Choosing Your Car Plastic Trim: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for car plastic trim

In the competitive landscape of the automotive industry, sourcing high-quality car plastic trim can pose significant challenges for international B2B buyers. Factors such as varying quality standards, supplier reliability, and regional compliance regulations can complicate the procurement process. This guide on car plastic trim not only addresses these hurdles but also offers comprehensive insights into the types of plastic trims available, their diverse applications, and effective strategies for vetting suppliers.

From understanding the latest advancements in plastic materials to evaluating cost implications, this resource is designed to equip buyers from Africa, South America, the Middle East, and Europe—such as Vietnam and Brazil—with the essential knowledge to make informed purchasing decisions. By delving into the nuances of plastic trim restoration and protection products, we aim to enhance the aesthetic appeal and longevity of vehicles, ultimately contributing to customer satisfaction and brand loyalty.

Whether you are looking to restore faded trims or seeking durable solutions that withstand harsh environmental conditions, this guide empowers you with actionable strategies and best practices. Let’s embark on this journey to navigate the global market for car plastic trim with confidence and clarity.

Understanding car plastic trim Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| ABS Plastic Trim | High impact resistance, lightweight, and easy to mold | Automotive interiors, exteriors, and accessories | Pros: Cost-effective, durable. Cons: Can be prone to UV degradation. |

| Polypropylene Trim | Excellent chemical resistance and flexibility | Underbody components, bumpers, and trims | Pros: Lightweight, resistant to moisture. Cons: May not provide a premium look. |

| PVC Trim | Versatile, can be rigid or flexible, good weather resistance | Decorative trims, moldings, and seals | Pros: Cost-effective, easy to install. Cons: Limited durability in extreme conditions. |

| TPO Trim | Thermoplastic Olefin, good UV resistance, and recyclability | Exterior applications like bumpers and grilles | Pros: Environmentally friendly, excellent durability. Cons: Higher initial cost. |

| Polycarbonate Trim | High impact strength, transparency, and heat resistance | Lighting covers, windows, and structural components | Pros: Strong and durable. Cons: More expensive than other plastics. |

What are the characteristics of ABS Plastic Trim, and when should it be used?

ABS (Acrylonitrile Butadiene Styrene) plastic trim is known for its high impact resistance and lightweight properties. It is easily molded, making it a popular choice for both interior and exterior automotive applications. B2B buyers should consider ABS for components that require durability without adding significant weight, such as dashboards and exterior moldings. However, it’s important to note that while ABS is cost-effective, it may degrade over time when exposed to UV rays unless treated with protective coatings.

How does Polypropylene Trim differ from other types?

Polypropylene trim is recognized for its excellent chemical resistance and flexibility. It is commonly used in underbody components and bumpers, where exposure to harsh environments is expected. This type of trim is particularly suitable for buyers looking for lightweight materials that can withstand moisture and chemicals. However, it may not deliver the premium aesthetic that some applications require, which could be a consideration for brands focusing on luxury markets.

What makes PVC Trim a versatile option for automotive applications?

PVC (Polyvinyl Chloride) trim is highly versatile, available in both rigid and flexible forms. It is often used for decorative trims, moldings, and seals due to its affordability and ease of installation. B2B buyers should consider PVC for applications where cost-effectiveness is a priority. While PVC is user-friendly and widely available, its durability may be limited in extreme environmental conditions, which could necessitate more frequent replacements.

Why is TPO Trim becoming a popular choice in the automotive industry?

TPO (Thermoplastic Olefin) trim is gaining popularity due to its excellent UV resistance and recyclability. It is typically used in exterior applications like bumpers and grilles, where durability is crucial. B2B buyers looking for environmentally friendly options may find TPO appealing, as it combines performance with sustainability. However, the initial cost of TPO can be higher than other materials, which may impact budget-conscious buyers.

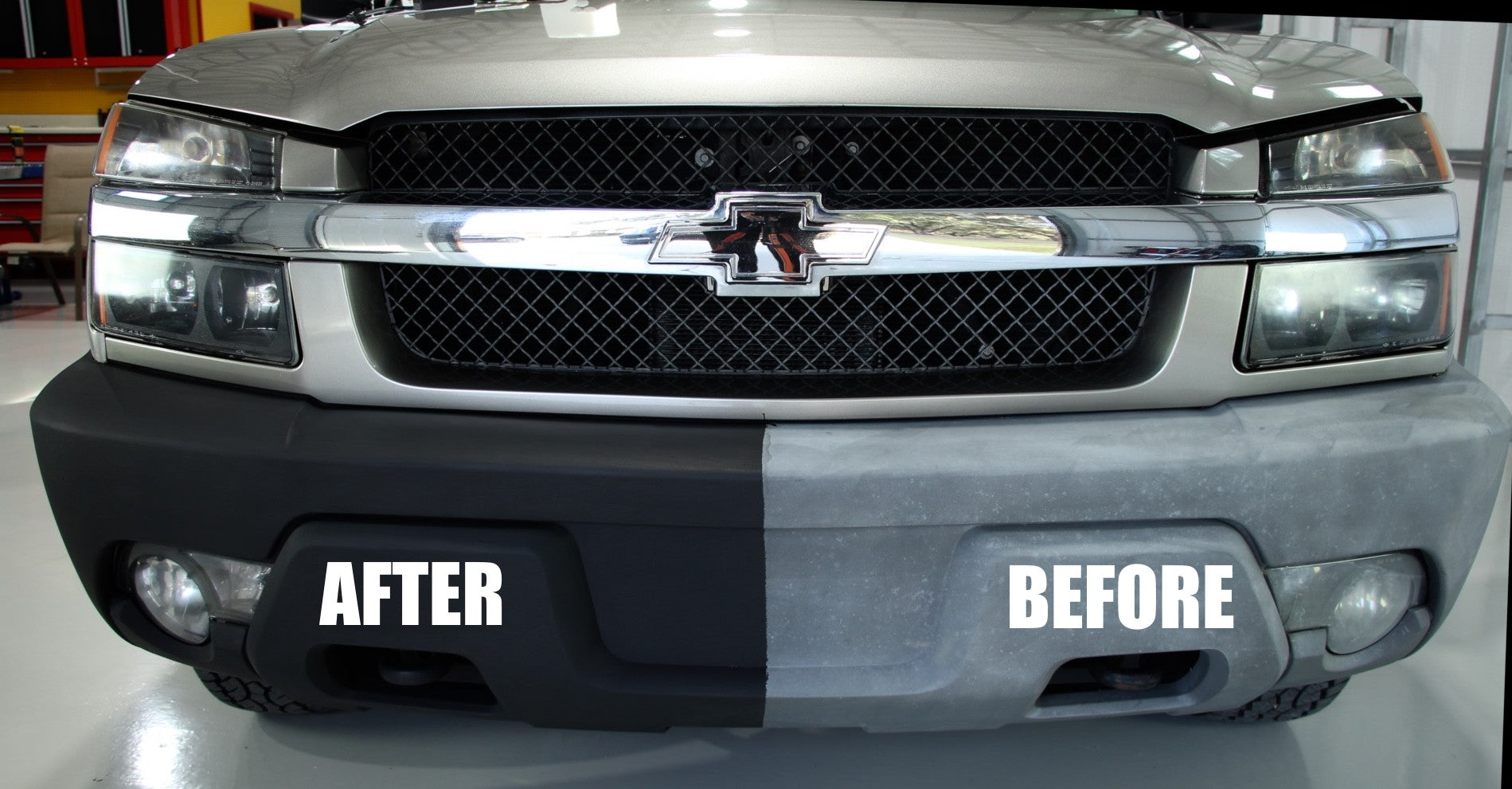

Illustrative image related to car plastic trim

When should Polycarbonate Trim be considered for automotive parts?

Polycarbonate trim is known for its high impact strength and heat resistance, making it ideal for applications requiring transparency, such as lighting covers and windows. This material is suitable for buyers who prioritize durability and safety in automotive components. While polycarbonate offers significant advantages in strength and clarity, it comes with a higher price tag, which may be a deterrent for some businesses focused on cost reduction.

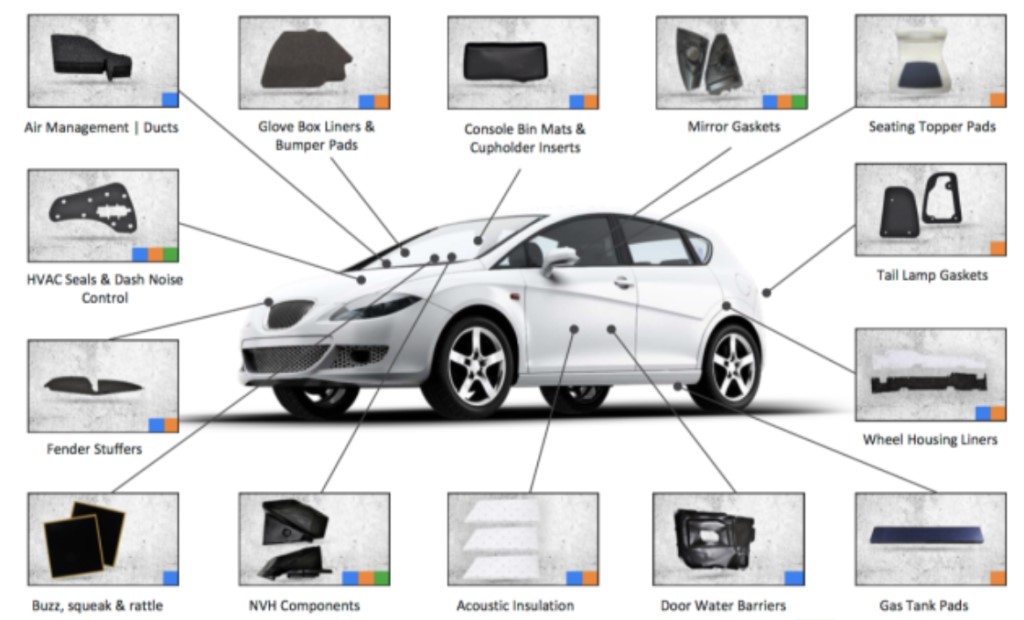

Key Industrial Applications of car plastic trim

| Industry/Sector | Specific Application of car plastic trim | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Interior and exterior trim components | Enhanced aesthetics and functionality of vehicles | Quality, durability, and compliance with industry standards |

| Automotive Aftermarket | Restoration and detailing products | Improved vehicle resale value and customer satisfaction | Availability of specialized products for different materials |

| Transportation & Logistics | Protective trim for fleet vehicles | Reduced maintenance costs and improved vehicle longevity | Bulk purchasing options and compatibility with various vehicle models |

| Automotive Parts Supply | Custom trim solutions for OEMs and suppliers | Tailored products meeting specific design needs | Customization capabilities and lead times for production |

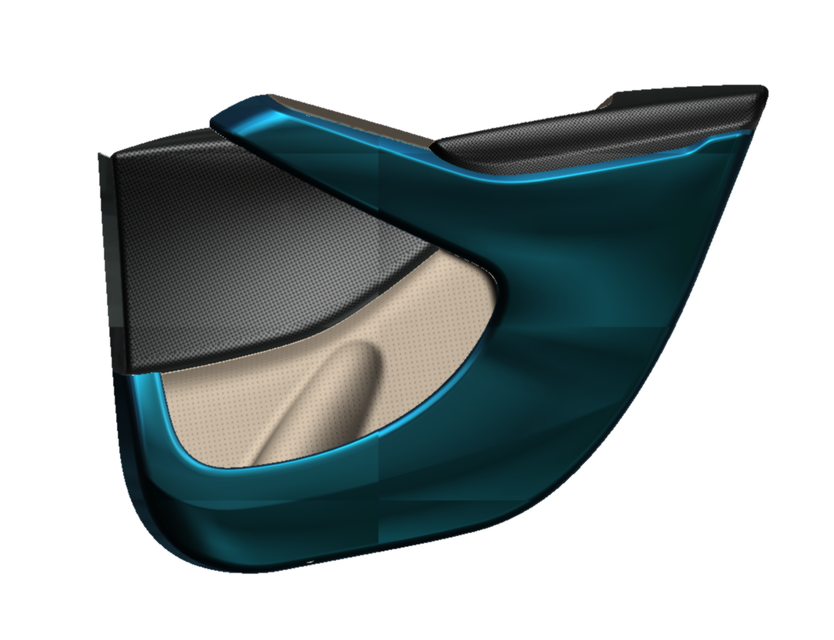

| Vehicle Customization | Trim for aftermarket modifications and upgrades | Increased market appeal and personalization options | Availability of diverse styles and finishes for customization |

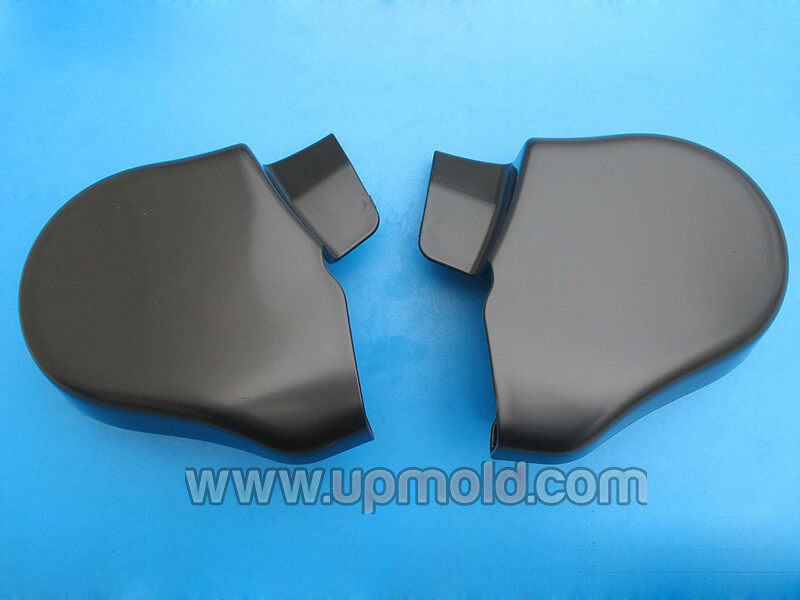

How is Car Plastic Trim Used in Automotive Manufacturing?

In the automotive manufacturing sector, car plastic trim is crucial for both interior and exterior components. It enhances the aesthetic appeal of vehicles while providing functional benefits such as sound insulation and protection from environmental damage. Manufacturers must ensure that the trim meets stringent quality and durability standards, especially in regions with extreme weather conditions. International buyers should prioritize suppliers who can provide materials that comply with local regulations and are resistant to UV degradation and wear.

What Role Does Car Plastic Trim Play in the Automotive Aftermarket?

The automotive aftermarket relies heavily on car plastic trim for restoration and detailing products. These trims are essential for maintaining the vehicle’s appearance and functionality, directly impacting resale value and customer satisfaction. Buyers in this sector should consider sourcing high-quality restoration products that effectively address fading, cracking, and other damage caused by environmental factors. Availability of specialized products tailored for different materials and finishes is a key consideration for international buyers looking to meet diverse consumer needs.

How is Car Plastic Trim Utilized in Transportation & Logistics?

In the transportation and logistics industry, car plastic trim serves as protective components for fleet vehicles. This application helps reduce maintenance costs by safeguarding against wear and tear from daily operations. Businesses in this sector should focus on sourcing durable and resilient trims that can withstand the rigors of transportation. Additionally, bulk purchasing options can provide cost savings and ensure consistency across fleet vehicles, making it an essential consideration for international buyers managing large fleets.

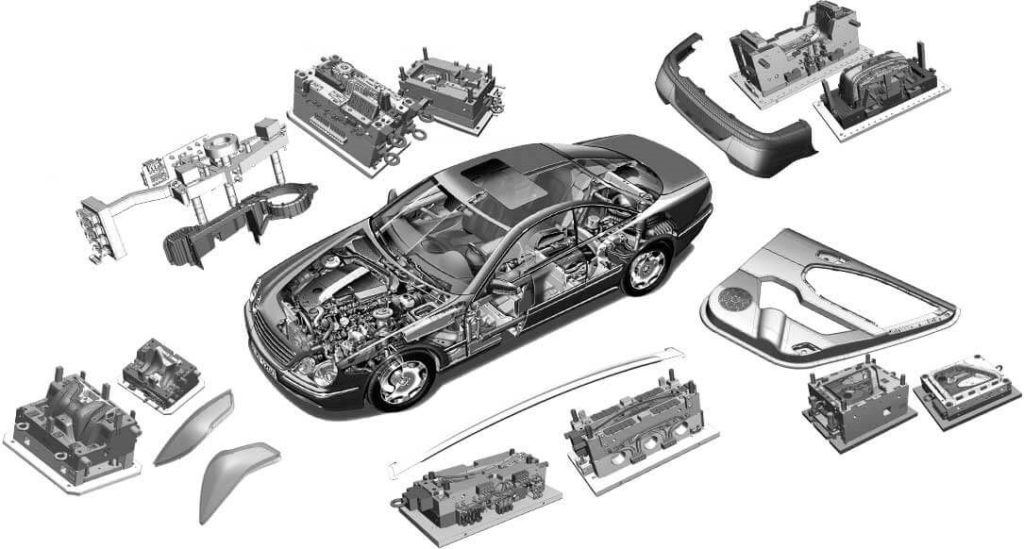

What Custom Solutions Can Car Plastic Trim Provide to Automotive Parts Suppliers?

Automotive parts suppliers often require custom trim solutions to meet the specific design and functionality needs of OEMs. Car plastic trim can be tailored to fit various vehicle models and design specifications, offering suppliers a competitive edge in the market. Key factors for sourcing include the supplier’s ability to provide customization options and the lead times for production. International buyers should seek partners who can deliver high-quality, bespoke trims that align with their design requirements.

Illustrative image related to car plastic trim

How Does Car Plastic Trim Enhance Vehicle Customization Opportunities?

In the vehicle customization market, car plastic trim is vital for aftermarket modifications and upgrades. It allows consumers to personalize their vehicles, enhancing market appeal and driving sales. Buyers in this sector should look for suppliers offering a diverse range of styles, finishes, and materials to cater to various consumer preferences. Ensuring that the trim components are compatible with existing vehicle designs is crucial for maintaining quality and performance in customized vehicles.

3 Common User Pain Points for ‘car plastic trim’ & Their Solutions

Scenario 1: Maintaining a Professional Appearance Amidst Environmental Challenges

The Problem: B2B buyers in the automotive sector often face the challenge of maintaining the aesthetic appeal of car plastic trim, especially in regions with harsh environmental conditions, such as high UV exposure in Africa or humidity in South America. Faded, cracked, or weather-beaten trim not only detracts from the vehicle’s overall appearance but can also diminish resale value. Buyers are concerned that neglecting these components can lead to increased repair costs and customer dissatisfaction.

The Solution: To effectively combat the effects of environmental stressors, it’s crucial to invest in high-quality trim restoration products specifically designed to withstand local conditions. Sourcing products that offer UV protection and weather resistance is key. Look for suppliers that provide detailed specifications, such as the chemical composition and durability ratings of their trim products. Implement a regular maintenance schedule that includes applying protective coatings every few months, ensuring the trim remains vibrant and intact. Additionally, consider training your staff on proper cleaning techniques that prevent damage during routine maintenance.

Illustrative image related to car plastic trim

Scenario 2: Balancing Cost-Effectiveness with Quality in Bulk Purchasing

The Problem: For international B2B buyers, particularly those in emerging markets, balancing cost with quality when sourcing car plastic trim can be a daunting task. Buyers often find themselves inundated with options that vary widely in price and quality, making it difficult to determine which products will provide the best value in the long run. Poor quality trims can lead to frequent replacements, impacting profitability and operational efficiency.

The Solution: To navigate this issue, buyers should adopt a strategic sourcing approach that includes thorough market research and supplier vetting. Start by establishing a clear set of criteria that defines quality for your specific needs, such as durability, resistance to fading, and warranty terms. Engage in pilot testing with a small order of various products to assess their performance over time before committing to bulk purchases. Additionally, build relationships with manufacturers who can provide insights on their production processes and product longevity. This proactive approach not only helps in selecting the right products but also fosters a sense of partnership that can lead to better pricing and service agreements.

Scenario 3: Overcoming Installation and Compatibility Issues

The Problem: A common pain point for B2B buyers is the difficulty in ensuring that the plastic trim products they purchase are compatible with existing vehicle models. Inconsistent sizing and installation challenges can result in additional labor costs and project delays, which are particularly frustrating for automotive workshops that thrive on efficiency and quick turnaround times.

The Solution: To mitigate compatibility issues, buyers should prioritize sourcing from manufacturers that offer comprehensive product specifications, including detailed measurements and compatibility lists for various vehicle makes and models. Utilizing a standardized installation guide or template can also streamline the installation process and reduce errors. Furthermore, consider investing in training sessions for your installation team on best practices for fitting and securing plastic trim. Establishing a feedback loop with your team can help identify recurring issues, allowing you to adjust your sourcing strategy accordingly. By taking these steps, you can enhance operational efficiency and ensure customer satisfaction through high-quality installations.

Illustrative image related to car plastic trim

Strategic Material Selection Guide for car plastic trim

What Are the Key Materials Used for Car Plastic Trim?

When selecting materials for car plastic trim, several options are commonly utilized, each with distinct properties, advantages, and limitations. Understanding these materials is crucial for international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, where compliance and local preferences can significantly influence purchasing decisions.

Which Polypropylene (PP) Properties Make It Ideal for Car Trim?

Polypropylene (PP) is a widely used thermoplastic polymer known for its excellent chemical resistance and durability. It can withstand temperatures ranging from -30°C to 100°C, making it suitable for various climates. The material is lightweight, which helps in reducing overall vehicle weight and improving fuel efficiency.

Pros: Polypropylene offers high impact resistance and is relatively inexpensive, making it a cost-effective choice for manufacturers. Its recyclability also aligns with growing sustainability trends.

Cons: However, PP can be less resistant to UV light, leading to color fading and brittleness over time. This necessitates additional treatments or coatings to enhance its longevity.

Illustrative image related to car plastic trim

Impact on Application: PP is compatible with various automotive cleaning agents, which is essential for maintenance. Buyers should consider UV protection treatments to extend the material’s life.

Considerations for International Buyers: Compliance with ASTM standards is crucial, especially regarding environmental regulations. Buyers should also be aware of local preferences for color and finish.

How Does Acrylonitrile Butadiene Styrene (ABS) Compare?

Acrylonitrile Butadiene Styrene (ABS) is another popular choice for car plastic trim due to its excellent toughness and impact resistance. It performs well in temperatures ranging from -20°C to 80°C, making it suitable for a variety of environments.

Illustrative image related to car plastic trim

Pros: ABS is known for its ability to be easily molded, allowing for intricate designs and finishes. It also offers good resistance to chemicals and is less prone to fading compared to PP.

Cons: The primary drawback of ABS is its higher cost compared to PP. Additionally, it can be more susceptible to scratches and may require protective coatings.

Impact on Application: ABS is compatible with most automotive cleaning products, but care should be taken with abrasive materials that could scratch the surface.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding VOC emissions, particularly in regions with stringent environmental laws.

What Advantages Does Polyvinyl Chloride (PVC) Offer for Car Trim?

Polyvinyl Chloride (PVC) is a versatile plastic that is often used in automotive applications due to its durability and resistance to environmental factors. It can withstand temperatures between -10°C and 60°C, making it suitable for various climates.

Pros: PVC is highly resistant to moisture, chemicals, and UV light, making it an excellent choice for outdoor applications. It is also relatively inexpensive and can be produced in a variety of colors and finishes.

Cons: However, PVC can be less flexible compared to other materials, which may limit its use in certain applications. Additionally, concerns about the environmental impact of PVC production and disposal are growing.

Impact on Application: PVC is compatible with many automotive cleaning agents but may require specific formulations to avoid degradation.

Illustrative image related to car plastic trim

Considerations for International Buyers: Compliance with international standards such as DIN and JIS is essential. Buyers should also consider the growing demand for eco-friendly alternatives.

Why Is Thermoplastic Elastomer (TPE) Gaining Popularity?

Thermoplastic elastomers (TPE) combine the properties of rubber and plastic, offering flexibility and durability. They can handle temperatures from -40°C to 90°C, making them suitable for various automotive applications.

Pros: TPE provides excellent resistance to UV light and weathering, making it ideal for exterior trim. Its flexibility allows for easy molding into complex shapes.

Illustrative image related to car plastic trim

Cons: The primary limitation is the cost, as TPE is generally more expensive than traditional plastics. Additionally, its processing can be more complex, requiring specialized equipment.

Impact on Application: TPE is compatible with a range of automotive cleaning products, but buyers should ensure that the formulations do not contain harsh chemicals that could degrade the material.

Considerations for International Buyers: Buyers should be aware of local preferences for material performance and compliance with relevant standards, particularly in regions with strict automotive regulations.

Summary Table of Material Selection for Car Plastic Trim

| Material | Typical Use Case for car plastic trim | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene (PP) | Interior trim, bumpers | Cost-effective and lightweight | UV sensitivity and potential fading | Low |

| Acrylonitrile Butadiene Styrene (ABS) | Dashboard components, trims | Excellent toughness and design flexibility | Higher cost and scratch susceptibility | Medium |

| Polyvinyl Chloride (PVC) | Weather stripping, exterior trim | Moisture and UV resistance | Limited flexibility and environmental concerns | Low |

| Thermoplastic Elastomer (TPE) | Seals, gaskets, and flexible trims | Flexibility and UV resistance | Higher cost and complex processing | High |

This analysis provides a comprehensive overview of the materials commonly used for car plastic trim, enabling international B2B buyers to make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for car plastic trim

What Are the Main Stages of Manufacturing Car Plastic Trim?

The manufacturing of car plastic trim involves several critical stages, each designed to ensure the final product meets the stringent quality and aesthetic standards of the automotive industry. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in manufacturing car plastic trim is selecting the right materials, typically thermoplastics such as polypropylene (PP), polyvinyl chloride (PVC), or acrylonitrile butadiene styrene (ABS). These materials are chosen for their durability, flexibility, and ability to withstand environmental factors like UV exposure and temperature fluctuations.

Once selected, raw materials undergo preprocessing, which may include drying to remove moisture and granulation into smaller pellets. This ensures uniformity in the molding process, reducing defects in the final product.

Forming: What Techniques Are Used to Shape Plastic Trim?

The next stage is forming, where the prepped materials are shaped into the desired trim components. Common techniques include:

-

Injection Molding: This is the most prevalent method, where heated plastic is injected into a mold under high pressure. This technique allows for complex shapes and high production volumes.

-

Extrusion: Used for continuous profiles, extrusion involves forcing melted plastic through a die to create long sections of trim that can be cut to size.

-

Blow Molding: Often utilized for hollow components, this method involves inflating a heated plastic tube inside a mold, creating lightweight structures.

These techniques must be carefully managed to ensure consistency in thickness and finish, which are crucial for both aesthetics and functionality.

Assembly: How Are Different Components Joined Together?

After forming, the next step is assembly, where different trim pieces are combined. This may involve techniques such as:

-

Adhesive Bonding: Suitable for joining dissimilar materials or complex geometries, high-performance adhesives ensure a strong bond without compromising flexibility.

-

Mechanical Fastening: Clips, screws, or rivets may be used to secure components, providing a robust and easily serviceable solution.

-

Ultrasonic Welding: This technique uses high-frequency sound waves to create heat and fuse materials together, ideal for thermoplastics.

Quality control during assembly is crucial, as any misalignment or improper joining can lead to defects that affect the overall quality of the trim.

Finishing: What Processes Enhance the Aesthetic and Functional Qualities?

Finishing processes add the final touches to car plastic trim, enhancing both appearance and durability. Typical finishing techniques include:

-

Surface Treatment: This may involve sanding, painting, or applying a protective coating. Coatings enhance UV resistance and improve the aesthetic appeal by providing a glossy or matte finish.

-

Texturing: Adding texture can improve grip and reduce glare, important for interior trims.

-

Quality Checks: Final inspections are conducted to ensure that trim pieces meet all specifications regarding color, finish, and dimensions.

How Is Quality Assurance Implemented in Car Plastic Trim Manufacturing?

Quality assurance is vital in the manufacturing process of car plastic trim, ensuring that products meet international standards and customer expectations.

What International Standards Guide Quality Control?

Manufacturers of car plastic trim typically adhere to several international quality standards, such as:

-

ISO 9001: This standard focuses on quality management systems, ensuring a consistent approach to quality across all processes.

-

ISO/TS 16949: Specifically for the automotive industry, this standard outlines the requirements for a quality management system in the design and development, production, installation, and servicing of automotive products.

In addition, specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply depending on the trim’s usage and market.

What Are the Key Quality Control Checkpoints During Production?

Quality control is implemented at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Regular checks during manufacturing monitor parameters such as temperature, pressure, and material flow to identify defects early.

-

Final Quality Control (FQC): The finished products undergo thorough inspections, including visual checks, dimensional measurements, and functional testing, to ensure compliance with specifications.

What Common Testing Methods Are Used to Verify Quality?

Common testing methods employed in the automotive plastic trim sector include:

-

Mechanical Testing: Assessing tensile strength, impact resistance, and flexibility to ensure the trim can withstand everyday use.

-

Environmental Testing: Subjecting products to UV light, humidity, and temperature variations to evaluate durability under different conditions.

-

Adhesion Testing: Ensuring that coatings or finishes adhere properly to the base material, critical for long-term performance.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits of the manufacturing facilities can provide insights into the production processes and quality management systems in place.

-

Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including results from IQC, IPQC, and FQC tests.

-

Utilize Third-Party Inspection Services: Engaging third-party inspectors to evaluate products before shipment can ensure compliance with quality standards and specifications.

What Are the Quality Control Nuances for International Buyers?

B2B buyers must also consider regional differences in quality standards and regulations. For example, while ISO certifications are globally recognized, specific markets may have additional requirements that need to be understood and met.

Furthermore, language barriers and cultural differences can impact communication regarding quality expectations. It is advisable to establish clear guidelines and expectations upfront and maintain open lines of communication throughout the manufacturing process.

By understanding the manufacturing processes and quality assurance measures in place for car plastic trim, B2B buyers can make informed decisions, ensuring they select suppliers that meet their quality and performance standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car plastic trim’

To assist B2B buyers in sourcing high-quality car plastic trim, this guide outlines a systematic approach to ensure informed procurement decisions. By following these steps, buyers can streamline the sourcing process, minimize risks, and enhance the overall quality of their automotive products.

Step 1: Define Your Technical Specifications

Clearly outlining the technical specifications for the plastic trim is essential. This includes material types (e.g., ABS, PVC), dimensions, and performance characteristics (e.g., UV resistance, temperature tolerance). Providing these details to potential suppliers helps ensure they understand your requirements and can deliver products that meet your standards.

- Material Considerations: Ensure the selected plastic is suitable for automotive applications, considering factors like durability and weather resistance.

- Custom Dimensions: Specify any unique size or shape requirements to avoid compatibility issues.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in automotive plastic trim. Utilize online directories, trade shows, and industry forums to compile a list of candidates. This foundational step is crucial to discover suppliers with proven expertise and a solid reputation in the market.

- Industry Networks: Leverage industry connections and networks to gather recommendations for reliable suppliers.

- Geographical Considerations: Consider local suppliers to reduce shipping costs and lead times, especially for international procurement.

Step 3: Evaluate Potential Suppliers

Before making any commitments, vet potential suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Evaluating their experience and product quality is vital to ensure they align with your sourcing needs.

Illustrative image related to car plastic trim

- Quality Certifications: Verify if suppliers hold relevant certifications (e.g., ISO 9001) to demonstrate adherence to quality standards.

- Client Testimonials: Look for feedback from previous clients to gauge the supplier’s reliability and product performance.

Step 4: Request Samples and Perform Testing

Once you have shortlisted suppliers, request samples of their plastic trim products. Testing these samples is crucial to assess their quality, durability, and performance against your specifications.

- Testing Parameters: Evaluate samples for colorfastness, resistance to environmental factors, and overall finish.

- Comparative Analysis: Compare samples from multiple suppliers to identify the best fit for your requirements.

Step 5: Negotiate Terms and Pricing

Engage in discussions with your selected suppliers to negotiate pricing, payment terms, and delivery schedules. Effective negotiation can lead to better pricing and favorable terms, which is essential for maintaining budgetary constraints.

- Bulk Discounts: Inquire about bulk purchase discounts to maximize cost efficiency.

- Payment Flexibility: Consider terms that align with your cash flow management strategies.

Step 6: Finalize Contracts and Agreements

After reaching an agreement, ensure that all terms are documented in a formal contract. This contract should outline specifications, pricing, delivery schedules, and quality assurances to mitigate risks.

- Legal Review: Have legal experts review contracts to ensure compliance and protection of your interests.

- Contingency Plans: Include clauses for dispute resolution and contingencies for supply chain disruptions.

Step 7: Establish Quality Control Measures

After procurement, establish quality control measures to monitor the incoming plastic trim. This step is crucial to maintain product quality and ensure compliance with your specifications.

- Inspection Protocols: Implement a standardized inspection process upon receipt of goods.

- Feedback Loop: Create a system for providing feedback to suppliers based on product performance and any quality issues encountered.

By following these steps, B2B buyers can effectively navigate the sourcing process for car plastic trim, ensuring they obtain high-quality products that meet their specific needs while fostering strong supplier relationships.

Illustrative image related to car plastic trim

Comprehensive Cost and Pricing Analysis for car plastic trim Sourcing

What are the Key Cost Components in Car Plastic Trim Sourcing?

When sourcing car plastic trim, understanding the intricate cost structure is vital for international B2B buyers. The primary cost components include:

-

Materials: The type and quality of plastic used significantly impact costs. High-performance materials, such as ABS or polycarbonate, offer durability but come at a premium. Buyers should evaluate material specifications against their performance needs.

-

Labor: Labor costs vary by region. Countries with lower labor costs, such as Vietnam or Brazil, can offer competitive pricing, but this might come with trade-offs in craftsmanship or consistency. Understanding local labor laws and practices can help in negotiating better terms.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and administrative expenses. Efficient manufacturers in regions with advanced production facilities may provide better pricing due to lower overhead costs.

-

Tooling: Custom tooling is often necessary for specialized trim designs. This is a significant upfront investment, and its cost should be amortized over the expected production volume. Lower tooling costs may be found with suppliers who have flexible manufacturing processes.

-

Quality Control (QC): Investing in quality control processes is essential to ensure product consistency and reliability. Buyers should inquire about a supplier’s QC measures, as inadequate QC can lead to higher costs in the long run due to defects and returns.

-

Logistics: Shipping costs, customs duties, and tariffs can substantially affect total costs. Different Incoterms (International Commercial Terms) dictate responsibilities for shipping and insurance, influencing pricing strategies.

-

Margin: Finally, suppliers will add their profit margin to cover costs and achieve profitability. Buyers should benchmark margins across suppliers to ensure competitiveness.

How Do Price Influencers Affect Car Plastic Trim Costs?

Several factors influence the final pricing of car plastic trim:

-

Volume/MOQ: Higher order volumes typically lead to lower per-unit prices due to economies of scale. Negotiating minimum order quantities (MOQs) can be beneficial for buyers looking to reduce costs.

-

Specifications and Customization: Custom designs or specific material requirements can increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Quality and Certifications: Products meeting international quality standards, such as ISO or TS certifications, may carry a premium. However, they can also reduce the risk of quality issues down the line.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more for their experience and reliability, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding and negotiating Incoterms can significantly affect logistics costs. Buyers should clarify responsibilities to avoid unexpected expenses.

What Tips Can Help B2B Buyers Negotiate Cost-Efficient Deals?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, here are key tips for effective negotiation:

-

Understand Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term costs, including maintenance, warranty, and logistics. A cheaper product may lead to higher TCO if it requires frequent replacements.

-

Leverage Competition: Engage multiple suppliers to create competitive pressure. This can lead to better pricing and terms, especially if suppliers are aware of competing offers.

-

Negotiate for Flexibility: Discuss payment terms, lead times, and delivery schedules. Flexibility can lead to cost savings and improved cash flow management.

-

Research Market Prices: Stay informed about market trends and typical pricing in different regions. This knowledge empowers buyers to negotiate effectively and recognize fair pricing.

-

Focus on Relationship Building: Establishing long-term relationships with suppliers can lead to better deals and priority treatment in terms of quality and service.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on supplier negotiations, market conditions, and specific buyer requirements. Always consult with multiple suppliers to confirm current pricing and terms.

Illustrative image related to car plastic trim

Alternatives Analysis: Comparing car plastic trim With Other Solutions

Introduction to Alternative Solutions for Car Trim

When considering solutions for vehicle trim, it’s essential for B2B buyers to evaluate various options beyond traditional car plastic trim. Different technologies and methods can offer unique advantages, depending on the specific application and environmental conditions. This analysis will provide a detailed comparison of car plastic trim against alternative solutions, helping buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Car Plastic Trim | Vinyl Trim | Metal Trim |

|---|---|---|---|

| Performance | Durable, UV resistant | Flexible, less durable | Highly durable, rust-prone |

| Cost | Moderate | Low to moderate | High |

| Ease of Implementation | Easy to install and replace | Easy to install but requires special adhesives | Complex installation requiring skilled labor |

| Maintenance | Low maintenance, easy to clean | Moderate, requires conditioning | High, needs regular polishing |

| Best Use Case | Everyday vehicles, SUVs | Budget-friendly solutions for economy cars | High-end vehicles, custom builds |

Detailed Breakdown of Alternatives

Vinyl Trim

Vinyl trim is a popular alternative due to its affordability and flexibility. It is often used in budget-friendly vehicles. While it is easier to install and often requires no specialized tools, vinyl is less durable than plastic, especially in harsh weather conditions. Maintenance involves regular conditioning to prevent cracking and fading, which can add to long-term costs. Therefore, vinyl is best suited for vehicles that do not face extreme environmental exposure.

Metal Trim

Metal trim is known for its premium appearance and durability. It can withstand harsh conditions and provides a high-end look that appeals to luxury vehicle manufacturers. However, the installation process is more complex, often requiring skilled labor and specialized tools. Maintenance is also more demanding, as metal trim can rust and requires regular polishing to maintain its aesthetic appeal. This makes metal trim ideal for high-end vehicles or custom builds where appearance is paramount, but it may not be practical for mass-market vehicles.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers, selecting the right trim solution involves weighing the specific requirements of their vehicle types and target market. Car plastic trim offers a balance of durability and ease of maintenance, making it suitable for a wide range of everyday vehicles. In contrast, vinyl trim can serve as a cost-effective solution for budget-conscious models, while metal trim is best reserved for high-end applications where aesthetics and durability are critical. Ultimately, understanding the unique characteristics of each option will enable buyers to make strategic decisions that align with their business objectives and customer expectations.

Essential Technical Properties and Trade Terminology for car plastic trim

What Are the Key Technical Properties of Car Plastic Trim?

When sourcing car plastic trim, understanding its technical specifications is crucial for ensuring quality and performance. Here are some essential properties to consider:

Illustrative image related to car plastic trim

1. Material Grade

The material grade refers to the specific type of plastic used in the trim, which can vary widely. Common materials include polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polyvinyl chloride (PVC). Each material has distinct properties concerning durability, flexibility, and resistance to environmental factors like UV exposure and temperature fluctuations. Choosing the right material grade is vital for the longevity and aesthetic appeal of the trim.

2. Tolerance

Tolerance indicates the acceptable variation in dimensions during the manufacturing process. In the automotive industry, precise tolerances are crucial for ensuring that components fit seamlessly during assembly. For example, a tolerance of ±0.5 mm is common for trim parts, allowing for slight variations while maintaining functionality. Understanding tolerance levels helps buyers ensure compatibility with existing vehicle components, reducing the risk of costly rework or failures.

3. UV Resistance

UV resistance measures the material’s ability to withstand degradation from ultraviolet radiation. Since car trim is often exposed to sunlight, selecting materials with high UV resistance is essential to prevent fading, cracking, or warping over time. This property not only affects the trim’s appearance but also its durability, making it a critical factor for international buyers operating in regions with high sun exposure.

4. Impact Resistance

Impact resistance denotes how well the trim can withstand sudden force or shock without breaking. This property is particularly important in automotive applications, where trim may encounter various physical stresses during use. Materials that offer high impact resistance can enhance the overall safety and longevity of vehicles, making them more appealing to B2B buyers focused on quality.

5. Chemical Resistance

Chemical resistance refers to the material’s ability to withstand exposure to various chemicals, including oils, solvents, and cleaning agents. Trim parts often come into contact with these substances, so selecting materials with high chemical resistance is vital for maintaining appearance and functionality over time. This property is especially relevant for international markets, where different regions may have varied environmental conditions and chemical exposure.

Illustrative image related to car plastic trim

Which Trade Terminology Should B2B Buyers Understand When Sourcing Car Plastic Trim?

Navigating the procurement process involves familiarizing oneself with industry-specific terminology. Here are several key terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to the companies that manufacture components used in the assembly of vehicles. In the context of car plastic trim, sourcing OEM parts ensures compatibility and quality, as these components are designed to meet specific vehicle standards. Buyers should prioritize OEM products for reliability and performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers, as it impacts inventory management and cost-effectiveness. Buyers should negotiate MOQs that align with their production needs to avoid overstock or supply shortages.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. It serves as a critical tool for B2B buyers in comparing offers from different suppliers. A well-structured RFQ can lead to better pricing and terms, ultimately benefiting the buyer’s bottom line.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to manage logistics effectively and understand their obligations during the shipping process.

Illustrative image related to car plastic trim

5. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. In the automotive industry, lead times can significantly impact production schedules. Buyers should communicate clearly with suppliers about expected lead times to ensure timely delivery and avoid production delays.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance their sourcing strategies for car plastic trim. This knowledge not only improves procurement efficiency but also contributes to the overall quality and performance of the vehicles they manufacture or sell.

Navigating Market Dynamics and Sourcing Trends in the car plastic trim Sector

What Are the Key Market Dynamics and Sourcing Trends in the Car Plastic Trim Sector?

The car plastic trim sector is currently experiencing a transformative phase driven by several global dynamics. The automotive industry is increasingly shifting towards lightweight materials to enhance fuel efficiency and reduce emissions. Plastic trims, known for their versatility and lower weight compared to traditional materials, are becoming indispensable in vehicle design. Emerging markets, particularly in Africa, South America, and Southeast Asia, are witnessing a surge in automotive production, driven by rising disposable incomes and urbanization. This trend is creating robust demand for durable and aesthetically pleasing plastic trims.

Additionally, technology plays a pivotal role in sourcing trends. Automation in manufacturing processes and the rise of digital platforms for procurement are reshaping how businesses connect with suppliers. B2B buyers are increasingly leveraging data analytics to make informed sourcing decisions, ensuring they select suppliers that offer not just competitive pricing but also quality assurance and reliable delivery timelines. The growing emphasis on customization means that suppliers must be agile and capable of producing bespoke solutions to meet specific client needs.

Illustrative image related to car plastic trim

How Is Sustainability Influencing Sourcing in the Car Plastic Trim Industry?

Sustainability is becoming a cornerstone of sourcing strategies in the car plastic trim sector. The environmental impact of plastic production and disposal is under scrutiny, prompting many companies to seek ‘green’ alternatives. Ethically sourced materials, such as recycled plastics or bio-based polymers, are gaining traction among B2B buyers who aim to align with global sustainability goals. Certifications like ISO 14001 or materials certified by organizations like the Forest Stewardship Council (FSC) signal a commitment to reducing environmental footprints.

Moreover, the importance of ethical supply chains cannot be overstated. B2B buyers are increasingly prioritizing suppliers who adhere to fair labor practices and sustainable sourcing methods. This shift not only enhances brand reputation but also mitigates risks associated with supply chain disruptions. As consumer awareness around environmental issues rises, automotive manufacturers are recognizing that sustainable practices in sourcing are not merely a trend but a necessity for long-term competitiveness.

What Is the Evolution of Car Plastic Trim in the Automotive Industry?

The evolution of car plastic trim has been significant, moving from purely functional components to essential elements of vehicle design and branding. Initially, plastic trims were used primarily for cost-effectiveness and weight reduction. However, advancements in technology have enabled manufacturers to produce high-quality, durable trims that offer aesthetic appeal and functionality.

In the 1980s and 1990s, the introduction of advanced polymers allowed for greater design flexibility, leading to the incorporation of trims that enhance vehicle aesthetics. Today, innovations such as UV-resistant coatings and advanced finishing techniques have further improved the performance and longevity of plastic trims. As the automotive industry continues to evolve, particularly with the shift towards electric vehicles, the demand for sophisticated and sustainable plastic trims is expected to grow, presenting new opportunities for B2B buyers in this sector.

Frequently Asked Questions (FAQs) for B2B Buyers of car plastic trim

-

How do I solve fading and discoloration on car plastic trim?

To address fading and discoloration on car plastic trim, consider using high-quality trim restoration products specifically designed for automotive plastics. Look for solutions that offer UV protection and conditioning properties to restore the trim’s original color and shine. Regular maintenance, including cleaning and applying a protectant, can prevent further damage from environmental factors. Be sure to follow the manufacturer’s instructions for application to achieve optimal results. -

What is the best product for restoring black plastic trim?

The best products for restoring black plastic trim typically contain specialized formulations that rejuvenate and protect the surface. Look for trim restorers that are silicone-free and utilize natural oils to avoid greasy residues. Products like “Solution Finish” or similar high-performance restorers are well-regarded for their ability to penetrate and restore the original finish, providing long-lasting protection against UV rays and environmental damage. -

What are the key factors to consider when sourcing car plastic trim suppliers?

When sourcing car plastic trim suppliers, evaluate their production capabilities, quality certifications, and experience in the automotive sector. It’s essential to assess their compliance with international standards, especially in markets across Africa, South America, the Middle East, and Europe. Additionally, consider their ability to provide customized solutions, minimum order quantities (MOQ), and reliable logistics support to ensure timely deliveries. -

How can I ensure the quality of car plastic trim products?

To ensure the quality of car plastic trim products, request samples before placing bulk orders. Conduct thorough supplier audits, checking for quality certifications such as ISO or IATF 16949. Establish clear quality assurance (QA) protocols, including inspection processes during production and before shipment. Collaborating with suppliers who have a track record of quality and reliability is crucial for maintaining product standards. -

What are common payment terms in international B2B transactions for car plastic trim?

Common payment terms in international B2B transactions may include options like Letters of Credit (LC), advance payments, or payment upon delivery. Many suppliers may require a deposit (typically 30%) before production, with the balance payable upon shipment or delivery. Discussing payment terms upfront and ensuring mutual agreement can help avoid potential disputes and facilitate smoother transactions. -

What is the typical minimum order quantity (MOQ) for car plastic trim?

Minimum order quantities (MOQ) for car plastic trim can vary significantly depending on the supplier and product type. While some suppliers may offer flexible MOQs as low as 100 units, others may require orders in the thousands to justify production costs. It’s essential to communicate your needs and negotiate MOQs that align with your business strategy and budget. -

How can I customize car plastic trim to meet specific requirements?

Customization of car plastic trim can often be achieved by collaborating closely with your supplier. Discuss your specific requirements regarding color, finish, and dimensions. Many suppliers offer design services and can create molds tailored to your specifications. Providing detailed specifications and samples can facilitate the customization process, ensuring the final product meets your expectations. -

What logistics considerations should I keep in mind when importing car plastic trim?

When importing car plastic trim, consider logistics factors such as shipping methods, customs clearance, and delivery timelines. Choose a shipping method that balances cost and speed, and ensure compliance with local import regulations. Working with a logistics partner experienced in international shipping can help navigate customs procedures and reduce potential delays, ensuring your products arrive on time and in good condition.

Top 8 Car Plastic Trim Manufacturers & Suppliers List

1. Dura Coating – Plastic Trim Detailer

Domain: dura-coating.com

Registered: 2019 (6 years)

Introduction: Product Name: Plastic Trim Detailer

Description: A solution designed to keep the plastic trim of vehicles looking glossy and fresh, providing a showroom floor shine. It restores the appearance of black trim that has faded due to UV rays.

Sizes Available: 15ML, 30ML, 50ML, Pro Size

Price: Starting from $59.95

Additional Products: DDE Spray Detailer & No Touch Engine Bay Cleaner (from $39.95), DDE -…

2. Autogeek – Exterior Trim & Metal Restoration Products

Domain: autogeek.net

Registered: 2000 (25 years)

Introduction: Exterior Trim & Metal Restoration products are designed to clean, condition, and protect vinyl, rubber, and plastic surfaces on cars. These products help restore and maintain the trim, preventing issues like drying, cracking, and fading caused by environmental elements. The text emphasizes that while washing and waxing are important, attention to trim restoration significantly enhances the overall…

3. Turtle Wax – Trim Restorer

Domain: turtlewax.com

Registered: 1995 (30 years)

Introduction: Trim Restorer: A powerful, silicon-infused formula that restores plastic and trim, providing a shiny gloss and UV protection. Hybrid Solutions Pro Graphene Flex Wax: A polymer-infused wax that works on plastic and trim without polishing agents. Hybrid Solutions Ceramic Spray Coating: A protective coating suitable for plastic and trim. Turtle Wax Inside and Out Protectant: A versatile protectant fo…

4. Chemical Guys – Nonsense All Purpose Cleaner & Tire+Trim Gel

Domain: chemicalguys.com

Registered: 2003 (22 years)

Introduction: Nonsense All Purpose Cleaner: A strong yet gentle super cleaner effective on most surfaces, including hard plastic exterior trims, carpets, and fabric surfaces. Tire+Trim Gel: A premium oil-based gel that deeply nourishes and moisturizes faded trim, applies evenly, and finishes dry-to-the-touch without slinging. Exterior Detailing Brush: A brush designed to clean textured trim. Microfiber Towels: …

5. Torque Detail – Plastic Restore™

Domain: torquedetail.com

Registered: 2018 (7 years)

Introduction: Product Name: Plastic Restore™ – Restores Plastic, Vinyl & Rubber Surfaces (8oz Bottle)

Sale Price: $12.99

Reviews: 253 reviews

Key Features:

– Easy to Apply: Simply spray on and wipe off.

– Effective on Most Surfaces: Works on trim, rubber, vinyl, polypropylene, and rubberized plastics.

– Molecular Restoration: Uses nanotechnology to deeply permeate plastic and restore it to its original state.

-…

6. Armor All – Outlast Trim & Plastic Restorer

Domain: armorall.com

Registered: 1993 (32 years)

Introduction: Armor All® Outlast™ Trim & Plastic Restorer rejuvenates worn and weathered exterior trim, plastic and rubber surfaces. It restores plastic and vinyl like new, protects surfaces for more than 100 car washes (tested with 120 consecutive automatic car wash cycles), and helps prevent fading, discoloration, and oxidation. It is safe for all trim colors and can be applied to bumpers, door handles, side …

7. Auto Obsessed – Solution Finish Trim Restorer

Domain: autoobsessed.com

Registered: 2010 (15 years)

Introduction: Solution Finish Trim Restorer is recommended for permanently restoring black plastic trim. It effectively repairs sun-faded, UV-damaged plastic, providing a long-lasting solution compared to other methods like heating or applying trim dressings.

8. Detail King – Trim Kote & Revival Bumper Dressing

Domain: blog.detailking.com

Registered: 1999 (26 years)

Introduction: Trim Kote Car Trim Restorer: A semi-permanent dye that restores faded plastic trim to its original color, suitable for unpainted plastic and vinyl trim. Cost-effective solution for detailing businesses. Revival Bumper & Trim Dressing: Conditions and protects exterior plastic, vinyl, and rubber trim, shielding against UV damage, weathering, and chemicals, providing a long-lasting, professional-grad…

Strategic Sourcing Conclusion and Outlook for car plastic trim

In navigating the complex landscape of car plastic trim sourcing, international buyers must prioritize strategic partnerships and high-quality products. The importance of selecting durable, UV-resistant materials cannot be overstated, as these attributes not only enhance the aesthetic appeal of vehicles but also ensure longevity and reduce maintenance costs. By investing in reputable suppliers who offer innovative restoration and protection solutions, companies can improve their overall product offerings and customer satisfaction.

Illustrative image related to car plastic trim

Furthermore, leveraging technology and data analytics can facilitate smarter sourcing decisions, allowing buyers to identify emerging trends and optimize their supply chains. With a growing demand for environmentally friendly materials, sourcing sustainably can also provide a competitive edge in local and global markets.

As we look to the future, the car plastic trim industry is poised for significant growth, especially in regions like Africa, South America, the Middle East, and Europe. Buyers should seize this opportunity to establish strong relationships with suppliers who align with their quality and sustainability goals. Embrace these insights to enhance your sourcing strategy and position your business for success in this evolving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to car plastic trim