materials, verifying that they comply with industry standards. The wires are then cleaned and coated if necessary, with options like galvanization to enhance corrosion resistance.

2. Forming

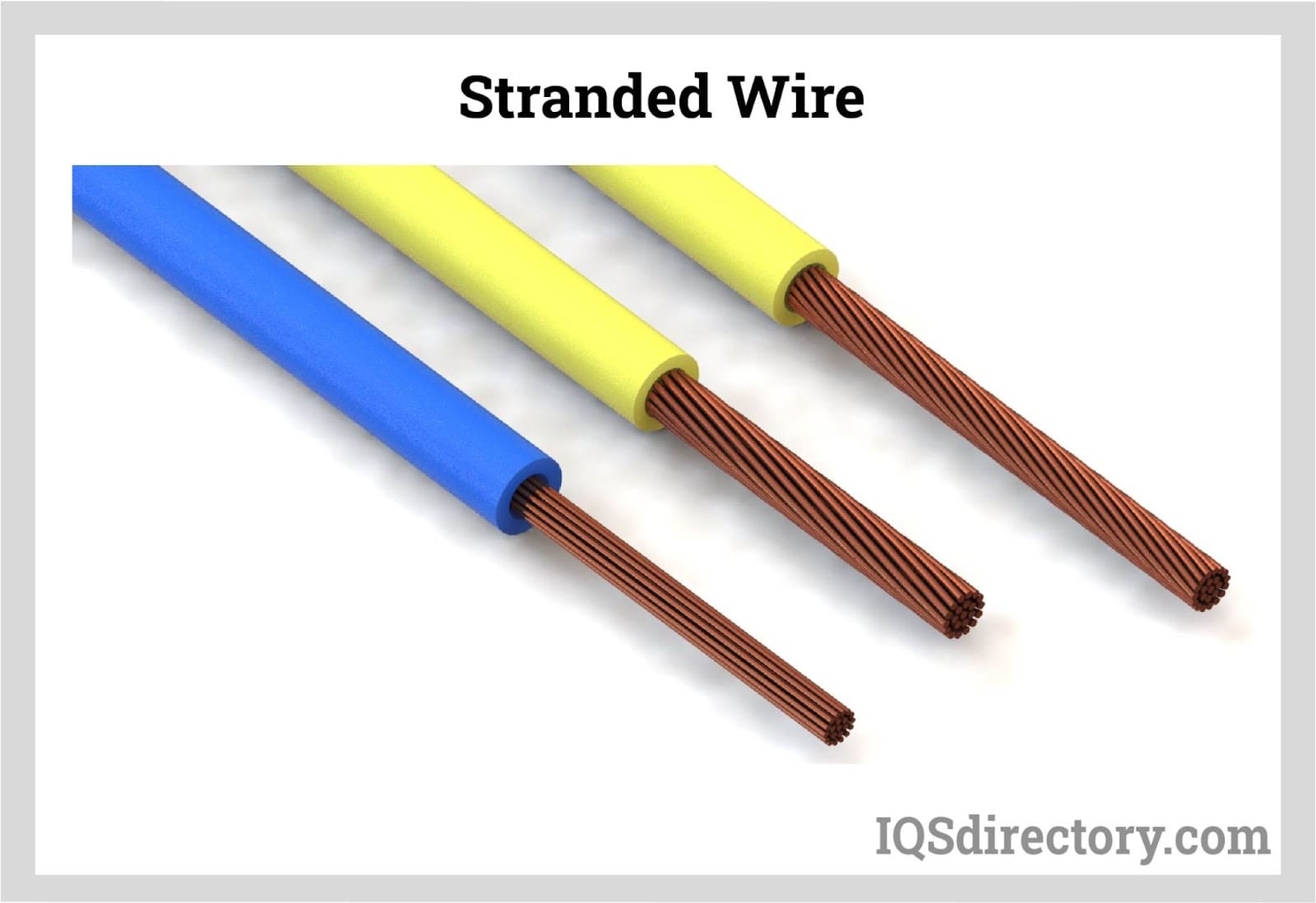

Once the materials are prepared, the forming process begins. This involves twisting multiple strands of wire together to create the wire rope. Techniques such as strand laying or braiding are employed, depending on the desired characteristics of the final product. For instance, non-rotating wire ropes require precise stranding to prevent torque buildup. Advanced machinery is often used to maintain uniformity and precision throughout this stage.

3. Assembly

Following the forming process, the wire rope is assembled with various end fittings and terminals. This step is crucial as it determines how the wire rope will interact with other machinery or components. Customization is common, allowing B2B buyers to specify lengths, diameters, and fitting types tailored to their applications. This flexibility is a significant advantage for international buyers who may have unique requirements based on local standards or specific project needs.

4. Finishing

The final stage is finishing, where the assembled wire rope undergoes treatments to improve performance characteristics. This can include additional coatings for enhanced durability or specific finishes that reduce friction. Quality checks are performed at this stage to ensure that the wire rope meets all specifications before moving on to the quality assurance process.

How Is Quality Assurance Implemented in C&M Wire and Rope Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of wire and rope products, particularly given the safety-critical applications in which they are used. Various international standards and industry-specific certifications guide the QA processes.

Relevant International Standards and Certifications

International standards such as ISO 9001 set the framework for quality management systems, ensuring that manufacturers maintain consistent quality throughout their processes. Additionally, industry-specific certifications like CE marking for European markets and API (American Petroleum Institute) standards for oil and gas applications provide further assurance of product safety and reliability.

Key Quality Control Checkpoints

Quality control (QC) is integrated at multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials for compliance with specifications. Material certificates and test reports are often required from suppliers.

-

In-Process Quality Control (IPQC): During the manufacturing process, operators conduct regular checks to monitor critical parameters, such as wire tension and stranding accuracy, ensuring that any deviations are addressed promptly.

-

Final Quality Control (FQC): Before the wire rope is packaged and shipped, a comprehensive final inspection is conducted. This includes testing for tensile strength, flexibility, and other performance metrics, typically using standardized testing methods.

What Testing Methods Are Commonly Used for C&M Wire and Rope Products?

To verify the quality and safety of wire and rope products, several testing methods are employed:

-

Tensile Testing: This method measures the strength of the wire rope under load, ensuring it can withstand the specified weight limits.

-

Fatigue Testing: This assesses how the wire rope performs under repeated loading and unloading, simulating real-world conditions.

-

Bending and Abrasion Tests: These tests evaluate the wire rope’s flexibility and resistance to wear, crucial for applications where the rope will be subject to movement and friction.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality assurance practices of their suppliers.

Conducting Audits and Assessments

One of the most effective ways to ensure supplier quality is to conduct regular audits. This can be done through on-site visits or by requesting detailed reports on quality control processes. Additionally, engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing and QA practices.

Requesting Documentation and Certifications

B2B buyers should request all relevant documentation, including:

-

Certificates of Compliance: These documents confirm that products meet specific standards and regulations.

-

Quality Control Reports: Regular QC reports provide insights into the testing results and any corrective actions taken by the manufacturer.

-

Audit Reports: If available, these reports can show the outcomes of previous audits, highlighting areas of compliance and potential risks.

What Are the Quality Control Nuances for International Buyers?

For international buyers, understanding the nuances of quality control in wire and rope manufacturing is essential. Different regions may have varying requirements and standards, making it crucial for buyers to familiarize themselves with both local and international regulations.

Illustrative image related to c&m wire and rope

Navigating Regional Standards

For example, while ISO standards are widely recognized, specific industries may have additional local certifications that must be adhered to. Buyers should also be aware of the logistical challenges that can affect product quality, such as shipping conditions and customs regulations, which may impact the integrity of the wire and rope upon arrival.

By understanding these factors and actively engaging with suppliers about their manufacturing and quality assurance processes, international B2B buyers can make informed decisions, ensuring that they receive high-quality wire and rope products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘c&m wire and rope’

To assist international B2B buyers in sourcing C&M wire and rope, this guide provides a structured approach that emphasizes key considerations throughout the procurement process. By following this checklist, you can ensure that your sourcing decisions are informed, efficient, and tailored to your specific needs.

Illustrative image related to c&m wire and rope

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical requirements for the wire and rope products you need. This includes specifications such as material type (e.g., steel, stainless steel, galvanized), diameter, length, and load capacity. Precise specifications help streamline communication with suppliers and ensure that the products meet your operational requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of C&M wire and rope. Look for manufacturers with a strong track record and positive customer reviews. Utilize industry directories, trade shows, and online platforms to compile a list of potential suppliers, focusing on those with experience in your specific industry.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications and comply with industry standards. Certifications such as ISO 9001 for quality management and ISO 14001 for environmental management demonstrate a commitment to quality and sustainability. This step is crucial for ensuring that the products you procure are reliable and safe for use.

Step 4: Request Samples and Technical Data

Once you have narrowed down your list of suppliers, request product samples and technical data sheets. Evaluate the quality of the materials and the precision of manufacturing. Analyze the samples in the context of your project requirements to ensure they meet your expectations for performance and durability.

Step 5: Assess Customization Capabilities

Many projects require customized solutions to address specific challenges. Inquire about the supplier’s ability to provide tailored wire and rope products, such as unique lengths, coatings, or fittings. A supplier that offers customization can better meet your needs and enhance the functionality of your procurement.

Illustrative image related to c&m wire and rope

Step 6: Review Pricing and Payment Terms

Carefully evaluate pricing structures and payment terms from shortlisted suppliers. Compare quotes while considering factors such as bulk discounts, delivery costs, and payment flexibility. Transparent pricing helps avoid unexpected costs and ensures that you stay within budget.

Step 7: Establish Communication Channels

Effective communication is vital throughout the sourcing process. Establish clear channels for ongoing dialogue with your chosen supplier. Regular updates on production timelines, shipment tracking, and any potential issues will facilitate smoother transactions and foster a strong working relationship.

By following this practical sourcing guide, B2B buyers can navigate the complexities of procuring C&M wire and rope products with confidence, ensuring they meet their operational needs while fostering sustainable and reliable supplier partnerships.

Comprehensive Cost and Pricing Analysis for c&m wire and rope Sourcing

Understanding the cost structure and pricing dynamics for C&M wire and rope sourcing is essential for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. This analysis delves into the critical components of costs, the various factors influencing pricing, and offers strategic tips for buyers to optimize their procurement processes.

What Are the Key Cost Components in C&M Wire and Rope Manufacturing?

-

Materials: The primary cost driver in wire and rope manufacturing is the raw materials used. Steel, stainless steel, and specialized coatings significantly impact pricing. Fluctuations in global metal prices can affect overall costs, making it crucial for buyers to stay informed about market trends.

-

Labor: Labor costs include wages for skilled technicians and engineers who ensure high-quality production standards. Companies that offer customization options may incur higher labor costs due to the specialized skill sets required for design and manufacturing.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, including utilities, maintenance, and administrative costs. Efficient manufacturing processes can help mitigate these costs, impacting the final price point for buyers.

-

Tooling: Investment in tooling and machinery is necessary for producing various wire and rope specifications. Advanced machinery can enhance production efficiency but comes with higher initial costs that may be passed on to buyers.

-

Quality Control (QC): Ensuring that wire and rope products meet industry standards requires a robust QC process. Costs associated with testing and certification can influence pricing, particularly for products intended for critical applications in sectors like construction and marine.

-

Logistics: Shipping and handling costs play a significant role in the final pricing, especially for international buyers. Factors such as distance, shipping method, and customs duties must be considered to avoid unexpected expenses.

-

Margin: Manufacturers typically include a profit margin in their pricing structure. This margin can vary based on market competition, product demand, and the level of customization required.

How Do Price Influencers Affect C&M Wire and Rope Procurement?

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes generally lead to lower per-unit costs. Buyers should negotiate MOQs that align with their purchasing capabilities to optimize pricing.

-

Specifications and Customization: Customized products often come at a premium. Understanding the specific needs and balancing them with cost considerations is vital for effective procurement.

-

Quality and Certifications: Products with industry certifications (e.g., ISO, ASTM) often command higher prices due to the assurance of quality and safety. Buyers must evaluate whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a proven track record may charge higher prices due to their perceived value, while newer suppliers may offer competitive rates to build their client base.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, which can significantly affect total costs.

What Are the Best Practices for Negotiating C&M Wire and Rope Prices?

-

Research and Benchmarking: Buyers should conduct market research to understand prevailing prices and identify competitive offers. This knowledge empowers them during negotiations.

-

Total Cost of Ownership (TCO): Instead of focusing solely on the upfront cost, buyers should consider the TCO, which includes maintenance, operational costs, and potential downtime. This approach provides a clearer picture of long-term value.

-

Leverage Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often yield benefits such as loyalty discounts and improved service.

-

Be Transparent About Needs: Clearly communicating specific requirements and volume forecasts to suppliers can help them provide tailored pricing and solutions that meet buyer expectations.

-

Flexibility in Payment Terms: Negotiating favorable payment terms can improve cash flow and reduce the financial burden on buyers, making it easier to manage procurement costs.

In conclusion, understanding the comprehensive cost structure, recognizing price influencers, and employing strategic negotiation tactics can significantly enhance the procurement process for C&M wire and rope. International buyers must remain vigilant and informed to secure the best possible outcomes in their sourcing endeavors.

Alternatives Analysis: Comparing c&m wire and rope With Other Solutions

Exploring Alternatives to C&M Wire and Rope: A Comparative Analysis

In the industrial landscape, selecting the right lifting and rigging solution is crucial for ensuring operational efficiency and safety. While C&M wire and rope are renowned for their strength and versatility, it’s essential for B2B buyers to consider alternative solutions that may better suit their specific needs. Below is a comparative analysis of C&M wire and rope against two viable alternatives: synthetic ropes and chain slings.

| Comparison Aspect | C&M Wire And Rope | Synthetic Ropes | Chain Slings |

|---|---|---|---|

| Performance | High tensile strength; durable | Lightweight; flexible; UV resistant | Heavy-duty; excellent load capacity |

| Cost | Moderate to high | Generally lower | Moderate to high |

| Ease of Implementation | Requires specialized fittings; heavier | Easier to handle; often lighter | Requires proper rigging knowledge |

| Maintenance | Regular inspection needed | Minimal maintenance; resistant to wear | Requires periodic checks for wear |

| Best Use Case | Heavy lifting in construction, mining, marine | Lifting in environments with limited space; outdoor applications | Heavy-duty lifting and rigging in industrial settings |

Pros and Cons of Synthetic Ropes as an Alternative

Synthetic ropes, such as those made from nylon or polyester, offer several advantages over traditional wire ropes. They are significantly lighter, making them easier to handle and transport, which can reduce labor costs. Their flexibility allows for use in tight spaces where wire rope may be cumbersome. Additionally, synthetic ropes are resistant to UV damage and chemicals, making them ideal for outdoor applications. However, they have lower tensile strength compared to steel wire ropes and may require more frequent replacement, especially in high-stress applications.

Pros and Cons of Chain Slings as an Alternative

Chain slings provide a robust alternative to wire rope, particularly in heavy-duty applications. They excel in scenarios requiring high load capacities and are not susceptible to abrasion, making them ideal for rugged environments. Chain slings also feature adjustable lengths, providing flexibility in lifting operations. However, they tend to be heavier and may require more extensive training for safe and effective use. Maintenance involves regular inspections to check for wear and damage, which can be more intensive compared to synthetic options.

Illustrative image related to c&m wire and rope

Making the Right Choice for Your Needs

When selecting between C&M wire and rope and its alternatives, B2B buyers should assess their specific operational needs and environmental conditions. Consider factors such as load requirements, the frequency of use, and the working environment. For instance, if weight and flexibility are priorities, synthetic ropes may be more suitable. In contrast, for heavy-duty applications that demand high strength and durability, chain slings or wire rope would be preferable. Ultimately, the best choice will depend on a comprehensive evaluation of performance requirements, cost considerations, and maintenance capabilities, ensuring that the selected solution aligns with the operational goals of the business.

Essential Technical Properties and Trade Terminology for c&m wire and rope

Understanding the essential technical properties and terminology associated with C&M wire and rope is crucial for B2B buyers looking to make informed purchasing decisions. This section outlines key specifications and common trade jargon that will enhance your understanding of this specialized industry.

What Are the Key Technical Properties of C&M Wire and Rope?

1. Material Grade

The material grade of wire rope significantly impacts its strength and durability. Common materials include steel, stainless steel, and galvanized steel. Each material has unique characteristics; for instance, stainless steel offers enhanced corrosion resistance, making it ideal for marine and industrial applications. Selecting the right material grade ensures the wire rope can withstand the specific environmental conditions it will face.

2. Diameter

The diameter of the wire rope is a critical specification that affects load capacity and flexibility. Larger diameters generally offer increased strength, while smaller diameters provide better maneuverability. Understanding the required diameter for your application helps in selecting a wire rope that meets safety and performance standards.

3. Breaking Strength

Breaking strength refers to the maximum load a wire rope can handle before failure. This specification is vital in ensuring safety in lifting operations. Buyers should always consider the working load limit, which is typically a fraction of the breaking strength, to prevent accidents and equipment failures.

4. Construction Type

Wire ropes can be constructed in various ways, including 6×19, 6×37, and 8×19 configurations. Each construction type offers different benefits in terms of flexibility, abrasion resistance, and fatigue life. Understanding the construction type helps in selecting the most appropriate wire rope for specific applications, such as lifting, towing, or rigging.

Illustrative image related to c&m wire and rope

5. Tolerance

Tolerance in wire rope refers to the allowable deviation in dimensions and properties from specified values. This is important for ensuring compatibility with fittings and hardware. High tolerance levels are particularly crucial in precision applications where safety and performance are paramount.

What Are Common Trade Terminology Terms in the Wire and Rope Industry?

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the wire and rope industry, understanding OEM relationships can help buyers identify trusted suppliers and ensure compatibility with existing equipment.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell in a single order. This term is crucial for B2B buyers as it affects budgeting and inventory management. Understanding MOQ can help businesses plan their purchases effectively and avoid overstocking or stockouts.

Illustrative image related to c&m wire and rope

3. RFQ (Request for Quotation)

An RFQ is a formal document issued by a buyer to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. Using RFQs allows buyers to compare offers and negotiate better terms, ensuring they get the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help B2B buyers understand shipping responsibilities, risk transfer, and cost allocation, which are critical for successful global trade.

5. Certification Standards

Certification standards, such as ISO or ASTM, indicate that products meet specific quality and safety criteria. Buyers should prioritize suppliers that adhere to these standards to ensure product reliability and compliance with industry regulations.

By understanding these technical properties and trade terms, B2B buyers can navigate the complexities of the C&M wire and rope market more effectively, ensuring they make informed decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the c&m wire and rope Sector

What Are the Key Market Drivers and Trends in the C&M Wire and Rope Sector?

The C&M wire and rope sector is experiencing robust growth, driven by several global dynamics. Key industries such as construction, mining, marine, and oil and gas are fueling demand for high-quality wire rope products. The rise of infrastructure projects across Africa, South America, and the Middle East is particularly significant, as countries in these regions invest heavily in modernization and expansion. Additionally, the increasing adoption of automation in industrial processes is leading to a demand for specialized wire rope products that can meet stringent operational requirements.

Emerging technologies are also reshaping sourcing trends. For instance, the integration of digital tools for supply chain management and inventory tracking is becoming commonplace among B2B buyers. This technological shift allows for enhanced transparency and efficiency in sourcing, enabling buyers to make informed decisions based on real-time data. Furthermore, there is a growing trend toward customization, with buyers seeking tailored solutions that address specific operational challenges, such as unique load requirements or environmental conditions.

How Are Sustainability and Ethical Sourcing Transforming the C&M Wire and Rope Sector?

Sustainability is a pivotal consideration for B2B buyers in the C&M wire and rope market. Increasing environmental awareness among consumers and regulatory bodies is prompting companies to adopt more sustainable practices. This includes the use of recycled materials and environmentally friendly manufacturing processes, which can significantly reduce the carbon footprint associated with wire rope production.

Ethical sourcing is equally important, as buyers are increasingly prioritizing suppliers that demonstrate a commitment to social responsibility. This trend is particularly relevant in regions like Africa and South America, where ethical labor practices can influence purchasing decisions. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) are becoming essential benchmarks for suppliers aiming to establish credibility in the marketplace. Buyers are encouraged to seek out manufacturers that not only comply with these standards but also actively participate in initiatives that promote environmental stewardship and community welfare.

How Has the C&M Wire and Rope Sector Evolved Over Time?

The evolution of the C&M wire and rope sector can be traced back to the industrial revolution, when the demand for reliable lifting and support systems surged. Initially, wire ropes were made from natural fibers, but advancements in metallurgy and manufacturing techniques led to the development of steel wire ropes, which offered superior strength and durability. Over the decades, innovations such as the introduction of stainless steel and galvanized coatings have further enhanced the performance and longevity of wire ropes, making them indispensable in various applications.

Today, the sector continues to evolve with a focus on customization and technology integration, allowing manufacturers to cater to specific industry needs. As global markets expand and diversify, the C&M wire and rope sector remains a critical component of industrial infrastructure, adapting to meet the challenges of modern manufacturing and construction demands.

Conclusion

Understanding the dynamics of the C&M wire and rope sector is essential for international B2B buyers looking to make informed sourcing decisions. As market trends shift toward sustainability and customization, companies that embrace these changes will not only enhance their competitive edge but also contribute positively to the environment and society. By prioritizing ethical sourcing and leveraging technology, buyers can ensure they are well-positioned to navigate the complexities of this evolving industry.

Illustrative image related to c&m wire and rope

Frequently Asked Questions (FAQs) for B2B Buyers of c&m wire and rope

-

How do I choose the right type of wire rope for my application?

Choosing the right wire rope depends on several factors, including the load capacity, environmental conditions, and specific application requirements. Consider the material—steel, stainless steel, or galvanized wire rope—based on corrosion resistance needs. Evaluate the rope construction, such as stranded or braided, for flexibility and strength. Additionally, consulting with suppliers who offer customization can help tailor the specifications to your project’s unique demands, ensuring optimal performance and safety. -

What are the key considerations for international shipping of wire rope products?

When shipping wire rope internationally, it’s crucial to understand customs regulations, import duties, and shipping costs. Ensure that your supplier provides all necessary documentation, such as certificates of origin and compliance. Additionally, consider the logistics provider’s experience with heavy and bulk shipments, as well as their ability to handle specific regional challenges. Timely communication with your supplier about shipping timelines and tracking is essential to avoid delays in your supply chain. -

What is the minimum order quantity (MOQ) for wire rope products?

Minimum order quantities for wire rope can vary widely among suppliers. Typically, MOQs depend on the type of wire rope, customization requirements, and production capabilities of the manufacturer. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms. Some suppliers may offer flexibility on MOQs for repeat customers or larger contracts, so establishing a long-term relationship can be beneficial. -

What payment terms should I expect when sourcing wire rope internationally?

Payment terms in international B2B transactions can range from upfront payments to net 30 or net 60 days after delivery. Common methods include wire transfers, letters of credit, and payment platforms like PayPal or escrow services. Discussing payment terms upfront with suppliers is essential to ensure both parties are comfortable and protected. Be aware of potential foreign exchange risks and fees, especially when dealing with suppliers in different currencies. -

How can I ensure the quality of wire rope products before purchasing?

To ensure quality, request certifications and test reports from suppliers that verify compliance with industry standards. It’s beneficial to review product samples, if possible, and inquire about the manufacturing process, including any quality control measures in place. Some suppliers may offer third-party testing services to validate the integrity of their products. Establishing a clear understanding of warranty and return policies can also safeguard your investment. -

What customization options are available for wire rope products?

Many manufacturers offer customization options for wire rope, including specific lengths, diameters, and coatings tailored to your application needs. You can also request additional features such as specialized fittings or end terminations. Engaging directly with the supplier’s engineering team can provide insights into the best solutions for your application. Custom solutions often enhance performance and safety, particularly in demanding environments. -

How can I vet a wire rope supplier before making a purchase?

Vetting a wire rope supplier involves assessing their experience, reputation, and financial stability. Check references and reviews from previous clients to gauge their reliability and service quality. It’s also advisable to confirm their certifications and compliance with international standards. If possible, visit their facility or request a virtual tour to inspect their manufacturing processes and capabilities, ensuring they align with your expectations. -

What industries commonly use wire rope, and how can that inform my purchase?

Wire rope is widely used in industries such as construction, mining, oil and gas, and marine applications. Understanding the specific requirements and standards of your industry can inform your purchasing decision, ensuring you select the right product for your needs. For example, marine applications may require corrosion-resistant materials, while construction may prioritize tensile strength. Engaging with suppliers familiar with your industry can provide valuable insights and tailored recommendations.

Top 5 C&M Wire And Rope Manufacturers & Suppliers List

1. C & M Wire Rope Supply Co – Construction Equipment

Domain: constructionequipment.com

Registered: 1995 (30 years)

Introduction: This company, C & M Wire Rope Supply Co – Construction Equipment, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. C & M Wire Rope – Industrial Supplies

Domain: app.makersrow.com

Registered: 2012 (13 years)

Introduction: This company, C & M Wire Rope – Industrial Supplies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. American Crane – CM Chain and Wire Rope Products

Domain: store.americancrane.com

Registered: 1996 (29 years)

Introduction: CM Chain and Wire Rope products available at American Crane & Equipment Corp. include various chain loads and components. Key items include: 1. Chain Load 7/16″ C/H D/B – Price: $55.34, Capacity: 2 US t to 7-1/2 US t. 2. Chain Load 1/4″ – Price: $23.32. 3. Chain Load 1/4″ Z/P C/H – Price: $23.09. 4. Chain Load S/S 0.250 – Price: $65.74. 5. Hand Chain Guard – Price: $1.07, Capacity: 3 US t. 6. Hand…

4. ShopMTN – CM Wire Rope Clips

Domain: shopmtn.com

Registered: 2015 (10 years)

Introduction: {“product_name”: “CM Wire Rope Clips”, “product_code”: “M246-2”, “regular_price”: “$20.16”, “size_variants”: [{“size”: “1/4”, “price”: “$20.16”, “sold_in_sets”: true}, {“size”: “3/8”, “price”: “$24.63”, “sold_in_sets”: true}, {“size”: “1/2”, “price”: “$17.60”, “sold_in_sets”: false}], “description”: “Wire Rope Clips are used to secure the end of wire rope when forming a loop for wire rope turn-bac…

5. C&M Corporation – CM-Brake Spline Friction Disc

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: C&M Corporation Other Business & Industrial Equipment includes various products such as: 1. CM-brake spline friction disc for sm frame cm hoist – $60.00 2. CM-FRICTION DISC BRAKE P/N?? – $70.00 3. CM 17-A Anchor Shackle No Bolt – $99.00 4. CM Series Control Unit CM-S4 44536-0040 – $100.00 5. CM HAMMERLOK 3/8″ 10.0MM COUPLING LINK – $22.00 6. CM 4X1304 1-1/8″ Hook Latch Kit, 4,000 Lbs. Load Limit -…

Strategic Sourcing Conclusion and Outlook for c&m wire and rope

As the global demand for high-quality wire rope products continues to rise, strategic sourcing becomes imperative for B2B buyers in industries such as construction, mining, and transportation. By collaborating with established manufacturers like C&M Wire Rope & Supply, companies can access a diverse range of products tailored to meet their specific needs, including steel, stainless steel, and galvanized wire ropes. The emphasis on customization, quality, and sustainability not only enhances operational efficiency but also supports environmental responsibility—an increasingly important consideration in today’s market.

International buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize partnerships with suppliers that offer comprehensive services, including splicing, inspection, and certification. These value-added services ensure that products meet rigorous safety and performance standards, reducing potential risks associated with equipment failure.

Looking ahead, the wire rope market is poised for growth, driven by advancements in technology and an increasing focus on safety and efficiency. As you consider your sourcing strategies, seize the opportunity to engage with trusted suppliers who can provide innovative solutions and support your business objectives. Embrace the future of wire rope sourcing and position your organization for success in a competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to c&m wire and rope

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.