Unlocking Value: A Strategic Analysis of the Rolled Ring Market

Introduction: Navigating the Global Market for rolled ring

In the competitive landscape of global manufacturing, sourcing high-quality rolled rings can present a significant challenge for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. The need for durable, cost-effective solutions is paramount, especially in industries such as oil and gas, aerospace, and power generation. This guide aims to demystify the complexities of the rolled ring market by providing a comprehensive overview of various types, applications, and sourcing strategies that can empower international buyers to make informed purchasing decisions.

Within these pages, you will find detailed insights into seamless rolled rings, their manufacturing processes, and the advantages they hold over traditional methods. We will explore critical factors in supplier vetting, including quality assurance practices and lead times, which are essential for maintaining operational efficiency. Additionally, this guide addresses cost considerations and offers tips on negotiating favorable terms with suppliers, ensuring that you maximize value while minimizing risk.

By equipping you with the knowledge needed to navigate the global market for rolled rings, this guide serves as a vital resource for decision-makers seeking reliable partners. Whether you’re in Brazil, Saudi Arabia, or elsewhere, understanding the nuances of this market can lead to enhanced supply chain resilience and operational success.

Understanding rolled ring Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Seamless Rolled Rings | Manufactured without seams, providing superior integrity | Aerospace, Oil & Gas, Power Generation | Pros: High strength, reduced material waste. Cons: Higher initial cost. |

| Open Die Rolled Rings | Formed by upsetting and piercing, often used for larger sizes | Heavy Machinery, Marine Applications | Pros: Versatile sizes, strong grain structure. Cons: Longer lead times. |

| Hot Rolled Rings | Produced through traditional hot rolling methods | Construction, General Manufacturing | Pros: Cost-effective, easy to fabricate. Cons: Less precision than seamless. |

| Custom Forged Rings | Tailored shapes and sizes for specific applications | Automotive, Industrial Equipment | Pros: Optimized for unique requirements. Cons: May require extensive design consultation. |

| Alloy Steel Rolled Rings | Made from various alloys for enhanced properties | High-stress environments, Aerospace | Pros: Improved toughness and fatigue resistance. Cons: Higher cost and complexity in sourcing. |

What are the Characteristics of Seamless Rolled Rings?

Seamless rolled rings are crafted without any seams, which enhances their structural integrity and makes them ideal for high-demand applications. They are produced using advanced rolling techniques that minimize material waste and ensure tight tolerances. B2B buyers in industries like aerospace and oil & gas prefer these rings for their ability to withstand extreme conditions. While they offer superior performance and durability, the initial investment can be higher compared to other types.

How Do Open Die Rolled Rings Differ from Other Types?

Open die rolled rings are created through a process that involves upsetting and piercing a preform, allowing for larger sizes and unique geometries. This method produces a strong grain structure, enhancing the ring’s resistance to fatigue. They are particularly suited for heavy machinery and marine applications, where size and strength are crucial. However, buyers should consider that the lead times may be longer due to the nature of the manufacturing process.

Why Choose Hot Rolled Rings for General Manufacturing?

Hot rolled rings are produced using traditional methods that allow for quick and cost-effective fabrication. These rings are versatile and widely used in construction and general manufacturing due to their affordability. However, they may lack the precision of seamless rolled rings, making them less suitable for high-stress applications. Buyers should weigh the trade-offs between cost and required specifications when considering hot rolled options.

What Are the Benefits of Custom Forged Rings?

Custom forged rings are designed to meet specific application requirements, offering tailored shapes and sizes. This flexibility makes them ideal for industries like automotive and industrial equipment, where unique specifications are common. While they provide optimized performance, the need for extensive design consultation can increase the lead time and complexity of the procurement process. Buyers must assess whether the benefits justify the additional investment.

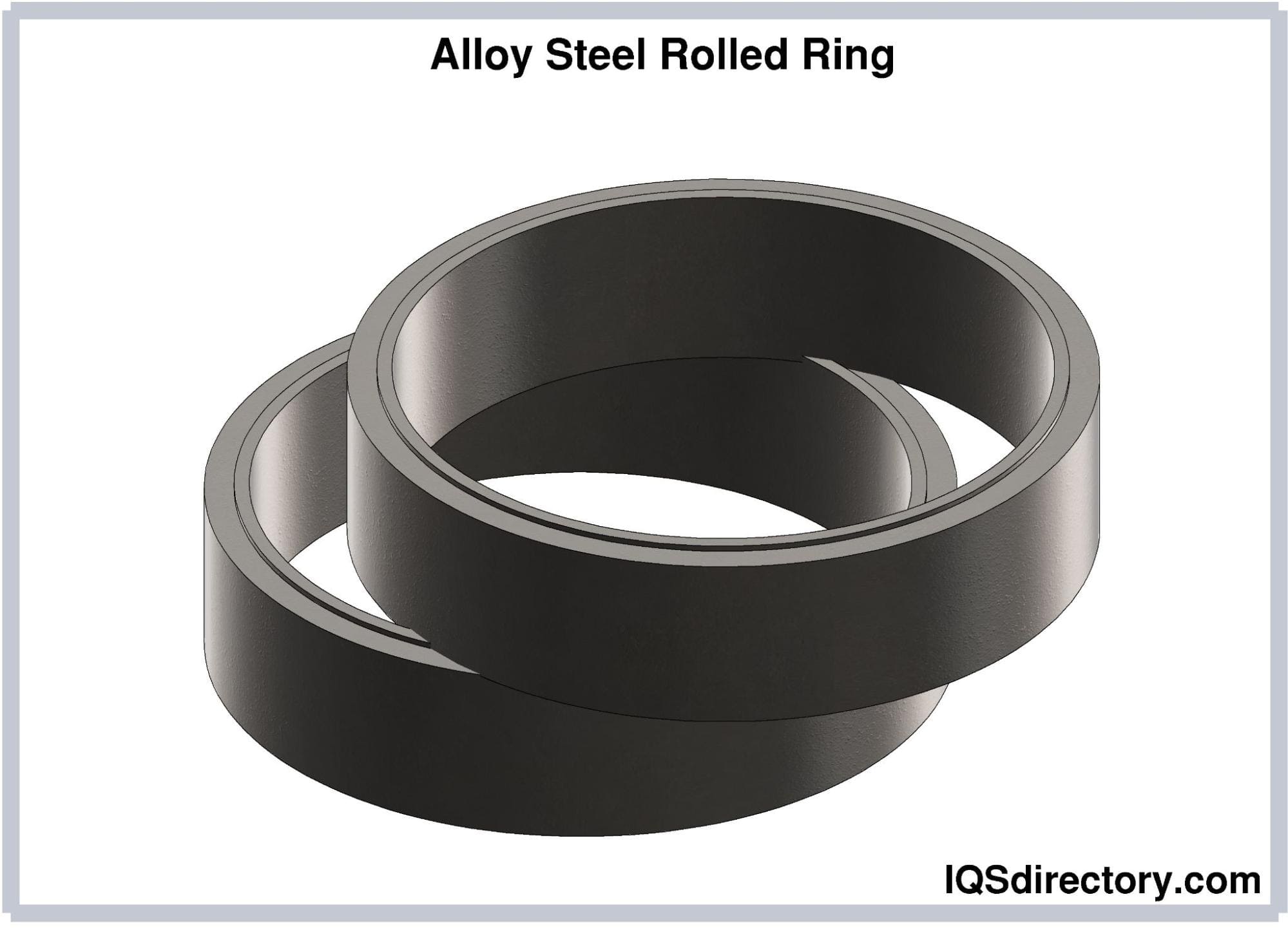

How Do Alloy Steel Rolled Rings Enhance Performance?

Alloy steel rolled rings are made from various alloys that enhance their mechanical properties, making them suitable for high-stress environments, including aerospace applications. The improved toughness and fatigue resistance of these rings can lead to longer service life and reduced failure rates. However, sourcing alloy steel can be more complex and costly, so buyers should consider their specific application requirements and budget constraints when opting for these materials.

Key Industrial Applications of rolled ring

| Industry/Sector | Specific Application of rolled ring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Components for drilling rigs | Enhanced strength and fatigue resistance in high-stress environments | Sourcing high-quality materials, compliance with industry standards, and timely delivery for project schedules |

| Power Generation | Turbine housings and rotor components | Improved durability and performance under extreme conditions | Need for precise tolerances, metallurgical testing, and heat treatment options |

| Aerospace | Structural components for aircraft | Lightweight yet strong materials that meet stringent safety standards | Certification of materials, traceability, and adherence to aerospace regulations |

| Automotive | Gear rings and bearing housings | Cost-effective manufacturing with reduced material waste | Availability of custom sizes, quick lead times, and machining capabilities |

| Construction | Heavy-duty support rings for structures | Increased load-bearing capacity and longevity | Customization options, compliance with local building codes, and material certifications |

How Are Rolled Rings Used in the Oil & Gas Industry?

In the oil and gas sector, rolled rings are critical for manufacturing components of drilling rigs, such as bearing housings and pressure vessels. Their seamless construction provides superior integrity, making them ideal for high-stress applications encountered during drilling operations. Buyers in this industry should prioritize suppliers who can guarantee high-quality materials that comply with industry standards, as well as those who can deliver on time to align with project schedules.

What Role Do Rolled Rings Play in Power Generation?

In power generation, rolled rings are utilized in turbine housings and rotor components where they must withstand extreme temperatures and pressures. The forged nature of these rings ensures enhanced durability and performance, significantly reducing the risk of failure. International buyers should look for manufacturers that offer metallurgical testing and heat treatment options to meet the specific requirements of their applications, ensuring reliability in critical energy generation processes.

Why Are Rolled Rings Essential in Aerospace Applications?

The aerospace industry relies on rolled rings for structural components in aircraft due to their lightweight and high-strength properties. These rings must meet stringent safety and performance standards, making it crucial for suppliers to provide certified materials with traceability. Buyers should focus on sourcing from manufacturers that comply with aerospace regulations and can demonstrate a proven track record in delivering quality products that enhance aircraft safety and efficiency.

How Do Rolled Rings Benefit the Automotive Sector?

In the automotive industry, rolled rings are commonly used for gear rings and bearing housings, where their cost-effective manufacturing process minimizes material waste. The seamless design allows for high precision, which is essential for ensuring optimal performance and longevity of automotive components. Buyers should seek suppliers who can offer customization options and quick lead times to meet the fast-paced demands of automotive manufacturing.

What Are the Advantages of Using Rolled Rings in Construction?

Rolled rings serve as heavy-duty support rings in construction, providing increased load-bearing capacity and longevity for various structures. Their strength and durability make them an excellent choice for critical applications where safety is paramount. When sourcing rolled rings for construction, buyers should consider suppliers who can customize products to meet local building codes and provide necessary material certifications to ensure compliance and safety in their projects.

3 Common User Pain Points for ‘rolled ring’ & Their Solutions

Scenario 1: Delays in Supply Chain Affecting Production Timelines

The Problem: A common challenge faced by B2B buyers of rolled rings is the unpredictability of supply chain logistics, particularly in international markets. Buyers may find themselves waiting extended periods for their rolled ring orders to arrive, leading to production delays. This is especially problematic for industries such as aerospace and energy, where timely delivery is crucial to project schedules and can affect contractual obligations.

The Solution: To mitigate supply chain delays, B2B buyers should establish relationships with suppliers that offer guaranteed delivery programs and transparent lead times. When sourcing rolled rings, inquire about the supplier’s production capabilities, including their ability to handle urgent requests or provide expedited shipping options. Additionally, consider suppliers with local distribution centers in your region or those that have proven track records of fast shipping times. This proactive approach can significantly reduce lead times and ensure your production schedules remain on track.

Scenario 2: Quality Concerns with Rolled Rings

The Problem: Quality inconsistencies can be a significant headache for buyers of rolled rings, particularly when sourcing from multiple suppliers. Variations in material properties, dimensions, and structural integrity can lead to failures in critical applications, resulting in costly downtime and safety risks. This is a pressing concern in sectors like automotive and oil and gas, where the reliability of components is non-negotiable.

The Solution: To address quality concerns, buyers should conduct thorough due diligence when selecting suppliers. This includes reviewing certifications, quality assurance processes, and past performance metrics. Request samples or conduct pilot runs to evaluate the consistency and quality of rolled rings before placing large orders. Additionally, opt for suppliers that provide detailed metallurgical testing and documentation, ensuring that the products meet the necessary industry standards. Engaging in regular communication with your suppliers about quality expectations can further enhance product reliability.

Scenario 3: Difficulty in Specifying the Right Rolled Ring Dimensions

The Problem: Another prevalent issue for B2B buyers is the challenge of accurately specifying the dimensions and material requirements for rolled rings. Inaccurate specifications can lead to the procurement of unsuitable products, causing delays and increased costs associated with reordering or modifying components. This scenario is particularly acute in industries like construction and manufacturing, where precision is critical.

The Solution: To overcome difficulties in specification, B2B buyers should engage in collaborative discussions with their suppliers early in the design process. Utilize the expertise of supplier engineers who can offer insights into the most appropriate materials and dimensions based on application requirements. Providing detailed application context—such as environmental conditions, load requirements, and manufacturing processes—can help suppliers recommend the best rolled ring configurations. Additionally, buyers should consider leveraging design software or tools that can assist in visualizing the necessary specifications, ensuring a more accurate order process. By investing time in proper specification, buyers can avoid costly mistakes and streamline their procurement processes.

Strategic Material Selection Guide for rolled ring

What Are the Key Properties of Common Materials Used in Rolled Rings?

When selecting materials for rolled rings, understanding their properties is crucial for ensuring optimal performance in various applications. Below is an analysis of four common materials: carbon steel, alloy steel, stainless steel, and titanium. Each material has unique characteristics that can significantly influence the performance, durability, and cost-effectiveness of the final product.

How Does Carbon Steel Perform in Rolled Ring Applications?

Key Properties: Carbon steel is known for its high tensile strength and excellent machinability. It performs well under moderate temperature and pressure conditions, making it suitable for a wide range of applications. However, it has limited corrosion resistance unless treated.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and availability. It is durable and can be heat-treated to enhance its properties. However, its susceptibility to rust and corrosion can be a significant drawback, particularly in humid or corrosive environments.

Impact on Application: Carbon steel is often used in applications where high strength is required, such as in the automotive and construction industries. However, it may not be suitable for environments exposed to moisture or corrosive substances.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local environmental conditions and the need for protective coatings. Compliance with standards such as ASTM A36 is essential for ensuring quality and performance.

What Advantages Do Alloy Steels Offer for Rolled Rings?

Key Properties: Alloy steels incorporate elements like chromium, nickel, and molybdenum to enhance strength, toughness, and wear resistance. They can withstand higher temperatures and pressures compared to carbon steel.

Pros & Cons: The key advantage of alloy steels is their enhanced performance characteristics, making them ideal for demanding applications in industries such as aerospace and oil and gas. However, they are more expensive and may require more complex manufacturing processes.

Impact on Application: Alloy steels are suitable for high-stress applications where durability and resistance to fatigue are critical. This makes them a preferred choice for components in heavy machinery and energy sectors.

Considerations for International Buyers: Buyers in the Middle East and Europe should ensure compliance with relevant standards like ASTM and DIN. The higher cost may be justified by the performance benefits in critical applications.

Why Choose Stainless Steel for Rolled Rings?

Key Properties: Stainless steel is renowned for its corrosion resistance and ability to maintain strength at high temperatures. It is also non-magnetic and has good weldability.

Pros & Cons: The primary advantage of stainless steel is its durability and longevity, making it ideal for applications exposed to harsh environments. However, it is generally more expensive than carbon and alloy steels, and machining can be more challenging.

Impact on Application: Stainless steel is widely used in industries like food processing, pharmaceuticals, and marine applications where hygiene and corrosion resistance are paramount.

Considerations for International Buyers: Buyers in Europe and the Middle East often prefer stainless steel due to its compliance with health and safety standards. Understanding the specific grades (e.g., 304, 316) is essential for meeting application requirements.

What Makes Titanium an Attractive Option for Rolled Rings?

Key Properties: Titanium is known for its high strength-to-weight ratio and exceptional corrosion resistance. It can withstand extreme temperatures and is biocompatible, making it suitable for medical applications.

Pros & Cons: The main advantage of titanium is its lightweight and high performance in extreme conditions. However, it is significantly more expensive and can be difficult to machine, which may increase manufacturing costs.

Impact on Application: Titanium is ideal for aerospace, medical, and high-performance automotive applications where weight savings and durability are critical.

Illustrative image related to rolled ring

Considerations for International Buyers: Buyers from regions like Brazil should be aware of the higher costs associated with titanium. Compliance with international standards and certifications is crucial, especially for aerospace applications.

Summary Table of Material Selection for Rolled Rings

| Material | Typical Use Case for Rolled Ring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Automotive and construction applications | Cost-effective and widely available | Limited corrosion resistance | Low |

| Alloy Steel | Aerospace and oil & gas components | Enhanced strength and toughness | Higher cost and manufacturing complexity | Med |

| Stainless Steel | Food processing and marine applications | Excellent corrosion resistance | More expensive and challenging to machine | High |

| Titanium | Aerospace and medical applications | High strength-to-weight ratio | Very high cost and difficult to machine | High |

This guide provides a comprehensive overview of the materials commonly used in rolled rings, helping international B2B buyers make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for rolled ring

What Are the Main Stages in the Manufacturing Process of Rolled Rings?

The manufacturing of rolled rings involves several critical stages that ensure the final product meets the required specifications. These stages can be broadly categorized into material preparation, forming, assembly, and finishing.

How Is Material Prepared for Rolled Rings?

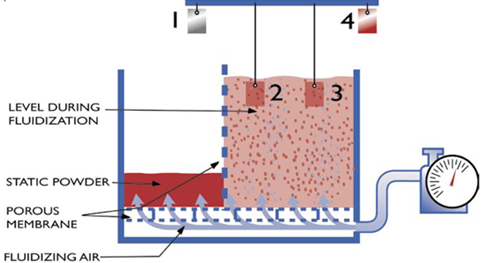

Material preparation is the initial phase where the raw materials, typically carbon, alloy, or stainless steel, are selected based on the application’s requirements. The chosen material is then cut into preforms, which are designed to achieve the desired dimensions through the rolling process. This stage often includes heating the material to enhance its malleability, making it easier to shape during the subsequent forming process.

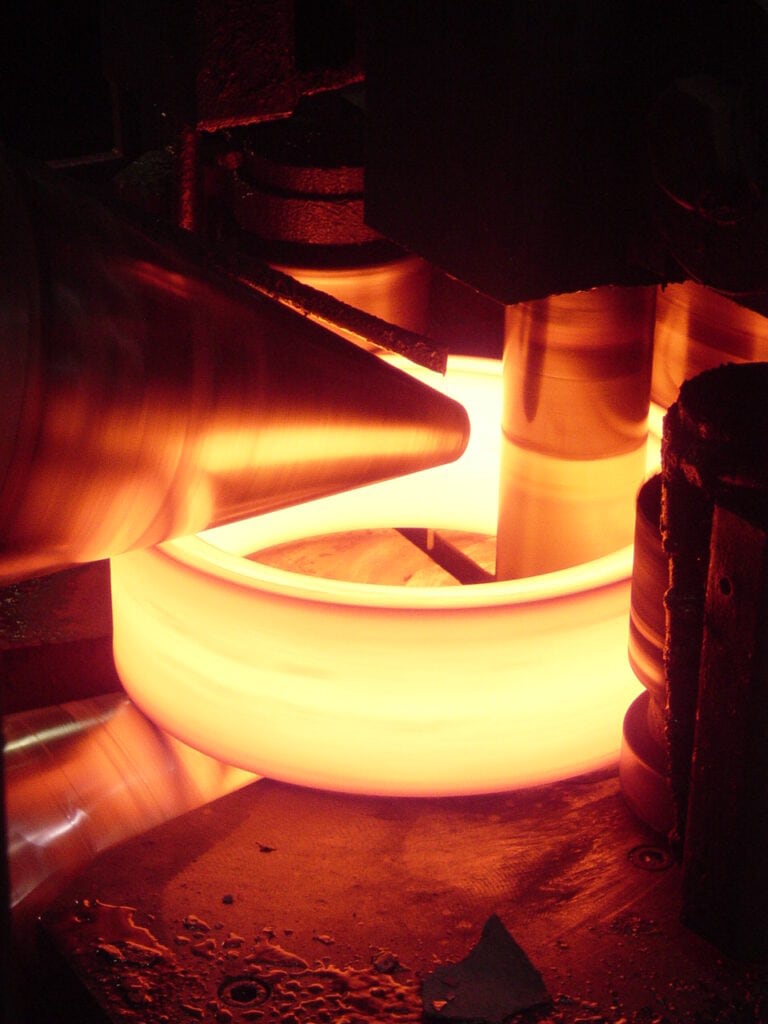

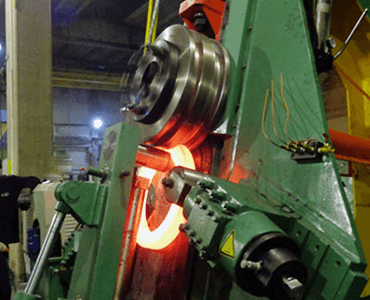

What Techniques Are Used in the Forming Stage?

The forming stage is where the preform undergoes significant transformation. This process starts with upsetting, where the material is thickened at one end to create a central hole. The preform is then placed in a ring mill, where radial and axial pressures are applied to expand the material into a ring shape. Techniques such as seamless rolling are employed to produce a uniform thickness and eliminate weld lines, ensuring superior structural integrity. This method is particularly advantageous for high-stress applications, as it yields rings with a controlled grain flow that enhances strength and fatigue resistance.

Illustrative image related to rolled ring

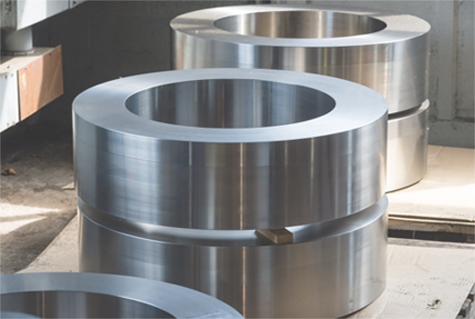

What Are the Key Steps in the Assembly and Finishing Processes?

Once the rings are formed, they undergo assembly, which may involve additional operations such as segmenting or parting, depending on the specific requirements of the order. Finishing processes typically include machining, heat treatment, and surface finishing. Machining may involve CNC techniques to achieve precise dimensions and surface finishes, while heat treatment processes like quenching and tempering enhance the mechanical properties of the rings. These finishing touches are crucial for applications in demanding industries such as aerospace, oil and gas, and power generation.

How Is Quality Assurance Implemented in Rolled Ring Manufacturing?

Quality assurance is a fundamental aspect of rolled ring manufacturing, ensuring that each product meets international and industry-specific standards. Compliance with ISO 9001 is essential for establishing a robust quality management system. Additionally, industry standards such as CE marking for European markets and API specifications for oil and gas applications play a significant role in defining quality benchmarks.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically structured around several checkpoints throughout the manufacturing process. Incoming Quality Control (IQC) examines raw materials upon arrival to ensure they meet the specified standards. In-Process Quality Control (IPQC) is conducted during the manufacturing stages, monitoring parameters such as temperature, pressure, and dimensional accuracy to prevent defects. Finally, Final Quality Control (FQC) assesses the finished products against all specifications before they are shipped to customers.

What Testing Methods Are Commonly Used in Rolled Ring Quality Assurance?

Several testing methods are employed to verify the quality and integrity of rolled rings. Mechanical testing, including tensile, impact, and hardness tests, evaluates the physical properties of the material. Non-destructive testing (NDT) techniques, such as ultrasonic and magnetic particle testing, are utilized to detect any internal or surface defects without compromising the integrity of the rings. Chemical analysis, including PMI (Positive Material Identification), ensures that the material composition meets the specified requirements.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is crucial. Conducting audits is one effective method. Buyers can request on-site inspections to assess the manufacturing processes and QC systems in place. Additionally, suppliers should provide documentation, such as quality control reports, certifications, and test results, to demonstrate compliance with relevant standards.

Engaging third-party inspection services can also provide an unbiased assessment of the supplier’s capabilities and adherence to quality standards. This approach is particularly important for buyers from regions like Africa, South America, and the Middle East, where access to reliable suppliers may be limited.

What Are the Quality Control Considerations for International B2B Buyers?

Navigating quality control nuances is essential for international B2B buyers. Different regions may have varying standards and regulations, making it vital to understand the specific requirements for the markets they operate in. For instance, buyers in Europe may prioritize CE certification, while those in the Middle East may focus on API specifications.

Establishing clear communication with suppliers about quality expectations and compliance requirements is crucial. Buyers should also consider the implications of tariffs, customs regulations, and import/export restrictions that could affect the procurement process.

Illustrative image related to rolled ring

Conclusion: Ensuring Quality in Rolled Ring Manufacturing

In summary, the manufacturing processes for rolled rings are intricate and multifaceted, encompassing material preparation, forming, assembly, and finishing. Quality assurance is integral to this process, with various checkpoints and testing methods ensuring that the final products meet international standards. For B2B buyers, understanding these processes and establishing robust verification practices is essential to securing high-quality rolled rings that meet their specific needs. By prioritizing quality and compliance, buyers can enhance their procurement strategies and foster successful partnerships with suppliers across the globe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rolled ring’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure rolled rings. Rolled rings are critical components in various industries, from aerospace to oil and gas, and ensuring a successful sourcing process is vital for operational efficiency and product integrity. Following these steps will help you make informed decisions and establish fruitful partnerships with reliable suppliers.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider the dimensions, material types, and tolerances required for your application. Specific attributes may include:

– Material: Carbon, alloy, or stainless steel.

– Dimensions: Outer diameter, thickness, and any specific shape requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in rolled rings. Look for companies with a strong reputation in the industry, positive customer feedback, and relevant certifications. Pay attention to:

– Experience: Suppliers with extensive experience in your industry often understand specific challenges and requirements.

– Capabilities: Ensure they can meet your technical specifications and production volume.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that suppliers hold the necessary certifications. Certifications such as ISO 9001 or API 6A indicate adherence to quality management and industry standards. These certifications are crucial as they reflect:

– Quality Assurance: Certified suppliers often have established processes to ensure product quality and consistency.

– Compliance: Certifications ensure that the supplier meets international standards, which is especially important for global operations.

Illustrative image related to rolled ring

Step 4: Request Samples and Technical Data

Ask for samples and detailed technical data to evaluate the quality of the rolled rings. This step allows you to assess the supplier’s manufacturing capabilities and the performance of their products. Focus on:

– Material Properties: Request documentation on mechanical properties and any relevant testing results.

– Sample Inspection: Analyze the samples for adherence to your specifications and overall quality.

Step 5: Discuss Lead Times and Pricing

Engage in discussions about lead times and pricing structures with your shortlisted suppliers. Understanding their production capabilities and delivery timelines is essential for your planning. Key considerations include:

– Production Capacity: Ensure they can fulfill your order volume within your required timeframe.

– Pricing Transparency: Look for suppliers who provide clear pricing models and any potential additional costs.

Step 6: Assess Value-Added Services

Consider suppliers that offer additional services that could benefit your project. Value-added services might include machining, heat treatment, or non-destructive testing. These services can enhance the overall value of your procurement. Evaluate:

– Customization Options: Suppliers that can tailor their offerings to meet specific needs can save you time and costs.

– Post-Production Support: Inquire about their support for testing and quality assurance after the product is delivered.

Step 7: Establish Clear Communication Channels

Finally, ensure that there are established communication channels for ongoing discussions with your supplier. Effective communication helps in addressing any potential issues promptly and maintaining a smooth workflow. Consider:

– Single Point of Contact: Designate a representative from your team to liaise with the supplier.

– Regular Updates: Set expectations for regular updates regarding production status and delivery timelines.

Illustrative image related to rolled ring

By following these steps, B2B buyers can streamline their sourcing process for rolled rings, ensuring they partner with reliable suppliers who can meet their technical and operational needs.

Comprehensive Cost and Pricing Analysis for rolled ring Sourcing

What Are the Key Cost Components in Rolled Ring Manufacturing?

When sourcing rolled rings, understanding the underlying cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly affects pricing. Carbon, alloy, and stainless steels are commonly used, with prices fluctuating based on market conditions and alloy compositions. Specialty materials, such as titanium or superalloys, will incur higher costs due to their unique properties and processing requirements.

-

Labor: Skilled labor is essential for the precise manufacturing of rolled rings. This includes operators for machinery, quality control inspectors, and support staff. Labor costs vary by region and can be influenced by local wage standards.

-

Manufacturing Overhead: This encompasses the costs of running the manufacturing facility, including utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help minimize overhead, thereby reducing overall costs.

-

Tooling: Tooling costs are incurred for the machinery and equipment required to produce rolled rings. These costs can be significant, especially for custom or large-diameter rings, and may be amortized over production volumes.

-

Quality Control (QC): Rigorous quality assurance processes ensure that the rolled rings meet specified standards. QC costs include testing, inspections, and certifications, which are critical for industries such as aerospace and oil & gas where safety and performance are paramount.

-

Logistics: Transportation and shipping costs play a vital role in the total cost of ownership. International buyers must consider import duties, shipping fees, and potential delays, which can add substantial costs to the final price.

-

Margin: Suppliers will typically add a profit margin to cover their operational risks and ensure sustainability. This margin can vary based on the supplier’s market position, service level, and relationship with the buyer.

What Factors Influence Pricing for Rolled Rings?

Several factors can affect the pricing of rolled rings, particularly for international buyers:

-

Volume/MOQ: Pricing often scales with the volume of the order. Larger orders may benefit from economies of scale, leading to lower per-unit costs. Conversely, small orders may incur higher prices due to setup and tooling costs.

-

Specifications and Customization: Highly specific requirements or custom designs will typically result in increased costs. Buyers should clearly define specifications to receive accurate quotes and avoid unexpected charges.

-

Material Quality and Certifications: The level of material quality and any required certifications (e.g., ISO, AS9100) can influence pricing. Higher-quality materials and additional certifications often lead to higher costs but ensure better performance and reliability.

-

Supplier Factors: The reputation, experience, and capabilities of the supplier can significantly impact pricing. Established suppliers with proven track records may command higher prices due to their reliability and quality assurance.

-

Incoterms: The chosen Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs. This can affect the overall cost and risk associated with the transaction.

How Can Buyers Optimize Their Rolled Ring Sourcing Strategy?

International buyers should consider several strategies to enhance cost-efficiency in their rolled ring sourcing:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially for larger orders or long-term contracts. Building strong relationships can lead to better pricing and service.

-

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on upfront costs, assess the total cost of ownership, including maintenance, operational efficiency, and lifecycle performance. This approach ensures that you invest in quality products that deliver long-term value.

-

Leverage Regional Insights: Buyers from Africa, South America, the Middle East, and Europe should stay informed about regional market conditions and material availability. Understanding local supply chain dynamics can help in negotiating better terms and identifying potential cost savings.

-

Be Aware of Pricing Nuances: Fluctuations in material costs, labor rates, and currency exchange rates can all impact pricing. Buyers should monitor these factors closely to time their purchases effectively.

Disclaimer on Pricing

Prices for rolled rings can vary widely based on the aforementioned factors. It is advisable for buyers to request detailed quotes from multiple suppliers to ensure a competitive price and to verify the specific terms and conditions applicable to their order.

Alternatives Analysis: Comparing rolled ring With Other Solutions

Exploring Alternatives to Rolled Rings: Key Comparisons for B2B Buyers

When considering manufacturing solutions for components requiring high strength and structural integrity, rolled rings stand out due to their unique production process and material properties. However, there are several alternative methods available, each with its own advantages and drawbacks. Understanding these alternatives can help B2B buyers make informed decisions tailored to their specific industry needs.

Illustrative image related to rolled ring

Comparison Table

| Comparison Aspect | Rolled Ring | Open Die Forged Rings | Fabricated Rings |

|---|---|---|---|

| Performance | High strength, low waste, superior integrity | Excellent toughness, controlled grain flow | Variable quality, often weaker due to joints |

| Cost | Generally cost-effective for large orders | Higher initial costs, but can save on material | Usually lower initial costs, but higher long-term due to waste |

| Ease of Implementation | Streamlined production, quick lead times | Requires specialized equipment, longer lead times | Simple to implement with standard equipment |

| Maintenance | Low maintenance due to durability | Low maintenance with high fatigue resistance | Higher maintenance due to potential joint weaknesses |

| Best Use Case | High-performance applications in aerospace, oil & gas | Heavy-duty applications requiring high strength | Low-stress applications where cost is a priority |

Detailed Breakdown of Alternatives

Open Die Forged Rings

Open die forged rings are manufactured through a process that involves heating metal and shaping it using hammers or presses. This method produces rings with excellent toughness and controlled grain flow, enhancing strength and impact resistance. While the initial costs may be higher due to the specialized equipment required, the durability and longevity of forged rings can lead to reduced costs over time, especially in demanding applications. However, the lead times can be longer, and this method may not be suitable for smaller orders.

Fabricated Rings

Fabricated rings are created by cutting and welding metal plates to form a ring shape. This method can often be less expensive initially since it utilizes standard fabrication equipment. However, fabricated rings may suffer from variable quality due to the potential for weak joints, which can lead to issues in high-stress environments. They are typically best suited for low-stress applications where cost is a primary concern. Buyers should consider the trade-offs in performance and durability when choosing this method.

Conclusion: Making the Right Choice for Your Needs

Selecting the appropriate manufacturing solution hinges on understanding the specific requirements of your application. For projects demanding high strength, low waste, and superior integrity, rolled rings are often the best choice. Conversely, if initial costs are a major concern and the application does not require high performance, fabricated rings may suffice. For heavy-duty applications, open die forged rings offer exceptional toughness and durability, albeit at a higher cost. B2B buyers should evaluate their needs in terms of performance, cost, and application requirements to determine the most suitable option for their projects.

Essential Technical Properties and Trade Terminology for rolled ring

What Are the Key Technical Properties of Rolled Rings?

When sourcing rolled rings, understanding their technical properties is crucial for ensuring they meet specific application requirements. Below are some essential specifications that B2B buyers should consider:

-

Material Grade

The choice of material significantly impacts the performance and longevity of rolled rings. Common materials include carbon steel, alloy steel, stainless steel, and specialized alloys like titanium or superalloys. Each material offers different strengths, corrosion resistances, and thermal properties, making it vital to select the right grade for your application, particularly in industries like aerospace or oil and gas. -

Tolerance

Tolerance refers to the allowable variation in dimensions and is critical for ensuring that the rolled rings fit seamlessly within their intended applications. Tighter tolerances can lead to higher manufacturing costs but are often necessary for precision engineering tasks. A precise fit reduces the risk of mechanical failure and enhances overall system reliability. -

Outside Diameter (O.D.) and Weight

Rolled rings come in various sizes, with O.D. ranging from a few inches to over 300 inches, and weights that can exceed 60,000 pounds. Understanding the size and weight specifications is essential for logistics and assembly, especially when dealing with large-scale projects where space and load capacities are constraints. -

Heat Treatment

Heat treatment processes like normalizing, quenching, and tempering can significantly enhance the mechanical properties of rolled rings. These treatments improve toughness, hardness, and fatigue resistance, making them suitable for demanding applications. B2B buyers should inquire about the heat treatment processes employed to ensure the rings will perform as required in their specific environments. -

Non-Destructive Testing (NDT)

NDT methods such as ultrasonic testing or magnetic particle testing are essential for verifying the integrity of rolled rings without damaging them. This testing ensures that the rings meet quality standards and are free from internal defects, which is particularly important in safety-critical applications.

What Are Common Trade Terms Related to Rolled Rings?

Familiarity with industry jargon can streamline communication and negotiations between buyers and suppliers. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the role of OEMs can help buyers identify reliable suppliers who provide quality components that meet specific design and performance standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers as it affects inventory costs and production planning. Negotiating MOQ can lead to better pricing or flexibility in order sizes, especially for smaller projects. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific goods or services. It helps standardize the purchasing process and ensures that all potential suppliers are evaluated on the same criteria, leading to informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs in international trade. Understanding these terms is vital for B2B transactions, as they clarify who bears the risk and costs at various stages of the shipping process. -

Lead Time

Lead time is the time taken from placing an order to the delivery of goods. In industries where timing is critical, understanding lead times can help buyers plan their production schedules effectively and manage inventory levels.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions when procuring rolled rings, ensuring they select the right products for their applications while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the rolled ring Sector

What Are the Current Market Dynamics and Key Trends in the Rolled Ring Sector?

The rolled ring sector is experiencing significant growth driven by global industrialization and increasing demand for high-strength components in various applications, particularly in aerospace, automotive, and energy sectors. Emerging markets in Africa, South America, and the Middle East are witnessing a surge in infrastructure projects, which in turn drives the demand for rolled rings. Notably, countries like Brazil and Saudi Arabia are investing heavily in oil and gas exploration, necessitating the use of durable and reliable components.

Key sourcing trends include the adoption of advanced manufacturing technologies such as automation and the Internet of Things (IoT), which enhance production efficiency and enable real-time monitoring of supply chains. Buyers are increasingly seeking suppliers who can guarantee quick lead times and flexibility in order quantities. For instance, some manufacturers now offer expedited shipping options, reducing the time to market for critical projects. Moreover, the trend towards just-in-time inventory systems is prompting buyers to partner with suppliers who can deliver high-quality products on short notice without compromising on standards.

As companies strive to optimize their supply chains, there is a growing emphasis on strategic partnerships with suppliers who can offer value-added services such as engineering support, customized solutions, and post-production processing. This shift is crucial for international buyers looking to enhance their competitive advantage in a global marketplace that is increasingly interconnected.

How Does Sustainability and Ethical Sourcing Impact the Rolled Ring Sector?

Sustainability has become a pivotal concern for B2B buyers, particularly in industries that are under scrutiny for their environmental impact. The rolled ring sector is no exception. Manufacturers are now focusing on sustainable practices, such as reducing energy consumption during production and minimizing waste through efficient manufacturing processes. For instance, seamless rolled rings, which produce less scrap material than traditional plate-cutting methods, are gaining popularity due to their superior integrity and lower environmental footprint.

Ethical sourcing is equally important, as buyers are increasingly aware of the social and environmental implications of their supply chains. Companies are seeking suppliers who adhere to ethical labor practices and have transparent sourcing strategies. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming key considerations when evaluating potential suppliers. Additionally, the use of recycled materials in the production of rolled rings can further enhance a company’s sustainability profile, making it a critical factor for buyers aiming to align with global sustainability goals.

Investing in suppliers with a strong commitment to sustainability and ethical practices not only helps mitigate risks but also enhances brand reputation, which is essential in today’s socially conscious market.

What Is the Historical Context of Rolled Rings and Their Evolution?

The rolled ring manufacturing process has evolved significantly over the last century, adapting to technological advancements and changing market demands. Initially, rings were produced through traditional forging methods, which were labor-intensive and limited in terms of size and complexity. However, the advent of modern rolling techniques has transformed the industry, allowing for the production of seamless rolled rings with enhanced strength and reduced material waste.

Illustrative image related to rolled ring

The introduction of computer numerical control (CNC) technology further revolutionized the sector by enabling precise engineering and customization of rolled rings. This evolution has made it possible for manufacturers to meet the growing demands of various industries, including aerospace and energy, where high-performance components are critical. Today, the rolled ring sector stands at the intersection of advanced manufacturing technology and sustainable practices, positioning itself as a vital contributor to global industrial development.

Frequently Asked Questions (FAQs) for B2B Buyers of rolled ring

-

How do I choose the right rolled ring supplier for my business needs?

Selecting the right supplier for rolled rings requires a thorough evaluation of their manufacturing capabilities, industry experience, and quality assurance processes. Look for suppliers with a proven track record in your specific industry, whether it’s aerospace, oil and gas, or automotive. Request samples to assess the quality of their products and inquire about their certifications, such as ISO standards. Additionally, consider their capacity for customization, lead times, and customer service responsiveness, as these factors can significantly impact your project’s success. -

What are the key benefits of using seamless rolled rings over other types of rings?

Seamless rolled rings offer superior structural integrity, strength, and resistance to fatigue compared to cast or welded rings. The forging process used to create these rings results in controlled grain flow, enhancing their performance in demanding applications. They also allow for tighter tolerances, which can reduce material waste and machining costs. This makes seamless rolled rings an ideal choice for critical components in industries such as aerospace, power generation, and heavy machinery, where reliability is paramount. -

What customization options are available for rolled rings?

Many suppliers offer extensive customization options for rolled rings, including variations in material type (such as carbon, alloy, or stainless steel), dimensions, and geometrical configurations. You can specify the thickness, inner and outer diameters, and even the cross-sectional shape to meet your specific application requirements. Additionally, value-added services like heat treatment, machining, and surface finishing can enhance the performance of the rings. Communicating your exact needs to the supplier will ensure you receive a product tailored to your operational demands. -

What is the minimum order quantity (MOQ) for rolled rings, and how does it vary by supplier?

Minimum order quantities (MOQs) for rolled rings can vary significantly by supplier and the specific product being requested. Some suppliers may accommodate small orders for prototyping or testing purposes, while others may have higher MOQs to justify production costs. It’s essential to clarify the MOQ during your initial discussions with potential suppliers and consider how it aligns with your project needs. If you require flexibility, seek suppliers that offer a range of options, including the possibility of smaller batch runs. -

What payment terms should I expect when sourcing rolled rings internationally?

Payment terms can vary widely depending on the supplier and your location. Common practices include payment upon order confirmation, partial payment upfront with the balance due upon delivery, or net payment terms (e.g., 30, 60, or 90 days). When sourcing rolled rings internationally, it is crucial to discuss these terms upfront to avoid misunderstandings. Additionally, consider using secure payment methods and exploring options for letters of credit or escrow services to protect your investment. -

How can I ensure quality assurance for the rolled rings I purchase?

To ensure quality assurance for your rolled rings, request detailed documentation from the supplier, including material certifications, inspection reports, and any relevant testing data. Many reputable suppliers conduct non-destructive testing (NDT) and mechanical testing to verify the integrity of their products. Inquire about their quality management systems and whether they hold certifications like ISO 9001. Establishing a clear quality assurance process before placing an order will help mitigate risks and ensure that the products meet your specifications. -

What logistics considerations should I be aware of when importing rolled rings?

Logistics play a crucial role in the timely delivery of rolled rings, especially for international shipments. Consider factors such as shipping methods, customs regulations, and potential tariffs that may apply to your order. Collaborate with your supplier to understand their shipping capabilities and lead times. It’s also beneficial to work with a reliable freight forwarder familiar with the specific import requirements of your country. Proper planning can minimize delays and unexpected costs associated with international logistics. -

How do I handle potential issues or disputes with my rolled ring supplier?

In the event of issues or disputes with your rolled ring supplier, maintaining open communication is vital. Start by addressing your concerns directly with the supplier to seek a resolution. If informal discussions do not yield results, refer to the contract terms, which should outline dispute resolution procedures. Consider mediation or arbitration as potential paths for resolving conflicts without resorting to litigation. Establishing a strong relationship and clear expectations upfront can help mitigate disputes and foster a collaborative partnership.

Top 7 Rolled Ring Manufacturers & Suppliers List

1. Scot Forge – Forged & Rolled Rings

Domain: scotforge.com

Registered: 1997 (28 years)

Introduction: Forged & Rolled Rings from Scot Forge offer tailored solutions for both small and large quantities. Key specifications include:

– Maximum outer diameter (O.D.): 252 inches

– Maximum face height: 49 inches

– Rolled ring weights: up to 60,000 lbs.

– Open die weights: up to 300,000 lbs.

– Downstream processing capabilities: heat treatment, testing, machining, segmenting, parting, or splitting perform…

2. Anglerings – Premium Ring Products

Domain: anglerings.com

Registered: 2004 (21 years)

Introduction: [{‘diameter’: ’10 inch’, ‘dimensions’: ‘1-1/4 x 1-1/4 x 1/8’, ‘orientation’: ‘Leg-Out’, ‘holes’: ‘6’, ‘price’: ‘$26.21’}, {‘diameter’: ’11 inch’, ‘dimensions’: ‘1-1/4 x 1-1/4 x 1/8’, ‘orientation’: ‘Leg-Out’, ‘holes’: ‘6’, ‘price’: ‘$27.64’}, {‘diameter’: ’12 inch’, ‘dimensions’: ‘1-1/2 x 1-1/2 x 1/8’, ‘orientation’: ‘Leg-Out’, ‘holes’: ‘8’, ‘price’: ‘$29.55’}, {‘diameter’: ’13 inch’, ‘dimensions’…

3. Frisa – Seamless Rolled Rings

Domain: frisa.com

Registered: 1997 (28 years)

Introduction: Seamless Rolled Rings – Rolled Ring Forgings

**Key Product Details:**

– **Material Options:** Carbon Steel, Alloy Steel, Stainless Steel, Tool Steel, Aluminium, Titanium, Superalloys, Customized Chemistries

– **Size Range:** Outer Diameter (O.D.) up to 315 inches

– **Weight Range:** Up to 55,000 lbs

– **Benefits:** High strength, toughness, torque, pressure, and fatigue resistance; superior to ca…

4. RM Forge – Seamless Rolled Rings & Custom Forged Solutions

Domain: rmforge.com

Registered: 2000 (25 years)

Introduction: Seamless Rolled Rings up to 250″ OD; Custom forged ring orders available; Materials: Carbon Steel (1004 – 1080, SA 105, SA 350, LF1, LF2, LF3, LF6, A707, A694), Stainless Steel (303, 304/L/H, 316/L/H, 310, 317/L, 321/H, 347/H, 410, 416, 420, 440, 17-4, 254 SMO, Nitronic 50®, Nitronic 60®, Duplex & Super Duplex SS, 2205 Duplex, Super Duplex 2507, Zeron 100®, Ferralium 255®), Alloy Steel (4130, 4140…

5. Arntzen Corporation – Rolled and Welded Steel Rings

Domain: arntzenrolling.com

Registered: 2000 (25 years)

Introduction: Arntzen Corporation specializes in the fabrication of rolled and welded steel rings and ring segments from formable grades of carbon steel, stainless steel, and nickel alloys. Key specifications include:

– Diameter: 10″ to 180″

– Thickness: 3/16″ to 3″

– Materials: Carbon Steel, Stainless Steel, Nickel Alloys

– Fabrication Methods: Rolled and welded, open butt joints or fully welded, thermal stres…

6. Ferralloy – Rolled Ring Forgings

Domain: ferralloy.com

Registered: 1998 (27 years)

Introduction: Rolled ring forgings are versatile products used across various industries including aerospace, energy, automotive, and oil and gas. In aerospace, they are used for manufacturing engine components like compressor discs, turbine shafts, and landing gear components, providing strength and durability under extreme conditions. In the energy sector, rolled rings are essential for wind turbine shafts an…

7. Ovako – Rolled and Forged Rings

Domain: ovako.com

Registered: 2001 (24 years)

Introduction: Rolled and Forged Rings from Ovako are produced with a commitment to consistent quality, utilizing strict control over the production chain from melt to rolling. They offer profiled rings with small allowances and tight tolerances, enabling efficient production and cost savings. The rings can be heat treated in various executions, including Normalised, Soft annealed, Stress relieved, Isothermally …

Strategic Sourcing Conclusion and Outlook for rolled ring

What Are the Key Takeaways for B2B Buyers in Rolled Rings?

In the competitive landscape of rolled rings, strategic sourcing is not just beneficial; it’s essential. Buyers should prioritize suppliers that demonstrate reliability, high-quality manufacturing, and the ability to meet specific engineering demands. Seamless rolled rings, with their superior structural integrity and reduced waste, present a cost-effective alternative to traditional fabrication methods. Suppliers like McInnes Rolled Rings and Scot Forge offer tailored solutions that enhance performance while minimizing costs.

How Can Buyers Leverage Strategic Sourcing for Future Success?

Investing in long-term partnerships with reputable manufacturers can significantly streamline procurement processes and lead to better pricing structures. By emphasizing collaboration, buyers can gain insights into the latest technologies and innovations, ensuring that they remain at the forefront of their industries. As global markets continue to evolve, understanding regional demands—especially in emerging markets in Africa, South America, and the Middle East—will be critical for success.

What’s Next for International B2B Buyers?

Now is the time for international B2B buyers to reassess their sourcing strategies and align them with the latest advancements in rolled ring technology. Embrace partnerships that offer not only products but also value-added services such as metallurgical testing and machining. By doing so, you can enhance your operational efficiency and position your business for sustainable growth in the years to come. Reach out to trusted suppliers today to explore how rolled rings can elevate your engineering projects and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to rolled ring

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.