Drum Of Oil: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for drum of oil

In the dynamic landscape of global commerce, sourcing high-quality drums of oil can pose significant challenges for B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. The complexities of supply chains, varying quality standards, and fluctuating prices can make it difficult to make informed purchasing decisions. This guide aims to simplify the process of navigating the global market for drums of oil, providing a comprehensive overview of types, applications, and best practices in supplier vetting.

From understanding the different grades and formulations of motor oil available in 55-gallon drums to recognizing the specific needs of your industry—whether automotive, industrial, or agricultural—this resource will empower buyers with the knowledge necessary to select the right products. We will delve into key factors influencing pricing, strategies for negotiating bulk purchases, and the importance of compliance with local regulations, ensuring your operations remain efficient and cost-effective.

By equipping international B2B buyers with actionable insights and expert guidance, this guide aims to enhance your purchasing strategy, allowing you to confidently engage with suppliers and optimize your procurement processes. Whether you are based in Brazil, Germany, or beyond, understanding these nuances will not only streamline your operations but also enhance your competitive edge in the market.

Understanding drum of oil Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Motor Oil | Mineral-based, multi-grade viscosity, cost-effective | Automotive repair shops, fleet services | Pros: Lower cost, widely available. Cons: Less protection than synthetic oils. |

| Synthetic Blend Motor Oil | Combination of synthetic and conventional oils, enhanced performance | High-performance vehicles, commercial fleets | Pros: Improved fuel economy, better protection. Cons: Higher price point than conventional. |

| Full Synthetic Motor Oil | Fully synthetic formulation, superior lubrication and longevity | Premium automotive service, industrial machinery | Pros: Excellent thermal stability, longer oil change intervals. Cons: Higher upfront cost. |

| Heavy Duty Motor Oil | Designed for commercial vehicles, high viscosity for extreme conditions | Trucking companies, construction equipment | Pros: Enhanced protection under load, longer engine life. Cons: May be overkill for light vehicles. |

| Specialty Motor Oil | Formulated for specific applications (e.g., racing, high mileage) | Performance tuning, specialized machinery | Pros: Tailored performance benefits. Cons: Limited availability and higher costs. |

What Are the Characteristics of Conventional Motor Oil?

Conventional motor oil is derived from crude oil and is the most traditional type of engine lubricant. It typically comes in multi-grade formulations, such as 10W-30 or 15W-40, which provide sufficient protection for a wide range of temperatures. B2B buyers in automotive repair shops or fleet services often prefer conventional oil for its cost-effectiveness and widespread availability. However, it may not offer the same level of protection as synthetic oils, making it less suitable for high-performance engines.

How Does Synthetic Blend Motor Oil Differ from Other Types?

Synthetic blend motor oil combines both synthetic and conventional oils to enhance performance while maintaining affordability. This type is particularly beneficial for businesses operating high-performance vehicles or commercial fleets that require better fuel efficiency and engine protection. The key consideration for B2B buyers is the balance between cost and performance; while it is more expensive than conventional oil, its benefits often justify the price for those needing improved engine performance.

Why Choose Full Synthetic Motor Oil for Your Business?

Full synthetic motor oil is engineered for superior lubrication and longevity, making it ideal for premium automotive services and industrial machinery. Its advanced formulation provides excellent thermal stability and reduces engine wear over time, allowing for extended oil change intervals. B2B buyers should consider the initial higher investment as a long-term cost-saving measure due to reduced maintenance needs and better engine protection.

What Makes Heavy Duty Motor Oil Essential for Certain Applications?

Heavy duty motor oil is specifically designed for commercial vehicles and equipment that operate under extreme conditions, such as trucking companies and construction sites. With its high viscosity and enhanced protective properties, it helps ensure engine longevity and performance under heavy loads. While it offers significant advantages for heavy machinery, B2B buyers should assess whether such robust oil is necessary for their lighter vehicles to avoid unnecessary costs.

When Should Specialty Motor Oil Be Considered?

Specialty motor oils are formulated for specific applications, such as racing engines or vehicles with high mileage. These oils provide tailored performance benefits that can significantly enhance engine efficiency and longevity. B2B buyers in niche markets, such as automotive performance tuning or specialized machinery, should consider these oils for their unique needs. However, availability may be limited, and costs can be higher, necessitating careful evaluation of the potential return on investment.

Key Industrial Applications of drum of oil

| Industry/Sector | Specific Application of drum of oil | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Bulk motor oil supply for repair shops | Ensures continuous operations and reduces downtime | Quality certifications (API, SAE), delivery logistics, local regulations |

| Manufacturing | Lubricants for machinery and equipment maintenance | Enhances equipment lifespan and operational efficiency | Compatibility with machinery, viscosity requirements, bulk pricing |

| Transportation & Logistics | Fuel and engine oils for fleet vehicles | Improves fuel efficiency and reduces maintenance costs | Sourcing from reliable suppliers, international shipping regulations |

| Agriculture | Engine oils for tractors and heavy equipment | Optimizes performance and minimizes agricultural downtime | Availability of specific formulations, environmental compliance |

| Energy & Mining | Lubricants for drilling and extraction equipment | Increases productivity and reduces equipment failures | Supplier stability, bulk order capabilities, and quality assurance |

How is Drum Oil Utilized in the Automotive Sector?

In the automotive industry, 55-gallon drums of motor oil are essential for repair shops and dealerships. These establishments rely on bulk oil supplies to ensure they can service vehicles efficiently without frequent restocking. The use of high-quality motor oils, certified by organizations like API or SAE, guarantees optimal engine performance and longevity. For international buyers, particularly in regions like Africa and South America, understanding local regulations regarding oil specifications is crucial to ensure compliance and avoid penalties.

What Role Does Drum Oil Play in Manufacturing?

In manufacturing, drum oil serves as a critical lubricant for machinery, ensuring smooth operation and preventing wear and tear. By using bulk lubricants, manufacturers can maintain their equipment more effectively, which enhances overall productivity and reduces downtime. Buyers in this sector should prioritize sourcing oils that meet the specific viscosity and compatibility requirements of their machinery, as well as considering the supplier’s ability to provide consistent quality and timely delivery.

How is Drum Oil Essential for Transportation and Logistics?

The transportation and logistics industry uses drum oil primarily for fueling and maintaining fleet vehicles. Bulk engine oils help improve fuel efficiency and reduce overall maintenance costs, which is vital for companies looking to optimize their operational budgets. International buyers must consider the logistics of sourcing these oils, including shipping regulations and potential tariffs, to ensure a smooth procurement process.

Why is Drum Oil Important for Agriculture?

In agriculture, drum oil is vital for the maintenance of tractors and other heavy equipment. Using the right engine oils helps optimize performance, ensuring that machinery operates efficiently during critical planting and harvesting periods. Buyers should focus on sourcing oils specifically formulated for agricultural applications, considering factors such as environmental impact and compliance with local agricultural regulations.

Illustrative image related to drum of oil

How Does Drum Oil Benefit the Energy and Mining Industries?

For the energy and mining sectors, drum oil is indispensable for lubricating drilling and extraction equipment. These environments demand high-performance lubricants that can withstand extreme conditions while minimizing equipment failures. Buyers in these sectors should prioritize suppliers who can guarantee the quality and reliability of their products, as well as those who have the capacity to meet bulk order requirements, ensuring uninterrupted operations in challenging environments.

3 Common User Pain Points for ‘drum of oil’ & Their Solutions

Scenario 1: Inventory Management Challenges with Drum Oil Purchases

The Problem: For B2B buyers, managing inventory levels of drum oil can be a significant challenge, especially for businesses operating in regions with fluctuating demand, such as Africa and South America. Buyers may find themselves either overstocked—leading to increased storage costs and potential product degradation—or understocked, resulting in production delays and dissatisfied customers. The unpredictability of oil prices can further complicate inventory planning, making it difficult for businesses to maintain a cost-effective supply chain.

The Solution: To effectively manage inventory, B2B buyers should implement a just-in-time (JIT) inventory strategy. This approach involves closely monitoring oil consumption patterns and aligning purchases with production schedules. Utilizing inventory management software can provide real-time analytics, helping businesses predict demand more accurately. Additionally, establishing a strong relationship with reliable suppliers can ensure timely deliveries, allowing for smaller, more frequent orders that reduce storage costs. By leveraging data analytics and supplier partnerships, businesses can maintain optimal inventory levels of drum oil without compromising on quality or availability.

Scenario 2: Quality Assurance Concerns with Bulk Oil Purchases

The Problem: Quality assurance is a significant concern when purchasing drum oil, especially for international buyers who may face challenges in verifying product quality before making bulk purchases. Inconsistent oil quality can lead to engine failures, increased maintenance costs, and reputational damage for businesses relying on high-performance machinery. Buyers may struggle with the lack of transparency regarding the oil’s formulation and certifications, leading to uncertainty about whether the product meets industry standards.

The Solution: To mitigate quality assurance issues, B2B buyers should prioritize sourcing oil from reputable manufacturers that provide detailed product specifications and certifications. Conducting thorough research into the supplier’s reputation and reviewing third-party quality test results can help in making informed decisions. Establishing a quality control protocol that includes sampling and testing shipments upon arrival can further ensure that the oil meets the required standards. Additionally, buyers should consider establishing long-term contracts with suppliers that guarantee product quality and consistency, fostering a partnership based on trust and reliability.

Scenario 3: Compliance and Regulatory Challenges in Drum Oil Usage

The Problem: B2B buyers often face complex regulatory requirements concerning the storage and disposal of drum oil, particularly in regions like Europe and the Middle East where environmental regulations are stringent. Non-compliance can result in hefty fines, legal complications, and damage to the company’s reputation. Understanding the local regulations regarding oil storage, spill prevention, and disposal can be daunting, especially for companies operating across multiple jurisdictions.

The Solution: To navigate compliance challenges, buyers should invest in comprehensive training programs for staff that cover local regulations and best practices in oil handling and disposal. Collaborating with environmental consultants can provide insights into the latest regulations and help establish compliant operational procedures. Additionally, implementing an environmentally friendly waste management system for used oil disposal can enhance compliance and demonstrate corporate responsibility. Regular audits and updates to the compliance strategy will ensure that the business remains aligned with evolving regulations, minimizing risks associated with non-compliance. By prioritizing compliance, companies can protect their interests while contributing positively to environmental sustainability.

Strategic Material Selection Guide for drum of oil

What Are the Common Materials Used for Drums of Oil?

When selecting materials for drums of oil, several factors come into play, including the chemical compatibility with the oil, durability, cost-effectiveness, and compliance with international standards. Below, we analyze four common materials used in the manufacturing of oil drums: steel, plastic, aluminum, and composite materials.

How Does Steel Perform as a Material for Drums of Oil?

Steel is the most traditional material for oil drums, known for its strength and durability. It typically has a high temperature and pressure rating, making it suitable for various oil types. Steel drums are resistant to punctures and physical damage, which is crucial during transport and storage.

Pros: Steel drums offer excellent durability and can withstand harsh environmental conditions. They are also recyclable, which adds to their sustainability profile.

Cons: The primary disadvantage of steel is its susceptibility to corrosion, especially when exposed to moisture or certain chemicals. Additionally, steel drums can be heavier than alternatives, which may increase shipping costs.

International Considerations: Buyers should ensure that the steel used meets relevant standards such as ASTM or DIN, particularly for transportation in regions like Africa or South America, where environmental conditions may vary significantly.

What Are the Advantages of Plastic Drums for Oil Storage?

Plastic drums, often made from high-density polyethylene (HDPE), have become increasingly popular due to their lightweight nature and resistance to corrosion. They are particularly effective for storing oils that may react with metal.

Pros: The lightweight nature of plastic drums reduces shipping costs, and they are resistant to rust and corrosion. They also have a lower manufacturing cost compared to steel.

Cons: However, plastic drums may not offer the same level of durability as steel, making them more prone to punctures and physical damage. Their temperature and pressure ratings are also generally lower.

Illustrative image related to drum of oil

International Considerations: Compliance with international standards like JIS for plastic materials is essential. Buyers in Europe and the Middle East should be aware of regulations regarding plastic waste and recycling.

Why Choose Aluminum Drums for Oil?

Aluminum drums are lightweight and resistant to corrosion, making them ideal for specific applications, especially in industries where weight is a critical factor. They also have a good temperature resistance and can handle a variety of oils.

Pros: The primary advantage of aluminum is its resistance to corrosion and lightweight properties, which facilitate easier handling and transport.

Illustrative image related to drum of oil

Cons: However, aluminum drums can be more expensive than both steel and plastic options, and they may not be as durable under heavy physical stress.

International Considerations: Buyers should ensure that aluminum drums comply with standards such as ASTM B209 for aluminum alloys. This is particularly important in regions like Germany, where stringent quality standards are enforced.

What Role Do Composite Materials Play in Drum Manufacturing?

Composite materials, which combine different substances to enhance performance, are increasingly used in oil drum manufacturing. These materials can offer a balance of durability, weight, and chemical resistance.

Pros: Composite drums are often lighter than steel and offer excellent chemical resistance, making them suitable for a variety of oils and fluids.

Cons: The main limitation is that composite materials can be more expensive to manufacture, which may affect the overall cost of the drums.

International Considerations: Compliance with international standards is crucial for composite materials, particularly in regions with strict environmental regulations. Buyers should verify that the materials meet relevant safety and performance standards.

Summary Table of Material Selection for Drums of Oil

| Material | Typical Use Case for drum of oil | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General oil storage | Excellent durability and strength | Susceptible to corrosion | Medium |

| Plastic | Chemical-resistant applications | Lightweight and corrosion-resistant | Less durable than steel | Low |

| Aluminum | Lightweight transport | Corrosion-resistant and lightweight | Higher cost and less durable | High |

| Composite | Specialized chemical storage | Excellent chemical resistance | Higher manufacturing costs | High |

This strategic material selection guide provides B2B buyers with essential insights into the various materials available for drums of oil, helping them make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for drum of oil

What Are the Main Stages in the Manufacturing Process of Oil Drums?

Manufacturing oil drums involves a series of meticulous processes designed to ensure durability and compliance with industry standards. The main stages typically include material preparation, forming, assembly, and finishing.

Illustrative image related to drum of oil

-

Material Preparation: The production begins with the selection of high-quality steel or plastic, which is crucial for the drum’s integrity. For metal drums, cold-rolled steel is commonly used, while high-density polyethylene (HDPE) is preferred for plastic variants. The materials undergo rigorous testing for tensile strength and corrosion resistance before processing.

-

Forming: This stage involves shaping the material into drum forms. For steel drums, techniques such as deep drawing or spinning are employed. In deep drawing, sheets of steel are pressed into a mold to create the drum’s shape. For plastic drums, the blow-molding process is utilized, where heated plastic is inflated into a mold.

-

Assembly: After forming, the components of the drum are assembled. This includes attaching the top and bottom ends to the cylindrical body. For metal drums, welding or riveting is often used, while plastic drums may utilize heat sealing techniques.

-

Finishing: The final stage includes surface treatment and coating. For steel drums, protective coatings are applied to prevent rust and enhance durability. This may involve galvanization or the application of an epoxy resin. Plastic drums are often treated with UV stabilizers to prevent degradation from sunlight exposure.

Which Key Techniques Are Essential in the Manufacturing of Oil Drums?

Several specialized techniques are vital for ensuring the quality and functionality of oil drums. These include:

-

Welding and Riveting: Essential for ensuring that the seams of metal drums are airtight and leak-proof. High-quality welding minimizes the risk of failure under pressure or during transportation.

-

Blow Molding: This technique allows for the production of seamless plastic drums, enhancing their strength and reducing the risk of leaks.

-

Coating Technologies: Advanced coatings not only provide protection from physical damage but also improve chemical resistance. This is especially critical for drums intended to hold various types of oil and lubricants.

How Is Quality Assurance Integrated into Oil Drum Manufacturing?

Quality assurance (QA) is a critical component in the manufacturing of oil drums, ensuring that products meet both international standards and specific customer requirements.

-

International Standards Compliance: Manufacturers often adhere to ISO 9001, which focuses on maintaining quality management systems. Additionally, industry-specific standards such as those from the American Petroleum Institute (API) and the European Union’s CE marking are crucial for ensuring that oil drums are safe for use and environmentally compliant.

-

Quality Control Checkpoints: Various checkpoints are established throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet the required specifications.

-

In-Process Quality Control (IPQC): Continuous monitoring during production helps identify defects early, allowing for immediate corrective actions.

-

Final Quality Control (FQC): This final inspection assesses the completed drums for dimensional accuracy, structural integrity, and surface finish.

What Common Testing Methods Are Used in Oil Drum Quality Assurance?

Quality testing methods are essential for verifying that oil drums can withstand the rigors of transportation and use. Common methods include:

-

Hydrostatic Testing: This method involves filling the drum with water and pressurizing it to check for leaks. It simulates the conditions the drum will face when filled with oil.

-

Drop Testing: Drums are dropped from various heights to ensure they can endure impacts without structural failure.

-

Chemical Resistance Testing: This assesses how the drum material reacts with different oils and chemicals, ensuring that the contents do not compromise the drum’s integrity.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to ensure that their suppliers maintain rigorous quality control standards. Here are some strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality assurance practices directly. This can help identify areas for improvement and ensure compliance with international standards.

-

Quality Assurance Reports: Requesting detailed reports on quality testing and inspections can provide insights into the supplier’s commitment to maintaining high standards. Buyers should look for documentation related to IQC, IPQC, and FQC.

-

Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased evaluation of the supplier’s quality control measures. This is particularly useful for international transactions, where buyers may not have the capacity to perform on-site inspections.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of several nuances in quality control and certification:

-

Regulatory Compliance: Different countries have varying regulations regarding the import and use of oil drums. Buyers must ensure that their suppliers comply with both local and international regulations to avoid legal complications.

-

Cultural and Logistical Considerations: Understanding cultural differences can aid in communication with suppliers. Additionally, logistical factors, such as shipping and customs clearance, can impact the quality assurance process. Buyers should account for these when planning their procurement strategies.

-

Adaptation to Local Standards: While international certifications like ISO 9001 are widely recognized, some regions may have specific local standards that also need to be adhered to. Buyers should verify that their suppliers are compliant with these local standards to ensure smooth operations.

In conclusion, understanding the manufacturing processes and quality assurance mechanisms in the production of oil drums is crucial for B2B buyers. By focusing on these aspects, buyers can make informed decisions that align with their operational needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘drum of oil’

Introduction

In today’s competitive market, sourcing high-quality oil in bulk, such as 55-gallon drums, requires a strategic approach. This checklist serves as a practical guide for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. Following these steps will help ensure that you make informed decisions, optimize your procurement process, and secure reliable suppliers.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of any successful procurement strategy. Determine the type of oil needed, including viscosity grades (e.g., 5W-30, 10W-40), and whether you require synthetic or conventional options.

- Consider the applications: Identify the machinery or vehicles that will use the oil to ensure compatibility.

- Regulatory compliance: Check for any local or international standards that the oil must meet, such as API certifications.

Step 2: Research Reputable Suppliers

Conduct thorough research to identify potential suppliers who specialize in the type of oil you require. Look for companies with a strong reputation in the industry and positive customer reviews.

Illustrative image related to drum of oil

- Check their history: Consider how long they have been in business and their experience in international trade.

- Review their product range: Ensure they offer a variety of options that meet your specifications.

Step 3: Evaluate Supplier Certifications

Before making a purchase, verify that your chosen suppliers hold the necessary certifications. This step is crucial for ensuring product quality and compliance with industry standards.

- Look for ISO certifications: These indicate that the supplier adheres to international quality management standards.

- API certifications: Ensure that the oils meet the American Petroleum Institute’s standards, which can signify quality and reliability.

Step 4: Request Samples for Testing

Always request samples before finalizing any bulk order. Testing samples allows you to assess the oil’s performance and compatibility with your equipment.

- Conduct performance tests: Analyze the samples under conditions similar to those in your operational environment.

- Check for stability and cleanliness: Ensure that the oil does not contain contaminants that could harm your machinery.

Step 5: Negotiate Terms and Pricing

Once you have selected a supplier, engage in negotiations to secure favorable terms. This includes pricing, delivery schedules, and payment terms.

- Bulk pricing advantages: Leverage your order volume to negotiate discounts.

- Clarify delivery logistics: Ensure the supplier can meet your timeline and discuss any potential shipping costs.

Step 6: Establish a Purchase Agreement

After negotiations, draft a formal purchase agreement that outlines all terms discussed. This document protects both parties and ensures mutual understanding.

- Include quality guarantees: Specify the quality standards expected and any recourse for non-compliance.

- Set clear timelines: Define delivery dates and penalties for delays to hold the supplier accountable.

Step 7: Monitor Supply Chain Performance

After the order is placed, continuously monitor the supplier’s performance. Regular assessments help ensure they consistently meet your requirements.

- Track delivery timelines: Ensure that shipments arrive as scheduled to avoid disruptions in your operations.

- Solicit feedback from users: Gather input from your team regarding the oil’s performance and any issues that arise.

By following this checklist, B2B buyers can streamline their sourcing process for drum oil, ensuring they partner with reliable suppliers and secure high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for drum of oil Sourcing

What Are the Key Cost Components in Drum of Oil Sourcing?

When evaluating the cost structure for sourcing drums of oil, several key components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The primary cost driver is the type of oil being sourced, whether conventional, synthetic, or blended. High-quality base oils and additives significantly influence the price. For instance, fully synthetic oils often come at a premium compared to conventional oils.

-

Labor: Labor costs encompass the workforce involved in production, packaging, and quality assurance. Skilled labor may command higher wages, particularly in regions with stringent regulatory standards for oil production.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, equipment maintenance, and facility management. Efficient production processes can help reduce these costs.

-

Tooling: The initial investment in machinery and tools for production can be substantial. Suppliers may pass on these costs to buyers, especially if they require specialized equipment for custom oil formulations.

-

Quality Control (QC): Ensuring that the oil meets industry standards and certifications (e.g., API, SAE) incurs additional costs. Regular testing and compliance checks are vital to maintaining product integrity.

-

Logistics: Transportation and storage costs can vary widely depending on the geographic location of the supplier and the buyer. International shipping, especially for bulk orders, requires careful consideration of freight costs and potential customs duties.

-

Margin: Finally, suppliers will add a margin to cover their operational costs and profit. The margin can vary based on market competition, supplier reputation, and product demand.

How Do Price Influencers Impact the Sourcing of Drum of Oil?

Several factors can influence the pricing of oil drums in the B2B market. Understanding these influencers can help buyers make more informed purchasing decisions.

-

Volume/MOQ: Suppliers often provide better pricing for larger orders due to economies of scale. Buyers should negotiate minimum order quantities (MOQ) to benefit from lower unit prices.

-

Specifications and Customization: Custom formulations or specific oil grades may come with additional costs. Buyers should clearly define their requirements to avoid unexpected price hikes.

-

Materials: The choice between different oil types (e.g., synthetic vs. conventional) will directly impact pricing. Buyers should assess their performance needs against budget constraints.

-

Quality and Certifications: Oils that meet higher quality standards or possess additional certifications typically command higher prices. Buyers should weigh the importance of these factors against their operational requirements.

-

Supplier Factors: The supplier’s reputation, location, and reliability can influence pricing. Established suppliers may charge more, but they often provide assurances regarding quality and delivery.

-

Incoterms: The agreed terms of trade (e.g., FOB, CIF) can affect the total cost of ownership. Buyers should understand the implications of these terms on shipping costs and risk management.

What Are the Best Buyer Tips for Cost-Efficiency in Drum of Oil Sourcing?

For international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, several strategic tips can enhance cost-efficiency.

-

Negotiate Effectively: Leverage your purchasing power by negotiating pricing and terms with suppliers. Demonstrating a potential for repeat business can lead to better deals.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Factor in logistics, storage, and potential downtime costs associated with inferior products. This holistic view can lead to more sustainable purchasing decisions.

-

Understand Pricing Nuances: Be aware of regional market dynamics. Prices can fluctuate based on local demand, availability, and geopolitical factors. Keeping abreast of these trends can inform better timing for purchases.

-

Build Relationships: Establishing strong relationships with suppliers can lead to improved service, better pricing, and priority during high-demand periods. Regular communication fosters trust and collaboration.

-

Stay Informed About Regulatory Changes: Compliance with local and international regulations can impact pricing and availability. Buyers should stay updated to ensure they are sourcing compliant products.

In conclusion, a comprehensive understanding of cost components, price influencers, and strategic negotiation tactics can empower B2B buyers in their sourcing efforts for drums of oil, ensuring they make informed and cost-effective decisions.

Alternatives Analysis: Comparing drum of oil With Other Solutions

Introduction to Alternative Solutions for Oil Storage and Usage

In the industrial sector, the choice of oil storage and usage solutions is critical for operational efficiency and cost management. While the traditional drum of oil remains a popular choice, alternative solutions have emerged that can offer unique benefits. This section examines these alternatives, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table of Oil Solutions

| Comparison Aspect | Drum Of Oil | Bulk Oil Storage Systems | Oil Blending Systems |

|---|---|---|---|

| Performance | Reliable for various applications; provides consistent viscosity and quality. | Offers high capacity and can cater to large-scale operations efficiently. | Enables customization of oil formulations based on specific needs. |

| Cost | Moderate initial investment; cost-effective for small to medium operations. | Higher upfront costs due to installation and equipment; lower per-liter costs over time. | Variable costs depending on the formulation; can be cost-effective for specialized needs. |

| Ease of Implementation | Simple setup; widely available; familiar to most users. | Requires infrastructure investment and training for staff. | Complex implementation; requires expertise for blending processes. |

| Maintenance | Low maintenance; periodic inspections needed. | Requires regular maintenance of storage tanks and monitoring systems. | Regular calibration and maintenance are necessary to ensure blending accuracy. |

| Best Use Case | Ideal for small to medium businesses, automotive shops, and repair facilities. | Best for large-scale industrial operations, manufacturing plants, and fleet services. | Suitable for companies needing custom oil formulations for specific machinery or applications. |

Detailed Breakdown of Alternatives

Bulk Oil Storage Systems

Bulk oil storage systems allow businesses to store large quantities of oil in tanks rather than drums. This system is particularly advantageous for large-scale operations that require frequent oil replenishment. The primary benefit is reduced costs per liter and the ability to quickly refill machinery, minimizing downtime. However, the initial investment in infrastructure can be significant, and companies must ensure they have the necessary training for staff to handle and monitor the system efficiently.

Oil Blending Systems

Oil blending systems provide the flexibility to create customized oil formulations tailored to specific operational needs. This method is particularly beneficial for organizations that operate specialized machinery requiring unique lubrication properties. While the blending process can lead to significant cost savings over time, it demands a higher level of expertise and regular maintenance to ensure precision in the blending process. Companies need to weigh the benefits of customization against the complexity and costs associated with implementing such systems.

Conclusion: How to Choose the Right Oil Solution

Selecting the right oil solution depends on various factors, including the scale of operations, specific lubrication needs, and budget constraints. For small to medium-sized businesses, a drum of oil is often sufficient due to its low initial cost and ease of use. In contrast, larger operations may benefit from bulk oil storage systems that offer greater efficiency and lower long-term costs. Meanwhile, companies with specialized lubrication requirements may find oil blending systems to be the best fit, despite their higher complexity and initial investment. By carefully assessing these alternatives, B2B buyers can make informed decisions that align with their operational goals and financial capabilities.

Essential Technical Properties and Trade Terminology for drum of oil

What are the Key Technical Properties of a Drum of Oil?

Understanding the technical specifications of oil drums is crucial for B2B buyers to ensure compatibility with operational needs and compliance with industry standards. Here are essential properties to consider:

-

Material Grade

Oil drums are typically made from high-quality steel or high-density polyethylene (HDPE). The material grade affects durability, corrosion resistance, and the drum’s ability to withstand temperature fluctuations. Steel drums are generally preferred for heavy-duty applications due to their strength, while HDPE drums are often lighter and resistant to certain chemicals, making them suitable for specific oil types. -

Capacity

The capacity of oil drums usually ranges from 30 to 55 gallons (approximately 114 to 208 liters). Knowing the drum capacity helps businesses estimate storage needs and determine how many drums are required for bulk orders. This is particularly important for manufacturers and distributors to streamline logistics and inventory management. -

Viscosity Grade

Viscosity grades, such as 5W-30 or 10W-40, indicate the oil’s thickness and flow characteristics at different temperatures. This property is vital for ensuring that the oil performs optimally in various climates and operating conditions. Buyers should select the viscosity that matches their machinery specifications to enhance performance and reduce wear. -

API Certification

The American Petroleum Institute (API) provides certification that oil meets certain performance standards. An API certification, such as API SN or GF-6, is crucial for B2B buyers to validate the quality and reliability of the oil. This certification helps in meeting regulatory requirements and assures end-users of the oil’s performance capabilities. -

Shelf Life

Understanding the shelf life of oil is important for inventory management. Most motor oils have a shelf life of around 2-5 years when stored properly. Buyers should consider this property to avoid wastage and ensure they are using fresh products, especially in industries where oil quality directly affects operational efficiency. -

Packaging Type

Drums may come with different types of closures, such as screw caps or bungs. The type of packaging affects ease of use and the ability to maintain oil quality. For instance, bungs are designed to minimize contamination and leakage, which is critical for maintaining the integrity of the oil.

What are Common Trade Terms in the Oil Industry?

Navigating the oil industry involves understanding specific jargon and trade terms that facilitate smoother transactions and communications. Here are key terms to be familiar with:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the oil industry, it indicates that the oil meets the specifications required by the original equipment manufacturer of vehicles or machinery. This is vital for buyers looking to maintain warranties and ensure compatibility. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchases effectively and manage costs, particularly when dealing with bulk orders of oil drums. This term is crucial for cash flow management and inventory control. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for a specific quantity of products. B2B buyers use RFQs to compare offers from different vendors and negotiate better deals. This is a common practice in procurement processes, especially for bulk purchases. -

Incoterms

International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who is responsible for shipping costs and risk at various points in the supply chain. Understanding Incoterms is essential for managing logistics and reducing unexpected costs. -

Bulk Oil Delivery

This term refers to the transportation of oil in large quantities, often via tanker trucks or ships. For B2B buyers, knowing about bulk delivery options can lead to cost savings and efficiency in supply chain management. It is also crucial for planning storage and handling. -

Lead Time

Lead time is the time taken from placing an order to the delivery of the product. Understanding lead times helps businesses manage their supply chain more effectively and ensures that they have the necessary stock on hand when needed, thus minimizing downtime in operations.

By familiarizing yourself with these technical properties and trade terms, you can make more informed purchasing decisions and better navigate the complexities of the oil industry.

Navigating Market Dynamics and Sourcing Trends in the drum of oil Sector

What Are the Current Market Dynamics and Key Trends in the Drum of Oil Sector?

The drum of oil sector is influenced by various global drivers that shape its market landscape. A significant trend is the increasing demand for bulk purchasing, particularly from medium to large-scale businesses that seek cost-effective solutions. This trend is especially prominent in regions like Africa, South America, and the Middle East, where economic development is driving a growing vehicle fleet and industrial machinery use. Consequently, international buyers are prioritizing suppliers who can offer competitive pricing and reliable logistics.

Technological advancements are also reshaping the sourcing landscape. The rise of e-commerce platforms and digital supply chain management tools enables buyers to compare prices, track shipments, and manage inventory more efficiently. In Europe, for instance, businesses are adopting advanced analytics to forecast demand, allowing them to optimize orders and reduce excess inventory. Moreover, sustainability initiatives are pushing companies to seek suppliers who can demonstrate environmentally responsible practices, adding a new layer of complexity to sourcing decisions.

Emerging markets are increasingly becoming focal points for investment in the oil sector. Countries like Brazil and Nigeria are ramping up their oil production capabilities, creating opportunities for international partnerships. This shift not only provides access to local resources but also requires understanding regional regulations and compliance measures. B2B buyers must stay informed about these dynamics to navigate the complexities of sourcing in an evolving global market.

How Is Sustainability Impacting the Sourcing of Drums of Oil?

Sustainability is no longer a peripheral concern but a central tenet of sourcing strategies in the drum of oil sector. With growing awareness of environmental issues, buyers are increasingly scrutinizing the ecological impact of their purchases. This includes the carbon footprint of production and transportation, as well as the lifecycle of the products themselves. Companies are now expected to adopt sustainable practices, such as using biodegradable or recyclable materials in their packaging.

The importance of ethical supply chains has never been greater. Buyers are looking for suppliers who can provide transparency regarding their sourcing practices. This includes adherence to international labor standards and responsible sourcing of raw materials. Certifications such as ISO 14001 for environmental management and FSC (Forest Stewardship Council) for sustainable wood products are becoming critical factors in supplier selection.

Moreover, the push for “green” certifications is reshaping the product offerings in the market. Brands that can demonstrate compliance with sustainability standards or offer eco-friendly oil formulations are gaining a competitive edge. As such, B2B buyers should prioritize suppliers who are committed to ethical sourcing and sustainable practices to align with their corporate social responsibility goals.

Illustrative image related to drum of oil

What Is the Historical Context of the Drum of Oil Sector for B2B Buyers?

The drum of oil sector has evolved significantly over the decades, adapting to both technological advancements and changing market demands. Initially, the industry was characterized by small-scale production and localized distribution. However, as global trade expanded, the need for standardized oil products in bulk became evident, leading to the widespread adoption of 55-gallon drums.

Over time, the introduction of synthetic oils and advanced formulations has transformed product offerings, allowing for better performance and longer intervals between oil changes. This evolution reflects a broader trend toward specialization and customization in the oil market, catering to diverse industrial needs. As businesses increasingly prioritize efficiency and sustainability, understanding this historical context provides valuable insights for B2B buyers navigating the current landscape.

In conclusion, recognizing market dynamics, prioritizing sustainability, and understanding historical trends are essential for B2B buyers in the drum of oil sector. By leveraging these insights, companies can make informed sourcing decisions that align with their operational goals and environmental responsibilities.

Frequently Asked Questions (FAQs) for B2B Buyers of drum of oil

-

How do I ensure the quality of oil in a 55-gallon drum?

To ensure the quality of oil in a 55-gallon drum, it’s essential to partner with reputable suppliers who provide certification for their products, such as API (American Petroleum Institute) and ILSAC (International Lubricant Standardization and Approval Committee) standards. Request detailed product specifications, including viscosity ratings and performance data. Additionally, consider conducting third-party quality assessments or audits, especially for bulk purchases, to verify the oil’s composition and performance characteristics before finalizing your order. -

What is the best type of motor oil for heavy-duty vehicles?

For heavy-duty vehicles, the best type of motor oil is typically a full synthetic oil with high viscosity ratings, such as 15W-40 or 5W-40. These oils provide superior protection against wear and tear, especially in extreme conditions. Brands like Shell Rotella T4 or Truegard are recommended for their high-performance capabilities. Always consider the manufacturer’s specifications for the vehicles you are servicing to ensure compatibility and optimal performance. -

What are the payment terms typically offered for bulk oil purchases?

Payment terms for bulk oil purchases can vary widely depending on the supplier and the buyer’s creditworthiness. Common terms include net 30, net 60, or cash in advance. It’s advisable to negotiate terms that suit your cash flow needs, possibly including discounts for early payments or larger orders. Always ensure that payment terms are clearly outlined in the purchase agreement to avoid misunderstandings. -

How can I verify the reliability of an oil supplier?

To verify the reliability of an oil supplier, conduct thorough research including checking their business history, customer reviews, and industry certifications. Request references from other clients, particularly those in similar industries or regions. Engage in direct communication to assess their responsiveness and willingness to provide documentation. Participating in trade fairs or industry expos can also provide insights into the supplier’s reputation and reliability. -

What is the minimum order quantity (MOQ) for purchasing oil in drums?

The minimum order quantity (MOQ) for purchasing oil in drums can differ by supplier, often ranging from one drum to several depending on their inventory policies. Some suppliers may have flexible MOQs for new customers or larger orders. Always clarify the MOQ before placing an order to ensure it aligns with your operational needs and budget. -

Can I customize the oil blend according to my needs?

Yes, many suppliers offer customization options for oil blends to meet specific operational requirements. This can include adjusting the viscosity, adding additives for enhanced performance, or formulating oils for particular climates or machinery. Discuss your needs with the supplier to explore available customization options and any associated costs or minimum order requirements for tailored blends. -

What are the logistics considerations for importing oil?

When importing oil, key logistics considerations include compliance with local regulations, customs duties, and shipping costs. Ensure that all documentation, such as Bill of Lading, Certificates of Origin, and Safety Data Sheets, is in order to facilitate smooth customs clearance. Additionally, consider the mode of transportation (sea or air), as it can significantly impact delivery times and costs. Partnering with a logistics provider experienced in oil transport can help navigate these complexities. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should implement stringent quality assurance measures, including regular testing of oil batches and adherence to industry standards. Expect to receive documentation that outlines their QA processes, including details on testing frequency, methods, and results. Furthermore, inquire about their return and replacement policies in case of quality issues. A transparent QA process demonstrates the supplier’s commitment to delivering reliable products.

Top 8 Drum Of Oil Manufacturers & Suppliers List

1. Kellerheartt – TRUEGARD SYN BLEND 5W30 Motor Oil

Domain: kellerheartt.com

Registered: 2011 (14 years)

Introduction: Motor Oil in 55 Gallon Drums: Brands include Pennzoil and Shell. Free Shipping available. Products include: TRUEGARD SYN BLEND 5W30 Motor Oil – 55 Gallon Drum, TRUEGARD 10W30 SYN BLEND Motor Oil – 55 Gallon Drum, Shell Rotella T4 Triple Protection 15W. Prices range from $589.24 to $1,201.40. All products are API SN/GF certified. Reviews for TRUEGARD 5W30: 4.97/5.0 (29 reviews), TRUEGARD 10W30: 5.0…

2. Safety-Kleen – High-Performance Engine Oils

Domain: store.safety-kleen.com

Registered: 1995 (30 years)

Introduction: Oil Grade Products | High-Performance Engine Oils & Industrial Lubricants | Safety-Kleen

– Product Types: Motor Oils, Driveline Fluids, Hydraulic Fluids, Gear Oils, Greases, Antifreeze, Windshield Fluid, Solvents and Chemistries, Industrial & Lab Chemistries, Bulk Products, Cleaning Products, Spill Control & Containment, Facility Maintenance, Waste Reduction & Recycling.

– Motor Oil Options:

-…

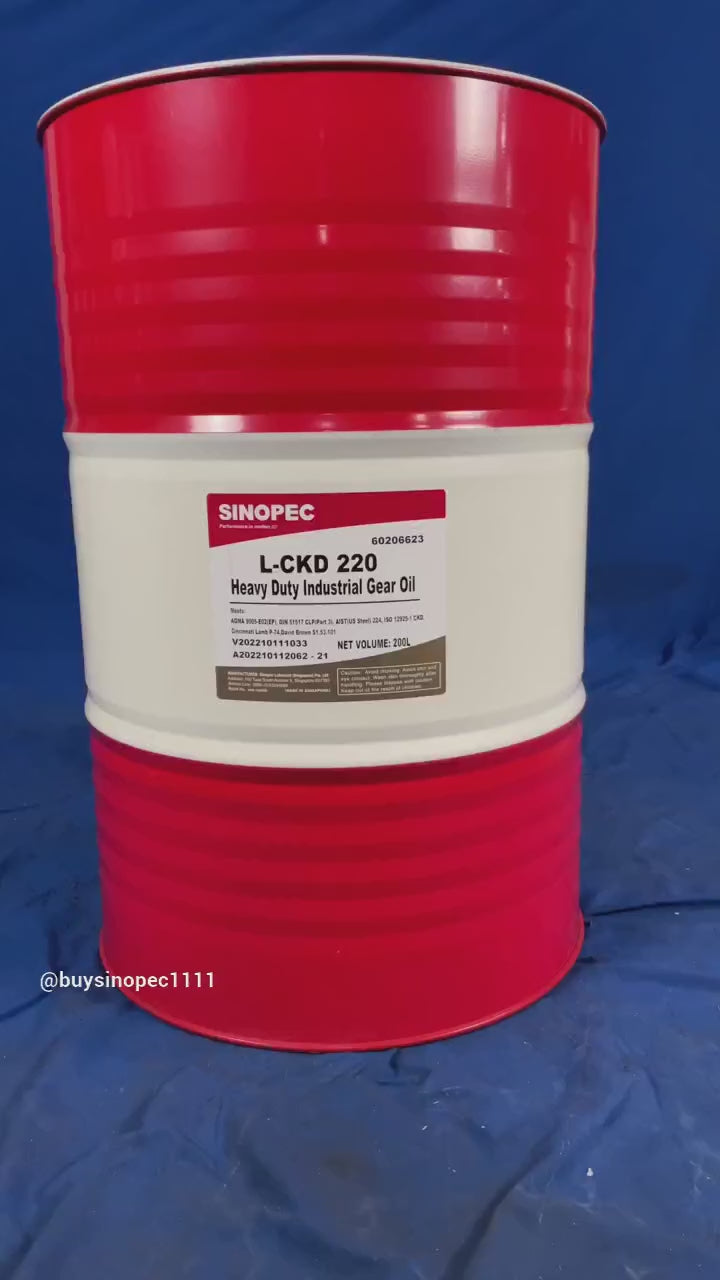

3. Sinopec – Full Synthetic & Synthetic Blend Engine Oils

Domain: buysinopec.com

Registered: 2013 (12 years)

Introduction: Drums available for various oil products including:

– 0W20 Full Synthetic Gasoline Engine Oil – 55 Gallon Drum, Sale price: $799.00

– 0W40 Full Synthetic Gasoline Engine Oil – 55 Gallon Drum, Sale price: $1,299.00

– 10W-30 Synthetic Blend Gasoline Engine Oil – 55 Gallon Drum, Sale price: $549.00

– 10W30 4T Synthetic Motorcycle Oil – 55 Gallon Drum, Sale price: $999.00

– 10W30 Synthetic Diesel Engi…

4. Gulf – Super Duty Engine Oil 40

Domain: avepetroleum.com

Registered: 2015 (10 years)

Introduction: {“product_name”: “Gulf Super Duty Engine Oil 40”, “packaging”: “55 Gallon Drum”, “price_single”: 814.42, “price_4_pack”: 3029.64, “price_8_pack”: 5863.84, “volume”: “55 Gal.”, “availability”: “IN STOCK”, “features”: [“Very good wear protection of valve train components and bearings”, “Oxidation resistance to protect against excessive viscosity increase”, “Suitable for equipment operating in severe…

5. RedLine Tools – Cutting/Machining Oil

Domain: redlinetools.com

Registered: 2008 (17 years)

Introduction: {“Product Type”:”Cutting/Machining Oil”,”Brand”:”RedLine Tools”,”Item Weight”:”9.00 lbs per GL”,”Quantity”:”55 Gallon Drum”,”Item Number”:”RO412D”,”Manufacturer”:”RedLine Tools”,”Shipping”:”This item must ship freight”,”Price”:”$40.47″,”Availability”:”IN STOCK”}

6. Drum Oil & Propane – Quality Energy Services

Domain: drumoil.com

Registered: 1999 (26 years)

Introduction: Drum Oil & Propane offers a range of quality energy services including:

– Fuel Delivery: Heating Oil Delivery, Propane Delivery, Automatic Delivery

– Heating Services: Heating Installations, Heating Tune-Ups & Maintenance, Oil Tank Protection

– Indoor Air Quality Products

– Service Plans

– Financing Options

– Emergency Service

– A/C Services: A/C Installations, A/C Tune-Ups & Maintenance

T…

7. Centra Foods – Canola Oil in 55 Gallon Drums

Domain: centrafoods.com

Registered: 2008 (17 years)

Introduction: Canola Oil in 55 Gallon Drums available for bulk retail. Suitable for manufacturers, restaurants, soap makers, and home chefs. Options for non-GMO and organic oils. Direct shipping from manufacturing plant with options for partial or full pallets. Custom bulk oil pricing available for larger manufacturers or distributors.

8. Evinrude – 55-Gallon XD30 Drum

Domain: domo-online.com

Registered: 2007 (18 years)

Introduction: 55 Gallon Drums/Pallet Orders include the following products: 1. 55-Gallon Evinrude XD30 Drum – $1,905.99 2. 55-Gallon Drum Evinrude XD50 Oil – $2,163.99 3. 55-Gallon Drum Evinrude XD100 Oil – $2,549.99 4. 55 Gallon Drum Mercury Quicksilver Premium Plus Oil – $2,394.99 5. 55 Gallon Drum Mercury Quicksilver Optimax Oil DFI – $2,692.99 6. 55 Gallon Mercury Quicksilver 25W40 Synthetic Blend 4-Stroke …

Strategic Sourcing Conclusion and Outlook for drum of oil

What Are the Key Takeaways for B2B Buyers in Sourcing Drum Oil?

In the competitive landscape of oil procurement, strategic sourcing of 55-gallon drums of oil is crucial for maximizing operational efficiency and cost-effectiveness. Buyers should prioritize reputable suppliers that offer a diverse range of high-quality products, ensuring compliance with international standards. Understanding the specific needs of your operations—whether for heavy-duty applications or synthetic blends—can lead to better purchasing decisions. Additionally, leveraging bulk purchasing options can significantly reduce costs, providing long-term savings.

How Can Strategic Sourcing Enhance Your Oil Procurement Process?

Effective strategic sourcing not only streamlines procurement processes but also fosters strong supplier relationships that can lead to better pricing and service options. By engaging with suppliers who understand the regional demands and environmental regulations specific to markets in Africa, South America, the Middle East, and Europe, businesses can position themselves for sustainable growth.

Illustrative image related to drum of oil

What’s Next for International B2B Buyers in the Oil Sector?

As the global oil market continues to evolve, staying ahead requires proactive engagement and adaptability. Buyers are encouraged to explore innovative sourcing strategies, such as diversifying supplier bases and incorporating technology for better supply chain visibility. By doing so, you can ensure a consistent supply of quality oil products that meet your operational demands. Embrace the future of oil procurement—begin optimizing your sourcing strategy today to enhance your competitive edge in the marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.