Contract Filling: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for contract filling

Navigating the complexities of sourcing contract filling services can be a daunting task for international B2B buyers, especially when considering the diverse needs of various markets. Contract filling is essential for businesses looking to efficiently package their products while maintaining quality and compliance with industry standards. This guide aims to demystify the contract filling landscape, providing insights into the types of services available, applications across multiple industries, supplier vetting processes, and cost considerations.

As businesses from Africa, South America, the Middle East, and Europe seek to expand their reach, understanding the nuances of contract filling becomes crucial. Whether you are a startup looking to launch a new product or an established company aiming to scale operations, this guide equips you with the knowledge needed to make informed purchasing decisions. You will learn how to identify reputable suppliers, evaluate their capabilities, and align their services with your specific requirements.

By addressing key challenges and offering actionable insights, this comprehensive resource empowers you to navigate the global market confidently. From selecting the right container types to understanding the implications of production volume, this guide is your roadmap to successful partnerships in contract filling, ultimately driving your business growth in competitive international markets.

Understanding contract filling Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Liquid Filling | Handles a variety of viscosities; uses dedicated equipment for food and non-food products. | Cosmetics, food & beverage, pharmaceuticals | Pros: Versatile for different products; scalable. Cons: Requires careful handling to avoid contamination. |

| Powder Filling | Specializes in dry goods; separate facilities to prevent cross-contamination. | Nutraceuticals, chemicals, household products | Pros: Efficient for bulk production; customizable. Cons: May require more specialized equipment. |

| Stick Pack Filling | Eco-friendly packaging; smaller footprint; suitable for various products. | Promotions, single-serve applications | Pros: Reduces material waste; ideal for testing new products. Cons: Limited to small quantities. |

| Tube Filling | Focused on cosmetic and personal care products; seals for freshness. | Cosmetics, lotions, creams | Pros: Preserves product integrity; good for high-end products. Cons: May not suit all product types. |

| Bulk Filling | Designed for high-volume production; customizable options for various containers. | Commercial applications, food processing | Pros: Cost-effective for large runs; fast turnaround. Cons: Less flexibility for small orders. |

What are the Characteristics and Suitability of Liquid Filling Services?

Liquid filling services are essential for businesses needing to package a wide range of products, from cosmetics to pharmaceuticals. These services are distinguished by their ability to handle varying viscosities, ensuring that both thin liquids and thicker formulations can be efficiently filled. Companies seeking liquid filling solutions should consider their specific product requirements, including the need for dedicated facilities to avoid cross-contamination, especially in food and pharmaceutical applications. The scalability of liquid filling operations makes them suitable for both small batches and large-scale production runs.

How Does Powder Filling Cater to Diverse Industries?

Powder filling is particularly advantageous for companies in industries such as nutraceuticals and chemicals. This type of contract filling specializes in dry goods and utilizes separate facilities to prevent cross-contamination between different product types. Businesses should evaluate their production needs, especially if they require large quantities or specific packaging styles. Powder filling services can offer customization, making them ideal for unique formulations. However, buyers must also consider the potential need for specialized machinery, which could impact initial costs.

What are the Benefits of Stick Pack Filling for Product Launches?

Stick pack filling presents an innovative solution for companies looking to minimize their environmental impact while providing single-serve options. This type of filling reduces packaging waste and is particularly suitable for promotional campaigns or new product introductions. Businesses should assess the feasibility of stick pack filling based on their target market and product type, as this format is ideal for trial sizes or limited editions. However, the limitation to smaller quantities may restrict its use for large-scale production.

How Does Tube Filling Preserve Product Integrity?

Tube filling services are tailored for cosmetic and personal care products, ensuring that items like lotions and creams are sealed for freshness and integrity. This method is particularly beneficial for high-end brands that prioritize quality and presentation. Companies should consider the compatibility of their products with tube filling, as not all formulations may be suitable. The ability to maintain product integrity makes tube filling an attractive option, but it may come at a higher cost compared to other filling methods.

Why Choose Bulk Filling for High-Volume Production?

Bulk filling services are designed for businesses looking to maximize efficiency in high-volume production. These services offer customizable options for various container types, making them ideal for commercial applications and food processing. Companies should evaluate their production scale and budget, as bulk filling is cost-effective for large runs but may lack flexibility for smaller orders. The speed of bulk filling operations can significantly reduce time-to-market, making it a strategic choice for rapidly growing businesses.

Key Industrial Applications of contract filling

| Industry/Sector | Specific Application of Contract Filling | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Cosmetics | Filling of lotions, creams, and serums | Enables brands to scale production without heavy capital investment. | Ensure compliance with local regulations; consider lead times. |

| Food and Beverage | Liquid and powder filling for sauces and snacks | Allows for rapid market entry with diverse product offerings. | Assess food safety certifications and facility capabilities. |

| Pharmaceuticals | Filling of liquids and tablets | Guarantees high-quality standards and reduces production costs. | Verify facility certifications and experience with sensitive products. |

| Household Products | Filling of cleaning agents and detergents | Optimizes resource allocation and enhances product availability. | Check for eco-friendly practices and container compatibility. |

| Nutraceuticals | Filling of vitamins and supplements | Facilitates compliance with health regulations and product traceability. | Look for expertise in formulation and testing services. |

How is Contract Filling Used in the Cosmetics Industry?

In the cosmetics sector, contract filling is crucial for brands looking to fill lotions, creams, and serums efficiently. By outsourcing this process, companies can avoid the significant capital investment associated with purchasing filling machinery. This flexibility allows brands to respond quickly to market trends and seasonal demands. International buyers should prioritize suppliers who comply with local regulations and can provide scalable solutions, ensuring timely delivery and quality assurance.

What are the Applications of Contract Filling in Food and Beverage?

Contract filling services in the food and beverage industry cater to both liquid and powder products, such as sauces, dressings, and snack foods. This outsourcing enables businesses to quickly enter the market with diverse offerings without the need for extensive in-house facilities. For companies in regions like Africa and South America, it’s essential to evaluate suppliers based on food safety certifications and their ability to handle various packaging formats, ensuring compliance with local health standards.

Why is Contract Filling Important for Pharmaceuticals?

In the pharmaceutical sector, contract filling plays a vital role in the production of liquids and tablets, where precision and adherence to strict quality standards are paramount. Outsourcing this function allows companies to reduce production costs while maintaining high-quality output. B2B buyers should investigate the supplier’s certifications and experience with sensitive products to ensure compliance with regulatory requirements and to mitigate risks associated with product safety and efficacy.

Illustrative image related to contract filling

How Does Contract Filling Benefit Household Products Manufacturers?

For manufacturers of household products, such as cleaning agents and detergents, contract filling offers a streamlined approach to scaling production. This method helps businesses optimize resource allocation, enabling them to focus on marketing and product development. Buyers should consider suppliers that demonstrate eco-friendly practices and compatibility with various container types, as sustainability is increasingly important in global markets.

What Role Does Contract Filling Play in the Nutraceuticals Sector?

Contract filling services are essential for the nutraceutical industry, particularly for vitamins and supplements, where regulatory compliance and product traceability are critical. By partnering with a contract filler, companies can ensure their products meet health regulations while benefiting from reduced overhead costs. Buyers in this sector should seek suppliers with expertise in formulation and testing services, as this can enhance product quality and consumer trust in international markets.

3 Common User Pain Points for ‘contract filling’ & Their Solutions

Scenario 1: Navigating Compliance in Diverse Markets

The Problem: B2B buyers often struggle with the complexities of regulatory compliance when dealing with contract filling, especially when operating in multiple regions like Africa, Europe, and the Middle East. Each market has its own set of regulations regarding product safety, labeling, and packaging. This can lead to significant challenges, including delays in product launches, increased costs, and even potential legal issues if products do not meet local standards.

The Solution: To effectively navigate these regulatory waters, buyers should prioritize partnerships with contract filling companies that have experience in the specific markets they are targeting. It’s vital to inquire about the contractor’s certifications and compliance history in your desired regions. Additionally, conducting thorough research on local regulations will empower buyers to communicate their needs clearly. Engaging a legal consultant who specializes in international trade can also provide insights into compliance requirements. By ensuring that your contract filling partner is well-versed in local laws, you can streamline the compliance process, reduce risks, and expedite your product’s time to market.

Scenario 2: Managing Production Scalability Challenges

The Problem: Many B2B companies experience fluctuating demand for their products, making it difficult to manage production levels effectively. This can be particularly challenging for businesses that need to transition between small test runs and large-scale production. Inadequate scalability can lead to excess inventory, wasted resources, and missed market opportunities.

The Solution: Buyers should look for contract filling partners that offer flexible production options and can easily scale operations up or down based on demand. It’s important to assess a contractor’s capabilities for both small batch and large volume runs before entering into an agreement. Implementing a demand forecasting strategy, combined with regular communication with your contract filler, can also help align production schedules with market needs. Additionally, consider requesting pilot runs to test both the quality and efficiency of the contractor’s processes before committing to larger orders. This proactive approach will ensure that you can meet market demands without incurring unnecessary costs or production delays.

Scenario 3: Achieving Consistent Quality Across Batches

The Problem: A common pain point for B2B buyers in the contract filling space is the inconsistency in product quality across different production batches. Variability in filling processes, equipment used, and raw materials can lead to significant discrepancies that affect customer satisfaction and brand reputation.

The Solution: To ensure consistent quality, buyers should implement a robust quality assurance framework when selecting a contract filling partner. Start by requesting detailed information about their quality control measures, including any certifications such as ISO standards. Additionally, establishing clear quality benchmarks and conducting regular audits can help maintain product integrity. Buyers should also consider investing in third-party quality testing services to verify that each batch meets specified standards. Creating a feedback loop with your contract filler—where both parties can discuss quality issues—will foster a collaborative environment focused on continuous improvement, ensuring that every product meets your brand’s high expectations.

Illustrative image related to contract filling

Strategic Material Selection Guide for contract filling

When selecting materials for contract filling, it is essential to consider the specific properties and applications of each material type. This guide analyzes four common materials used in contract filling—glass, plastic, metal, and biodegradable materials—highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Glass in Contract Filling?

Glass is a traditional material widely used in the contract filling industry, particularly for cosmetics and pharmaceuticals. It boasts excellent chemical resistance and is impermeable, ensuring product integrity. Glass can withstand high temperatures, making it suitable for hot-filling processes. However, its weight and fragility can pose challenges in transportation and handling.

Pros: Glass provides a premium feel and is often perceived as more environmentally friendly due to its recyclability. It also offers superior barrier properties against moisture and gases.

Cons: The primary drawbacks include higher transportation costs due to weight and the risk of breakage. Additionally, glass manufacturing can be complex and costly, which may not be ideal for all applications.

Impact on Application: Glass is compatible with a wide range of media, including sensitive formulations that require protection from light and air.

Considerations for International Buyers: Compliance with international standards such as ASTM and FDA regulations is crucial. Buyers should also consider local recycling capabilities and consumer preferences regarding packaging materials.

How Does Plastic Compare as a Material for Contract Filling?

Plastic is a versatile and lightweight alternative to glass, commonly used in various industries, including food and cosmetics. It is available in multiple forms, such as PET, HDPE, and LDPE, each offering distinct properties. Plastics can be engineered to meet specific temperature and pressure ratings, providing flexibility in design and application.

Pros: The main advantages of plastic include its lightweight nature, cost-effectiveness, and the ability to produce complex shapes. Additionally, many plastics can be recycled, aligning with sustainability goals.

Cons: However, plastics may have lower barrier properties compared to glass and can be susceptible to chemical interactions with certain products. The manufacturing process can also generate significant waste if not managed properly.

Impact on Application: Plastic is suitable for a wide range of media, but compatibility testing is essential for sensitive formulations.

Illustrative image related to contract filling

Considerations for International Buyers: Buyers should ensure that the selected plastic complies with local regulations regarding food safety and environmental impact. Understanding the local market’s preferences for packaging materials can also guide material selection.

What Role Does Metal Play in Contract Filling Applications?

Metal containers, particularly aluminum and tin, are commonly used for products like aerosols and certain food items. Metals provide excellent barrier properties and durability, making them suitable for products that require a longer shelf life.

Pros: The primary advantages of metal include their strength, recyclability, and ability to withstand high pressure. They also offer a premium appearance, which can enhance brand perception.

Cons: On the downside, metal can be more expensive than plastic and may require specialized filling equipment. Corrosion resistance is a concern, especially for products with high acidity.

Illustrative image related to contract filling

Impact on Application: Metal is compatible with a variety of products, including those sensitive to light and oxygen.

Considerations for International Buyers: Compliance with international standards such as ISO and local regulations is vital. Buyers should also consider the availability of recycling facilities for metal packaging in their region.

Are Biodegradable Materials a Viable Option for Contract Filling?

Biodegradable materials, such as PLA (polylactic acid), are emerging as sustainable alternatives in contract filling. These materials are derived from renewable resources and can break down in composting environments, appealing to environmentally conscious consumers.

Pros: The key advantages include their reduced environmental impact and the growing consumer demand for sustainable packaging solutions.

Cons: However, biodegradable materials may have limited shelf life and require specific conditions for degradation, which can complicate logistics and storage.

Impact on Application: Compatibility with various media is often favorable, but testing is necessary to ensure performance under different conditions.

Considerations for International Buyers: Buyers should be aware of local regulations regarding biodegradable materials and consumer preferences for sustainability. Understanding the supply chain for these materials is also critical.

| Material | Typical Use Case for contract filling | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Pharmaceuticals, cosmetics | Excellent chemical resistance | Fragile and heavy | High |

| Plastic | Food, personal care products | Lightweight and cost-effective | Lower barrier properties | Medium |

| Metal | Aerosols, food items | Strong and recyclable | Higher cost and corrosion risk | High |

| Biodegradable | Sustainable products | Eco-friendly and renewable | Limited shelf life | Medium |

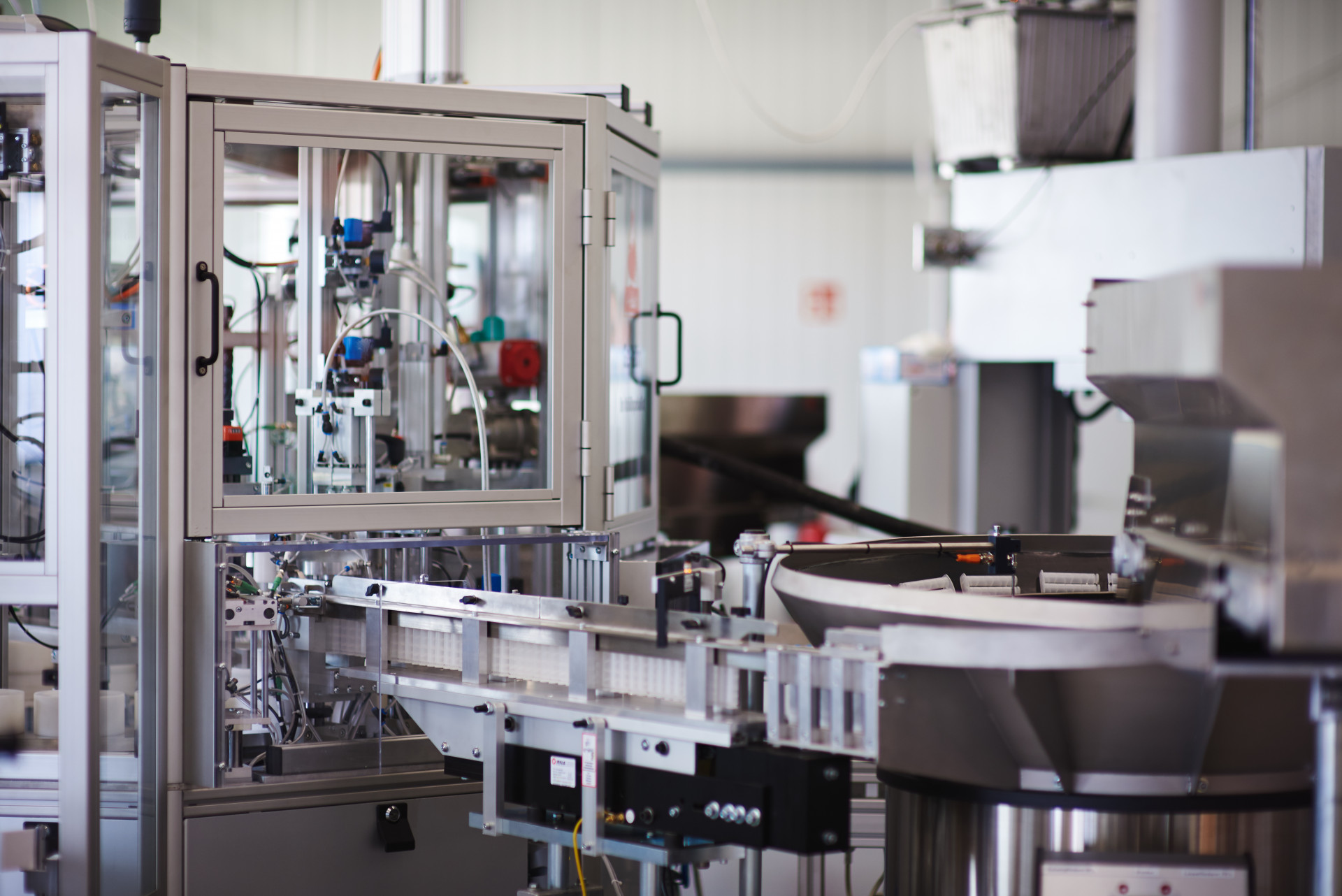

In-depth Look: Manufacturing Processes and Quality Assurance for contract filling

What Are the Main Stages of the Manufacturing Process in Contract Filling?

The manufacturing process in contract filling encompasses several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring that the final product meets the required specifications and quality standards.

How Is Material Prepared for Contract Filling?

Material preparation is the foundational step in the contract filling process. This stage involves sourcing and inspecting raw materials, which can include liquids, powders, or pastes. For B2B buyers, ensuring that the supplier adheres to stringent sourcing protocols is crucial. Suppliers often conduct Incoming Quality Control (IQC) to verify the quality of raw materials before they enter the production line. This can involve checking for purity, viscosity, and compatibility with the intended filling process.

What Techniques Are Used in Forming and Filling Products?

Once materials are prepared, they move into the forming stage. This can include blending or mixing for homogeneity, especially in products like cosmetics or pharmaceuticals. The filling process itself employs various techniques depending on the material consistency. For liquids, automatic piston fillers or gravity fillers are commonly used, while powders may require auger filling systems.

B2B buyers should consider suppliers that utilize advanced technology, such as high-speed filling lines and automated systems, as these can significantly enhance efficiency and reduce human error. Additionally, having the flexibility to handle diverse container types—like jars, tubes, or pouches—can be advantageous for brands looking to differentiate their products on the market.

Illustrative image related to contract filling

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance (QA) is paramount in contract filling, and international standards play a critical role in ensuring product consistency and safety. Key certifications to look for include ISO 9001, which focuses on quality management systems, and industry-specific standards such as CE marking for European markets or API standards for pharmaceuticals.

How Are Quality Control Checkpoints Established?

Quality control checkpoints are integral to maintaining product integrity throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials before production.

- In-Process Quality Control (IPQC): Continuous monitoring during the filling process to identify any deviations from specified parameters.

- Final Quality Control (FQC): Comprehensive testing of finished products to ensure they meet quality specifications before packaging and shipment.

These checkpoints help mitigate risks associated with production errors, which can lead to costly recalls or reputational damage.

What Common Testing Methods Are Utilized in Contract Filling?

Testing methods are essential for verifying product quality and safety. Common methods include:

- Viscosity Testing: Ensuring liquids maintain the correct thickness for optimal filling.

- Microbial Testing: Particularly important in food and pharmaceutical applications to prevent contamination.

- Stability Testing: Assessing how products hold up over time under various conditions, including light, temperature, and humidity.

B2B buyers should inquire about the specific testing protocols employed by potential suppliers and request detailed reports to ensure compliance with international quality standards.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is crucial for B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, where regulations may vary significantly. Here are key steps buyers can take:

-

Conduct Supplier Audits: Regular audits of the supplier’s facilities can reveal their adherence to quality standards and operational practices. This can include checking their certifications, equipment, and overall cleanliness.

-

Request Quality Assurance Documentation: Suppliers should provide comprehensive QA reports, including results from IQC, IPQC, and FQC. This documentation serves as a verification of their commitment to quality.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and product quality. This can be particularly important for buyers unfamiliar with local suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, navigating quality control nuances can be complex. Different regions may have distinct regulatory requirements and quality standards. For instance, products destined for the European market must comply with CE marking, while those in the Middle East may require adherence to GSO standards.

Buyers should also consider the potential impact of import/export regulations and tariffs, which can affect product pricing and availability. Establishing clear communication with suppliers regarding these aspects can facilitate smoother transactions and ensure compliance with all necessary regulations.

Illustrative image related to contract filling

Conclusion: Ensuring Quality in Contract Filling

The contract filling process is a multifaceted operation that requires meticulous attention to detail at every stage, from material preparation to final quality checks. For B2B buyers, understanding the intricacies of manufacturing and quality assurance can significantly influence product success in competitive markets. By selecting suppliers who prioritize quality and adhere to international standards, businesses can mitigate risks and enhance their brand reputation.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘contract filling’

To successfully navigate the procurement of contract filling services, B2B buyers must follow a structured approach. This step-by-step guide will help you assess potential suppliers effectively, ensuring that your product filling and packaging needs are met with quality and efficiency.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clarify your product’s requirements. Consider the type of material (liquid, powder, or viscous), the container styles (bottles, jars, tubes), and any specific filling techniques required. Having clear specifications helps suppliers understand your needs and provide accurate quotes.

- Material Characteristics: Identify the viscosity and any special handling needs.

- Container Options: Decide on the packaging formats that best suit your product.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable contract filling companies. Look for providers that specialize in your industry, whether it’s cosmetics, food, or pharmaceuticals. A well-established supplier can offer insights and best practices relevant to your product type.

Illustrative image related to contract filling

- Industry Experience: Seek suppliers with a proven track record in your specific sector.

- Client Testimonials: Review case studies or testimonials from similar businesses to gauge satisfaction.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold the necessary certifications, such as FDA or ISO standards, to ensure compliance with safety and quality regulations. This is particularly crucial in regulated industries like food and pharmaceuticals.

- Quality Assurance: Certifications indicate a commitment to maintaining high standards.

- Regulatory Compliance: Ensure the supplier adheres to local and international regulations applicable to your product.

Step 4: Request and Compare Quotes

Once you have a shortlist of suppliers, request detailed quotes that outline pricing, minimum order quantities, and lead times. Comparing these elements will help you identify the best fit for your budget and timeline.

- Pricing Structure: Understand how costs vary with order size and any additional services offered.

- Flexibility: Assess whether the supplier can accommodate changes in order volume or specifications.

Step 5: Assess Production Capabilities

Evaluate the production capabilities of each supplier. Look for their equipment, technology, and capacity to handle your specific product requirements. A supplier with advanced machinery may offer better efficiency and quality.

- Filling Technology: Inquire about their filling methods (manual vs. automated).

- Scalability: Ensure the supplier can scale operations if your business grows.

Step 6: Verify Quality Control Processes

Quality control is vital in contract filling. Ask suppliers about their quality assurance processes, including testing, inspections, and batch tracking. A robust quality control system minimizes the risk of defects in your products.

- Testing Procedures: Understand how they test for consistency and safety.

- Traceability: Ensure they can track products through the filling process for quality assurance.

Step 7: Initiate a Trial Run

Before committing to a long-term contract, consider initiating a small trial run. This allows you to assess the supplier’s performance, product quality, and overall service without significant risk.

- Feedback Loop: Use this opportunity to provide feedback and make adjustments as necessary.

- Performance Metrics: Evaluate the trial against your quality and timeline expectations to inform your final decision.

Following these steps will empower B2B buyers to make informed decisions when sourcing contract filling services, ensuring that their products reach the market efficiently and effectively.

Comprehensive Cost and Pricing Analysis for contract filling Sourcing

What are the Key Cost Components in Contract Filling Services?

Understanding the cost structure of contract filling services is essential for international B2B buyers looking to optimize their sourcing strategies. The primary cost components include:

-

Materials: This encompasses the cost of containers, closures, and any supplementary materials such as labels or packaging. The choice of materials can significantly impact the overall cost, with premium materials naturally leading to higher expenses.

-

Labor: Labor costs are determined by the complexity of the filling process, the skill level of the workforce, and the location of the facility. Automated systems may reduce labor costs but require higher initial investments.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and equipment depreciation. Facilities with advanced machinery may have higher overheads but can offer efficiencies that lead to lower per-unit costs.

-

Tooling: Custom tooling for specific products can be a significant upfront cost. Buyers should assess whether their production runs justify the investment in specialized equipment.

-

Quality Control (QC): Ensuring compliance with industry standards and certifications is critical, particularly for sectors like food and pharmaceuticals. QC measures often add to the cost but are essential for maintaining product integrity.

-

Logistics: Shipping and handling costs, particularly for international buyers, can vary greatly based on distance, shipping methods, and volume. Understanding Incoterms is crucial for accurately estimating these costs.

-

Margin: Suppliers will add a margin to cover their operational costs and profit. This margin can vary based on supplier reputation, service quality, and market competition.

How Do Price Influencers Affect Contract Filling Costs?

Several factors influence pricing in contract filling, and understanding these can help buyers negotiate better deals:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should consider their demand forecast to optimize order sizes.

-

Specifications and Customization: Custom formulations, unique packaging requirements, or specialized filling processes can drive costs up. Buyers should evaluate the necessity of such customizations against their budget.

-

Material Selection: The choice of raw materials can heavily influence pricing. High-quality or organic materials may come at a premium, while standard options can be more cost-effective.

-

Quality and Certifications: Suppliers with relevant industry certifications (e.g., FDA, ISO) may charge higher prices due to the assurance of compliance and quality. Buyers should weigh the importance of these certifications against their product needs.

-

Supplier Factors: Supplier location, reputation, and experience can impact pricing. Established suppliers may command higher prices but often provide greater reliability and quality assurance.

-

Incoterms: Understanding shipping terms is crucial for international buyers. Incoterms define the responsibilities of buyers and sellers in shipping, which can affect overall costs.

What Buyer Tips Can Enhance Cost Efficiency in Contract Filling?

To maximize value when sourcing contract filling services, international buyers should consider the following strategies:

-

Negotiate Effectively: Engage in open discussions with suppliers about pricing structures and be prepared to negotiate on volume discounts, payment terms, and lead times.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on initial pricing, consider the TCO, which includes materials, shipping, storage, and potential rework costs. A slightly higher upfront cost may result in savings over time.

-

Conduct Market Research: Understanding market rates and competitor offerings can empower buyers during negotiations. This knowledge can also reveal potential suppliers who offer better value.

-

Be Aware of Pricing Nuances: Pricing may differ significantly across regions due to economic conditions, labor costs, and material availability. Buyers from Africa, South America, the Middle East, and Europe should be mindful of these variations when sourcing.

-

Request Transparent Pricing: Ask suppliers for a detailed breakdown of costs to understand where your money is going. This transparency will help in making informed decisions and identifying potential cost-saving areas.

Disclaimer

Prices and cost components outlined in this analysis are indicative and may vary based on specific requirements, market conditions, and supplier capabilities. Buyers are encouraged to conduct thorough due diligence and obtain quotes tailored to their unique needs.

Alternatives Analysis: Comparing contract filling With Other Solutions

In today’s competitive market, businesses often face the challenge of selecting the most efficient and cost-effective method for product filling and packaging. Contract filling has emerged as a popular choice, but several alternatives exist that may also meet specific operational needs. Understanding the strengths and weaknesses of these alternatives is crucial for B2B buyers aiming to optimize their production processes.

| Comparison Aspect | Contract Filling | In-House Filling | Bulk Packaging Solutions |

|---|---|---|---|

| Performance | High efficiency with scalable options | Varies by equipment | High speed for large volumes |

| Cost | Cost-effective for small to medium runs | High initial investment | Economies of scale for large orders |

| Ease of Implementation | Quick setup, minimal investment | Complex setup required | Requires specialized equipment |

| Maintenance | Minimal, handled by service provider | Ongoing maintenance needed | Low maintenance, but equipment-intensive |

| Best Use Case | Short runs, product testing | Large volume production | High-volume, standardized products |

What Are the Advantages and Disadvantages of In-House Filling?

In-house filling allows companies to maintain full control over their production processes. It can be particularly advantageous for businesses that require strict quality control and have the capacity to invest in specialized equipment. However, this approach often involves significant upfront costs for machinery and a commitment to ongoing maintenance. Additionally, the variability in performance can lead to inefficiencies, especially for smaller production runs.

Illustrative image related to contract filling

How Do Bulk Packaging Solutions Compare?

Bulk packaging solutions are ideal for businesses focusing on large volumes of standardized products. They offer high-speed filling capabilities and can significantly reduce per-unit costs due to economies of scale. However, they may lack the flexibility required for smaller runs or unique product specifications. Businesses that choose this option must ensure they have the necessary infrastructure to support high-volume operations, which can present challenges for those without existing capabilities.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting the right filling and packaging solution, B2B buyers should carefully evaluate their specific needs, including production volume, budget constraints, and desired flexibility. Contract filling stands out for its adaptability, particularly for businesses needing to test new products or manage seasonal demands without the burden of heavy investment. In contrast, in-house filling may suit larger companies looking to streamline processes and maintain quality control, while bulk packaging solutions cater to those focused on cost efficiency for large-scale operations. Ultimately, the choice should align with the strategic goals and operational capacities of the business.

Essential Technical Properties and Trade Terminology for contract filling

What Are the Critical Technical Properties in Contract Filling?

When considering contract filling services, it’s essential to understand specific technical properties that can affect product quality, efficiency, and cost. Here are some critical specifications:

1. Material Grade

Material grade refers to the quality and type of materials used for both packaging and the product itself. This can include plastics, glass, and metals, each having different properties that may affect product integrity and safety. For B2B buyers, ensuring the right material grade is crucial for compliance with industry standards and for maintaining product shelf life.

2. Viscosity Tolerance

Viscosity tolerance indicates the acceptable range of fluid thickness for products to be filled. Different products, from lotions to thick creams, require specific filling equipment and techniques to ensure accurate dosages and prevent spillage. Understanding viscosity tolerance helps buyers select the right contract filling partner equipped to handle their product’s unique characteristics.

3. Fill Volume Accuracy

Fill volume accuracy is the precision with which a filling machine dispenses product into containers. Inaccuracies can lead to financial losses and regulatory issues. B2B buyers should prioritize contract fillers who guarantee high fill volume accuracy to ensure consistent product quality and consumer satisfaction.

4. Container Compatibility

Container compatibility refers to the types of containers that can be used for filling processes, such as bottles, jars, tubes, or pouches. Each container type can affect the filling method and the final product presentation. For buyers, selecting a contract filler with versatile container compatibility can enhance branding and marketing opportunities.

Illustrative image related to contract filling

5. Production Capacity

Production capacity is the maximum output a contract filling service can achieve within a specified timeframe. Understanding this metric is vital for B2B buyers to ensure that their contract partner can meet demand fluctuations, whether for short runs or large-scale productions. This capacity also influences lead times and overall project timelines.

6. Quality Assurance Standards

Quality assurance standards encompass the processes and certifications a contract filling service adheres to, such as FDA regulations or ISO certifications. These standards are critical for ensuring product safety and quality. Buyers should verify that their contract filling partner meets relevant quality assurance standards to mitigate risks associated with product recalls or compliance issues.

What Are Common Trade Terms in Contract Filling?

Understanding industry terminology can facilitate better communication and negotiations with contract filling partners. Here are some commonly used trade terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In contract filling, it often refers to the original brand that provides the formulation to be filled. Recognizing OEM relationships can help buyers understand the chain of production and accountability.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers as it can significantly impact budget and inventory decisions. Understanding MOQs helps buyers plan their orders effectively, especially for new product launches.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing on specified products or services. In contract filling, it allows buyers to compare costs and services from different providers, facilitating informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that outline the responsibilities of buyers and sellers in shipping goods. Understanding these terms is crucial for B2B buyers engaged in international transactions, as they clarify who is responsible for shipping costs, insurance, and risk during transport.

5. Turnkey Solutions

Turnkey solutions refer to services where the provider manages all aspects of production, from filling to packaging. This term is significant for buyers looking for streamlined processes that reduce the complexity of managing multiple vendors.

Illustrative image related to contract filling

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when engaging with contract filling services, ultimately ensuring that their products meet market demands effectively and efficiently.

Navigating Market Dynamics and Sourcing Trends in the contract filling Sector

What Are the Current Market Dynamics and Key Trends in Contract Filling?

The contract filling sector is witnessing significant growth driven by globalization, increased consumer demand for diverse products, and the rise of e-commerce. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly outsourcing filling processes to capitalize on specialized expertise and equipment. This shift allows companies to streamline operations, reduce overhead, and focus on core competencies. Emerging trends include the adoption of automated filling technologies, which enhance efficiency and reduce labor costs, and the use of data analytics to optimize production schedules and inventory management.

Additionally, there is a growing emphasis on flexibility in production runs. Companies are increasingly looking for partners who can accommodate both small test batches and large-scale production without compromising quality. This trend is particularly relevant for businesses introducing seasonal products or those testing market responses. The expansion of sustainability practices, including eco-friendly packaging solutions and waste reduction strategies, is also reshaping buyer expectations and supplier offerings in the contract filling landscape.

How Is Sustainability and Ethical Sourcing Influencing Contract Filling?

Sustainability has become a pivotal concern for international B2B buyers in the contract filling sector. The environmental impact of packaging waste and production processes has prompted companies to seek partners committed to ethical sourcing and sustainable practices. Buyers are increasingly favoring suppliers who utilize biodegradable materials, recyclable packaging, and renewable energy sources in their operations.

Illustrative image related to contract filling

Moreover, certifications such as ISO 14001 (Environmental Management) and B Corp status are gaining importance as they signify a commitment to sustainability and ethical practices. Buyers are encouraged to inquire about their partners’ environmental policies and certifications to ensure alignment with their own corporate social responsibility goals. This focus on sustainability not only enhances brand reputation but also meets the growing consumer demand for environmentally conscious products, making it a crucial consideration in supplier selection.

What Is the Brief Evolution of the Contract Filling Sector?

The contract filling industry has evolved significantly over the past few decades, transitioning from manual filling processes to highly automated, sophisticated systems. Initially, contract filling was primarily a service for small-scale producers lacking the capital for in-house filling operations. As globalization expanded, the demand for contract filling services surged, driven by the need for efficiency and scalability in production.

Technological advancements have played a vital role in this evolution, with innovations in automation and precision filling improving quality and reducing turnaround times. Today, the sector encompasses a wide range of industries, including cosmetics, food and beverage, pharmaceuticals, and more, reflecting the diverse needs of international B2B buyers. This evolution underscores the increasing importance of strategic partnerships in navigating the complexities of modern supply chains and meeting consumer demands effectively.

Illustrative image related to contract filling

Frequently Asked Questions (FAQs) for B2B Buyers of contract filling

-

How do I choose the right contract filling partner for my product?

Choosing the right contract filling partner involves assessing their expertise in your specific industry, reviewing their certifications, and evaluating their production capabilities. Look for a partner that has experience with similar products and can accommodate your required fill sizes and container types. It’s also essential to check their quality assurance processes and if they can provide scalability as your business grows. Engaging in preliminary discussions and requesting samples can help gauge their reliability and alignment with your brand values. -

What are the minimum order quantities (MOQs) for contract filling services?

Minimum order quantities for contract filling can vary significantly between providers. Some companies offer flexible MOQs, allowing you to start with small batches—sometimes as few as 50 units—while others may require higher quantities for cost-effectiveness. When sourcing, clarify the MOQ with potential partners to ensure they can meet your initial production needs without compromising your budget. Understanding their pricing structure based on volume can also help you make an informed decision. -

What payment terms should I expect when working with contract filling suppliers?

Payment terms can vary widely among contract filling suppliers, but common practices include upfront deposits, milestone payments, or net payment terms (e.g., net 30 or net 60 days). Discussing payment terms upfront is crucial to avoid misunderstandings later. Many suppliers may require a percentage of the total order cost as a deposit before commencing production, especially for first-time clients. Ensure you are comfortable with the terms, as they can affect your cash flow and overall project timeline. -

How can I ensure quality assurance in contract filling processes?

To ensure quality assurance, inquire about the supplier’s certifications (such as ISO, FDA, or GMP) and their quality control procedures. Ask about their testing methods for raw materials, in-process checks, and final product inspections. It’s beneficial to establish clear quality criteria and guidelines in your contract, along with the potential for third-party audits. Regular communication and updates during the production process can also help maintain quality standards and address any issues promptly. -

What types of customization options are available for contract filling?

Most contract filling suppliers offer a range of customization options, including different container types, sizes, and labeling choices. You can often select specific formulations, colors, or packaging styles that align with your brand identity. Some providers also offer blending and formulation services to create unique product formulations before the filling process. Discussing your specific needs with potential partners can help you understand the extent of their customization capabilities and how they can support your branding efforts. -

What logistics considerations should I keep in mind when sourcing contract filling services internationally?

When sourcing contract filling services internationally, consider shipping costs, customs duties, and potential delays. It’s crucial to understand the logistics capabilities of your supplier, including their ability to handle international shipping and compliance with local regulations. Additionally, discussing lead times upfront can help you plan your inventory and avoid stockouts. Working with a logistics partner familiar with international trade can streamline the process and ensure timely delivery of your products. -

What are the benefits of outsourcing contract filling compared to in-house production?

Outsourcing contract filling offers several advantages, including cost savings on equipment and labor, access to specialized expertise, and increased flexibility. It allows businesses to focus on core competencies such as marketing and product development while relying on experts for filling and packaging. Additionally, contract fillers often have advanced technology and processes that can improve efficiency and product quality. This can be especially beneficial for businesses looking to scale quickly or test new products without significant upfront investment. -

How do I handle communication and collaboration with my contract filling supplier?

Effective communication with your contract filling supplier is vital for a successful partnership. Establish clear lines of communication and regular check-ins to discuss project updates, timelines, and any challenges that may arise. Utilize project management tools to track progress and maintain documentation of agreements and changes. It’s also helpful to designate a point of contact on both sides to facilitate smoother interactions and ensure that both parties are aligned on expectations and deliverables throughout the process.

Top 5 Contract Filling Manufacturers & Suppliers List

1. ActionPak – Turnkey Industrial Contract Filling Services

Domain: actionpakinc.com

Registered: 1997 (28 years)

Introduction: ActionPak offers turnkey industrial contract filling services for food, beverage, pharmaceutical, cosmetic, and non-food applications. Key offerings include:

1. **Bag & Pouch Filling**: Flexible solutions for liquid and powder applications, with options for unprinted stock pouches and customizable pressure sensitive labels.

2. **Liquid Filling**: Dedicated facilities for food and non-food produc…

2. LinkedIn – Professional Networking Platform

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, LinkedIn – Professional Networking Platform, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Case Mason – Contract Filling and Packaging Services

Domain: casemason.com

Registered: 2001 (24 years)

Introduction: Case Mason offers a variety of contract filling and packaging services, including:

1. **Contract Filling Services**:

– **Cosmetic Filling**: Over 50 years of experience, versatile fill sizes and container options.

– **Nail Polish Filling**: 30 years of experience, high-speed production up to 30 million units/year, handles various viscosities and unique package shapes.

– **Bottle Filling*…

4. ProcurementIQ – Market Intelligence Reports

Domain: procurementiq.com

Registered: 2016 (9 years)

Introduction: Market Intelligence Reports include opportunity assessment, market dynamics, recent developments, positive and warning trends, buyer power levers, price environment and market pricing, geographic wage rates, global market updates, total cost of ownership, cost structure benchmarks and analysis, supply chain and vendors, global supplier breakdown, market share concentration, regulation and business…

5. C.L. Smith – Contract Filling Solutions

Domain: clsmith.com

Registered: 1998 (27 years)

Introduction: Contract Filling Solutions offered by C.L. Smith include: Liquid Filling for chemicals, cleaners, lubricants; Powder Filling for various powdered substances; Granular Filling for agricultural and industrial materials; Custom Packaging tailored to product specifications and branding. Quality Assurance includes stringent standards and certifications by IFS PACsecure. Scalable solutions accommodate s…

Strategic Sourcing Conclusion and Outlook for contract filling

What Are the Key Takeaways for International B2B Buyers in Contract Filling?

In the evolving landscape of contract filling, strategic sourcing emerges as a critical component for businesses aiming to enhance their operational efficiency and market reach. By partnering with reliable contract filling providers, companies can leverage advanced technologies and expertise, ensuring high-quality production while minimizing overhead costs. The flexibility to accommodate varying order sizes—from small test runs to large-scale production—allows businesses to respond swiftly to market demands and consumer trends.

How Can Strategic Sourcing Benefit Your Business?

Investing in strategic sourcing not only streamlines your supply chain but also fosters innovation and adaptability. As global markets expand, particularly in regions like Africa, South America, the Middle East, and Europe, the importance of scalable and customizable solutions in contract filling cannot be overstated. Whether you are launching a new product or scaling an existing line, selecting the right partner can significantly impact your success.

What’s Next for Your Contract Filling Strategy?

As you navigate the complexities of contract filling, consider the potential for growth and collaboration with seasoned partners in the industry. The future is bright for businesses willing to embrace these strategic partnerships. Now is the time to act—evaluate your options, engage with contract filling providers, and position your brand for success in the global marketplace. Reach out today to explore tailored solutions that meet your unique needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.