Unlocking Value: A Strategic Analysis of the Water Chill Market

Introduction: Navigating the Global Market for water chill

In an increasingly competitive global marketplace, sourcing reliable and efficient water chill solutions can pose significant challenges for B2B buyers, especially those operating in regions such as Africa, South America, the Middle East, and Europe. The demand for high-quality water chillers is rising, driven by the need for effective cooling solutions across various sectors, including hospitality, food service, and industrial applications. This comprehensive guide is designed to equip international B2B buyers with the essential knowledge to navigate the complexities of the water chill market.

Within this guide, you will discover a detailed overview of the different types of water chillers available, ranging from undersink models to large-scale industrial systems. We will explore their applications, helping you identify the best solutions for your specific needs. Additionally, we provide insights on supplier vetting processes, ensuring that you partner with reputable manufacturers that meet international standards. Cost considerations are also addressed, enabling you to make budget-conscious decisions without compromising on quality.

By leveraging the insights and strategies outlined in this guide, B2B buyers can confidently approach their purchasing decisions, ensuring they select the right water chill solutions tailored to their operational demands. With a focus on actionable information, this guide empowers you to enhance your business’s efficiency and customer satisfaction through optimal water chilling solutions.

Understanding water chill Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Undersink Water Chillers | Compact design, quick connect setup, optimal for RO systems | Residential, small offices | Pros: Space-saving, easy installation. Cons: Limited capacity compared to larger systems. |

| Water-Cooled Chillers | High capacity, uses water for cooling, suitable for industrial use | Manufacturing, large-scale food service | Pros: Efficient cooling, lower energy consumption. Cons: Requires water supply and drainage. |

| Point-of-Use Water Chillers | Instant access to chilled water, often paired with filtration systems | Hospitality, healthcare, education | Pros: Immediate access, enhances drinking experience. Cons: May require regular maintenance. |

| Commercial Water Chillers | Larger systems designed for high demand, customizable capacities | Large restaurants, industrial kitchens | Pros: High output, customizable for specific needs. Cons: Higher upfront costs, complex installation. |

| Wall-Mounted Water Chillers | Space-efficient, designed for limited spaces, aesthetically pleasing | Offices, retail spaces | Pros: Saves floor space, visually appealing. Cons: Limited capacity, may require wall reinforcement. |

What are the characteristics and suitability of Undersink Water Chillers for B2B buyers?

Undersink water chillers are designed for compact installation beneath sinks, making them ideal for businesses with limited space. They typically connect easily to existing reverse osmosis (RO) systems, providing chilled water efficiently. These chillers are particularly suitable for residential settings and small offices where demand is moderate. B2B buyers should consider factors such as installation ease, maintenance requirements, and compatibility with existing filtration systems when selecting an undersink chiller.

How do Water-Cooled Chillers serve industrial applications?

Water-cooled chillers are engineered for high-capacity cooling and are commonly used in industrial settings. These systems utilize water as a cooling medium, making them energy-efficient and suitable for environments requiring substantial cooling, such as manufacturing plants and large-scale food service operations. B2B buyers should evaluate the water supply and drainage requirements, as well as the system’s efficiency ratings, to ensure it meets their operational needs.

What benefits do Point-of-Use Water Chillers offer for various sectors?

Point-of-use water chillers provide instant access to chilled water, making them a popular choice in sectors like hospitality, healthcare, and education. These systems can be easily integrated with existing water filtration setups, enhancing the quality of drinking water. When considering a point-of-use chiller, buyers should assess the volume of water needed, maintenance schedules, and the potential for increased customer satisfaction through improved drinking water quality.

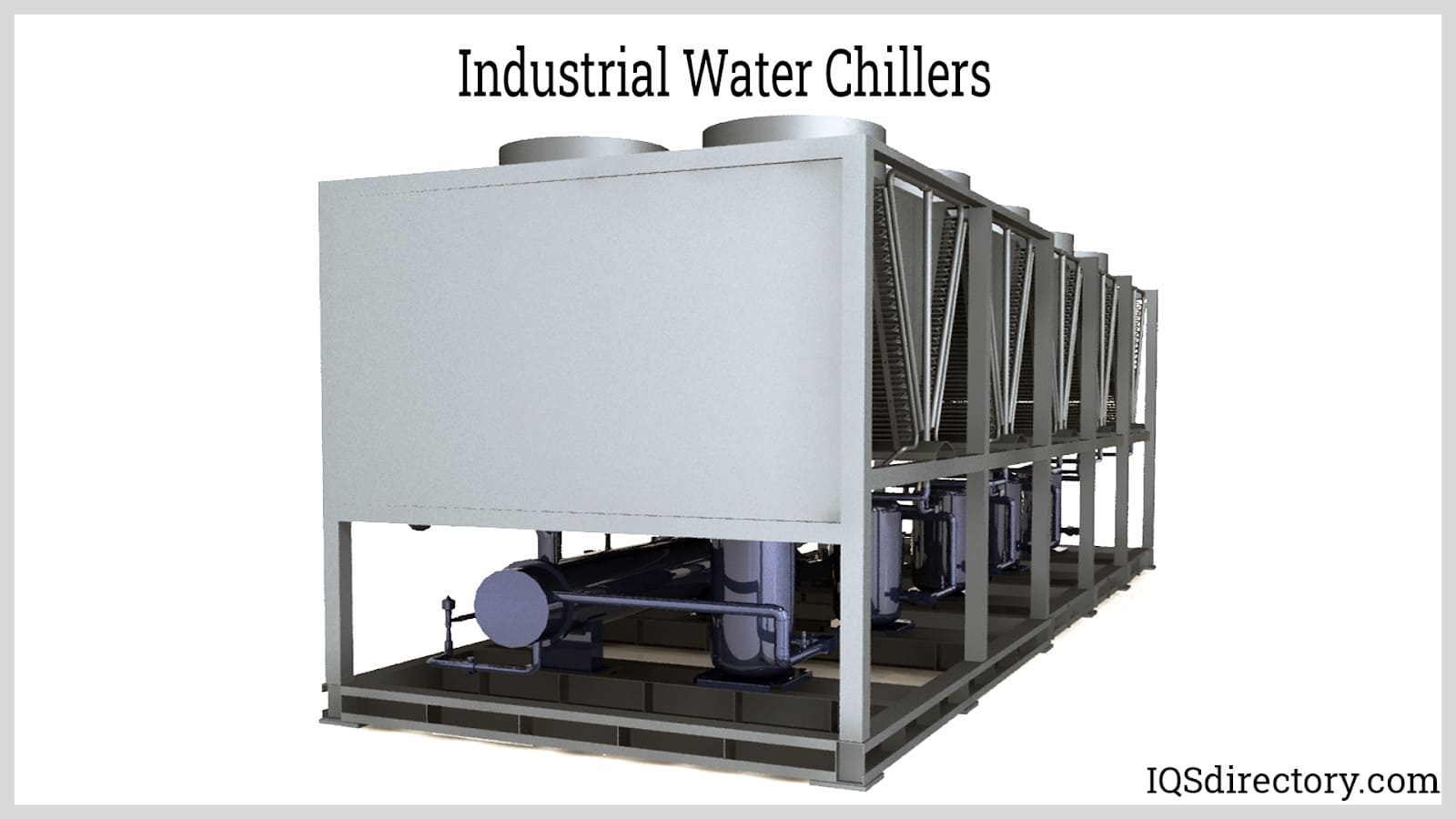

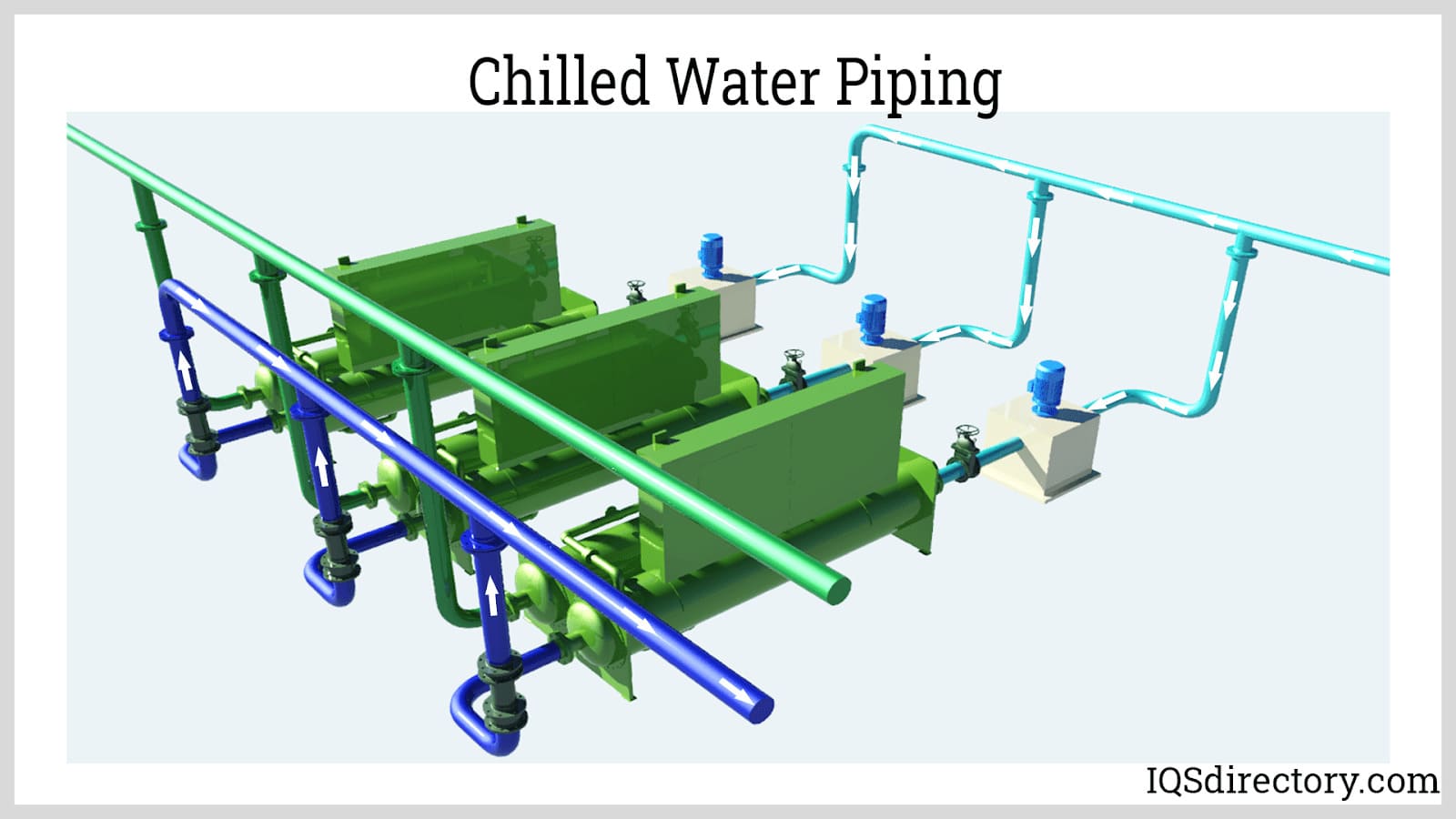

Illustrative image related to water chill

Why are Commercial Water Chillers essential for high-demand environments?

Commercial water chillers are designed to meet the demands of high-traffic businesses such as restaurants and industrial kitchens. These systems can be customized to fit specific cooling needs, offering high output and reliability. However, the initial investment and installation complexity can be significant. B2B buyers should focus on assessing their cooling requirements and budget constraints to select a system that balances performance and cost-effectiveness.

What advantages do Wall-Mounted Water Chillers provide in commercial settings?

Wall-mounted water chillers are designed to maximize space efficiency while providing chilled water in aesthetically pleasing units. They are suitable for offices and retail environments where floor space is at a premium. Buyers should consider the installation requirements, including wall strength and support, as well as the chiller’s capacity to ensure it meets the demands of the intended application.

Key Industrial Applications of water chill

| Industry/Sector | Specific Application of water chill | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Beverage cooling systems for restaurants and bars | Ensures optimal serving temperatures, enhancing customer experience | Energy efficiency, compatibility with existing systems, maintenance support |

| Manufacturing | Process cooling in industrial plants | Maintains equipment performance and extends lifespan | Reliability, capacity to handle specific cooling loads, local service availability |

| Healthcare | Chilled water supply for medical facilities | Provides safe drinking water and maintains laboratory conditions | Compliance with health regulations, durability, easy installation |

| Hospitality | Cooling systems for hotels and resorts | Improves guest satisfaction with chilled amenities | Space constraints, aesthetic considerations, energy consumption |

| Agricultural | Cooling systems for post-harvest processing | Preserves freshness and quality of produce | Adaptability to local climate conditions, energy use, and water quality standards |

How is Water Chill Used in the Food & Beverage Industry?

In the food and beverage sector, water chill systems are critical for ensuring beverages are served at optimal temperatures. Restaurants and bars utilize these systems to maintain the quality and taste of drinks, which directly impacts customer satisfaction and sales. International buyers should consider energy efficiency and compatibility with existing equipment when sourcing these chillers, as these factors can significantly affect operational costs and customer experience.

What Role Does Water Chill Play in Manufacturing?

Manufacturing industries rely on water chillers for process cooling, which is essential for maintaining machinery performance and preventing overheating. By ensuring that equipment operates within optimal temperature ranges, businesses can extend machinery lifespan and reduce downtime. When sourcing chillers, companies must evaluate the reliability and capacity of the systems to handle their specific cooling loads, along with the availability of local maintenance services to ensure uninterrupted operations.

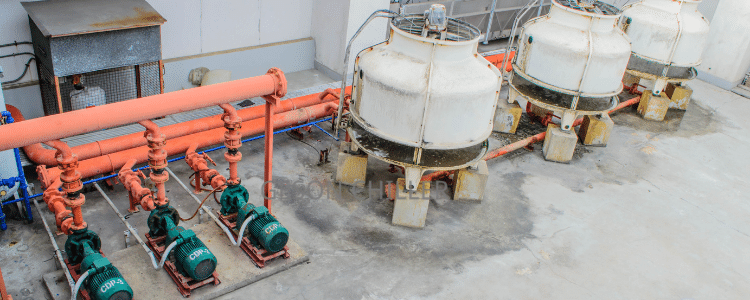

Illustrative image related to water chill

Why is Water Chill Essential in Healthcare Facilities?

In healthcare settings, chilled water systems are used to provide safe drinking water for patients and staff, as well as to maintain controlled conditions in laboratories. These systems must comply with strict health regulations to ensure safety and reliability. Buyers in this sector should prioritize durability and ease of installation, as well as the ability to meet specific cooling requirements, to ensure that they are investing in systems that enhance patient care and operational efficiency.

How Do Hotels Benefit from Water Chill Systems?

Hotels and resorts utilize water chill systems to provide guests with chilled water and beverages, which enhances the overall guest experience. These systems can be integrated into various amenities, including swimming pools and fitness centers, to ensure guest comfort. When sourcing these systems, hospitality businesses should consider space constraints and aesthetic factors, as well as energy consumption, to ensure that the chillers contribute positively to their sustainability goals.

What Importance Does Water Chill Have in Agriculture?

In agriculture, particularly in post-harvest processing, water chill systems are crucial for preserving the freshness and quality of produce. By maintaining optimal temperatures during storage and transportation, these systems help reduce spoilage and extend shelf life. Buyers in this sector should look for systems that can adapt to local climate conditions and meet specific water quality standards, ensuring that they maintain the integrity of their products while minimizing waste.

Illustrative image related to water chill

3 Common User Pain Points for ‘water chill’ & Their Solutions

Scenario 1: Inconsistent Cooling Performance in High Demand Situations

The Problem: B2B buyers often encounter challenges when their water chill systems fail to provide consistent cooling, especially during peak usage times. This inconsistency can lead to customer dissatisfaction in commercial settings such as restaurants, hotels, or office buildings, where access to chilled water is crucial. For example, a hotel might experience complaints from guests if the chilled water supply fails during a busy summer season, leading to a potential loss of business and reputation.

The Solution: To ensure optimal performance under high demand, buyers should look for water chillers that come equipped with features designed for scalability and efficiency. When sourcing a water chiller, consider models that have a higher capacity and faster cooling capabilities, such as those that can chill multiple gallons per hour. Implementing a system that includes redundancy, such as dual chillers, can help maintain a consistent supply even during peak times. Additionally, regular maintenance schedules and performance monitoring can prevent potential breakdowns. Buyers should prioritize suppliers who offer comprehensive warranties and technical support to ensure any issues can be resolved quickly.

Scenario 2: Integration Challenges with Existing Filtration Systems

The Problem: Another common pain point for B2B buyers is the difficulty in integrating water chill systems with existing reverse osmosis (RO) or filtration systems. Many businesses have already invested in water filtration technology, and finding a compatible chiller can be a logistical nightmare. Incompatibility can lead to increased costs, delays in installation, and potential operational disruptions, affecting overall service delivery.

The Solution: To effectively integrate a water chiller with existing filtration systems, buyers should focus on universal compatibility options that are explicitly designed to work with various RO systems. When making a purchase, it’s essential to consult with the supplier regarding the specifications and compatibility of the chiller with the current filtration setup. Additionally, buyers should consider working with vendors who provide detailed installation guides and support, ensuring a smoother transition. This proactive approach minimizes installation delays and helps maintain continuous access to chilled water, enhancing customer satisfaction.

Illustrative image related to water chill

Scenario 3: Limited Space for Installation and Operation

The Problem: Many B2B environments, particularly urban settings, face space constraints that make it challenging to install traditional water chillers. For instance, small cafes or mobile food vendors might not have the room for bulky equipment, leading to the need for innovative solutions that still meet their cooling needs without compromising their operational space.

The Solution: To address space limitations, businesses should explore compact water chiller models that are designed for under-sink installation or have a smaller footprint. These units often provide efficient cooling while fitting seamlessly into tight spaces. Buyers should assess the dimensions and installation requirements of potential chillers before making a decision. Furthermore, consulting with suppliers who specialize in space-saving designs can yield additional insights and options. Investing in a compact chiller not only saves space but can also enhance the overall aesthetic of the service area, allowing businesses to maximize both functionality and customer experience.

Strategic Material Selection Guide for water chill

What Are the Key Materials Used in Water Chillers?

When selecting materials for water chillers, it is essential to consider their properties, advantages, disadvantages, and how they align with the specific needs of international B2B buyers. Here, we analyze four common materials: stainless steel, copper, plastic, and aluminum.

How Does Stainless Steel Perform in Water Chillers?

Key Properties: Stainless steel is renowned for its excellent corrosion resistance and high-temperature tolerance, making it suitable for a variety of environments. It typically withstands pressures up to 150 psi, depending on the grade used.

Pros & Cons: The durability of stainless steel ensures a long lifespan, reducing the need for frequent replacements. However, it is relatively expensive compared to other materials, which can increase initial investment costs. Manufacturing complexity is moderate, as stainless steel requires specialized welding techniques.

Illustrative image related to water chill

Impact on Application: Stainless steel is compatible with a wide range of media, including potable water and various cooling fluids, making it a versatile choice for diverse applications.

Considerations for International Buyers: Compliance with international standards such as ASTM A240 for stainless steel is crucial. Buyers from regions like Europe and the Middle East may also prefer grades that meet specific health and safety regulations.

What Role Does Copper Play in Water Chillers?

Key Properties: Copper offers excellent thermal conductivity, which enhances the efficiency of heat exchange in chillers. It can handle high pressures, typically around 100 psi, and has natural antimicrobial properties.

Pros & Cons: The primary advantage of copper is its superior heat transfer capabilities, leading to energy savings. However, it is more expensive than plastic and can be prone to corrosion if not properly maintained. The manufacturing process can be complex due to the need for precise soldering techniques.

Impact on Application: Copper is ideal for applications requiring rapid cooling, such as in commercial kitchens or laboratories. However, it may not be suitable for all types of fluids, particularly those that are highly acidic or alkaline.

Considerations for International Buyers: Compliance with standards like ASTM B280 for copper tubing is essential. Buyers in regions like Brazil and South Africa should consider local corrosion rates and maintenance practices.

How Do Plastics Compare in Water Chillers?

Key Properties: Plastics, such as polypropylene and PVC, are lightweight and resistant to corrosion and chemical degradation. They typically handle pressures up to 50 psi, making them suitable for low-pressure applications.

Pros & Cons: The low cost and ease of manufacturing make plastics an attractive option for budget-conscious buyers. However, they may not withstand high temperatures as well as metals and can have a shorter lifespan under constant use.

Impact on Application: Plastics are suitable for applications involving non-potable water or less demanding cooling needs. They are often used in residential systems or small-scale commercial units.

Considerations for International Buyers: Buyers should ensure that the chosen plastic complies with relevant standards, such as ASTM D1784 for PVC. In regions like Africa and South America, where UV exposure can be high, selecting UV-resistant plastics is essential.

What Advantages Does Aluminum Offer for Water Chillers?

Key Properties: Aluminum is lightweight and has good thermal conductivity, making it a popular choice for many cooling applications. It can typically handle pressures up to 80 psi.

Pros & Cons: The primary advantage of aluminum is its balance between cost and performance. However, it is less durable than stainless steel and can corrode if not adequately treated or coated.

Illustrative image related to water chill

Impact on Application: Aluminum is suitable for applications where weight is a concern, such as portable chillers. However, it may not be ideal for environments with high humidity or corrosive agents.

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum extrusions is necessary. Buyers in Europe may also look for anodized finishes to enhance corrosion resistance.

Summary of Material Selection for Water Chillers

| Material | Typical Use Case for water chill | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Commercial & industrial applications | Excellent durability & corrosion resistance | Higher initial cost | High |

| Copper | High-efficiency cooling systems | Superior thermal conductivity | More expensive & corrosion-prone | High |

| Plastic | Residential & low-pressure systems | Lightweight & cost-effective | Limited temperature/pressure tolerance | Low |

| Aluminum | Portable & lightweight chillers | Good thermal conductivity & lightweight | Less durable & potential for corrosion | Medium |

This guide provides a comprehensive overview of material selection for water chillers, aiding international B2B buyers in making informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for water chill

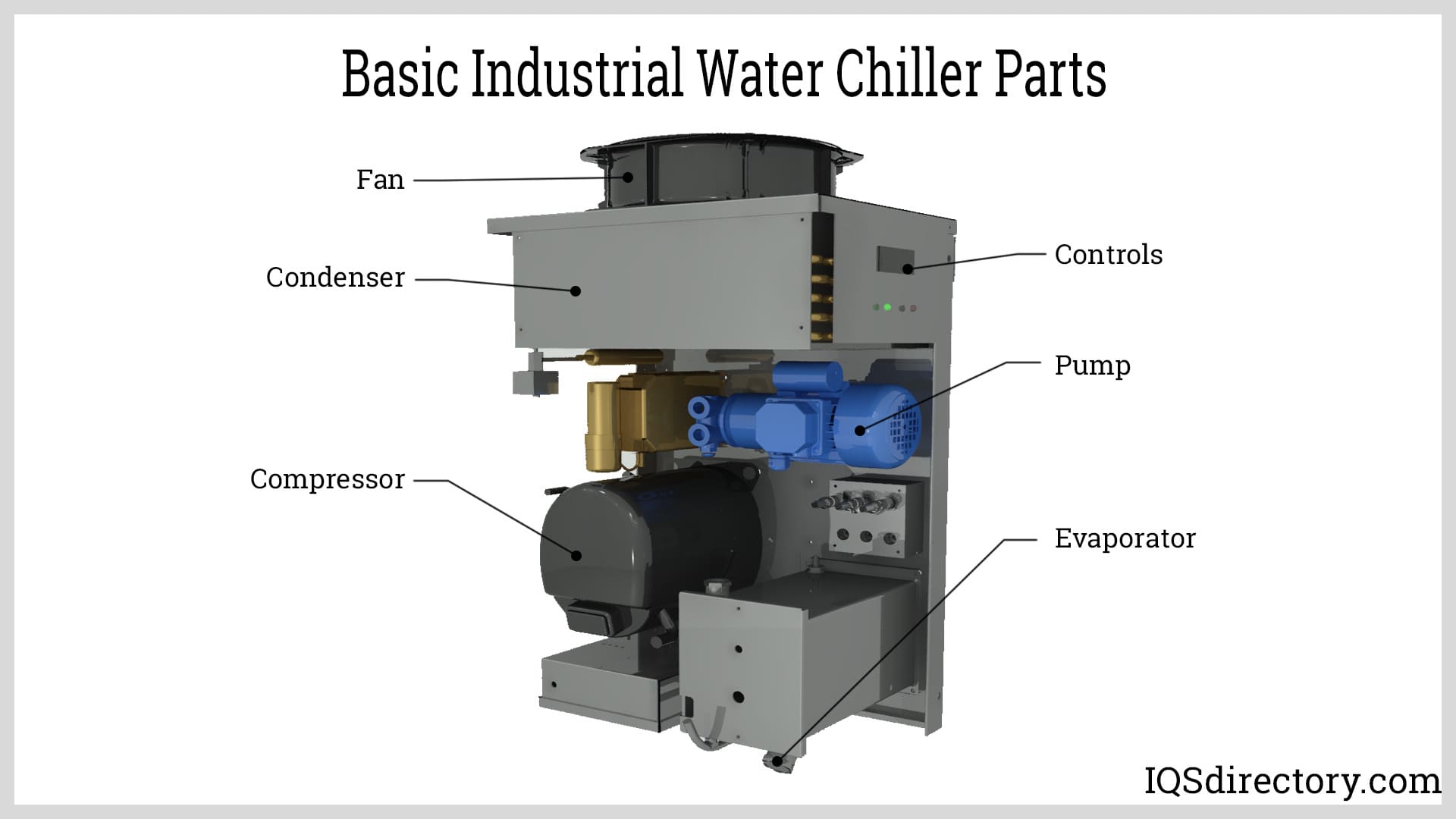

What Are the Key Stages in the Manufacturing Process of Water Chillers?

The manufacturing process of water chillers encompasses several critical stages, ensuring that the end product meets high standards of performance and reliability.

Material Preparation

The first step involves sourcing high-quality materials suitable for the construction of water chillers. Common materials include stainless steel for water tanks, copper for coils, and durable plastics for external housing. Suppliers often prioritize materials that offer corrosion resistance and thermal conductivity. B2B buyers should seek manufacturers who have established relationships with reputable suppliers, ensuring the integrity of the materials used.

Illustrative image related to water chill

Forming Techniques

Once materials are sourced, they undergo forming processes. This typically includes cutting, bending, and shaping metals and plastics into the required components. Advanced techniques such as CNC machining and laser cutting are frequently employed to achieve precision. Manufacturers may also use molding processes for plastic components, ensuring consistency in design and functionality. B2B buyers should inquire about the technology and machinery used in forming, as this can impact the quality of the final product.

Assembly Processes

The assembly stage is where various components come together to form the water chiller. This process often involves manual labor as well as automated systems for efficiency. Key components, including compressors, heat exchangers, and control systems, are assembled with a focus on minimizing leaks and ensuring optimal airflow. Manufacturers typically follow standardized assembly procedures to maintain quality. Buyers should assess whether the manufacturer utilizes skilled labor and automated processes to enhance accuracy and reduce the risk of defects.

Finishing Touches

After assembly, water chillers undergo finishing processes, which can include painting, polishing, and applying protective coatings. This not only enhances the aesthetic appeal but also provides additional protection against environmental factors. Depending on the market, manufacturers may also focus on achieving specific certifications for their finishes, such as lead-free or low-VOC paints. B2B buyers should look for manufacturers that adhere to environmentally friendly practices and can provide documentation of their finishing processes.

How is Quality Assurance Implemented in Water Chiller Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that water chillers meet both international and industry-specific standards.

What International Standards Should B2B Buyers Be Aware Of?

Manufacturers of water chillers often comply with international standards such as ISO 9001, which focuses on quality management systems. Compliance with ISO standards demonstrates a commitment to continuous improvement and customer satisfaction. Additionally, certifications like CE mark (indicating conformity with health, safety, and environmental protection standards) and API (American Petroleum Institute) certifications are crucial for specific markets. B2B buyers should prioritize suppliers with documented certifications, as this reflects a manufacturer’s adherence to quality and safety standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are essential for maintaining product integrity throughout the manufacturing process. These checkpoints typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the assembly phase, manufacturers conduct inspections to catch defects early, ensuring that components are correctly assembled and functioning as intended.

- Final Quality Control (FQC): Before products are shipped, a comprehensive inspection is performed to verify overall performance and compliance with specifications.

B2B buyers should inquire about the specific QC processes employed by potential suppliers and request access to QC reports for transparency.

What Common Testing Methods Are Used to Ensure Quality?

Testing methods for water chillers vary depending on the manufacturer but typically include:

- Performance Testing: Assessing the chiller’s cooling efficiency, flow rate, and temperature consistency under various conditions.

- Leak Testing: Ensuring that all joints and connections are secure to prevent water leakage, which can lead to significant issues.

- Durability Testing: Subjecting products to stress tests that simulate real-world conditions to ensure long-term reliability.

B2B buyers should request information on the testing protocols used by manufacturers, including any third-party testing certifications that may enhance credibility.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control practices is crucial for B2B buyers looking to establish long-term partnerships. Here are several strategies:

Illustrative image related to water chill

-

Audits: Conducting on-site audits allows buyers to observe manufacturing practices and quality assurance processes in real-time. This can provide insights into the supplier’s commitment to quality.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the QC processes and outcomes. These reports should outline inspection results, testing methods, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing capabilities and product quality. This is particularly important for international buyers, as it can help bridge the gap between different regulatory standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, must navigate various regulatory landscapes and quality expectations. Here are key considerations:

-

Regional Standards: Different regions may have specific regulations governing product safety and quality. For instance, the EU has stringent standards that manufacturers must comply with to sell products in the European market. Buyers should ensure that suppliers are familiar with these regulations.

-

Cultural Considerations: Understanding cultural differences in business practices can help in negotiations and relationship building. Building trust through transparency about quality control can enhance partnerships.

-

Logistics and Supply Chain: Quality control does not end at manufacturing. B2B buyers should consider the entire supply chain, including how products are stored and transported. Ensuring that suppliers have robust logistics practices can help maintain product integrity from factory to final destination.

In conclusion, the manufacturing processes and quality assurance practices for water chillers are crucial aspects that B2B buyers should thoroughly evaluate. By understanding these processes and implementing rigorous verification methods, buyers can ensure they partner with reliable manufacturers who meet their quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘water chill’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure water chillers, ensuring that you make informed decisions tailored to your business needs. Whether you are in Africa, South America, the Middle East, or Europe, understanding the key considerations in sourcing water chillers will help you select the right product and supplier.

1. Define Your Technical Specifications

Before initiating your procurement process, clearly outline the technical specifications required for your water chiller. This includes parameters such as capacity (gallons per hour), temperature range, and compatibility with existing systems like Reverse Osmosis (RO) setups. Establishing these specifications upfront helps narrow down options and ensures that the selected chiller meets your operational needs.

2. Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers with a strong reputation in the water chiller market. Look for manufacturers with experience in your specific region and industry. Utilize online platforms, trade shows, and industry publications to gather a list of potential suppliers who meet your criteria.

- Tip: Pay attention to customer reviews and case studies to gauge reliability.

3. Evaluate Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications for quality and safety standards. Look for certifications such as ISO 9001, CE, or other relevant local standards that confirm compliance with industry regulations. Certifications are critical as they reflect a commitment to quality and can significantly impact your operational efficiency.

4. Request Product Samples or Demonstrations

Before finalizing your purchase, request samples or arrange for product demonstrations. This allows you to assess the performance and reliability of the water chillers first-hand. Evaluate key features such as cooling efficiency, ease of installation, and maintenance requirements.

- Note: If possible, conduct a test installation to verify compatibility with your existing systems.

5. Negotiate Pricing and Terms

Engage in negotiations with shortlisted suppliers to secure the best pricing and terms. Discuss bulk purchase discounts, warranty conditions, and after-sales support. Understanding the total cost of ownership, including installation and maintenance, is vital for making a financially sound decision.

6. Verify Supply Chain Capabilities

Assess the supplier’s supply chain and logistics capabilities to ensure timely delivery of your water chillers. Investigate their inventory management practices, lead times, and shipping options to avoid disruptions in your operations. A reliable supplier should demonstrate a robust logistics plan to meet your business timelines.

Illustrative image related to water chill

7. Establish a Support and Maintenance Plan

Once you have procured your water chillers, establish a support and maintenance plan with the supplier. This should include routine maintenance schedules, troubleshooting support, and access to spare parts. A solid support plan can help extend the lifespan of your equipment and minimize downtime.

By following these steps, B2B buyers can confidently navigate the procurement process for water chillers, ensuring they select the right products and suppliers to meet their business needs.

Comprehensive Cost and Pricing Analysis for water chill Sourcing

What Are the Key Cost Components for Water Chiller Sourcing?

When sourcing water chillers, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The choice of materials significantly impacts the overall cost. High-quality components, such as stainless steel for tanks and durable plastics for housing, can lead to higher initial costs but improve longevity and performance, ultimately reducing maintenance expenses.

-

Labor: Labor costs vary by region and manufacturing process. In countries with higher labor costs, such as Germany, the overall price may be elevated. Conversely, sourcing from regions with lower labor rates can provide cost savings, though this may affect quality.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses associated with production. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Custom designs may require specific tooling, which can add to the initial investment. Buyers should assess whether the tooling costs are justified by the expected volume of sales or custom specifications.

-

Quality Control (QC): Implementing rigorous QC processes can increase costs, but they are essential for ensuring product reliability and compliance with international standards, which can be particularly important for markets in Europe and North America.

-

Logistics: Shipping costs can vary dramatically based on distance, shipping method, and Incoterms. Understanding these factors is vital for calculating total costs.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. This margin can fluctuate based on market demand and competition.

How Do Pricing Influencers Affect Water Chiller Costs?

Several factors influence pricing, including volume (Minimum Order Quantity – MOQ), specifications/customization, materials used, quality certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Larger orders often qualify for volume discounts, significantly reducing the per-unit cost. Buyers should negotiate MOQs to optimize pricing.

-

Specs/Customization: Customized units may incur additional costs due to unique specifications. It’s essential to balance customization with budget constraints.

-

Materials: The type of materials chosen affects both performance and cost. Sustainable or high-performance materials may command a premium but can lead to long-term savings.

-

Quality/Certifications: Products certified to international standards (e.g., CE, NSF) may have higher upfront costs but can enhance marketability and acceptance in stringent regulatory environments.

-

Supplier Factors: Supplier reputation, reliability, and service level can affect pricing. A reputable supplier may charge more but offer better support and assurance of quality.

-

Incoterms: Understanding shipping terms is crucial. For example, DDP (Delivered Duty Paid) may seem more expensive upfront but can simplify the process for buyers, particularly in international transactions.

What Negotiation Tips Can Help B2B Buyers in Water Chiller Sourcing?

-

Understand Total Cost of Ownership (TCO): Beyond initial purchase prices, consider maintenance, energy efficiency, and lifespan. A higher upfront cost may yield lower operational costs over time.

-

Leverage Market Research: Gather information on competing products and pricing to strengthen negotiation positions. Knowledge of the market allows buyers to negotiate from an informed standpoint.

-

Explore Multiple Suppliers: Engaging with multiple suppliers can create competitive pressure, leading to better pricing and terms.

-

Ask for Flexibility: Don’t hesitate to request adjustments on pricing or terms, especially if you are willing to commit to larger orders.

-

Consider Long-Term Partnerships: Establishing a long-term relationship with a supplier can lead to better pricing and service over time.

Are There Pricing Nuances for International B2B Buyers?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of additional pricing nuances. Currency fluctuations, tariffs, and local regulations can significantly affect costs. It’s advisable to factor in these elements when budgeting for procurement.

Moreover, understanding local market conditions can provide insights into pricing strategies and help buyers negotiate effectively. Always request detailed quotations that include all potential costs to avoid unexpected expenses during the purchasing process.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and current pricing.

Alternatives Analysis: Comparing water chill With Other Solutions

Exploring Alternatives to Water Chilling Solutions

In the realm of cooling solutions for water, various alternatives exist that cater to different needs and operational environments. As businesses seek efficient and cost-effective methods to provide chilled water, understanding the strengths and weaknesses of these alternatives can aid in making informed decisions. Below is a comparative analysis of ‘water chill’ systems against two notable alternatives: traditional refrigeration systems and evaporative cooling systems.

Illustrative image related to water chill

| Comparison Aspect | Water Chill | Traditional Refrigeration | Evaporative Cooling |

|---|---|---|---|

| Performance | Efficient cooling for point-of-use applications; typically chills up to 3 gallons per hour. | High capacity cooling; suitable for large-scale operations. | Effective in dry climates; can lower temperatures significantly. |

| Cost | Moderate initial cost; typically ranges from $1,500 to $2,000. | Higher upfront investment and operating costs due to energy consumption. | Lower installation costs; uses less energy but may require more maintenance. |

| Ease of Implementation | Simple installation; often fits under sinks and connects easily to existing systems. | Requires more complex installation; may need additional space and infrastructure. | Relatively easy to set up, but effectiveness depends on environmental conditions. |

| Maintenance | Low maintenance; typically requires occasional cleaning. | Moderate to high maintenance; involves regular servicing and potential repairs. | Requires frequent maintenance to ensure pads are clean and functioning. |

| Best Use Case | Ideal for residential and small commercial applications needing quick access to chilled water. | Best suited for large facilities, such as industrial plants or hotels, requiring substantial cooling. | Most effective in arid regions where humidity is low, ideal for outdoor settings. |

What are the Pros and Cons of Traditional Refrigeration Systems?

Traditional refrigeration systems are well-established in various industries for their ability to deliver consistent and powerful cooling. They excel in larger applications, such as restaurants, hotels, and manufacturing facilities, where high volumes of chilled water are necessary. However, they come with a higher initial cost and ongoing energy expenses. Maintenance can also be a burden, as these systems require regular servicing to operate efficiently and avoid breakdowns. For businesses with the budget and space, they can provide reliable cooling solutions.

How Does Evaporative Cooling Compare?

Evaporative cooling systems offer a unique approach by leveraging the natural process of water evaporation to cool air. These systems are particularly effective in dry climates, making them a popular choice in regions with low humidity. Their installation costs are generally lower than traditional refrigeration, and they consume less energy, leading to reduced operational costs. However, their efficiency can diminish in humid conditions, and they require consistent maintenance to ensure optimal performance. For businesses located in the right climate, evaporative cooling can be a cost-effective and environmentally friendly solution.

Conclusion: How Can B2B Buyers Choose the Right Cooling Solution?

Selecting the appropriate cooling solution for chilled water needs involves considering factors such as operational requirements, budget constraints, and environmental conditions. For small to medium-sized businesses seeking quick access to chilled water, a water chill system offers an efficient and straightforward solution. Conversely, larger operations may benefit from the robust capabilities of traditional refrigeration systems, while businesses in arid climates might find evaporative cooling to be the most economical choice. By evaluating these alternatives against specific operational needs, B2B buyers can make informed decisions that align with their strategic goals.

Essential Technical Properties and Trade Terminology for water chill

Understanding the technical properties and trade terminology associated with water chill systems is crucial for international B2B buyers. This section outlines key specifications and common jargon that will aid in making informed purchasing decisions.

Illustrative image related to water chill

What Are the Essential Technical Specifications for Water Chillers?

-

Cooling Capacity (BTU/h or kW)

This specification indicates the amount of heat that a chiller can remove from water per hour. It is typically measured in British Thermal Units per hour (BTU/h) or kilowatts (kW). Understanding the cooling capacity is vital for ensuring that the chiller can meet specific temperature requirements in commercial settings, such as food service or manufacturing processes. -

Temperature Range

The operational temperature range of a water chiller defines the minimum and maximum temperatures it can maintain. For instance, some chillers can cool water down to 39.2°F (4°C), while others may operate effectively at higher temperatures. This specification is critical for buyers to ensure that the chiller aligns with their intended application, whether for drinking water, industrial processes, or HVAC systems. -

Material Grade and Construction

Water chillers are often constructed from materials such as stainless steel or aluminum. The material grade impacts durability, corrosion resistance, and overall performance. For B2B buyers, understanding the material properties is essential for evaluating the lifespan and maintenance needs of the equipment, especially in diverse environments like those found in Africa or South America. -

Power Consumption (Watts)

This specification refers to the electrical power required for the chiller to operate effectively. Lower power consumption is often preferred, as it translates to reduced operating costs. Buyers should consider the energy efficiency of chillers, especially in regions where electricity costs are high, or sustainability is a priority. -

Installation Requirements

Installation specifications detail the necessary space, plumbing connections, and electrical requirements for optimal chiller operation. Understanding these requirements helps buyers assess whether they have the necessary infrastructure to support the chiller, thereby avoiding costly modifications post-purchase.

What Common Trade Terms Should B2B Buyers Know?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. For B2B buyers, understanding OEM relationships can help in sourcing components or entire systems that are compatible with existing infrastructure. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This is a critical term for buyers as it affects inventory management and cash flow. Understanding MOQ can help businesses plan their purchases to avoid excess stock or missed opportunities. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. For B2B buyers, issuing an RFQ can help in comparing offers from multiple vendors, ensuring they receive competitive pricing and terms. -

Incoterms (International Commercial Terms)

These are a set of predefined international trade terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers. Knowing Incoterms is essential for B2B transactions, as they define who is responsible for shipping, insurance, and tariffs, thus minimizing misunderstandings in international logistics. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is delivered. Understanding lead times is vital for B2B buyers to manage their supply chain effectively and ensure that projects proceed on schedule.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when purchasing water chill systems, ultimately leading to enhanced operational efficiency and cost savings.

Navigating Market Dynamics and Sourcing Trends in the water chill Sector

What Are the Key Trends Influencing the Water Chill Market?

The global water chill sector is experiencing transformative shifts driven by several key factors. First, the increasing demand for high-quality drinking water across various regions, particularly in Africa and the Middle East, is propelling the adoption of advanced water cooling technologies. This trend is further fueled by rising health awareness and the preference for chilled water over traditional options. Additionally, the integration of Internet of Things (IoT) technologies is enhancing operational efficiencies, allowing for real-time monitoring and management of water chillers, which is particularly appealing to B2B buyers seeking cost-effective solutions.

Emerging trends also indicate a growing inclination toward energy-efficient systems. With energy costs rising globally, water chillers that offer lower energy consumption are becoming increasingly desirable. Buyers are more inclined to invest in solutions that not only meet their immediate cooling needs but also contribute to long-term cost savings. Furthermore, the global supply chain dynamics are reshaping sourcing strategies, with companies looking to diversify their suppliers to mitigate risks associated with geopolitical tensions and economic fluctuations. This creates opportunities for international buyers to explore new partnerships in emerging markets, particularly in South America and Africa.

How Is Sustainability Reshaping the Water Chill Sector?

Sustainability is becoming a cornerstone in the sourcing strategies of B2B buyers in the water chill sector. The environmental impact of traditional cooling systems has prompted a shift towards eco-friendly alternatives. Manufacturers are now focusing on developing water chillers with sustainable materials and energy-efficient technologies that minimize carbon footprints. This shift not only aligns with global sustainability goals but also meets the growing consumer demand for environmentally responsible products.

Ethical sourcing practices are equally crucial. B2B buyers are increasingly prioritizing suppliers who demonstrate transparency in their supply chains and adhere to ethical labor practices. Certifications such as Energy Star, Green Seal, and ISO 14001 are becoming essential indicators for assessing the sustainability credentials of water chill products. These certifications provide buyers with assurance that they are making responsible purchasing decisions that contribute positively to the environment and society.

Illustrative image related to water chill

How Has the Water Chill Sector Evolved Over Time?

The evolution of the water chill sector reflects broader technological advancements and changing consumer preferences. Initially, water chillers were primarily mechanical devices focused on basic cooling capabilities. However, the advent of modern technologies has transformed them into sophisticated systems capable of integrating with filtration systems and smart home devices. Over the years, the emphasis has shifted from mere functionality to enhancing user experience and environmental sustainability.

As the market continues to evolve, international B2B buyers must stay informed about these changes to make strategic sourcing decisions that align with their business goals and the growing demand for high-quality, sustainable water cooling solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of water chill

-

How do I select the right water chiller for my business needs?

When selecting a water chiller, consider your specific cooling requirements, such as the desired temperature range and the volume of chilled water needed per hour. Evaluate compatibility with existing systems, such as reverse osmosis units, and check the chiller’s energy efficiency ratings. It’s also crucial to assess the physical dimensions to ensure it fits within your operational space. Consulting with suppliers for expert recommendations based on your industry can streamline the selection process. -

What are the key features to look for in a commercial water chiller?

Key features to consider include cooling capacity (measured in BTUs), energy efficiency ratings, and the type of refrigerant used. Look for models with durable construction, like stainless steel, to enhance longevity. Additional features such as easy installation, low maintenance requirements, and noise levels should also be evaluated. Certifications like C-UL-US and CE can provide assurance of quality and safety standards. -

What customization options are available for water chillers?

Many manufacturers offer customization options for their water chillers, including size, cooling capacity, and specific temperature settings. You can also request tailored designs to accommodate unique installation spaces or brand-specific finishes. Discussing your specific requirements with suppliers can lead to solutions that better fit your operational needs and branding efforts. -

What is the minimum order quantity (MOQ) for water chillers when sourcing internationally?

Minimum order quantities vary by supplier and can depend on factors such as the type of chiller and customization requests. Typically, MOQs can range from a single unit for standard models to larger quantities for customized orders. It’s advisable to communicate directly with potential suppliers to understand their MOQ policies and negotiate terms that align with your purchasing strategy. -

What payment terms should I expect when sourcing water chillers?

Payment terms for international purchases often vary by supplier but commonly include options like 30% upfront payment with the balance due prior to shipment. Some suppliers may offer net 30 or net 60 terms based on your creditworthiness and relationship history. It’s essential to clarify all payment conditions, including currency, to avoid misunderstandings and ensure smooth transactions. -

How can I ensure quality assurance when sourcing water chillers?

To ensure quality, request detailed product specifications and certifications from suppliers. Consider conducting factory audits or requesting samples before placing large orders. Establish a clear quality assurance process that includes inspection protocols upon receipt of goods. Building strong relationships with reputable suppliers and maintaining open communication can also enhance trust and reliability. -

What logistics considerations should I keep in mind when importing water chillers?

Logistics considerations include shipping methods, lead times, and customs regulations in your country. Depending on the size and weight of the chillers, you may choose between air freight for speed or sea freight for cost-effectiveness. Ensure that your supplier provides necessary documentation for customs clearance, and consider working with a freight forwarder to navigate the logistics process efficiently. -

What are the common maintenance practices for commercial water chillers?

Regular maintenance of water chillers includes cleaning filters, checking refrigerant levels, and inspecting electrical components. Schedule routine servicing to ensure optimal performance and to extend the lifespan of the unit. Keeping a maintenance log can help track service schedules and identify potential issues early. Training staff on basic troubleshooting can also mitigate downtime and enhance operational efficiency.

Top 10 Water Chill Manufacturers & Suppliers List

1. Express Water – Universal Undersink Water Chiller

Domain: expresswater.com

Registered: 2007 (18 years)

Introduction: Universal Undersink Water Chiller by Express Water

– SKU: PC2000

– Compatibility: Designed for use with Reverse Osmosis Water Filtration Systems

– Features: Effectively cools filtered water for a refreshing taste

– Setup: Easy ¼” quick connect installation

– Maximum Pressure Limit: 50 psi recommended for optimal performance

– Recommended Use: Best installed after a Reverse Osmosis system

2. EKWB – EK-Quantum Velocity² D-RGB

Domain: performance-pcs.com

Registered: 2000 (25 years)

Introduction: All Products/Water Cooling/Water Chillers – Performance-PCs.com Products VIEW ALL. New EKWB Intel CPU Block! EK-Quantum Velocity² D-RGB – 1700 Nickel + Plexi is the new high-performance premium quality CPU water block for the new Intel® socket LGA 1700-based platform.

3. Elkay – Drinking Water Chillers

Domain: elkay.com

Registered: 1995 (30 years)

Introduction: This company, Elkay – Drinking Water Chillers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Mountain Plumbing – Mountain Chill® Water Chiller

Domain: mountainplumbing.com

Registered: 1998 (27 years)

Introduction: Mountain Chill® Water Chiller

– Model: MT670-2

– Cooling Capacity: Cools water to between 39.2° F to 50° F

– Tank Size: Large 1/2 Gallon Stainless Steel Tank

– Output: Chills up to 3 gallons per hour

– Construction: Lead Free

– Installation: Attaches to Point-of-Use Accessory Faucet

– Dimensions: 16″ Wide x 10-1/8″ High x 11-3/4″ Deep

– Warranty: 3 Year Compressor Warranty

– Certifications: C-UL-U…

5. Pentair AES – Chillers

Domain: pentairaes.com

Registered: 2012 (13 years)

Introduction: Chillers from Pentair AES are designed for various applications, offering efficient cooling solutions. They feature advanced technology for optimal performance, energy efficiency, and reliability. The product range includes options suitable for both residential and commercial use, with varying capacities to meet different cooling needs. Key specifications include temperature control, durable const…

6. Filtrine – Water Cooled Chillers

Domain: filtrine.com

Registered: 1998 (27 years)

Introduction: Filtrine’s Water Cooled Chillers are self-contained liquid chillers designed for industrial and medical processes. Key features include:

– Water cooled condenser (Model W option)

– Storage method of cooling with stainless steel chiller barrel and evaporator

– Coolant circulation pump sized for proper flow rate and pressure

– Ambient temperature operating range from -30°F [-34°C] to 130°F [54°C…

7. Pro Drinking Fountains – Remote Water Chillers

Domain: prodrinkingfountains.com

Registered: 2011 (14 years)

Introduction: Remote Water Chillers and Remote Cooling Packages available for order online 24/7. Contact via phone at 888-503-7937 or chat online Monday to Friday from 9AM to 5PM EST. Products include various models from manufacturers such as ELKAY, Halsey Taylor, HAWS, and OASIS, featuring ADA compliant options, bottle filling stations, outdoor fountains, and more. The chillers are designed for commercial use,…

8. GARVEE – Water Chiller

Domain: garvee.com

Registered: 2022 (3 years)

Introduction: Water Chiller – Efficient Cooling Systems | GARVEE

9. Whaley Products – Water-Cooled Chillers

Domain: whaleyproducts.com

Registered: 1999 (26 years)

Introduction: Water-cooled chillers are designed for efficient cooling in various industrial processes. Whaley Products, Inc. manufactures high-performance water-cooled chillers for markets including chemical processing, food and beverage processing, metal manufacturing, HVAC, and more. Key features include:

– Customizable options for standard and custom-designed chillers.

– Available capacities range from 1.5…

10. Pod Company – The Pod Chiller

Domain: podcompany.com

Registered: 2009 (16 years)

Introduction: Product Name: The Pod Chiller – Water Chiller for Ice Bath

Regular Price: $1,197.00 USD

Sale Price: $799.00 USD

Cooling Capability: Cools to 39°F

Water Filtration: 20-micron water filtration

Features:

– Most powerful yet efficient chiller in its class

– No plumbing or special installation required

– Engineered to perform like $4000+ chillers at a fraction of the price

Recommended Add-ons:

– The …

Strategic Sourcing Conclusion and Outlook for water chill

How Can Strategic Sourcing Enhance Your Water Chilling Solutions?

In conclusion, the strategic sourcing of water chillers is essential for international B2B buyers aiming to enhance their operational efficiency and customer satisfaction. By carefully selecting suppliers that offer high-quality, energy-efficient, and reliable water chilling systems, businesses can significantly reduce operational costs while ensuring that they meet the growing demand for chilled water solutions in various industries.

Investing in advanced water chillers, such as those compatible with reverse osmosis systems, not only guarantees superior water quality but also aligns with sustainability goals. Moreover, understanding local market dynamics across regions like Africa, South America, the Middle East, and Europe can inform better procurement decisions and foster long-term partnerships.

As the demand for chilled water solutions continues to rise, particularly in warmer climates and urban environments, now is the time for B2B buyers to leverage strategic sourcing to secure innovative and competitive solutions. Embrace this opportunity to enhance your product offerings and meet customer expectations for quality and convenience. Reach out to trusted suppliers and start your journey toward optimized water chilling solutions today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to water chill

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.