Is Your Shipping Palette Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for shipping palette

Shipping pallets serve as the backbone of global logistics, yet many international B2B buyers face significant challenges when it comes to sourcing the right type for their operations. Selecting a suitable shipping palette is not just about cost; it involves understanding the materials, load capacities, and environmental conditions that can impact the integrity of your shipment. This guide will delve into the various types of pallets available—wood, plastic, and more—while exploring their specific applications across different industries.

Additionally, we will provide insights on how to effectively vet suppliers, ensuring that you partner with reliable manufacturers who meet international quality standards. Cost considerations will also be thoroughly examined, empowering you to make informed financial decisions that align with your budget and operational needs.

For B2B buyers in diverse regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Saudi Arabia—this guide serves as an essential resource. By equipping you with actionable insights and best practices, we aim to streamline your procurement process, enhance your supply chain efficiency, and ultimately improve the reliability of your shipping operations. Whether you’re new to pallet sourcing or looking to refine your strategy, this comprehensive guide will position you to navigate the complexities of the global market with confidence.

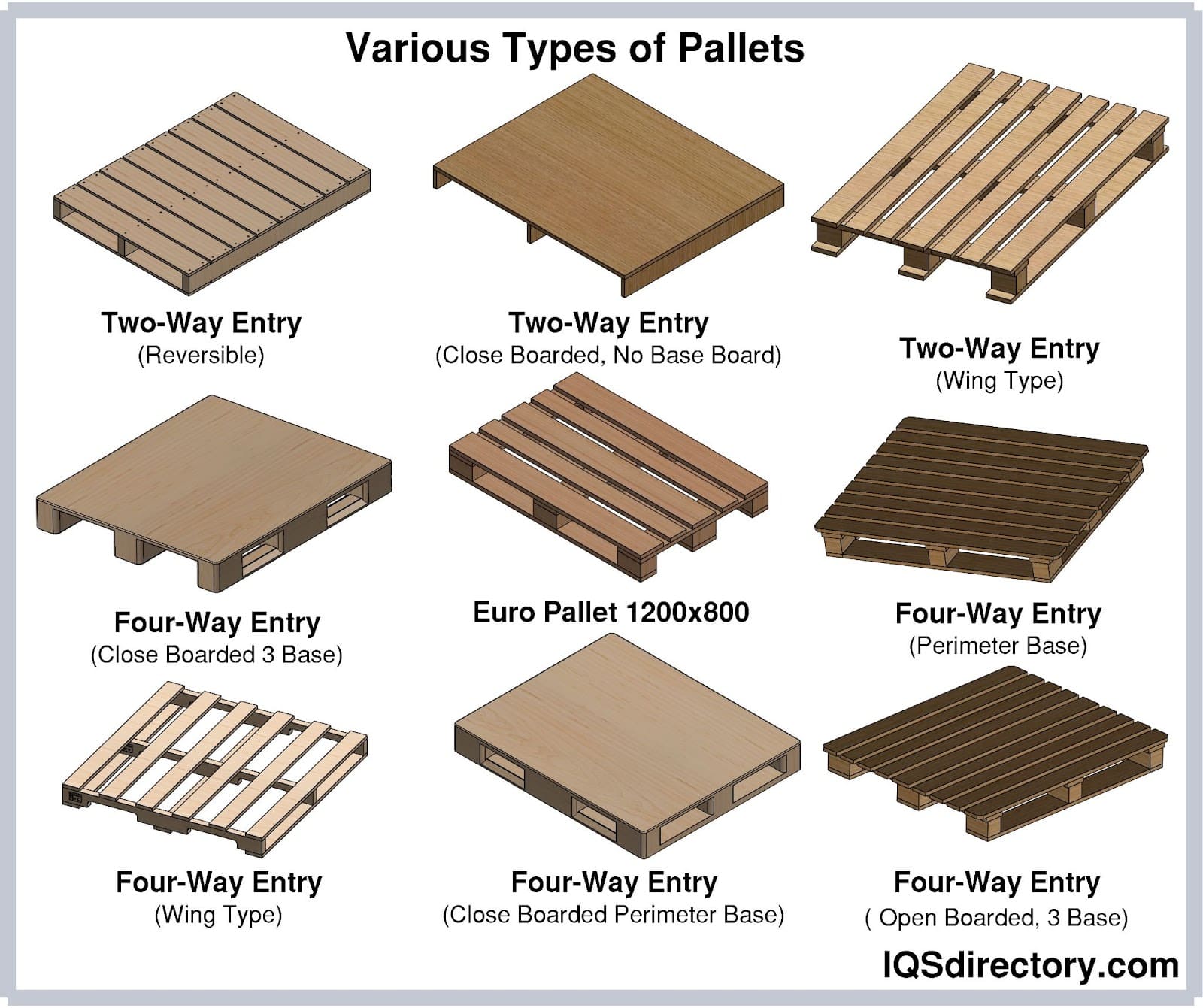

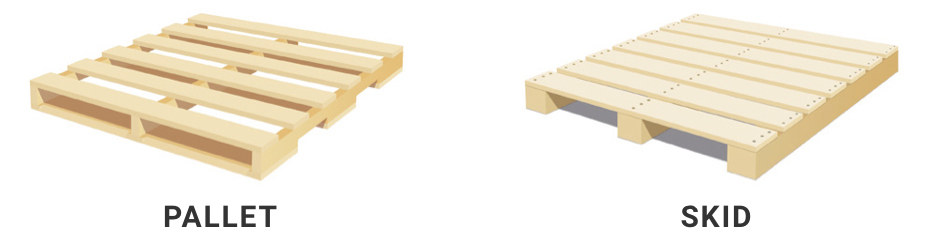

Understanding shipping palette Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Wood Pallet | Typically measures 40″ x 48″; strong, durable, reusable | General freight shipping | Pros: Cost-effective, widely available; Cons: Susceptible to moisture damage, potential pest issues. |

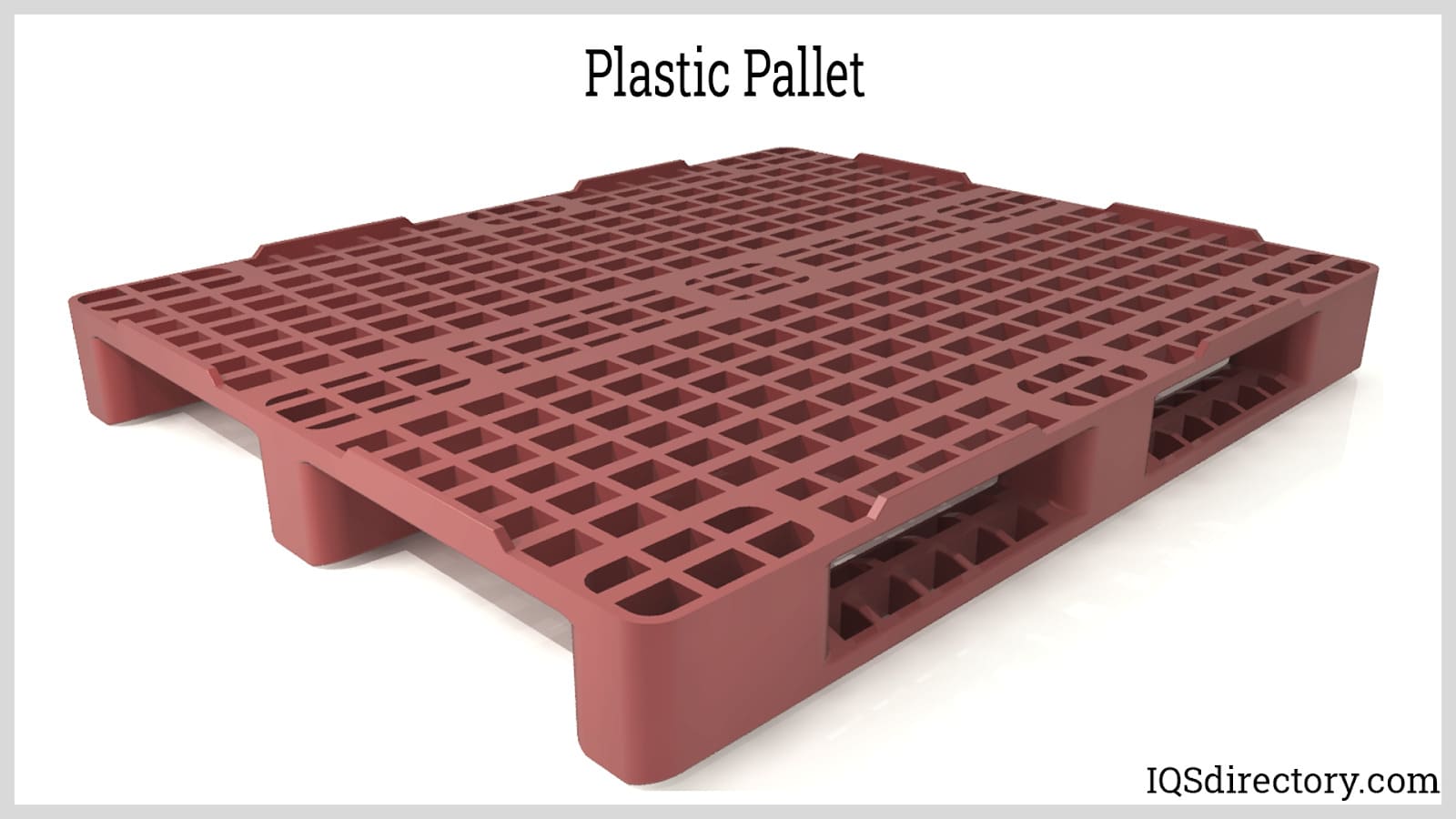

| Plastic Pallet | Made from high-density polyethylene; reusable, solid deck options | Food and pharmaceutical industries | Pros: Durable, resistant to moisture; Cons: Higher initial cost, heavier than wood. |

| Corrugated Fiberboard Pallet | Lightweight, made from recycled materials; not reusable | Lightweight shipments | Pros: Eco-friendly, low cost; Cons: Easily damaged, not suitable for heavy loads. |

| Pressed Block Pallet | Made from compressed wood fibers; lightweight | Retail and consumer goods | Pros: Affordable, light; Cons: Lacks strength and durability compared to wood. |

| Molded Pulp Pallet | Made from recycled paper pulp; biodegradable | Exporting goods, especially perishables | Pros: Environmentally friendly; Cons: Not sturdy, often single-use only. |

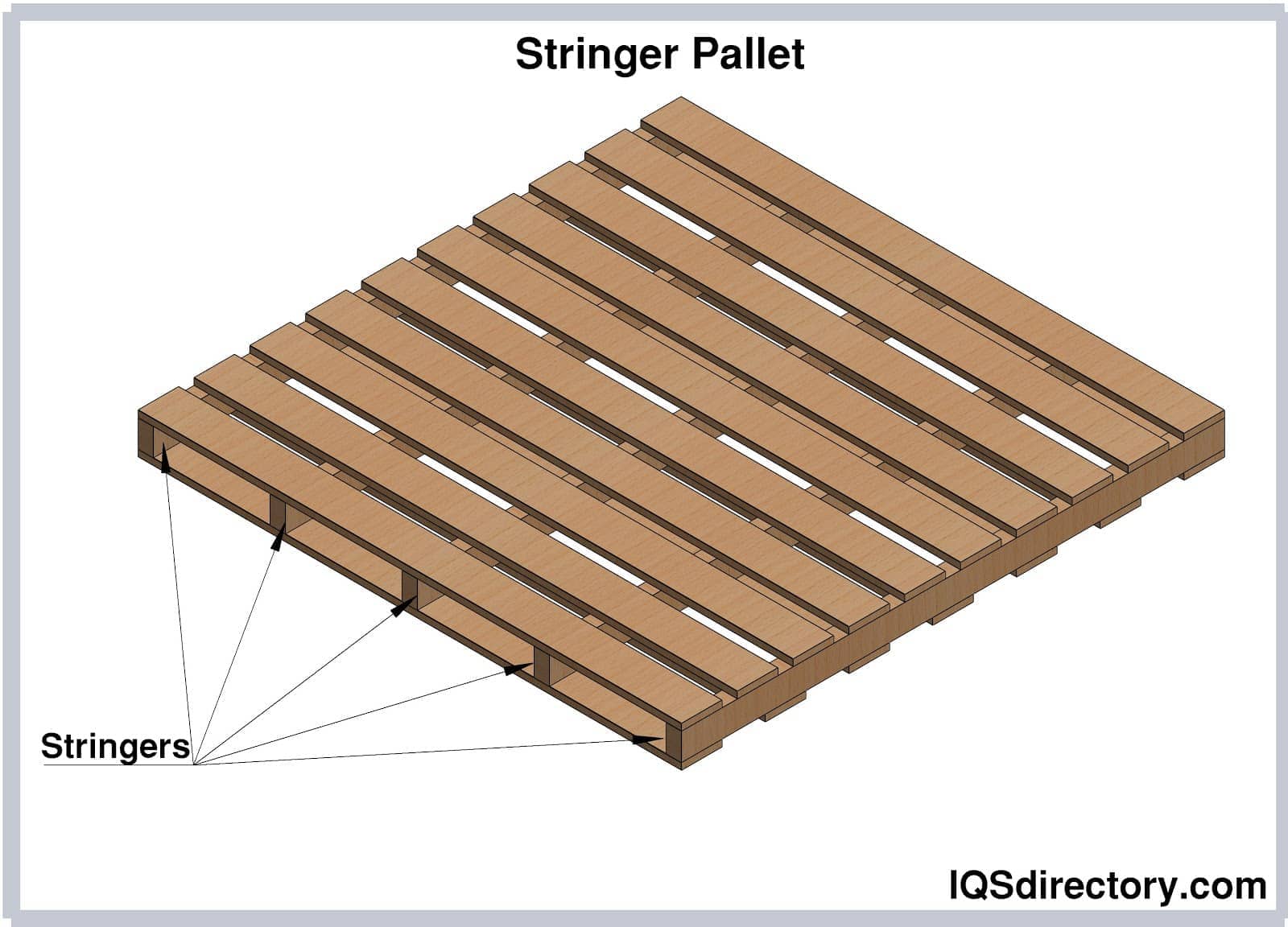

What Are the Characteristics of Standard Wood Pallets?

Standard wood pallets are the backbone of many shipping operations, typically measuring 40″ x 48″. Their robust construction makes them suitable for a wide range of products, providing strong support during handling and transit. While they are cost-effective and reusable, buyers should be aware of potential moisture damage and pest issues, particularly in humid climates. When purchasing, consider the load capacity, condition of the pallets, and the potential need for repairs.

How Do Plastic Pallets Compare in Terms of Durability?

Plastic pallets are manufactured from high-density polyethylene, offering exceptional durability and resistance to moisture, making them ideal for industries such as food and pharmaceuticals. Their solid deck design prevents damage during loading and unloading, enhancing product safety. However, buyers should weigh the higher initial costs against the long-term benefits of reusability and reduced maintenance. These pallets are especially suitable for international shipping where hygiene standards are paramount.

Why Are Corrugated Fiberboard Pallets Used for Lightweight Shipments?

Corrugated fiberboard pallets are lightweight and made from recycled materials, making them an eco-friendly option for shipping lightweight items. They are often used in scenarios where cost is a primary concern, such as promotional items or low-value goods. However, their susceptibility to moisture and lack of reusability limit their application. B2B buyers should consider the nature of the products being shipped and the environmental conditions they may encounter during transit.

What Are the Advantages of Pressed Block Pallets?

Pressed block pallets are constructed from compressed wood fibers, providing a lightweight and affordable alternative for shipping. They are particularly useful for retail and consumer goods where cost efficiency is crucial. However, their lack of durability compared to traditional wood pallets means they may not withstand heavy loads. Buyers should assess the types of products being shipped and the required strength before opting for this pallet type.

When Should Molded Pulp Pallets Be Considered for Shipping?

Molded pulp pallets are made from recycled paper pulp and are biodegradable, making them an attractive option for environmentally conscious businesses. They are commonly used for exporting perishables where lightweight and eco-friendly solutions are prioritized. However, their limited sturdiness often makes them suitable for single-use applications only. Buyers should evaluate the trade-off between sustainability and the need for structural integrity based on their shipping requirements.

Key Industrial Applications of shipping palette

| Industry/Sector | Specific Application of Shipping Palette | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Transporting bulk food items and beverages | Ensures product safety, maintains freshness, and reduces spoilage | Compliance with food safety regulations, moisture resistance, and durability |

| Pharmaceuticals | Shipping medical supplies and pharmaceuticals | Protects sensitive products from contamination and damage | Need for sterilization, regulatory compliance, and temperature control |

| Automotive | Storing and shipping automotive parts | Streamlines supply chain efficiency and reduces damage | Heavy-duty options, standardized sizes for compatibility, and durability |

| Consumer Goods | Distributing retail products to warehouses | Facilitates efficient inventory management and reduces handling costs | Consideration for product weight, stacking capabilities, and ease of transport |

| Electronics | Shipping delicate electronic components | Minimizes risk of damage from static and physical impacts | Anti-static materials, custom sizes for specific products, and cushioning options |

How are Shipping Palettes Used in the Food and Beverage Industry?

In the food and beverage sector, shipping palettes are essential for transporting bulk items like grains, beverages, and packaged goods. Their design ensures that products remain stable during transit, minimizing spoilage and maintaining freshness. International buyers, particularly from regions such as Africa and South America, must consider moisture resistance and compliance with food safety regulations when sourcing palettes. Selecting durable materials helps withstand environmental fluctuations, ensuring that products reach their destination in optimal condition.

What Role Do Shipping Palettes Play in Pharmaceuticals?

Shipping palettes are crucial in the pharmaceutical industry for transporting sensitive medical supplies and drugs. These palettes help protect products from contamination and physical damage, ensuring compliance with stringent regulations. Buyers in the Middle East and Europe should prioritize palettes that can be sterilized and maintain temperature control during transit. The right choice of palette can prevent costly damage and ensure that pharmaceuticals are delivered safely and efficiently.

Illustrative image related to shipping palette

Why are Shipping Palettes Important in the Automotive Sector?

In the automotive industry, shipping palettes are used to store and transport parts efficiently. They facilitate streamlined supply chain operations, reducing the risk of damage during handling and transportation. Buyers in this sector must focus on heavy-duty palettes that can support substantial weights and conform to industry standards for compatibility. Additionally, selecting palettes that allow for easy forklift access enhances operational efficiency in warehouses and distribution centers.

How Do Shipping Palettes Enhance Distribution in Consumer Goods?

Shipping palettes are vital for the efficient distribution of consumer goods to warehouses and retail locations. They enable better inventory management by allowing for easy stacking and transport of products, which reduces handling costs. For international buyers, considerations such as the weight of the products and the stacking capabilities of the palettes are critical. Choosing the right palette can significantly impact the overall logistics strategy, ensuring timely delivery and reduced operational delays.

What Are the Benefits of Using Shipping Palettes for Electronics?

In the electronics sector, shipping palettes are employed to transport delicate components that require protection from static and physical impacts. Using palettes designed with anti-static materials minimizes the risk of damage during transit. Buyers, especially in regions with high humidity or varying temperatures, should consider custom-sized palettes that fit specific products, along with cushioning options to enhance protection. Properly sourced palettes can lead to significant cost savings by reducing product damage and ensuring safe delivery.

Illustrative image related to shipping palette

3 Common User Pain Points for ‘shipping palette’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance for International Shipping

The Problem: One of the significant challenges faced by B2B buyers shipping palettes internationally is navigating the complex web of regulatory compliance. Different countries have varying regulations regarding the import and export of goods, including specific requirements for pallets. For instance, some regions, particularly in Europe, have strict phytosanitary standards to prevent the spread of pests and diseases. This can lead to delays, additional costs, and potential fines if the pallets do not meet these requirements.

The Solution: To overcome regulatory hurdles, B2B buyers should invest in standardized pallets that comply with international regulations, such as ISPM 15 for wood packaging. This standard ensures that wooden pallets have been treated to eliminate pests, making them acceptable for global shipping. Buyers should also partner with logistics providers who are well-versed in the regulations of the destination countries. This partnership can facilitate smoother customs clearance and reduce the risk of non-compliance. Additionally, staying informed about the latest regulatory changes through industry publications and trade associations can help buyers adapt their shipping strategies proactively.

Scenario 2: Ensuring Load Stability During Transit

The Problem: Another common pain point for B2B buyers is the challenge of ensuring load stability during transit. Improperly loaded or secured palettes can lead to product damage, loss, and costly returns. For example, products may shift during transportation, causing breakage or spoilage, which is particularly concerning for industries dealing with fragile goods or perishable items.

The Solution: To enhance load stability, buyers should adopt best practices for pallet loading and securing. Utilizing techniques such as column stacking or interlocking cartons can significantly improve load integrity. It’s also essential to use appropriate securing materials, such as stretch wrap or edge boards, to prevent movement during transit. Investing in professional packing services or consulting with packaging engineers can provide tailored solutions that suit specific products and shipping conditions. Buyers should also consider testing their pallet loading methods in conditions that simulate real shipping scenarios to identify potential weaknesses.

Scenario 3: Managing Costs While Maintaining Quality

The Problem: Cost management is a critical concern for B2B buyers, especially when it comes to sourcing pallets. While it may be tempting to opt for the cheapest option, low-quality pallets can lead to increased damage rates and additional costs in the long run. Buyers often find themselves in a dilemma between saving money upfront and ensuring the integrity of their shipments.

Illustrative image related to shipping palette

The Solution: To balance cost and quality, buyers should evaluate the total cost of ownership (TCO) when selecting pallets. This approach involves considering factors such as durability, reusability, and the potential for damage during transit. Investing in high-quality, reusable pallets can provide long-term savings by reducing replacement costs and minimizing product damage. Buyers should also explore bulk purchasing options, which can lead to significant discounts without compromising on quality. Conducting a thorough market analysis to compare different pallet types and their performance in real-world scenarios can empower buyers to make informed decisions that align with their budget and quality standards.

Strategic Material Selection Guide for shipping palette

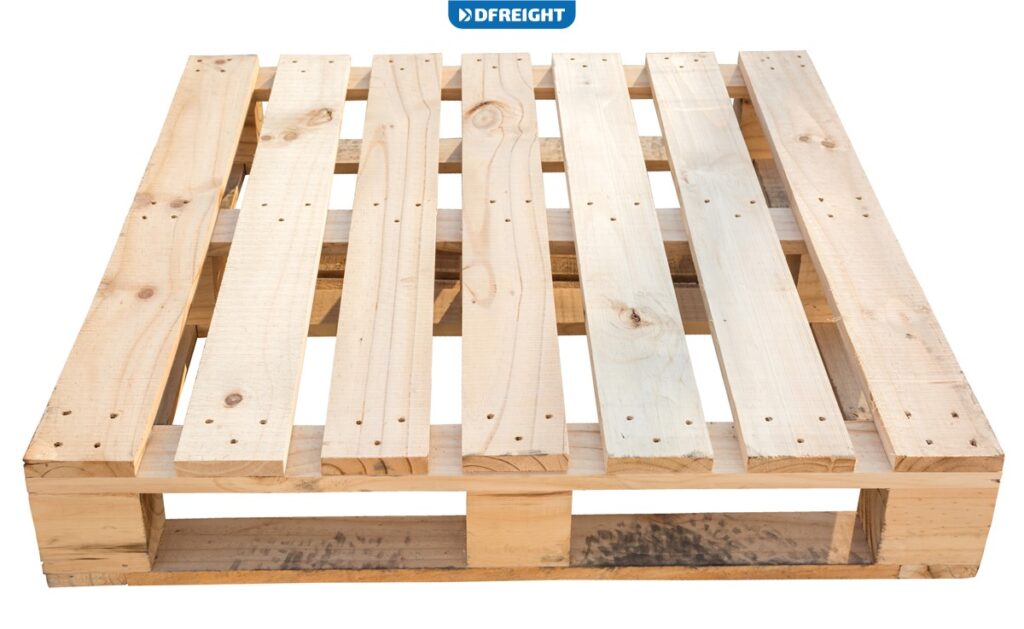

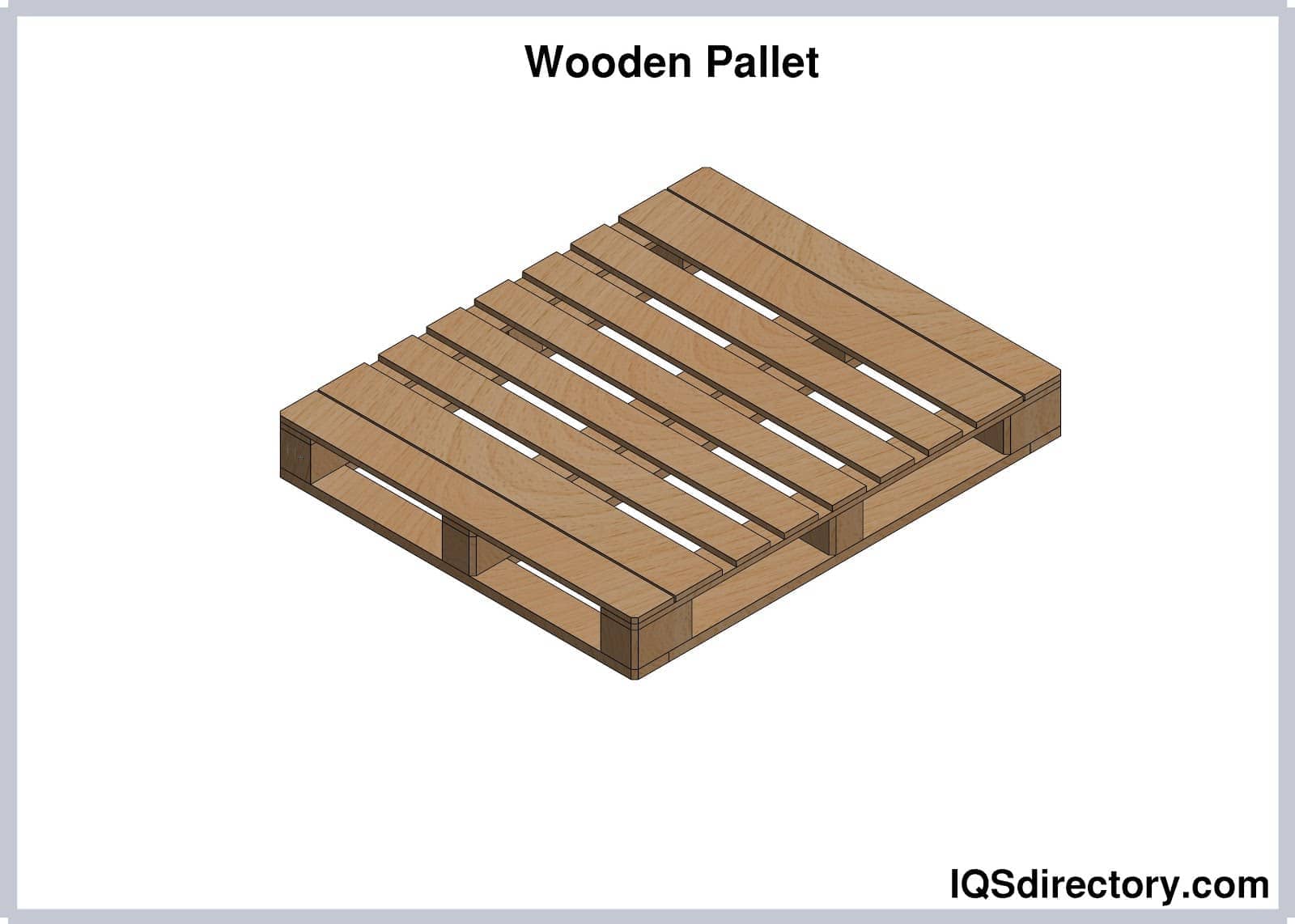

What Are the Key Properties of Wood Pallets for Shipping?

Wood pallets are the most common choice for shipping due to their strength and versatility. Typically made from hardwood or softwood, they can support significant weight and withstand various environmental conditions. Key properties include a temperature rating that can endure normal shipping conditions and a pressure rating that ensures they can handle heavy loads without deforming. Wood pallets are also biodegradable, making them an environmentally friendly option.

Pros: They are generally low-cost, readily available, and can be repaired if damaged. Their natural composition allows for good friction, preventing slippage during transport.

Illustrative image related to shipping palette

Cons: Wood is susceptible to moisture and pests, which can lead to degradation over time. Additionally, they may not be suitable for all types of products, especially those sensitive to contamination.

Impact on Application: Wood pallets are compatible with a wide range of products, but they may require additional treatment for international shipping to comply with regulations like ISPM 15, which mandates heat treatment or fumigation to prevent pest transfer.

How Do Plastic Pallets Compare for Shipping?

Plastic pallets are increasingly popular in various industries due to their durability and resistance to moisture and chemicals. They typically have a higher temperature and pressure rating than wood, making them suitable for more demanding applications.

Illustrative image related to shipping palette

Pros: They are reusable, easy to clean, and resistant to rot, mold, and insects. Their solid construction provides excellent support and stability during transport.

Cons: The initial cost of plastic pallets is generally higher than wood, and they can be heavier, which may increase shipping costs. Additionally, some designs may have a slippery surface, making it challenging to secure loads effectively.

Impact on Application: Plastic pallets are ideal for industries that require high hygiene standards, such as food and pharmaceuticals. However, buyers must ensure compliance with specific industry standards, such as FDA regulations for food contact materials.

Illustrative image related to shipping palette

What Are the Benefits of Metal Pallets for Shipping?

Metal pallets, often made from aluminum or steel, offer exceptional strength and durability. They can withstand extreme temperatures and heavy loads, making them suitable for industrial applications.

Pros: They are incredibly strong, resistant to corrosion, and can be used in harsh environments. Metal pallets are also easy to clean and disinfect, making them suitable for sensitive applications.

Cons: The cost of metal pallets is significantly higher than wood or plastic, which can be a barrier for many businesses. They are also heavier, which may affect shipping logistics.

Impact on Application: Metal pallets are ideal for heavy machinery or automotive parts. However, they may not be compliant with all shipping regulations in certain regions, so international buyers should verify local standards.

Illustrative image related to shipping palette

What Are the Considerations for Corrugated Fiberboard Pallets?

Corrugated fiberboard pallets are lightweight and made from recycled materials, making them an eco-friendly option. They are designed for single-use applications and are often used for lightweight products.

Pros: They are inexpensive, lightweight, and recyclable, which aligns with sustainability goals. Their design allows for easy customization and branding.

Cons: They are not durable and can be easily damaged by moisture or heavy loads. They are typically not reusable, which can lead to higher long-term costs.

Impact on Application: Best suited for low-weight products, corrugated fiberboard pallets may not be suitable for international shipping due to their fragility and lack of compliance with robust shipping standards.

Illustrative image related to shipping palette

| Material | Typical Use Case for shipping palette | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood Pallets | General freight shipping | Low cost and readily available | Susceptible to moisture and pests | Low |

| Plastic Pallets | Food and pharmaceutical industries | Durable and easy to clean | Higher initial cost and weight | High |

| Metal Pallets | Heavy machinery and automotive parts | Exceptional strength and corrosion resistance | High cost and heavier weight | High |

| Corrugated Fiberboard Pallets | Lightweight product shipping | Eco-friendly and customizable | Easily damaged and not reusable | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for shipping palette

What Are the Main Stages of the Manufacturing Process for Shipping Pallets?

The manufacturing of shipping pallets involves several critical stages that ensure the final product meets the required specifications for strength, durability, and usability. Understanding these stages helps B2B buyers make informed decisions about their pallet procurement.

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Common materials for pallets include wood, plastic, and metal. For wooden pallets, high-quality timber is sourced, often from sustainable forests, ensuring compliance with environmental regulations. The wood is then cut to size, debarked, and dried to reduce moisture content, which is essential for preventing warping and decay. Plastic pallets, on the other hand, begin with the procurement of plastic resin, which is then processed through methods like injection molding or extrusion to create the pallet shape.

2. Forming

After material preparation, the next stage is forming. For wooden pallets, this involves assembling the cut timber pieces into a frame. The boards are typically joined using nails, screws, or adhesives, depending on the design and intended load capacity. For plastic pallets, the forming process includes molding the resin into the desired shape. This stage is crucial as it determines the pallet’s structural integrity and load-bearing capabilities.

3. Assembly

Assembly involves putting together the various components of the pallet. For wooden pallets, this may include adding support stringers or cross members to enhance strength and stability. In the case of plastic pallets, additional features such as reinforced corners or slip-resistant surfaces might be incorporated during this phase. Quality checks are often conducted at this stage to ensure that all components are correctly aligned and securely attached.

4. Finishing

The final stage of manufacturing is finishing, where pallets undergo treatments to enhance their durability and appearance. For wooden pallets, this may involve sanding, staining, or applying protective coatings to resist moisture and pests. Plastic pallets may be treated with UV stabilizers to prevent degradation from sunlight exposure. This stage not only improves the pallets’ aesthetic but also extends their lifespan, making them more suitable for international shipping.

What Are the Key Quality Assurance Practices in Pallet Manufacturing?

Quality assurance (QA) is critical in the pallet manufacturing process, ensuring that the products meet international and industry-specific standards. Buyers should be aware of these practices to ensure they are sourcing high-quality pallets.

Relevant International Standards for Shipping Pallets

Several international standards govern the quality and safety of shipping pallets. The most prominent is ISO 9001, which outlines the requirements for a quality management system (QMS). Compliance with ISO 9001 ensures that manufacturers consistently produce products that meet customer and regulatory requirements. Additionally, for pallets intended for the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

What Are the QC Checkpoints Throughout the Manufacturing Process?

Quality control (QC) checkpoints are essential throughout the manufacturing process. These checkpoints can be categorized into three main stages:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. For wooden pallets, this includes checking for defects, moisture content, and compliance with specifications. For plastic pallets, the resin quality is assessed.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections ensure that each stage meets quality standards. This includes monitoring dimensions, joint integrity, and overall construction quality. Any deviations are addressed immediately to prevent defective products from moving forward.

-

Final Quality Control (FQC): Once pallets are fully assembled and finished, a final inspection is conducted. This includes load testing, ensuring that pallets can support the specified weight without deforming. Aesthetic checks are also performed to ensure that the pallets meet branding and presentation standards.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is crucial for B2B buyers, especially when sourcing pallets internationally. Here are some effective strategies:

Conducting Supplier Audits

One of the most direct methods to assess a supplier’s quality control is to conduct an audit. This involves visiting the manufacturing facility to review their processes, quality assurance measures, and compliance with international standards. During the audit, buyers can evaluate the equipment used, the cleanliness of the facility, and the qualifications of the personnel involved in production.

Requesting Quality Reports

Buyers should request detailed quality reports from suppliers. These reports should include information on the QC processes implemented, results of any testing conducted, and compliance with relevant standards. An established supplier should be willing to provide this information, demonstrating transparency and commitment to quality.

Engaging Third-Party Inspection Services

For added assurance, B2B buyers can engage third-party inspection services to evaluate the quality of pallets before shipment. These inspectors can conduct random sampling and testing to ensure that the pallets meet the specified standards. This step is particularly important for international shipments, where discrepancies in quality can lead to significant financial losses.

Illustrative image related to shipping palette

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. These include:

Compliance with Regional Standards

Different regions may have varying standards for shipping pallets. For instance, pallets used in Europe must comply with the European Pallet Association (EPAL) standards, which dictate specific design and material requirements. Buyers should familiarize themselves with these standards to ensure compliance and avoid issues during customs clearance.

Understanding Import Regulations

Buyers should also be aware of import regulations that may affect pallet quality. For example, many countries have strict regulations regarding the import of wooden pallets to prevent the spread of pests. Ensuring that pallets are treated and certified according to international standards (such as ISPM 15) is essential for avoiding delays or rejections at the border.

Cultural and Market Considerations

Finally, understanding cultural and market-specific preferences can influence pallet choice. For instance, businesses in the Middle East may prefer plastic pallets for their durability and ease of cleaning, while those in Africa may prioritize cost-effectiveness. Buyers should align their quality expectations with market demands to optimize their supply chain.

Conclusion

The manufacturing processes and quality assurance measures for shipping pallets are integral to ensuring that products reach their destination safely and efficiently. By understanding the complexities of these processes, B2B buyers can make informed decisions that align with their operational needs and quality standards. Whether engaging with local suppliers or sourcing internationally, a thorough comprehension of manufacturing and QC practices will facilitate better procurement strategies and ultimately enhance supply chain performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shipping palette’

To assist B2B buyers in procuring shipping pallets, this guide provides a practical step-by-step checklist. It outlines critical considerations to ensure you select the right pallets for your shipping needs, maximizing efficiency and minimizing costs.

Illustrative image related to shipping palette

Step 1: Define Your Technical Specifications

Establishing the technical requirements for your pallets is the first step in the sourcing process. Consider the dimensions, weight capacity, and material type needed for your products. For instance, if you’re shipping heavy machinery components, opt for robust wood pallets; for lighter items, plastic pallets may suffice.

Step 2: Assess Your Shipping Environment

Understanding the conditions under which your pallets will be shipped is crucial. Will they be exposed to moisture or extreme temperatures? If so, you may want to avoid wood pallets that can warp or degrade. Ensure your chosen pallets are durable enough to withstand environmental fluctuations and handling stresses during transit.

Step 3: Evaluate Potential Suppliers

Before making a purchase, thoroughly vet potential suppliers. Request comprehensive company profiles, customer references, and case studies that demonstrate their capability to meet your needs. Look for suppliers with experience in your industry and those who can provide pallets that comply with international shipping standards.

- Supplier Certifications: Verify that your suppliers hold relevant certifications, such as ISO or those specific to pallet manufacturing. This can indicate their commitment to quality and safety standards.

Step 4: Check for Compliance with Regulations

Ensure that the pallets you are considering meet international shipping regulations, especially if you are importing or exporting. Different regions may have specific requirements regarding materials and treatments (such as ISPM 15 for wood pallets). Non-compliance can lead to costly delays or fines.

Illustrative image related to shipping palette

Step 5: Examine Cost vs. Quality

While price is a significant factor, it’s essential to balance cost with quality. Determine the total cost of ownership, including potential repair or replacement costs, against the durability and lifespan of the pallets. Investing in higher-quality pallets can lead to lower long-term costs due to reduced damage and fewer replacements.

Step 6: Plan for Return Logistics

Consider the logistics of returning pallets if you plan to reuse them. Discuss return policies with your supplier and evaluate their capability for managing reverse logistics. A robust return process can save you money and reduce waste, making your shipping operations more sustainable.

Step 7: Implement a Trial Run

Before committing to a large order, conduct a trial run with a small batch of pallets. This allows you to assess their performance under your specific shipping conditions. Monitor how well they hold up during transportation and whether they adequately protect your products. Gather feedback from your logistics team to make informed adjustments.

Illustrative image related to shipping palette

By following this checklist, B2B buyers can streamline their pallet procurement process, ensuring they select the most suitable options for their shipping needs while adhering to industry standards and maximizing operational efficiency.

Comprehensive Cost and Pricing Analysis for shipping palette Sourcing

What Are the Key Cost Components in Shipping Palette Sourcing?

When analyzing the cost structure for shipping pallets, several components play a significant role. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of material—wood, plastic, or corrugated fiberboard—directly influences the cost. Wooden pallets are generally less expensive but may not provide the durability needed for long-distance shipping. Plastic pallets, while reusable and more durable, come at a higher price point.

-

Labor: Labor costs can vary significantly based on geographic location. In regions with lower labor costs, such as some parts of Africa and South America, sourcing pallets may be more economical. However, skilled labor is often necessary for custom pallet designs, which can inflate labor costs.

-

Manufacturing Overhead: This includes costs associated with running production facilities, utilities, equipment maintenance, and administrative expenses. Manufacturers may pass these costs onto buyers, especially for smaller orders.

-

Tooling: Custom pallets often require specific tooling, which can lead to higher initial costs. Investing in tooling can be justified if the volume justifies the expense.

-

Quality Control (QC): Ensuring that pallets meet specific quality standards can add to the overall cost. Certifications such as ISPM 15 for wooden pallets, which prevent the spread of pests, can be a significant factor for international shipments.

-

Logistics: Transportation costs can vary widely based on the distance, mode of transport, and shipping terms (Incoterms). For international buyers, understanding the logistics involved in getting pallets from manufacturers to their location is crucial.

-

Margin: Suppliers will typically add a profit margin to cover their costs and generate profit. This margin can vary based on market demand, competition, and the supplier’s brand reputation.

How Do Price Influencers Impact Shipping Palette Costs?

Several factors influence the pricing of shipping pallets, particularly for international buyers.

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Ordering in bulk often results in lower per-unit costs, making it more economical for businesses with high shipping needs.

-

Specifications/Customization: Custom pallets tailored to specific products or shipping requirements can increase costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Materials and Quality/Certifications: Higher-quality materials and certifications will typically increase costs. Buyers should assess the value of durability and compliance against their shipping needs.

-

Supplier Factors: The supplier’s location, reputation, and operational efficiency can influence pricing. Engaging with multiple suppliers can provide competitive quotes and better terms.

-

Incoterms: Understanding the Incoterms involved in the transaction is vital. These terms define the responsibilities of buyers and sellers in shipping, affecting overall costs, especially for international transactions.

What Are Effective Buyer Tips for Negotiating Costs?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider several strategies to optimize costs when sourcing shipping pallets.

-

Negotiation: Always negotiate prices and terms with suppliers. Establishing a long-term relationship can lead to better rates and favorable payment terms.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider factors such as durability, reusability, and logistics costs to determine the most cost-effective option.

-

Pricing Nuances: Be aware that prices can fluctuate based on local market conditions, currency exchange rates, and geopolitical factors. Staying informed about these variables can help in making timely purchasing decisions.

-

Supplier Evaluation: Conduct thorough evaluations of potential suppliers, assessing their production capabilities, quality standards, and logistical support to avoid unexpected costs later in the process.

-

Bulk Buying: Leverage bulk buying to negotiate better prices and ensure supply continuity, especially for businesses with predictable shipping patterns.

Disclaimer

Prices for shipping pallets can vary widely based on numerous factors, including market conditions, material costs, and supplier pricing strategies. The insights provided here are indicative and should be supplemented with direct quotes from suppliers for accurate budgeting and planning.

Alternatives Analysis: Comparing shipping palette With Other Solutions

When considering logistics and shipping solutions, it’s essential for international B2B buyers to explore alternatives to traditional shipping pallets. While pallets are widely used for their efficiency and versatility, other methods can also meet specific needs, depending on the nature of the cargo, budget constraints, and operational goals. Below, we compare shipping pallets with two viable alternatives: freight boxes and crates.

| Comparison Aspect | Shipping Palette | Freight Boxes | Crates |

|---|---|---|---|

| Performance | High load capacity; suitable for various weights and sizes | Good for smaller, lighter shipments; limited load capacity | Excellent for heavy or fragile items; customizable sizes |

| Cost | Generally cost-effective; reusability can lower long-term costs | Moderate cost; often cheaper than pallets for small shipments | Higher initial investment; durable, but may not be reusable |

| Ease of Implementation | Requires proper loading and securing techniques | Easy to pack and seal; minimal training needed | Requires careful packing; may need custom design |

| Maintenance | Moderate; requires inspection and repair of damaged pallets | Minimal; typically single-use or recyclable | High; may need refurbishment for repeated use |

| Best Use Case | Bulk shipments, heavy items, or items needing stability | Small, individual items, or lightweight goods | Heavy, fragile, or high-value items requiring protection |

What Are the Advantages and Disadvantages of Freight Boxes Compared to Shipping Palettes?

Freight boxes present a practical alternative to shipping pallets, especially for smaller shipments. They are typically easier to handle and require less training for staff, making them a straightforward option for many businesses. However, their capacity is limited compared to pallets, which may necessitate more shipments and higher overall costs for larger volumes. Freight boxes are often disposable or recyclable, which can be beneficial for companies focused on sustainability but may not provide the same long-term value as reusable pallets.

How Do Crates Offer Unique Benefits Over Shipping Palettes?

Crates are another alternative that excels in protecting fragile or heavy items during transport. They can be customized to fit specific cargo dimensions, providing an excellent fit that minimizes movement and damage. However, crates often come with a higher upfront cost and may require additional maintenance or refurbishment after multiple uses. They are best suited for high-value shipments where the protection of the contents is paramount, but may not be the most economical choice for bulk shipping.

How Can B2B Buyers Choose the Right Shipping Solution?

Selecting the right shipping solution depends on several factors including the nature of the products being shipped, budget constraints, and the desired level of protection. Shipping pallets are ideal for bulk and heavy loads, offering efficiency and reusability. In contrast, freight boxes are better for smaller, lighter shipments where ease of use is a priority. Crates should be considered for items that require extra protection due to fragility or value. By carefully assessing these aspects, B2B buyers can make informed decisions that align with their operational needs and shipping objectives.

Essential Technical Properties and Trade Terminology for shipping palette

What Are the Key Technical Properties of Shipping Pallets?

When selecting pallets for shipping, understanding the technical specifications is crucial for ensuring safe and efficient transport of goods. Here are the essential properties to consider:

1. Material Grade

Pallets can be made from various materials, primarily wood, plastic, or metal. The material grade affects the pallet’s strength, durability, and weight capacity. For instance, high-grade hardwood pallets offer superior strength and longevity, making them suitable for heavy loads and repeated use. In contrast, lower-grade materials may suffice for lighter, one-time shipments. Selecting the right material grade is vital for maintaining product integrity during transport.

2. Weight Capacity

The weight capacity of a pallet indicates the maximum load it can safely support without risk of failure. This specification is critical for B2B buyers, as shipping goods exceeding the pallet’s weight capacity can lead to damage, financial loss, and safety hazards during handling. Understanding the weight capacity helps businesses choose the right pallets for their specific shipping needs.

Illustrative image related to shipping palette

3. Dimensions and Tolerance

Standard pallet dimensions, such as 40″ x 48″, play a significant role in compatibility with transport and storage systems. Tolerance refers to the allowable variation in dimensions, which is crucial for ensuring that pallets fit seamlessly into shipping containers or warehouse racking systems. Proper dimensions and tolerances help optimize space and reduce shipping costs, making it an essential consideration for international buyers.

4. Stiffness and Flexural Strength

Stiffness refers to a pallet’s resistance to bending under load, while flexural strength measures its ability to withstand forces without breaking. These properties are particularly important for maintaining stability during transport. A pallet with high stiffness and flexural strength minimizes the risk of load shifting, thus protecting the cargo and ensuring safe delivery.

5. Durability and Environmental Resistance

Durability encompasses a pallet’s ability to withstand wear and tear during shipping and handling. Environmental resistance is crucial for pallets exposed to various climates and conditions, especially for international shipments. Selecting durable pallets that can resist moisture, temperature fluctuations, and physical stress helps ensure that goods arrive at their destination in optimal condition.

What Are Common Trade Terms Associated with Shipping Pallets?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some key terms to familiarize yourself with:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of pallets, it often involves suppliers that create pallets specifically designed for particular products or machinery.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers to understand, as it impacts purchasing decisions and inventory management. Knowing the MOQ helps businesses plan their procurement strategy efficiently.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests pricing information from suppliers for specific products. When sourcing pallets, submitting an RFQ can help businesses compare prices, quality, and terms from multiple suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding the delivery of goods. Understanding these terms is essential for B2B buyers involved in international shipping, as they dictate who bears the risk and costs at each stage of transport.

5. LTL (Less Than Truckload)

LTL shipping refers to the transportation of relatively small freight that does not require a full truckload. This term is significant for businesses that need to ship smaller quantities of goods on pallets, allowing them to save costs compared to full truckload shipping.

By familiarizing yourself with these technical properties and trade terms, you can enhance your shipping strategy, ensuring that your goods are transported efficiently and safely across international borders.

Navigating Market Dynamics and Sourcing Trends in the shipping palette Sector

What Are the Key Market Trends Impacting the Shipping Palette Sector?

The shipping palette sector is undergoing significant transformation driven by global trade dynamics and technological advancements. Key trends include the increasing demand for standardized shipping solutions, which streamline logistics and reduce costs. In regions like Africa, South America, the Middle East, and Europe, buyers are particularly focused on efficiency and reliability in their supply chains. For instance, the rise of e-commerce is compelling businesses to optimize shipping methods, leading to a surge in the adoption of pallets that cater to diverse product types and sizes.

Emerging B2B technologies such as IoT (Internet of Things) and automation are also reshaping the landscape. IoT devices enable real-time tracking of shipments, improving transparency and allowing businesses to respond swiftly to disruptions. Additionally, automation in pallet manufacturing and handling enhances productivity and reduces labor costs, which is especially beneficial for international buyers navigating complex logistics.

As supply chains become increasingly globalized, the need for robust and adaptable shipping palettes is more pronounced. Buyers are seeking suppliers who can offer customized solutions, including diverse materials and designs tailored to specific shipping needs, thereby ensuring product safety and integrity throughout transit.

Illustrative image related to shipping palette

How Is Sustainability Influencing Shipping Palette Sourcing Decisions?

Sustainability has become a pivotal factor in sourcing decisions within the shipping palette sector. Businesses are increasingly aware of the environmental impact of their supply chains, prompting a shift towards more sustainable practices. This includes selecting materials that minimize ecological footprints, such as recycled wood or certified sustainably sourced materials.

Ethical supply chains are gaining importance as buyers, particularly from regions like Europe and the Middle East, prioritize suppliers who adhere to environmental and social governance (ESG) standards. Certifications such as the Forest Stewardship Council (FSC) for wood pallets or the use of biodegradable materials in plastic palettes can enhance a company’s reputation and marketability.

Moreover, sustainable packaging solutions are not only beneficial for the planet but also offer economic advantages. Companies that invest in ‘green’ certifications often experience cost savings in waste management and improve their brand loyalty among environmentally conscious consumers. As the global market evolves, suppliers who align their practices with sustainability will likely gain a competitive edge.

What Is the Historical Context of Shipping Palettes in B2B Trade?

The evolution of shipping palettes dates back to the early 20th century when they were first introduced to facilitate the efficient handling of goods. Initially made from wood, these palettes revolutionized cargo transport by enabling the stacking and movement of products with forklifts and pallet jacks. Over the decades, the design and materials of palettes have diversified significantly, incorporating plastics and composites to meet varying industry needs.

As global trade expanded, the standardization of palette sizes emerged, enabling interoperability across different regions and industries. This standardization has been crucial for international B2B transactions, particularly for companies in Africa, South America, and the Middle East, where logistics infrastructure may vary widely. The ongoing innovations in palette technology, such as collapsible designs and advanced materials, reflect the sector’s adaptability to changing market demands and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of shipping palette

-

1. How do I select the right type of pallet for my shipment?

Choosing the right pallet type depends on several factors, including the weight of the load, the nature of the products being shipped, and the transport conditions. For heavy loads, standard wood pallets are recommended due to their strength and durability. If moisture is a concern, consider plastic pallets, which are reusable and resistant to environmental changes. Always ensure the pallet meets industry standards for functionality and can be handled with standard equipment like forklifts. -

2. What are the common issues faced when shipping pallets internationally?

Common issues in international pallet shipping include compliance with local regulations, customs delays, and damage during transit. It’s vital to be aware of the import/export regulations specific to your destination country to avoid fines or shipment rejections. Additionally, using high-quality pallets and securing loads properly can mitigate damage risks. Partnering with a reliable logistics provider familiar with international shipping can also streamline the process. -

3. What are the minimum order quantities (MOQ) for shipping pallets?

Minimum order quantities for shipping pallets can vary significantly by supplier and region. Typically, you may encounter MOQs ranging from 50 to 500 pallets. It is advisable to discuss your specific needs with suppliers, as some may offer flexibility for first-time buyers or bulk orders. Always consider your storage capacity and shipping frequency when determining your order size. -

4. How can I ensure quality assurance for the pallets I purchase?

To ensure quality assurance, request certifications from suppliers that indicate compliance with international standards, such as ISPM 15 for wood pallets. Conducting a supplier audit can also help assess their manufacturing processes and quality control measures. Consider ordering samples before making a large purchase to evaluate the durability and suitability of the pallets for your specific needs. -

5. What payment terms should I expect when sourcing pallets internationally?

Payment terms can vary widely among suppliers, but common practices include advance payment, letters of credit, or payment upon delivery. It’s essential to negotiate terms that align with your cash flow while ensuring security for both parties. Establishing a clear agreement upfront can help avoid misunderstandings and build trust in your supplier relationship. -

6. How do I secure my load on a pallet for international shipping?

To secure your load, use materials like stretch wrap, edge boards, and banding. Stretch wrap keeps the load intact, while edge boards protect the corners and increase stability. Additionally, consider using load protectors and bracing for heavier items. Properly securing your load reduces the risk of damage during transit and ensures compliance with shipping regulations. -

7. Can pallets be customized for specific shipping needs?

Yes, pallets can often be customized to meet specific shipping requirements, including size, material, and design features. Custom pallets can accommodate unique product dimensions or weight capacities. When discussing customization with suppliers, provide detailed specifications to ensure the final product meets your logistical needs and adheres to industry standards. -

8. What should I consider when vetting a pallet supplier?

When vetting a pallet supplier, consider their experience in the industry, product quality, delivery capabilities, and customer service. Request references and reviews from previous clients to gauge reliability. Additionally, check if they comply with international shipping standards and certifications. Establishing a good relationship with a trusted supplier can significantly enhance your shipping operations.

Top 7 Shipping Palette Manufacturers & Suppliers List

1. FedEx – Key Pallet Considerations

Domain: fedex.com

Registered: 1991 (34 years)

Introduction: Pallets are portable platforms used for handling, storing, and shipping products. Key considerations when choosing a pallet include: 1. Strength – must support the weight of the load; 2. Stiffness – should resist bending and deforming; 3. Durability – must withstand shipping conditions; 4. Functionality – should conform to industry standards for transport; 5. Price – balance cost and quality. Reco…

2. ULINE – Pallets and Shipping Solutions

Domain: uline.com

Registered: 1995 (30 years)

Introduction: Pallets, Plastic Pallets, Shipping Pallets in Stock – ULINE includes various types of pallets such as Export Pallets, New Wood Pallets, Rackable Pallets, Economy Plastic Pallets, Industrial Plastic Pallets, Heavy Duty Nestable Pallets, Solid Top Rackable Pallets, Heavy Duty Export Pallets, Rackable Export Pallet, Closed Deck Export Pallet, Stackable Pallets, Extended Pallet, Plastic Drum Pallets, …

3. Cable Ties and More – Fast Delivery & Easy Returns

Domain: cabletiesandmore.com

Registered: 2006 (19 years)

Introduction: This company, Cable Ties and More – Fast Delivery & Easy Returns, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. FreightQuote – Pallet Shipping Solutions

Domain: freightquote.com

Registered: 1998 (27 years)

Introduction: Standard pallet sizes include: 48″ x 40″, 42″ x 42″, and 48″ x 48″. The most common type is the GMA pallet, which measures 48″ x 40″. Other types of pallets mentioned are Stringer pallets, Block pallets, Solid Deck pallets, Double Face pallets, and Double Wing pallets. Key advantages of pallet shipping include protection, movability, sustainability, standardization, and cost-effectiveness. Factors…

5. Pallet Shipping Solutions – Electronic Equipment

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Pallet dimensions: 4′ x 4′; Weight: 475-500 pounds; Type of equipment: electronic equipment (class 110.0); Shipping distance: approximately 2600 miles (west coast to east coast in the US); Delivery requirements: liftgate delivery; Shipping quotes: UPS – approximately $1650, FedEx – over $2200; Chosen carrier: R&L Carrier with a quote of $675.

6. Blacksite Studio – Shipping Pallets Kit

Domain: blacksitestudio.com

Registered: 2017 (8 years)

Introduction: Shipping Pallets SKU: IND#2004 Price: $9.99 Quantity: 10x shipping pallets per kit Scale: 28mm Details kit Comes on sprues, ready to use once assembled Miniatures shown for scale purposes only.

7. A-1 Auto Transport – Pallet Shipping Services

Domain: a1autotransport.com

Registered: 2001 (24 years)

Introduction: Pallet Shipping Services by A-1 Auto Transport offer affordable rates averaging $0.50–$0.90 per pound, with costs determined by dimensions, weight, and delivery zone. Standard transit times range from 2–7 business days, with expedited LTL options available. Compliance with FMCSA and DOT packaging standards is required. The service includes a best price guarantee, potentially saving customers 20% c…

Strategic Sourcing Conclusion and Outlook for shipping palette

As the global landscape of shipping and logistics continues to evolve, the importance of strategic sourcing for shipping pallets cannot be overstated. By focusing on key factors such as strength, durability, and cost-effectiveness, businesses can optimize their supply chain management and enhance overall operational efficiency. Choosing the right pallet type—whether wood, plastic, or alternative materials—can significantly impact both shipping costs and product integrity during transit.

For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding local regulations and logistics nuances is crucial. Engaging with reliable suppliers who can provide high-quality pallets tailored to your specific needs will not only streamline your shipping processes but also contribute to sustainability efforts through reusable options.

Looking ahead, the demand for innovative shipping solutions will only increase. By investing in strategic sourcing now, businesses can position themselves for success in a competitive market. Take action today by evaluating your pallet sourcing strategy and exploring partnerships that align with your long-term shipping goals. Embrace the future of logistics and ensure your operations are equipped to thrive in an interconnected world.

Illustrative image related to shipping palette

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.