A B2B Buyer’s Guide to Bonnet Hood Scoop: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for bonnet hood scoop

Navigating the global market for bonnet hood scoops presents a unique challenge for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The complexity of sourcing high-quality, functional hood scoops that meet varying regulatory standards and performance requirements can be daunting. This guide aims to simplify that process by providing a comprehensive overview of the types of bonnet hood scoops available, their diverse applications in automotive performance enhancement, and critical insights into supplier vetting practices.

In this guide, you will find detailed information on the various styles and materials of hood scoops—ranging from ABS plastic to aluminum—and their respective benefits. We will also delve into essential considerations such as installation methods, compatibility with different vehicle models, and the cost implications for bulk purchases. By equipping you with these insights, this guide empowers international B2B buyers to make informed purchasing decisions that align with their specific operational needs.

Whether you are sourcing for automotive production, aftermarket modifications, or performance enhancements, understanding the market landscape is crucial. With our expert recommendations and actionable strategies, you will be better positioned to navigate the complexities of the bonnet hood scoop market, ensuring you select the right products that enhance both vehicle aesthetics and functionality.

Understanding bonnet hood scoop Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cowl Induction Scoop | Located near the windshield, increases air intake efficiency | Performance vehicles, racing cars | Pros: Enhances engine performance; Cons: May require custom installation. |

| Shaker Scoop | Protrudes through the hood, moves with engine vibrations | Muscle cars, vintage restorations | Pros: Unique aesthetic; Cons: Limited compatibility with modern designs. |

| Functional Hood Scoop | Directs airflow into the engine compartment for cooling | High-performance vehicles, off-road trucks | Pros: Improves engine cooling; Cons: Can be expensive and complex to install. |

| Universal Hood Scoop | Fits various models, lightweight materials like ABS plastic | Custom builds, aftermarket modifications | Pros: Versatile; Cons: May need adjustments for a perfect fit. |

| Aerodynamic Scoop | Designed for high-speed performance, low-profile design | Sports cars, racing applications | Pros: Reduces drag; Cons: Higher price point. |

What Are the Characteristics of Cowl Induction Scoops?

Cowl induction scoops are designed to be mounted at the rear of the hood, typically near the windshield. This positioning takes advantage of the high-pressure zone created by the windshield’s curvature, allowing for improved airflow into the engine compartment. They are particularly suitable for performance and racing vehicles where engine power is paramount. B2B buyers should consider the specific vehicle models they cater to, as these scoops often require custom fitting and may not be universally compatible.

How Does the Shaker Scoop Stand Out?

The shaker scoop is a distinctive feature in many muscle cars, protruding through the hood and vibrating with the engine’s movement. This design not only adds a unique visual appeal but also serves to enhance engine performance by drawing in more air. While ideal for vintage restorations and muscle car enthusiasts, B2B buyers should be aware of compatibility issues with modern vehicles and the potential need for specialized installation.

Why Choose Functional Hood Scoops?

Functional hood scoops are engineered to improve engine cooling by directing airflow directly into the engine compartment. They are commonly used in high-performance vehicles and off-road trucks where maintaining optimal engine temperature is crucial. B2B purchasers must assess the complexity and cost of installation, as well as the specific performance benefits they can offer to their customers.

What Makes Universal Hood Scoops a Practical Option?

Universal hood scoops are designed to fit a wide range of vehicle models, making them a versatile choice for aftermarket modifications. Typically made from lightweight materials such as ABS plastic, these scoops can be easily installed without significantly affecting vehicle weight. B2B buyers should consider the need for potential adjustments during installation, as the fit may not be perfect for every model.

How Do Aerodynamic Scoops Enhance Performance?

Aerodynamic scoops are specifically designed to minimize drag while maximizing airflow, making them ideal for high-speed applications. Their sleek and low-profile design is favored in sports cars and racing environments. B2B buyers looking to cater to performance-focused clientele should weigh the benefits of improved speed against the higher price point associated with these specialized scoops.

Key Industrial Applications of bonnet hood scoop

| Industry/Sector | Specific Application of bonnet hood scoop | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Performance | Enhancing air intake in performance vehicles | Improved engine efficiency and power output | Material quality, compatibility with vehicle models, installation ease |

| Racing & Motorsports | Utilization in race cars for aerodynamic advantages | Competitive edge through optimized airflow | Regulations compliance, weight considerations, customization options |

| Custom Vehicle Builds | Integration into modified vehicles for aesthetics | Enhanced visual appeal and market differentiation | Design specifications, durability, and custom fit options |

| Heavy Machinery | Cooling applications in industrial vehicles | Increased operational efficiency and longevity | Resistance to environmental factors, load capacity, and installation requirements |

| Classic Car Restoration | Replacement for vintage models to maintain authenticity | Preservation of historical value and functionality | Authenticity of design, material sourcing, and compatibility with original parts |

How is a bonnet hood scoop used in automotive performance applications?

In the automotive performance sector, bonnet hood scoops are essential for enhancing air intake in high-performance vehicles. They allow for increased airflow into the engine compartment, which can lead to improved engine efficiency and power output. This is particularly beneficial for international B2B buyers in regions such as Europe and the Middle East, where performance vehicles are in high demand. Buyers should consider the material quality and compatibility with specific vehicle models to ensure optimal performance and ease of installation.

What role do bonnet hood scoops play in racing and motorsports?

In racing and motorsports, bonnet hood scoops are strategically utilized to provide aerodynamic advantages. By optimizing airflow, these scoops can significantly enhance a vehicle’s performance on the track, giving teams a competitive edge. Buyers in this sector, especially from regions like South America and Africa, must ensure compliance with racing regulations, as well as consider weight and customization options to meet specific racing standards. The right scoop can make a difference in lap times and overall race performance.

How are bonnet hood scoops integrated into custom vehicle builds?

For custom vehicle builds, bonnet hood scoops serve both functional and aesthetic purposes. They can enhance the visual appeal of a modified vehicle while also providing practical benefits such as improved airflow. This is particularly valuable for businesses focused on customization in markets across Europe and the Middle East, where unique vehicle designs are sought after. When sourcing, companies should pay attention to design specifications, durability, and custom fit options to ensure that the scoop aligns with the overall vehicle design.

What benefits do bonnet hood scoops offer in heavy machinery applications?

In the heavy machinery sector, bonnet hood scoops are used to facilitate cooling in industrial vehicles. By increasing airflow to critical engine components, these scoops help maintain optimal operating temperatures, thereby increasing operational efficiency and extending the machinery’s lifespan. Buyers from regions like Africa, where heavy machinery is vital for mining and construction, should consider environmental resistance and load capacity when sourcing bonnet hood scoops to ensure reliability in harsh conditions.

Why are bonnet hood scoops important for classic car restoration projects?

Bonnet hood scoops are crucial in classic car restoration projects, as they help maintain the authenticity and functionality of vintage models. Restorers aim to preserve the historical value of the vehicle while ensuring it operates as intended. For buyers in Europe and the Middle East, where classic cars are highly valued, sourcing authentic designs and compatible materials is essential. Attention to detail in sourcing can significantly impact the success of restoration projects and the vehicle’s market value.

3 Common User Pain Points for ‘bonnet hood scoop’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

The Problem: B2B buyers frequently encounter issues with inconsistent quality when sourcing bonnet hood scoops from different suppliers. This inconsistency can lead to variations in performance, appearance, and durability, which can negatively impact customer satisfaction and brand reputation. For businesses in regions like Africa and South America, where local suppliers may not have stringent quality controls, this challenge can be particularly pronounced. Buyers often find themselves in a dilemma: how to ensure that the product they are purchasing meets their specifications and quality standards without incurring excessive costs.

The Solution: To address this issue, B2B buyers should prioritize establishing relationships with reputable suppliers who have a proven track record of delivering high-quality products. Conduct thorough research by reviewing supplier certifications, customer testimonials, and product samples. Utilize platforms that provide ratings and reviews to gauge the experiences of other buyers. Additionally, consider implementing a quality assurance protocol that includes inspecting samples before committing to large orders. This proactive approach not only helps in maintaining product consistency but also builds long-term partnerships with suppliers who can meet quality expectations reliably.

Scenario 2: Installation Challenges Leading to Performance Issues

The Problem: Another common pain point for B2B buyers is the challenge of installation, which can lead to performance issues with bonnet hood scoops. Improper installation can affect airflow efficiency, causing overheating or diminished engine performance. Buyers often face confusion regarding the correct mounting techniques or compatibility with different vehicle models, resulting in costly returns or modifications.

The Solution: To mitigate installation challenges, buyers should invest in comprehensive installation guides or seek suppliers that provide detailed instructional materials, including videos or diagrams. It’s essential to ensure that the chosen bonnet hood scoop is compatible with the specific vehicle model, which can be facilitated by utilizing a fitment guide or consulting with the supplier. Additionally, offering training sessions or workshops for installation teams can enhance their skills and reduce the likelihood of errors. Engaging with suppliers who provide customer support during the installation process can further assist in troubleshooting any potential issues, ensuring that the product performs optimally once installed.

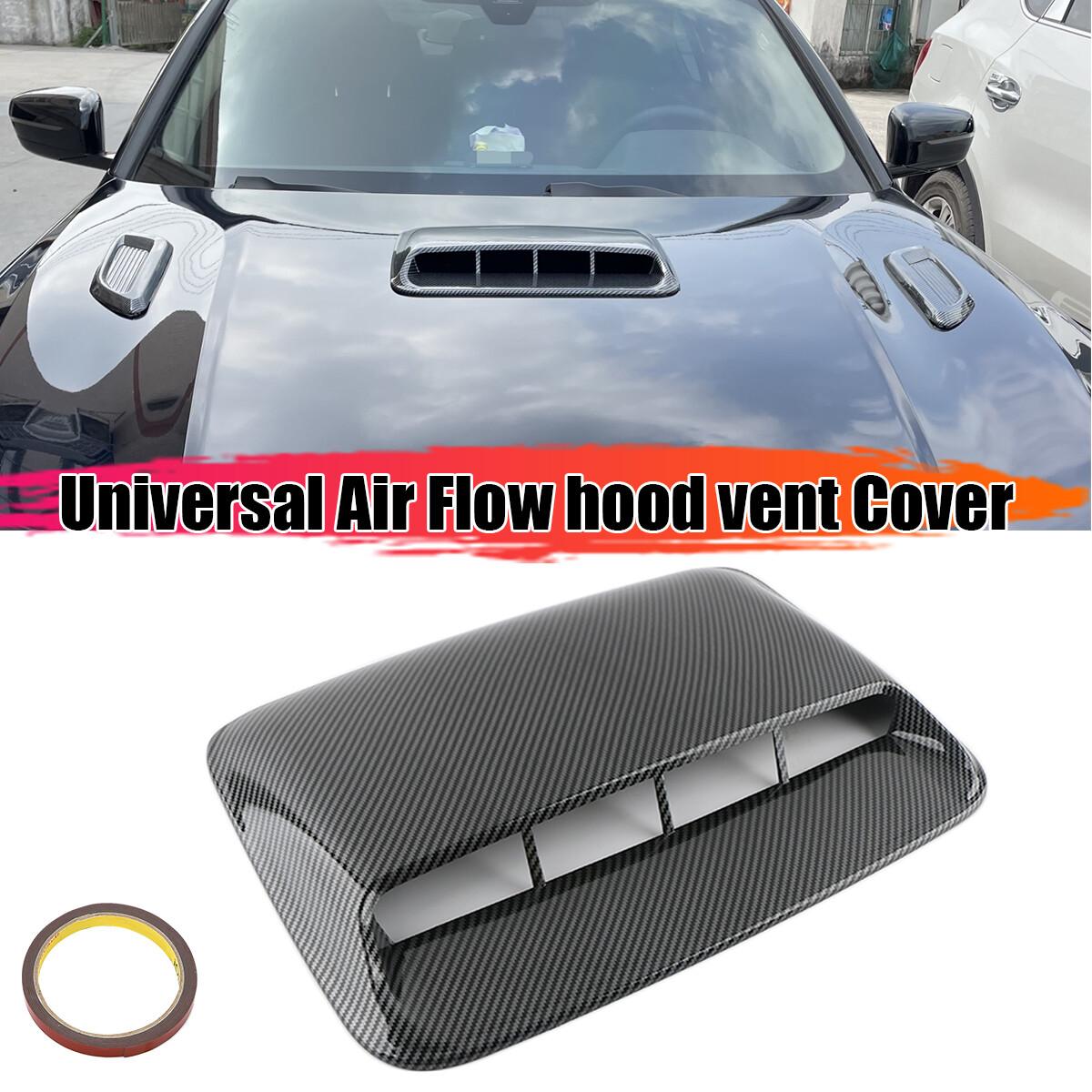

Scenario 3: Limited Availability of Customization Options

The Problem: B2B buyers often express frustration over the limited availability of customization options for bonnet hood scoops. Many suppliers offer only standard sizes and designs, which may not meet the specific aesthetic or functional requirements of different vehicle models. This limitation can hinder businesses looking to differentiate their products in competitive markets, particularly in diverse regions like the Middle East and Europe, where customization is highly valued.

Illustrative image related to bonnet hood scoop

The Solution: To overcome this hurdle, B2B buyers should seek suppliers that specialize in custom manufacturing or offer a wide range of customizable options. Engaging in discussions with manufacturers about specific requirements—such as materials, colors, or dimensions—can lead to tailored solutions that enhance product offerings. Additionally, establishing a partnership with a manufacturer that has the capability for bespoke designs can give businesses a competitive edge. Buyers should also consider leveraging technology, such as 3D modeling, to visualize custom designs before production, ensuring that the final product aligns with their vision and market needs. By prioritizing customization, businesses can better meet customer demands and stand out in a crowded marketplace.

Strategic Material Selection Guide for bonnet hood scoop

What Are the Key Properties of Common Materials Used for Bonnet Hood Scoops?

When selecting materials for bonnet hood scoops, several options stand out based on performance, cost, and suitability for various applications. The most common materials include ABS plastic, aluminum, fiberglass, and carbon fiber. Each material offers unique properties that can significantly influence the final product’s performance and market appeal.

How Does ABS Plastic Perform in Bonnet Hood Scoops?

ABS plastic is a popular choice for bonnet hood scoops due to its lightweight nature and ease of manufacturing. It has a temperature resistance of up to 80°C (176°F) and is resistant to many chemicals, making it suitable for various automotive applications. The primary advantage of ABS is its cost-effectiveness, allowing manufacturers to produce affordable products without sacrificing quality. However, ABS may not be as durable as metals, particularly in extreme weather conditions, which can lead to cracking or fading over time.

For international buyers, especially in regions like Africa and the Middle East, it’s essential to consider compliance with local automotive standards. ABS plastic can be produced in compliance with ASTM standards, which may be a requirement for certain markets.

Illustrative image related to bonnet hood scoop

What Are the Benefits of Using Aluminum for Hood Scoops?

Aluminum is another widely used material for bonnet hood scoops, known for its excellent strength-to-weight ratio and corrosion resistance. With a melting point around 660°C (1220°F), aluminum can withstand high temperatures, making it ideal for performance applications. The primary advantage of aluminum is its durability and aesthetic appeal, often being used in high-end automotive designs.

However, aluminum can be more expensive than ABS plastic, which may deter cost-sensitive buyers. Additionally, the manufacturing process can be more complex, requiring specialized techniques like welding or machining. For B2B buyers in Europe, particularly in Germany, aluminum products may need to meet specific DIN standards, adding another layer of compliance to consider.

How Does Fiberglass Compare as a Material Option?

Fiberglass is known for its rigidity and lightweight properties, making it a suitable choice for high-performance bonnet hood scoops. It can withstand temperatures up to 300°C (572°F) and offers excellent resistance to corrosion and UV degradation. The primary advantage of fiberglass is its ability to be molded into complex shapes, providing design flexibility.

On the downside, fiberglass can be more labor-intensive to manufacture, which may increase costs. Additionally, it is less impact-resistant than metals, making it potentially less durable in harsh environments. Buyers from South America should be aware of the local market’s acceptance of fiberglass products, as they may face competition from more traditional materials.

What Are the Advantages of Carbon Fiber for High-End Applications?

Carbon fiber is a premium material choice for bonnet hood scoops, particularly in high-performance and luxury vehicles. It boasts an exceptional strength-to-weight ratio and can withstand high temperatures, making it ideal for racing applications. Carbon fiber’s lightweight nature contributes to improved vehicle performance and fuel efficiency.

However, the primary disadvantage of carbon fiber is its high cost, which may limit its use to niche markets. Additionally, the manufacturing process is complex and requires specialized equipment. For international buyers, particularly in Europe and the Middle East, carbon fiber products may need to comply with stringent automotive regulations, including specific certifications.

Summary of Material Selection for Bonnet Hood Scoops

| Material | Typical Use Case for bonnet hood scoop | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| ABS Plastic | Universal applications in budget cars | Lightweight and cost-effective | Less durable in extreme conditions | Low |

| Aluminum | Performance and luxury vehicles | High strength and corrosion resistance | Higher cost and complex manufacturing | Medium |

| Fiberglass | High-performance applications | Excellent design flexibility | Labor-intensive and less impact-resistant | Medium |

| Carbon Fiber | Racing and high-end vehicles | Exceptional strength-to-weight ratio | Very high cost and complex manufacturing | High |

This guide provides a comprehensive overview of material options for bonnet hood scoops, helping international B2B buyers make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for bonnet hood scoop

What Are the Key Manufacturing Processes for Bonnet Hood Scoops?

The manufacturing of bonnet hood scoops involves several critical stages, each designed to ensure the final product meets both performance and aesthetic standards. Understanding these processes can help B2B buyers make informed decisions when sourcing these components.

What Materials Are Typically Used in Bonnet Hood Scoop Production?

The most common materials for bonnet hood scoops include ABS plastic, aluminum, and carbon fiber. ABS plastic is favored for its lightweight nature and ease of molding, making it a popular choice for universal hood scoops. Aluminum offers strength and a premium finish, while carbon fiber is used for high-performance applications due to its superior strength-to-weight ratio. Selecting the right material is essential for achieving durability and performance, especially in demanding environments.

How Are Bonnet Hood Scoops Formed?

The forming process generally starts with material preparation, where raw materials are cut and shaped into preliminary forms. Techniques such as injection molding for plastic and stamping or CNC machining for metals are commonly employed.

- Injection Molding: For ABS plastic scoops, this method allows for intricate designs and uniform thickness, ensuring consistency across production batches.

- Metal Stamping and CNC Machining: For aluminum scoops, these techniques provide precision and flexibility, enabling manufacturers to produce complex geometries that can enhance airflow and aesthetics.

After forming, the components may undergo secondary processes like trimming and deburring to ensure clean edges and proper fitment.

Illustrative image related to bonnet hood scoop

What Does the Assembly Process Entail for Bonnet Hood Scoops?

Assembly typically involves integrating the formed components with any necessary hardware, such as mounting brackets or vent covers. This stage may also include the application of adhesives or fasteners to secure parts together. Depending on the design, some scoops may feature a shaker mechanism that connects to the engine, requiring additional engineering to ensure functionality.

What Quality Assurance Measures Are Commonly Implemented?

Quality assurance is vital in ensuring that bonnet hood scoops meet both international and industry-specific standards. Key quality control checkpoints include:

- Incoming Quality Control (IQC): This step verifies the quality of raw materials upon arrival, ensuring that they meet specified standards before production begins.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor processes and identify any deviations from quality standards.

- Final Quality Control (FQC): Once production is complete, finished products undergo thorough testing to ensure they meet performance criteria and safety regulations.

Which International Standards Are Relevant for Bonnet Hood Scoop Manufacturing?

B2B buyers should look for manufacturers that adhere to international standards such as ISO 9001, which outlines quality management systems. Additionally, specific industry certifications like CE marking for products sold in Europe or API standards for components related to performance and safety may be relevant.

What Testing Methods Are Commonly Used for Quality Assurance?

Common testing methods for bonnet hood scoops include:

- Dimensional Inspection: Using calipers and gauges to ensure that all dimensions meet specified tolerances.

- Material Testing: Conducting tensile strength and impact resistance tests to verify the durability of materials used.

- Performance Testing: Assessing airflow efficiency and thermal resistance, especially for scoops designed for high-performance vehicles.

These tests ensure that the product not only meets aesthetic requirements but also performs effectively in real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of potential suppliers:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality assurance measures in place. This firsthand experience can provide valuable insights into the supplier’s capabilities.

- Quality Reports: Requesting detailed quality reports that outline testing results and compliance with standards can help buyers evaluate the reliability of the supplier.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and product quality. This is particularly important for international transactions where buyers may not have direct oversight.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, understanding local regulations and standards is crucial. Different countries may have specific requirements that affect product compliance. Buyers should ensure that their suppliers are familiar with these regulations and can provide documentation to verify compliance.

Additionally, cultural differences in business practices can affect quality control processes. Establishing clear communication channels and expectations can help bridge these gaps and foster a successful partnership.

Conclusion

Understanding the manufacturing processes and quality assurance measures for bonnet hood scoops is essential for B2B buyers looking to source reliable and high-performing products. By familiarizing themselves with material selection, manufacturing techniques, quality checkpoints, and international standards, buyers can make informed decisions that align with their business needs. Ensuring thorough verification of supplier quality control processes further enhances the likelihood of a successful procurement experience.

Illustrative image related to bonnet hood scoop

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bonnet hood scoop’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring bonnet hood scoops efficiently and effectively. Whether you’re looking to enhance vehicle performance or improve aesthetic appeal, following this checklist will ensure you make informed decisions while selecting the right products and suppliers.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for sourcing the right bonnet hood scoop. Consider factors such as size, material (e.g., ABS plastic or aluminum), and functional requirements like air intake capabilities. This ensures that the product aligns with your vehicle’s design and performance goals.

- Consider dimensions: Ensure that the scoop fits the specific make and model of the vehicles you are targeting.

- Material selection: Assess whether lightweight materials are necessary for performance improvements or if durability is a priority.

Step 2: Research Market Trends and Product Varieties

Understanding current market trends can give you insights into popular styles and technologies in bonnet hood scoops. Research various designs, such as cowl induction or shaker scoops, and their performance benefits.

- Analyze competitors: Look into what other businesses in your region are offering to identify gaps or opportunities.

- Evaluate performance data: Gather information on how different styles impact vehicle performance to guide your purchasing decisions.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This due diligence helps ensure you partner with reputable manufacturers.

- Check certifications: Ensure suppliers have the necessary industry certifications that demonstrate compliance with quality standards.

- Review customer feedback: Look for testimonials and reviews from previous clients to gauge supplier reliability and product quality.

Step 4: Request Samples for Quality Assessment

Requesting samples allows you to evaluate the product’s quality firsthand. This step is critical in determining whether the bonnet hood scoops meet your specifications and expectations.

- Inspect materials: Assess the durability and finish of the samples to ensure they meet your quality standards.

- Test installation: If possible, check how easy it is to install the samples on a vehicle, as this can affect the overall customer experience.

Step 5: Negotiate Pricing and Terms

Once you’ve identified suitable suppliers and evaluated their products, it’s time to negotiate pricing and terms. This step is essential for maximizing your profit margins while ensuring a fair deal.

Illustrative image related to bonnet hood scoop

- Discuss bulk pricing: Inquire about discounts for larger orders, which can significantly reduce your overall costs.

- Clarify shipping terms: Ensure that you understand shipping costs and timelines, especially if sourcing from international suppliers.

Step 6: Finalize Your Order and Establish Communication

After settling on a supplier, finalize your order with clear communication regarding expectations. This step is vital to avoid misunderstandings and ensure smooth transactions.

- Confirm lead times: Make sure both parties agree on delivery timelines to align with your inventory needs.

- Establish a communication channel: Set up regular updates or check-ins to monitor the order status and address any potential issues promptly.

Conclusion

By following this step-by-step sourcing checklist, B2B buyers can confidently procure bonnet hood scoops that enhance vehicle performance and aesthetics. Thorough research, supplier evaluation, and strategic negotiation are key to successful procurement in this competitive market.

Comprehensive Cost and Pricing Analysis for bonnet hood scoop Sourcing

What Are the Key Cost Components in Bonnet Hood Scoop Manufacturing?

When analyzing the cost structure for sourcing bonnet hood scoops, several critical components come into play. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of material—such as ABS plastic, aluminum, or carbon fiber—significantly impacts pricing. For example, ABS plastic scoops can start around $50, while aluminum options may range from $178 to $241, depending on finish and design.

-

Labor: Labor costs vary based on the manufacturing location and the complexity of the production process. Regions with lower labor costs can offer more competitive pricing, but it’s essential to consider the trade-off with quality.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, rent, and administrative expenses. Overhead can vary significantly depending on the production scale and efficiency of the manufacturing process.

-

Tooling: Tooling costs are incurred during the initial setup for production. Custom designs require specialized molds, which can drive up initial costs. However, high-volume orders can amortize these costs effectively over time.

-

Quality Control: Ensuring that each bonnet hood scoop meets specific standards is essential, especially for international buyers. Quality certifications may be necessary, which can add to the cost but ensure reliability and compliance with local regulations.

-

Logistics: Shipping and handling costs are crucial, especially for international transactions. Factors such as shipping distance, weight, and chosen Incoterms (e.g., FOB, CIF) can influence the total landed cost of the product.

-

Margin: Suppliers typically add a margin to cover their costs and generate profit. This can vary widely based on supplier relationships and market demand.

How Do Price Influencers Affect Bonnet Hood Scoop Sourcing?

Several key influencers can impact the pricing of bonnet hood scoops in B2B transactions:

-

Volume/MOQ: Purchasing in bulk can lead to significant discounts, making it more cost-effective for businesses to source larger quantities. Manufacturers often have minimum order quantities (MOQ) that can affect pricing flexibility.

-

Specifications and Customization: Customized designs may require additional tooling and labor, leading to higher prices. Buyers should clearly communicate their specifications to avoid unexpected costs.

-

Material Quality and Certifications: Higher-quality materials and certifications can increase initial costs but may reduce long-term maintenance expenses, providing a better Total Cost of Ownership (TCO).

-

Supplier Factors: Relationships with suppliers can influence pricing. Established suppliers may offer better terms, while new entrants might have lower prices to gain market share.

-

Incoterms: Understanding Incoterms is vital for international buyers, as they define the responsibilities of buyers and sellers concerning shipping costs, insurance, and risk. This can significantly affect the total cost of acquisition.

What Tips Should B2B Buyers Consider for Cost-Efficiency?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency when sourcing bonnet hood scoops:

-

Negotiation: Always negotiate terms with suppliers. Many are willing to adjust prices based on order size or payment terms.

-

Total Cost of Ownership: Consider the long-term implications of your purchase. Investing in higher-quality products may yield savings over time through reduced maintenance or better performance.

-

Understand Pricing Nuances: Prices can vary significantly based on regional demand, currency fluctuations, and local regulations. Conducting thorough market research can help identify the best sourcing opportunities.

-

Supplier Audits: Regularly auditing suppliers can ensure they meet quality and efficiency standards, which can prevent costly mistakes in the production process.

-

Leverage Technology: Use technology to streamline the procurement process. Platforms that facilitate supplier comparisons and logistics planning can enhance efficiency and reduce costs.

Disclaimer for Indicative Prices

Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always confirm current pricing directly with suppliers before making purchasing decisions.

Illustrative image related to bonnet hood scoop

Alternatives Analysis: Comparing bonnet hood scoop With Other Solutions

Exploring Alternatives to Bonnet Hood Scoops for Enhanced Vehicle Performance

In the automotive industry, especially for performance-oriented vehicles, enhancing airflow to the engine compartment is crucial. While bonnet hood scoops are a popular solution, several alternatives exist that can achieve similar results. This section explores these options, comparing them based on key aspects that matter to B2B buyers.

| Comparison Aspect | Bonnet Hood Scoop | Cowl Induction Hood Scoop | Ram Air Intake System |

|---|---|---|---|

| Performance | Increases airflow, enhances engine cooling | Superior airflow at higher speeds | Maximizes airflow for performance |

| Cost | Moderate ($50-$250) | Moderate to high ($100-$500) | High ($200-$1000) |

| Ease of Implementation | Relatively easy, often bolt-on | May require custom fitting | Complex installation, often requires professional help |

| Maintenance | Low maintenance, durable materials | Low to moderate, depends on design | High, requires regular checks and modifications |

| Best Use Case | General enhancement for various vehicles | Performance cars needing high-speed airflow | Racing applications or high-performance street vehicles |

Understanding Cowl Induction Hood Scoops: Pros and Cons

Cowl induction hood scoops are designed to take advantage of high-pressure zones created by the vehicle’s design, typically located at the rear of the hood. This design allows for improved airflow at higher speeds, making them a favored choice for performance vehicles. However, they may require custom fitting and can be more expensive than standard bonnet hood scoops. Additionally, the installation process may be more complex, which can deter some buyers seeking a straightforward upgrade.

Analyzing Ram Air Intake Systems: Advantages and Disadvantages

Ram air intake systems are engineered to maximize airflow into the engine, especially at high speeds. These systems typically involve a more intricate setup than bonnet hood scoops, often requiring professional installation. While they can significantly enhance engine performance, their higher cost and maintenance needs can be a drawback for some buyers. Regular checks are necessary to ensure optimal performance, making them more suitable for dedicated racing applications or high-performance street vehicles rather than general use.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the right solution for enhancing vehicle performance, B2B buyers must consider their specific needs, vehicle types, and budget constraints. Bonnet hood scoops offer a balance of affordability, ease of installation, and sufficient performance enhancement for a broad range of vehicles. In contrast, cowl induction hood scoops and ram air intake systems provide more specialized benefits but come with increased costs and installation complexities. Ultimately, understanding the performance requirements and maintenance capabilities will guide buyers in making the most informed decision for their automotive enhancements.

Illustrative image related to bonnet hood scoop

Essential Technical Properties and Trade Terminology for bonnet hood scoop

What Are the Key Technical Properties of a Bonnet Hood Scoop?

When evaluating bonnet hood scoops for purchase, it’s essential to consider specific technical properties that directly impact performance, compatibility, and installation. Below are critical specifications to keep in mind:

-

Material Composition

Hood scoops are typically made from materials such as ABS plastic, aluminum, or carbon fiber. ABS plastic is lightweight and offers good durability, making it a popular choice for universal applications. Aluminum, while heavier, provides better strength and heat resistance. Understanding the material helps in assessing durability, weight impact on the vehicle, and resistance to environmental factors. -

Dimensions

The size of the scoop, including length, width, and height, is crucial for ensuring proper fitment on the vehicle’s hood. Standard dimensions may vary, but common sizes range from 263mm in length to 207mm in width for universal scoops. Accurate measurements are vital for avoiding installation issues and ensuring optimal airflow into the engine compartment. -

Surface Finish

The finish of the hood scoop can affect both aesthetic appeal and performance. Options may include textured coatings or smooth finishes, and some scoops can be painted to match the vehicle’s color. The surface finish also influences air resistance and can enhance or diminish the scoop’s effectiveness in directing airflow. -

Installation Type

Hood scoops may feature various installation methods, including bolt-on, adhesive, or riveted designs. Bolt-on scoops are generally preferred for their ease of installation and the ability to remove them without damaging the vehicle. Understanding the installation type is crucial for B2B buyers to ensure compatibility with their specific vehicle models. -

Functional Design

Some scoops are designed for specific functions, such as cowl induction or ram air intake, which enhance engine performance by increasing airflow. Knowing the functional design helps buyers select the right scoop that aligns with their performance goals and vehicle specifications. -

Weight Tolerance

Each scoop has a weight rating, which indicates how much additional weight can be accommodated without negatively impacting vehicle performance. This specification is particularly important for high-performance vehicles where weight distribution is critical.

What Are Common Terms in the Bonnet Hood Scoop Trade?

Understanding industry jargon is essential for effective communication and negotiation in the bonnet hood scoop market. Here are several commonly used terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. Buyers often seek OEM products for their guaranteed fit and compatibility, ensuring that the hood scoop meets factory specifications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers to understand as it affects inventory management and budgeting. Suppliers may set MOQs to maintain profitability and manage production costs. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It is a key step in the procurement process, allowing buyers to compare pricing, terms, and conditions from different vendors. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms helps B2B buyers navigate shipping logistics, costs, and risks associated with international trade. -

Fitment

This term refers to how well a hood scoop integrates with a specific vehicle model. Proper fitment ensures that the scoop functions as intended and does not interfere with other vehicle components. -

Aftermarket

Aftermarket products are those manufactured by third-party companies, rather than the vehicle’s original manufacturer. Buyers often explore aftermarket options for unique designs, enhanced performance, or cost-effectiveness compared to OEM parts.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when selecting bonnet hood scoops, ensuring compatibility and performance that meets their needs.

Illustrative image related to bonnet hood scoop

Navigating Market Dynamics and Sourcing Trends in the bonnet hood scoop Sector

What Are the Current Market Dynamics and Key Trends in the Bonnet Hood Scoop Sector?

The global bonnet hood scoop market is witnessing a dynamic transformation driven by several key factors. First, the increasing demand for vehicle personalization and performance enhancements is propelling the growth of aftermarket modifications. International buyers from regions such as Africa, South America, the Middle East, and Europe, particularly Germany and Saudi Arabia, are increasingly looking for hood scoops that not only enhance engine performance but also improve the aesthetic appeal of vehicles.

Emerging technologies, such as advanced manufacturing techniques including 3D printing and CNC machining, are reshaping how bonnet scoops are produced. These innovations enable manufacturers to create customized designs that meet specific customer preferences while maintaining cost-effectiveness. Additionally, the rise of e-commerce platforms facilitates easier access to a wider range of products, allowing B2B buyers to source products directly from manufacturers around the globe.

Another important trend is the shift towards universal compatibility in hood scoop designs. As buyers seek versatile products that can fit multiple vehicle models, manufacturers are increasingly focusing on creating universal solutions that require minimal customization. This trend not only simplifies the procurement process for B2B buyers but also enhances inventory management by reducing the need for a vast array of specific parts.

How Important Is Sustainability and Ethical Sourcing in the Bonnet Hood Scoop Sector?

Sustainability and ethical sourcing are becoming essential considerations in the bonnet hood scoop market. The environmental impact of automotive accessories, particularly those made from non-biodegradable materials, has prompted buyers to seek out products that align with green practices. Many manufacturers are now investing in sustainable materials, such as recycled plastics or bio-based composites, to cater to the growing demand for eco-friendly options.

Furthermore, ethical supply chains are crucial for building trust with international B2B buyers. Sourcing from suppliers who adhere to fair labor practices and environmental regulations not only enhances brand reputation but also mitigates risks associated with supply chain disruptions. Certifications such as ISO 14001 (Environmental Management) and materials marked as “green” or “eco-friendly” are increasingly sought after by buyers looking to align their purchasing decisions with corporate social responsibility goals.

By prioritizing sustainability, B2B buyers can also capitalize on the growing market of environmentally conscious consumers, thus expanding their business opportunities. As regulations around sustainability tighten globally, being proactive in sourcing practices can provide a competitive edge in the bonnet hood scoop sector.

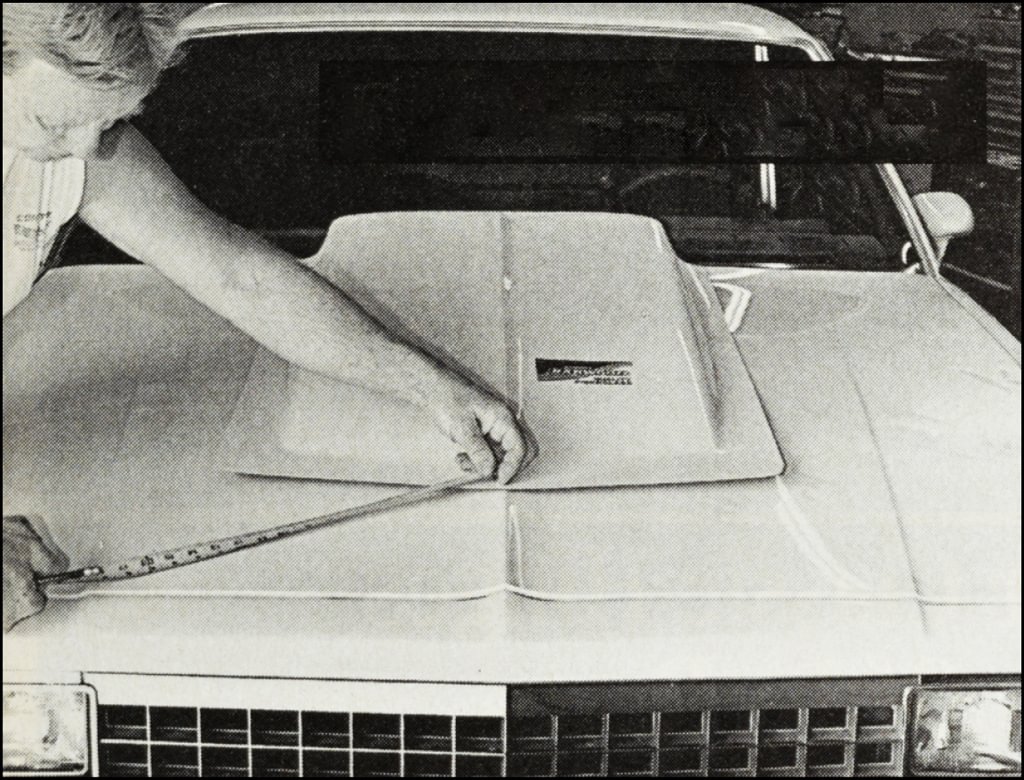

What Is the Evolution of the Bonnet Hood Scoop and Its Significance for B2B Buyers?

The bonnet hood scoop has evolved significantly from its origins in the muscle car era, where it primarily served as a functional component to enhance engine performance. Initially, these scoops were designed to improve airflow into the engine compartment, providing a crucial advantage in racing scenarios. Over the decades, their role expanded from purely functional to aesthetic, with designs becoming increasingly aggressive and varied.

Illustrative image related to bonnet hood scoop

Today, the bonnet hood scoop serves a dual purpose: enhancing performance while also allowing vehicle owners to express their individuality. For B2B buyers, understanding this evolution is crucial, as it highlights the importance of both functionality and design in consumer preferences. This knowledge can inform purchasing decisions, ensuring that the products sourced not only meet performance standards but also resonate with the aesthetic desires of end-users, thereby maximizing sales potential.

As the market continues to evolve, staying informed about historical trends can help B2B buyers anticipate future developments, making strategic sourcing decisions that align with consumer expectations and industry innovations.

Frequently Asked Questions (FAQs) for B2B Buyers of bonnet hood scoop

-

How do I choose the right bonnet hood scoop for my vehicle?

Selecting the right bonnet hood scoop involves considering your vehicle’s make and model, as well as your performance goals. Begin by identifying the scoop’s compatibility with your engine’s air intake system. Look for universal options if your vehicle model is not listed. Additionally, assess the material (e.g., ABS plastic or aluminum) for durability and aesthetics. Consider the scoop style, such as cowl or shaker, to match your vehicle’s design and airflow needs. Finally, consult with suppliers for expert recommendations tailored to your specific requirements. -

What is the best hood scoop for enhancing engine performance?

The best hood scoop for enhancing engine performance is typically one designed to maximize airflow, such as a cowl induction scoop. These scoops are strategically positioned to capture high-pressure air at the rear of the hood, funneling it directly into the engine compartment. Look for features like adjustable vents or ram-air capabilities, which can further improve efficiency. Additionally, consider the scoop’s height and mounting location to ensure it operates above the boundary layer of slow-moving air for optimal performance. -

What are the key factors to consider when sourcing bonnet hood scoops internationally?

When sourcing bonnet hood scoops internationally, consider factors such as supplier reliability, product quality, and compliance with local regulations. Verify supplier credentials through trade references and certifications. Additionally, assess shipping logistics, including lead times and costs, to ensure timely delivery. Currency fluctuations can impact pricing, so be aware of exchange rates. Lastly, evaluate after-sales support and return policies to mitigate risks associated with international transactions. -

What is the typical minimum order quantity (MOQ) for bonnet hood scoops?

The typical minimum order quantity (MOQ) for bonnet hood scoops can vary significantly by supplier and product type, ranging from as low as 50 units to several hundred. When negotiating with manufacturers, inquire about their MOQ policies to find a balance between meeting your needs and minimizing inventory risk. Some suppliers may offer flexibility for first-time buyers or smaller businesses, so it’s advisable to communicate your requirements clearly to explore potential options. -

How can I customize bonnet hood scoops for my business needs?

Customizing bonnet hood scoops can involve altering dimensions, materials, or finishes to meet your specific requirements. Many suppliers offer customization options such as color choices, logo placements, or specific design features. Engage in detailed discussions with manufacturers to specify your needs, ensuring they can accommodate your requests. Request prototypes if available, to evaluate the design before placing a larger order. Always confirm lead times and additional costs associated with customization to align with your project timeline and budget. -

What payment terms should I expect when ordering bonnet hood scoops?

Payment terms for ordering bonnet hood scoops can vary by supplier and region. Common arrangements include full payment upfront, a deposit followed by the balance upon delivery, or net terms (e.g., 30 days after invoicing). It’s essential to clarify these terms before committing to an order. Additionally, inquire about accepted payment methods, which may include bank transfers, credit cards, or letters of credit for larger transactions. Ensure that the terms align with your cash flow management and risk tolerance. -

What quality assurance (QA) measures should I look for in bonnet hood scoop suppliers?

When vetting suppliers for bonnet hood scoops, look for established quality assurance (QA) measures such as ISO certification or adherence to industry standards. Request information on their manufacturing processes, including material sourcing and production methods. Inquire about inspection protocols, testing for durability, and compliance with safety regulations. Additionally, consider suppliers that offer warranty terms or guarantees on their products, which can provide added confidence in their quality. -

How do logistics impact the sourcing of bonnet hood scoops internationally?

Logistics play a critical role in the international sourcing of bonnet hood scoops, affecting both cost and delivery timelines. Factors such as shipping methods (air vs. sea), customs clearance processes, and import duties can significantly influence overall expenses. Collaborate with logistics partners experienced in international trade to streamline the shipping process. Be proactive in understanding local regulations in your target market to avoid unexpected delays or costs. Timely communication with suppliers regarding shipping schedules can also help manage inventory effectively.

Top 6 Bonnet Hood Scoop Manufacturers & Suppliers List

1. eBay – Car & Truck Hood Scoops & Vents

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Car & Truck Hood Scoops & Vents available on eBay. Key materials include Aluminum, Carbon Fiber, Chrome, Fiberglass, and Stainless Steel. Popular products include: 1. Gold JDM Password Billet Hood Spacer Riser Kit for Acura Integra Honda CRX Civic – $11.39 2. JDM Universal Car Decorative Air Flow Intake Hood Scoop Vent Bonnet Cover C19 – $45.99 3. Genuine Ford Mustang GT500 Hood Scoop Assembly OE …

2. Rising Tuning – Universal Bonnet Scoop Hood Vent

Domain: risingtuning.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “Universal Bonnet Scoop Hood Air Hood Vent Intake”, “material”: “ABS-plastic”, “dimensions”: {“length”: “263mm”, “width1”: “207mm”, “width2”: “80mm”, “hole_length”: “165mm”}, “weight”: “lightweight”, “surface_finish”: “Black (textured coating)”, “installation”: “can be installed without affecting the weight of your car”, “compatibility”: “universal product, some fine works needed”…

3. Summit Racing – Hood Scoops

Domain: summitracing.com

Registered: 1995 (30 years)

Introduction: Hood Scoops for Cars & Trucks at Summit Racing. Key details include: Brands – Summit Racing, Harwood, United Pacific, Dominator Race Products, OER, Allstar Performance, Rough Country, Auto Ventshade, Scott Drake, Auto Metal Direct, S&B Filters, Coast to Coast International Body Parts. Styles – Cowl induction, Z28, Shaker scoop, Allstar Circle Track, Hood vents, Aero, Mustang Shelby, Smooth Top, Wr…

4. Speedway Motors – Hot Rod Hood Scoops

Domain: speedwaymotors.com

Introduction: This company, Speedway Motors – Hot Rod Hood Scoops, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Air Design – Cowl Hood Scoops for 2021-2025+ Ford F-150

Domain: airdesignusa.com

Registered: 2015 (10 years)

Introduction: Air Design offers a wide selection of high-quality Cowl Hood Scoops for pickup trucks and cars, made with durable Tri-Flex ABS thermoplastic. Each hood scoop comes with automotive grade adhesive tape for quick and easy installation, requiring no drilling. Key products include:

– 2021-2025+ Ford F-150 Hood Scoop – $379.00

– 2021-2025+ Ford Bronco Hood Scoop – $379.00

– 2021-2025+ Ford Maverick Hood…

6. RealTruck – Hood Scoops & Shocks

Domain: realtruck.com

Registered: 1998 (27 years)

Introduction: Hood Scoops & Hood Shocks available at RealTruck. Free shipping on orders over $100. Key products include: 1. S&B Air Hood Scoops – From: $99.00 2. RealTruck AVS Hood Scoop – From: $104.99 3. Rugged Ridge Jeep Cowl Hood Scoop – From: $29.99 4. Rugged Ridge Locking Hood Catches – From: $79.99 (same day rapidship) 5. Dee Zee Fender Hood Delete Kit – From: $143.92 6. Westin LED Hood Scoops – From: $4…

Strategic Sourcing Conclusion and Outlook for bonnet hood scoop

In conclusion, the strategic sourcing of bonnet hood scoops presents significant opportunities for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. Key takeaways emphasize the importance of selecting high-quality materials, such as ABS plastic and aluminum, which provide durability and aesthetic appeal. Understanding installation methods—whether bolt-on, riveted, or adhesive—can streamline the procurement process and enhance customer satisfaction.

Moreover, the demand for customizable options allows businesses to cater to specific vehicle models and consumer preferences, creating a competitive edge in the marketplace. As buyers increasingly seek performance enhancements and unique styling for vehicles, the role of hood scoops in improving airflow and engine efficiency cannot be overstated.

Looking ahead, international buyers are encouraged to leverage strategic sourcing to optimize their supply chains and stay ahead of market trends. Engaging with reliable suppliers who offer free shipping and fast delivery can further enhance your operational efficiency. Embrace these opportunities to elevate your product offerings and meet the evolving demands of your customers in the global automotive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.