Is Your Catering Food Warmers Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for catering food warmers

In the competitive landscape of the catering industry, sourcing reliable catering food warmers can present a significant challenge for B2B buyers. Ensuring that food remains at optimal temperatures during preparation and service is crucial for maintaining quality and customer satisfaction. This guide serves as a comprehensive resource, covering various types of catering food warmers, including chafers, countertop warmers, and insulated carriers, alongside their specific applications in diverse culinary settings.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Germany, face unique market dynamics that influence their purchasing decisions. This guide delves into essential factors such as supplier vetting, cost considerations, and best practices for integrating warming solutions into existing operations. By providing actionable insights, this guide empowers international buyers to make informed decisions that align with their business needs and regional requirements.

Understanding the nuances of catering food warmers not only enhances service efficiency but also ensures compliance with local food safety standards. As the demand for high-quality catering services continues to rise globally, equipping your business with the right food warming solutions is paramount for success. Explore this guide to navigate the complexities of the global market and elevate your catering offerings to meet customer expectations.

Understanding catering food warmers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Chafers & Chafer Sets | Stainless steel construction, often with lids | Buffets, catering events, restaurants | Pros: Elegant presentation, easy to use; Cons: Requires heating source. |

| Countertop Drop-In Food Warmers | Built-in heating elements, often designed for specific pan sizes | Cafeterias, catering services, food trucks | Pros: Space-efficient, customizable; Cons: Limited capacity. |

| Heated Countertop Merchandisers | Display food while keeping it warm, glass fronts | Convenience stores, fast-casual dining | Pros: Attracts customers, versatile; Cons: Higher upfront cost. |

| Insulated Food & Beverage Carriers | Lightweight, insulated materials for transport | Delivery services, off-site catering | Pros: Maintains temperature during transport; Cons: Limited to short durations. |

| Bain Marie Heaters | Water bath heating for even temperature distribution | Restaurants, catering, buffets | Pros: Ideal for delicate foods; Cons: Requires more maintenance. |

What are Chafers and How Are They Used in Catering?

Chafers are essential for buffet-style service and catering events, providing an elegant way to keep food warm. Typically made of stainless steel, they often come with lids to retain heat and moisture. B2B buyers should consider the capacity and compatibility with heating sources when purchasing chafers, as they need to be paired with fuel sources or electric warmers for effective operation.

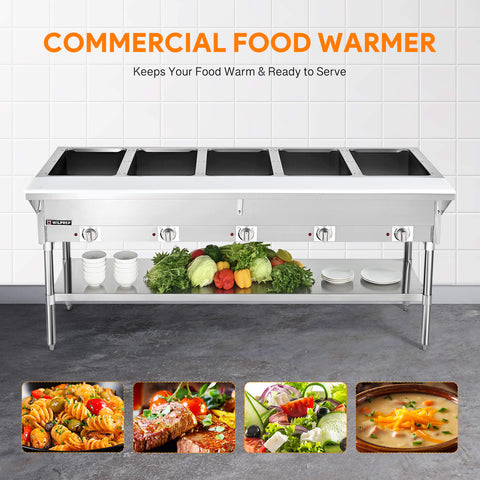

How Do Countertop Drop-In Food Warmers Benefit Catering Businesses?

Countertop drop-in food warmers are designed to fit into countertops, providing a sleek and efficient way to keep food warm. They often feature built-in heating elements and are customizable to fit various pan sizes. For B2B buyers, the space-saving design is a significant advantage, especially in busy kitchens or food trucks, but they may have limitations in terms of capacity.

Why Choose Heated Countertop Merchandisers for Food Display?

Heated countertop merchandisers are ideal for businesses that want to display food while keeping it warm. With glass fronts, they not only maintain temperature but also attract customers in settings like convenience stores and fast-casual dining. While they provide excellent visibility and versatility, B2B buyers should be prepared for a higher upfront investment compared to other warming solutions.

Illustrative image related to catering food warmers

What Are the Advantages of Insulated Food & Beverage Carriers?

Insulated food and beverage carriers are crucial for delivery services and off-site catering, designed to keep food at the right temperature during transport. These carriers are lightweight and often feature durable materials. For B2B buyers, they are a practical solution for maintaining food quality, although their effectiveness is typically limited to shorter durations.

How Do Bain Marie Heaters Support Food Preservation?

Bain Marie heaters utilize a water bath to provide gentle, even heating, making them ideal for delicate dishes that require temperature control. Commonly used in restaurants and catering, they help preserve the quality of food without overcooking. B2B buyers should consider the maintenance requirements and ensure the heater’s capacity aligns with their operational needs when investing in this type of warmer.

Key Industrial Applications of catering food warmers

| Industry/Sector | Specific Application of Catering Food Warmers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Buffet service in hotels and restaurants | Enhances guest experience with hot, ready-to-serve food | Energy efficiency, durability, and ease of cleaning |

| Catering Services | Off-site catering events | Maintains food quality during transportation | Insulation quality, portability, and temperature control |

| Retail Food Service | Displaying hot food items in convenience stores | Increases impulse purchases by showcasing fresh, warm food | Aesthetic design, capacity, and safety features |

| Event Management | Food service for large gatherings and corporate events | Streamlines food service and reduces waste | Size, functionality, and customization options |

| Educational Institutions | Meal service in schools and universities | Supports healthy eating by keeping food warm and accessible | Compliance with health standards, capacity, and ease of use |

How are Catering Food Warmers Used in the Hospitality Sector?

In the hospitality industry, catering food warmers are essential for buffet services in hotels and restaurants. They keep dishes at the optimal serving temperature, enhancing the guest experience and ensuring food safety. Buyers in this sector should consider energy-efficient models that can handle high volumes while being easy to clean. Additionally, durability is crucial, as these units are often in continuous use.

Illustrative image related to catering food warmers

What Role Do Catering Food Warmers Play in Off-Site Catering Services?

For catering services, especially those operating off-site, food warmers are vital for maintaining food quality during transportation. These warmers ensure that meals arrive at events hot and ready to serve, minimizing food waste and customer complaints. Buyers should prioritize insulated carriers with reliable temperature control features and portability, as these factors significantly impact service quality and customer satisfaction.

How Do Retail Food Services Benefit from Catering Food Warmers?

In retail food service environments, such as convenience stores, catering food warmers are used to display hot food items. This practice increases impulse purchases by showcasing fresh, warm options to customers. When sourcing these warmers, businesses should focus on aesthetic design and safety features, as well as capacity to accommodate varying customer demands throughout the day.

Why are Catering Food Warmers Important for Event Management?

Event management companies rely on catering food warmers to streamline food service for large gatherings and corporate events. These units help maintain food temperature, ensuring that meals are served efficiently and with minimal waste. Buyers should consider the size and functionality of the warmers, as well as any customization options that may enhance their service delivery during events.

How are Catering Food Warmers Utilized in Educational Institutions?

In educational institutions, catering food warmers play a crucial role in meal service, helping to keep food warm and accessible for students. This not only promotes healthy eating habits but also ensures compliance with health standards. Buyers in this sector should focus on capacity and ease of use, as well as adherence to health regulations, to ensure that meals are served safely and efficiently.

3 Common User Pain Points for ‘catering food warmers’ & Their Solutions

Scenario 1: Ensuring Consistent Food Temperature During Events

The Problem: B2B buyers often face the challenge of maintaining the ideal serving temperature of food during catering events. Fluctuating temperatures can lead to food becoming either too cold or overcooked, compromising quality and safety. For example, a catering service might prepare hot dishes, but if they lack effective food warmers, the food may cool down during transport or while waiting to be served, leading to customer dissatisfaction and potential health risks.

The Solution: To address this issue, it is crucial to invest in high-quality, insulated food carriers and warming equipment. Buyers should look for products that offer consistent heat distribution and adjustable temperature controls, such as countertop food warmers and chafing dishes with thermostatic features. Additionally, using insulated food delivery bags can help maintain temperatures during transport. It is advisable to select equipment that is specifically designed for the volume of food being served, ensuring that all dishes remain at safe temperatures without overcooking. Regular maintenance and monitoring of these devices will also help in maintaining their efficiency and reliability.

Scenario 2: Managing Limited Space in Catering Operations

The Problem: Many catering businesses operate in environments with limited kitchen space, which can make it challenging to find suitable equipment that does not hinder workflow. Inadequate space often leads to overcrowded work areas and inefficient operations, especially during peak service times. This can result in delays and increased stress for staff, ultimately affecting service quality.

The Solution: B2B buyers should consider versatile food warmers that are compact yet efficient, such as countertop warming drawers or drop-in food warmers. These appliances can be strategically placed to optimize space without sacrificing functionality. Furthermore, utilizing stackable chafing dishes and multi-functional equipment can help maximize limited areas. When selecting equipment, buyers should assess the layout of their kitchen and choose products that fit seamlessly into existing workflows. Investing in modular systems that allow for easy rearrangement can also enhance operational efficiency.

Scenario 3: Navigating Compliance and Safety Regulations

The Problem: Catering businesses are often confronted with stringent health and safety regulations regarding food storage and serving temperatures. Non-compliance can lead to significant fines and damage to reputation, especially in regions with rigorous food safety standards. B2B buyers may find it challenging to keep up with these regulations, particularly if they are sourcing equipment from different suppliers who may not provide adequate guidance.

The Solution: It is essential for buyers to choose food warmers that are certified by recognized safety standards, such as NSF or UL listings. When sourcing equipment, buyers should inquire about compliance with local regulations and ensure that the products are designed to maintain safe food temperatures. Additionally, implementing regular staff training on food safety practices and the proper use of warming equipment can help mitigate risks. To further enhance compliance, consider investing in temperature monitoring systems that provide real-time data on food temperatures, alerting staff to any deviations from safety standards. By prioritizing compliance in equipment selection and training, businesses can safeguard their operations and build trust with clients.

Illustrative image related to catering food warmers

Strategic Material Selection Guide for catering food warmers

What Are the Key Materials Used in Catering Food Warmers?

When selecting materials for catering food warmers, it is crucial to consider properties that affect performance, durability, and compliance with international standards. Here, we analyze four common materials used in the manufacturing of catering food warmers: stainless steel, aluminum, plastic, and glass.

How Does Stainless Steel Perform in Catering Food Warmers?

Stainless steel is widely favored in the catering industry due to its excellent corrosion resistance and ability to withstand high temperatures. It typically has a temperature rating of up to 1,500°F, making it ideal for food warmers that require consistent heat retention. The material is also easy to clean and maintain, which is essential for hygiene in food service environments.

Pros: Stainless steel is highly durable and resistant to rust, which extends the lifespan of food warmers. It also provides a professional appearance, which is appealing in catering settings.

Cons: The primary drawback is its cost, as stainless steel is generally more expensive than other materials. Additionally, its weight can make transport and handling more cumbersome.

Impact on Application: Stainless steel is compatible with a wide range of food types, ensuring that it can be used for various catering needs without leaching harmful substances.

What Advantages Does Aluminum Offer for Food Warmers?

Aluminum is another popular choice for catering food warmers due to its lightweight nature and excellent thermal conductivity. This material can handle temperatures up to 1,200°F and is often used in portable food warmers.

Pros: Aluminum is cost-effective and easy to manufacture, allowing for a variety of designs and shapes. Its lightweight nature makes it ideal for catering operations that require mobility.

Illustrative image related to catering food warmers

Cons: While aluminum is corrosion-resistant, it is not as durable as stainless steel and can be prone to dents and scratches. It also has a lower temperature tolerance compared to stainless steel.

Impact on Application: Aluminum is suitable for short-term food holding but may not be ideal for long-term storage due to its potential to warp under high heat.

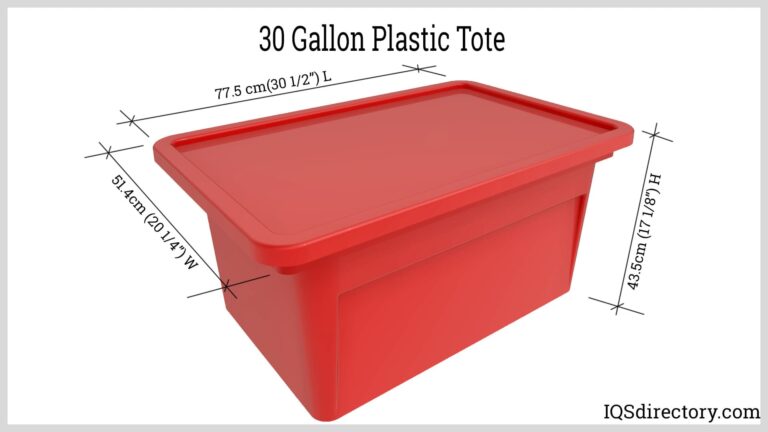

How Do Plastics Fit into the Catering Food Warmer Landscape?

Plastic materials, particularly high-density polyethylene (HDPE) and polypropylene, are used in some catering food warmers, especially for insulated carriers. These plastics can handle temperatures up to 200°F and are often used in conjunction with other materials.

Pros: Plastics are lightweight, cost-effective, and offer good insulation properties. They are also resistant to many chemicals, making them suitable for various food types.

Illustrative image related to catering food warmers

Cons: The main limitation is their lower temperature tolerance, which restricts their use in high-heat applications. Plastics can also degrade over time when exposed to heat and sunlight.

Impact on Application: While suitable for transporting food, plastics may not be ideal for direct heating applications, limiting their versatility in catering.

What Role Does Glass Play in Catering Food Warmers?

Glass is often used in display food warmers due to its aesthetic appeal and ability to showcase food. Tempered glass can withstand temperatures up to 400°F, making it suitable for certain applications.

Pros: Glass provides a clear view of the food, enhancing presentation and customer appeal. It is also easy to clean and does not retain odors.

Cons: The primary disadvantage is its fragility; glass can break easily, posing safety risks. Additionally, it is heavier than other materials, which can complicate transport.

Impact on Application: Glass is best suited for display purposes rather than for high-heat applications, making it ideal for buffets or catering events where aesthetics are paramount.

Summary Table of Material Selection for Catering Food Warmers

| Material | Typical Use Case for catering food warmers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-end food warmers and chafers | Excellent durability and corrosion resistance | Higher cost and weight | High |

| Aluminum | Portable food warmers and trays | Lightweight and cost-effective | Less durable, prone to dents | Medium |

| Plastic | Insulated food carriers | Good insulation and chemical resistance | Lower temperature tolerance | Low |

| Glass | Display warmers for buffets | Aesthetic appeal and easy to clean | Fragile and heavier | Medium |

This analysis provides B2B buyers with insights into material selection for catering food warmers, enabling informed purchasing decisions that align with operational needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for catering food warmers

What Are the Main Stages of Manufacturing Catering Food Warmers?

The manufacturing process for catering food warmers involves several critical stages that ensure the final product meets both functionality and safety standards. Understanding these stages helps B2B buyers assess the quality and reliability of their suppliers.

Illustrative image related to catering food warmers

Material Preparation: Which Materials Are Commonly Used?

The first step in manufacturing catering food warmers is material preparation. Common materials include stainless steel, aluminum, and high-grade plastics, chosen for their durability, heat resistance, and ease of cleaning. Suppliers often source these materials from certified vendors to ensure they comply with international standards.

Once the materials are acquired, they undergo inspection to verify quality and consistency. This step is crucial, as any defects at this stage can compromise the integrity of the final product.

What Techniques Are Used for Forming and Assembling Food Warmers?

The forming process typically involves cutting, bending, and shaping the raw materials into the desired components of food warmers, such as chafing dishes, warming drawers, and heat lamps. Advanced techniques like laser cutting and CNC machining are often employed to ensure precision and minimize waste.

Assembly follows forming, where various components are joined together. This may involve welding, riveting, or using adhesives, depending on the design specifications. Automated assembly lines are increasingly common, enhancing efficiency and reducing human error.

How Is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance (QA) is a continuous process integrated into each stage of manufacturing. The goal is to ensure that every food warmer meets the necessary quality and safety standards before it reaches the market.

What International Standards Should B2B Buyers Be Aware Of?

For B2B buyers, it is essential to understand the relevant international standards that govern food warmer manufacturing. ISO 9001 is a widely recognized standard for quality management systems, ensuring that manufacturers maintain consistent quality in their processes. Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and NSF (National Sanitation Foundation) for food safety are critical indicators of compliance.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This is conducted upon receipt of raw materials to verify their quality against predefined specifications.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various parameters such as dimensions, weight, and functionality are monitored to ensure compliance with design specifications.

-

Final Quality Control (FQC): Before shipping, each unit undergoes a comprehensive inspection, including functionality tests, safety assessments, and aesthetic evaluations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control measures of their suppliers. Here are several methods:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, QC checkpoints, and overall facility conditions. This firsthand observation can provide valuable insights into the supplier’s capabilities.

-

Quality Reports: Requesting detailed quality reports can offer transparency into the supplier’s QC processes and any historical issues that may have arisen.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s products and processes. This is particularly crucial for international transactions, where local laws and quality standards may vary.

What Testing Methods Are Commonly Used for Catering Food Warmers?

Several testing methods are employed to ensure the safety and functionality of catering food warmers:

-

Thermal Performance Testing: This assesses the unit’s ability to maintain the desired temperature over a specified period, ensuring food safety and quality.

-

Electrical Safety Testing: For electric warmers, tests are conducted to check for electrical safety standards, including insulation resistance and grounding.

-

Durability Testing: Products are subjected to stress tests that simulate real-world usage to ensure longevity and reliability.

Are There Specific Quality Control Nuances for International B2B Buyers?

International B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Regulatory Compliance: Different regions have distinct regulations regarding food safety and equipment standards. Buyers must ensure that the products comply with local regulations, which may require additional certifications.

-

Cultural Considerations: Understanding local market needs and preferences can influence the choice of materials and design features. For instance, food warmers intended for outdoor use in hot climates may require different materials compared to those used in cooler regions.

-

Logistical Challenges: Importing food warmers can present challenges such as customs regulations and shipping delays. Buyers should work closely with suppliers to ensure all documentation is in order and that products are shipped in compliance with international trade laws.

Conclusion: The Importance of Manufacturing Processes and Quality Assurance

In summary, a thorough understanding of the manufacturing processes and quality assurance practices for catering food warmers is essential for B2B buyers. By focusing on material preparation, forming, assembly, and rigorous quality control, buyers can make informed decisions when selecting suppliers. Awareness of international standards and testing methods further enhances the ability to procure high-quality products, ensuring customer satisfaction and operational success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘catering food warmers’

When sourcing catering food warmers, it’s essential to approach the process systematically to ensure that the equipment meets your operational needs while adhering to quality and safety standards. This guide offers a checklist of critical steps to help B2B buyers make informed decisions.

1. Identify Your Specific Needs

Understanding the requirements of your catering business is the first step. Consider factors such as the types of food you will be serving, the volume of food to be held, and the duration for which food needs to be kept warm. This will guide you in selecting the appropriate type of warmer, whether it’s a chafing dish, soup kettle, or countertop warmer.

2. Define Your Technical Specifications

Before initiating supplier discussions, establish your technical specifications. This includes power requirements (e.g., voltage), capacity (e.g., quart size), and desired features (e.g., adjustable thermostats, insulated designs). Clear specifications help in narrowing down options and ensure that the equipment fits seamlessly into your existing setup.

3. Research and Compare Supplier Options

Conduct thorough research to identify potential suppliers. Look for companies that specialize in catering equipment and have a strong reputation in your target markets, such as Africa, South America, the Middle East, and Europe. Compare product offerings, pricing, and customer reviews to create a shortlist of reliable suppliers.

Illustrative image related to catering food warmers

4. ✅ Verify Supplier Certifications

It’s crucial to confirm that suppliers adhere to industry standards and certifications. Look for certifications such as NSF, UL, or CE, which indicate compliance with safety and health regulations. This step not only ensures product quality but also protects your business from potential liabilities.

5. Request Samples and Product Demonstrations

Before making a bulk purchase, request samples or arrange for product demonstrations. This allows you to assess the quality and functionality of the warmers firsthand. Pay attention to factors like ease of use, heating efficiency, and ease of cleaning, as these will impact your operational efficiency.

6. Understand Warranty and After-Sales Support

Review the warranty terms and after-sales support offered by the supplier. A robust warranty reflects the manufacturer’s confidence in their product, while comprehensive after-sales support ensures you have assistance for maintenance and troubleshooting. This is particularly important for equipment that is critical to your catering operations.

7. Negotiate Terms and Finalize the Purchase

Once you have selected a supplier, negotiate terms that work for both parties. Discuss pricing, delivery schedules, and payment terms. Ensure that everything is documented in a purchase agreement to avoid misunderstandings later on. A well-negotiated contract can lead to better pricing and service terms.

By following these steps, B2B buyers can streamline the sourcing process for catering food warmers, ensuring they select the right equipment that aligns with their business needs while minimizing risks.

Comprehensive Cost and Pricing Analysis for catering food warmers Sourcing

When sourcing catering food warmers, understanding the cost structure and pricing dynamics is crucial for B2B buyers. This analysis will delve into the components that influence costs, the factors that affect pricing, and practical tips for making informed purchasing decisions.

Illustrative image related to catering food warmers

What are the Key Cost Components of Catering Food Warmers?

The cost structure for catering food warmers encompasses several components:

-

Materials: The primary materials used in food warmers include stainless steel, aluminum, and various heating elements. Stainless steel, known for its durability and ease of cleaning, typically incurs higher costs compared to aluminum, which is lighter but less robust.

-

Labor: Labor costs vary by region and can significantly impact the overall price. In countries with higher wage standards, such as Germany, labor costs will be a larger factor compared to regions in Africa or South America.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment depreciation. Efficient manufacturing processes can help reduce these costs, enabling suppliers to offer competitive pricing.

-

Tooling: Custom tooling for specialized food warmer designs can lead to higher initial costs. However, these costs may be amortized over larger production runs, making high-volume orders more economical.

-

Quality Control (QC): Ensuring that products meet safety and quality standards involves additional expenses. Certifications like NSF and UL can enhance a product’s marketability but may also increase production costs.

-

Logistics: Transportation costs for shipping warmers can vary based on distance, mode of transport, and customs duties. International buyers should consider these logistics costs when evaluating suppliers.

-

Margin: Suppliers typically apply a markup on production costs to ensure profitability. Understanding the typical margins in the catering equipment industry can help buyers gauge fair pricing.

How Do Price Influencers Affect Catering Food Warmer Costs?

Several factors can influence the pricing of catering food warmers:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Higher volumes often lead to lower per-unit costs, making it advantageous for businesses with larger catering operations.

-

Specifications and Customization: Tailored products that meet specific needs or branding requirements will generally come at a premium. Buyers should assess whether custom features are necessary or if standard models suffice.

-

Material Quality and Certifications: Higher quality materials and certifications can increase costs but may also enhance product longevity and safety. Buyers should weigh these benefits against budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding international shipping terms is essential for cost management. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) can influence total landed costs.

What Buyer Tips Can Enhance Cost Efficiency in Sourcing?

For international B2B buyers, especially from diverse regions like Africa, South America, the Middle East, and Europe, the following tips can enhance sourcing efficiency:

-

Negotiation: Always engage in negotiations. Suppliers may have flexibility in pricing, especially for bulk orders or long-term contracts.

-

Total Cost of Ownership (TCO): Assess not just the initial purchase price but also the long-term costs associated with maintenance, energy consumption, and potential repairs. Investing in higher-quality warmers can yield savings over time.

-

Pricing Nuances for International Buyers: Currency fluctuations can impact costs. Establishing contracts in stable currencies or hedging against currency risk can help maintain budget integrity.

-

Research and Compare Suppliers: Utilize platforms that allow for the comparison of multiple suppliers, their prices, and product features. This can provide insights into industry standards and help identify competitive offers.

-

Stay Updated on Market Trends: Prices can fluctuate based on market demand and supply chain disruptions. Keeping abreast of trends in manufacturing and global logistics can aid in making timely purchasing decisions.

In conclusion, a thorough understanding of the cost structure and pricing influencers, coupled with strategic purchasing practices, can significantly benefit B2B buyers in the catering equipment sector. While indicative prices can guide initial assessments, comprehensive analysis and negotiation remain key to achieving the best value.

Alternatives Analysis: Comparing catering food warmers With Other Solutions

Understanding Alternatives to Catering Food Warmers

When catering to diverse clientele, businesses must ensure that food is served at optimal temperatures. While catering food warmers provide a reliable solution, there are several alternatives that can also maintain food quality and temperature. This section explores these alternatives, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Catering Food Warmers | Insulated Food Carriers | Heat Lamps |

|---|---|---|---|

| Performance | Maintains food at safe serving temperatures for extended periods. | Keeps food warm during transport; less effective at long-term holding. | Provides immediate heat; best for short-term warming. |

| Cost | Moderate to high initial investment depending on capacity and features. | Generally lower cost; varies by brand and insulation quality. | Relatively low cost; simple design. |

| Ease of Implementation | Easy to set up and operate; often plug-and-play. | Requires knowledge of load management for optimal performance. | Simple installation; requires electric outlet. |

| Maintenance | Regular cleaning required; durable but may need parts replacement over time. | Minimal maintenance; cleanable but may wear out with heavy use. | Low maintenance; bulbs need replacement periodically. |

| Best Use Case | Ideal for buffets, large events, and long-term food holding. | Best for transporting food to events while maintaining warmth. | Suitable for short-term events like appetizers or small servings. |

Pros and Cons of Insulated Food Carriers

Insulated food carriers are designed to transport food while maintaining temperature. They offer a cost-effective solution for catering businesses that frequently transport meals. The main advantage of these carriers is their ability to keep food warm without the need for electricity, making them highly portable. However, they are not ideal for long-term food holding, as their effectiveness diminishes over time. Additionally, they require careful packing to ensure food safety and temperature retention.

Pros and Cons of Heat Lamps

Heat lamps are an excellent option for short-term food warming, commonly used in buffet setups or at food stations. They provide instant heat and can be easily adjusted to maintain the desired temperature. The primary benefit of heat lamps is their low cost and simplicity in operation. However, they are not suitable for all types of food, as they can dry out certain dishes or create uneven heating. Moreover, they require an electric outlet and may not be practical for outdoor events without power access.

Choosing the Right Solution for Your Catering Needs

In selecting the most suitable solution for maintaining food temperature, B2B buyers should evaluate their specific operational needs. Catering food warmers excel in performance and longevity, making them ideal for large-scale events where food needs to be held for extended periods. Insulated food carriers are perfect for businesses focused on delivery and transport, while heat lamps serve well in settings requiring quick service. By weighing these factors against budget constraints and operational requirements, businesses can make informed decisions that enhance their catering efficiency and customer satisfaction.

Essential Technical Properties and Trade Terminology for catering food warmers

What Are the Key Technical Properties of Catering Food Warmers?

When selecting catering food warmers, understanding the technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to consider:

-

Material Grade

– Catering food warmers are typically constructed from stainless steel, aluminum, or high-grade plastic. Stainless steel is favored for its durability, resistance to corrosion, and ease of cleaning. Aluminum offers lightweight portability but may not be as robust. Understanding material grade is vital as it impacts longevity and maintenance costs, critical factors for B2B buyers. -

Temperature Range

– The temperature range indicates how effectively a warmer can maintain food at safe serving temperatures. Most commercial food warmers operate between 140°F to 180°F (60°C to 82°C). This specification is essential for compliance with food safety standards, especially in regions where regulations are strict. -

Power Consumption

– Measured in watts, power consumption influences operational costs. For instance, a food warmer that operates at 850 watts will consume more energy than one at 500 watts. Buyers should consider energy efficiency to reduce long-term operational costs while ensuring adequate warming capacity. -

Capacity

– The capacity of food warmers is typically measured in quarts or liters, indicating how much food can be stored and served at once. Catering businesses must assess their service volume to select warmers that meet their operational needs without overcrowding, which can lead to uneven heating. -

Heat Source

– Catering food warmers may use electric, gas, or induction heating. Electric warmers are popular for their convenience, while gas warmers are often preferred in outdoor settings. Understanding the heat source helps buyers align their equipment with their operational environment and energy availability. -

Control Mechanisms

– Many modern food warmers feature adjustable thermostats and digital displays for precise temperature control. This property is important for maintaining food quality and safety, allowing caterers to customize settings based on different menu items.

What Are Common Trade Terms in the Catering Food Warmer Industry?

Familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers evaluate product quality and warranty support. -

MOQ (Minimum Order Quantity)

– MOQ specifies the least number of units a supplier is willing to sell. This is crucial for businesses that need to manage inventory efficiently and can also impact pricing strategies. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing for specific products or services. Issuing an RFQ allows buyers to compare costs and negotiate better deals, making it a standard practice in procurement. -

Incoterms (International Commercial Terms)

– These are pre-defined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Knowing Incoterms helps businesses understand shipping, insurance, and liability, which is essential for smooth cross-border trade. -

Lead Time

– Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is essential for planning inventory and ensuring timely service delivery, particularly in catering businesses where timing is critical. -

Warranty Period

– This term indicates the duration for which the manufacturer guarantees the product against defects. A longer warranty period often signifies confidence in product quality and can be a significant factor in purchasing decisions.

Understanding these technical specifications and trade terms empowers international B2B buyers to make informed decisions when sourcing catering food warmers, ensuring they meet operational needs while adhering to industry standards.

Navigating Market Dynamics and Sourcing Trends in the catering food warmers Sector

What Are the Current Market Dynamics and Key Trends Influencing Catering Food Warmers?

The catering food warmers sector is currently experiencing robust growth driven by several global factors. A surge in the food service industry, particularly due to the rise of catering services and food delivery platforms, is a significant driver. This trend is particularly prominent in regions such as Africa, South America, the Middle East, and Europe, where consumer preferences are shifting toward convenient dining options. Additionally, technological advancements are reshaping sourcing practices. Smart food warmers equipped with IoT capabilities allow for better temperature control and energy efficiency, appealing to tech-savvy businesses looking to optimize operations.

Emerging trends also indicate a growing emphasis on multifunctional equipment. B2B buyers are increasingly seeking food warmers that can serve multiple purposes—such as holding, warming, and even displaying food—thus streamlining their operations. The rise of online marketplaces has further transformed sourcing dynamics, enabling international buyers to access a wider range of products and suppliers. This shift encourages competitive pricing and innovation in product offerings, allowing buyers to make more informed decisions.

How Is Sustainability and Ethical Sourcing Shaping the Catering Food Warmers Market?

Sustainability has become a cornerstone of purchasing decisions in the catering food warmers sector. As environmental concerns escalate, businesses are increasingly prioritizing eco-friendly products and practices. The production and disposal of food warming equipment can have significant environmental impacts, leading many companies to seek suppliers that adhere to sustainable manufacturing processes. This includes using recyclable materials and minimizing waste during production.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are now more inclined to partner with manufacturers that demonstrate a commitment to fair labor practices and transparency in sourcing. Certifications such as Energy Star, NSF, and UL can signal a product’s compliance with environmental standards, making them attractive to B2B buyers focused on sustainability. By investing in ‘green’ food warmers, companies not only enhance their brand image but also contribute to a healthier planet.

What Is the Historical Context of Catering Food Warmers in the B2B Sector?

The evolution of catering food warmers dates back several decades, initially focusing on basic heating methods like chafing dishes and heat lamps. Over time, advancements in technology and materials have transformed these products into more sophisticated appliances capable of precise temperature control and energy efficiency. The introduction of electric food warmers in the late 20th century marked a significant turning point, allowing for greater versatility and ease of use in catering operations.

In recent years, the market has shifted towards smart technology integration, enabling features such as remote monitoring and automated temperature adjustments. This evolution reflects the broader trends in the food service industry, where efficiency, convenience, and sustainability are paramount. As international B2B buyers continue to demand more from their suppliers, understanding the historical context of these products can provide valuable insights into future developments and innovations in the catering food warmers market.

Frequently Asked Questions (FAQs) for B2B Buyers of catering food warmers

-

How do I ensure the food warmers I purchase are of high quality?

To ensure high-quality food warmers, start by researching reputable manufacturers with a track record in the industry. Look for certifications such as NSF or ETL, which indicate compliance with safety and sanitation standards. Request product samples for testing and verify customer reviews and testimonials. Engaging in site visits or virtual factory tours can also provide insights into the production processes and quality control measures employed by suppliers. -

What is the best type of food warmer for catering events?

The best type of food warmer for catering events often depends on the specific needs of your service. For buffet-style catering, chafing dishes are popular due to their aesthetic appeal and ability to keep food warm for extended periods. For mobile catering, consider insulated food carriers or countertop warmers that are easy to transport. Evaluate factors such as capacity, heating method, and ease of cleaning when making your choice. -

How can I customize food warmers to fit my brand?

Many manufacturers offer customization options for food warmers, including branding, size, and color. Discuss your specific requirements with potential suppliers, including logo placement and unique design features that reflect your brand identity. Ensure to inquire about minimum order quantities (MOQs) for custom products, as these can vary significantly between manufacturers. -

What should I consider regarding minimum order quantities (MOQs) for food warmers?

When sourcing food warmers, MOQs can significantly impact your purchasing strategy. Consider your current and anticipated demand to avoid overstocking. If you are a new business or have a limited budget, look for suppliers with flexible MOQs or those willing to negotiate smaller orders. Additionally, assess whether bulk purchasing can lead to discounts, which can improve your overall cost efficiency. -

What payment terms should I expect when purchasing from international suppliers?

Payment terms can vary widely between suppliers, but common practices include upfront deposits (often 30-50%) with the balance due before shipment. Inquire about payment methods accepted, such as letters of credit or PayPal, which can offer additional security. Always clarify the terms in your purchase agreement, including any applicable taxes or tariffs for international transactions. -

How do I verify the credibility of a supplier in the catering equipment industry?

Verifying a supplier’s credibility involves several steps. Start by checking their business registration and any industry certifications. Request references from previous clients and read online reviews. Conduct background checks through platforms like Alibaba or ThomasNet, which provide insights into supplier ratings and performance. Engaging in direct communication can also help gauge their responsiveness and professionalism. -

What logistics considerations should I keep in mind when importing food warmers?

When importing food warmers, consider logistics factors such as shipping methods, customs clearance, and delivery timelines. Work with a reliable freight forwarder who can manage the complexities of international shipping and ensure compliance with local regulations. Be aware of potential import duties and taxes that could affect your total cost, and plan for adequate warehousing or storage upon arrival. -

How do I ensure that food warmers meet safety and health standards in my country?

To ensure compliance with safety and health standards, familiarize yourself with the regulations specific to your country or region. This may include certifications like CE marking in Europe or specific food safety guidelines in Africa or South America. Request documentation from your supplier that demonstrates compliance with these standards. Regular inspections and maintenance of your equipment can also help ensure ongoing compliance.

Top 3 Catering Food Warmers Manufacturers & Suppliers List

1. Equippers – Food Warming Equipment

Domain: equippers.com

Registered: 1999 (26 years)

Introduction: Food Warming and Holding Equipment & Accessories include: Chafers & Accessories, Countertop, Drop-In Food Warmers & Soup Kettles, Countertop Warming Drawers & Chip Warmers, Food Rethermalizers / Bain Marie Heaters, Heat Strips, Lamps & Warming Trays, Heated Countertop Merchandisers, Insulated Catering & Delivery Bags, Insulated Food & Beverage Carriers & Accessories.

2. Costway – 24 Inches Freestanding Natural Gas Range

Domain: costway.com

Registered: 2002 (23 years)

Introduction: {“products”:[{“name”:”24 Inches Freestanding Natural Gas Range with 4 Burners Cooktop”,”price”:”$1,499″,”original_price”:”$2,998″,”status”:”Out of Stock”},{“name”:”30 Inches 120V Natural Gas Range with 5 Burners Cooktop”,”price”:”$1,699″,”original_price”:”$2,830″,”status”:”Out of Stock”},{“name”:”36 Inches Freestanding Natural Gas Range with 6 Burners Cooktop”,”price”:”$2,399″,”original_price”:”$3…

3. VEVOR – Electric Buffet Server & Food Warmer

Domain: vevor.com

Registered: 2009 (16 years)

Introduction: VEVOR Food Warmer: Steam Tables, Countertop Warmers & More. Key products include: 1. VEVOR Electric Buffet Server & Food Warmer – 25.6″ x 15″, Portable Stainless Steel, Temp Control, $43.90. 2. VEVOR Water Bath Canner – 15 Quart, 304 Food Grade Stainless Steel, $129.99. 3. VEVOR 3-Tier Commercial Food Warmer Display Countertop Pizza Cabinet with Light, $275.99. 4. Commercial Food Heat Lamp – 2-hea…

Strategic Sourcing Conclusion and Outlook for catering food warmers

In navigating the complex landscape of catering food warmers, strategic sourcing emerges as a critical factor for success. By leveraging reliable suppliers and understanding the diverse range of equipment—from chafers and insulated carriers to countertop warmers—buyers can optimize their operations and enhance service delivery. The variety of options available, including electric chafing dishes and heated merchandisers, allows businesses to cater effectively to different culinary needs and customer preferences.

Illustrative image related to catering food warmers

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should prioritize partnerships with suppliers who offer quality products that meet local standards and regulations. This not only ensures compliance but also fosters customer trust through consistent food safety and quality.

Looking ahead, the catering industry is poised for growth, driven by the increasing demand for high-quality food service solutions. Now is the time to invest in state-of-the-art food warming equipment that can elevate your catering capabilities. By strategically sourcing innovative products, your business can stay competitive and responsive to market changes, ensuring you remain a preferred choice for your clientele. Embrace this opportunity to enhance your catering operations and drive success in an evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to catering food warmers

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.