A B2B Buyer’s Guide to Mini Bulldozer: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for mini bulldozer

In today’s dynamic construction landscape, sourcing a mini bulldozer presents unique challenges for international B2B buyers. As the demand for versatile, compact machinery grows, companies from Africa, South America, the Middle East, and Europe—particularly in regions like Germany and Saudi Arabia—must navigate a complex market filled with diverse options and specifications. Understanding the right types of mini bulldozers and their applications is crucial for making informed purchasing decisions that align with specific project needs and regional demands.

This comprehensive guide addresses the intricacies of selecting the ideal mini bulldozer, covering essential topics such as types, applications, supplier vetting processes, and cost considerations. We delve into the features that matter most—such as engine reliability, maneuverability, and available attachments—equipping buyers with the insights needed to evaluate various models effectively. Furthermore, we provide valuable tips for assessing suppliers, ensuring that you partner with reputable manufacturers and distributors who can meet your quality and service expectations.

By the end of this guide, you will have the knowledge and tools necessary to navigate the global mini bulldozer market confidently. Whether you’re enhancing your fleet or embarking on a new project, this resource aims to empower your decision-making process, ultimately leading to successful investments in machinery that drive your business forward.

Understanding mini bulldozer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| S-Series | Compact size, low-cost, customizable attachments | Landscaping, small construction, garden work | Pros: Affordable, versatile; Cons: Limited power for heavy-duty tasks |

| Crawler Dozers | Higher horsepower, robust build, excellent traction | Site preparation, heavy grading, road construction | Pros: Powerful, efficient; Cons: Higher initial investment, heavier weight |

| Electric Mini Dozers | Zero emissions, quieter operation, advanced technology | Urban construction, eco-friendly projects | Pros: Sustainable, low operational costs; Cons: Limited battery life, higher upfront cost |

| Remote-Controlled Dozers | Operated via remote control for enhanced safety | Hazardous environments, demolition work | Pros: Increased safety, precision; Cons: Requires training, potential technical issues |

| Multi-Functional Dozers | Equipped with various attachments for diverse tasks | Agriculture, forestry, utility work | Pros: Highly versatile, reduces need for multiple machines; Cons: Complexity in operation, maintenance costs |

What are the characteristics and suitability of the S-Series mini bulldozer?

The S-Series mini bulldozer is designed for affordability and versatility, making it ideal for landscaping and small construction projects. Its compact size allows it to operate in tight spaces, while customizable attachments enhance its functionality for tasks such as grading and snow plowing. B2B buyers should consider the S-Series for projects where budget constraints are paramount, but they should also note that its lower horsepower may limit its performance in heavy-duty applications.

How do Crawler Dozers stand out for heavy-duty applications?

Crawler dozers are recognized for their robust construction and higher horsepower, making them suitable for demanding tasks like site preparation and road construction. Their excellent traction and stability on uneven terrain enable efficient grading and moving of heavy materials. For B2B buyers, investing in crawler dozers is ideal for larger projects requiring consistent power, although the initial investment is higher compared to smaller models.

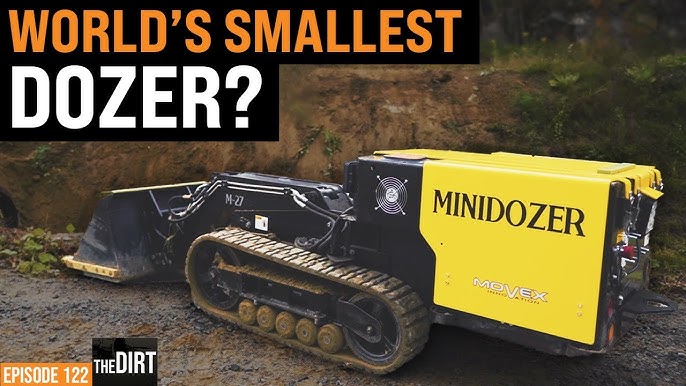

Illustrative image related to mini bulldozer

Why are Electric Mini Dozers becoming popular in urban construction?

Electric mini dozers offer a sustainable solution with zero emissions and quieter operation, aligning with the growing demand for eco-friendly machinery in urban environments. Their advanced technology often includes features that enhance efficiency and reduce operational costs. B2B buyers should consider electric mini dozers for projects emphasizing sustainability, but they must also be aware of the limitations, such as battery life and higher upfront costs.

What advantages do Remote-Controlled Dozers provide in hazardous environments?

Remote-controlled dozers enhance safety by allowing operators to work from a distance, particularly in hazardous environments or during demolition tasks. This technology increases precision and reduces the risk of accidents. B2B buyers should weigh the benefits of improved safety against the need for operator training and potential technical challenges that may arise with remote operation.

How do Multi-Functional Dozers enhance operational efficiency?

Multi-functional dozers are equipped with various attachments, enabling them to perform a wide range of tasks from agriculture to utility work. Their versatility reduces the need for multiple machines, streamlining operations and saving costs. For B2B buyers, this type of dozer is an attractive option, but they should consider the complexity of operation and potential maintenance costs associated with the diverse functionalities.

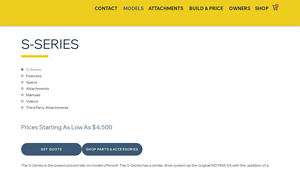

Illustrative image related to mini bulldozer

Key Industrial Applications of mini bulldozer

| Industry/Sector | Specific Application of mini bulldozer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Site Preparation and Grading | Efficiently prepares sites for building, reducing labor costs | Local dealer support, parts availability, and service options |

| Landscaping | Land Clearing and Landscaping | Enhances aesthetic appeal and functionality of outdoor spaces | Compatibility with various attachments for landscaping tasks |

| Agriculture | Soil Preparation and Farm Road Maintenance | Improves crop yields and accessibility to fields | Engine power, track type (rubber vs. steel), and fuel efficiency |

| Mining and Quarrying | Material Movement and Site Rehabilitation | Increases operational efficiency and reduces downtime | Durability, ease of maintenance, and availability of spare parts |

| Utilities and Infrastructure | Utility Line Installation and Maintenance | Streamlines installation processes and minimizes disruption | Size and maneuverability for urban settings, and operator training |

How is a Mini Bulldozer Used in Construction Projects?

In the construction sector, mini bulldozers are invaluable for site preparation and grading. These compact machines efficiently clear and level land, making them ideal for residential and commercial projects. By utilizing mini bulldozers, businesses can significantly reduce labor costs and complete tasks more quickly. Buyers should prioritize sourcing from local dealers to ensure easy access to parts and service, especially in regions like Africa and South America where support infrastructure may vary.

What Role Does a Mini Bulldozer Play in Landscaping?

In landscaping, mini bulldozers are used for land clearing, grading, and creating aesthetic features like terraces and flower beds. Their compact size allows for maneuverability in tight spaces, making them perfect for residential gardens and commercial landscapes. The ability to attach various implements enhances their versatility. Buyers should consider compatibility with attachments tailored for landscaping to maximize functionality, particularly in European markets where design preferences may differ.

How Can Mini Bulldozers Enhance Agricultural Operations?

In agriculture, mini bulldozers facilitate soil preparation and maintain farm roads, ensuring better access to fields. They help in leveling land, which is crucial for effective irrigation and crop growth. This efficiency can lead to improved yield and reduced operational costs. When sourcing mini bulldozers for agricultural use, buyers should focus on engine power and track type, as these factors impact performance in varying soil conditions, especially in the diverse terrains of Africa and South America.

What Advantages Do Mini Bulldozers Offer in Mining and Quarrying?

Mini bulldozers are essential for moving materials and rehabilitating mining sites. Their compact design allows them to operate in confined spaces, increasing efficiency in material handling. This capability reduces downtime, contributing to higher productivity. Buyers in the mining sector must prioritize durability and ease of maintenance when sourcing mini bulldozers, as these machines face harsh operating conditions, particularly in the Middle East where temperatures can be extreme.

How are Mini Bulldozers Utilized in Utility Installation?

In utilities and infrastructure, mini bulldozers are employed for installing and maintaining utility lines. Their ability to navigate urban environments makes them ideal for minimizing disruption during installation. By streamlining these processes, businesses can improve service delivery and customer satisfaction. When sourcing for this application, buyers should consider the machine’s size and maneuverability, ensuring it meets the specific requirements of urban landscapes in regions like Europe and the Middle East.

3 Common User Pain Points for ‘mini bulldozer’ & Their Solutions

Scenario 1: Difficulty in Maneuvering in Tight Spaces

The Problem: One of the primary challenges faced by B2B buyers of mini bulldozers is maneuverability in confined areas. Construction sites, especially in urban settings, often have limited space due to existing structures, utilities, or landscaping. Buyers may find that larger machines cannot operate effectively in these environments, leading to inefficiencies and increased labor costs as they attempt to complete tasks manually or with inadequate equipment.

The Solution: To address this issue, buyers should prioritize mini bulldozers that feature advanced maneuverability technologies, such as zero-turn capabilities. Models equipped with this technology can rotate 360 degrees in tight spaces, allowing operators to navigate around obstacles without needing extensive clearance. Additionally, opting for mini bulldozers with compact designs and shorter wheelbases will further enhance agility. When sourcing equipment, engage with manufacturers that offer customizable options, enabling you to select features tailored to your specific operational needs, such as specialized attachments for various tasks. Training operators on effective maneuvering techniques can also optimize the use of space, ensuring that projects remain on schedule.

Scenario 2: Maintenance and Downtime Concerns

The Problem: Another significant pain point for B2B buyers is the maintenance and potential downtime associated with mini bulldozers. Frequent breakdowns can be costly, leading to project delays and increased operational expenses. Buyers may struggle with understanding the maintenance requirements of different models, which can vary significantly in terms of reliability and serviceability.

Illustrative image related to mini bulldozer

The Solution: To mitigate these concerns, it is crucial for buyers to conduct thorough research on the maintenance histories of various mini bulldozer brands and models. Choose equipment from reputable manufacturers known for durability and ease of maintenance. Look for features such as accessible engine compartments and straightforward service points, which can reduce downtime during routine checks. Additionally, consider investing in a maintenance plan that includes regular servicing and access to genuine replacement parts. Establishing a preventative maintenance schedule can help identify issues before they escalate, ensuring that your equipment remains operational and your projects stay on track.

Scenario 3: Limited Versatility for Diverse Projects

The Problem: B2B buyers often find that their mini bulldozer lacks the versatility to handle various tasks required across different projects. For instance, a machine that excels in grading may not perform well in excavation or landscaping applications. This limitation can lead to the need for multiple pieces of equipment, increasing capital expenditure and complicating fleet management.

The Solution: To enhance versatility, buyers should opt for mini bulldozers that support a wide range of attachments and accessories. When evaluating options, ensure the machine can accommodate tools such as rippers, blades, and box scrapers that allow for multiple functionalities, from grading to excavation. Consult with manufacturers about compatible third-party attachments that can expand the machine’s capabilities without significant additional investment. Additionally, consider models with robust hydraulic systems that can easily support various implements. Training operators to switch between attachments efficiently will maximize the bulldozer’s utility across projects, ultimately streamlining operations and reducing the need for multiple machines.

Strategic Material Selection Guide for mini bulldozer

What Are the Key Materials Used in Mini Bulldozers?

When selecting materials for mini bulldozers, several factors must be considered, including performance characteristics, cost-effectiveness, and compliance with international standards. Below, we analyze four common materials used in the construction of mini bulldozers, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Steel: The Backbone of Mini Bulldozers

Key Properties: Steel is known for its high tensile strength and durability, making it ideal for structural components. It can withstand high temperatures and pressures, ensuring long-term performance under demanding conditions.

Illustrative image related to mini bulldozer

Pros & Cons: The primary advantage of steel is its exceptional strength and resistance to deformation, which is critical for heavy-duty applications. However, it is susceptible to corrosion if not properly treated, which can lead to maintenance challenges. Additionally, while steel is generally cost-effective, high-grade steel can be more expensive.

Impact on Application: Steel is commonly used for the frame, blade, and other load-bearing components of mini bulldozers. Its compatibility with various media, including soil and gravel, makes it a versatile choice.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure that the steel used complies with local standards such as ASTM or DIN. Corrosion resistance is particularly important in humid or coastal areas.

Illustrative image related to mini bulldozer

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is lightweight and has excellent corrosion resistance, making it suitable for components that require reduced weight without sacrificing strength.

Pros & Cons: The lightweight nature of aluminum can enhance maneuverability and fuel efficiency in mini bulldozers. However, it is generally less strong than steel, which may limit its use in high-load applications. The cost of aluminum can also be higher compared to standard steel.

Impact on Application: Aluminum is often used in non-structural components, such as covers and panels, where weight reduction is beneficial. Its corrosion resistance is advantageous in environments with high moisture levels.

Considerations for International Buyers: Buyers in Europe, particularly Germany, may prefer aluminum for its lightweight properties, especially in applications requiring compliance with stringent environmental regulations.

Rubber: Essential for Tracks and Tires

Key Properties: Rubber provides excellent flexibility and traction while offering resistance to wear and tear. It can also absorb shock, which is beneficial for operator comfort.

Pros & Cons: The main advantage of rubber is its ability to conform to uneven surfaces, providing better traction on varied terrains. However, rubber components may have a shorter lifespan compared to metals, particularly in harsh conditions. The cost can vary based on the quality and formulation of the rubber used.

Impact on Application: Rubber is primarily used for tracks and tires, enabling mini bulldozers to operate on different surfaces without damaging them. This versatility is crucial for landscaping and construction applications.

Considerations for International Buyers: Buyers from South America and Africa should consider the local terrain when selecting rubber components, as durability may vary based on environmental conditions.

Illustrative image related to mini bulldozer

Composite Materials: The Future of Mini Bulldozers?

Key Properties: Composite materials combine different substances to achieve superior strength-to-weight ratios and enhanced corrosion resistance. They can be tailored to meet specific performance requirements.

Pros & Cons: Composites are lightweight and resistant to corrosion, making them an attractive option for modern mini bulldozer designs. However, they can be more expensive to manufacture and may require specialized handling during installation.

Impact on Application: Composites are increasingly used in non-structural components and protective covers, where weight savings and corrosion resistance are priorities.

Considerations for International Buyers: Buyers in Europe may find composites appealing due to their innovative properties, but they should ensure that these materials meet local standards for safety and performance.

Summary Table of Material Properties

| Material | Typical Use Case for mini bulldozer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame, blade, structural components | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Non-structural components | Lightweight and corrosion-resistant | Lower strength compared to steel | High |

| Rubber | Tracks and tires | Excellent traction and shock absorption | Shorter lifespan in harsh conditions | Medium |

| Composite | Protective covers, non-structural | Lightweight and customizable | Higher manufacturing complexity | High |

This strategic material selection guide provides valuable insights for B2B buyers in various regions, helping them make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for mini bulldozer

What Are the Key Stages in the Manufacturing Process of Mini Bulldozers?

The manufacturing process for mini bulldozers involves several critical stages, each designed to ensure efficiency, quality, and reliability. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The manufacturing process begins with the selection of high-grade materials, typically including steel and various alloys for structural components. Suppliers often conduct a thorough evaluation of raw materials to ensure they meet specific mechanical properties and performance criteria. Materials are then cut to size using advanced laser cutting or plasma cutting techniques, ensuring precision and minimal waste. -

Forming

Following material preparation, the forming stage involves shaping the cut materials into the required components. Techniques such as stamping, bending, and welding are commonly employed. For instance, the chassis and frame are typically welded together using robotic welding systems that provide consistency and strength. This stage may also include the fabrication of specialized parts, such as hydraulic systems and engine mounts, which are crucial for the bulldozer’s performance. -

Assembly

Once the components are formed, they are assembled into the final product. This stage is often organized in a production line format, where workers or robots systematically install parts such as the engine, tracks, and control systems. Quality checks are integrated into the assembly process, where operators verify that each component meets design specifications before moving on to the next assembly stage. -

Finishing

The finishing stage encompasses painting, coating, and final inspections. Typically, mini bulldozers undergo a surface treatment process to enhance durability and resistance to corrosion. This may include powder coating or galvanizing. Final inspections are conducted to ensure that all mechanical and electrical systems function correctly, and that the overall quality of the finish meets industry standards.

What Quality Assurance Measures Are Implemented in Mini Bulldozer Manufacturing?

Quality assurance (QA) is paramount in the production of mini bulldozers, ensuring that every unit meets international standards and customer expectations. Several key practices and standards are utilized throughout the manufacturing process.

-

International Standards for Quality Control

Adherence to international quality standards such as ISO 9001 is critical. This standard outlines a framework for quality management systems, emphasizing continuous improvement and customer satisfaction. Manufacturers often seek certifications that demonstrate compliance, giving B2B buyers confidence in the product’s quality. -

Industry-Specific Certifications

In addition to ISO standards, mini bulldozer manufacturers may also pursue industry-specific certifications, such as CE marking for products sold within the European Economic Area (EEA) and API standards for equipment used in the oil and gas industry. These certifications ensure that the machinery complies with relevant safety and environmental regulations. -

Quality Control Checkpoints

Quality control is integrated at multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet the specified quality standards before they are used in production.

- In-Process Quality Control (IPQC): During the manufacturing process, various inspections are conducted to verify that components are being produced correctly and that any defects are identified early.

- Final Quality Control (FQC): Once the mini bulldozer is fully assembled, a comprehensive inspection is conducted. This includes functional tests, safety checks, and aesthetic evaluations to ensure that the product meets all specifications.

- Common Testing Methods

Various testing methods are employed to validate the quality and performance of mini bulldozers. These may include:

- Load Testing: Assessing the machine’s capability to handle specified loads without structural failure.

- Hydraulic Testing: Ensuring that hydraulic systems function correctly under pressure.

- Performance Testing: Evaluating the bulldozer’s speed, maneuverability, and operational efficiency in real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensuring a reliable purchase.

-

Supplier Audits

Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality assurance measures. Buyers can assess compliance with international standards and industry-specific certifications firsthand. -

Reviewing Quality Control Reports

Requesting detailed quality control reports from suppliers can help buyers evaluate the effectiveness of their QA processes. These reports should include data on defect rates, compliance with testing protocols, and results from previous inspections. -

Third-Party Inspections

Engaging third-party inspection agencies can offer an unbiased evaluation of a supplier’s manufacturing practices. These agencies can conduct audits, perform testing, and provide certification that assures buyers of the product’s quality.

What Are the Quality Control Nuances for International B2B Buyers?

When navigating the complexities of international trade, particularly in regions such as Europe, Africa, and the Middle East, buyers should be aware of specific nuances related to quality control.

Illustrative image related to mini bulldozer

-

Understanding Regional Standards

Different regions may have distinct regulatory requirements and standards for machinery. For example, CE marking in Europe indicates compliance with safety and environmental regulations, while other regions may have their own certifications. Buyers should familiarize themselves with these standards to avoid compliance issues. -

Logistical Considerations

Shipping and transport can impact the quality of mini bulldozers. Buyers should inquire about how suppliers ensure that products are protected during transit, including the use of suitable packaging and handling procedures. -

Cultural Differences

Business practices and expectations can vary significantly across regions. B2B buyers should approach negotiations and quality assurance discussions with cultural sensitivity, ensuring clear communication regarding quality standards and expectations.

By understanding the manufacturing processes and quality assurance measures associated with mini bulldozers, international B2B buyers can make informed decisions that align with their operational needs and market requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mini bulldozer’

To effectively source a mini bulldozer, a systematic approach is essential to ensure that your investment meets your operational needs and budget constraints. This guide outlines a step-by-step checklist to help you navigate the procurement process efficiently.

Step 1: Define Your Technical Specifications

Begin by identifying the specific requirements for the mini bulldozer. Consider factors such as engine power, weight, and operational capabilities to ensure the machine is suitable for your intended applications, whether it’s grading, landscaping, or construction.

– Power and Size: Determine the horsepower and weight that best fit your projects.

– Attachments: Assess the compatibility of attachments like blades or rippers based on your usage needs.

Step 2: Set Your Budget and Financial Parameters

Establish a clear budget for your purchase, including not just the initial cost but also ongoing expenses such as maintenance, fuel, and insurance. Understanding your total cost of ownership will help you evaluate options more effectively.

– Initial Investment: Factor in purchase price and potential financing options.

– Long-Term Costs: Include maintenance and operational costs to avoid budget overruns.

Step 3: Research and Shortlist Suppliers

Conduct thorough research to identify reputable suppliers of mini bulldozers. Look for companies with strong market presence and positive customer feedback. Creating a shortlist will streamline your evaluation process.

– Supplier Reputation: Check online reviews, industry forums, and professional networks for insights on supplier reliability.

– Local vs. International: Consider the benefits of sourcing locally, such as reduced shipping times and easier communication.

Illustrative image related to mini bulldozer

Step 4: Evaluate Potential Suppliers

Before committing, vet potential suppliers meticulously. Request comprehensive company profiles, product catalogs, and references from other clients in similar industries or regions to validate their credibility.

– Case Studies: Ask for examples of successful projects completed with their equipment.

– Warranty and Support: Inquire about warranty terms and after-sales support to ensure you have assistance when needed.

Step 5: Review Certifications and Compliance

Verify that the mini bulldozer complies with local regulations and industry standards. This step is crucial to avoid legal issues and ensure safety on job sites.

– Certifications: Check for ISO certifications or other relevant quality standards.

– Environmental Compliance: Confirm adherence to environmental regulations, especially in regions with strict guidelines.

Step 6: Request Quotes and Compare Offers

Once you have a shortlist of suppliers, request detailed quotations. Comparing offers will help you understand the market pricing and identify the best value for your investment.

– Breakdown of Costs: Ensure quotes include a detailed breakdown of costs, including shipping, installation, and any additional fees.

– Negotiation Opportunities: Look for potential negotiation points, such as bulk order discounts or payment terms.

Step 7: Finalize the Purchase Agreement

After selecting a supplier, review the purchase agreement thoroughly before signing. Ensure all terms are clear, including delivery timelines, payment schedules, and warranty conditions.

– Legal Review: If necessary, consult with legal experts to review the contract for any unfavorable terms.

– Payment Terms: Confirm payment terms that suit your financial planning and cash flow management.

Illustrative image related to mini bulldozer

By following these steps, B2B buyers can make informed decisions and secure a mini bulldozer that aligns with their operational needs and budget, ultimately enhancing their project efficiency and productivity.

Comprehensive Cost and Pricing Analysis for mini bulldozer Sourcing

What Are the Key Cost Components in Mini Bulldozer Manufacturing?

When sourcing mini bulldozers, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: This encompasses the raw materials needed for production, such as steel, engines, hydraulic systems, and tracks. The quality of materials significantly influences durability and performance, impacting the overall cost.

-

Labor: Skilled labor is essential for assembly and quality control. Labor costs can vary significantly based on the manufacturing location, with regions like Europe and North America typically having higher labor costs compared to countries in Africa or South America.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead, benefiting the final pricing.

-

Tooling: The investment in specialized tools for production can be substantial, especially for custom designs. Tooling costs need to be amortized over production volume, influencing unit pricing.

-

Quality Control (QC): Ensuring that each bulldozer meets safety and performance standards incurs additional costs. Certification processes, particularly for international markets, can further add to QC expenses.

-

Logistics: Transportation costs, which vary based on distance and method (air, sea, or land), play a significant role in the final price. Import duties and tariffs can also affect the total cost for international buyers.

-

Margin: Finally, manufacturers apply a profit margin to cover risks and ensure profitability. This margin can fluctuate based on market demand, competition, and the supplier’s pricing strategy.

How Do Pricing Influencers Affect Mini Bulldozer Costs?

Several factors can influence the pricing of mini bulldozers, including:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to reduced per-unit costs due to economies of scale. Negotiating favorable terms based on projected volumes can yield significant savings.

-

Specifications and Customization: Unique specifications or custom features will increase costs. Buyers should assess the necessity of these customizations against their budget and operational needs.

-

Materials and Quality Certifications: Premium materials and certifications (ISO, CE) enhance product reliability but also elevate costs. Buyers should weigh the importance of certifications against potential savings from lower-quality options.

-

Supplier Factors: The reliability and reputation of the supplier can affect pricing. Established suppliers may offer higher prices due to brand trust, while lesser-known manufacturers might provide competitive rates but could pose risks regarding quality and support.

-

Incoterms: The agreed terms of shipment (e.g., FOB, CIF) affect the total cost of ownership. Understanding these terms helps buyers anticipate additional costs related to transportation and insurance.

What Are Effective Buyer Tips for Negotiating Mini Bulldozer Prices?

To maximize value when sourcing mini bulldozers, consider the following strategies:

-

Negotiation: Leverage your purchasing power by discussing bulk purchase discounts or favorable payment terms. Building a strong relationship with suppliers can lead to better negotiation outcomes.

-

Cost-Efficiency: Evaluate total cost of ownership (TCO), including maintenance, fuel efficiency, and potential resale value. A lower initial purchase price may not always translate to savings if long-term operational costs are higher.

-

Pricing Nuances for International Buyers: For buyers in regions like Africa, South America, the Middle East, and Europe, currency fluctuations and local economic conditions can impact pricing. Be aware of these factors when making purchasing decisions.

-

Research and Compare: Conduct thorough market research to compare prices and features across different suppliers. This can help identify the best value options and inform negotiation discussions.

-

Ask for Trial Runs: If possible, request a trial period for the mini bulldozer to evaluate performance before committing to a purchase. This reduces the risk of investing in equipment that may not meet operational needs.

Disclaimer on Indicative Prices

Prices for mini bulldozers can vary widely based on specifications, supplier, and market conditions. The prices mentioned in this analysis are indicative and should not be considered fixed. Always consult with suppliers for accurate quotes tailored to your requirements.

Alternatives Analysis: Comparing mini bulldozer With Other Solutions

Exploring Alternatives to Mini Bulldozers for Construction and Landscaping

When evaluating machinery for construction or landscaping tasks, it’s essential to consider various options that can achieve similar goals. While mini bulldozers are compact and versatile, other machines may offer specific advantages depending on the project requirements. This section compares mini bulldozers with compact track loaders and small excavators, providing insights that can help B2B buyers make informed decisions.

| Comparison Aspect | Mini Bulldozer | Compact Track Loader | Small Excavator |

|---|---|---|---|

| Performance | Excellent for grading and pushing dirt; limited digging capability. | Versatile with strong lifting and pushing capabilities; can use various attachments. | Superior digging depth and precision; ideal for trenching and excavation. |

| Cost | Generally lower initial investment, starting around $4,500. | Higher upfront cost, typically ranging from $20,000 to $50,000. | Varies widely but often starts around $15,000, depending on size and features. |

| Ease of Implementation | Simple operation with a learning curve for new users; ideal for smaller tasks. | Moderate complexity; operators may need training to use attachments effectively. | Requires skilled operators for efficient operation, especially in tight spaces. |

| Maintenance | Low maintenance; straightforward design allows for easy repairs. | Moderate maintenance needs; requires regular inspections and possible attachment upkeep. | Higher maintenance due to more complex hydraulic systems and components. |

| Best Use Case | Ideal for small grading, landscaping, and residential projects. | Best for diverse tasks, including landscaping, grading, and site preparation. | Excellent for digging, trenching, and utility installation in various terrains. |

What Are the Advantages and Disadvantages of Compact Track Loaders?

Compact track loaders (CTLs) are versatile machines that excel in various tasks, making them a strong alternative to mini bulldozers. Their ability to use multiple attachments, such as buckets, forks, and grapples, allows for greater flexibility on the job site. However, CTLs come with a higher purchase price and require skilled operators to maximize their capabilities. Their maintenance can also be more demanding due to the complexity of the hydraulic systems and attachments.

Why Consider Small Excavators Over Mini Bulldozers?

Small excavators offer significant advantages for specific tasks that require precision, such as digging and trenching. They provide superior digging depth and control compared to mini bulldozers, making them ideal for utility work and foundational projects. However, their higher initial costs and the need for skilled operators can be drawbacks. Additionally, their larger footprint may limit maneuverability in tight spaces compared to the compact size of mini bulldozers.

How Can Buyers Choose the Right Solution for Their Needs?

Selecting the right equipment depends on several factors, including the specific tasks at hand, budget constraints, and the skill level of the operators. For B2B buyers in construction and landscaping, understanding the unique strengths and weaknesses of mini bulldozers, compact track loaders, and small excavators is crucial. Evaluate the project requirements, consider the total cost of ownership (including maintenance and operational costs), and assess the skill level of available operators to make a well-informed decision. By aligning the equipment choice with project needs, businesses can enhance productivity and optimize resource allocation.

Essential Technical Properties and Trade Terminology for mini bulldozer

What Are the Key Technical Properties of a Mini Bulldozer?

When considering the purchase of a mini bulldozer, understanding its technical specifications is crucial for making informed decisions. Here are some essential properties to evaluate:

Illustrative image related to mini bulldozer

-

Operating Weight

The operating weight of a mini bulldozer typically ranges from 1,500 to 8,000 pounds (680 to 3,600 kg). This specification is vital as it influences the machine’s stability, maneuverability, and transportability. Heavier machines tend to provide better traction and stability on uneven terrain, making them suitable for more demanding applications. -

Engine Power

Engine power is usually measured in horsepower (HP) or kilowatts (kW). Mini bulldozers generally feature engines with power ratings between 20 HP (15 kW) and 50 HP (37 kW). The power output directly affects the machine’s performance, including its ability to push materials and navigate challenging landscapes. Higher power ratings allow for more efficient operation in tougher conditions. -

Blade Width and Type

The blade width can significantly affect the bulldozer’s productivity. Common widths range from 4 to 6 feet (1.2 to 1.8 meters). Different blade types (e.g., straight, angle, or universal) cater to various tasks such as grading, clearing, and pushing materials. Understanding the blade specifications is essential for ensuring the machine meets specific project requirements. -

Track Type and Material

Mini bulldozers often come with either rubber or steel tracks. Rubber tracks provide a smoother ride and are less damaging to finished surfaces, while steel tracks are more durable and suited for rugged terrains. The choice of track type can influence operational efficiency and the machine’s ability to perform in different environments. -

Hydraulic System Capacity

The hydraulic system’s capacity, typically rated in gallons per minute (GPM) or liters per minute (LPM), dictates the bulldozer’s lifting and digging performance. A more powerful hydraulic system allows for faster operation of attachments, enhancing productivity. This specification is particularly important for businesses that require quick turnaround times on job sites. -

Fuel Efficiency

Fuel efficiency is a critical consideration for operational costs. Mini bulldozers with fuel-efficient engines not only reduce fuel consumption but also lower overall operational expenses. Buyers should look for models that offer optimal fuel-to-power ratios, especially in regions where fuel prices can significantly impact project budgets.

What Are Common Trade Terms in the Mini Bulldozer Market?

Familiarity with industry jargon can facilitate smoother transactions and better negotiations. Here are some key terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM products is crucial for ensuring compatibility and quality in the mini bulldozer market. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is essential when negotiating bulk purchases, as it can affect pricing and inventory management. Knowing the MOQ helps buyers plan their procurement strategies effectively. -

RFQ (Request for Quotation)

An RFQ is a standard business process used to invite suppliers to submit price quotes for specific products or services. This term is significant for buyers looking to compare costs and negotiate favorable terms for mini bulldozer purchases. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with Incoterms is vital for international buyers to avoid misunderstandings regarding shipping, insurance, and risk transfer. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is crucial for project planning and ensuring that equipment arrives when needed, especially for time-sensitive projects. -

Warranty Period

The warranty period is the timeframe during which the manufacturer guarantees the product’s performance and quality. Knowing the warranty details helps buyers assess the long-term value and reliability of the mini bulldozer, providing peace of mind in their investment.

By grasping these technical properties and trade terms, B2B buyers can navigate the mini bulldozer market more effectively, ensuring they make informed purchasing decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the mini bulldozer Sector

What Are the Key Market Dynamics and Sourcing Trends in the Mini Bulldozer Sector?

The mini bulldozer market is witnessing significant growth, driven by the increasing demand for compact and versatile construction equipment in emerging economies. Regions such as Africa, South America, the Middle East, and Europe are showing a marked rise in infrastructure development, urbanization, and agricultural projects, fueling the need for efficient earthmoving machinery. The global mini bulldozer market is projected to expand, driven by technological advancements that enhance performance and user experience, such as zero-turn capabilities and improved engine efficiency.

Emerging B2B technology trends are reshaping sourcing strategies in this sector. Buyers are increasingly leveraging online platforms for procurement, allowing for better price comparison and access to a broader range of suppliers. Additionally, the integration of IoT technology in mini bulldozers is gaining traction, enabling real-time data monitoring for performance and maintenance, thereby optimizing operational efficiency. For international buyers, understanding local market dynamics, such as regulatory requirements and import tariffs, is critical in making informed sourcing decisions.

How Can Sustainability and Ethical Sourcing Impact the Mini Bulldozer Sector?

The environmental impact of construction machinery is under increasing scrutiny, making sustainability a pivotal consideration for B2B buyers in the mini bulldozer sector. The industry is moving towards more sustainable practices, such as using eco-friendly materials and reducing carbon footprints. Buyers should prioritize manufacturers that adopt sustainable production methods, such as recycling components and minimizing waste during manufacturing.

Ethical sourcing is also gaining prominence, with buyers increasingly seeking suppliers who adhere to fair labor practices and have transparent supply chains. Certifications for green manufacturing processes, such as ISO 14001, and the use of recyclable materials in mini bulldozer production are becoming essential criteria for procurement decisions. By aligning with suppliers who prioritize sustainability, buyers can enhance their corporate social responsibility (CSR) initiatives and appeal to environmentally conscious consumers.

What is the Evolution of Mini Bulldozers in the Construction Industry?

The evolution of mini bulldozers has significantly transformed the construction landscape. Originally designed for small-scale applications, these machines have adapted to meet the growing demands of urban construction and landscaping. Over the years, advancements in technology have led to the development of more compact, powerful, and versatile models that can tackle a variety of tasks, from grading to snow removal.

The introduction of features such as zero-turn technology and improved engine designs has made mini bulldozers more maneuverable and efficient, allowing them to operate in confined spaces. As construction projects become more complex, the adaptability and efficiency of mini bulldozers will continue to drive their popularity, establishing them as indispensable tools for contractors and builders worldwide.

Illustrative image related to mini bulldozer

Frequently Asked Questions (FAQs) for B2B Buyers of mini bulldozer

-

How do I choose the right mini bulldozer for my project?

When selecting a mini bulldozer, consider factors such as the machine’s horsepower, operating weight, and intended application. For instance, if you’re working on residential landscaping or small site grading, a model with around 25-50 HP may suffice. Evaluate attachments compatibility for specific tasks, such as rippers or blades, which can enhance functionality. Additionally, check the machine’s maneuverability and transportability, especially if you need to move it between job sites frequently. Always consult with suppliers for recommendations based on your project needs. -

What are the key features to look for in a mini bulldozer?

Key features to consider include engine performance, track system (rubber vs. steel), turning radius, and ease of maintenance. A powerful engine ensures efficiency, while a robust track system enhances traction on various terrains. Look for models with zero-turn capabilities, which allow for maneuverability in tight spaces. Safety features, such as non-slip pads and LED lighting, are also important for operator comfort and safety. Ensure the bulldozer has easy access for maintenance to minimize downtime. -

What is the typical lead time for ordering a mini bulldozer internationally?

Lead times for international orders can vary significantly based on the manufacturer, model, and location. Generally, you can expect a lead time of 4 to 12 weeks from order placement to delivery. Factors influencing this timeline include manufacturing capacity, shipping logistics, and customs clearance processes in your country. It’s advisable to communicate with your supplier for specific timelines and ensure that all documentation is in order to expedite the process. -

What are the common payment terms for purchasing mini bulldozers?

Payment terms can vary widely depending on the supplier and the order size. Common practices include a deposit of 30-50% upon order confirmation, with the balance due before shipping or upon delivery. Some suppliers may offer financing options or extended payment terms for larger purchases. Always clarify payment methods accepted, such as wire transfers or letters of credit, and ensure that all terms are documented in the sales agreement to avoid disputes. -

How can I verify the credibility of a mini bulldozer supplier?

To vet suppliers, start by researching their business history, customer reviews, and industry reputation. Request references from previous clients and reach out to them for feedback on their experiences. Verify the supplier’s certifications and compliance with international quality standards. Additionally, consider visiting their facility or attending trade shows to assess their operations firsthand. Engaging with local industry associations can also provide insights into the supplier’s reliability. -

What customization options are typically available for mini bulldozers?

Customization options for mini bulldozers often include various attachments, such as blades, rippers, and buckets, tailored to specific tasks. Some manufacturers allow for modifications in color, branding, or additional safety features. It’s essential to discuss your specific needs with the supplier to determine available options. Keep in mind that custom orders may affect lead times and pricing, so inquire about these factors during the selection process. -

What are the logistics considerations when importing mini bulldozers?

Logistics for importing mini bulldozers involve several key considerations, including shipping methods, customs regulations, and import duties. Determine whether to use sea freight or air freight based on cost and urgency. Understand your country’s import regulations, including documentation required and tariffs applicable to construction equipment. Collaborating with a freight forwarder experienced in heavy machinery can streamline the process and ensure compliance with all legal requirements. -

What quality assurance measures should I expect from a mini bulldozer supplier?

A reputable mini bulldozer supplier should implement stringent quality assurance processes, including regular equipment inspections and adherence to international manufacturing standards. Request documentation of quality certifications, such as ISO, and inquire about warranty policies covering defects. Suppliers should also provide maintenance and operation manuals to ensure proper handling. Always clarify the terms of service and support available after purchase, which can impact the longevity and performance of your equipment.

Top 4 Mini Bulldozer Manufacturers & Suppliers List

1. Struck Equipment – S-Series Ride-On Model

Domain: struckequipment.com

Registered: 2024 (1 years)

Introduction: S-Series is the lowest priced ride-on model offered by Struck Equipment. It features a Vanguard 12V3 small engine with 6.5 HP, Overhead Valve (OHV) technology, and a 3-in-1 control to eliminate oil/fuel dilution. The S-Series includes a centrifugal-clutch and foot throttle for better control. It can pull smaller logs, grade driveways, and plow snow. Available attachments include rippers, blades, r…

2. Cat – Small Dozers

Domain: cat.com

Registered: 1993 (32 years)

Introduction: This company, Cat – Small Dozers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Deere – Excavators and Loaders

Domain: deere.com

Registered: 1990 (35 years)

Introduction: Operating Weight: 11,000 – 25,000 kg (24,251 – 55,116 lbs.), 26,000+ kg (57,320+ lbs.), 7,500 – 10,999 kg (16,535 – 24,248 lbs.) Net Power: 101 – 190 kW (135 – 255 hp), 190 – 300 kW (255 – 402 hp), 50 – 100 kW (67 – 134 hp) Performance Tier: G-Tier, P-Tier Engine Tier: Final Tier 4, Tier 3 Track on Ground: 2000 – 2500 mm (79 – 98 in.), 2600 – 3299 mm (102 – 130 in.), 3300 – 3500 mm (130 – 138 in.)…

4. Mini Dozers – Scale Model Bulldozers

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Mini dozers, related interests include various tractor models such as Wheel Horse, Bobcat, International Harvester, Case, John Deere, and Oliver. Featured items include mini bulldozers, scale model bulldozers, and homemade tractors. Specific mentions of models like the Struck MAGNATRAC RS1000 mini bulldozer and Oliver OC-4 crawler with dozer. Other related interests include garden tractors, compac…

Strategic Sourcing Conclusion and Outlook for mini bulldozer

In the evolving landscape of construction and landscaping equipment, strategic sourcing of mini bulldozers offers significant advantages for international buyers. By understanding the diverse range of models available, from affordable options like the S-Series to robust machines from industry leaders such as Caterpillar, buyers can tailor their equipment choices to meet specific operational needs. Key considerations include the versatility of attachments, engine reliability, and adaptability to various terrains, which enhance productivity across different project types.

Moreover, leveraging local dealer networks can facilitate smoother procurement processes and ensure access to essential parts and maintenance services. As market demand continues to grow in regions like Africa, South America, the Middle East, and Europe, staying informed about technological advancements and pricing strategies will be crucial for making informed purchasing decisions.

Looking ahead, the mini bulldozer market is poised for expansion, driven by increasing urbanization and infrastructure development. We encourage international buyers to explore partnerships with reputable suppliers and prioritize strategic sourcing to maximize operational efficiency and cost-effectiveness. Embrace the opportunity to invest in high-quality equipment that can drive your projects forward and position your business for success in a competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.