Unlocking Value: A Strategic Analysis of the Glass Cooker Price Market

Introduction: Navigating the Global Market for glass cooker price

In today’s competitive landscape, sourcing glass cookers at optimal prices presents a significant challenge for international B2B buyers. With the increasing demand for stylish and efficient cooking solutions, understanding the nuances of glass cooker pricing is essential for making informed purchasing decisions. This comprehensive guide explores various types of glass cookers, their applications, and the factors influencing their costs, catering specifically to buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Brazil.

Navigating the global market for glass cookers involves not only identifying the right product but also vetting suppliers to ensure reliability and quality. This guide provides actionable insights on how to assess suppliers, compare prices, and understand the value propositions of different models, from traditional gas cooktops to modern electric ranges. By breaking down the complexities of pricing structures, including considerations for shipping and tariffs, we empower buyers to negotiate better deals and make strategic investments that align with their business goals.

Whether you are a distributor looking to expand your offerings or a retailer aiming to meet consumer demands, this guide serves as a vital resource for navigating the intricacies of the glass cooker market. Equip yourself with the knowledge needed to make confident purchasing decisions and enhance your competitive edge in the global marketplace.

Understanding glass cooker price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Glass Cookers | Smooth glass surface, radiant heating elements | Restaurants, catering services | Pros: Easy to clean, precise temperature control. Cons: Potential for scratches, slower heating compared to gas. |

| Gas Glass Cooktops | High-performance burners, glass surface for aesthetics | Hotels, commercial kitchens | Pros: Quick heating, more control over flame. Cons: Requires gas line installation, safety concerns with gas leaks. |

| Induction Glass Cookers | Magnetic heating technology, sleek glass surface | High-end restaurants, residential use | Pros: Energy-efficient, cool-to-touch surface. Cons: Requires compatible cookware, higher upfront costs. |

| Built-in Glass Cooktops | Integrated design, customizable sizes and configurations | Modern kitchens, luxury apartments | Pros: Space-saving, seamless integration. Cons: Installation complexity, potentially higher costs. |

| Portable Glass Cookers | Compact design, typically electric or induction-based | Food trucks, temporary catering setups | Pros: Versatile, easy to transport. Cons: Limited cooking capacity, may lack advanced features. |

What Are Electric Glass Cookers and Their B2B Suitability?

Electric glass cookers are characterized by their smooth glass surface and radiant heating elements. They are commonly used in restaurants and catering services due to their ease of cleaning and precise temperature control. B2B buyers should consider the maintenance costs and potential for surface scratches, which may affect aesthetics over time. The ability to maintain a consistent cooking temperature makes them ideal for dishes requiring precision, thereby enhancing operational efficiency.

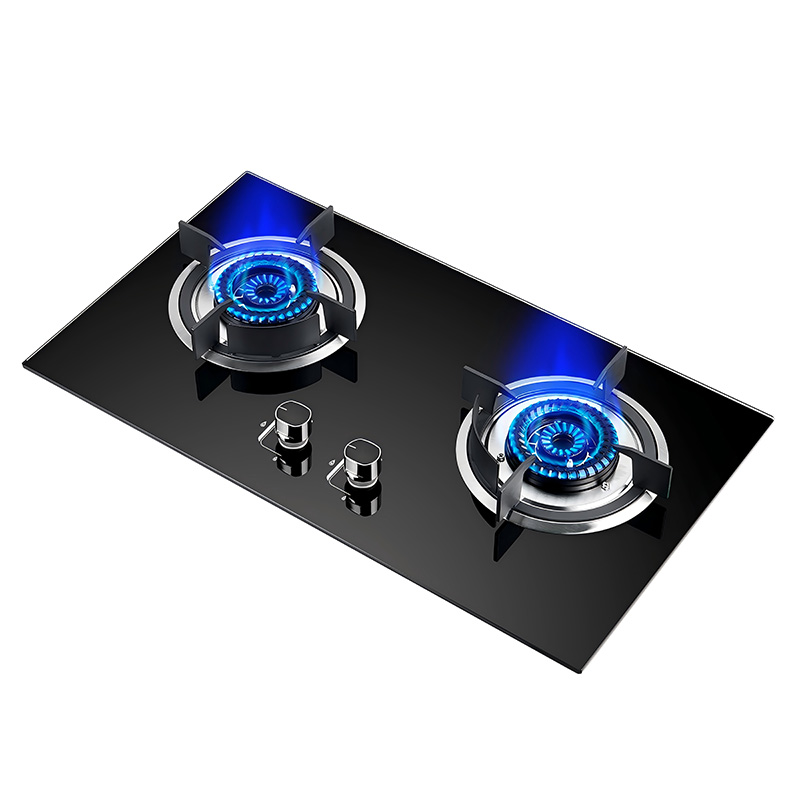

Why Choose Gas Glass Cooktops for Commercial Applications?

Gas glass cooktops are distinguished by their high-performance burners and elegant glass surfaces. These cooktops are particularly favored in hotels and commercial kitchens, where rapid heating and flame control are essential for food preparation. Buyers should weigh the benefits of quick cooking times against the need for gas line installations and safety measures to prevent gas leaks. Their ability to provide a traditional cooking experience can be advantageous in culinary settings that emphasize flavor and technique.

How Do Induction Glass Cookers Stand Out in the Market?

Induction glass cookers utilize magnetic heating technology, offering a sleek and modern cooking solution. They are particularly suited for high-end restaurants and residential use due to their energy efficiency and safety features, such as a cool-to-touch surface. B2B buyers must consider the compatibility of cookware and the higher initial investment, but the long-term energy savings and speed of cooking can justify the costs in a professional kitchen environment.

What Are the Advantages of Built-in Glass Cooktops for Modern Kitchens?

Built-in glass cooktops provide a seamless and integrated design that is customizable to fit various kitchen layouts. They are ideal for modern kitchens and luxury apartments, offering space-saving solutions without compromising on style. B2B buyers should assess the installation complexity and potential costs, as these cooktops often require professional installation. Their aesthetic appeal and functionality make them a popular choice in upscale culinary environments.

Why Consider Portable Glass Cookers for Temporary Setups?

Portable glass cookers are compact and versatile, typically powered by electricity or induction. They are ideal for food trucks and temporary catering setups where space is limited. Buyers should evaluate their cooking capacity and the absence of advanced features, which may restrict their use in high-demand cooking environments. However, their mobility and ease of transport make them a practical option for businesses that require flexibility in their cooking solutions.

Key Industrial Applications of glass cooker price

| Industry/Sector | Specific Application of glass cooker price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Restaurant kitchens outfitted with glass cookers | Enhanced cooking efficiency and aesthetic appeal | Durability, ease of cleaning, and energy efficiency |

| Retail | Kitchen appliance retailers offering glass cooktops | Competitive pricing and diverse product range | Supplier reliability, warranty offerings, and logistics |

| Residential | Home appliance distributors targeting upscale markets | High demand for stylish and modern cooking solutions | Product variety, local market preferences, and pricing |

| Food Processing | Industrial kitchens in food production facilities | Improved cooking precision and reduced preparation time | Compliance with safety standards and energy consumption |

| Catering Services | Mobile catering units utilizing portable glass cookers | Versatility in cooking methods and portability | Size options, fuel type compatibility, and maintenance support |

How is Glass Cooker Price Utilized in the Hospitality Sector?

In the hospitality industry, glass cookers are increasingly being adopted in restaurant kitchens. Their sleek design not only enhances the kitchen’s aesthetics but also improves cooking efficiency. These cookers allow chefs to monitor cooking processes easily, which is crucial in high-paced environments. B2B buyers in this sector should consider the durability and energy efficiency of glass cookers, as well as their ease of cleaning to maintain high hygiene standards.

What Role Does Glass Cooker Price Play in Retail Markets?

Retailers specializing in kitchen appliances can leverage glass cooktops to attract customers seeking modern and stylish cooking solutions. Offering a diverse range of glass cookers at competitive prices can enhance a retailer’s market position. International buyers, especially from regions like Africa and South America, should focus on supplier reliability and warranty options to ensure customer satisfaction and minimize returns.

How Are Glass Cookers Beneficial for Residential Distributors?

Residential distributors targeting upscale markets find glass cookers to be a valuable addition to their product lines. These cooktops appeal to consumers looking for functionality combined with a modern aesthetic. Buyers in this segment should prioritize product variety to cater to diverse consumer preferences and consider local market trends in design and pricing strategies.

Why Are Glass Cookers Important in Food Processing Industries?

In food processing facilities, the use of glass cookers can significantly enhance cooking precision and reduce preparation times. These cookers allow for better temperature control, which is essential for food safety and quality. B2B buyers in this sector must ensure that the cookers comply with local safety standards and consider the energy consumption rates to optimize operational costs.

How Do Catering Services Benefit from Glass Cookers?

Mobile catering units benefit immensely from the versatility of portable glass cookers. These appliances allow caterers to prepare a variety of dishes on-site, enhancing service delivery and customer satisfaction. Buyers in the catering industry should evaluate size options and fuel type compatibility to ensure that the cookers meet the specific needs of their operations, alongside considerations for maintenance support to minimize downtime.

Illustrative image related to glass cooker price

3 Common User Pain Points for ‘glass cooker price’ & Their Solutions

Scenario 1: Navigating Price Variability in Different Markets

The Problem: B2B buyers often encounter significant price fluctuations for glass cookers across various markets. This is particularly pronounced for international buyers from regions like Africa and South America, where local economic conditions, import duties, and currency exchange rates can dramatically affect pricing. For example, a buyer in Nigeria may find that the same model of a glass cooker is priced much higher than in Europe due to additional tariffs or shipping costs. This inconsistency can complicate budgeting and financial forecasting for businesses looking to maintain competitive pricing.

The Solution: To effectively manage price variability, buyers should establish relationships with multiple suppliers across different regions. Conducting thorough market research to understand local pricing structures can also help identify more cost-effective options. Leveraging trade agreements or negotiating bulk purchase discounts can further mitigate price discrepancies. Additionally, utilizing a centralized procurement strategy can streamline purchasing decisions and provide better oversight on pricing trends, allowing businesses to adjust their strategies based on real-time data.

Scenario 2: Assessing Quality vs. Cost in Glass Cookers

The Problem: Another common challenge for B2B buyers is balancing the cost of glass cookers with their quality and durability. Lower-priced options may seem attractive initially, but they often come with trade-offs in performance and longevity, leading to higher replacement costs in the long run. For instance, a buyer may be tempted to purchase a cheaper model, only to find that it doesn’t withstand high usage in a commercial kitchen, resulting in dissatisfaction from clients and increased operational costs.

The Solution: To ensure a smart investment, buyers should prioritize quality assessments alongside price evaluations. This can be achieved by requesting samples or demonstrations before making bulk purchases. Additionally, seeking out brands with strong warranties and customer service can provide peace of mind. Engaging in peer reviews and leveraging online resources to compare product performance ratings can also help buyers make informed decisions. Ultimately, investing in higher-quality glass cookers may yield better value over time, reducing the frequency of replacements and associated costs.

Scenario 3: Understanding Total Cost of Ownership for Glass Cookers

The Problem: Many B2B buyers focus solely on the initial purchase price of glass cookers, neglecting the total cost of ownership (TCO), which includes energy consumption, maintenance, and operational efficiency. For instance, a glass cooker with a lower upfront price may consume more energy or require more frequent repairs, leading to higher overall costs. This oversight can significantly impact a company’s bottom line, especially in industries where every expense is scrutinized.

The Solution: Buyers should adopt a comprehensive approach to evaluating glass cookers by calculating the TCO during the procurement process. This involves considering factors such as energy efficiency ratings, expected lifespan, and maintenance requirements. Utilizing tools like life cycle cost analysis can help quantify these factors, allowing buyers to compare options more effectively. Additionally, consulting with industry experts or leveraging insights from supplier partnerships can provide valuable information on the long-term performance of different models. By focusing on TCO, businesses can make more strategic purchasing decisions that align with their financial goals.

Strategic Material Selection Guide for glass cooker price

What Are the Key Materials Used in Glass Cookers and Their Properties?

When selecting materials for glass cookers, several options are available, each with distinct properties that impact performance, durability, and cost. Understanding these materials is crucial for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe.

How Does Tempered Glass Perform in Glass Cookers?

Tempered glass is a widely used material in the manufacture of glass cookers due to its enhanced strength and thermal resistance. It can withstand high temperatures, typically rated up to 250°C (482°F), and is resistant to thermal shock, making it ideal for cooking applications. The primary advantage of tempered glass is its durability; it is less likely to break under thermal stress compared to regular glass.

However, tempered glass can be more expensive than other materials due to the manufacturing process, which involves heating and rapid cooling. Additionally, while it is resistant to scratches, it can still be prone to chipping if not handled carefully. For international buyers, compliance with safety standards such as ASTM C1048 (for heat-treated glass) is essential, as it ensures the product meets safety and performance expectations.

What Role Does Ceramic Glass Play in Glass Cookers?

Ceramic glass is another popular choice for glass cooktops, known for its excellent thermal stability and resistance to thermal shock. It can handle temperatures exceeding 400°C (752°F) and is often used in induction cooktops. The smooth surface of ceramic glass is easy to clean, which is a significant advantage for end-users.

On the downside, ceramic glass can be more expensive than tempered glass and may require more complex manufacturing processes. Additionally, while it is highly durable, it can be susceptible to cracking under sudden temperature changes. For B2B buyers, understanding local standards like DIN 12600 (for safety glass) is crucial, as it impacts product acceptance in different markets.

How Does Borosilicate Glass Compare for Glass Cookers?

Borosilicate glass is known for its exceptional resistance to thermal shock and chemical corrosion, making it suitable for various cooking applications. It can withstand temperatures up to 500°C (932°F) and is often used in laboratory settings as well as kitchenware. The primary advantage of borosilicate glass is its versatility and durability, making it suitable for both commercial and residential cooking.

However, borosilicate glass is generally more expensive than tempered or ceramic glass and can be more challenging to manufacture. For international buyers, it is essential to consider compliance with standards such as ASTM E438, which governs the performance of borosilicate glass in various applications.

What Are the Benefits of Using Stainless Steel for Cooktop Frames?

While not a cooking surface material, stainless steel is often used in the frames of glass cookers due to its durability and aesthetic appeal. Stainless steel is resistant to corrosion and can withstand high temperatures, making it suitable for kitchen environments. Its sleek appearance also enhances the overall design of glass cookers.

Illustrative image related to glass cooker price

The downside is that stainless steel can be prone to scratching and may require regular maintenance to maintain its appearance. For buyers in regions like Africa and South America, where humidity can be high, selecting stainless steel with a protective coating can be beneficial. Compliance with standards such as ASTM A240 is vital for ensuring the quality of stainless steel used in cooktop applications.

Summary Table of Material Properties for Glass Cookers

| Material | Typical Use Case for glass cooker price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Tempered Glass | Cooktops and oven doors | High thermal resistance and strength | Higher cost; prone to chipping | Medium |

| Ceramic Glass | Induction cooktops | Excellent thermal stability and easy to clean | More expensive; sensitive to thermal shock | High |

| Borosilicate Glass | Laboratory and kitchen applications | Exceptional thermal shock resistance | Higher cost; complex manufacturing | High |

| Stainless Steel | Cooktop frames and structures | Durable and corrosion-resistant | Prone to scratching; maintenance required | Medium |

Understanding the properties, advantages, and limitations of these materials will help international B2B buyers make informed decisions when sourcing glass cookers, ensuring compliance with local standards and meeting market demands effectively.

In-depth Look: Manufacturing Processes and Quality Assurance for glass cooker price

The manufacturing of glass cookers involves several critical processes and quality assurance measures that are essential for ensuring product reliability and safety. B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe, need to understand these processes to make informed purchasing decisions.

What are the Main Stages of Manufacturing Glass Cookers?

Material Preparation: What Materials Are Used in Glass Cooker Production?

The manufacturing of glass cookers begins with the selection of high-quality materials. The primary components include tempered glass, which is crucial for the cooktop, and various metals for the burner assemblies and frames. Tempered glass is preferred due to its strength and resistance to thermal shock. Additionally, manufacturers often utilize stainless steel for its durability and resistance to corrosion.

Illustrative image related to glass cooker price

During the material preparation phase, suppliers must ensure that all materials meet specific industry standards. This includes sourcing from verified suppliers to guarantee quality and consistency. B2B buyers should inquire about the origin of these materials and whether they adhere to international standards.

Forming: How is the Glass Cooktop Shaped?

Once materials are prepared, the forming process begins. For glass cooktops, this typically involves heating the tempered glass to a specific temperature to make it malleable. The glass is then shaped into the desired form using molds. This process may also include cutting the glass to fit specific dimensions required for different cooker models.

Advanced manufacturing techniques, such as CNC (Computer Numerical Control) machining, are often employed to achieve precise cuts and shapes. This ensures that the glass fits perfectly within the cooker frame and aligns with burner placements.

Assembly: What Are the Key Steps in Assembling Glass Cookers?

The assembly stage is where the individual components are brought together to create the final product. This includes mounting the glass cooktop onto the metal frame, installing burners, and connecting electrical components for features such as ignition and temperature control.

Quality control is essential during the assembly phase. Workers are trained to follow strict assembly protocols to minimize errors. Each unit should be assembled under conditions that prevent contamination and damage to the glass surface.

Finishing: How is the Final Product Prepared for Sale?

The finishing stage involves applying coatings or treatments to enhance the glass’s performance and aesthetic appeal. Common practices include applying anti-fingerprint coatings or cleaning treatments to ensure the surface remains pristine and easy to maintain.

After finishing, the cookers undergo a thorough cleaning process to remove any residues from manufacturing. This step is crucial for ensuring that the final product is ready for consumer use without additional preparation.

What Quality Assurance Measures Are Essential for Glass Cookers?

What International Standards Should B2B Buyers Be Aware Of?

Quality assurance in glass cooker manufacturing involves adhering to various international standards. The ISO 9001 certification is a fundamental requirement, as it outlines criteria for quality management systems. Manufacturers with this certification demonstrate their commitment to consistent quality and customer satisfaction.

In addition to ISO standards, B2B buyers should be aware of CE marking, which indicates compliance with European health, safety, and environmental protection standards. Products sold in the Middle East may also need to comply with GCC standards.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to ensure that defects are identified and addressed promptly. The main checkpoints include:

-

Incoming Quality Control (IQC): This is performed on raw materials before they enter the production line. Materials are inspected for defects and compliance with specifications.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC involves real-time monitoring of production to ensure that assembly and forming processes meet quality standards.

-

Final Quality Control (FQC): This is the last inspection before products are packaged for shipment. FQC checks for overall functionality, aesthetic quality, and packaging integrity.

What Testing Methods Are Commonly Used for Glass Cookers?

Manufacturers employ various testing methods to ensure safety and performance. Common tests include:

- Thermal Shock Testing: Evaluates the glass’s ability to withstand rapid temperature changes.

- Pressure Testing: Ensures that gas burners can operate safely under pressure.

- Electrical Safety Testing: Confirms that electrical components meet safety standards to prevent hazards.

B2B buyers should ask suppliers about the specific testing methods used and request documentation demonstrating compliance with these tests.

How Can B2B Buyers Verify Supplier Quality Control?

What Audit and Reporting Practices Should Be Followed?

To ensure that suppliers maintain high-quality standards, B2B buyers should conduct regular audits. This may involve on-site inspections or requesting detailed reports on manufacturing practices and quality control procedures. Buyers should look for comprehensive documentation that includes:

- Quality management system certifications (e.g., ISO 9001)

- Results from recent quality audits

- Certificates of compliance for materials used

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. Third-party inspectors typically evaluate manufacturing facilities, assess compliance with international standards, and perform product testing.

B2B buyers should consider incorporating third-party inspections as a standard part of their procurement process, especially when dealing with international suppliers. This not only enhances trust but also mitigates risks associated with product quality.

What Are the Nuances of Quality Control for International B2B Buyers?

For international buyers, particularly those from regions like Africa, South America, and the Middle East, understanding local regulations and standards is vital. Each market may have specific requirements that differ from international norms. Therefore, B2B buyers should engage with local experts or regulatory bodies to ensure compliance with regional laws.

Additionally, language barriers and cultural differences may impact communication regarding quality standards. Buyers should establish clear communication channels with suppliers and ensure that expectations are well-defined and documented.

Conclusion

In summary, the manufacturing processes and quality assurance measures for glass cookers are intricate and vital for ensuring product safety and performance. B2B buyers must be diligent in understanding these processes and verifying that suppliers adhere to international standards. By focusing on material preparation, forming, assembly, finishing, and robust quality control practices, buyers can confidently source high-quality glass cookers that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘glass cooker price’

Introduction

This sourcing guide aims to assist international B2B buyers in effectively procuring glass cookers. Understanding the price dynamics, supplier capabilities, and market trends is essential for making informed purchasing decisions. By following this checklist, buyers can streamline their sourcing process and ensure they acquire the best value for their investment.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is fundamental in sourcing glass cookers. Consider factors such as size, type (gas, electric, or induction), and specific features like self-cleaning options or smart technology. This clarity will help you communicate effectively with suppliers and ensure that the products meet your operational needs.

Step 2: Research Market Prices

Conduct thorough research on current market prices for glass cookers. Prices can vary significantly based on features, brand, and region. Utilize online platforms and industry reports to gather pricing benchmarks, which will enable you to negotiate better deals and avoid overpaying.

Step 3: Evaluate Potential Suppliers

Before making any commitments, it is crucial to vet potential suppliers comprehensively. Request detailed company profiles, including their manufacturing capabilities, quality control processes, and customer references. Additionally, assess their experience in serving markets similar to yours, as local regulations and preferences can impact product suitability.

Step 4: Verify Supplier Certifications

Ensure that your selected suppliers hold relevant certifications and compliance standards. Certifications such as ISO 9001 for quality management or specific safety standards for kitchen appliances are vital indicators of reliability and product quality. Confirm these certifications through official documentation or third-party verification.

Step 5: Request Sample Products

Before finalizing your order, request samples of the glass cookers to evaluate their quality firsthand. This step allows you to assess the product’s functionality, design, and overall performance. Pay attention to the details, such as the smoothness of the glass surface and the responsiveness of the burners.

Illustrative image related to glass cooker price

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Aim for favorable conditions that align with your budget and operational timelines. Be clear about your expectations to avoid misunderstandings later on.

Step 7: Establish a Communication Plan

Set up a robust communication plan with your supplier to ensure seamless interaction throughout the procurement process. Regular updates on production timelines, shipping details, and any potential issues will help maintain transparency and build a strong business relationship.

By following this checklist, B2B buyers can navigate the complexities of sourcing glass cookers effectively, ensuring they secure high-quality products at competitive prices.

Illustrative image related to glass cooker price

Comprehensive Cost and Pricing Analysis for glass cooker price Sourcing

What Are the Key Cost Components in Sourcing Glass Cookers?

When sourcing glass cookers, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality and type of glass, metals for burners, and electronic components significantly influence the price. High-grade materials may incur higher costs but offer durability and performance.

-

Labor: Labor costs vary based on the region of production. Skilled labor is often required for assembly, especially for precision components, impacting overall pricing.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and administrative expenses associated with the production facility. Efficient operations can help mitigate these costs.

-

Tooling: The initial investment in molds and tools for manufacturing glass cookers is a one-time expense but can be substantial. Custom designs may require additional tooling costs.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes adds to the cost. Certifications such as ISO or CE can enhance product credibility but may involve extra costs.

-

Logistics: Shipping costs, including freight charges, insurance, and duties, can vary widely depending on the destination. Import tariffs can also affect pricing, especially in international transactions.

-

Margin: Suppliers typically build in a profit margin, which can vary depending on market conditions and competition.

How Do Price Influencers Affect Glass Cooker Pricing?

Several factors influence the pricing of glass cookers, making it essential for buyers to be aware of these nuances:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can lead to significant discounts. Suppliers often have MOQs that can affect pricing; negotiating lower MOQs might be possible for new buyers.

-

Specifications and Customization: Custom designs or specific features (such as integrated smart technology) can increase costs. Buyers should carefully assess their needs against additional expenses for custom specifications.

-

Material Quality and Certifications: Higher quality materials and products with certifications (like energy efficiency ratings) typically come at a premium. This investment can lead to long-term savings through reduced energy costs.

-

Supplier Factors: The reputation, location, and financial stability of suppliers can affect pricing. Established suppliers may charge higher prices due to perceived reliability and quality assurance.

-

Incoterms: Understanding Incoterms is crucial for international buyers. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, Freight) dictate who bears shipping costs and risks, influencing the final price.

What Buyer Tips Can Help Negotiate Better Prices for Glass Cookers?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiation Strategies: Always negotiate pricing, especially for bulk orders. Be prepared to discuss payment terms, delivery schedules, and potential discounts for larger orders.

-

Cost-Efficiency Considerations: Evaluate the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors like energy efficiency, maintenance costs, and warranty offerings that can impact long-term expenses.

-

Pricing Nuances for International Buyers: Be aware of fluctuations in currency exchange rates and their impact on pricing. Establishing a stable pricing agreement can mitigate risks associated with currency volatility.

-

Research and Compare Suppliers: Engage in thorough market research to compare prices and offerings from multiple suppliers. This not only helps in finding competitive pricing but also in identifying the best quality products.

-

Understand Local Regulations: Different regions may have varying regulations regarding appliance standards. Ensure compliance with local requirements to avoid additional costs or import delays.

Disclaimer on Indicative Prices

Prices for glass cookers can fluctuate based on market conditions, material costs, and supplier pricing strategies. It is advisable for buyers to conduct their own market research and obtain quotes from multiple suppliers to secure the best deal.

Alternatives Analysis: Comparing glass cooker price With Other Solutions

Understanding Alternatives to Glass Cookers: Key Comparisons

When evaluating kitchen solutions for cooking, B2B buyers often consider various technologies that can meet their culinary needs. Glass cookers are popular for their aesthetic appeal and ease of cleaning, but several alternatives can also deliver effective cooking performance. This section provides a comparative analysis of glass cookers against two viable alternatives: gas cooktops and induction cooktops.

| Comparison Aspect | Glass Cooker Price | Gas Cooktop | Induction Cooktop |

|---|---|---|---|

| Performance | High, with even heating | High, immediate heat | Very high, instant heat |

| Cost | $500 – $2,000 | $300 – $1,500 | $600 – $2,500 |

| Ease of Implementation | Moderate, requires installation | Moderate, requires gas line | High, requires electricity |

| Maintenance | Low, easy to clean | Moderate, requires regular cleaning | Low, easy to clean |

| Best Use Case | Residential kitchens | Restaurants, homes | Modern kitchens, energy-efficient setups |

What Are the Pros and Cons of Gas Cooktops?

Gas cooktops are a traditional alternative that many chefs prefer for their immediate heat control. They offer high performance, allowing for quick temperature adjustments, which is particularly advantageous in commercial kitchens. The cost of gas cooktops varies widely, typically ranging from $300 to $1,500, depending on features and brand. However, they require a gas line and regular maintenance to ensure safety and efficiency. Cleaning can be more intensive due to grease buildup, which may deter some users. Gas cooktops are best suited for environments where precise cooking is essential, making them ideal for restaurants and culinary professionals.

How Do Induction Cooktops Compare to Glass Cookers?

Induction cooktops represent a modern, energy-efficient cooking solution that uses electromagnetic energy to heat pots and pans directly. This technology offers very high performance with instant heat and precise temperature control, often making cooking faster and safer. The price range for induction cooktops is typically between $600 and $2,500, depending on the model and features. While they are easy to clean and maintain, induction cooktops require specific cookware that is compatible with magnetic fields, which can be a limitation for some users. They are best suited for modern residential kitchens focused on energy efficiency and rapid cooking times.

Making the Right Choice: How Should B2B Buyers Decide?

In selecting the right cooking solution, B2B buyers should consider several factors, including performance requirements, budget constraints, and kitchen design. Glass cookers offer a balance of aesthetics and functionality, while gas cooktops provide unmatched control for traditional cooking methods. Induction cooktops, on the other hand, cater to those seeking efficiency and modern technology. By evaluating these aspects against their specific needs, buyers can make informed decisions that align with their culinary objectives and operational requirements.

Essential Technical Properties and Trade Terminology for glass cooker price

What Are the Key Technical Properties of Glass Cookers That Influence Pricing?

When considering the procurement of glass cookers, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some essential properties that significantly impact both the functionality and pricing of these appliances:

Illustrative image related to glass cooker price

-

Material Grade

Glass cookers are often made from tempered or ceramic glass, which provides high durability and resistance to thermal shock. The grade of glass used can affect the cooker’s lifespan and safety standards. For B2B buyers, specifying the material grade is vital to ensure compliance with local regulations and to meet customer expectations for quality. -

Burner Efficiency

The efficiency of the burners, typically measured in BTUs (British Thermal Units), indicates how quickly and effectively heat is transferred. High BTU ratings can translate to faster cooking times, which is essential for commercial kitchens where time is critical. Buyers should assess burner efficiency to ensure they are investing in products that can meet high-demand cooking needs. -

Temperature Control Precision

Precision in temperature control can significantly affect cooking results. Many glass cookers feature advanced control systems that allow for fine adjustments. This capability is essential for professional chefs and businesses that require consistent cooking outcomes. Buyers should prioritize models with precise temperature control to enhance culinary quality. -

Size and Capacity

The dimensions and cooking capacity of glass cookers are critical factors for both residential and commercial applications. Common sizes range from compact models suitable for small kitchens to larger units designed for extensive meal preparation. B2B buyers must consider the available space and required capacity to ensure the cooker meets operational needs. -

Energy Efficiency Rating

Energy efficiency ratings, such as ENERGY STAR certifications, indicate how much energy the appliance consumes compared to its output. Higher efficiency not only reduces operational costs but also aligns with sustainability goals. B2B buyers should evaluate energy efficiency to minimize long-term expenses and support eco-friendly initiatives. -

Safety Features

Safety features, including automatic shut-off mechanisms and child locks, are crucial for both residential and commercial environments. These features help prevent accidents and ensure compliance with safety regulations. Buyers should verify that the cookers they are considering meet the necessary safety standards to protect their investments and clientele.

Which Trade Terms Are Commonly Used in the Glass Cooker Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some key trade terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of glass cookers, OEMs can offer tailored solutions to meet specific buyer requirements. Understanding OEM relationships helps buyers source quality products that align with their brand. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for buyers to understand because it impacts inventory management and pricing strategies. Knowing the MOQ helps businesses plan their purchases effectively and negotiate better terms. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers requesting pricing for specific products. It typically includes details about the desired specifications and quantities. Utilizing RFQs can streamline the procurement process and ensure that buyers receive competitive pricing from multiple suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international rules that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and manage risks associated with international transactions. -

Lead Time

This refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is critical for effective supply chain management, especially in industries where timely delivery is crucial. Buyers should consider lead times when planning their procurement schedules. -

Warranty Period

The warranty period indicates how long a product is covered for defects or malfunctions. A robust warranty can provide peace of mind for buyers, as it reflects the manufacturer’s confidence in their product. Understanding warranty terms is essential for assessing long-term value and risk management.

By grasping these technical specifications and trade terms, B2B buyers can make more strategic decisions when sourcing glass cookers, ultimately leading to better investment outcomes.

Navigating Market Dynamics and Sourcing Trends in the glass cooker price Sector

What Are the Current Market Dynamics and Trends Affecting Glass Cooker Prices?

The global market for glass cookers is influenced by several key factors, including advancements in cooking technology, changing consumer preferences, and economic conditions across various regions. Internationally, there is a growing demand for energy-efficient appliances, which has led to an increase in the popularity of induction and electric glass cooktops. Buyers from regions such as Africa, South America, the Middle East, and Europe are particularly interested in products that combine aesthetics with functionality, as modern kitchens increasingly focus on design.

Emerging trends in sourcing include the adoption of smart technologies that allow for remote monitoring and control of cooking appliances, enhancing convenience for users. Additionally, the rise of e-commerce platforms has transformed traditional supply chains, allowing buyers to access a broader range of products and suppliers. This shift necessitates that B2B buyers remain agile and informed about the latest technological developments and pricing strategies to remain competitive.

In terms of market dynamics, fluctuations in raw material prices and supply chain disruptions, particularly due to geopolitical tensions and the COVID-19 pandemic, are influencing glass cooker prices. Buyers are encouraged to establish robust relationships with suppliers to navigate these challenges effectively and leverage bulk purchasing options to secure favorable pricing.

How Can Sustainability and Ethical Sourcing Impact Glass Cooker Price Sourcing?

The importance of sustainability in the glass cooker market cannot be overstated, particularly as consumers become more environmentally conscious. B2B buyers must consider the environmental impact of sourcing decisions, focusing on suppliers that prioritize sustainable practices. This includes the use of recycled materials in production and adherence to eco-friendly manufacturing processes.

Ethical sourcing is also critical, as buyers should seek suppliers with transparent supply chains and fair labor practices. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices. Such certifications not only enhance a company’s reputation but can also lead to cost savings in the long term through more efficient resource use.

Incorporating ‘green’ materials into the product lineup can appeal to a growing segment of eco-conscious consumers, making sustainable sourcing a strategic imperative for B2B buyers. By prioritizing suppliers who are committed to sustainability, businesses can differentiate themselves in the competitive market and potentially justify higher pricing based on the added value of their products.

What is the Historical Context of Glass Cookers in the Market?

The evolution of glass cookers dates back to the late 20th century when manufacturers began exploring materials that offered both aesthetic appeal and functional benefits. Initially, traditional metal cooktops dominated the market; however, as consumer preferences shifted toward modern designs, glass cooktops gained traction due to their sleek appearance and ease of cleaning.

Over the years, advancements in technology have led to the development of more efficient heating methods, such as induction cooking, which uses magnetic fields to heat pots and pans directly. This shift not only improved energy efficiency but also enhanced cooking performance, making glass cookers a popular choice among consumers.

Today, glass cookers represent a significant segment of the kitchen appliance market, characterized by continuous innovation in design and functionality. As the industry evolves, B2B buyers must stay informed about historical trends to better anticipate future developments and adapt their sourcing strategies accordingly.

Frequently Asked Questions (FAQs) for B2B Buyers of glass cooker price

1. How do I determine the right glass cooker for my business needs?

When selecting a glass cooker for your business, consider factors such as the type of cooking you do (gas, electric, or induction), the size and capacity required, and specific features like self-cleaning, smart technology, or multiple burners. Assess your target market’s preferences, as cultural cooking practices may influence the demand for specific features. Additionally, it’s crucial to evaluate the durability of the glass surface and the overall design to ensure it aligns with your branding and operational efficiency.

2. What factors influence the price of glass cookers in international markets?

The price of glass cookers can vary significantly based on several factors including manufacturing costs, shipping fees, import duties, and currency fluctuations. Brand reputation and product features also play a critical role; high-end models with advanced technology typically come at a premium. Additionally, regional demand and supply conditions can affect pricing. For B2B buyers, understanding these factors can aid in negotiating better deals with suppliers.

Illustrative image related to glass cooker price

3. How can I vet suppliers for glass cookers?

To vet suppliers, start by checking their reputation through online reviews, industry certifications, and trade references. Request samples to evaluate product quality firsthand. Additionally, inquire about their manufacturing processes and compliance with international safety standards. It’s also beneficial to establish communication with previous clients to gauge their experience. Attending trade shows or industry expos can provide valuable insights into a supplier’s credibility and product offerings.

4. What is the typical minimum order quantity (MOQ) for glass cookers?

Minimum order quantities (MOQs) for glass cookers can vary widely depending on the supplier and the specific product. Generally, MOQs range from 50 to 200 units for bulk orders. Some manufacturers may offer lower MOQs for custom orders or new buyers. It’s essential to discuss your needs with potential suppliers to negotiate favorable terms, especially if you are a new business or testing a new market.

5. What payment terms should I expect when purchasing glass cookers internationally?

Payment terms can vary by supplier and region, but common practices include a 30% deposit upon order confirmation with the balance due before shipment. Some suppliers may offer net 30 or net 60 terms for established businesses. Using secure payment methods such as letters of credit or escrow services can provide additional protection. Always clarify payment terms upfront to avoid misunderstandings.

6. How do I ensure quality assurance for glass cookers?

Implementing a robust quality assurance (QA) process is vital when sourcing glass cookers. This includes requesting certifications that comply with international safety standards. Conduct factory audits, if possible, and establish quality control checkpoints throughout the production process. Additionally, consider third-party inspection services to verify product quality before shipment. Documenting these processes will help build trust with your clients and ensure product consistency.

Illustrative image related to glass cooker price

7. What are the logistics considerations for importing glass cookers?

When importing glass cookers, consider shipping options, customs regulations, and potential tariffs. Choose a reliable logistics partner with experience in handling appliances to ensure safe transport. Familiarize yourself with the documentation required for customs clearance, such as invoices, packing lists, and certificates of origin. Additionally, factor in lead times for production and shipping to manage inventory effectively.

8. Can I customize the design of glass cookers for my brand?

Yes, many suppliers offer customization options for glass cookers, including specific sizes, colors, and features that align with your brand identity. Discuss your design requirements with potential manufacturers and inquire about their capabilities. Keep in mind that customizations may affect the MOQ and lead time. Collaborating closely with the supplier during the design phase will ensure the final product meets your specifications and market demands.

Top 6 Glass Cooker Price Manufacturers & Suppliers List

1. GASLAND Chef – Glass Gas Cooktop

Domain: gaslandchef.com

Registered: 2018 (7 years)

Introduction: GASLAND Chef Glass Gas Cooktop – NEW Tempered Glass and Enamel Glass Stove. Available sizes: 24 Inch, 30 Inch, 36 Inch. Features: smooth glass surface, high-performance burners, precise temperature control. Models include: 24″ 4 Burner Tempered Glass Gas Cooktop ($309.99), 30″ 5 Burner Black Enamel Gas Cooktop ($379.99), 36″ 5 Burner Black Enamel Gas Cooktop ($459.99), 30″ 5 Burner Black Enamel Ga…

2. Insignia™ – 5 Cu. Ft. Freestanding Electric Range

Domain: bestbuy.com

Registered: 1994 (31 years)

Introduction: Glass Top Stove – Best Buy Appliances Labor Day Sale Ends Sept. 10. Insignia™ – 5 Cu. Ft. Freestanding Electric Range – Stainless Steel/Black, Model: NS-RGRCESS4, SKU: 6555625, Rating: 4.7 out of 5 stars with 232 reviews. KitchenAid – 6.4 Cu. Ft. Self-Cleaning Slide-In Electric Convection Range – Black Stainless Steel with Printshield Finish, Model: KSEG700EBS, SKU: 5732342, Rating: 4.3 out of 5 s…

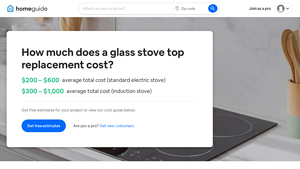

3. HomeGuide – Glass Stove Top Replacement Costs

Domain: homeguide.com

Registered: 1995 (30 years)

Introduction: Average cost to replace a glass stove top: $200 – $600 for standard electric stoves, $300 – $1,000 for induction stoves. Replacement cost factors include materials ($150 – $700), labor ($50 – $300), brand, number of burners, reason for replacement, and location. Labor rates: appliance repair technician ($50 – $125/hour), handyperson ($50 – $80/hour). Replacement time: 1 to 2 hours. Glass stove top…

4. IKEA – Glass Ceramic Cooktops

Domain: ikea.com

Registered: 1995 (30 years)

Introduction: Product Name: FROMMESTA Glass ceramic cooktop, black, 30″; Price: $499.00; Product Name: FÖRVÄLLA Glass ceramic cooktop, black, 30″; Price: $599.00; Features: Sleek and modern design, easy to clean, expandable cooking zones, fits atop most countertops, available with four or five cooking surfaces, minimalist design with white circles on a black background, compatible cookware includes stainless st…

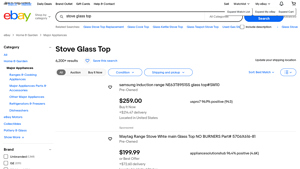

5. Stove Glass Top – Key Product

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Key product details for Stove Glass Top on eBay include: 1. Brands: Unbranded, GE, Whirlpool, Frigidaire, Kenmore, Jenn-Air, Samsung, Maytag. 2. Types: Burner, Knob, Glass, Control Board, Control Panel, Door, Bake Element. 3. Colors: Black, White, Silver, Multicolor, Gray, Beige, Brown, Blue, Clear, Green. 4. Set Includes: Knob, Burner, Control Board, Door, Burner Cap, Bake Element, Control Panel,…

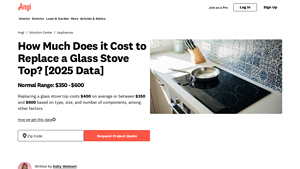

6. Angi – Glass Stove Top Replacement

Domain: angi.com

Registered: 1996 (29 years)

Introduction: Replacing a glass stove top costs $400 on average, with a normal range of $350 to $600. Factors affecting the cost include the type of glass (tempered or ceramic), number of burners, size, type of stove (induction or electric), warranty coverage, additional features, and labor costs. Tempered glass costs between $200 and $600, while ceramic glass ranges from $400 to $1,000. Induction stove top rep…

Strategic Sourcing Conclusion and Outlook for glass cooker price

In the evolving landscape of glass cooker pricing, strategic sourcing remains pivotal for B2B buyers aiming to optimize procurement processes. By leveraging insights into market trends, regional pricing variations, and supplier capabilities, companies can make informed decisions that enhance their competitiveness. Notably, the demand for glass cookers is on the rise across diverse markets, including Africa, South America, the Middle East, and Europe, driven by an increasing preference for modern and aesthetically pleasing kitchen appliances.

Understanding the nuances of glass cooker features, such as energy efficiency and advanced cooking technologies, can further influence purchasing decisions. Buyers are encouraged to explore partnerships with reliable suppliers who offer a range of options at competitive prices, ensuring they secure the best value without compromising quality.

Looking ahead, the glass cooker market is poised for growth, with innovations in design and functionality expected to drive demand even higher. International B2B buyers, particularly from regions like Nigeria and Brazil, should act now to capitalize on emerging opportunities and strengthen their supply chains. Engaging in strategic sourcing will not only provide access to quality products but also enhance overall business resilience in a dynamic marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to glass cooker price

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.