A B2B Buyer’s Guide to Barcode Clothing Labels: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for barcode clothing labels

In the rapidly evolving landscape of the apparel industry, sourcing reliable barcode clothing labels presents a significant challenge for international B2B buyers. As businesses strive for efficiency in inventory management and product tracking, the demand for high-quality barcode solutions has surged. This comprehensive guide delves into the diverse types of barcode clothing labels available, including heat seal, sew-on, and iron-on options, each tailored to meet specific operational needs.

Buyers will discover critical applications for these labels, from enhancing supply chain logistics to ensuring compliance with international retail standards. Moreover, the guide will equip buyers with essential insights on supplier vetting processes, enabling them to select reputable manufacturers and distributors. Cost considerations, including bulk pricing and customization options, will also be explored, ensuring that decision-makers can make informed financial commitments.

Designed specifically for B2B professionals from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—this guide empowers stakeholders to navigate the complexities of sourcing barcode clothing labels effectively. By leveraging the insights contained within, businesses can streamline their operations, enhance product traceability, and ultimately drive growth in a competitive global market.

Understanding barcode clothing labels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Sew-On Barcode Labels | Durable, high-quality fabric with a sewing flap for easy attachment | Textile manufacturing, apparel production | Pros: Secure attachment, withstands multiple washes. Cons: Requires sewing equipment, more time-consuming to apply. |

| Iron-On Barcode Labels | Coated with heat seal film, allowing quick application with an iron | Laundry services, rental clothing management | Pros: Quick and easy application, suitable for various fabrics. Cons: May not adhere well to all fabric types, requires heat source. |

| Thermal Transfer Barcode Labels | Printed using thermal transfer technology for high durability | Inventory management, retail tracking | Pros: High-quality print, resistant to fading. Cons: Requires specialized printers, may incur additional costs. |

| Preprinted Barcode Labels | Ready-to-use labels with specific barcodes already printed | Retail, warehouse management | Pros: Saves time, no setup needed. Cons: Limited customization options, may not fit all applications. |

| Custom Barcode Labels | Tailored designs and barcodes to meet specific needs | Branding, specialty clothing lines | Pros: Fully customizable, enhances brand identity. Cons: Higher cost, longer lead times for production. |

What Are Sew-On Barcode Labels and When to Use Them?

Sew-on barcode labels are crafted from durable fabric and feature a flap that facilitates easy attachment during garment production. They are ideal for businesses focused on textiles, as they can endure multiple washes and maintain their integrity. When purchasing, consider the sewing capabilities of your production line and the specific textile properties, such as weight and texture, to ensure compatibility.

How Do Iron-On Barcode Labels Work?

Iron-on barcode labels utilize a heat seal film that bonds the label to the fabric when applied with an iron. These labels are particularly advantageous for laundry services and rental clothing management, offering a quick application method. Buyers should assess the fabric types they plan to use these labels on, as the effectiveness of adhesion can vary, and the need for a heat source is essential.

What Are Thermal Transfer Barcode Labels and Their Benefits?

Thermal transfer barcode labels are printed using specialized thermal transfer printers, providing high durability and resistance to fading. They are commonly employed in inventory management and retail tracking, where longevity and readability are crucial. Businesses should invest in the necessary printing equipment and consider the cost implications, as these labels may require a more significant upfront investment but offer long-term benefits.

Why Choose Preprinted Barcode Labels?

Preprinted barcode labels come ready-to-use with specific barcodes, making them a time-efficient solution for businesses in retail and warehouse management. They eliminate the need for printing setup, allowing for immediate use. However, buyers should consider the limitations in customization, as these labels may not cater to all specific needs or branding requirements.

What Advantages Do Custom Barcode Labels Offer?

Custom barcode labels are tailored to meet unique business requirements, providing opportunities for branding and specialized applications. They are ideal for companies looking to enhance their identity through labeling. While they offer maximum flexibility and personalization, buyers should be prepared for potentially higher costs and longer lead times, as custom orders typically require more extensive production processes.

Key Industrial Applications of barcode clothing labels

| Industry/Sector | Specific Application of barcode clothing labels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Inventory management for clothing lines | Enhances tracking accuracy, reduces stock discrepancies | Ensure labels are durable and compatible with scanning systems |

| Healthcare | Patient garment tracking in hospitals | Improves patient safety and garment retrieval efficiency | Labels must withstand frequent laundering and sterilization |

| Hospitality | Tracking linens and uniforms in hotels | Streamlines laundry processes and inventory control | Consider moisture resistance and visibility of barcodes |

| Textile Rentals | Tracking rental garments and equipment | Facilitates easy identification and return processes | Look for labels that are durable under various conditions |

| Manufacturing | Quality control in garment production | Enhances traceability and compliance with standards | Ensure labels can be printed with variable data and are cost-effective |

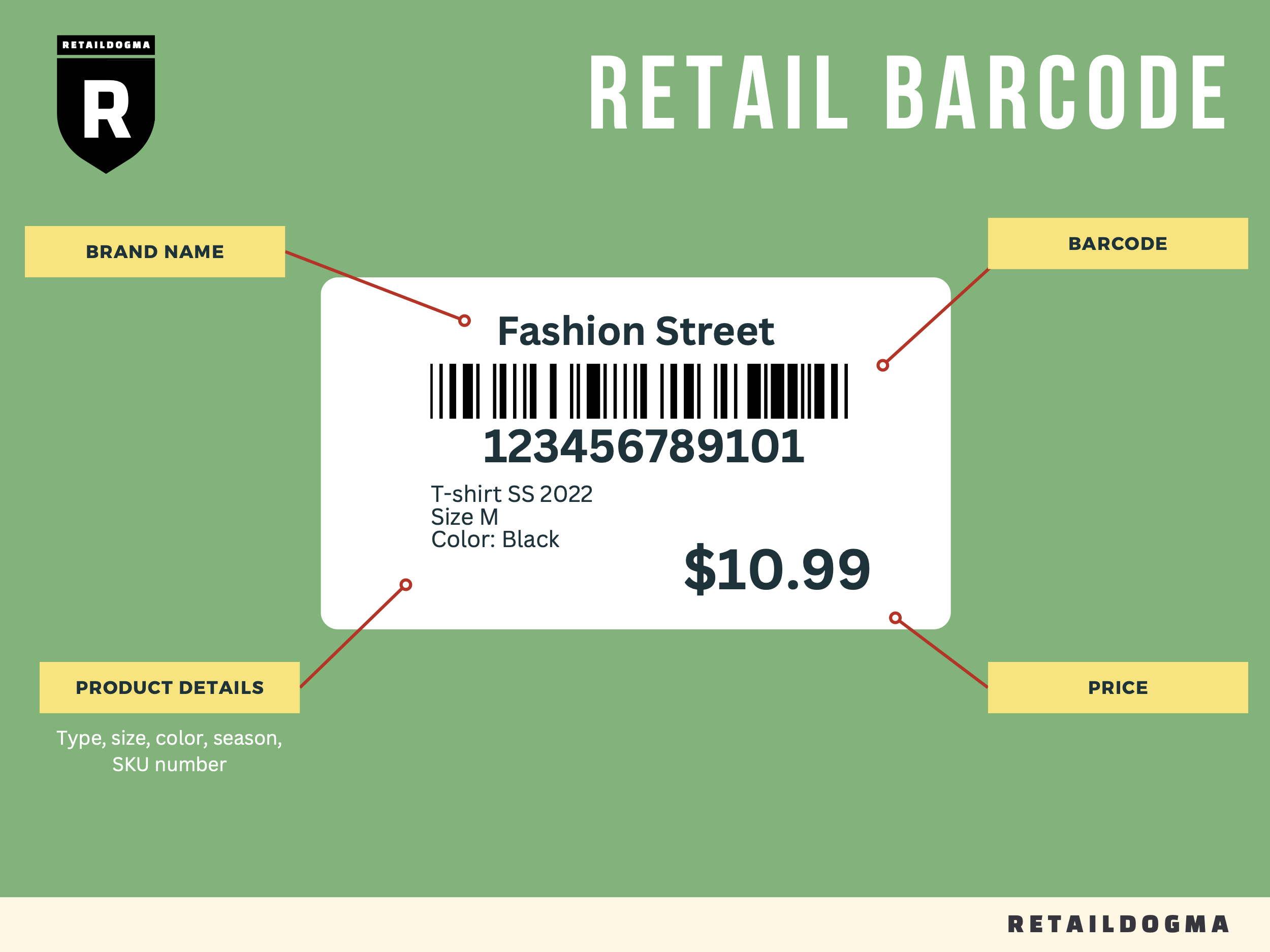

How Are Barcode Clothing Labels Used in Retail Inventory Management?

In the retail sector, barcode clothing labels are pivotal for effective inventory management. They facilitate real-time tracking of stock levels, ensuring that businesses can maintain optimal inventory without overstocking or stockouts. This is particularly valuable in regions like Europe and South America, where market dynamics can shift rapidly. B2B buyers should prioritize labels that are durable, compatible with various scanning systems, and capable of withstanding the rigors of retail environments.

What Role Do Barcode Clothing Labels Play in Healthcare Garment Tracking?

In healthcare settings, barcode clothing labels are essential for tracking patient garments, ensuring that each item can be quickly identified and returned to the correct patient after laundering. This application is crucial for enhancing patient safety and operational efficiency in hospitals. Buyers in the healthcare sector should seek labels that can endure frequent laundering and sterilization processes, while also remaining legible throughout their lifecycle.

How Do Hospitality Businesses Benefit from Barcode Labels for Linens and Uniforms?

In the hospitality industry, barcode clothing labels simplify the management of linens and uniforms. They allow for streamlined tracking during laundry processes, ensuring that items are efficiently sorted and returned to the correct rooms or staff members. This not only enhances operational efficiency but also improves guest satisfaction. Buyers should consider labels that are moisture-resistant and feature clear, easily scannable barcodes to ensure functionality in high-paced environments.

Why Are Barcode Labels Important for Textile Rental Services?

For businesses in the textile rental industry, barcode clothing labels are crucial for tracking rental garments and equipment. They enable easy identification, ensuring that items are returned to the correct inventory and minimizing losses. This application is particularly relevant in regions with growing rental markets, such as parts of Africa and the Middle East. Buyers should look for labels that can withstand various environmental conditions and are designed for high visibility to facilitate quick identification.

How Can Barcode Labels Enhance Quality Control in Manufacturing?

In manufacturing, barcode clothing labels play a significant role in quality control processes. They help in tracking garments through various production stages, ensuring compliance with industry standards and enhancing traceability. This is essential for manufacturers looking to optimize their processes and maintain high-quality outputs. B2B buyers should consider sourcing labels that can be printed with variable data and are cost-effective to meet the demands of high-volume production.

Illustrative image related to barcode clothing labels

3 Common User Pain Points for ‘barcode clothing labels’ & Their Solutions

Scenario 1: Difficulty in Ensuring Label Durability for Frequent Wash Cycles

The Problem: Many B2B buyers, particularly those in the textile and apparel industries, struggle with the longevity of barcode clothing labels when subjected to repeated laundering. Traditional labels often fade, peel, or become unreadable after just a few washes, leading to lost inventory, inefficiencies in tracking, and increased operational costs. This issue is particularly pronounced in regions where clothing items are frequently washed, such as in commercial laundries or rental clothing services.

The Solution: To address this challenge, B2B buyers should opt for high-quality iron-on or sew-on barcode labels designed specifically for durability. When sourcing these labels, ensure they are made from wash-resistant materials and are tested for resilience in commercial laundering settings. Products like those offered by WePrintBarcodes and Unitherm provide labels with heat seal technology, which allows for a strong bond to fabric that withstands multiple wash cycles. Additionally, buyers should consider conducting small-scale tests before a full rollout to confirm the labels’ performance in their specific laundering environment.

Scenario 2: Incompatibility with Existing Inventory Management Systems

The Problem: Another common pain point is the lack of compatibility between barcode labels and existing inventory management systems. Many businesses utilize specific software solutions that may not integrate seamlessly with the barcode formats or data structures offered by label suppliers. This disconnect can lead to inefficient tracking processes, increased labor costs, and potential errors in inventory counts.

The Solution: To mitigate this issue, buyers should engage with label providers who offer customizable solutions that can be tailored to meet the specific requirements of their inventory management systems. When discussing options with suppliers, communicate your current software capabilities and ask for labels that support common data formats, such as CSV or Excel imports. Additionally, inquire if the supplier can assist in creating a barcode printing station that includes software integration, ensuring a smoother workflow. This proactive approach can save significant time and resources by streamlining inventory management processes.

Scenario 3: Uncertainty in Label Application Methods and Best Practices

The Problem: Many B2B buyers face challenges when it comes to the application methods of barcode clothing labels. Whether using sew-on, iron-on, or adhesive labels, businesses may experience confusion regarding the best practices for application, leading to improper adhesion and scanning issues. This uncertainty can result in additional costs due to re-labeling or lost inventory due to unreadable codes.

The Solution: To overcome this hurdle, buyers should prioritize suppliers that provide comprehensive application guides and support materials. For instance, Unitherm offers detailed instructions on applying iron-on labels, including recommended temperatures and times for heat application. Additionally, consider investing in training sessions for staff responsible for labeling, as hands-on experience can dramatically reduce application errors. Establishing a standard operating procedure (SOP) for label application can also ensure consistency and reliability across all labeling processes. By prioritizing proper application techniques, businesses can enhance the longevity and effectiveness of their barcode clothing labels, ultimately improving operational efficiency.

Strategic Material Selection Guide for barcode clothing labels

What Are the Key Materials Used for Barcode Clothing Labels?

When selecting materials for barcode clothing labels, it is essential to consider various factors such as durability, application environment, and compliance with international standards. Below is an analysis of three common materials used in the manufacturing of barcode clothing labels: polyester, cotton, and vinyl.

How Does Polyester Perform as a Material for Barcode Clothing Labels?

Polyester is a synthetic fabric known for its strength and durability. It can withstand high temperatures and is resistant to shrinking and stretching, making it ideal for various applications in the textile industry. Polyester labels can endure multiple wash cycles without fading or losing their integrity, which is crucial for clothing labels that require longevity.

Pros: Polyester is lightweight, cost-effective, and offers excellent resistance to moisture and abrasion. It is also compatible with various printing methods, ensuring high-quality barcodes.

Illustrative image related to barcode clothing labels

Cons: While polyester is durable, it may not be as biodegradable as natural fibers, which can be a concern for environmentally conscious brands. Additionally, it may not perform well in extreme temperatures, which could affect the barcode’s readability.

Impact on Application: Polyester labels are suitable for garments that undergo frequent washing and require high visibility. They are often used in the apparel industry for tracking inventory and managing rental clothing.

Considerations for International Buyers: Buyers from regions such as Europe and South America should ensure that polyester labels comply with regulations regarding chemical safety and environmental impact, such as REACH in Europe.

What Are the Advantages of Using Cotton for Barcode Clothing Labels?

Cotton is a natural fiber that offers comfort and breathability, making it a popular choice for clothing labels. Cotton labels can be printed with high-resolution barcodes and are often preferred for their softness against the skin.

Pros: Cotton labels are biodegradable, making them an eco-friendly option. They are also highly absorbent and can be treated to enhance durability, making them suitable for various applications.

Illustrative image related to barcode clothing labels

Cons: Cotton labels may not be as durable as synthetic options, particularly in harsh washing conditions. They can fade over time and may require special care to maintain their appearance.

Impact on Application: Cotton labels are often used in high-end fashion and organic clothing lines where sustainability is a priority. They are also suitable for items that require gentle washing.

Considerations for International Buyers: Buyers should consider compliance with organic certification standards, especially in markets like Germany, where consumer demand for sustainable products is high.

Illustrative image related to barcode clothing labels

How Does Vinyl Compare as a Material for Barcode Clothing Labels?

Vinyl is a synthetic material known for its versatility and resistance to water and chemicals. It is often used in applications where durability and moisture resistance are paramount.

Pros: Vinyl labels are highly durable and can withstand extreme conditions, including exposure to chemicals and moisture. They are also easy to clean and maintain, making them ideal for industrial applications.

Cons: Vinyl can be less breathable than natural fibers, which may not be suitable for all clothing types. Additionally, the production of vinyl can have environmental implications, making it less favorable for eco-conscious brands.

Impact on Application: Vinyl labels are commonly used in industrial settings, such as uniforms or workwear, where durability and moisture resistance are critical.

Considerations for International Buyers: Buyers should ensure that vinyl labels meet international safety standards and regulations, particularly in regions with strict environmental laws.

Summary Table of Material Selection for Barcode Clothing Labels

| Material | Typical Use Case for barcode clothing labels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | General apparel, rental clothing | High durability and moisture resistance | Less biodegradable | Medium |

| Cotton | High-end fashion, organic clothing | Eco-friendly and comfortable | Less durable in harsh conditions | Medium |

| Vinyl | Industrial uniforms, workwear | Excellent moisture and chemical resistance | Less breathable and eco-friendly | High |

This guide should assist B2B buyers in making informed decisions about material selection for barcode clothing labels, considering both performance and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for barcode clothing labels

What Are the Main Stages of Manufacturing Barcode Clothing Labels?

Manufacturing barcode clothing labels involves several critical stages that ensure both functionality and durability. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to barcode clothing labels

-

Material Preparation: The process begins with sourcing high-quality materials, typically polyester or fabric blends that are suitable for barcode printing. The choice of material is crucial as it affects the label’s durability against various environmental conditions, such as washing, drying, and exposure to chemicals. Suppliers often conduct pre-production quality checks to ensure materials meet specific industry standards.

-

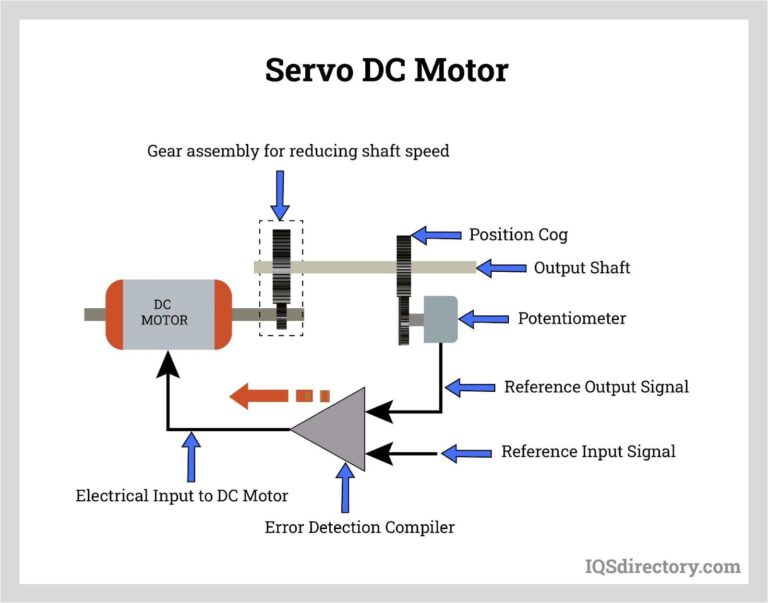

Forming: In this stage, the selected materials are cut into the required shapes and sizes based on customer specifications. Advanced cutting techniques, including laser cutting or die-cutting, are commonly used to achieve precise dimensions. This is critical for ensuring that the barcodes are printed accurately and can be scanned without issues.

-

Assembly: Once the materials are cut, the next step is to apply the barcode printing. Techniques such as thermal transfer printing or direct thermal printing are employed to ensure high-resolution barcodes that are resistant to fading. Depending on the product, labels may be sewn on, ironed on, or applied with adhesive backing. The choice of application technique can significantly influence the label’s longevity and usability.

-

Finishing: The final stage involves applying any protective coatings and conducting a thorough inspection. Labels may undergo lamination or coating with heat-seal film to enhance their resistance to water, abrasion, and other environmental factors. This stage is crucial for ensuring that the labels can withstand repeated laundering and maintain their scannability.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is vital throughout the manufacturing process to ensure that barcode clothing labels meet the required specifications and industry standards. Key international standards, such as ISO 9001, serve as benchmarks for quality management systems.

-

International Standards and Industry-Specific Regulations: B2B buyers should be aware of various quality certifications relevant to barcode labels. For instance, CE marking indicates compliance with European health, safety, and environmental protection standards. Buyers in industries like textiles may also need to consider certifications specific to their sector, such as API for certain applications.

-

Quality Control Checkpoints: The manufacturing process typically incorporates several quality control checkpoints:

– Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

– In-Process Quality Control (IPQC): Quality checks during the production process help identify and rectify issues in real-time, ensuring that defects do not accumulate.

– Final Quality Control (FQC): After production, finished products are inspected for defects, barcode readability, and compliance with customer specifications before shipment. -

Common Testing Methods: Various testing methods are employed to verify the quality of barcode labels. These may include:

– Barcode Verification: Ensures that the printed barcodes meet specific standards for scannability, typically conducted using specialized verification equipment.

– Durability Testing: Labels may be subjected to washing, abrasion, and exposure to chemicals to assess their performance under real-world conditions.

What Strategies Can B2B Buyers Use to Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to mitigate risks associated with sourcing. Here are strategies to consider:

-

Conduct Supplier Audits: Regular audits can provide insights into a supplier’s quality management practices. Buyers should request access to audit reports and certifications to verify compliance with international standards.

-

Request Quality Assurance Documentation: Suppliers should provide comprehensive documentation, including quality control plans, testing results, and certifications. This transparency allows buyers to assess the supplier’s commitment to quality.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing process. These services can assess compliance with quality standards and provide recommendations for improvement.

-

Seek References and Reviews: Engaging with other businesses that have sourced from the supplier can provide valuable insights into their reliability and product quality. Positive testimonials and case studies can be a good indicator of a supplier’s performance.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control is crucial for international B2B buyers. Different regions may have varying standards and practices that can affect sourcing decisions.

-

Cultural Considerations: Buyers should recognize that quality expectations may differ across cultures. For example, European buyers may prioritize compliance with stringent environmental standards, while buyers in other regions may focus more on cost-effectiveness.

-

Regulatory Compliance: Buyers must be aware of local regulations that may impact the importation and use of barcode labels. For instance, certain countries may require specific labeling information, such as care instructions or material composition, which can influence the design and production process.

-

Logistical Challenges: International shipping can introduce additional quality risks, such as damage during transit. Buyers should ensure that suppliers use appropriate packaging and handling procedures to mitigate these risks.

-

Continuous Improvement: Engaging in ongoing dialogue with suppliers about quality expectations and improvement initiatives can foster a collaborative approach to quality assurance. This can lead to better product outcomes and a stronger partnership.

By understanding the manufacturing processes and quality assurance practices associated with barcode clothing labels, B2B buyers can make informed decisions that enhance their sourcing strategies and ensure high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘barcode clothing labels’

Introduction

This practical sourcing guide is designed to assist B2B buyers in navigating the procurement process for barcode clothing labels. By following this checklist, you will ensure that you select high-quality labels that meet your specific requirements, ultimately enhancing your inventory management and tracking capabilities.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical needs. This includes the type of barcode (e.g., UPC, QR codes), label material (iron-on, sew-on, or heat seal), and size requirements. Defining these specifications upfront will streamline your search and help in communicating effectively with suppliers.

Step 2: Research Potential Suppliers

Take the time to identify and research multiple suppliers who specialize in barcode clothing labels. Look for companies that have a proven track record in your industry. Pay attention to their experience with international shipping, especially if you’re sourcing from regions like Africa, South America, or Europe, as this may influence delivery times and costs.

Step 3: Evaluate Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications that validate their product quality and manufacturing processes. Certifications such as ISO 9001 can indicate a commitment to quality management. This step is crucial for minimizing risks associated with poor-quality labels that could impact your operations.

Step 4: Request Samples and Test Quality

Before placing a bulk order, request samples of the labels to assess their quality. Check for durability, print clarity, and the ease of application. Pay special attention to how the labels perform under various conditions, such as laundering or exposure to moisture, to ensure they meet your operational needs.

Step 5: Confirm Customization Options

Many suppliers offer customization options for barcode labels, including size, color, and printing capabilities. Confirm that the supplier can accommodate your specific branding requirements, such as including your logo or specific text. Customization can enhance brand visibility and improve the overall presentation of your products.

Step 6: Review Pricing and Payment Terms

Carefully analyze the pricing structures provided by potential suppliers. Look for transparency in costs, including any additional fees for customization, shipping, or handling. Additionally, clarify payment terms to avoid unexpected costs later in the procurement process, ensuring they align with your budget.

Step 7: Establish a Communication Plan

Once you select a supplier, establish a clear communication plan to facilitate smooth interactions throughout the procurement process. This includes setting expectations for response times, updates on production schedules, and any potential issues that may arise. Effective communication helps build a strong relationship and ensures that your needs are met promptly.

By following these steps, you can confidently procure barcode clothing labels that support your business operations, enhance inventory tracking, and strengthen your brand’s presence in the marketplace.

Comprehensive Cost and Pricing Analysis for barcode clothing labels Sourcing

What are the Key Cost Components in Sourcing Barcode Clothing Labels?

When sourcing barcode clothing labels, several cost components come into play. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of label material—whether paper, vinyl, or fabric—greatly affects the cost. High-quality materials that are durable and wash-resistant typically come at a premium. For example, iron-on labels often require specialized coatings to ensure they withstand laundering.

-

Labor: Labor costs vary based on the complexity of the labeling process. Custom designs or unique printing requirements can increase labor costs, especially if specialized skills are needed.

-

Manufacturing Overhead: This includes costs related to factory operation, utilities, and administrative expenses. Efficient manufacturing processes can help minimize overhead costs, ultimately benefiting the buyer.

-

Tooling: This refers to the setup costs for printing and cutting the labels. Custom designs often require unique tooling, which can lead to higher initial costs but may be justified by the benefits of tailored solutions.

-

Quality Control (QC): Ensuring that labels meet quality standards incurs additional costs. Buyers should prioritize suppliers who implement rigorous QC measures to avoid issues that can arise from defective labels.

-

Logistics: Shipping costs can vary significantly based on the supplier’s location, the chosen shipping method, and any import/export duties. International buyers must account for these logistics costs in their total budget.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. Understanding the supplier’s pricing structure can aid in negotiating better terms.

How Do Price Influencers Affect Barcode Label Costs?

Several factors can influence the pricing of barcode clothing labels, which buyers should consider when sourcing:

-

Volume/MOQ: Suppliers often provide discounts for bulk orders. Understanding the minimum order quantities (MOQs) and leveraging larger orders can lead to substantial savings.

-

Specifications/Customization: Custom labels with specific designs, colors, or additional features will typically incur higher costs. Buyers should assess whether customization is necessary for their application to manage costs effectively.

-

Materials and Quality Certifications: Labels that require certifications for specific applications (e.g., FDA compliance for health-related products) may be priced higher. Buyers should weigh the need for certifications against their budget.

-

Supplier Factors: The reputation and reliability of a supplier can impact pricing. Established suppliers may charge more due to their proven quality and service, but they also provide assurance against potential supply chain disruptions.

-

Incoterms: Understanding the terms of shipping (such as FOB, CIF, etc.) can significantly affect costs. Buyers should clarify these terms to avoid unexpected expenses.

What Are Effective Buyer Tips for Cost-Efficiency?

To optimize costs when sourcing barcode clothing labels, international B2B buyers should consider the following strategies:

-

Negotiate Terms: Engage suppliers in discussions about pricing, especially for larger orders. Building a good relationship can lead to favorable terms and discounts.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the sticker price. Consider logistics, potential defects, and the lifespan of the labels in your TCO analysis. A cheaper label may lead to higher costs down the line if it fails to perform.

-

Understand Pricing Nuances for International Procurement: Buyers from regions such as Africa, South America, the Middle East, and Europe must be aware of local market conditions, currency fluctuations, and import duties that can affect the final price.

-

Request Samples: Before committing to a large order, request samples to evaluate the quality and durability of the labels. This can help avoid costly mistakes and ensure the product meets specifications.

-

Leverage Technology: Utilize software solutions that allow for efficient data management and label printing. This can reduce labor costs and improve accuracy in orders.

In conclusion, understanding the comprehensive cost structure, price influencers, and effective negotiation strategies can empower international B2B buyers to make informed decisions when sourcing barcode clothing labels. Always keep in mind that prices may vary, and it is advisable to obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing barcode clothing labels With Other Solutions

Exploring Alternatives to Barcode Clothing Labels: A Comprehensive Comparison

In the realm of inventory management and tracking, barcode clothing labels are a popular solution for businesses seeking efficiency and accuracy. However, several alternative technologies and methods can also achieve similar objectives. This analysis delves into these alternatives, comparing them against barcode clothing labels to help B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Barcode Clothing Labels | RFID Tags | QR Code Labels |

|---|---|---|---|

| Performance | High accuracy in scanning; requires line-of-sight | Very high accuracy; can scan multiple tags simultaneously | Good accuracy; requires a smartphone or scanner |

| Cost | Moderate (depends on volume) | Higher initial investment for tags and readers | Generally low cost; free apps available for scanning |

| Ease of Implementation | Easy to implement with existing systems | More complex; requires infrastructure for readers | Simple; can be printed in-house with minimal setup |

| Maintenance | Low; labels may wear over time | Moderate; tags are durable but require compatible readers | Low; QR codes can be reprinted easily |

| Best Use Case | Ideal for clothing inventory and tracking | Best for high-volume environments needing real-time data | Excellent for marketing and customer engagement |

Understanding RFID Tags as an Alternative to Barcode Clothing Labels

RFID (Radio Frequency Identification) tags offer an advanced solution for tracking clothing items. Unlike barcode labels, RFID does not require a direct line-of-sight for scanning, allowing for rapid inventory checks and tracking of multiple items simultaneously. The primary advantage of RFID is its ability to improve efficiency in high-volume environments, such as warehouses or retail stores. However, RFID systems can be costly to implement due to the need for specialized readers and infrastructure. Additionally, while RFID tags are durable and resistant to environmental conditions, their initial investment may deter smaller businesses.

Evaluating QR Code Labels as a Cost-Effective Tracking Solution

QR code labels present a more budget-friendly alternative for businesses looking to enhance their tracking capabilities. These codes can be easily generated and printed in-house, making them accessible for small to medium-sized enterprises. QR codes can be scanned using common smartphones, which eliminates the need for specialized equipment. However, their effectiveness may vary depending on the scanning device and lighting conditions. While QR codes are excellent for marketing and enhancing customer interaction—such as linking to product information or promotions—they may not offer the same level of durability and reliability as traditional barcode labels in a laundry or inventory context.

Conclusion: How to Choose the Right Solution for Your Business Needs

When deciding between barcode clothing labels and their alternatives, B2B buyers should carefully consider their specific operational requirements, budget constraints, and the intended use case. Barcode labels remain a reliable choice for straightforward inventory management, particularly in textiles. On the other hand, RFID tags may be more suitable for businesses needing real-time tracking capabilities and higher efficiency, albeit at a higher cost. For those looking for a cost-effective and versatile solution, QR codes offer a unique approach, especially in marketing applications. Ultimately, the right choice will align with your company’s operational goals, scale, and budget, ensuring that you achieve optimal efficiency in your inventory management processes.

Illustrative image related to barcode clothing labels

Essential Technical Properties and Trade Terminology for barcode clothing labels

When sourcing barcode clothing labels, understanding the essential technical properties and industry terminology is critical for making informed purchasing decisions. Here are key specifications and terms that every B2B buyer should be familiar with.

What Are the Key Technical Specifications for Barcode Clothing Labels?

-

Material Grade

The material used for barcode labels can vary significantly, affecting durability and usability. Common materials include polyester, nylon, and cotton blends. For clothing labels, choosing a high-quality, durable material is essential to ensure that the labels withstand laundering, abrasion, and environmental conditions. A suitable material grade prevents fading and ensures barcode legibility over time. -

Adhesive Type

The adhesive used in barcode labels determines how well they stick to the fabric. Labels may feature heat-sensitive adhesives for iron-on applications or strong permanent adhesives for sew-on options. Understanding the adhesive type is crucial for ensuring that the label remains intact through multiple washes, which is vital for tracking inventory in the textile industry. -

Barcode Format

Different barcode formats (e.g., UPC, QR code, Code 128) serve various purposes. Buyers must specify the required format based on their inventory management system or retail needs. The choice of barcode format influences scanning efficiency and compatibility with existing systems, making it a key consideration in the purchasing process. -

Print Quality and Resolution

The print quality, measured in DPI (dots per inch), affects the clarity and readability of the barcode. A higher DPI ensures that the barcode is crisp and easily scannable, which is particularly important in high-volume retail environments. Buyers should always inquire about the print quality to avoid issues with scanning during inventory management. -

Tolerance and Size Specifications

Tolerance refers to the allowable variation in dimensions, which is critical for ensuring that labels fit correctly onto clothing items. Each label should conform to specific size requirements based on the garment type and application method. Understanding size specifications helps buyers select the right labels that meet their operational needs without causing delays in production. -

Laundering Resistance

For labels that will be subjected to washing, it is essential to verify their resistance to laundering. This includes the ability to withstand high temperatures, detergents, and repeated cycles. Labels designed for this purpose typically feature a heat seal film that bonds securely to the fabric, ensuring longevity and functionality.

What Common Trade Terms Should B2B Buyers Understand?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of barcode labels, an OEM may provide labels that are customized for specific brands or clothing lines, ensuring brand consistency and compliance with industry standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest order quantity that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory costs effectively. Larger orders may lead to cost savings, but buyers must balance this against their actual needs and storage capabilities. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and other details for specific products. This is a vital step in the procurement process, allowing buyers to compare costs and terms from multiple suppliers before making a decision. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers operating across borders, as it clarifies the costs and risks involved in transportation. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is critical for supply chain management and ensuring that products arrive on schedule, especially in industries where timing is crucial. -

Batch Numbering

Batch numbering is a system used to track the production of a group of items. In the context of barcode labels, batch numbers can enhance traceability and quality control, allowing businesses to efficiently manage recalls or quality issues if they arise.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing barcode clothing labels, ensuring that they select products that meet their operational needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the barcode clothing labels Sector

What Are the Key Trends Shaping the Global Market for Barcode Clothing Labels?

The barcode clothing labels sector is experiencing significant transformations driven by technological advancements and evolving consumer expectations. One of the primary global drivers is the increasing demand for efficiency in inventory management and supply chain logistics. Businesses are adopting advanced barcode technologies, such as QR codes and RFID, to enhance tracking capabilities and streamline operations. This trend is particularly pertinent for international B2B buyers in Africa, South America, the Middle East, and Europe, where logistics efficiency can significantly impact operational costs.

Emerging technologies like cloud-based data management systems and automated printing solutions are also reshaping sourcing practices. These innovations enable businesses to print labels on-demand, reducing waste and inventory costs. Moreover, as e-commerce continues to flourish, the need for accurate product identification and tracking has never been more critical. This shift is prompting buyers to seek suppliers who can provide customizable solutions that integrate seamlessly with their existing systems.

Additionally, the globalization of supply chains necessitates a robust understanding of local regulations regarding labeling and compliance. For B2B buyers, this means sourcing from manufacturers who not only meet international standards but also possess a deep understanding of regional requirements, particularly in diverse markets like Germany and Brazil.

How Can Sustainability and Ethical Sourcing Impact Your B2B Decisions in Barcode Clothing Labels?

Sustainability is becoming a cornerstone of business operations, especially within the textile and labeling industries. As global awareness of environmental issues grows, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainability. In the barcode clothing labels sector, this translates into the use of eco-friendly materials and production processes that minimize environmental impact.

The importance of ethical supply chains cannot be overstated. Buyers are not only looking for products that meet their operational needs but also for those that align with their corporate social responsibility (CSR) goals. This shift is leading suppliers to adopt ‘green’ certifications and utilize sustainable materials, such as recycled paper or biodegradable plastics for labels. By sourcing from manufacturers who prioritize sustainability, businesses can enhance their brand reputation and appeal to environmentally conscious consumers.

In addition, regulatory pressures in various regions are driving the need for transparency in supply chains. Companies that can demonstrate their commitment to ethical sourcing and environmental stewardship are likely to gain a competitive edge. For international buyers, this means thoroughly vetting suppliers and considering their sustainability practices as part of the procurement process.

How Has the Barcode Clothing Labels Industry Evolved Over Time?

The evolution of the barcode clothing labels industry reflects broader technological advancements and shifts in consumer behavior. Initially, barcode labels were primarily used for basic inventory tracking. However, as the retail landscape evolved, so did the technology. The introduction of thermal transfer printing and more durable label materials allowed for better performance in various environments, including high-temperature and moisture-rich settings.

In recent years, the integration of digital technologies has further transformed the sector. The rise of e-commerce and online retail has necessitated more sophisticated tracking solutions, leading to the adoption of dynamic labeling systems. Today, businesses can easily customize labels based on real-time data, allowing for more agile inventory management.

Furthermore, the focus on sustainability has prompted many manufacturers to innovate their processes, producing labels that are not only functional but also environmentally responsible. As the industry continues to adapt to changing market dynamics, B2B buyers must stay informed about these developments to make strategic sourcing decisions that align with their business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of barcode clothing labels

-

How do I select the right type of barcode clothing labels for my business?

Selecting the right type of barcode clothing labels involves assessing your specific needs. Consider factors such as the type of fabric, the environment in which the label will be used, and the application method. For instance, if your garments will undergo frequent washing, opt for durable iron-on or sew-on labels that resist fading and abrasion. Additionally, evaluate the size and design of the label to ensure it fits well with your clothing line. Engaging with suppliers who offer samples can also aid in making an informed decision. -

What are the advantages of using iron-on versus sew-on barcode labels?

Iron-on labels are quick to apply and can be affixed without sewing equipment, making them ideal for businesses that require a fast turnaround. They bond securely to fabric using heat, ensuring durability through multiple washes. On the other hand, sew-on labels provide a more permanent solution, suitable for high-end garments where aesthetics are critical. They can be custom-designed to include care instructions or branding, offering versatility. Ultimately, the choice depends on your operational capabilities and the specific requirements of your clothing line. -

What minimum order quantities (MOQs) should I expect when sourcing barcode clothing labels?

MOQs for barcode clothing labels can vary significantly by supplier and the type of label ordered. Generally, you may find MOQs ranging from 100 to 1,000 labels, depending on customization and printing requirements. It is advisable to discuss your needs with potential suppliers to find flexibility in their MOQ policies, especially for smaller businesses or start-ups. Some suppliers may also offer bulk pricing for larger orders, which can help reduce costs as your business grows. -

How can I ensure the quality and readability of barcode labels?

To ensure the quality and readability of barcode labels, partner with reputable suppliers who conduct thorough quality assurance checks during the printing process. Request samples to verify that the barcodes scan correctly with your equipment. Additionally, inquire about the materials used in the labels, as high-quality thermal transfer printing and durable materials will enhance longevity and performance. Regularly test the labels in your operational environment to confirm they meet your specific scanning needs. -

What payment terms should I expect when purchasing barcode labels internationally?

Payment terms can vary among suppliers, but common practices include upfront payments, deposits, or net payment terms (e.g., net 30 days). For international transactions, be aware of factors such as currency conversion fees and potential tariffs. Establishing a clear agreement regarding payment terms is crucial, especially when dealing with large orders or custom products. Utilizing secure payment methods like letters of credit or PayPal can also provide added security for international transactions. -

What factors should I consider when vetting suppliers for barcode clothing labels?

When vetting suppliers, assess their industry experience, customer reviews, and production capabilities. Check for certifications that indicate adherence to quality standards, especially if you require compliance with specific regulations in your region. Request references from other clients and evaluate their responsiveness and customer service. Additionally, consider their ability to customize labels to suit your branding needs, as well as their lead times and logistics capabilities for international shipping. -

What logistics considerations should I keep in mind when ordering barcode labels?

Logistics is a critical aspect of ordering barcode labels, particularly for international shipping. Factor in shipping costs, delivery timelines, and customs clearance procedures. Collaborate with suppliers who have experience in international logistics to ensure smooth transportation of your labels. It’s also wise to discuss packaging options that protect your labels during transit. Establishing a reliable communication channel with your supplier can help address any shipping issues that may arise. -

Can I customize barcode labels with my branding and specific data?

Yes, most suppliers offer customization options for barcode labels, allowing you to include your branding elements such as logos, colors, and fonts. You can also specify the data that will be encoded in the barcode, such as product numbers or inventory information. Discuss your customization needs with the supplier to understand their capabilities and any associated costs. Providing high-quality artwork files and clear specifications can help ensure that the final product meets your expectations.

Top 6 Barcode Clothing Labels Manufacturers & Suppliers List

1. WePrintBarcodes – Iron-On & Sew-On Barcode Labels

Domain: weprintbarcodes.com

Registered: 2006 (19 years)

Introduction: WePrintBarcodes offers Iron-On and Sew-On Barcode Labels designed for textile products. The Sew-On Barcode Tags are available in sizes of 2″ x 1.375″ and are priced as follows: 250 Tags for $145.79, 500 Tags for $269.10, and 1000 Tags for $448.32. The Iron-On Barcode Labels come in two sizes: 1.5″ x 1″ priced at 250 Tags for $157.03, 500 Tags for $280.34, and 1000 Tags for $459.78; and 2″ x 1″ pri…

2. Unitherm Inc. – Iron On Barcode Labels

Domain: unitherminc.com

Registered: 2001 (24 years)

Introduction: Iron On Barcode Labels from Unitherm Inc. are designed for tracking clothing and fabric items. They are available as preprinted labels or blank labels for self-printing. Multiple sizes are in stock, with custom sizes available upon request. The labels are launderable and are applied using the U35 Label Press, bonding permanently to clothing through a Heat Seal Film process. They are printed with w…

3. MyAssetTag – Barcode Labels

Domain: myassettag.com

Registered: 2004 (21 years)

Introduction: Print Barcode Labels For Free – Printable Barcode Labels Review 4.8 stars from 9,630 reviews. The #1 Choice for Asset Tags. Free Shipping for US orders of $15.00 and more. Custom options include: Barcode Labels, 2D Code Labels, QR Code Labels, Multi-Part Labels. Asset Tags by Material: Metal, AlumiGuard, SolarGuard, PlioGuard, Sunguard, FoilGuard, Plastic, PermaGuard, EconoGuard, Tamper Proof. Siz…

4. Zebra – Barcode Labels and Printing Supplies

Domain: zebra.com

Introduction: Zebra offers a variety of barcode labels and tags designed for different industries including retail, healthcare, manufacturing, transportation and logistics, government, hospitality, and banking. Their printing supplies include labels and tags, receipt paper, ribbons, hospital bracelets, patient ID wristbands, RFID labels, cards, and more. Zebra’s products are known for high performance, print qu…

5. Barcodes Inc – Barcode and Label Solutions

Domain: barcodesinc.com

Registered: 1996 (29 years)

Introduction: UPC, Barcode and Label Generator Tools; Barcode Labels: Blank, Color, Fanfold, Shipping, Preprinted, Warning, Caution, Packing, Circle, Country of Origin, Mailing, ORM, Specialty, Metal, Tamper Evident, Custom, Warehouse, Asset, Inventory; Supplies: Thermal Printheads, Thermal Transfer Ribbons, Copier Printer Paper, Inkjet Cartridges, Toner; Mobile Computers: Handheld, Gun-Grip, Wearable, Tablet, …

6. Immago – Clothing Label & Data Solutions

Domain: immago.com

Registered: 2001 (24 years)

Introduction: {“Clothing Label Solutions”: “Cost effective and customised clothing label solutions including woven labels, swing tags, badges, patches, and other branded apparel trims.”, “Barcode & Variable Data Solutions”: “Secure data management systems to protect retail data accuracy and reduce costs of delivering information to product labels and tags.”, “RFID Anti-Theft & Product Tracking Solutions”: “Inte…

Strategic Sourcing Conclusion and Outlook for barcode clothing labels

In the evolving landscape of barcode clothing labels, strategic sourcing emerges as a vital component for international B2B buyers. By prioritizing quality, customization, and scalability, businesses can optimize their operations and enhance inventory management. The ability to select labels that withstand various environmental conditions, such as laundering and abrasion, ensures long-term reliability and performance. Furthermore, considering factors such as label type—iron-on versus sew-on—can significantly impact the efficiency of your supply chain.

Illustrative image related to barcode clothing labels

For companies in Africa, South America, the Middle East, and Europe, establishing strong partnerships with reputable suppliers can lead to cost-effective solutions that meet regional demands. As technology advances, the integration of barcode scanning systems and data management tools will further streamline processes, making it essential for businesses to remain agile and informed.

Looking ahead, investing in innovative barcode labeling solutions will not only bolster operational efficiency but also enhance customer satisfaction through improved tracking and inventory accuracy. Now is the time for B2B buyers to engage with suppliers, explore the latest offerings, and position their businesses for success in a competitive market. Embrace strategic sourcing today to unlock the full potential of your barcode labeling initiatives.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.