A Deep Dive into Heavy Rope Solution

Introduction: Navigating the Global Market for heavy rope

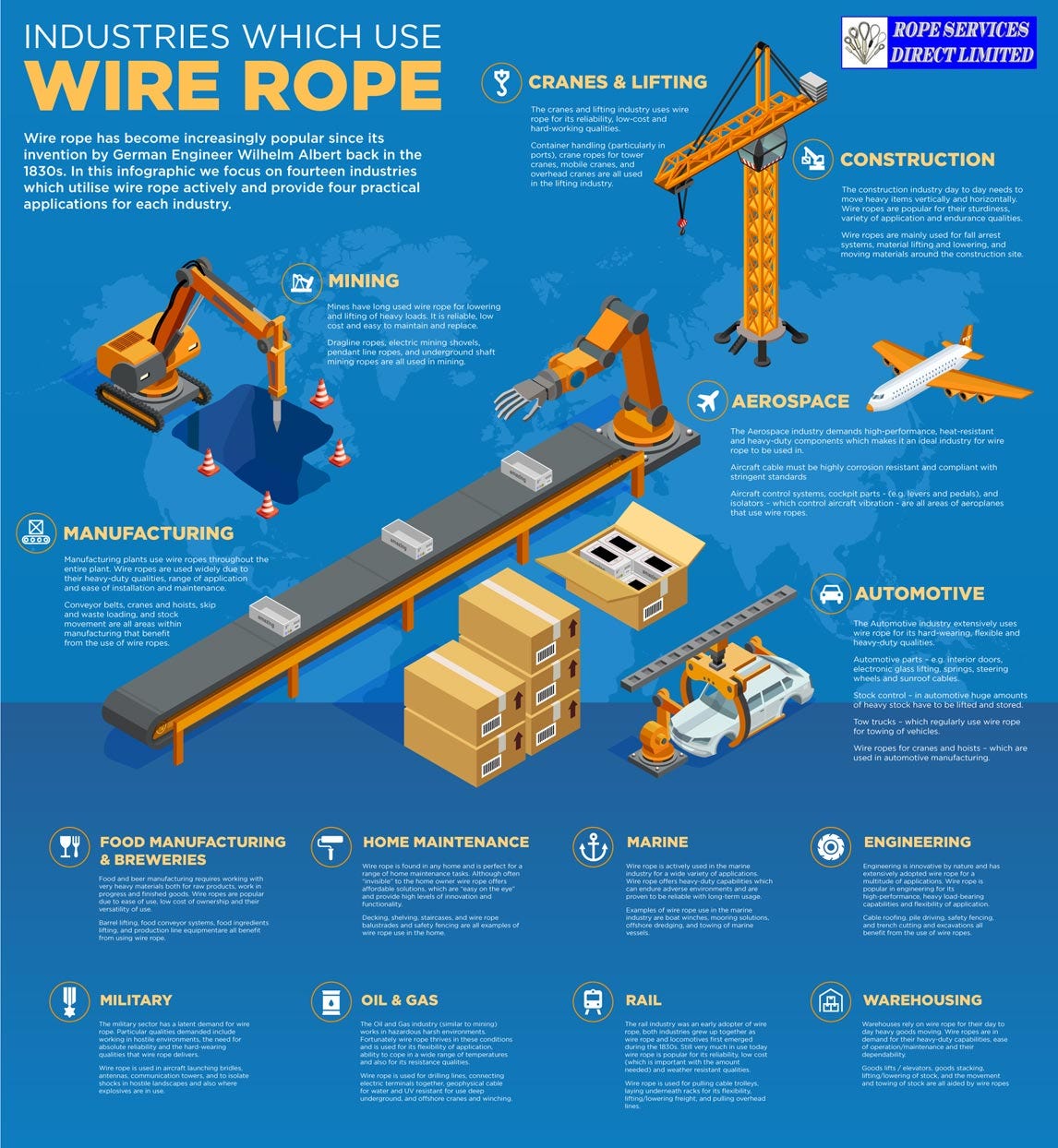

Heavy rope has emerged as a pivotal tool across various industries, from construction and shipping to fitness and sports. However, sourcing the right heavy rope can pose significant challenges, especially for international B2B buyers navigating diverse markets. With varying specifications, material options, and applications, making informed purchasing decisions is crucial. This guide serves as a comprehensive resource, detailing the different types of heavy rope, their applications, and the factors that impact pricing and supplier selection.

In this guide, we delve into the nuances of heavy rope, discussing its construction materials, such as polypropylene, nylon, and manila, and their respective benefits. We also explore key applications—ranging from industrial uses in towing and rigging to fitness applications like battle ropes for high-intensity training. Moreover, we provide insights on how to vet suppliers effectively, ensuring that you partner with reputable manufacturers who meet international quality standards.

Designed specifically for B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including markets like Saudi Arabia and Vietnam—this guide empowers you to make confident purchasing decisions. By understanding the landscape of heavy rope options and their applications, you can streamline your sourcing process, optimize costs, and enhance the performance of your projects or products.

Understanding heavy rope Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Battle Ropes | Long, thick ropes, typically anchored; used for HIIT. | Fitness centers, personal training studios | Pros: Effective for cardio and strength; versatile. Cons: Requires space and anchoring. |

| Weighted Battle Ropes | Incorporates weights along the length for added resistance. | Athletic training, rehabilitation programs | Pros: Increases strength and endurance; low impact. Cons: Heavier and less portable. |

| Hyper Ropes | Short, weighted ropes without the need for anchoring. | Home gyms, small training spaces | Pros: Portable, versatile, and space-saving. Cons: May not provide the same resistance as longer ropes. |

| Climbing Ropes | Designed for vertical climbing; made from durable materials. | Outdoor sports, climbing gyms | Pros: High strength-to-weight ratio; durable. Cons: Specific use case; not for general fitness. |

| Utility Ropes | Heavy-duty ropes used for lifting and towing. | Construction, maritime, and industrial sectors | Pros: Highly durable and versatile for various applications. Cons: Less focused on fitness; limited exercise use. |

What Are the Distinct Characteristics of Battle Ropes?

Battle ropes are designed for high-intensity interval training (HIIT) and are typically anchored to a fixed point. They are available in various lengths and thicknesses, allowing for different resistance levels. Suitable for fitness centers and personal training studios, these ropes can significantly enhance both cardiovascular endurance and muscle strength. When purchasing, buyers should consider the space requirements and anchoring needs, as these ropes can be cumbersome in smaller facilities.

Illustrative image related to heavy rope

How Do Weighted Battle Ropes Enhance Training?

Weighted battle ropes feature added resistance along their length, making them ideal for athletes looking to boost strength and endurance. These ropes are particularly beneficial in rehabilitation programs, as they provide low-impact options for high-intensity workouts. Buyers should evaluate the weight options and ensure they align with their training goals. While they offer excellent results, their heavier design may limit portability.

Why Choose Hyper Ropes for Space-Constrained Environments?

Hyper ropes are a modern innovation that eliminates the need for anchoring, making them perfect for home gyms and small training spaces. Their compact design allows for a full-body workout without the bulk of traditional battle ropes. Ideal for buyers in regions with limited space, these ropes can be easily transported and utilized in various environments. However, potential buyers should be aware that while they are versatile, they may not provide the same resistance as longer, anchored ropes.

What Are the Applications of Climbing Ropes in B2B Markets?

Climbing ropes are engineered for vertical ascents and are made from high-strength, durable materials. They find applications in outdoor sports and climbing gyms, where safety and reliability are paramount. Buyers in these sectors should prioritize quality and certification standards, ensuring the ropes meet safety regulations. However, their specific use case may limit their appeal to a broader fitness audience.

Illustrative image related to heavy rope

How Do Utility Ropes Serve Various Industries?

Utility ropes are heavy-duty options designed for lifting, towing, and other industrial applications. Commonly used in construction and maritime industries, these ropes are known for their durability and versatility. While they are not primarily focused on fitness, they can be valuable in specialized training environments. Buyers should assess the specific requirements of their applications, as utility ropes may not offer the fitness benefits associated with other heavy ropes.

Key Industrial Applications of heavy rope

| Industry/Sector | Specific Application of heavy rope | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Lifting and Rigging | Enhanced safety and efficiency in lifting heavy materials | Durability, tensile strength, and resistance to wear and tear |

| Marine and Shipping | Mooring and Towing | Reliable securing of vessels and cargo during transport | Corrosion resistance, UV protection, and load capacity |

| Agriculture | Crop Harvesting and Equipment Towing | Improved productivity and reduced downtime | Weather resistance, flexibility, and breaking strength |

| Fitness and Rehabilitation | Heavy Rope Training Equipment | Enhanced strength training and rehabilitation outcomes | Material quality, weight options, and length variations |

| Entertainment and Events | Staging and Rigging for Events | Secure setup of stages and installations | Weight capacity, ease of transport, and customization options |

How is Heavy Rope Used in Construction and What Problems Does It Solve?

In the construction industry, heavy rope is essential for lifting and rigging applications. It is used to hoist heavy materials, ensuring efficient transport from one level to another. The primary benefit is enhanced safety; robust heavy ropes minimize the risk of accidents during lifting operations. For international buyers, especially in regions like Africa and South America, sourcing ropes with high tensile strength and durability is critical due to varying environmental conditions and the demanding nature of construction projects.

What Role Does Heavy Rope Play in Marine and Shipping Applications?

Heavy rope is crucial in the marine and shipping sectors for mooring and towing vessels. Its ability to withstand harsh marine environments makes it indispensable for securing ships during docking and transporting cargo. The value lies in its reliability, which prevents accidents and cargo loss. Buyers from the Middle East and Europe must consider factors like corrosion resistance and UV protection when sourcing heavy ropes, ensuring they meet the rigorous demands of maritime operations.

How is Heavy Rope Utilized in Agriculture and What Benefits Does It Provide?

In agriculture, heavy rope is utilized for towing equipment and assisting in crop harvesting. Its strength and flexibility facilitate the movement of heavy machinery across uneven terrain, enhancing productivity and reducing downtime. For businesses in Africa and South America, where agricultural practices can be labor-intensive, sourcing ropes that offer weather resistance and high breaking strength is essential for reliable performance in various conditions.

Illustrative image related to heavy rope

Why is Heavy Rope Important for Fitness and Rehabilitation?

Heavy rope is increasingly popular in fitness and rehabilitation settings, serving as a tool for strength training and physical therapy. It provides a full-body workout, improving cardiovascular health and muscle strength. The versatility of heavy ropes allows for customized training regimens suitable for different fitness levels. B2B buyers in Europe and the Middle East should prioritize sourcing high-quality materials that offer weight options and varied lengths to meet diverse training needs.

How Does Heavy Rope Enhance Safety in Entertainment and Events?

In the entertainment industry, heavy rope is used for staging and rigging during events. It secures equipment and structures, ensuring safety for performers and audiences alike. The main benefit is the reliability it provides in high-stakes environments where safety is paramount. Buyers should look for ropes with high weight capacities and easy transport features, particularly when sourcing for international events in diverse locations such as Saudi Arabia and Vietnam.

3 Common User Pain Points for ‘heavy rope’ & Their Solutions

Scenario 1: Limited Space for Heavy Rope Training

The Problem: Many B2B buyers, particularly gym owners and fitness centers in urban areas, face the challenge of limited space. Traditional heavy ropes often require significant floor area for effective use, which can be a barrier for facilities that cater to high-density populations. This limitation not only affects the ability to offer a diverse range of training options but can also lead to decreased customer satisfaction as clients may be unable to access the equipment they need.

The Solution: To address this issue, consider sourcing unanchored or shorter heavy ropes, such as the Hyper Rope, which is designed for efficient use in compact spaces. These innovative options eliminate the need for a fixed anchor point while providing the same resistance benefits of traditional ropes. When selecting heavy ropes, prioritize those that are portable and versatile, allowing for various exercises to be performed in smaller areas. Additionally, create a flexible workout schedule that optimizes equipment use during peak hours, ensuring all clients have access to the heavy ropes without overcrowding.

Scenario 2: Safety Concerns with Heavy Rope Workouts

The Problem: Another significant concern for B2B buyers, especially in the health and fitness sector, is the safety of clients during heavy rope workouts. Improper use or inadequate training can lead to injuries, particularly in high-intensity environments where users may rush through exercises. This not only poses a risk to clients but can also expose businesses to liability issues and damage their reputation.

The Solution: To mitigate safety risks, implement comprehensive training programs for both staff and clients. Invest in educational resources that highlight proper form, technique, and the physiological benefits of heavy rope workouts. Additionally, consider integrating technology, such as video tutorials or virtual coaching, to guide users through their routines. Encourage gradual progression in workout intensity and duration to ensure clients build their strength and endurance safely. Regularly inspect equipment for wear and tear, and provide clear guidelines for safe usage to further protect clients and enhance their experience.

Scenario 3: Difficulty in Sourcing Quality Heavy Ropes

The Problem: B2B buyers often struggle to find reliable suppliers of high-quality heavy ropes that meet their specific needs. This issue is compounded by the varying standards and materials used in manufacturing, leading to confusion and potential dissatisfaction with purchased products. The wrong choice can affect workout effectiveness and result in higher replacement costs, which impacts the bottom line.

The Solution: To streamline the sourcing process, conduct thorough market research to identify reputable suppliers known for their quality and reliability. Look for manufacturers that provide detailed specifications, including material composition and intended use cases, to ensure that the heavy ropes align with your facility’s training goals. Establish partnerships with suppliers who offer customization options, allowing you to select the right weight and length for your target clientele. Additionally, request samples and conduct testing to assess the ropes’ durability and performance before making larger purchases. Engaging in open communication with suppliers about your requirements can lead to better-tailored solutions that enhance your training offerings and overall client satisfaction.

Illustrative image related to heavy rope

Strategic Material Selection Guide for heavy rope

What Are the Key Materials for Heavy Rope and Their Properties?

When selecting heavy rope for various applications, the choice of material significantly impacts performance, durability, and suitability for specific environments. Below, we analyze four common materials used in heavy ropes: polypropylene, polyester, nylon, and natural fibers.

How Does Polypropylene Perform as a Material for Heavy Rope?

Polypropylene is a lightweight synthetic material known for its excellent resistance to moisture and chemicals. It has a relatively low melting point of around 160°C (320°F), making it suitable for moderate temperature applications. Polypropylene ropes are buoyant, which makes them ideal for marine applications.

Pros: The primary advantages of polypropylene include its cost-effectiveness and resistance to rot and mildew. It is also lightweight, which can reduce shipping costs.

Cons: However, polypropylene ropes can degrade under UV exposure and may have lower tensile strength compared to other synthetic materials. This limits their lifespan in outdoor applications.

International Considerations: Buyers in regions like Africa and South America should consider the UV degradation factor, especially in sun-rich climates. Compliance with local standards such as ASTM D4444 can also be crucial for quality assurance.

Illustrative image related to heavy rope

What Are the Benefits of Polyester for Heavy Rope?

Polyester is another popular synthetic material known for its high strength and durability. It can withstand temperatures up to 200°C (392°F) and offers excellent resistance to abrasion and UV light.

Pros: Polyester ropes are highly resistant to stretching and maintain their strength even when wet. They are suitable for applications requiring high tensile strength, such as towing and lifting.

Cons: The primary drawback is the higher cost compared to polypropylene. Additionally, polyester can be heavier, which may affect shipping and handling.

Illustrative image related to heavy rope

International Considerations: In Europe and the Middle East, compliance with EN standards is essential. Buyers should also consider local preferences for durability and UV resistance, particularly in harsh climates.

How Does Nylon Compare as a Heavy Rope Material?

Nylon is renowned for its exceptional elasticity and strength, making it a top choice for applications requiring shock absorption, such as climbing and rescue operations. It can withstand temperatures up to 180°C (356°F).

Pros: The main advantages of nylon include its high tensile strength and resistance to abrasion. Its elasticity allows it to absorb shock loads effectively, making it ideal for dynamic applications.

Cons: However, nylon is more expensive than both polypropylene and polyester. It is also susceptible to UV degradation and can absorb water, which may affect its performance over time.

International Considerations: Buyers from regions like Saudi Arabia and Vietnam should be aware of the potential for UV damage in sunny environments. Compliance with international standards like ISO 105-B02 for UV resistance is advisable.

Illustrative image related to heavy rope

What Role Do Natural Fibers Play in Heavy Rope Applications?

Natural fibers, such as manila or sisal, have been used for centuries in rope-making. They are biodegradable and have a unique aesthetic appeal.

Pros: The primary advantage of natural fiber ropes is their environmental friendliness and traditional craftsmanship. They are also relatively inexpensive.

Cons: However, natural fibers have lower tensile strength and are susceptible to rot, mildew, and UV damage. This limits their use in demanding applications.

International Considerations: Buyers in Europe may prefer natural fibers for sustainability reasons, while those in harsher climates may need to consider the limitations of durability and moisture absorption.

Summary Table of Material Selection for Heavy Rope

| Material | Typical Use Case for heavy rope | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Marine applications | Cost-effective and moisture-resistant | UV degradation and lower tensile strength | Low |

| Polyester | Towing and lifting | High strength and UV resistance | Higher cost and heavier weight | Medium |

| Nylon | Climbing and rescue operations | Exceptional elasticity and strength | UV degradation and water absorption | High |

| Natural Fibers | Traditional applications | Environmentally friendly | Lower strength and susceptibility to rot | Low |

This strategic material selection guide provides actionable insights for B2B buyers, enabling informed decisions based on performance, durability, and compliance with international standards.

Illustrative image related to heavy rope

In-depth Look: Manufacturing Processes and Quality Assurance for heavy rope

What Are the Main Stages in the Manufacturing Process of Heavy Rope?

The manufacturing process of heavy rope involves several critical stages, each designed to ensure the final product meets industry standards and customer expectations. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in heavy rope manufacturing is selecting the appropriate raw materials. Common materials include high-tenacity polyester, nylon, and polypropylene, known for their strength, durability, and resistance to environmental conditions. Suppliers often conduct thorough quality checks on these materials to ensure they meet the necessary specifications. The fibers may be twisted or braided before they are cut to length, which is a crucial step in ensuring uniformity and strength.

-

Forming: In this stage, the prepared fibers undergo various techniques such as twisting, braiding, or weaving. Depending on the intended use of the rope, manufacturers may employ different braiding techniques to enhance strength and flexibility. For example, a double-braided rope combines an inner core and an outer sheath, providing increased durability and resistance to abrasion. The forming process is critical as it directly influences the rope’s performance characteristics, including tensile strength and flexibility.

-

Assembly: Once the rope is formed, it may undergo additional assembly processes, such as adding end fittings or splicing. This stage is essential for creating custom solutions that meet specific client requirements. For instance, heavy ropes used in marine applications may require specialized eye splices or shackles for secure connections. This customization not only enhances the functionality of the rope but also aligns with the specific operational needs of various industries.

-

Finishing: The final stage involves treating the rope to enhance its durability and performance. Finishing processes may include coating the rope with protective materials to improve resistance to UV light, chemicals, and moisture. Additionally, manufacturers may perform cutting, labeling, and packaging at this stage, ensuring that the product is ready for distribution. Proper finishing is vital as it affects the longevity and usability of the rope in real-world applications.

How Is Quality Assurance Implemented in Heavy Rope Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that heavy ropes meet international standards and customer specifications. The following outlines key aspects of QA in heavy rope production.

-

International Standards and Certifications: Many manufacturers adhere to international standards such as ISO 9001, which outlines quality management principles. Additionally, industry-specific certifications like CE (European Conformity) and API (American Petroleum Institute) are crucial for heavy ropes used in specialized applications. These standards help ensure that products are consistently manufactured to meet safety and performance requirements.

-

Quality Control Checkpoints: Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the factory. Suppliers must provide certificates of compliance to verify that the materials meet the required specifications.

– In-Process Quality Control (IPQC): During the manufacturing stages, QC personnel conduct regular inspections to ensure that the production process adheres to established protocols. This may include monitoring the braiding process for consistency and strength.

– Final Quality Control (FQC): After finishing, each batch of heavy ropes undergoes rigorous testing to ensure they meet performance standards. This may include tensile strength tests, abrasion resistance tests, and environmental exposure tests. -

Common Testing Methods: Various testing methods are employed to ensure the quality of heavy ropes. These may include:

– Tensile Testing: Measures the maximum load a rope can withstand before breaking.

– Abrasion Resistance Testing: Assesses how well the rope can endure wear and tear during use.

– Environmental Testing: Evaluates the rope’s performance under different environmental conditions, such as UV exposure or moisture.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those operating in diverse regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is paramount. Here are actionable steps buyers can take:

-

Conduct Audits: Regular audits of the supplier’s manufacturing facilities can provide insights into their quality assurance practices. Buyers should assess whether suppliers adhere to international standards and maintain robust quality control processes.

-

Request Quality Reports: Buyers should ask for detailed quality reports from suppliers that outline their QC processes, testing results, and any certifications obtained. These reports can offer transparency regarding the supplier’s commitment to quality.

-

Engage Third-Party Inspectors: Employing third-party inspection services can enhance the verification process. These independent entities can conduct random checks on batches, ensuring that the products meet the required specifications before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers face unique challenges regarding quality control, especially when sourcing heavy ropes from different regions. Understanding these nuances can facilitate smoother transactions:

-

Cultural and Regulatory Differences: Buyers should be aware of the cultural and regulatory environments of the countries they are sourcing from. Different regions may have varying standards for quality assurance, which can impact product performance and compliance.

-

Logistics and Shipping Considerations: Shipping heavy ropes internationally can present logistical challenges, including potential damage during transit. Buyers should discuss with suppliers how they package and ship products to minimize risk.

-

Language Barriers: Communication is vital for ensuring quality. Buyers should strive to establish clear lines of communication with suppliers and consider hiring translators if necessary to avoid misunderstandings regarding specifications and quality requirements.

-

Market-Specific Requirements: Different regions may have specific requirements for heavy ropes, especially in industries such as marine, construction, or oil and gas. Buyers should ensure that suppliers are familiar with and compliant with these local requirements.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions, ensuring they procure heavy ropes that meet their operational needs and industry standards.

Illustrative image related to heavy rope

Practical Sourcing Guide: A Step-by-Step Checklist for ‘heavy rope’

In the competitive landscape of B2B sourcing, finding the right heavy rope supplier can significantly impact operational efficiency and product quality. This guide aims to provide a structured approach for international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, to effectively procure heavy rope.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s critical to establish clear technical specifications for the heavy rope. Consider factors such as material composition (e.g., polyester, nylon), diameter, length, and intended use (e.g., battle ropes, towing ropes).

- Weight Capacity: Ensure the rope can withstand the specific loads it will encounter.

- Environmental Resistance: If the ropes will be used outdoors, verify UV and weather resistance.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers. Look for manufacturers and distributors with a proven track record in the heavy rope industry.

- Industry Experience: Focus on suppliers who have been in the business for several years and have experience with your specific type of heavy rope.

- Market Reputation: Check online reviews, testimonials, and case studies to gauge supplier reliability.

Step 3: Evaluate Supplier Certifications

Verification of supplier certifications is essential to ensure quality and compliance with industry standards.

- Quality Assurance: Look for ISO certifications or other relevant quality management systems that demonstrate a commitment to quality.

- Safety Standards: Ensure that the ropes meet safety regulations pertinent to your industry, such as EN or ASTM standards.

Step 4: Request Samples

Before finalizing an order, request samples of the heavy rope to assess quality and performance.

- Material Inspection: Evaluate the sample for durability, flexibility, and resistance to wear and tear.

- Testing: If possible, conduct tests in real-world conditions to ensure the rope meets your operational needs.

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier, negotiate terms to ensure a mutually beneficial agreement.

- Pricing Structure: Discuss bulk pricing, discounts for long-term contracts, and payment terms that align with your budget.

- Delivery Terms: Clarify shipping options, lead times, and responsibilities regarding customs and import duties.

Step 6: Establish a Communication Plan

Effective communication with your supplier is vital for smooth transactions and ongoing support.

- Point of Contact: Designate a primary contact person to streamline communication.

- Regular Updates: Schedule periodic check-ins to discuss order status, potential issues, and future needs.

Step 7: Monitor and Evaluate Performance

After procurement, continuously monitor the performance of the heavy rope and the supplier’s service.

- Feedback Loop: Establish a system for gathering feedback from your team about the rope’s performance.

- Supplier Review: Regularly assess supplier reliability, product quality, and responsiveness to ensure they continue to meet your expectations.

By following this comprehensive checklist, B2B buyers can navigate the complexities of sourcing heavy rope effectively, ensuring they select a supplier that meets their technical requirements and business needs.

Illustrative image related to heavy rope

Comprehensive Cost and Pricing Analysis for heavy rope Sourcing

What Are the Key Cost Components in Heavy Rope Sourcing?

When sourcing heavy ropes, understanding the cost structure is essential for international B2B buyers. The primary components include:

-

Materials: The choice of materials significantly impacts the overall cost. Heavy ropes are commonly made from synthetic fibers such as polypropylene or nylon, which vary in price based on quality and source. Premium materials, especially those with specific certifications for durability and safety, will increase costs.

-

Labor: Labor costs can fluctuate based on the region of manufacturing. Countries with lower labor costs, such as those in Southeast Asia, may offer competitive pricing, but quality should be assessed. Skilled labor is necessary for high-quality production, particularly for specialized ropes.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and administrative costs associated with production. Buyers should inquire about the supplier’s operational efficiency, as lean manufacturing practices can lower overhead costs.

-

Tooling: Customization of heavy ropes may require specialized tooling, which can add to initial costs. For bulk orders, manufacturers may absorb these costs, but they should be factored into the unit price for smaller orders.

-

Quality Control (QC): Rigorous QC processes ensure that heavy ropes meet specified standards. Suppliers with robust QC protocols may charge higher prices, but this investment can lead to reduced returns due to defects.

-

Logistics: Transportation costs are often significant, especially for international shipments. Factors such as distance, shipping mode (air vs. sea), and current freight rates will affect the final price.

-

Margin: Suppliers typically mark up prices to ensure profitability. Understanding the typical margin in the heavy rope industry can help buyers negotiate better deals.

How Do Price Influencers Affect Heavy Rope Costs?

Several factors can influence the pricing of heavy ropes:

-

Volume/MOQ: Buying in bulk often leads to lower per-unit costs. Understanding the Minimum Order Quantity (MOQ) can help buyers negotiate better pricing structures.

-

Specifications and Customization: Custom requirements, such as specific lengths, weights, or finishes, can increase costs. Buyers should clarify specifications upfront to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials and recognized certifications (like ISO or safety standards) command premium prices. Buyers should weigh the benefits of quality against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role in pricing. Established suppliers with good track records may charge more, but the assurance of quality and timely delivery can justify the investment.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for cost management. Terms like FOB (Free On Board) or CIF (Cost Insurance and Freight) will dictate who bears the shipping costs and risks, impacting the total price.

What Buyer Tips Can Help Optimize Costs for Heavy Rope Sourcing?

International B2B buyers can adopt several strategies to enhance cost efficiency:

-

Negotiation: Leverage volume discounts and long-term partnerships to negotiate better pricing. Building relationships with suppliers can also lead to more favorable terms.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost associated with using the ropes, including maintenance, lifespan, and potential replacements. A higher upfront cost may be justified if the product lasts longer.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and taxes that may affect overall costs. Engaging local experts or consultants can provide insights into regional pricing dynamics.

-

Local Market Insights: For buyers in regions like Africa, South America, or the Middle East, understanding local market conditions can uncover opportunities for cost savings. Local suppliers may provide competitive pricing compared to overseas manufacturers.

Disclaimer on Indicative Prices

Prices for heavy ropes can vary widely based on the factors outlined above. It is crucial for buyers to conduct thorough market research and engage directly with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing heavy rope With Other Solutions

Understanding Alternatives to Heavy Rope Training Solutions

When considering fitness equipment for strength and cardio training, heavy ropes have gained popularity for their versatility and effectiveness. However, several alternative solutions also offer similar benefits, catering to different training environments and needs. This section will compare heavy ropes with two viable alternatives: kettlebells and resistance bands, helping B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Heavy Rope | Kettlebells | Resistance Bands |

|---|---|---|---|

| Performance | High-intensity, full-body workout; excellent for cardio and strength. | Effective for strength training and endurance; versatile for various exercises. | Good for strength and flexibility; low impact and portable. |

| Cost | Moderate to high (varies by brand and length). | Moderate (varies by weight). | Low (affordable and widely available). |

| Ease of Implementation | Requires space and often an anchor point; can be challenging for beginners. | Requires basic technique knowledge; can be used anywhere. | Very easy to use; minimal setup required. |

| Maintenance | Low maintenance if stored properly; susceptible to wear if used improperly. | Low maintenance; durable if not dropped. | Very low maintenance; replaceable if damaged. |

| Best Use Case | Ideal for high-intensity workouts and group training sessions. | Excellent for strength training and functional fitness. | Suitable for rehabilitation, mobility, and general fitness. |

What Are the Pros and Cons of Kettlebells Compared to Heavy Ropes?

Kettlebells are a popular alternative for strength and cardio training. They offer a wide range of exercises that can improve overall strength, endurance, and flexibility. The primary advantage of kettlebells is their versatility; they can be used for swings, snatches, and squats, among other exercises. However, they require a certain level of technique to use effectively, which might be a barrier for beginners. Kettlebells also have a moderate cost, making them accessible but potentially more expensive than resistance bands. They are portable, allowing for workouts in various settings, but they do take up more space than bands.

How Do Resistance Bands Stack Up Against Heavy Ropes?

Resistance bands are an economical and highly portable alternative that can be easily integrated into any fitness routine. They are particularly beneficial for strength training and flexibility exercises and can be used for rehabilitation purposes. The main advantage of resistance bands is their low cost and ease of use; they require little to no setup, making them suitable for both beginners and experienced athletes. However, while they can provide a solid workout, they may not offer the same high-intensity experience as heavy ropes or kettlebells, especially for those looking for a full-body cardio workout. Their durability is also a consideration; while they require minimal maintenance, they can wear out over time and need to be replaced.

How Can B2B Buyers Choose the Right Training Solution?

When deciding between heavy ropes, kettlebells, and resistance bands, B2B buyers should consider their specific training goals, available space, and budget. Heavy ropes are ideal for those focused on high-intensity training and group workouts, while kettlebells provide versatility for strength training. Resistance bands are the best choice for budget-conscious buyers or those needing portability. Evaluating these factors will help businesses select the most effective training solutions tailored to their needs, ultimately enhancing their fitness offerings.

Essential Technical Properties and Trade Terminology for heavy rope

What Are the Key Technical Properties of Heavy Rope?

When evaluating heavy rope for industrial applications, several technical specifications are crucial for ensuring performance, safety, and durability. Here are some of the most significant properties:

1. Material Grade

Heavy ropes are typically constructed from materials such as polypropylene, nylon, or polyester. Each material has distinct characteristics; for example, nylon offers high tensile strength and elasticity, making it ideal for dynamic loads, while polyester is more UV-resistant and less prone to stretching. Understanding the material grade helps B2B buyers select the right rope for specific applications, affecting longevity and performance.

2. Diameter and Length

The diameter of heavy rope directly influences its strength and handling characteristics. Common diameters range from 1.5 inches to 2 inches, with lengths varying from 30 to 50 feet. A thicker rope can bear more weight but may be less flexible. Buyers need to consider both the load requirements and the operational environment when selecting the appropriate diameter and length to ensure safety and efficiency.

3. Weight and Density

The weight of heavy rope is a critical factor, as it impacts portability and ease of use. Heavier ropes are often more durable and resistant to wear but can be cumbersome to transport. Buyers must balance the need for a durable, heavy rope with the practical aspects of handling and storage, especially in regions with limited transportation infrastructure.

4. Tensile Strength

Tensile strength refers to the maximum load that a rope can withstand before breaking. This is a vital specification that ensures safety in heavy-duty applications. Tensile strength is usually expressed in pounds or kilograms and varies by material and diameter. B2B buyers should prioritize tensile strength based on the specific demands of their industry, particularly in sectors like construction or shipping, where failure can lead to significant safety hazards.

5. Stretch Resistance

Understanding how much a rope stretches under load is essential for applications requiring precision and stability. Ropes made from synthetic fibers tend to have lower stretch characteristics compared to natural fibers. Buyers should assess stretch resistance to ensure that the rope performs adequately under dynamic loads, particularly in applications involving lifting or towing.

Which Trade Terminology Should B2B Buyers Know?

In the heavy rope industry, familiarity with specific jargon can facilitate smoother transactions and negotiations. Here are key terms to understand:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. When sourcing heavy ropes, knowing whether a supplier is an OEM can provide insights into product quality and reliability, as OEMs typically adhere to strict manufacturing standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers as it affects inventory management and cash flow. For heavy rope, MOQs can vary significantly based on material and customization options.

Illustrative image related to heavy rope

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for a specific quantity of goods. This term is vital for B2B buyers looking to compare costs and negotiate terms effectively. A well-structured RFQ can lead to better pricing and improved supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and responsibilities, ensuring smoother logistics for heavy rope procurement.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. In the heavy rope industry, understanding lead times is essential for project planning and inventory management. Buyers should inquire about lead times to avoid disruptions in their supply chain.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing heavy rope, ensuring they select the right products to meet their operational needs.

Illustrative image related to heavy rope

Navigating Market Dynamics and Sourcing Trends in the heavy rope Sector

What Are the Current Market Dynamics and Key Trends in the Heavy Rope Sector?

The heavy rope market is experiencing significant growth driven by increased demand across various sectors, including fitness, construction, and maritime industries. Global buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly sourcing heavy ropes for applications ranging from high-intensity training equipment to industrial uses. Key trends influencing the market include the rise of functional fitness training, which has popularized heavy ropes like battle ropes for their efficiency and versatility. Additionally, advancements in material technology are leading to the development of lighter yet stronger ropes, enhancing performance while allowing for greater portability and ease of use.

Emerging B2B technologies such as e-commerce platforms and digital sourcing tools are revolutionizing the way buyers procure heavy ropes. International buyers can now access a wider variety of suppliers and products online, making it easier to compare prices and specifications. Furthermore, the integration of smart technologies, such as IoT sensors in ropes for monitoring performance and durability, is gaining traction. As manufacturers adapt to these technological changes, buyers are encouraged to seek suppliers who can provide innovative solutions tailored to their specific needs.

How Is Sustainability and Ethical Sourcing Impacting the Heavy Rope Industry?

Sustainability and ethical sourcing have become crucial considerations for international B2B buyers in the heavy rope sector. The environmental impact of traditional rope manufacturing processes has led to a push for more sustainable materials and practices. Buyers are increasingly prioritizing suppliers that utilize eco-friendly materials, such as recycled fibers or organic cotton, to produce heavy ropes. This shift not only reduces the carbon footprint associated with production but also aligns with the growing consumer demand for sustainable products.

Additionally, the importance of ethical supply chains cannot be overstated. Buyers are now more vigilant about the sourcing practices of their suppliers, seeking transparency and fairness throughout the production process. Certifications such as Global Recycle Standard (GRS) and OEKO-TEX® are becoming essential for suppliers aiming to demonstrate their commitment to sustainability and ethical practices. By investing in suppliers with these certifications, B2B buyers can enhance their brand reputation and meet the increasing demand for responsible sourcing.

Illustrative image related to heavy rope

What Is the Evolution and History of the Heavy Rope Industry?

The heavy rope industry has evolved significantly over the centuries, transitioning from traditional materials like hemp and cotton to synthetic fibers such as nylon and polyester. Initially used for maritime and agricultural purposes, heavy ropes have found their way into various sectors, including fitness and construction, due to their strength and versatility. The introduction of battle ropes in fitness culture during the early 2000s marked a pivotal shift, popularizing the use of heavy ropes in high-intensity training regimes.

As the fitness industry continues to evolve, heavy ropes are now being integrated into innovative training programs that emphasize functional fitness and versatility. This evolution has not only expanded the market for heavy ropes but has also driven advancements in manufacturing techniques, resulting in products that are lighter, more durable, and capable of meeting the diverse needs of modern buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of heavy rope

-

How do I choose the right heavy rope for my business needs?

Choosing the right heavy rope involves understanding your specific application and requirements. Consider factors such as the rope’s material, diameter, length, and weight. For industrial applications, look for durability and resistance to environmental conditions. If you require ropes for training purposes, assess the weight for optimal resistance and workout efficiency. Consulting with suppliers about your needs can also lead to tailored recommendations that suit your business. -

What is the best heavy rope for strength training?

The best heavy rope for strength training typically features a thicker diameter and substantial weight to provide adequate resistance. Ropes made from durable materials like polyester or nylon are recommended for their strength and longevity. For high-intensity interval training, unanchored weighted ropes are effective as they allow for a variety of movements while minimizing joint impact. Evaluate options based on user reviews and product specifications to ensure they align with your training goals. -

What are the minimum order quantities (MOQ) for heavy rope purchases?

Minimum order quantities (MOQ) for heavy ropes can vary significantly by supplier and region. Generally, MOQs range from 100 to 1,000 units, depending on the manufacturer’s production capabilities and the type of rope. For customized orders, MOQs may be higher due to the additional manufacturing processes involved. Always confirm MOQs during the negotiation phase to align your purchasing strategy with your inventory needs. -

What payment terms should I expect when sourcing heavy rope internationally?

Payment terms for international purchases of heavy rope often include options such as letters of credit, advance payments, or net payment terms (e.g., 30, 60, or 90 days). Many suppliers may request a deposit upfront, especially for custom orders. It’s essential to clarify these terms during negotiations to ensure you have a clear understanding of the payment schedule and any potential fees involved in international transactions. -

How can I vet suppliers for heavy rope to ensure quality and reliability?

To vet suppliers, start by researching their reputation through online reviews and industry ratings. Request samples to assess the quality of their heavy ropes firsthand. Additionally, inquire about their production processes, quality assurance protocols, and certifications (such as ISO standards). Establishing a clear line of communication and checking references from other businesses can also help gauge their reliability and service level. -

What are the key quality assurance practices for heavy rope manufacturing?

Key quality assurance practices in heavy rope manufacturing include thorough material inspections, consistent testing for tensile strength, and adherence to industry standards. Manufacturers may implement regular audits of their production processes and employ third-party testing services to verify quality. As a buyer, request documentation of these practices to ensure the ropes you purchase meet your specifications and safety requirements. -

How do logistics and shipping affect the cost of heavy rope procurement?

Logistics and shipping can significantly impact the overall cost of heavy rope procurement. Factors such as distance, shipping method (air freight vs. sea freight), and associated tariffs or duties can influence pricing. It’s crucial to discuss shipping options with your supplier and consider using a freight forwarder to optimize costs and ensure timely delivery. Understanding these logistics can help you budget more accurately for your procurement. -

What customization options are available for heavy ropes?

Customization options for heavy ropes often include variations in length, diameter, weight, and material. Some suppliers may also offer branding options, such as custom colors or printed logos. Discuss your specific requirements with potential suppliers to explore available options and any associated costs. Customization can enhance the functionality of the ropes for your particular applications, making them more suited to your business needs.

Top 6 Heavy Rope Manufacturers & Suppliers List

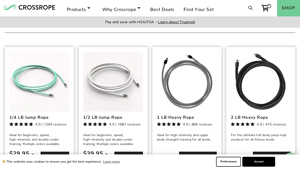

1. Hyperwear – Hyper Rope® Weighted Battle Ropes

Domain: hyperwear.com

Registered: 2003 (22 years)

Introduction: Hyper Rope® Weighted Battle Ropes: Sale price starting from $254.99 (Regular price $299.99). Features a heavy-weighted metal core for efficient training in smaller spaces. Low-impact design reduces torque on shoulder joints, suitable for diverse training groups. Recognized by Men’s Health as the Best Home Gym Battle Rope and Best Cardio Tool in 2022 and 2023. Benefits include improved cardiovascul…

2. RX Smart Gear – Heavy Cable Jump Ropes

Domain: rxsmartgear.com

Registered: 2010 (15 years)

Introduction: This company, RX Smart Gear – Heavy Cable Jump Ropes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Crossrope – 1/4 LB Jump Rope

Domain: crossrope.com

Registered: 2011 (14 years)

Introduction: [{‘name’: ‘1/4 LB Jump Rope’, ‘reviews’: 1204, ‘description’: ‘Ideal for beginners, speed, high-intensity and double-under training.’, ‘price’: ‘$29.95 – $34.95 USD’}, {‘name’: ‘1/2 LB Jump Rope’, ‘reviews’: 1081, ‘description’: ‘Ideal for beginners, speed, high-intensity and double-under training.’, ‘price’: ‘$39.95 – $44.95 USD’}, {‘name’: ‘1 LB Heavy Rope’, ‘reviews’: 866, ‘description’: ‘Ideal…

4. Picsil – Gigas Heavy Rope

Domain: us.picsilsport.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “Gigas Heavy Rope”, “weight”: “1kg”, “price”: “$94.95”, “discounted_price”: “$75.96”, “savings”: “$18.99”, “description”: “Weighted jump rope designed for Cross Training, helping to develop muscle while jumping rope.”, “cable_thickness”: “5mm”, “interchangeable_cables”: [“3mm”, “5mm”, “7mm”], “handle_weight”: “450 grams”, “cable_weight”: “100 grams”, “handle_length”: “145cm”, “mat…

5. IRON COMPANY – Heavy Ropes

Domain: ironcompany.com

Registered: 1999 (26 years)

Introduction: This company, IRON COMPANY – Heavy Ropes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. GetRXD – Heavy Jump Rope ROPEHVY

Domain: getrxd.com

Registered: 2011 (14 years)

Introduction: Heavy Jump Rope SKU ROPEHVY, Price: $60.00, Length: 10′, Diameter: 1.5″, Weight: 7 lbs, Features: Protective jacket and shrink-wrapped handles, Designed for strength gains at the wrist and forearms, Suitable for advanced jumpers (double-unders, triple-unders), Reinforced point of contact at the rope’s center.

Strategic Sourcing Conclusion and Outlook for heavy rope

What Are the Key Takeaways for B2B Buyers of Heavy Rope?

In today’s competitive landscape, strategic sourcing of heavy rope can significantly enhance operational efficiency and product quality. Buyers must prioritize suppliers who offer innovative, durable products tailored to specific applications, such as battle ropes for fitness or heavy-duty ropes for industrial uses. Establishing long-term relationships with reliable manufacturers not only ensures consistent supply but also fosters collaboration in product development and customization.

How Can Strategic Sourcing Enhance Your Supply Chain?

Investing in strategic sourcing practices enables businesses to mitigate risks, optimize costs, and improve procurement processes. By leveraging data analytics and market intelligence, companies can identify the best suppliers and negotiate favorable terms that align with their operational needs. Additionally, understanding regional market dynamics, especially in diverse regions like Africa, South America, the Middle East, and Europe, can provide a competitive edge.

What’s Next for International B2B Buyers?

As the demand for heavy rope products continues to grow, now is the time for international buyers to reevaluate their sourcing strategies. Embrace innovation and quality by seeking suppliers who are committed to sustainability and performance. By doing so, you position your business for success in an evolving marketplace. Engage with your suppliers today to explore the latest advancements in heavy rope technology, ensuring your operations remain at the forefront of industry standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.