Top 8 Centrifugal Blower Fan Design Suppliers (And How to Choose)

Introduction: Navigating the Global Market for centrifugal blower fan design

The global market for centrifugal blower fan design presents both opportunities and challenges for international B2B buyers. Sourcing high-performance centrifugal blower fans that meet specific operational requirements can be daunting, especially given the diverse applications across industries such as manufacturing, HVAC, and material handling. This guide aims to demystify the complexities of centrifugal blower fan design by providing a comprehensive overview of the various types, their applications, and essential factors to consider when selecting a supplier.

In this resource, buyers will explore the distinct characteristics of centrifugal blowers, including backward curved and plug fans, and understand how to assess their efficiency in high-pressure environments. Additionally, the guide covers critical aspects of supplier vetting, ensuring that buyers can identify reputable manufacturers who adhere to industry standards. Cost considerations, including maintenance and energy efficiency, are also discussed, enabling buyers to make informed financial decisions that align with their operational goals.

By equipping B2B buyers from Africa, South America, the Middle East, and Europe—specifically in markets like Germany and Saudi Arabia—with actionable insights, this guide empowers them to navigate the centrifugal blower fan landscape confidently. Whether you’re looking to enhance air circulation in a production facility or optimize ventilation systems, this resource serves as an essential tool for making strategic purchasing decisions that drive business success.

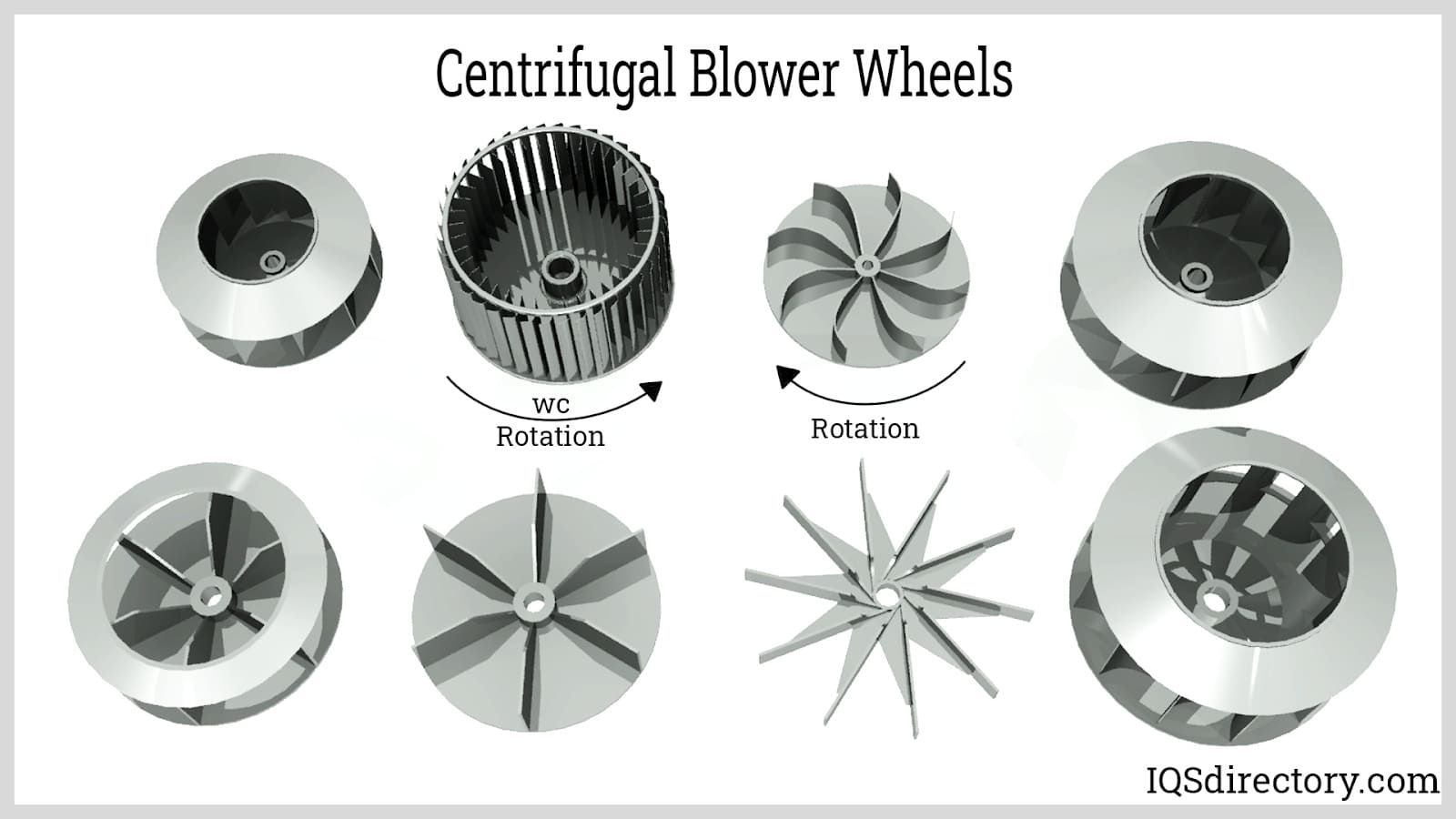

Understanding centrifugal blower fan design Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Backward Curved Centrifugal Fan | Curved blades that enhance efficiency at high speeds | HVAC systems, industrial ventilation | Pros: High efficiency, low noise. Cons: Limited pressure capability. |

| Backward Inclined Blower Fan | Blades angled backward for high pressure and flow | Dust collection, pneumatic conveying | Pros: Versatile, handles high back pressure. Cons: Can be larger and heavier. |

| Plug Fan | Compact design, integrates motor and impeller | Cleanrooms, air handling units | Pros: Space-saving, energy-efficient. Cons: Limited airflow volume. |

| Plenum Fan | Designed for use in duct systems, high static pressure | Air distribution in large facilities | Pros: Effective in high resistance systems. Cons: May require additional noise control. |

| Airfoil Fan | Aerodynamically shaped blades for optimal airflow | Large-scale industrial applications, ventilation | Pros: High performance, energy-efficient. Cons: More complex design can increase costs. |

What are the Characteristics of Backward Curved Centrifugal Fans?

Backward curved centrifugal fans feature blades that curve away from the direction of rotation. This design allows them to achieve higher efficiencies at elevated speeds, making them ideal for applications in HVAC systems and industrial ventilation. When purchasing, B2B buyers should consider the fan’s efficiency ratings and noise levels, as these fans tend to operate quietly while delivering consistent airflow. However, their pressure capabilities might be limited compared to other designs, which could be a critical factor depending on the application.

Why Choose Backward Inclined Blower Fans for Your Business?

Backward inclined blower fans are characterized by their blades angled backward relative to the direction of airflow. This design allows them to handle higher pressures and is particularly effective in dust collection and pneumatic conveying systems. B2B buyers should prioritize this type for applications requiring robust performance against back pressure. While they are versatile and durable, it’s important to note that they can be bulkier and heavier than other options, which may impact installation space and costs.

How Do Plug Fans Enhance Efficiency in Air Handling?

Plug fans are compact centrifugal fans that integrate the motor directly with the impeller, minimizing space and maximizing efficiency. They are primarily used in cleanrooms and air handling units, where effective air circulation is essential. B2B buyers looking for energy-efficient solutions in limited spaces will find plug fans particularly appealing. However, potential buyers should be aware that while they excel in energy savings, their airflow volumes may not match larger fan types, which could limit their application scope.

What are the Advantages of Plenum Fans in Duct Systems?

Plenum fans are specifically designed for high static pressure environments, making them ideal for use in duct systems where airflow resistance is significant. They are commonly employed in large facilities requiring effective air distribution. When selecting plenum fans, B2B buyers should consider their efficiency in overcoming resistance, although they may need to implement additional noise control measures due to the fan’s operational characteristics. Understanding the specific duct system requirements is crucial for optimal performance.

Why are Airfoil Fans Considered High-Performance Options?

Airfoil fans feature blades designed for optimal aerodynamic performance, delivering high airflow rates and energy efficiency. They are widely used in large-scale industrial applications and ventilation systems. B2B buyers should evaluate airfoil fans for their high performance, particularly in scenarios demanding significant air movement. However, the complexity of their design can lead to higher initial costs, so it’s essential to balance performance needs with budget constraints when making purchasing decisions.

Key Industrial Applications of centrifugal blower fan design

| Industry/Sector | Specific Application of centrifugal blower fan design | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Material Handling in Dust Collection Systems | Improves air quality and operational efficiency | Ensure compatibility with existing systems and dust type. |

| Food Processing | Ventilation in Processing Areas | Enhances hygiene and product quality | Consider regulatory compliance and ease of cleaning. |

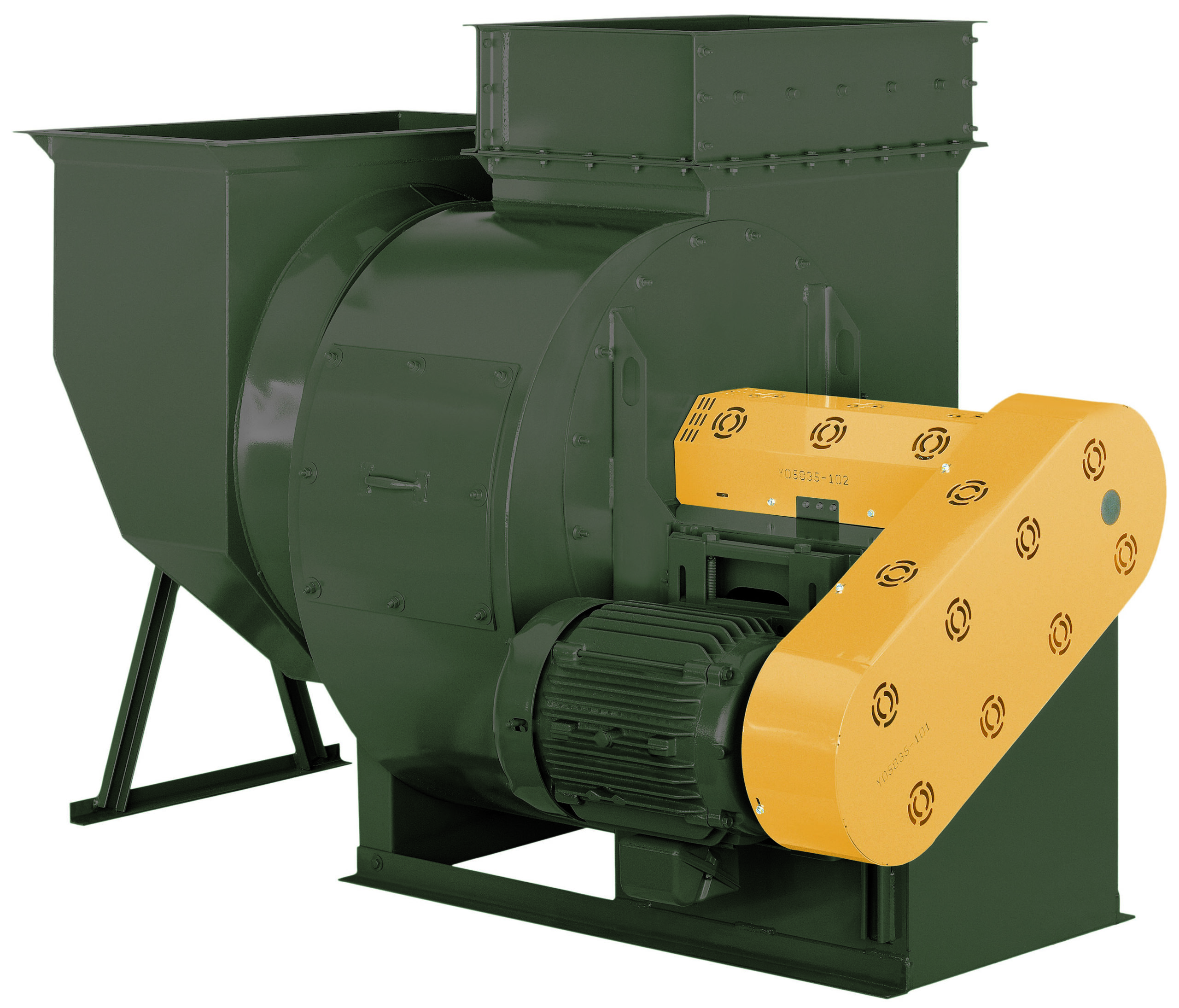

| Mining and Quarrying | Air Supply for Underground Operations | Ensures safety and improves worker comfort | Evaluate durability under harsh conditions and maintenance needs. |

| HVAC Systems | Airflow Management in Commercial Buildings | Increases energy efficiency and comfort | Assess energy consumption and noise levels. |

| Chemical Processing | Fume Extraction and Gas Handling | Protects worker safety and maintains product integrity | Look for corrosion-resistant materials and compliance with safety standards. |

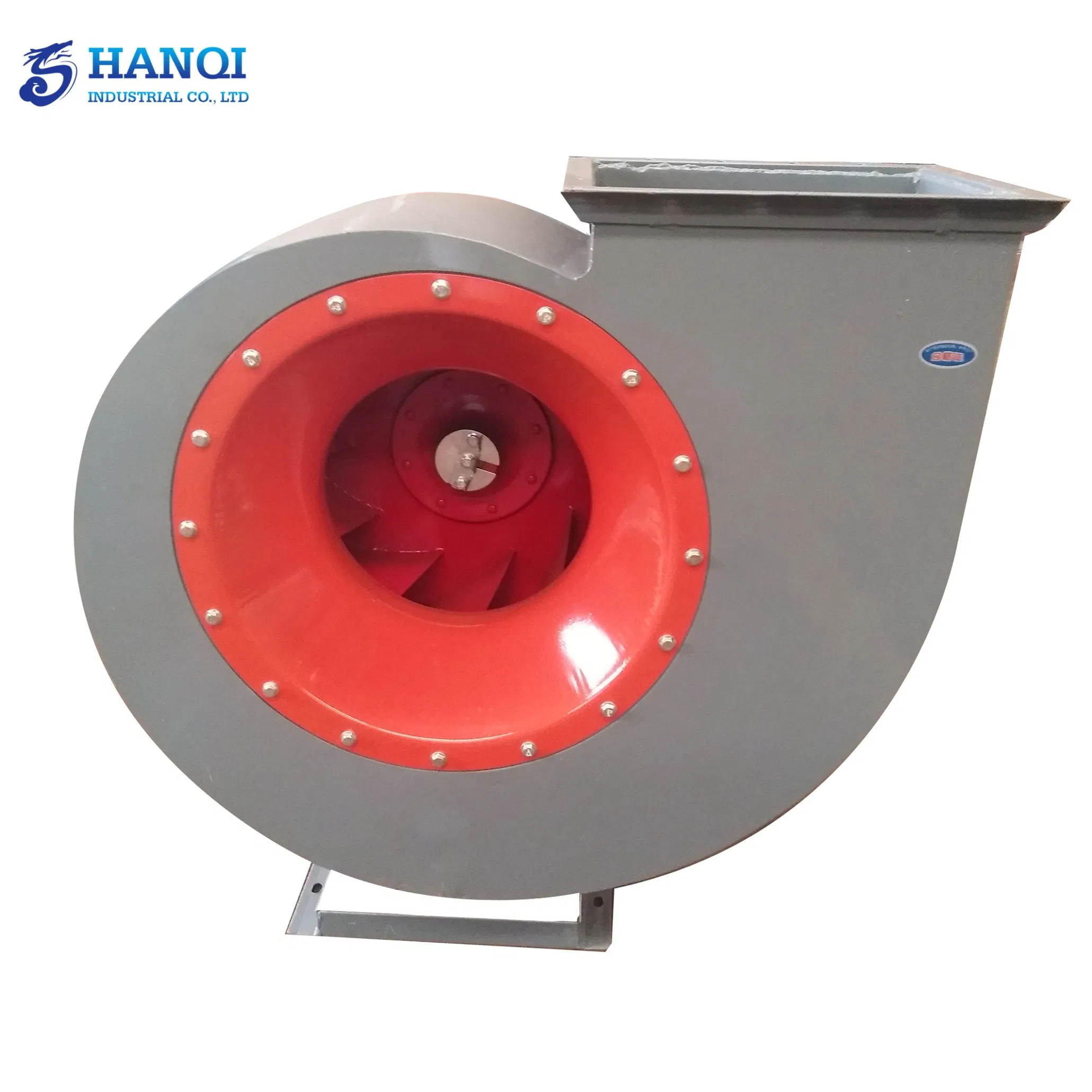

How Is Centrifugal Blower Fan Design Used in Manufacturing for Dust Collection?

In manufacturing, centrifugal blowers are integral to dust collection systems, enabling efficient material handling and improving air quality. These systems effectively remove airborne particles, which can be harmful to both workers and machinery. Buyers in this sector must consider the blower’s compatibility with existing equipment and the specific type of dust being handled to ensure optimal performance and compliance with health regulations.

What Role Does Centrifugal Blower Fan Design Play in Food Processing?

Centrifugal blowers are crucial in food processing, particularly for ventilation in processing areas. They help maintain hygienic conditions by ensuring proper airflow, which is vital for preventing contamination. B2B buyers should prioritize models that meet stringent food safety standards and are easy to clean, thus minimizing downtime and ensuring product quality.

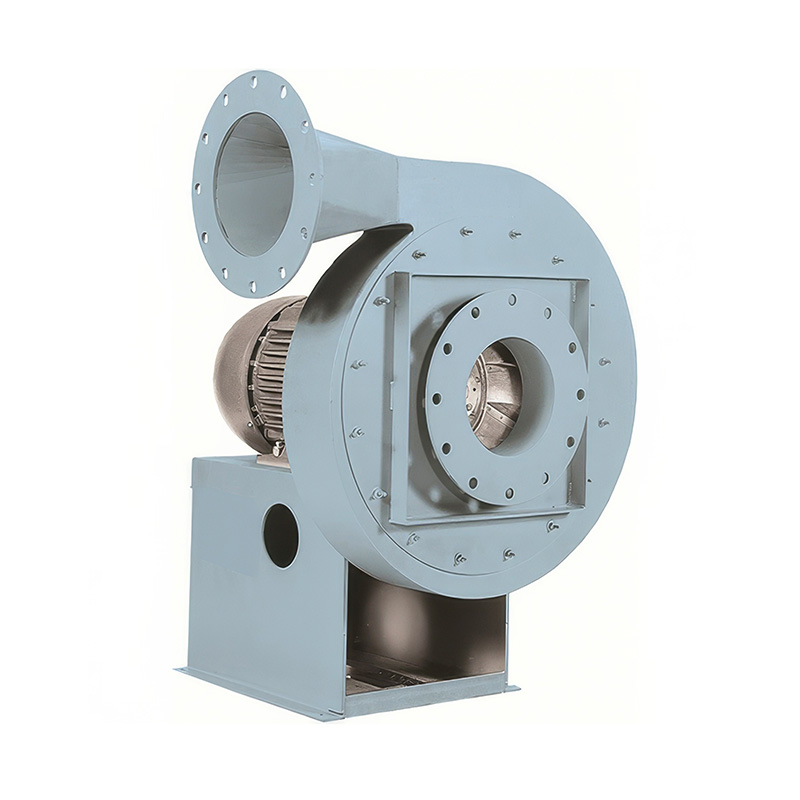

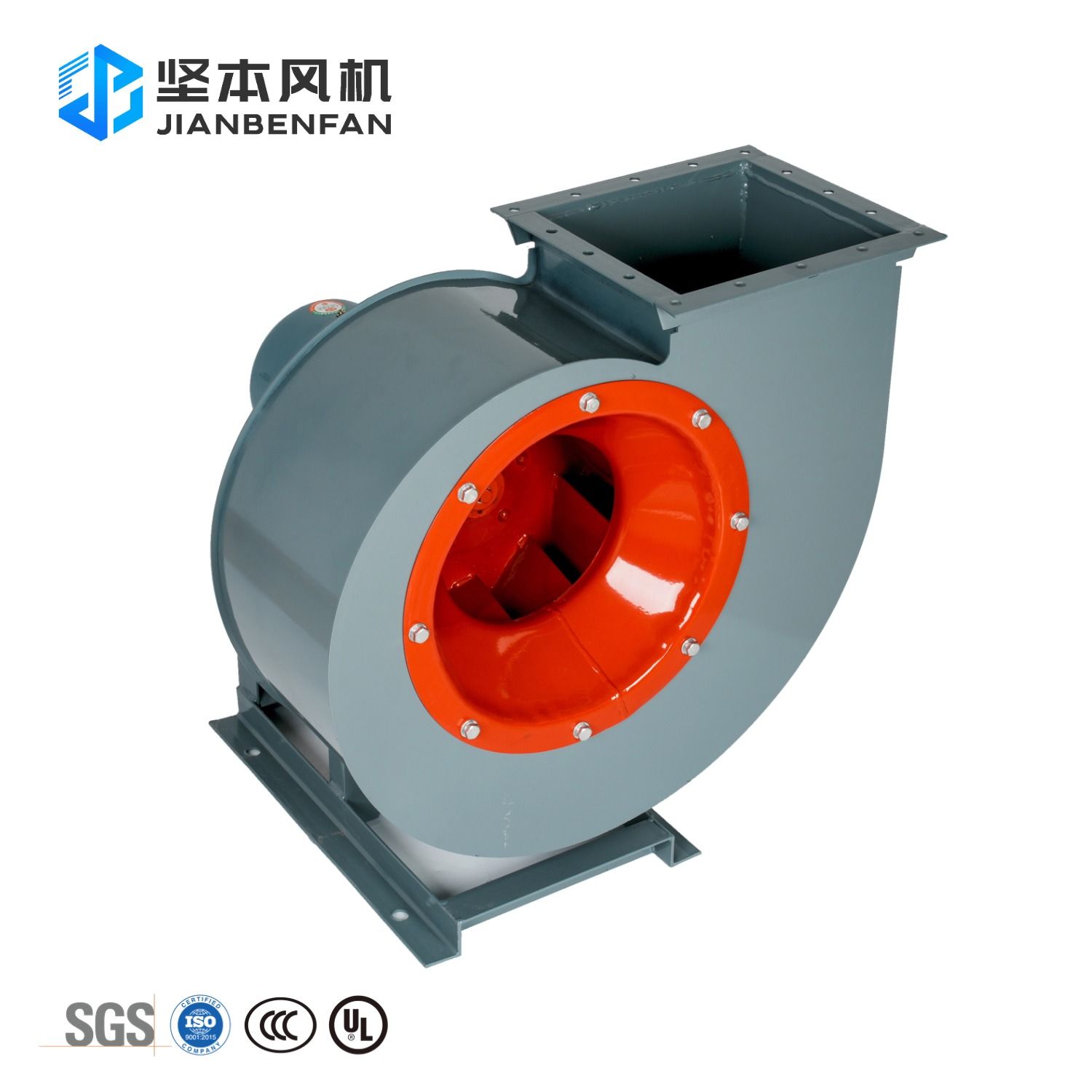

Illustrative image related to centrifugal blower fan design

How Are Centrifugal Blower Fans Used in Mining and Quarrying?

In mining and quarrying, centrifugal blowers provide essential air supply for underground operations, ensuring a safe working environment. They help mitigate harmful gases and enhance worker comfort by improving ventilation. Buyers must assess the blower’s durability and maintenance requirements, as these systems operate in harsh conditions where reliability is paramount.

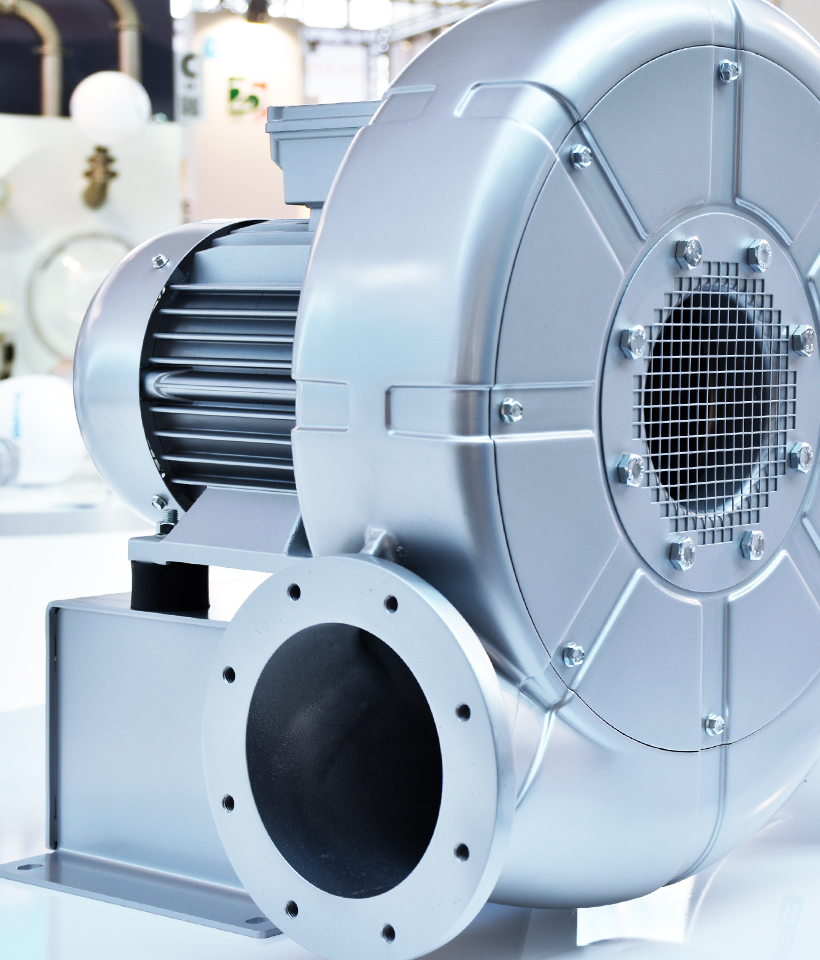

Why Are Centrifugal Blower Fans Important in HVAC Systems?

Centrifugal blowers are fundamental to managing airflow in HVAC systems within commercial buildings. They enhance energy efficiency and maintain comfortable indoor environments by effectively distributing air. When sourcing these blowers, businesses should evaluate energy consumption and noise levels to ensure a balance between performance and occupant comfort.

How Do Centrifugal Blower Fans Contribute to Chemical Processing?

In the chemical processing industry, centrifugal blowers are vital for fume extraction and gas handling. They protect worker safety by effectively removing hazardous fumes and maintaining product integrity. Buyers should focus on blowers made from corrosion-resistant materials and ensure they comply with industry safety standards to mitigate risks associated with chemical exposure.

3 Common User Pain Points for ‘centrifugal blower fan design’ & Their Solutions

Scenario 1: Inadequate Airflow Performance in Industrial Applications

The Problem:

B2B buyers often encounter issues with inadequate airflow performance in their industrial settings, leading to inefficiencies and potential downtime. This challenge typically arises when the centrifugal blower fan design does not align with the specific requirements of the application, such as dust collection, material conveyance, or ventilation. Factors such as incorrect fan sizing, improper blade design, or insufficient static pressure can exacerbate these issues, causing frustration and increased operational costs.

The Solution:

To tackle inadequate airflow performance, buyers should begin by conducting a thorough assessment of their specific airflow requirements, including desired airflow rates (CFM), static pressure, and the characteristics of the material being moved (e.g., density, temperature). Engage with manufacturers or suppliers who offer customized centrifugal blower solutions that can be tailored to meet your operational needs. Additionally, consider using advanced simulation software during the design phase to predict airflow performance accurately. This proactive approach allows you to select the appropriate fan type—be it backward curved, backward inclined, or plug fans—based on their specific strengths in handling varying airflow conditions. Regular performance reviews and maintenance checks can further ensure that the fan continues to operate at optimal efficiency.

Scenario 2: Noise and Vibration Issues Caused by Blower Fans

The Problem:

Noise and vibration generated by centrifugal blower fans can significantly impact the working environment, leading to employee dissatisfaction and potential compliance issues with occupational safety regulations. Many B2B buyers face challenges in managing noise levels without compromising airflow performance. This issue is particularly pronounced in settings where quiet operation is crucial, such as in laboratories, hospitals, or residential areas adjacent to industrial sites.

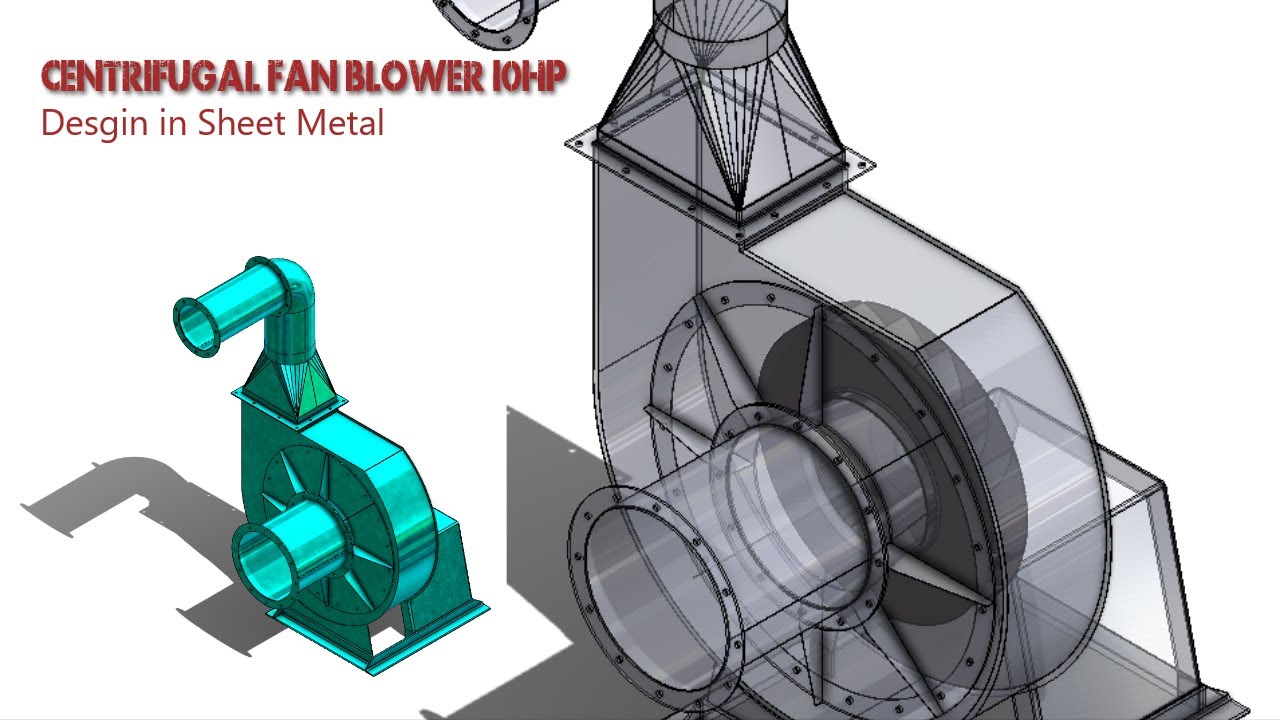

Illustrative image related to centrifugal blower fan design

The Solution:

To address noise and vibration concerns, buyers should prioritize the selection of centrifugal blower fans that feature sound-dampening technologies, such as insulated housing or acoustic enclosures. Additionally, opting for fans with lower RPMs can help reduce noise while still meeting airflow requirements. It’s also beneficial to conduct a vibration analysis during installation to identify any misalignment or imbalance in the system. Regular maintenance, including checking for loose components or worn bearings, can help mitigate vibration issues over time. Partnering with manufacturers that offer customizable solutions will allow for better integration of noise-reducing features tailored to your specific environment.

Scenario 3: High Energy Consumption Leading to Increased Operational Costs

The Problem:

Many B2B buyers are confronted with the challenge of high energy consumption associated with their centrifugal blower systems. This inefficiency can stem from outdated designs, improper fan selection, or suboptimal operational settings, ultimately leading to increased operational costs and a negative environmental impact. In regions with rising energy costs, this issue becomes even more pressing, particularly for companies striving for sustainability.

The Solution:

To combat high energy consumption, buyers should focus on selecting energy-efficient centrifugal blower designs that meet or exceed industry standards for efficiency. Consider fans equipped with variable frequency drives (VFDs), which allow for adjustable speed control based on real-time airflow demands, optimizing energy use. Implementing regular energy audits can provide insights into operational inefficiencies, enabling targeted improvements. Additionally, collaborating with manufacturers who specialize in energy-efficient designs can yield solutions that not only reduce energy consumption but also enhance overall system performance. Investing in modern technology and practices, such as predictive maintenance, can further extend the lifespan of blower systems and reduce energy waste.

Strategic Material Selection Guide for centrifugal blower fan design

What Are the Key Materials Used in Centrifugal Blower Fan Design?

When designing centrifugal blower fans, selecting the right materials is crucial for optimizing performance, durability, and cost-effectiveness. The choice of material affects various factors, including temperature and pressure ratings, corrosion resistance, and overall suitability for specific applications. Below, we analyze four common materials used in centrifugal blower fan design from a B2B perspective.

Illustrative image related to centrifugal blower fan design

How Do Aluminum and Its Alloys Perform in Centrifugal Blower Fan Applications?

Aluminum and its alloys are frequently used in centrifugal blower fan design due to their excellent strength-to-weight ratio and corrosion resistance. They typically have a temperature rating of up to 200°C (392°F) and can withstand moderate pressures.

Pros: Aluminum is lightweight, making it easier to handle and install. It also offers good thermal conductivity, which can help in dissipating heat effectively.

Cons: However, aluminum can be less durable than other materials when exposed to abrasive environments, leading to wear over time. Additionally, it is more expensive than some alternatives, which may affect budget-sensitive projects.

Impact on Application: Aluminum is particularly suitable for applications involving clean air and moderate humidity levels. It is not recommended for environments with highly corrosive chemicals.

Considerations for International Buyers: Buyers in regions like Europe and the Middle East should ensure compliance with standards such as DIN and ASTM for aluminum alloys.

What Role Does Steel Play in Centrifugal Blower Fan Design?

Steel, particularly carbon steel and stainless steel, is another common choice for centrifugal blower fans. It boasts high strength and can handle high pressures and temperatures, often exceeding 300°C (572°F) in specialized applications.

Pros: Steel’s durability makes it ideal for harsh environments, and stainless steel offers excellent corrosion resistance, which is vital for applications involving moisture or chemicals.

Cons: The downside is that steel is heavier than aluminum, which can complicate installation. Furthermore, it may require additional coatings or treatments to enhance corrosion resistance, adding to manufacturing complexity and cost.

Impact on Application: Steel is well-suited for industrial applications where high pressure and durability are required, such as in mining or chemical processing.

Illustrative image related to centrifugal blower fan design

Considerations for International Buyers: Compliance with international standards is critical, especially in regions like Germany, where stringent regulations exist for industrial equipment.

How Do Plastic Materials Enhance Centrifugal Blower Fan Performance?

Plastics, particularly high-performance thermoplastics like polycarbonate and polypropylene, are increasingly used in centrifugal blower fan design. These materials can withstand temperatures up to 120°C (248°F) and are resistant to many chemicals.

Pros: Plastics are lightweight and can be molded into complex shapes, facilitating innovative designs. They also offer good corrosion resistance and are cost-effective.

Cons: However, plastics may not be suitable for high-pressure applications and can degrade under UV exposure unless treated. Their mechanical properties can also be less reliable compared to metals.

Impact on Application: Plastics are ideal for applications where weight is a concern, such as in portable fans or in environments with corrosive substances.

Considerations for International Buyers: Buyers should verify that the plastics used meet relevant safety and environmental standards, particularly in Europe and North America.

Why Is Composite Material a Game-Changer in Centrifugal Blower Fan Design?

Composite materials, such as fiberglass-reinforced plastics, are gaining traction in centrifugal blower fan design due to their unique properties. They can handle temperatures up to 150°C (302°F) and offer excellent strength-to-weight ratios.

Pros: Composites are highly resistant to corrosion and can be designed to meet specific performance requirements, making them versatile for various applications.

Cons: The primary drawback is the higher manufacturing costs and complexity involved in producing composite components, which may deter budget-conscious buyers.

Impact on Application: Composites are particularly useful in environments where metal fatigue is a concern, such as in aerospace or marine applications.

Considerations for International Buyers: Compliance with industry standards is crucial, especially in regions with strict regulations regarding material safety and environmental impact.

Illustrative image related to centrifugal blower fan design

Summary Table of Material Selection for Centrifugal Blower Fans

| Material | Typical Use Case for centrifugal blower fan design | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Light-duty applications, clean air environments | Lightweight and corrosion-resistant | Less durable in abrasive settings | Medium |

| Steel | Heavy-duty industrial applications | High strength and pressure rating | Heavier and may require coatings | High |

| Plastic | Portable fans, corrosive environments | Lightweight and cost-effective | Not suitable for high-pressure use | Low |

| Composite | Aerospace, marine applications | Excellent strength-to-weight ratio | Higher manufacturing complexity | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions tailored to their specific operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for centrifugal blower fan design

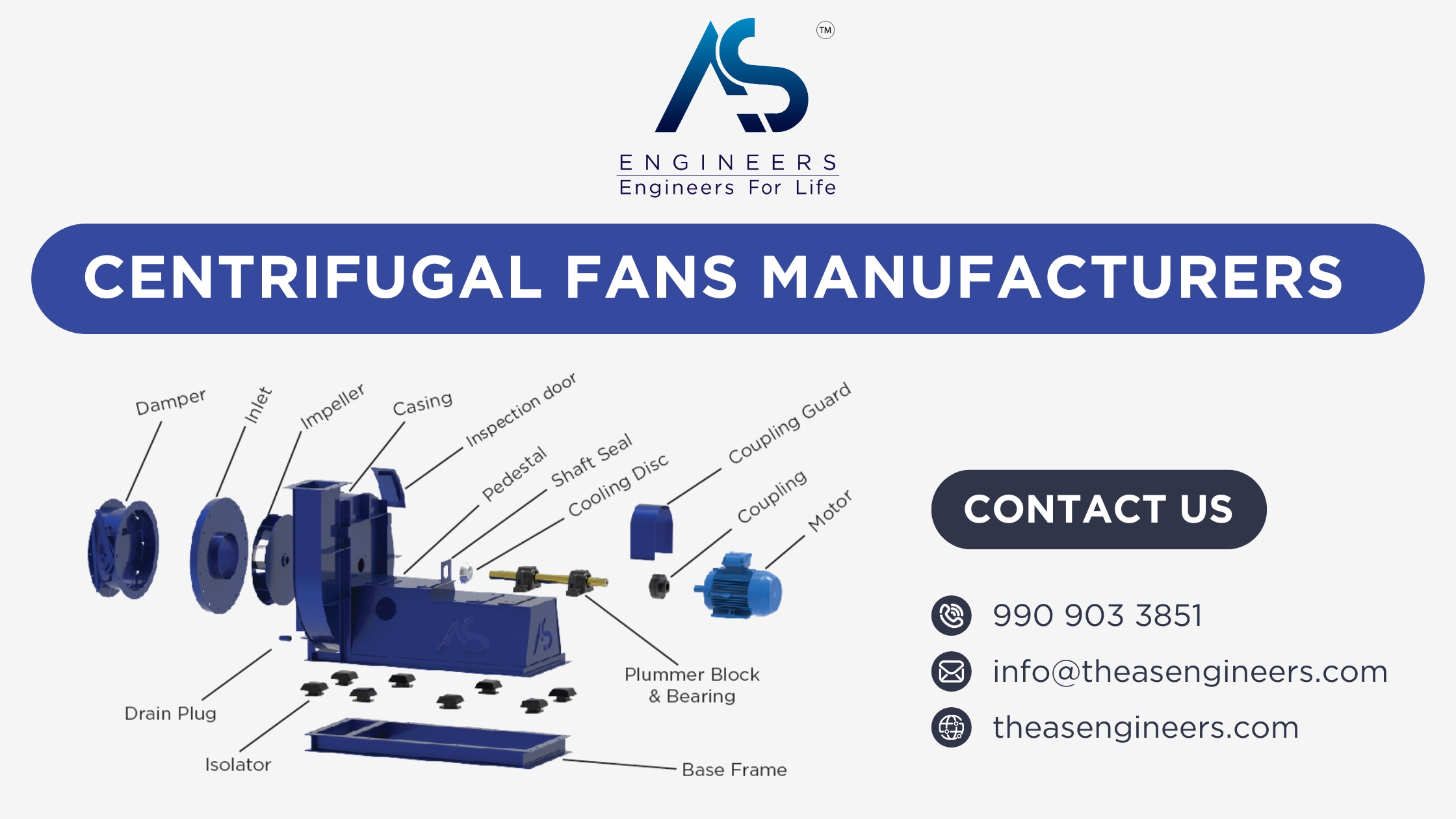

What Are the Key Stages in the Manufacturing Process of Centrifugal Blower Fans?

The manufacturing of centrifugal blower fans involves several critical stages that ensure the final product meets performance specifications and quality standards. Understanding these stages can help B2B buyers make informed decisions when sourcing from international suppliers.

Material Preparation: What Materials Are Used and How Are They Prepared?

The first step in the manufacturing process is material preparation. Centrifugal blower fans are typically constructed from durable materials such as steel, stainless steel, aluminum, or even composite materials. The choice of material often depends on the operational environment and application requirements.

Materials undergo rigorous quality checks to ensure they meet specifications. This includes verifying mechanical properties, thickness, and surface integrity. Suppliers may use advanced techniques such as spectrometry for material identification and tensile testing to assess strength. Once approved, the materials are cut into the required shapes and sizes for the next stages of production.

Illustrative image related to centrifugal blower fan design

How Are Centrifugal Blower Fans Formed?

The forming stage involves various techniques to shape the components of the blower fan. Common methods include:

- Stamping and Pressing: This is used for creating fan casings and impellers from sheets of metal. The process is efficient for producing high volumes of identical parts.

- Casting: For complex shapes or components requiring high strength, casting techniques such as sand casting or die casting may be employed.

- Machining: Precision machining processes, including CNC milling and turning, are used to achieve tight tolerances on critical components like shafts and impellers.

Each technique is selected based on the design requirements, production volume, and material characteristics.

What Does the Assembly Process Involve?

After forming, the next stage is assembly. This process is crucial as it determines the performance and reliability of the centrifugal blower fan. Key aspects of the assembly process include:

Illustrative image related to centrifugal blower fan design

- Component Fitting: Each component is fitted together with precision to ensure there are no gaps or misalignments that could affect airflow or efficiency.

- Welding and Fastening: Components may be welded or bolted together, depending on the design. This is often followed by a quality inspection to verify structural integrity.

- Balancing: Fans must be balanced to prevent vibrations during operation, which can lead to premature wear and failure. This is typically done using dynamic balancing techniques.

Proper assembly is vital, as any error can lead to significant operational issues down the line.

What Finishing Techniques Are Used to Enhance Performance and Longevity?

Finishing processes are employed to enhance the durability and performance of centrifugal blower fans. These may include:

- Surface Treatment: Processes such as anodizing, galvanizing, or powder coating are used to protect against corrosion and wear.

- Quality Coatings: Applying specialized coatings can improve airflow efficiency and reduce noise levels.

- Final Inspection: Before leaving the factory, each fan undergoes a thorough inspection for surface defects, dimensional accuracy, and overall quality.

The finishing stage not only improves the aesthetics but also extends the lifespan of the product.

How Is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that the final products meet established standards and customer expectations. B2B buyers should look for suppliers with robust QA protocols.

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 are essential for maintaining quality management systems. This certification ensures that manufacturers adhere to a set of quality benchmarks throughout their operations. In addition to ISO standards, industry-specific certifications like CE (European Conformity) and API (American Petroleum Institute) may be relevant, depending on the application of the centrifugal blower fans.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon receipt to ensure they meet specifications.

- In-Process Quality Control (IPQC): Inspections are conducted during the manufacturing process to catch defects early. This can include dimensional checks and visual inspections.

- Final Quality Control (FQC): Before shipment, products undergo comprehensive testing and inspection to verify performance and compliance with specifications.

These checkpoints help identify and rectify issues early, reducing the risk of defective products reaching customers.

What Common Testing Methods Are Used for Centrifugal Blower Fans?

Testing methods vary based on the intended application but commonly include:

- Performance Testing: Assessing airflow, pressure, and efficiency under various operational conditions.

- Noise Level Testing: Measuring sound output to ensure compliance with industry standards.

- Durability Testing: Simulating operational conditions to test longevity and reliability.

Documentation of these tests can provide valuable insights into the product’s expected performance in real-world applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider the following verification methods:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and adherence to international standards.

- Quality Reports: Requesting detailed QC reports can provide insights into testing methods, results, and any corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the manufacturer’s processes and products.

What Are the QC and Certification Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in QC and certification processes. Different regions may have varying standards and regulations, which can affect the acceptability of products. Understanding these differences is crucial for ensuring compliance and avoiding costly delays.

In conclusion, the manufacturing processes and quality assurance practices for centrifugal blower fans are complex and multi-faceted. By understanding these processes, B2B buyers can make informed decisions, ensuring that they source high-quality, reliable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘centrifugal blower fan design’

Introduction

In the competitive landscape of industrial equipment procurement, sourcing the right centrifugal blower fan design is critical for optimizing operational efficiency and performance. This guide serves as a practical checklist for B2B buyers, aiding in the systematic evaluation and selection of centrifugal blower fans tailored to specific applications. Following these steps will ensure that you make informed decisions that align with your technical requirements and business objectives.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical specifications. Identify the airflow requirements, static pressure, and application environment (e.g., dust collection, ventilation). This foundational step ensures that you select a centrifugal blower fan that meets your operational needs and complies with industry standards.

Illustrative image related to centrifugal blower fan design

- Airflow Capacity: Determine the required cubic feet per minute (CFM) based on your application.

- Static Pressure: Assess the pressure requirements, expressed in inches of water gauge (wg), to ensure compatibility with your system.

Step 2: Research Different Types of Centrifugal Blower Fans

Familiarize yourself with the various types of centrifugal blower fans available in the market. Each type, such as backward inclined, backward curved, and plug fans, offers distinct advantages based on the application.

- Backward Inclined Fans: Known for high efficiency and lower noise levels, suitable for general ventilation.

- Plug Fans: Ideal for high-pressure applications, often used in systems requiring compact designs.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your specific requirements. Request detailed company profiles, product catalogs, and case studies from buyers in similar industries.

- Supplier Experience: Look for suppliers with a proven track record in manufacturing centrifugal blowers for your industry.

- Client Testimonials: Seek feedback from existing customers to gauge reliability and product performance.

Step 4: Verify Supplier Certifications

Confirm that your chosen suppliers possess relevant certifications and comply with international standards. This step is crucial for ensuring product quality and safety.

- ISO Certification: Look for suppliers with ISO 9001 certification, indicating a commitment to quality management systems.

- Compliance with Local Regulations: Ensure that the products meet the specific regulations applicable in your region.

Step 5: Request Prototypes or Samples

Before finalizing your purchase, request prototypes or samples to evaluate the performance of the blower fans in your specific environment. Testing the product firsthand allows you to assess its suitability and efficiency.

- Performance Testing: Conduct airflow and pressure tests to verify that the blower meets your specifications.

- Material Quality Assessment: Inspect the materials used in construction to ensure durability and reliability.

Step 6: Discuss After-Sales Support and Warranty

Inquire about after-sales support and warranty options available from the supplier. A robust support system can significantly enhance the lifecycle and performance of your centrifugal blower fan.

- Technical Support: Ensure that the supplier offers technical assistance for installation and maintenance.

- Warranty Terms: Understand the warranty coverage to protect your investment against defects or failures.

Step 7: Compare Pricing and Payment Terms

Finally, compare pricing and payment terms from different suppliers to ensure you receive the best value. Look beyond the initial cost; consider the total cost of ownership, including installation and maintenance.

- Long-term Value: Evaluate the expected lifespan and efficiency of the blower to justify the investment.

- Flexible Payment Options: Negotiate terms that align with your budget and cash flow needs.

By adhering to this checklist, B2B buyers can confidently navigate the procurement of centrifugal blower fans, ensuring that they select the most suitable and cost-effective solutions for their operations.

Comprehensive Cost and Pricing Analysis for centrifugal blower fan design Sourcing

Analyzing the cost structure and pricing for centrifugal blower fan design sourcing is essential for international B2B buyers. Understanding the various components that contribute to the final price can help businesses make informed purchasing decisions and negotiate better terms.

What Are the Key Cost Components for Centrifugal Blower Fan Design?

The cost structure for centrifugal blower fans typically comprises several key components:

-

Materials: The choice of materials significantly impacts cost. Common options include aluminum, steel, and stainless steel. While aluminum is lightweight and cost-effective, stainless steel offers durability, especially in corrosive environments. Understanding the specific application will help in selecting the right material that balances performance and cost.

-

Labor: Labor costs vary depending on the manufacturing location and complexity of the fan design. Regions with lower labor costs, such as parts of Africa and South America, can offer competitive pricing. However, this may also affect the quality and consistency of the product.

-

Manufacturing Overhead: This includes costs associated with utilities, maintenance, and facility management. Efficient manufacturing processes can reduce overhead costs, ultimately benefiting buyers through lower prices.

-

Tooling: Custom designs may require specific tooling, which can add to upfront costs. Buyers should consider whether the investment in custom tooling will yield long-term savings and efficiencies.

-

Quality Control (QC): Ensuring product quality through rigorous testing and certification is vital. While higher QC standards may increase costs, they can prevent expensive failures and downtime, contributing to a better Total Cost of Ownership (TCO).

-

Logistics: Shipping costs can vary widely based on the origin and destination of the product, as well as the chosen Incoterms. Understanding logistics expenses is crucial, especially for international shipments.

-

Margin: Supplier margins can differ based on market positioning and competition. Buyers should be aware of typical margins in their industry to gauge fair pricing.

What Influences the Pricing of Centrifugal Blower Fans?

Several factors influence the pricing structure of centrifugal blower fans:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs. Buyers should assess their needs to determine the optimal order size.

-

Specifications and Customization: Customized designs often come at a premium. Buyers should weigh the benefits of customization against potential cost increases.

-

Quality and Certifications: Higher quality products with certifications (e.g., ISO standards) may command higher prices but can lead to greater reliability and lower maintenance costs.

-

Supplier Factors: The supplier’s reputation, location, and experience can impact pricing. Established suppliers may charge more but can offer better service and reliability.

-

Incoterms: Understanding shipping terms can significantly affect total costs. Different Incoterms dictate who bears the shipping and insurance costs, which can impact the final pricing.

How Can Buyers Negotiate Better Prices for Centrifugal Blower Fans?

Buyers should consider several strategies to negotiate favorable terms:

-

Leverage Volume Discounts: Consolidating orders can lead to significant savings. Discuss potential discounts for larger purchases with suppliers.

-

Explore Alternative Suppliers: Researching multiple suppliers can provide leverage in negotiations. It is essential to compare not only prices but also quality and service levels.

-

Assess Total Cost of Ownership: Instead of focusing solely on upfront costs, consider the TCO, including maintenance, energy efficiency, and expected lifespan. This holistic view can justify higher initial investments.

-

Be Aware of Pricing Nuances for International Transactions: Currency fluctuations, tariffs, and import duties can affect overall costs. Engage with suppliers familiar with the specific regulations in your region to avoid unexpected expenses.

Conclusion

The comprehensive analysis of cost components and pricing influencers in centrifugal blower fan design sourcing is critical for B2B buyers. By understanding these factors and implementing effective negotiation strategies, companies can optimize their purchasing decisions, ensuring they achieve both cost-effectiveness and product quality. As always, consider this analysis as a guideline, as actual prices may vary based on specific circumstances and market conditions.

Alternatives Analysis: Comparing centrifugal blower fan design With Other Solutions

Exploring Alternatives to Centrifugal Blower Fan Design

When considering the optimal solution for airflow management in industrial applications, it’s essential to evaluate various technologies. Centrifugal blower fans are widely used for their efficiency in moving air at high pressures. However, alternative solutions such as industrial fans and air compressors can also achieve similar goals. This analysis will compare these options based on several critical aspects to help B2B buyers make informed decisions.

| Comparison Aspect | Centrifugal Blower Fan Design | Industrial Fan | Air Compressor |

|---|---|---|---|

| Performance | High pressure, moderate volume | High volume, lower pressure | Variable pressure, high volume |

| Cost | Moderate to high initial cost | Generally lower initial cost | High initial cost, ongoing energy costs |

| Ease of Implementation | Requires specific installation | Easier installation in various environments | Complex setup, often requires additional infrastructure |

| Maintenance | Moderate; requires regular checks | Low; generally low wear components | High; regular servicing needed |

| Best Use Case | Dust collection, pressurization | Ventilation, cooling, large spaces | Pneumatic tools, air-driven processes |

What Are the Advantages and Disadvantages of Industrial Fans?

Industrial fans are designed for high-volume airflow but operate at lower pressures compared to centrifugal blowers. Their construction typically allows for easier installation and lower initial costs, making them an attractive option for facilities needing ventilation in large spaces. However, they may not be suitable for applications requiring high-pressure airflow, such as dust collection systems. Maintenance is generally low, but the performance may not meet the demands of specialized applications.

Illustrative image related to centrifugal blower fan design

How Do Air Compressors Compare to Centrifugal Blower Fans?

Air compressors generate pressure in compressible fluids, making them suitable for pneumatic applications. They can provide variable pressure outputs, which is ideal for tools and machinery that require compressed air. However, they often entail higher initial costs and significant ongoing energy expenses. Installation can be complex, requiring additional infrastructure like air lines and tanks. Furthermore, maintenance can be intensive, as compressors need regular servicing to ensure reliability. Despite these drawbacks, air compressors excel in scenarios where variable pressure and high air volume are crucial.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right airflow management solution depends on specific operational needs and constraints. B2B buyers should assess their requirements for airflow volume, pressure, installation complexity, and ongoing maintenance. Centrifugal blower fans are ideal for high-pressure applications, while industrial fans offer a cost-effective solution for general ventilation. On the other hand, air compressors are best suited for applications requiring variable pressure and pneumatic tools. By understanding the strengths and limitations of each option, buyers can make an informed choice that aligns with their operational objectives.

Essential Technical Properties and Trade Terminology for centrifugal blower fan design

What Are the Key Technical Properties in Centrifugal Blower Fan Design?

In the design of centrifugal blower fans, several critical technical specifications must be considered to ensure optimal performance and reliability. Understanding these properties is essential for B2B buyers looking to make informed purchasing decisions.

1. Material Grade

Centrifugal blower fans are typically constructed from materials such as steel, stainless steel, or aluminum. The choice of material affects durability, corrosion resistance, and overall performance. For instance, stainless steel is preferred in corrosive environments, while aluminum offers lightweight advantages. Selecting the appropriate material grade can enhance longevity and reduce maintenance costs.

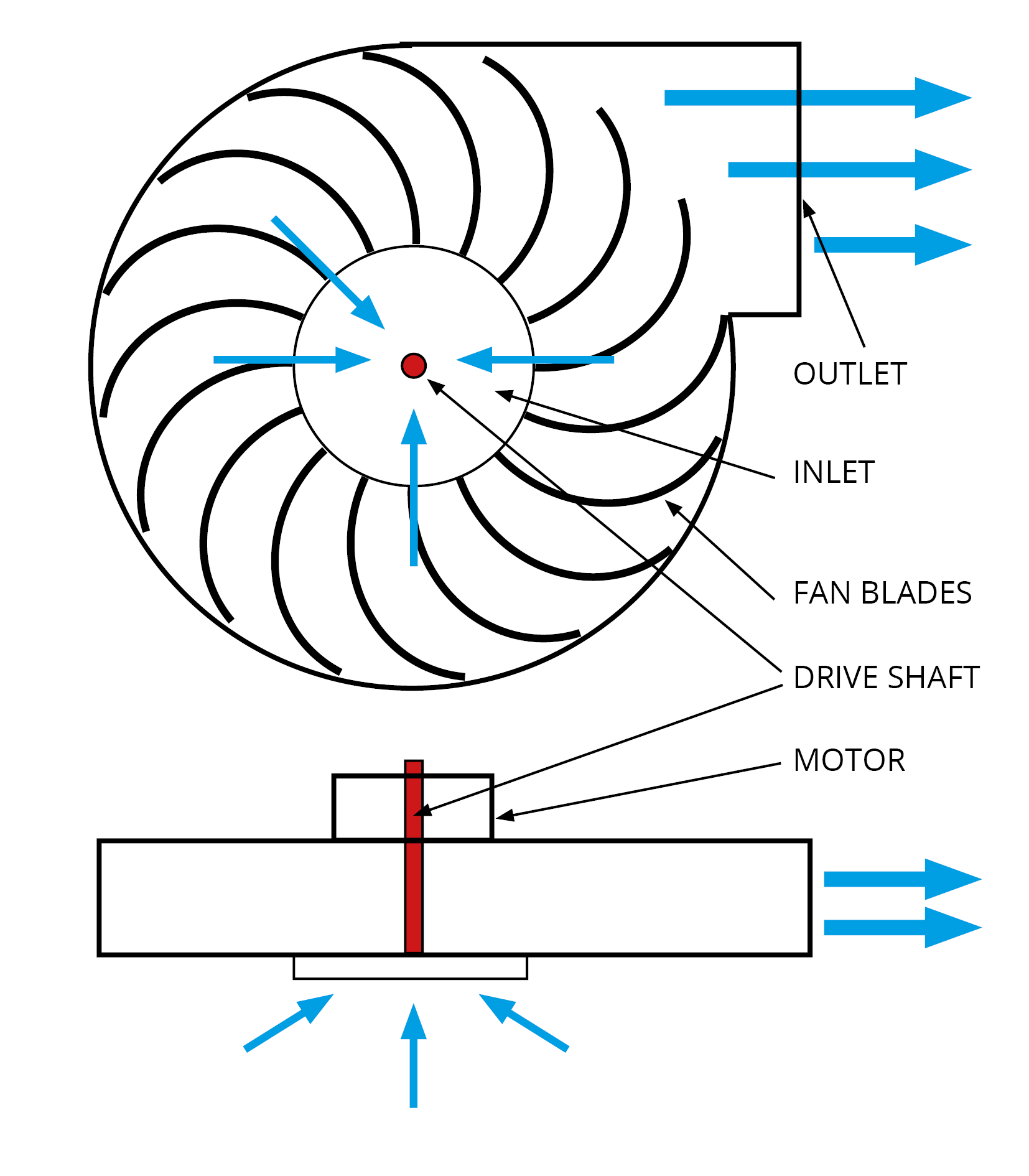

2. Airflow Capacity (CFM)

Airflow capacity, measured in Cubic Feet per Minute (CFM), indicates the volume of air the blower can move. This specification is crucial for determining whether the fan will meet the operational requirements of a facility. A higher CFM rating means the fan can handle more air, which is vital for applications requiring significant air exchange, such as dust collection and ventilation.

3. Static Pressure

Static pressure is the resistance to airflow in a system, measured in inches of water gauge (in. wg). Understanding static pressure is essential as it influences the fan’s efficiency and operational capabilities. Fans designed to operate at higher static pressures are suitable for applications where airflow is restricted, ensuring consistent performance even under challenging conditions.

4. Tolerance Levels

Tolerance levels refer to the permissible limits of variation in dimensions and performance specifications. In centrifugal blower fans, tight tolerances are critical for ensuring proper fit and function, minimizing vibrations, and enhancing efficiency. This is particularly important in high-speed applications where even minor discrepancies can lead to significant operational issues.

5. Efficiency Ratings

Efficiency ratings, often expressed as a percentage, indicate how effectively the blower converts input power into airflow. Higher efficiency ratings mean lower energy consumption, which is essential for cost-effective operation. B2B buyers should prioritize efficiency to reduce operating costs and meet sustainability goals.

What Are Common Trade Terms Used in Centrifugal Blower Fan Design?

Familiarity with industry jargon can streamline communication and negotiations in the procurement process. Here are several common terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers, as it can affect product quality and support. Buyers often seek OEM products for reliability and warranty purposes.

Illustrative image related to centrifugal blower fan design

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchases and manage inventory effectively. It is particularly relevant for businesses looking to optimize costs and ensure adequate supply without overcommitting.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically includes specifications and quantities of the required products. An RFQ is a critical step in the procurement process, helping buyers compare pricing and terms from multiple suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping costs, risk transfer, and delivery points. Understanding Incoterms is essential for B2B buyers engaged in global sourcing to avoid misunderstandings and ensure smooth transactions.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. It is a crucial factor for B2B buyers who need to align their procurement with production schedules. Understanding lead times can help businesses plan their operations more effectively and maintain workflow continuity.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions in the procurement of centrifugal blower fans, ultimately enhancing operational efficiency and cost-effectiveness.

Illustrative image related to centrifugal blower fan design

Navigating Market Dynamics and Sourcing Trends in the centrifugal blower fan design Sector

What Are the Current Market Dynamics and Key Trends in Centrifugal Blower Fan Design?

The centrifugal blower fan design sector is experiencing significant transformation driven by both technological advancements and shifting market demands. Global economic recovery post-pandemic, coupled with increasing industrial activities, has led to a surge in demand for efficient airflow solutions. In particular, sectors such as manufacturing, HVAC, and agriculture are increasingly relying on centrifugal blowers for their ability to handle high pressures while maintaining energy efficiency.

Emerging technologies, including IoT integration and automation, are reshaping how these systems operate. Smart centrifugal blowers equipped with sensors allow for real-time monitoring and optimization of airflow, leading to enhanced operational efficiency. This trend resonates particularly with international B2B buyers in regions such as Africa and South America, where there is a growing focus on modernizing industrial processes.

Sourcing trends are also evolving, with an emphasis on local suppliers to mitigate supply chain risks. Buyers are increasingly prioritizing partnerships with manufacturers who can deliver customized solutions tailored to specific industry needs, particularly in regions like Europe and the Middle East, where regulatory standards are stringent. As a result, suppliers are adapting their offerings, providing more flexible designs and scalable solutions that cater to diverse market requirements.

How Is Sustainability Shaping B2B Sourcing in the Centrifugal Blower Fan Industry?

Sustainability has become a cornerstone of B2B sourcing strategies, particularly in the centrifugal blower fan design sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Buyers are now more inclined to choose suppliers that prioritize sustainable practices, such as using eco-friendly materials and minimizing carbon footprints during production.

Ethical sourcing is equally important, as businesses recognize the value of transparent supply chains. International buyers are increasingly demanding certifications that validate the sustainability claims of manufacturers, such as ISO 14001 for environmental management or certifications for using recycled materials. In regions like Europe, where green initiatives are prominent, the importance of such certifications cannot be overstated.

Illustrative image related to centrifugal blower fan design

Moreover, the shift towards renewable energy sources is influencing the design of centrifugal blowers. Manufacturers are exploring materials and designs that not only enhance efficiency but also align with renewable energy applications, making their products more attractive to eco-conscious buyers. As sustainability becomes a competitive differentiator, B2B buyers must evaluate potential suppliers based on their commitment to ethical sourcing and environmental stewardship.

What Is the Historical Context of Centrifugal Blower Fan Design?

The evolution of centrifugal blower fan design can be traced back to the early industrial revolution when the need for efficient air movement in factories became paramount. Initially driven by steam power, these fans have undergone significant technological advancements, transitioning to electric motors that enhance efficiency and control.

Over the decades, the introduction of advanced materials and manufacturing techniques has allowed for the production of more durable and efficient blowers. The integration of computational fluid dynamics (CFD) in the design process has further refined performance, enabling manufacturers to create products that meet the increasing demands for energy efficiency and operational flexibility.

Illustrative image related to centrifugal blower fan design

Today, the centrifugal blower fan design sector stands at the intersection of innovation and sustainability, making it imperative for international B2B buyers to stay informed about historical trends as they navigate current market dynamics. Understanding this evolution not only provides context but also informs future sourcing decisions that prioritize efficiency and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of centrifugal blower fan design

-

How do I select the right centrifugal blower fan design for my industrial application?

Selecting the right centrifugal blower fan requires a thorough understanding of your specific application needs. Consider factors such as airflow requirements (measured in CFM), static pressure, and the type of material being conveyed. Additionally, evaluate the operational environment, including temperature and humidity levels, which may affect performance. Consulting with a supplier who understands your industry can help ensure you choose a blower that meets your operational efficiency and reliability expectations. -

What is the best centrifugal blower fan type for high-pressure applications?

For high-pressure applications, backward curved centrifugal fans are often the best choice. These fans are designed to handle higher pressures while maintaining efficient airflow. They excel in applications such as dust collection, pneumatic conveying, and HVAC systems where consistent pressure is crucial. When selecting a fan, consider the specific pressure and airflow requirements of your application to ensure optimal performance. -

What customization options are available for centrifugal blower fan designs?

Customization options for centrifugal blower fans can vary by manufacturer but typically include adjustments to size, material, and blade design. Buyers can request specific dimensions, motor types, and housing configurations to suit their unique needs. Additionally, some suppliers may offer bespoke solutions for specialized applications, allowing for modifications that enhance performance or efficiency. Engaging with a supplier early in the design process can facilitate a more tailored solution. -

What minimum order quantities (MOQs) should I expect when sourcing centrifugal blower fans?

Minimum order quantities for centrifugal blower fans can vary significantly based on the manufacturer and the complexity of the design. Generally, MOQs can range from a single unit for standard models to larger quantities for custom designs. It’s essential to discuss your requirements with potential suppliers, as many are willing to negotiate MOQs, especially for ongoing partnerships or bulk orders. -

What payment terms are commonly offered by suppliers of centrifugal blower fans?

Payment terms can differ widely among suppliers, but most B2B transactions include options such as net 30, net 60, or even upfront payment for custom designs. Some suppliers may also offer financing options or discounts for early payments. It’s advisable to clarify payment terms and negotiate conditions that align with your cash flow capabilities before finalizing any agreements. -

How can I ensure quality assurance (QA) for the centrifugal blower fans I purchase?

To ensure quality assurance, select suppliers that adhere to recognized industry standards and certifications, such as ISO 9001. Request documentation of testing procedures and quality control measures used during production. Additionally, consider visiting the manufacturing facility if possible, or inquire about third-party inspections to verify compliance with specifications. Establishing a clear QA process in your procurement agreement can help safeguard against defects and performance issues. -

What logistics considerations should I keep in mind when sourcing centrifugal blower fans internationally?

When sourcing internationally, consider shipping methods, lead times, and customs regulations that may affect delivery. Work with suppliers who have experience with international shipping to ensure compliance with local laws and efficient transportation. Additionally, factor in potential tariffs or duties that could impact overall costs. Planning for logistics early in the procurement process can minimize delays and unexpected expenses. -

How can I vet suppliers for centrifugal blower fan designs effectively?

Vetting suppliers requires a multifaceted approach. Start by researching their reputation through online reviews and industry references. Verify their experience in producing centrifugal blower fans and request case studies or testimonials from previous clients. Additionally, assess their production capabilities and certifications. Engaging in direct communication and asking probing questions about their processes and support can also help gauge their reliability and commitment to quality.

Top 8 Centrifugal Blower Fan Design Manufacturers & Suppliers List

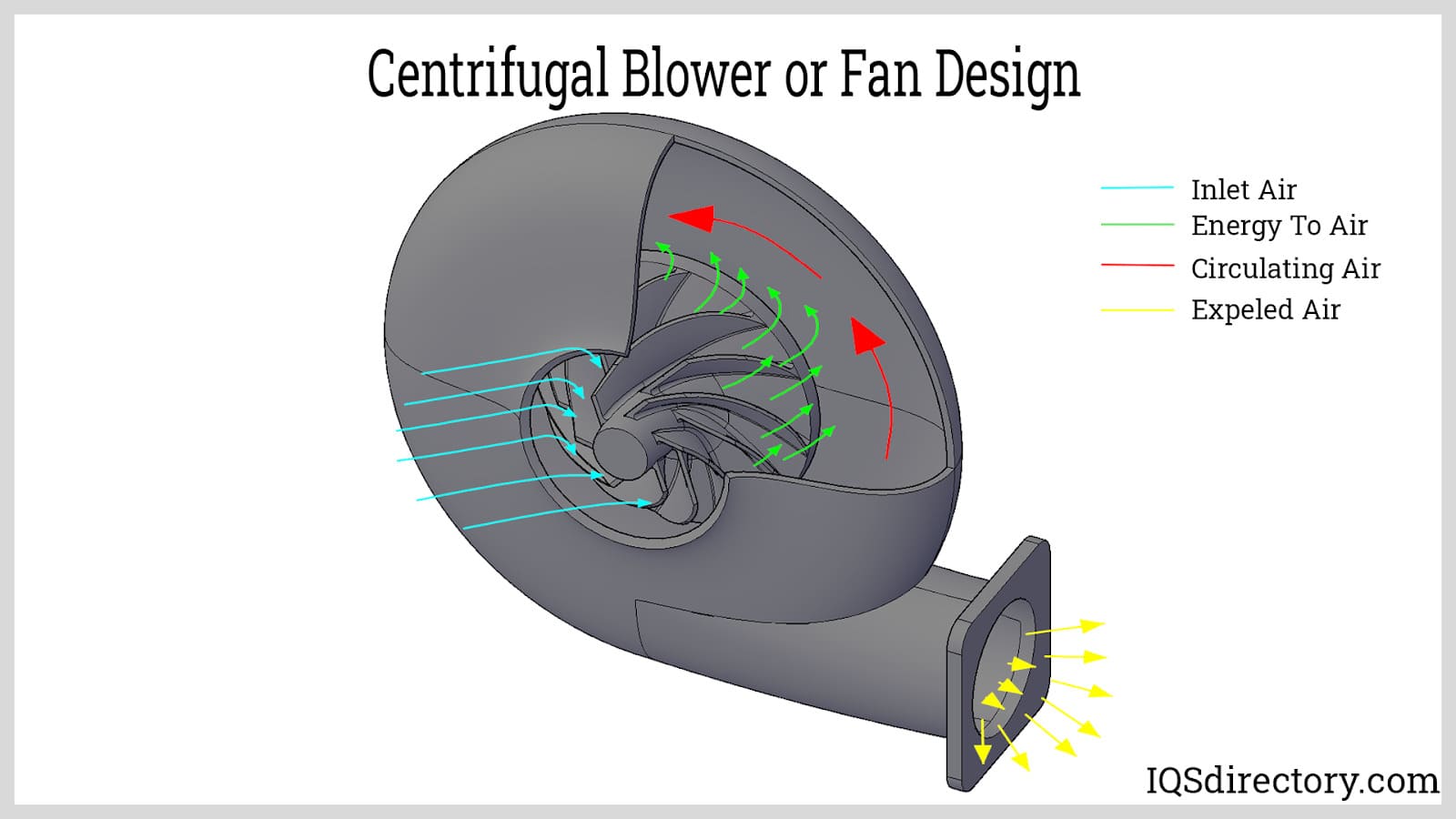

1. IQS Directory – Centrifugal Blowers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Centrifugal blowers are mechanisms designed to propel air using centrifugal force from a spinning impeller. Key components include the impeller, housing, and drive mechanism. Types of centrifugal blowers include: 1. Forward Curved Centrifugal Blowers: High static pressure and airflow, used in low-pressure applications like HVAC systems. 2. Backward Inclined Centrifugal Blowers: Higher efficiency a…

2. We Sell Fans – Forward Curved Wheel

Domain: wesellfans.com

Registered: 2006 (19 years)

Introduction: Centrifugal fans are categorized into three basic wheel types: Forward Curved, Radial, and Backward Curved.

1. **Forward Curved (FC) Wheel**:

– Provides large quantities of air at low pressures (3 to 5 inches of static pressure).

– Commonly used in furnace blowers and air handlers.

– Made of riveted or welded stamped sheet metal.

– Intended for clean air applications only.

– …

3. Cincinnati Fan – Centrifugal & Custom Fans

Domain: cincinnatifan.com

Registered: 1998 (27 years)

Introduction: Centrifugal Fans Models: HDAF (Airfoil Fan), HDBC (Backward Curved Fan), HDBI (Backward Inclined Fan), CPAF (Airfoil Plug Fan), CPF (Backward Inclined Plug Fan), LM & LMF (Volume Fan), PL (Plenum Fan), SQAF (Airfoil Square Fan), SQBI (Backward Inclined Square Fan). Custom Fans/Blowers Models: PB (Cast Aluminum Pressure Blower), PBS (Fabricated Steel Pressure Blower), SPB (Die-Formed Steel Pressure…

4. Northern Blower – Custom Centrifugal Fans & Blowers

Domain: northernblower.com

Registered: 1996 (29 years)

Introduction: Custom Centrifugal Fans & Blowers designed for challenging industrial processes. Key series and designs include: Series 4000 (Backward Curved Industrial, SISW, 5,000 to 250,000 ACFM, 48″ WG SP), Design 5010 (Airfoil, SISW & DIDW, 1,000 to 250,000 ACFM, 21″ WG SP), Design 5020 (Backward Inclined Blower, SISW & DIDW, 1,000 to 300,000 ACFM, 24″ WG SP), Series 5700 (Industrial Airfoil, SISW & DIDW, 5,…

5. Reddit – Blower Fan Performance Factors

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Blower fans have fixed constraints in impeller diameter and height, which limit performance improvements. The design factors affecting performance include impeller diameter, impeller housing design, impeller depth/height, and impeller blade count. Larger impellers provide better performance but are constrained by compatibility with GPU sizes. Housing design is crucial for performance but has been …

6. Hobby Machinist – Centrifugal Fan Project

Domain: hobby-machinist.com

Registered: 2010 (15 years)

Introduction: Centrifugal fan DIY project by MrCrankyface. Uses a 1-phase induction motor rated for 320W, drawing around 200W. Features a modular fan wheel design that can accommodate 4, 6, 8, 12, or 24 blades with adjustable angles. Initial tests showed airflow improvements with blade adjustments and gap modifications. Current testing includes a 60-blade fan and plans for a 100-blade fan to optimize airflow. F…

7. Air Blower Fan – Centrifugal & HVAC Blowers

Domain: airblowerfan.com

Registered: 2020 (5 years)

Introduction: Centrifugal AC Blowers: Single Fan Type (2,800~3,400 RPM), Single Fan Type (1,400~1,800 RPM), Duo-Fan Type, Double Suction Type; Centrifugal DC Blowers; Combustion Air Blowers; Draft Inducer / Air Blower Fan; Furnace Blowers; HVAC Blowers; Blower Fan Motors; Air Shower Blowers; Cross Flow Fan; Inflatable Blower Fans; Carpet Dryer; Air Booster Fans; Blower Wheel; Centrifugal Strip Type; Centrifugal…

8. Eng-Tips – Centrifugal Fan Design Essentials

Domain: eng-tips.com

Registered: 1997 (28 years)

Introduction: Centrifugal fan design considerations include increasing pressure to 400 mbar, calculating horsepower (410 kW), optimizing horsepower, and factors affecting design such as the number of blades, curvature, and shape. Suggested reference book: “Fan Engineering” by Howden.

Strategic Sourcing Conclusion and Outlook for centrifugal blower fan design

In conclusion, effective strategic sourcing in centrifugal blower fan design is crucial for international B2B buyers aiming to enhance operational efficiency and product quality. By selecting suppliers who prioritize innovation and reliability, businesses can secure high-performance blowers that meet diverse industrial needs. Understanding the various types of centrifugal blowers—such as backward curved and plug fans—enables buyers to tailor solutions for specific applications, from dust collection to moisture removal.

Investing in strategic sourcing not only reduces costs but also fosters long-term partnerships with manufacturers committed to continuous improvement. As industries across Africa, South America, the Middle East, and Europe evolve, the demand for energy-efficient and durable blower systems will only increase.

We encourage B2B buyers to proactively engage with suppliers, explore advanced designs, and leverage the latest technologies to remain competitive in their markets. The future of centrifugal blower fan design is bright, and those who prioritize strategic sourcing will be well-positioned to capitalize on emerging opportunities. Embrace this journey towards excellence and drive your business forward with smart sourcing decisions today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.